Anti-aging photoelectric displacement sensor

A photoelectric displacement and sensor technology, used in photovoltaic power generation, instruments, circuits, etc., can solve the problems of difficult uniformity of composition, difficult to achieve, and strict requirements for oxide layer thickness, and achieve simple preparation, low cost, and optimal sensitivity and linearity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

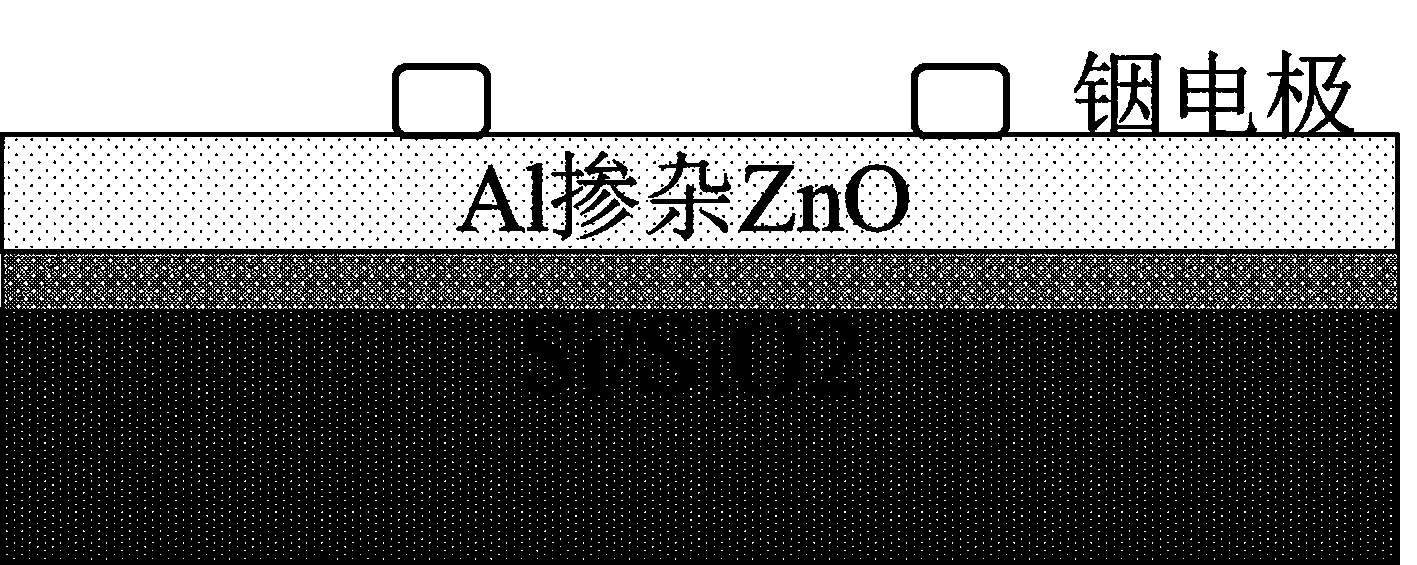

[0019] Clean the Si substrate with acetone and deionized water in an ultrasonic cleaner, dry it, put it into a magnetron sputtering chamber, and evacuate it to 10 -5 After Pa, pass in argon gas and adjust the gas flow meter to make the pressure reach 0.7Pa, set the sputtering power to 40W, and sputter the Al-doped ZnO target (2% Al 2 o 3 , 98% ZnO)200s, made into a thin film with a thickness of about 25 nm.

Embodiment 2

[0021] Clean the Si substrate with acetone and deionized water in an ultrasonic cleaner, dry it, put it into a magnetron sputtering chamber, and evacuate it to 10 -5 After Pa, pass in argon gas and adjust the gas flow meter to make the pressure reach 0.7Pa, set the sputtering power to 40W, and sputter the Al-doped ZnO target (2% Al 2 o 3 , 98% ZnO)400s, made into a thin film with a thickness of about 49 nm.

Embodiment 3

[0023] Clean the Si substrate with acetone and deionized water in an ultrasonic cleaner, dry it, put it into a magnetron sputtering chamber, and evacuate it to 10 -5 After Pa, pass in argon gas and adjust the gas flow meter to make the pressure reach 0.7Pa, set the sputtering power to 40W, and sputter the Al-doped ZnO target (2% Al 2 o 3 , 98% ZnO)600s, made into a thin film with a thickness of about 74 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com