Patents

Literature

637 results about "Zinc oxide thin films" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

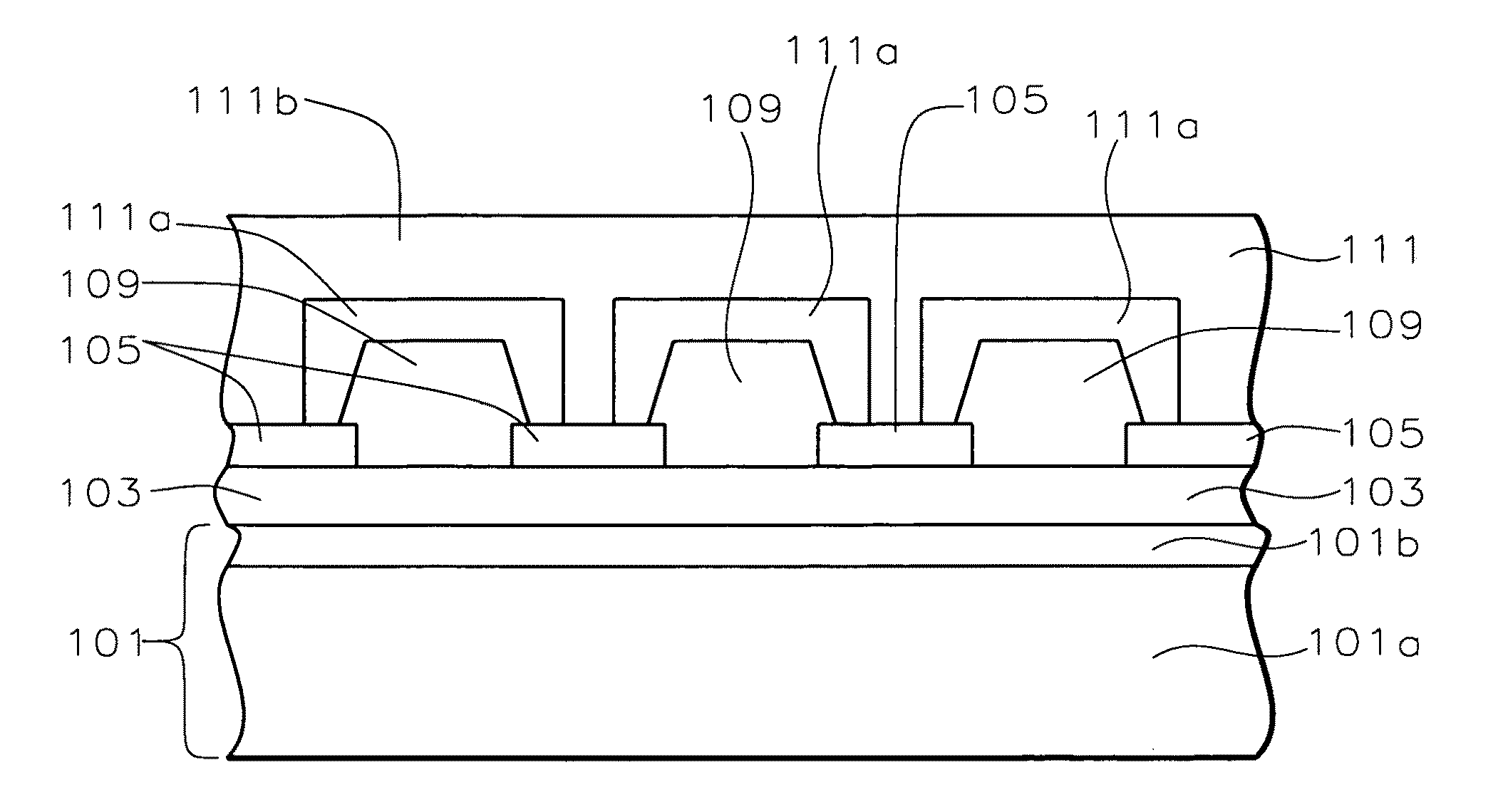

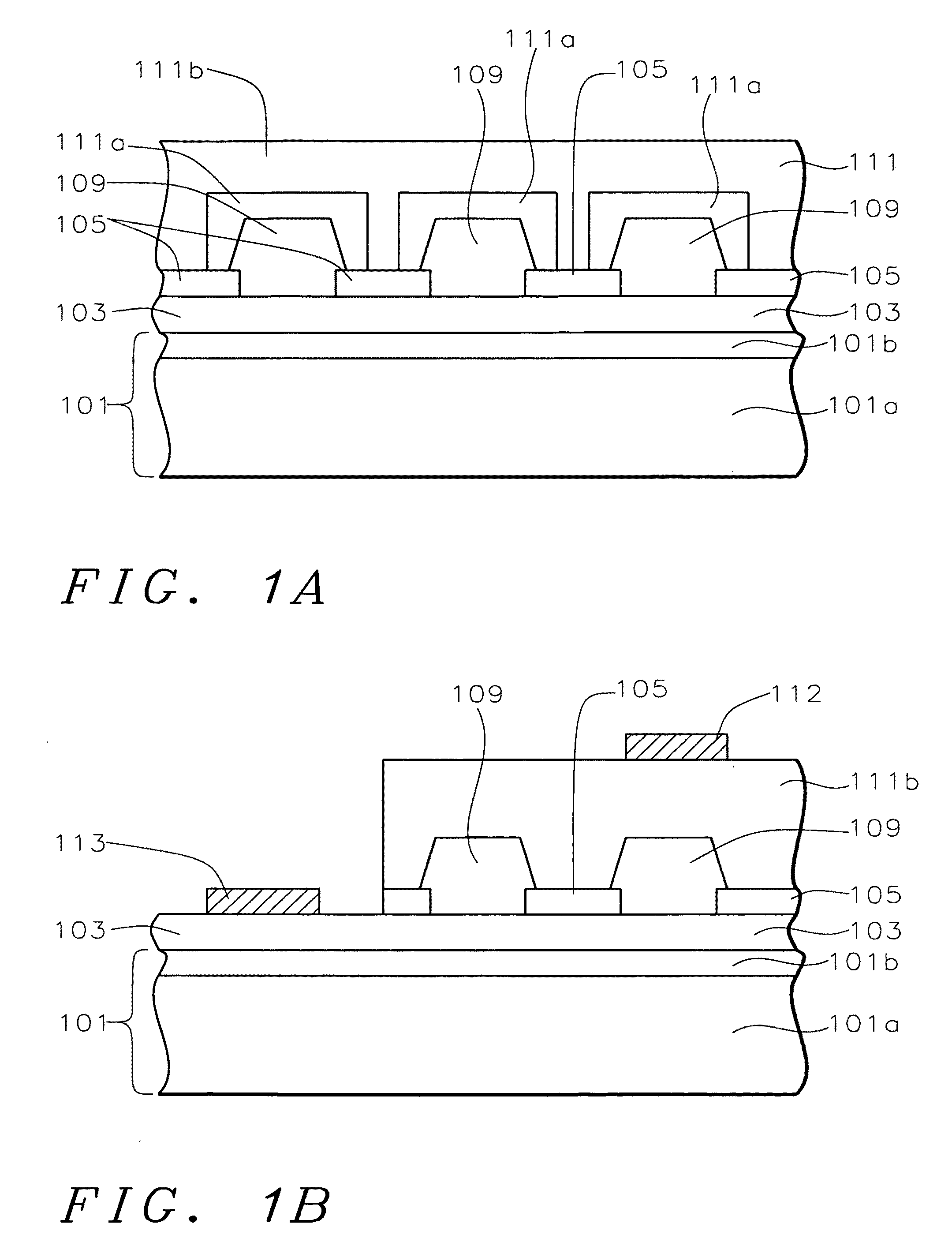

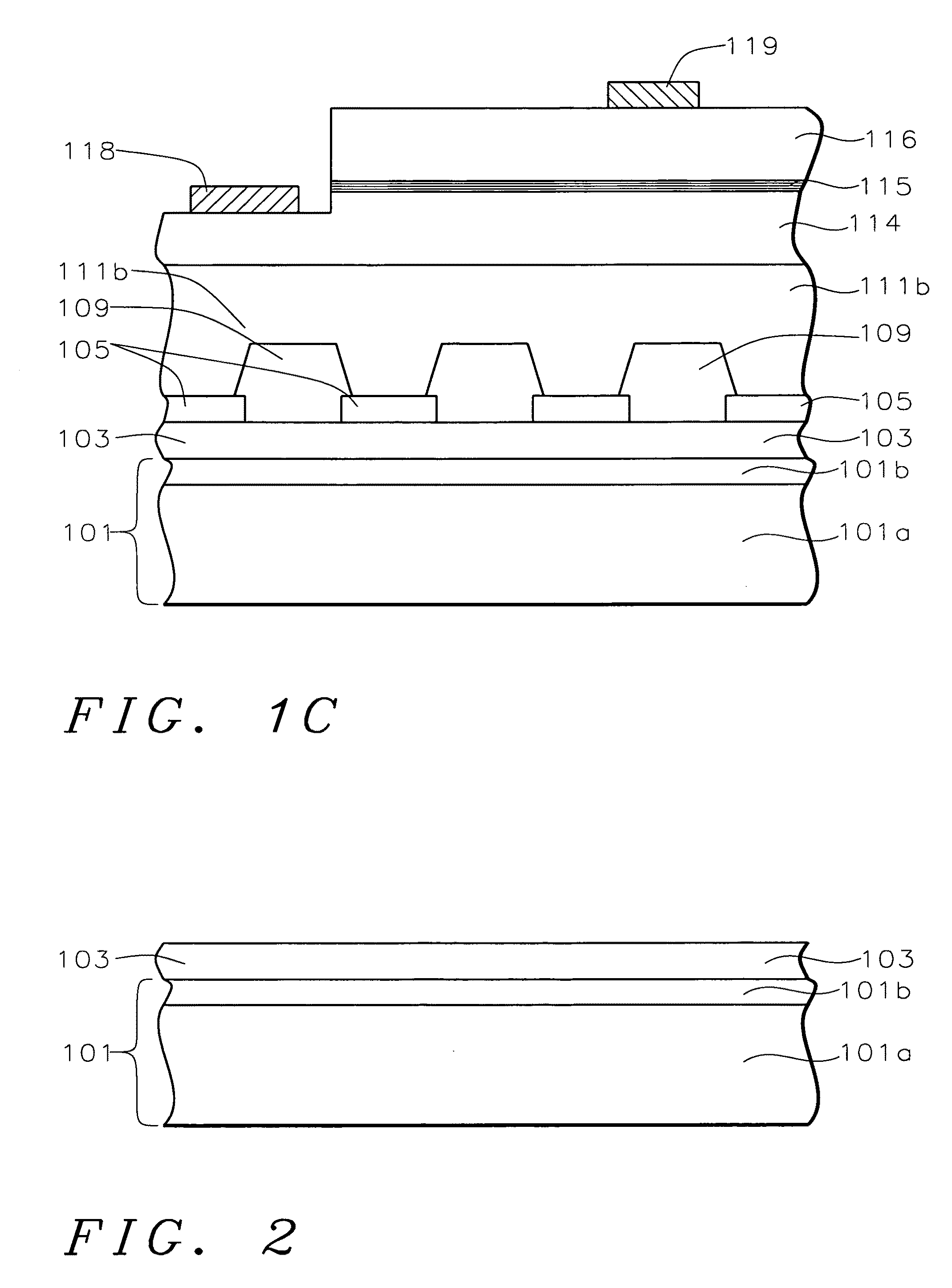

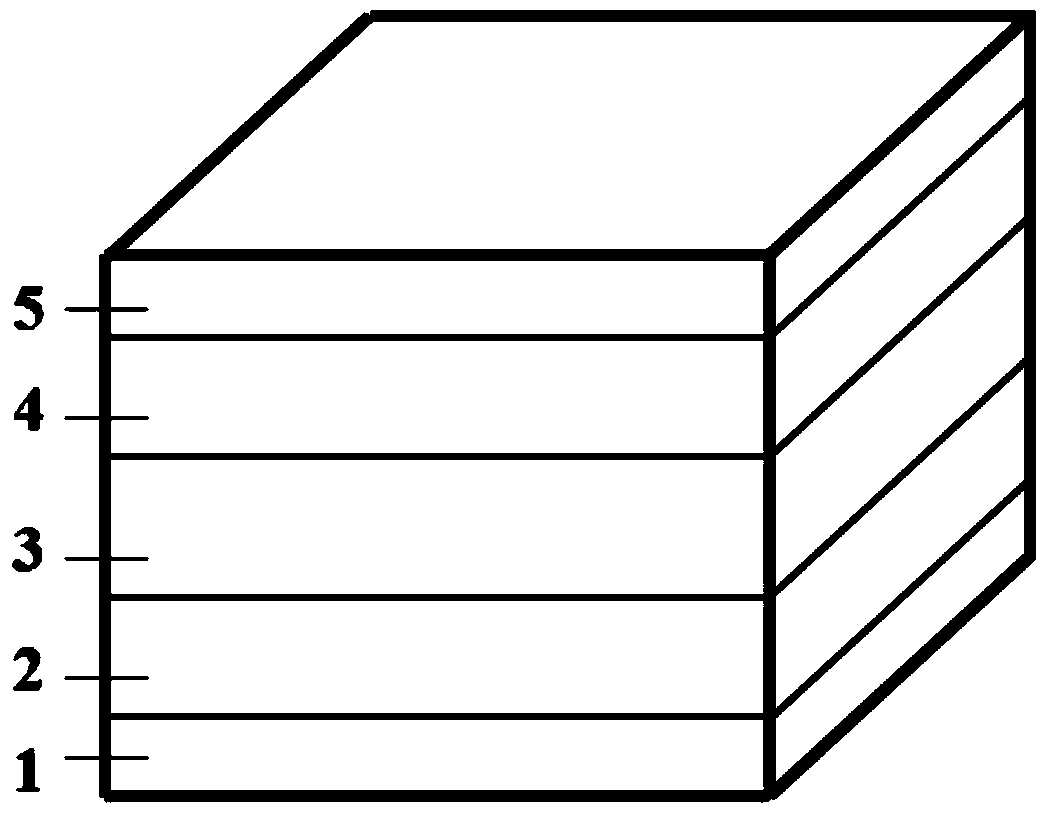

ZnO thin film transistor and method of forming the same

InactiveUS20070272922A1Semiconductor/solid-state device manufacturingSemiconductor devicesGate insulatorEngineering

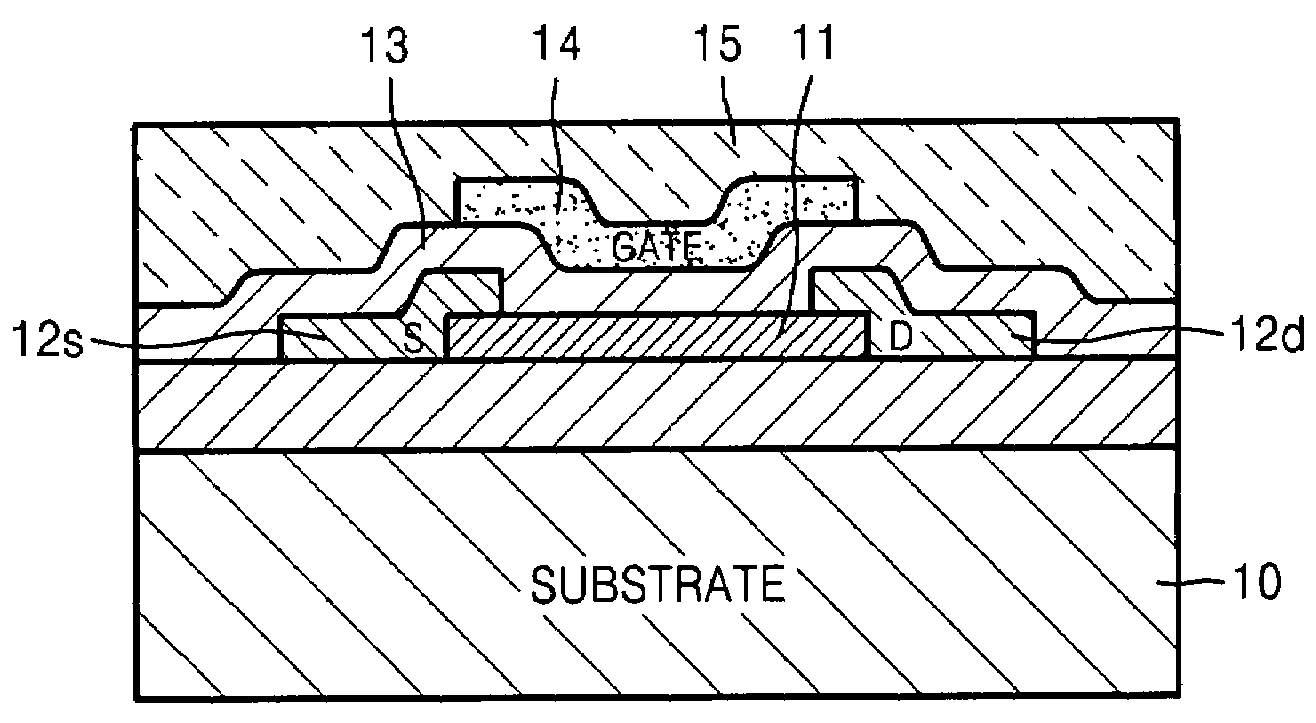

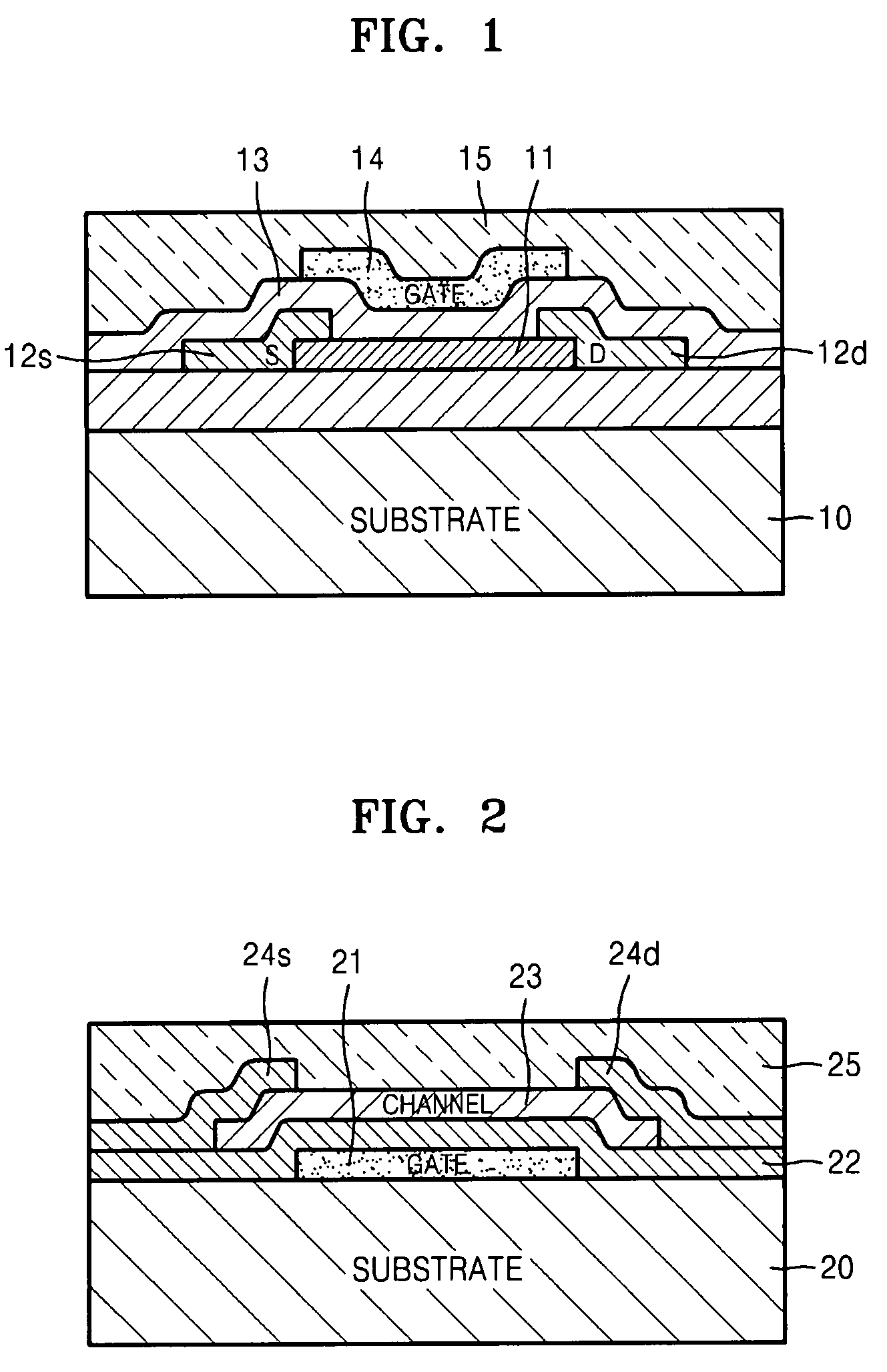

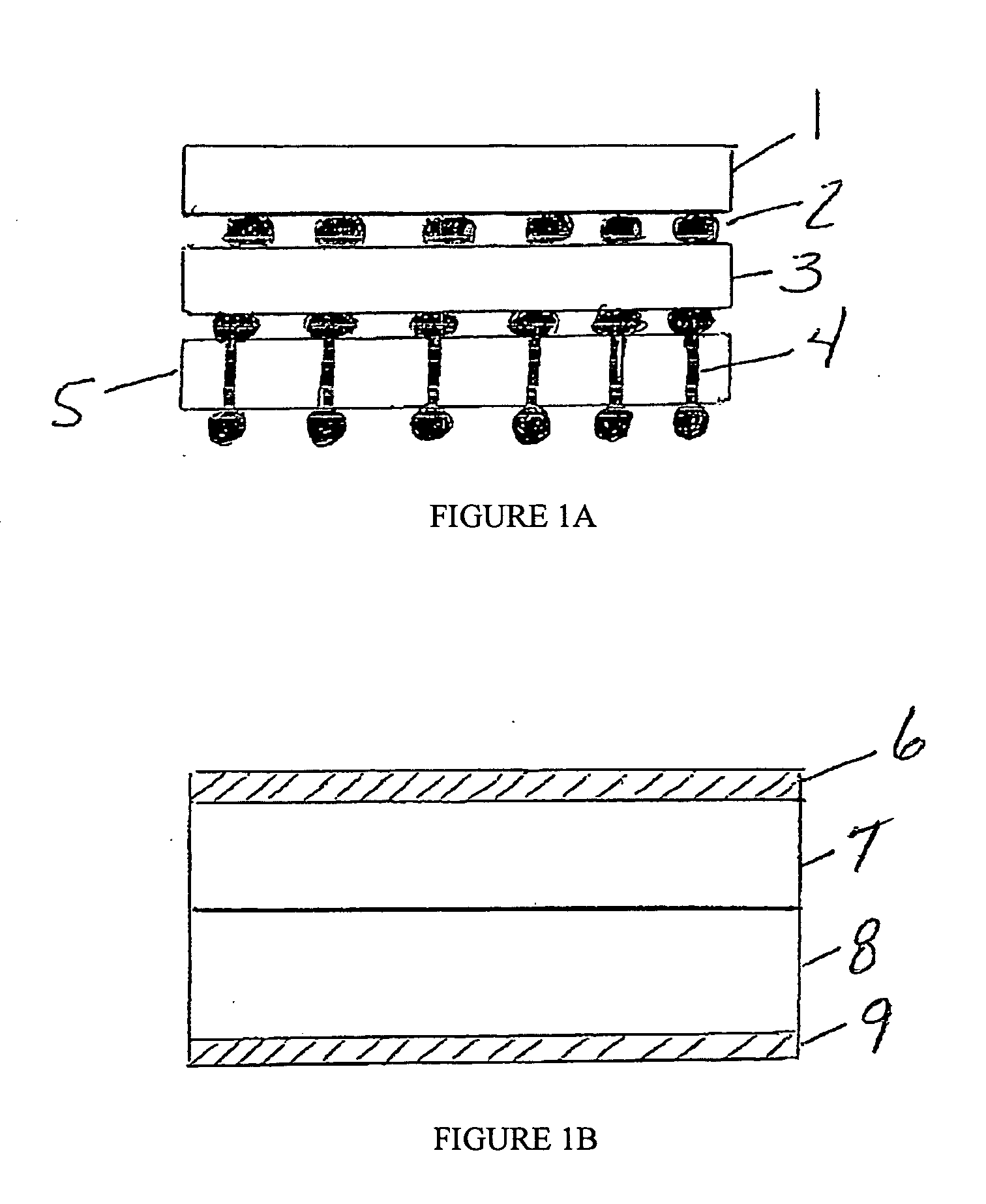

A zinc oxide (ZnO) thin film transistor (TFT) and method of forming the same are provided. The ZnO may include a ZnO semiconductor channel, a conductive ZnO gate forming an electric field around the ZnO semiconductor channel, an ZnO gate insulator interposed between the conductive ZnO gate and the ZnO semiconductor channel and an insulating ZnO passivation layer on the ZnO semiconductor channel, the conductive ZnO gate and the ZnO gate insulator to protect the ZnO semiconductor channel, the conductive ZnO gate, and the ZnO gate insulator. A thin film transistor (TFT) may be formed by forming a semiconductor channel, forming a conductive gate having an electric field around the semiconductor channel, forming a gate insulator between the conductive gate and the semiconductor channel, and forming an insulating passivation layer on the semiconductor channel, the conductive gate and the gate insulator.

Owner:SAMSUNG ELECTRONICS CO LTD

Semiconductor polysilicon component and method of manufacture thereof

InactiveUS6838308B2Improve responseTransistorPolycrystalline material growthOptoelectronicsGlass structure

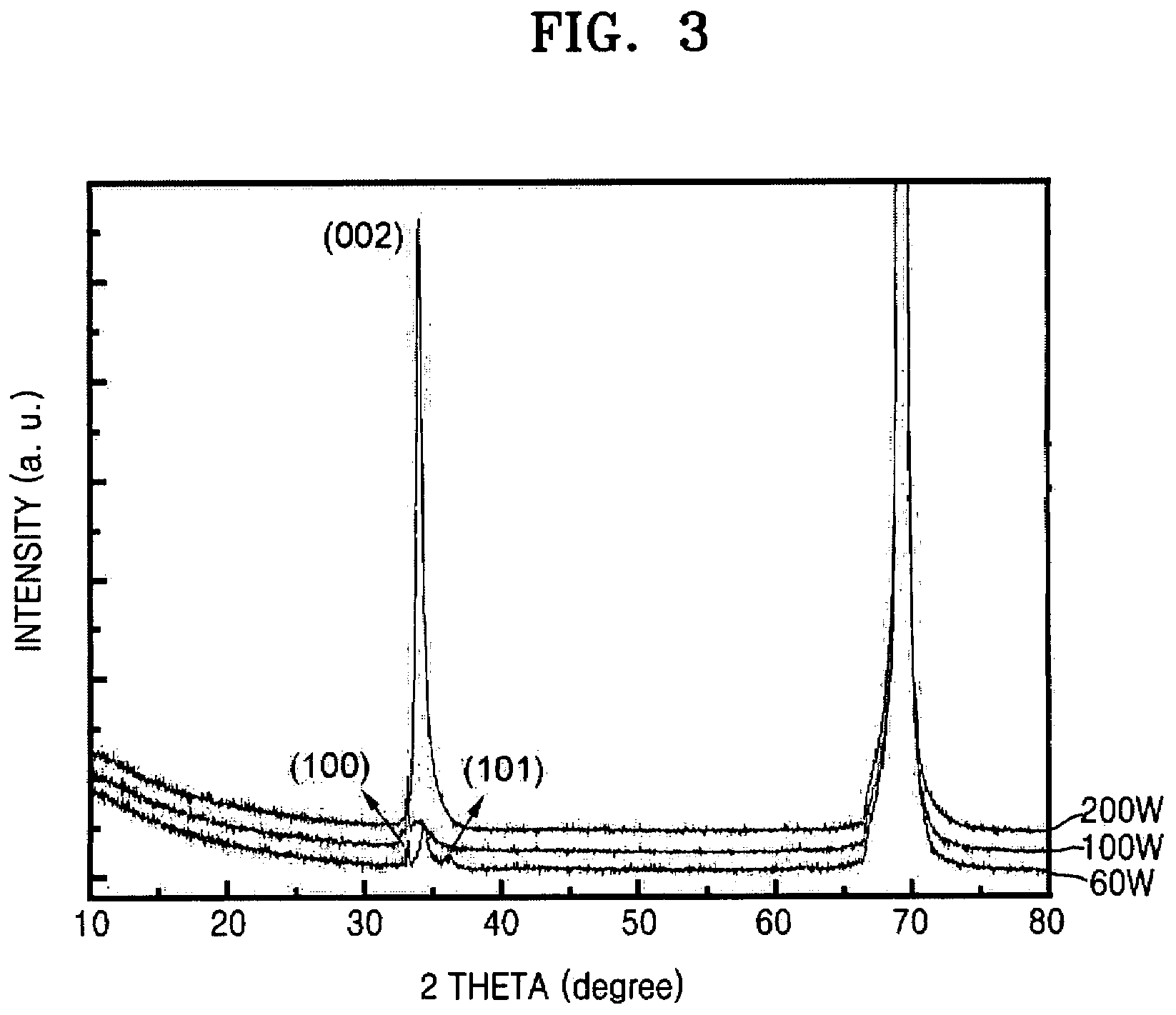

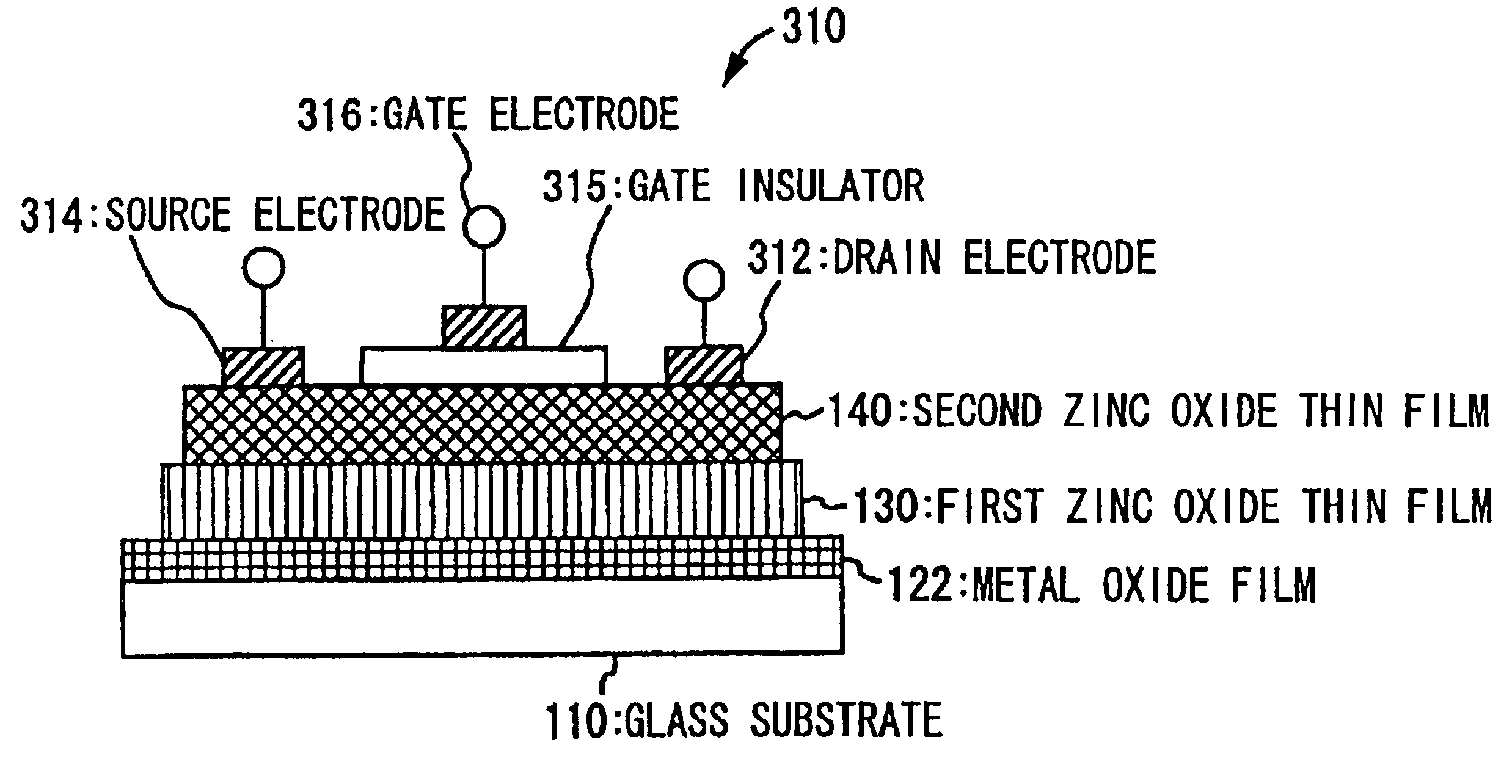

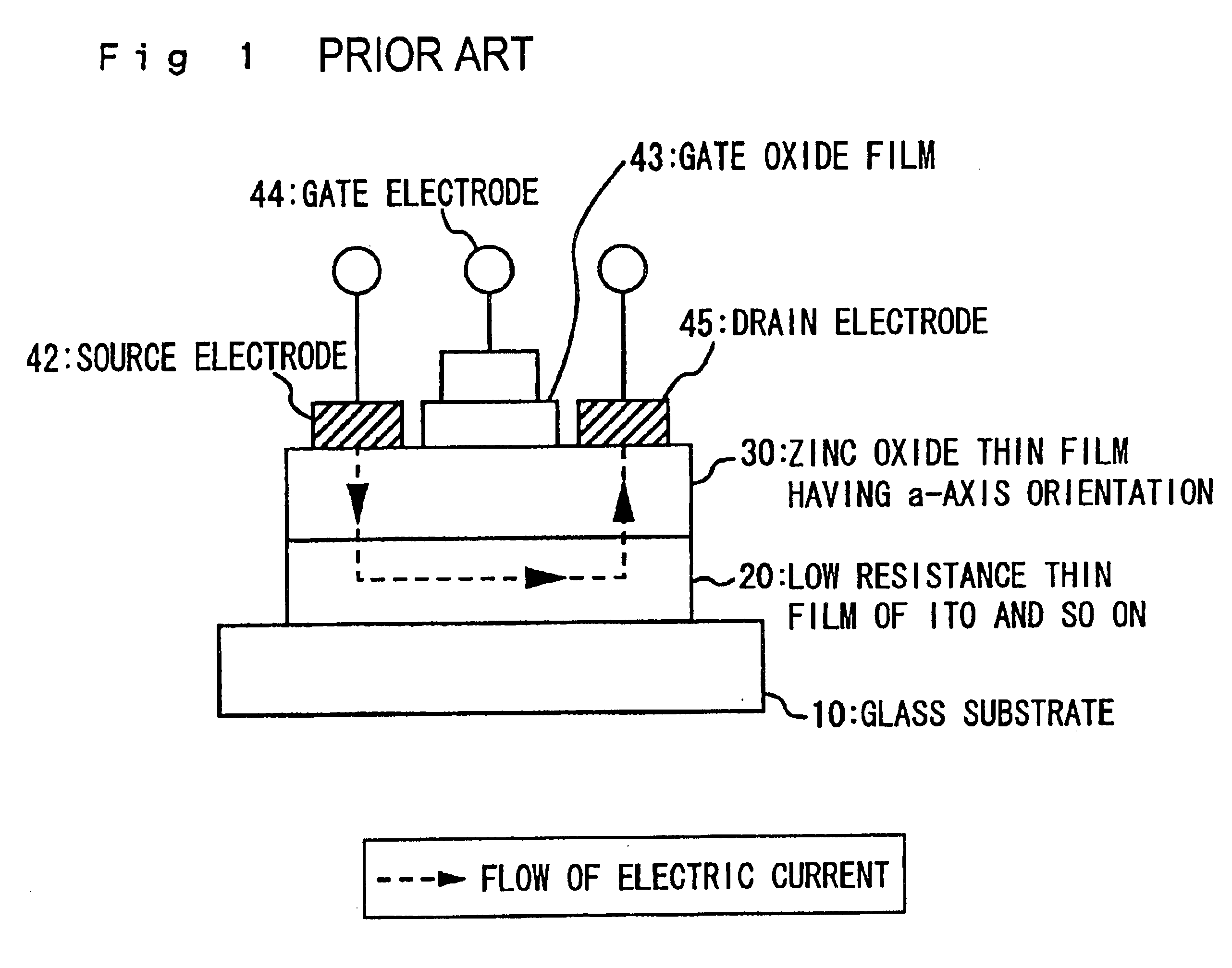

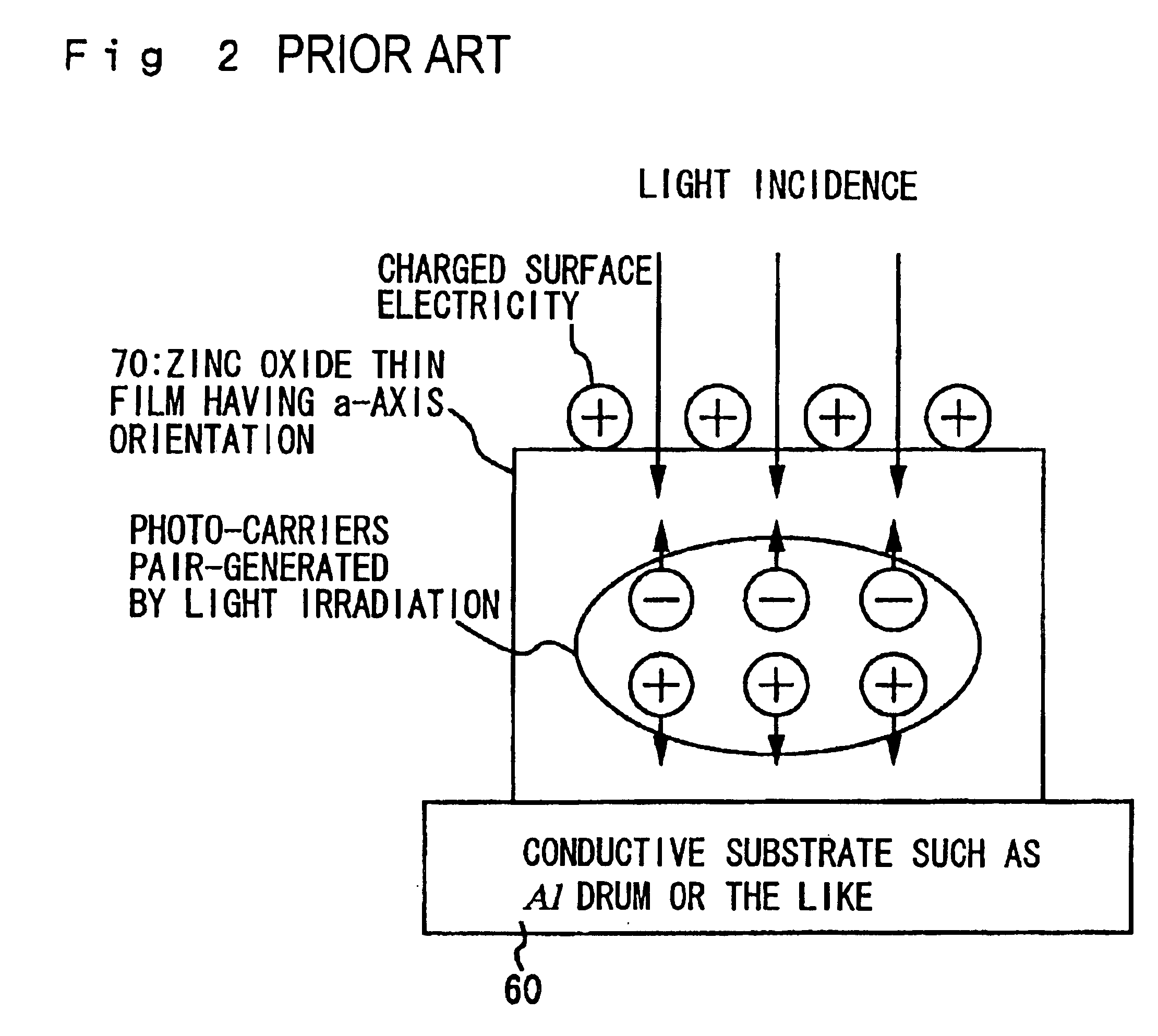

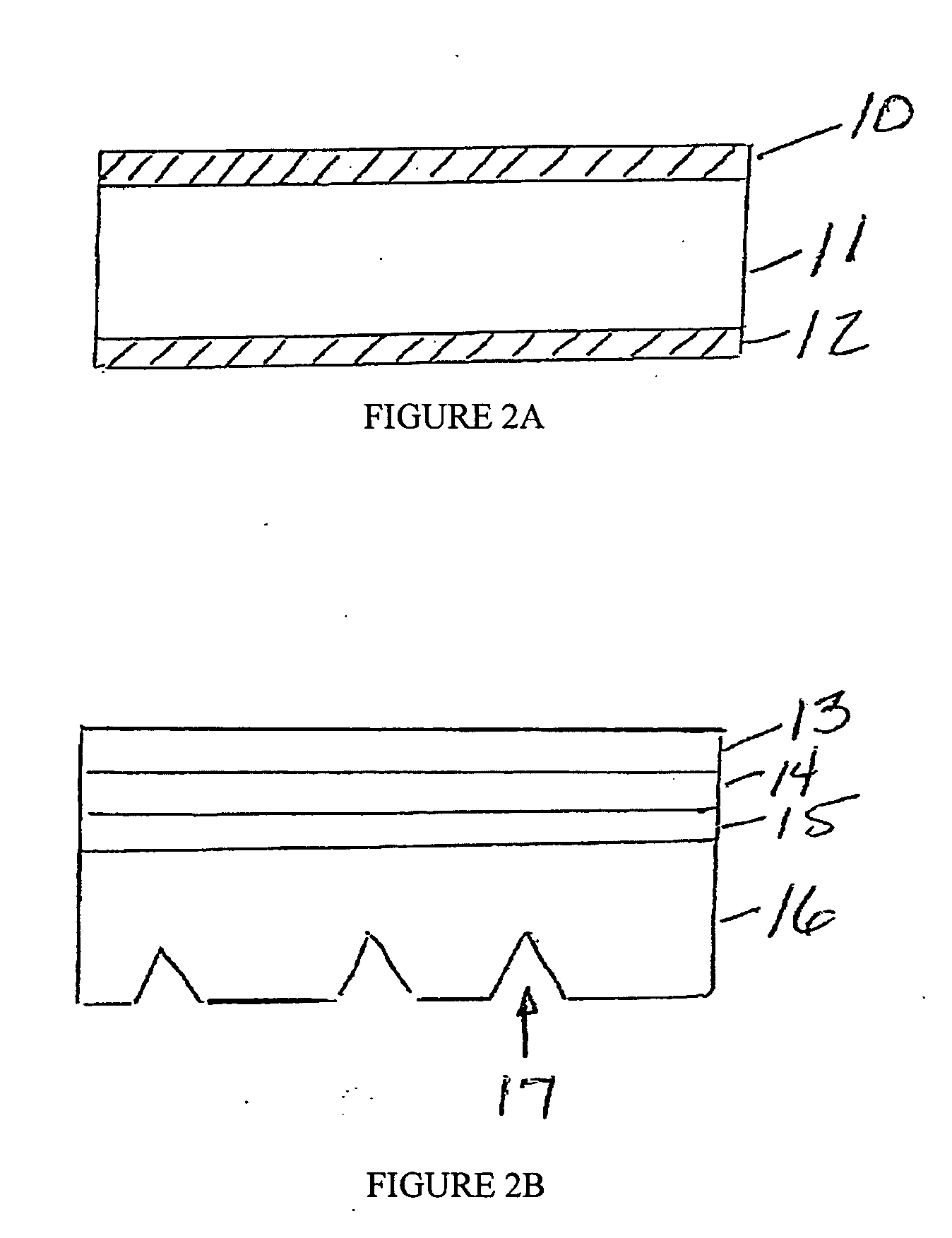

On a transparent substrate, by use of, for instance, vapor deposition, an Al film is formed. Subsequently, with a DC-bias applied on a surface of the Al film, a first zinc oxide thin film is formed by use of a sputtering method. On a surface of the first zinc oxide thin film, according to an atmospheric MO-CVD method, a second zinc oxide thin film is formed. When the second zinc oxide thin film deposited by use of an MO-CVD method is formed on the first zinc oxide thin film having a-axis orientation, the second zinc oxide thin film becomes to have the a-axis orientation. Since the Al thin film, owing to heat during the deposition by use of the MO-CVD method, is absorbed in the first zinc oxide thin film, the transparency is improved. As a result, a sample having a ZnO / ZnO / Al / glass structure becomes high in the transparency as a whole.

Owner:TOHOKU TECHNO ARCH CO LTD +1

Electronic light emissive displays incorporating transparent and conductive zinc oxide thin film

InactiveUS6541908B1Discharge tube luminescnet screensElectroluminescent light sourcesDisplay deviceOxide cathode

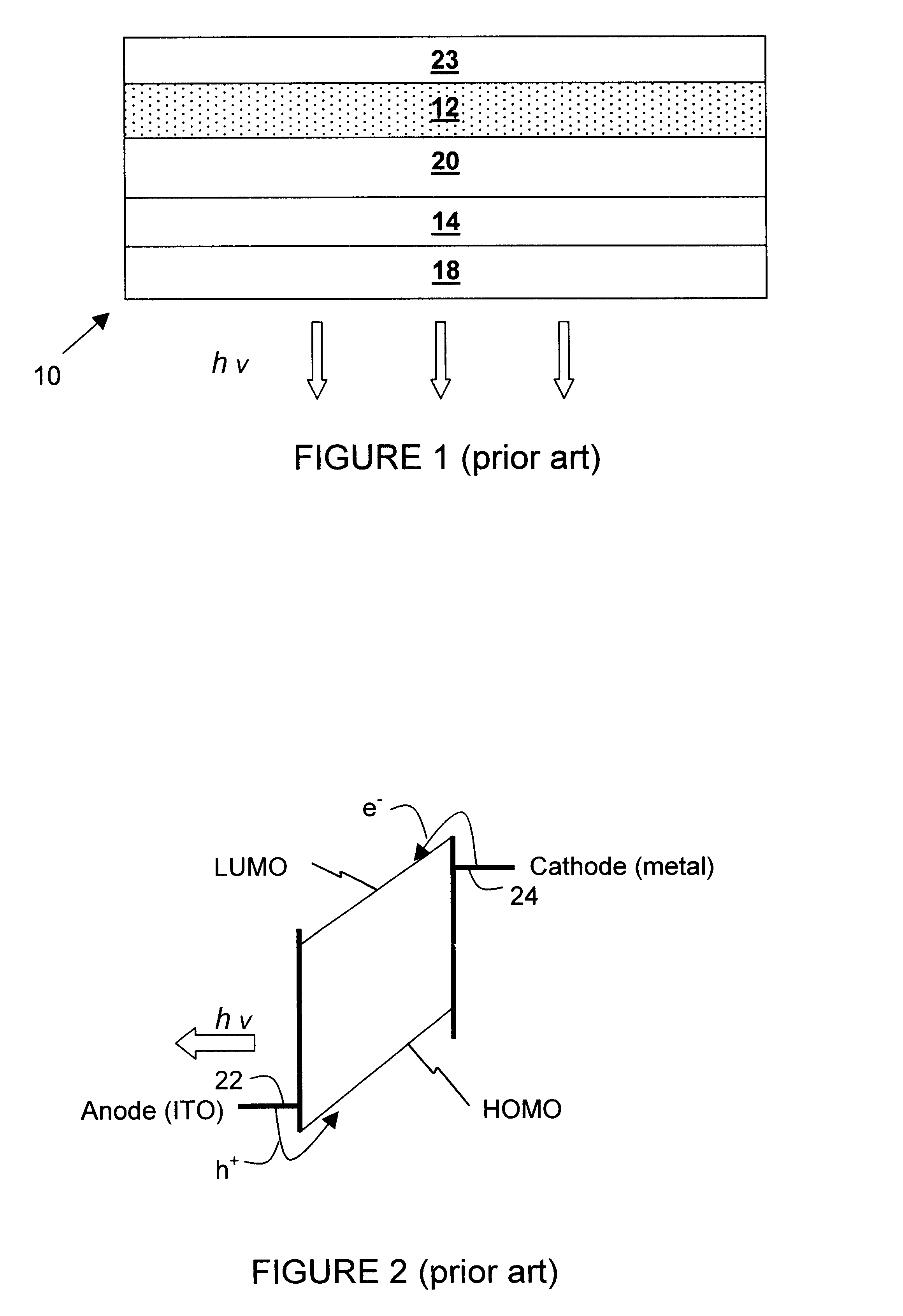

The present invention provides co-doped zinc oxide to flat panel, light emissive display devices and vacuum microelectronic devices to improve their efficiency and lifetime. This material has a low growth temperature and is compatible with metal oxide semiconductor (MOS) processing technology. It is tranparent, chemically stable and has a low work function, which result in many advantages when being used as the cathode for the aforementioned devices. In one embodiment of the emissive display device, an organic light diode (OLED) display has a high work function metal anode, such as platinum (Pt), gold (Au) or nickel (Ni) and a low work function co-doped zinc oxide cathode. Because of the energy level alignment provided by these two materials, the potential energy barriers to injection of electrons from the cathode and holes from the anode into the organic emissive medium are minimized so the display device operates more efficiently.

Owner:TELEDYNE SCI & IMAGING

Protective layers for sputter coated article

InactiveUS6833194B1Improve throughputTendency increaseVacuum evaporation coatingSputtering coatingLow emissivityMetal Primer

Owner:VITRO FLAT GLASS LLC

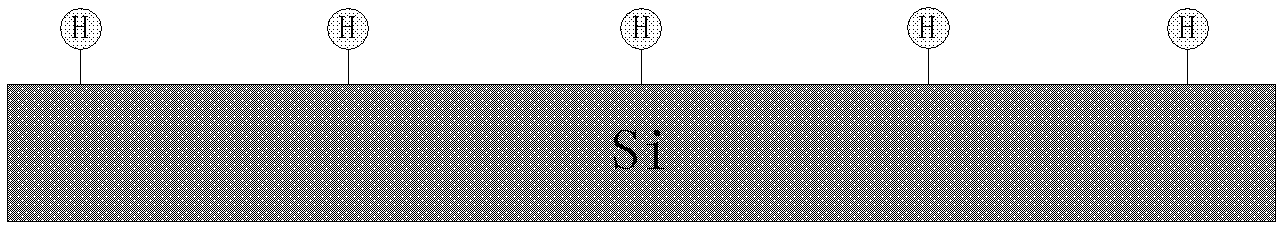

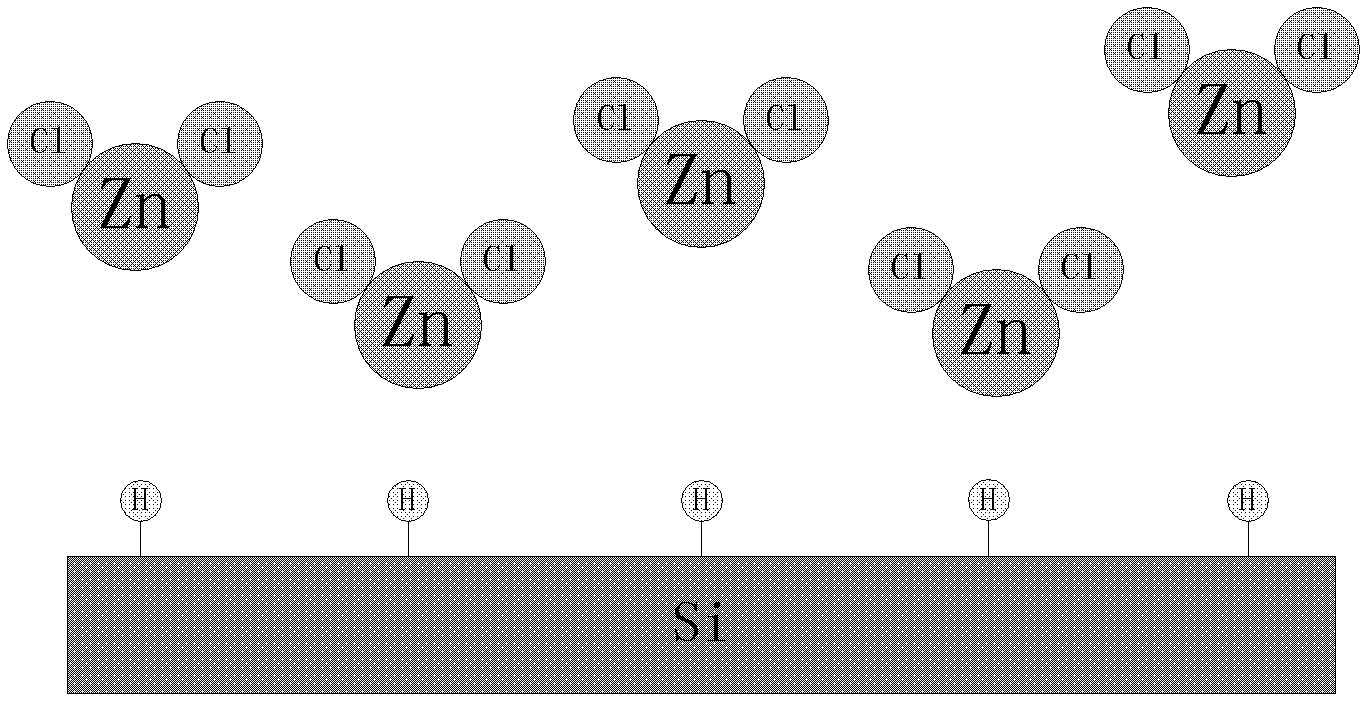

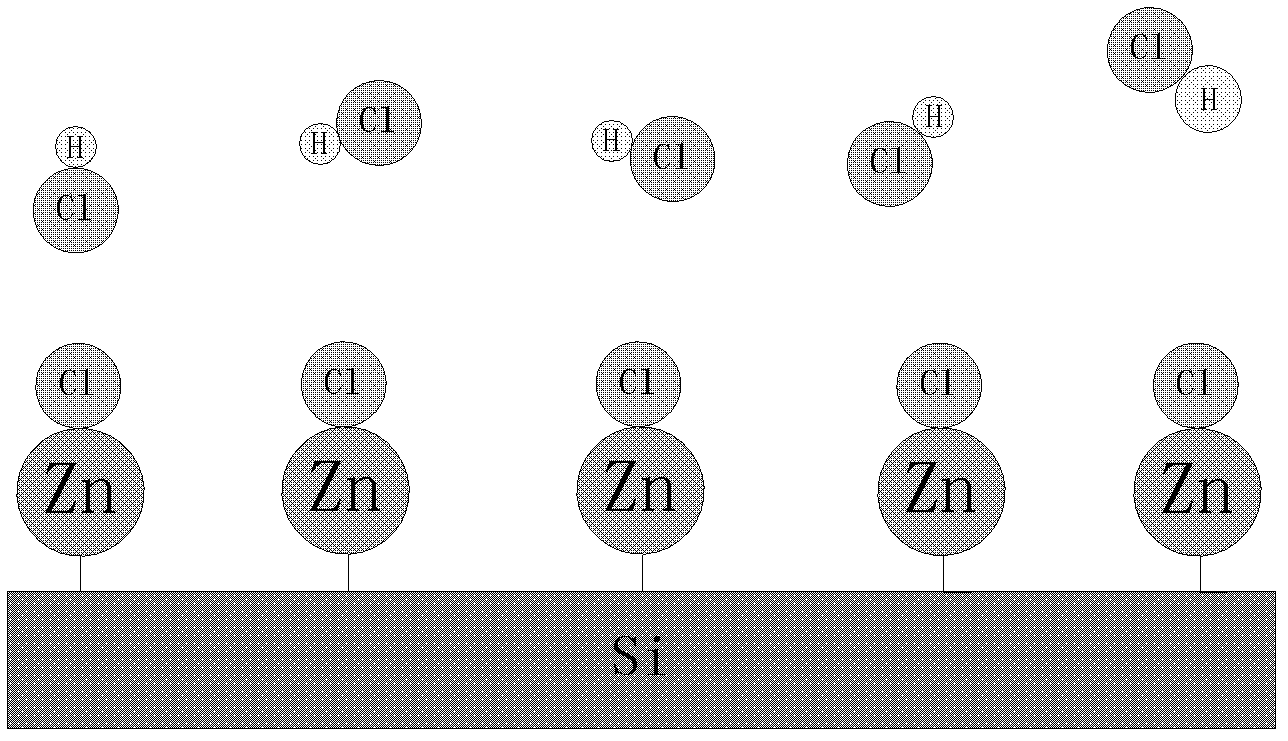

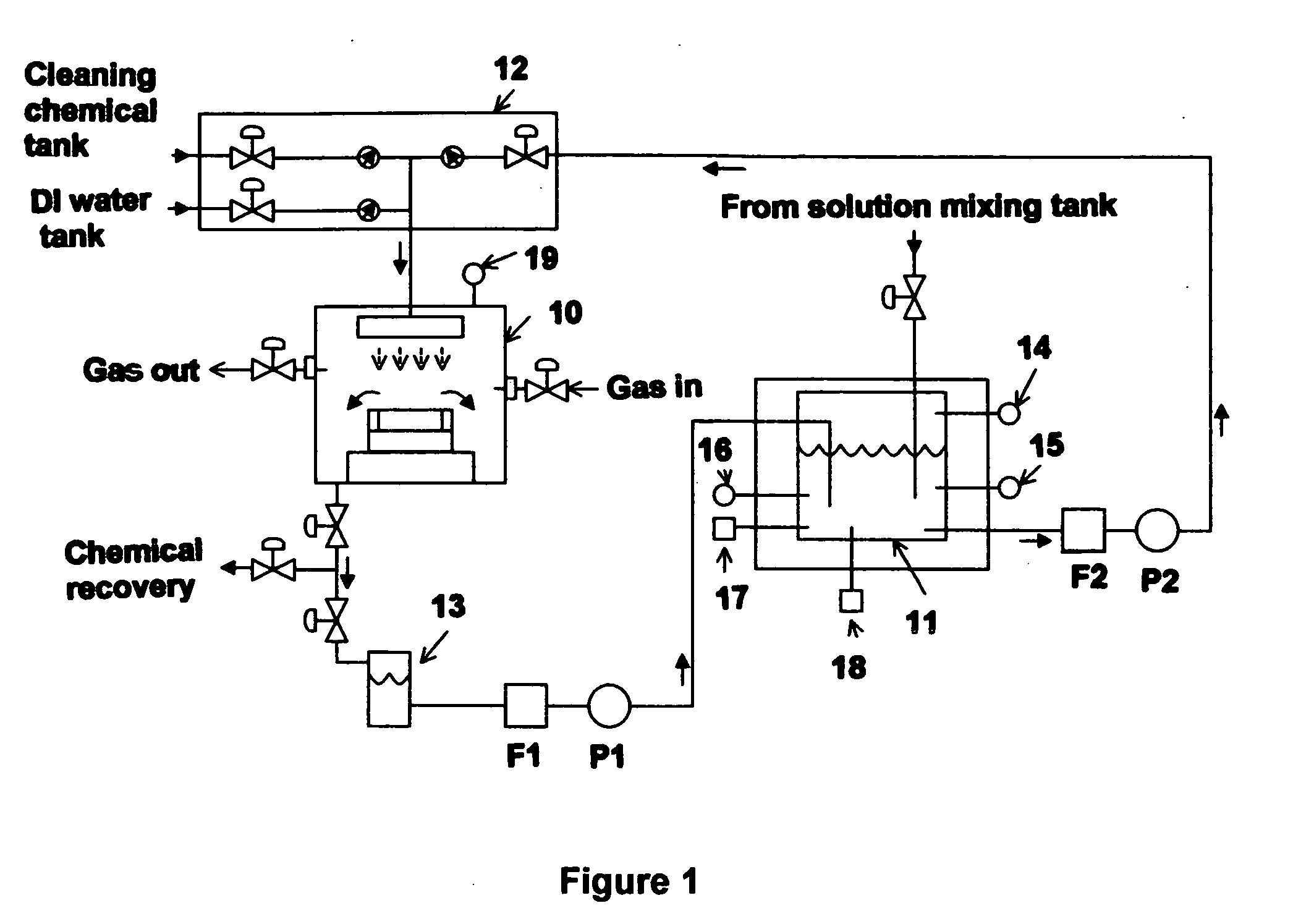

Preparation method of nitrogen-doped zinc oxide film

ActiveCN102304700AImprove performanceSimple methodFinal product manufactureSemiconductor/solid-state device manufacturingOxygenNitrogen gas

The invention relates to the technical field of zinc oxide preparation, and in particular relates to a preparation method of a nitrogen-doped zinc oxide film. The preparation method comprises: placing a silicon substrate in the reaction cavity of atomic layer deposition (ALD) equipment; introducing gas containing a zinc source into the reaction cavity of the ALD equipment, wherein the zinc atoms in the gas containing the zinc source are adsorbed to the silicon substrate; conveying hydrogen to the reaction cavity of the ALD equipment based on nitrogen as a carrier gas, and simultaneously carrying out plasma discharge; introducing an oxygen-containing source to the reaction cavity of the ALD equipment, wherein the zinc atoms which do not react with nitrogen atoms form zinc-oxygen bonds withthe oxygen atoms in the oxygen-containing source; and repeating the steps, so as to grow the zinc oxide film containing the nitrogen atoms layer by layer. In the preparation method provided by the invention, nitrogen doping is carried out on the zinc oxide film by utilizing the ALD equipment; the method is simple and practicable; by utilizing the characteristic of atomic layer deposition and single-layer cycle growth, the uniform nitrogen doping in the whole film structure can be achieved in the process of zinc oxide film growth so that the doped film is complete in structure and excellent inproperty.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

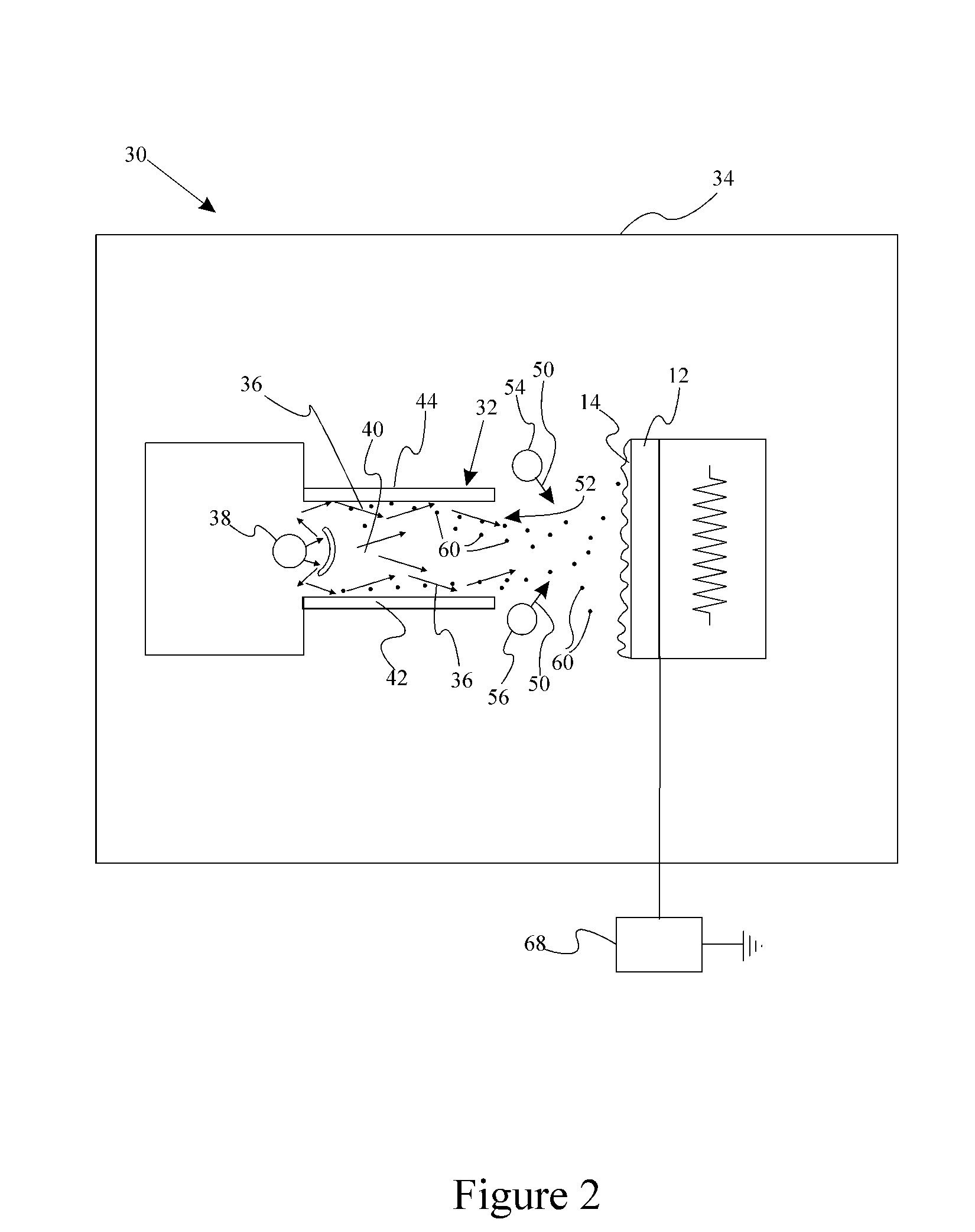

Method and process for deposition of textured zinc oxide thin films

InactiveUS20080308411A1Large widthLow costVacuum evaporation coatingSputtering coatingReactive gasZinc atom

A method for sputtering a textured zinc oxide coating onto a substrate by reactive-environment hollow cathode sputtering comprises providing a sputter reactor that has a cathode channel and a flow exit end. The cathode channel allows a gas stream to flow therein. This cathode channel is at least partially defined by a channel-defining surface that includes at least one zinc-containing target. A gas is flowed through the channel, such that the gas emerges from the flow exit. A plasma is then generated such that material is sputtered off the channel-defining surface to form a gaseous mixture containing zinc atoms that is transported to the substrate. A reactive gas is then introduced into the sputter reactor so that the reactive gas reacts with the zinc-containing gaseous mixture to form the textured zinc oxide coating.

Owner:NEW MILLENNIUM SOLAR EQUIP CORP

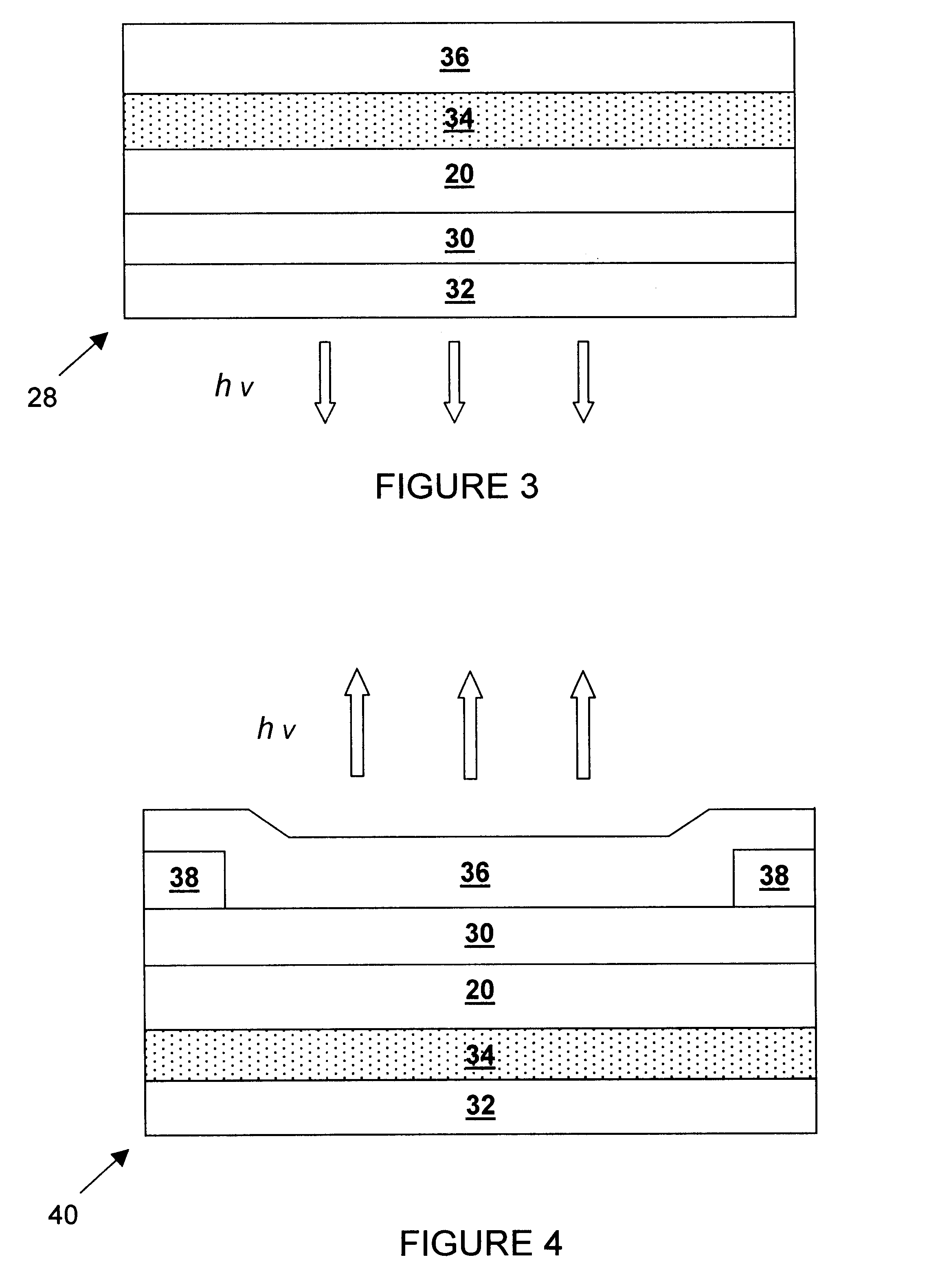

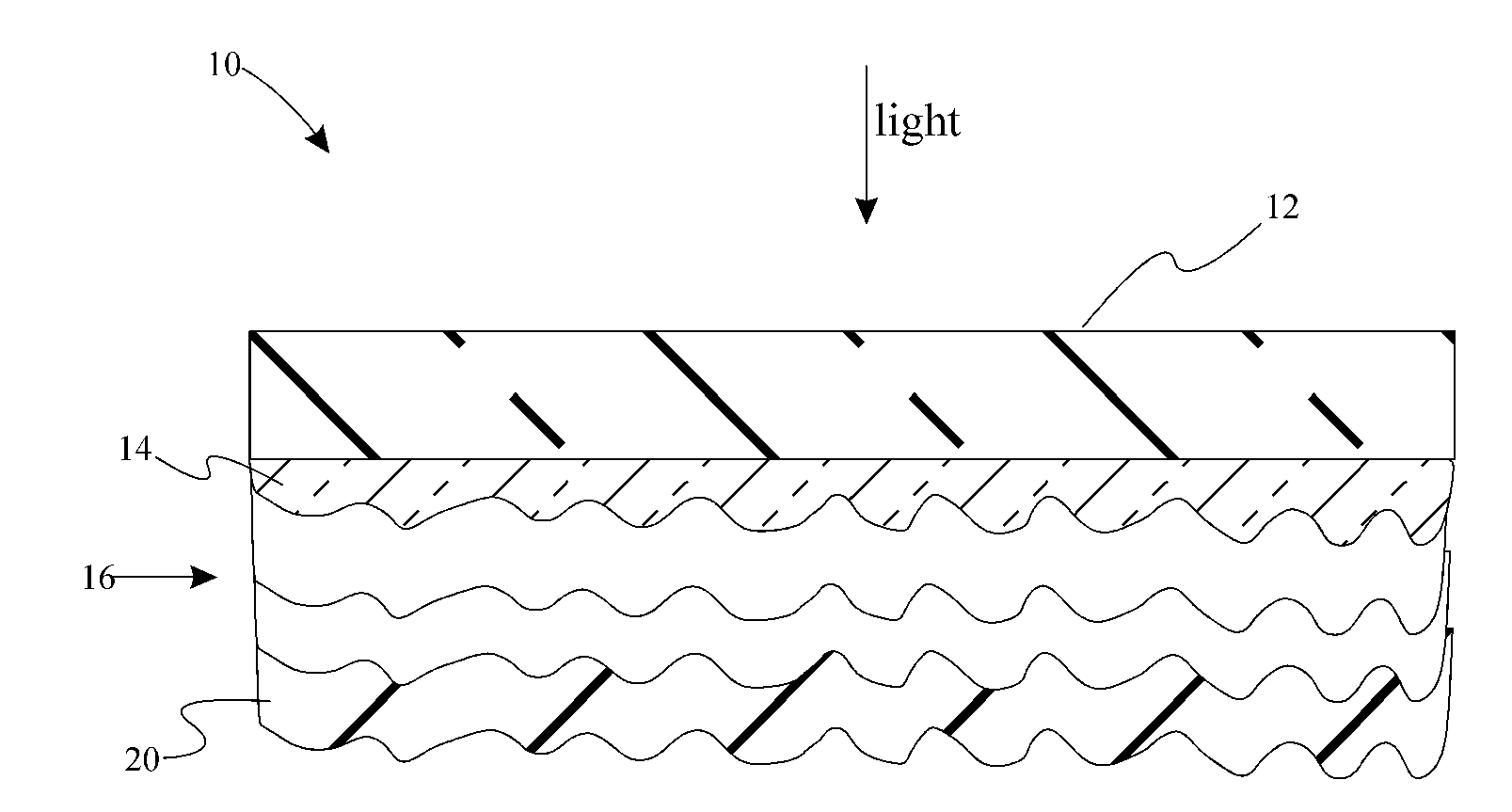

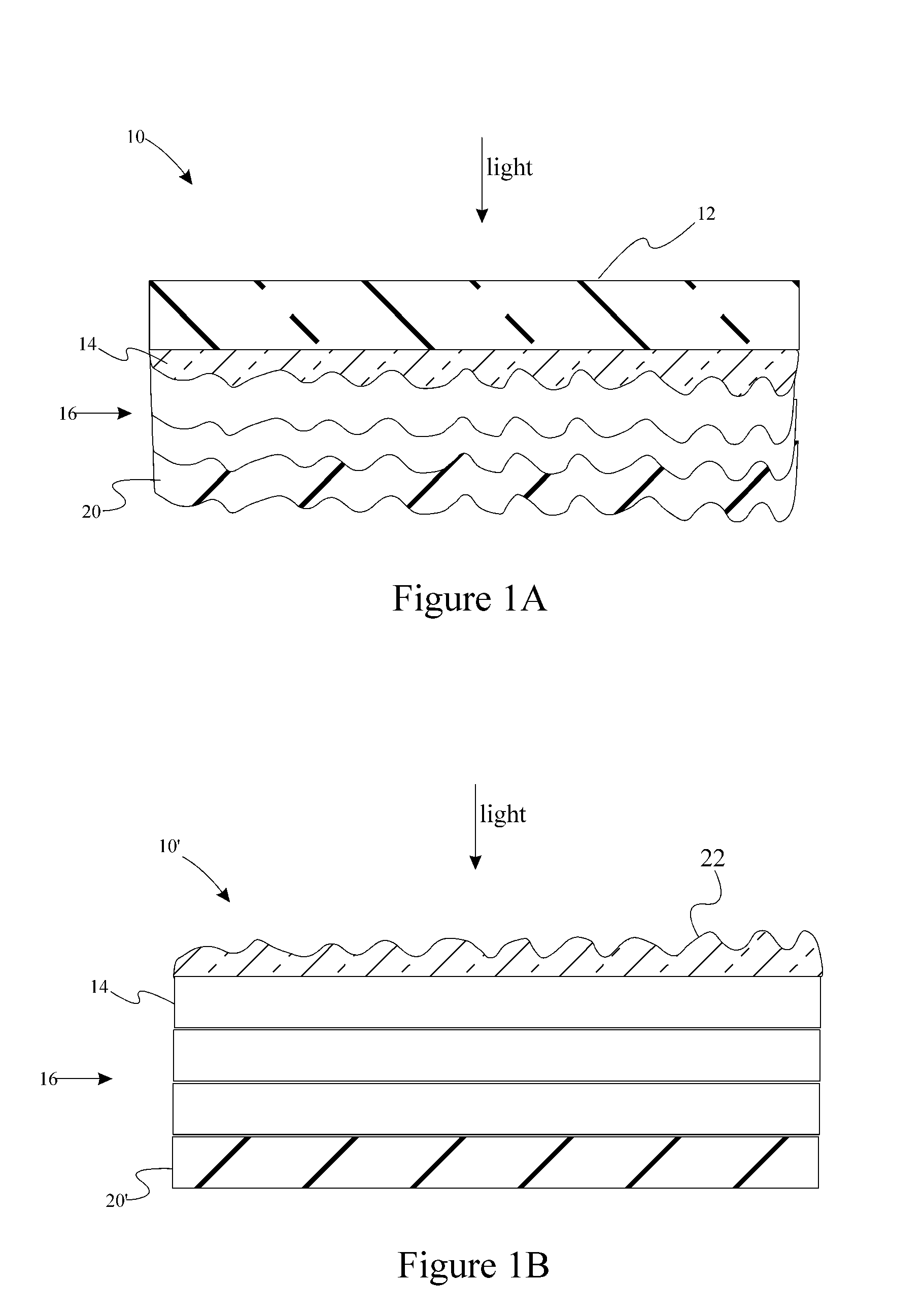

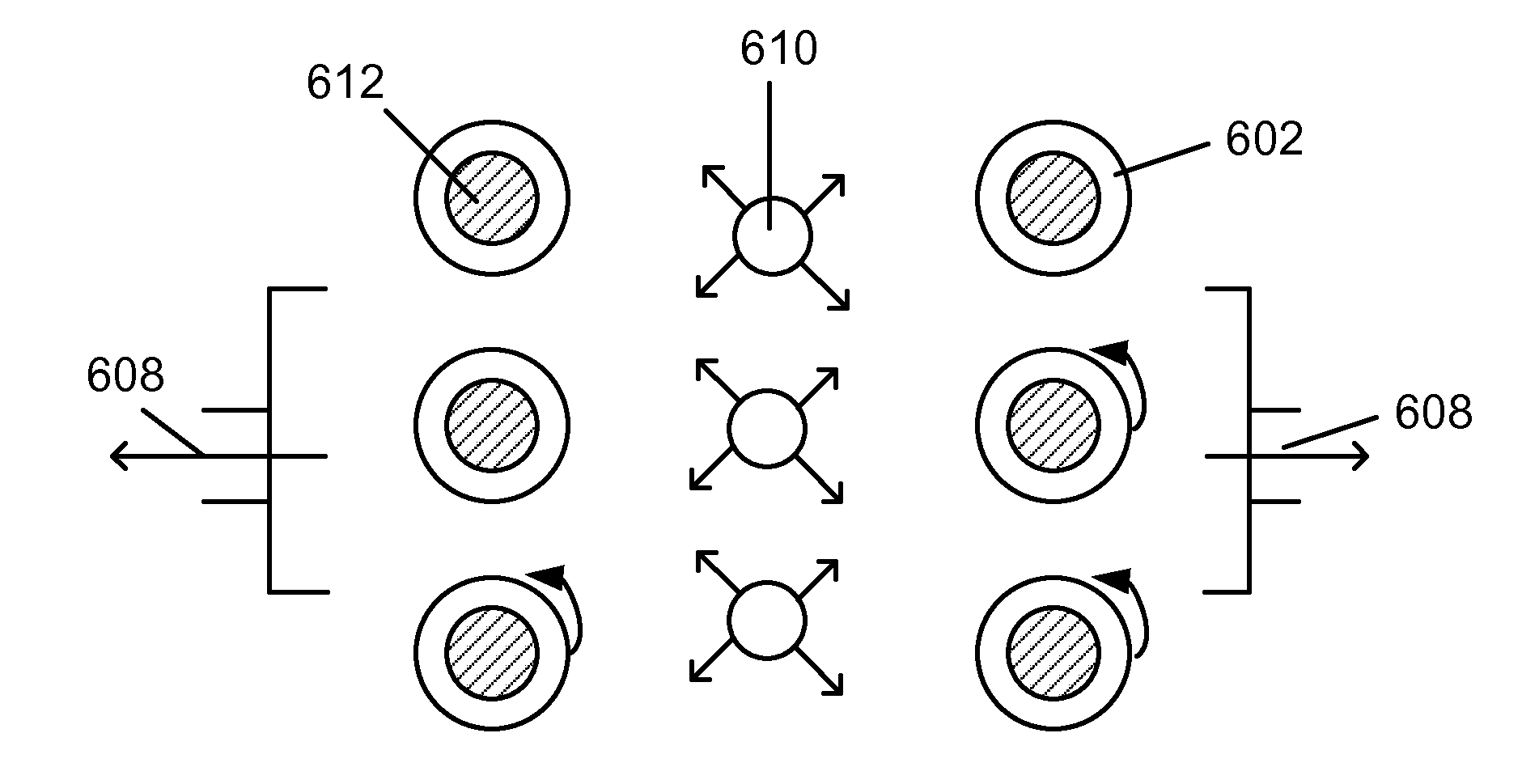

Dual sided processing and devices based on freestanding nitride and zinc oxide films

InactiveUS20100200837A1Improved current spreadingReduce absorptionSolid-state devicesSemiconductor/solid-state device manufacturingThermoelectric materialsRefractive index

Thin freestanding nitride films are used as a growth substrate to enhance the optical, electrical, mechanical and mobility of nitride based devices and to enable the use of thick transparent conductive oxides. Optoelectronic devices such as LEDs, laser diodes, solar cells, biomedical devices, thermoelectrics, and other optoelectronic devices may be fabricated on the freestanding nitride films. The refractive index of the freestanding nitride films can be controlled via alloy composition. Light guiding or light extraction optical elements may be formed based on freestanding nitride films with or without layers. Dual sided processing is enabled by use of these freestanding nitride films. This enables more efficient output for light emitting devices and more efficient energy conversion for solar cells.

Owner:GOLDENEYE

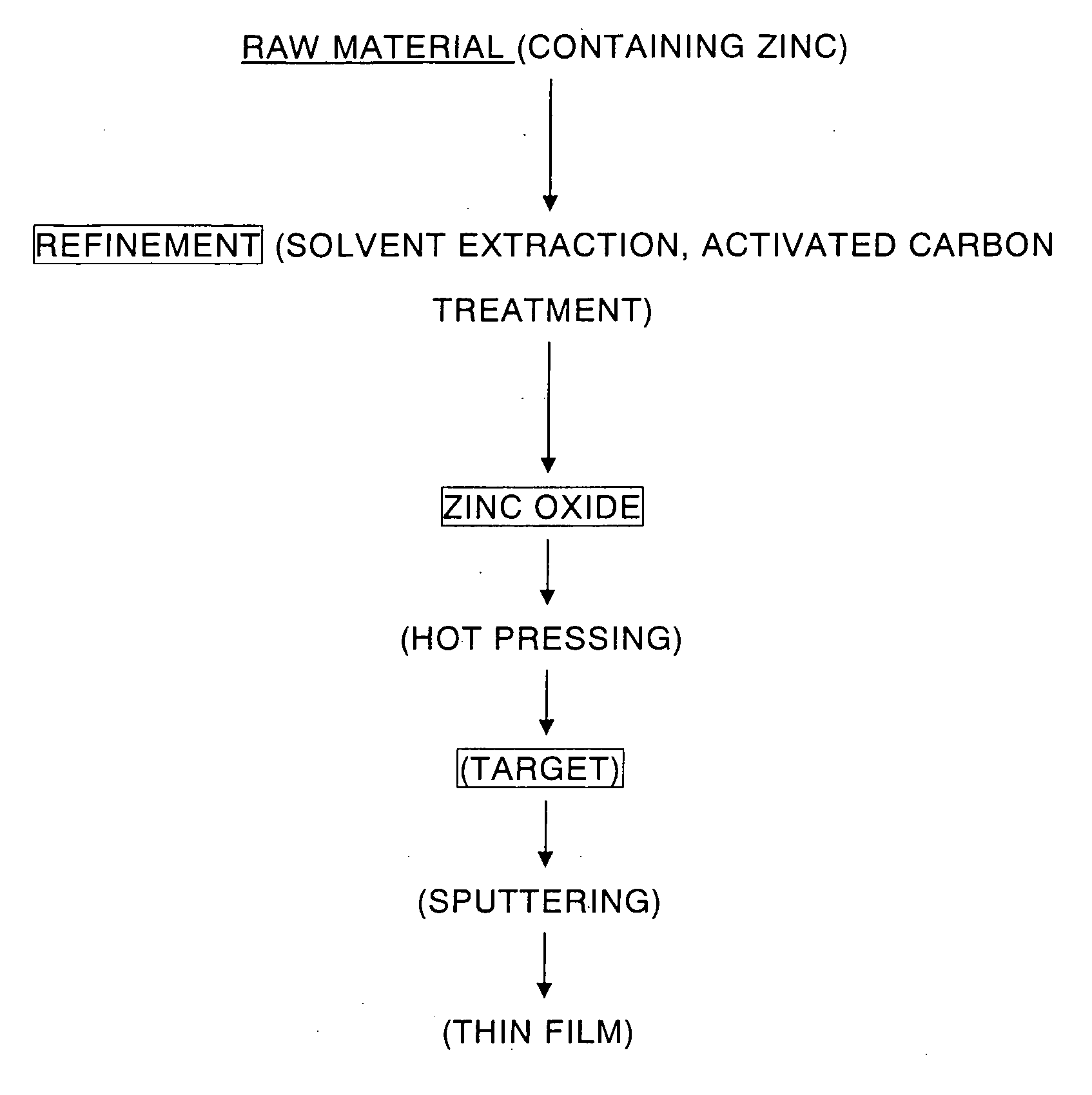

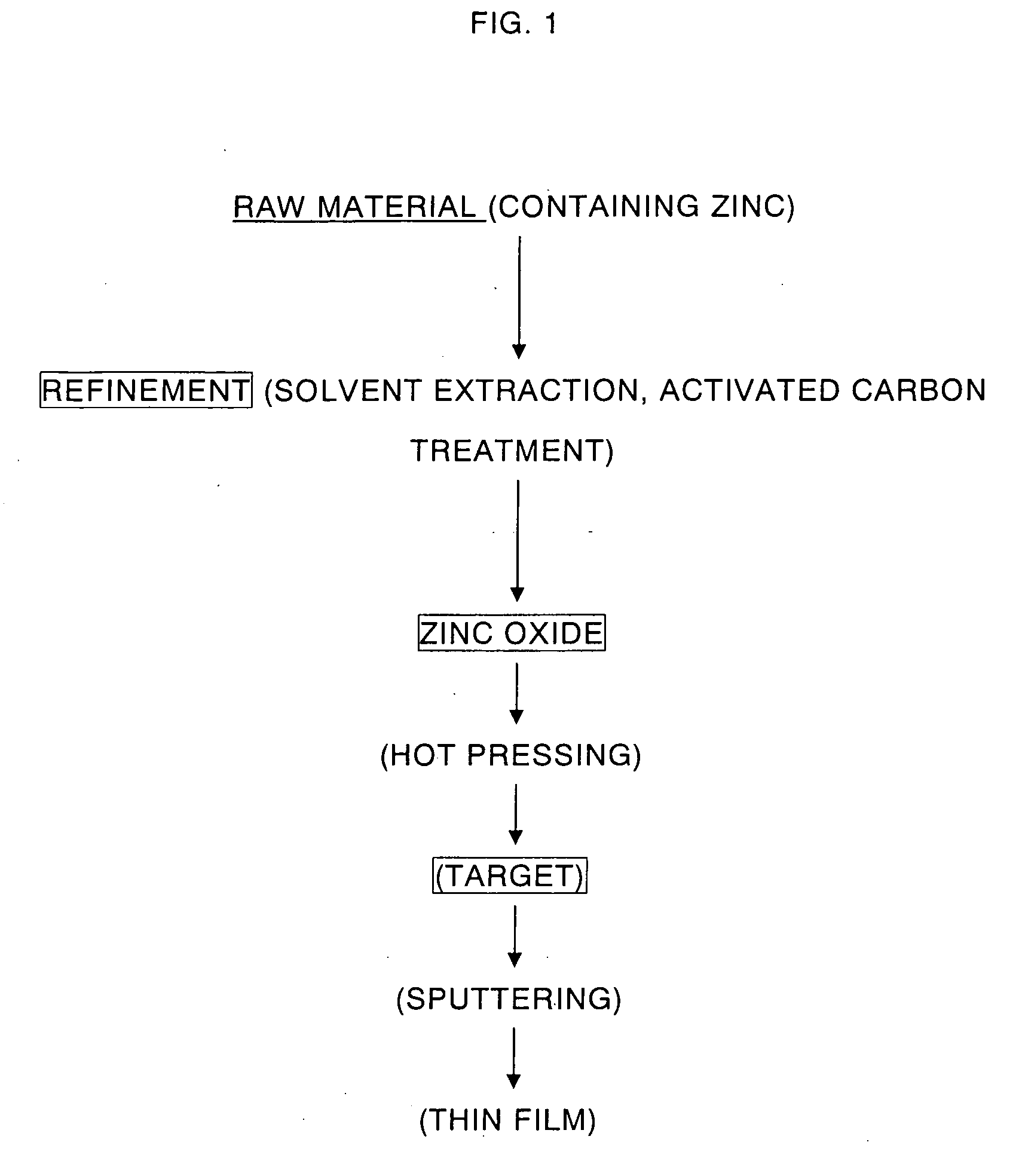

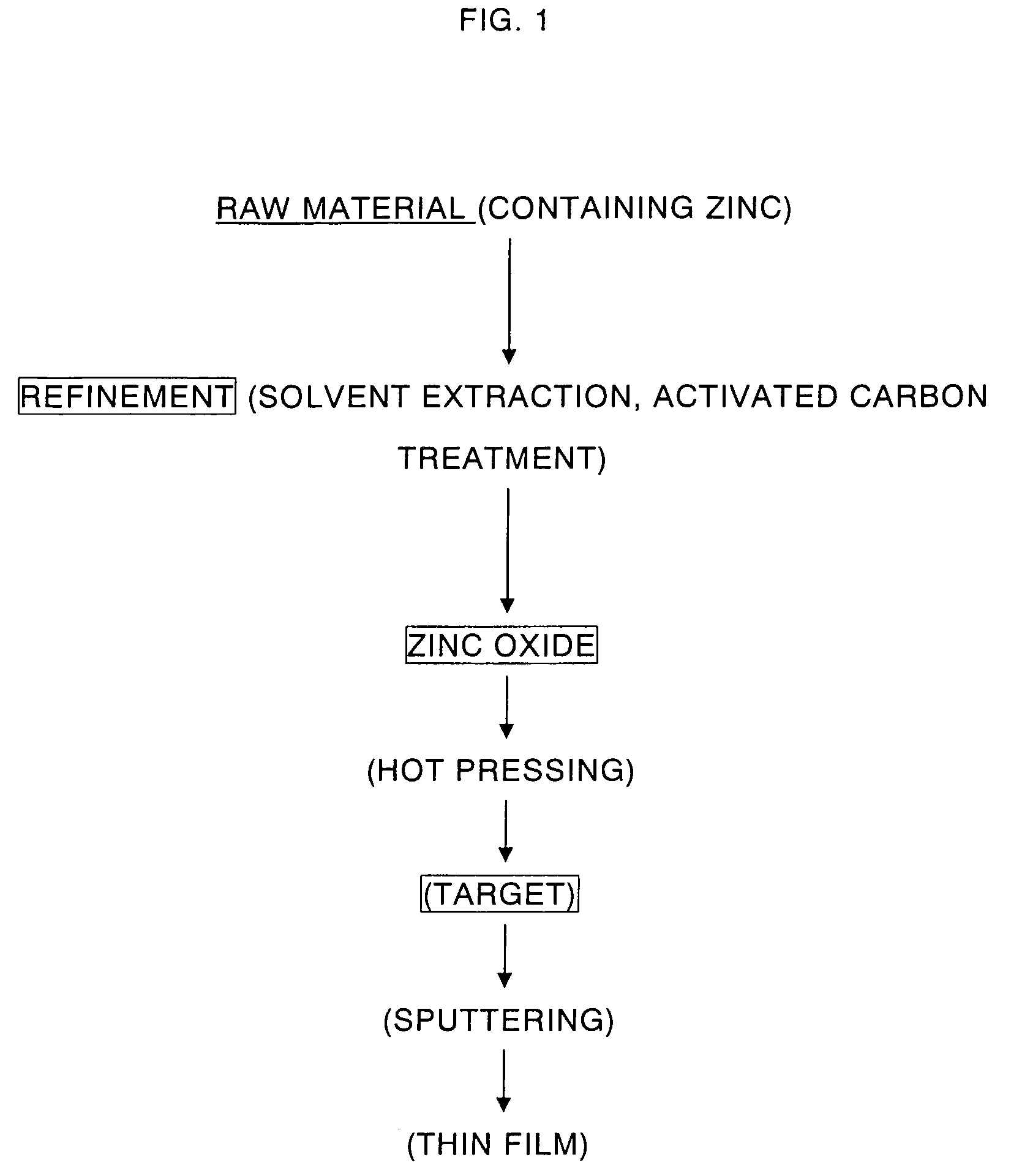

High purity zinc oxide powder and method for production thereof, and high purity zinc oxide target and thin film of high purity zinc oxide

InactiveUS20070098626A1High purityReduce manufacturing costCellsZinc halidesZinc hydroxideActivated carbon

Provided is a manufacturing method of high purity oxide powder including the steps of subjecting a raw material such as Zn-containing scrap to acid leaching or electrolytic extraction, thereafter performing solvent extraction and activated carbon treatment thereto in order to remove impurities, neutralizing the resultant solution freed of impurities with an alkaline solution to obtain zinc hydroxide, and firing the zinc hydroxide to obtain zinc oxide. Provided are high purity zinc oxide efficiently freed of impurities, in particular C, Cl, S and Pb impurities, at low cost and the manufacturing method thereof; a target manufactured by firing the high purity zinc oxide; and a high purity zinc oxide thin film obtained by the sputtering the target.

Owner:JX NIPPON MINING& METALS CORP

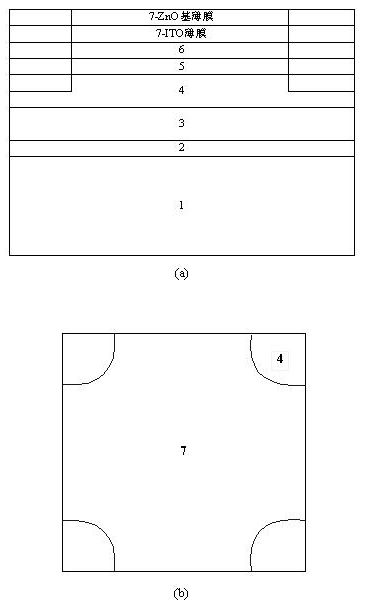

Amorphous zinc oxide thin film transistor and method of manufacturing the same

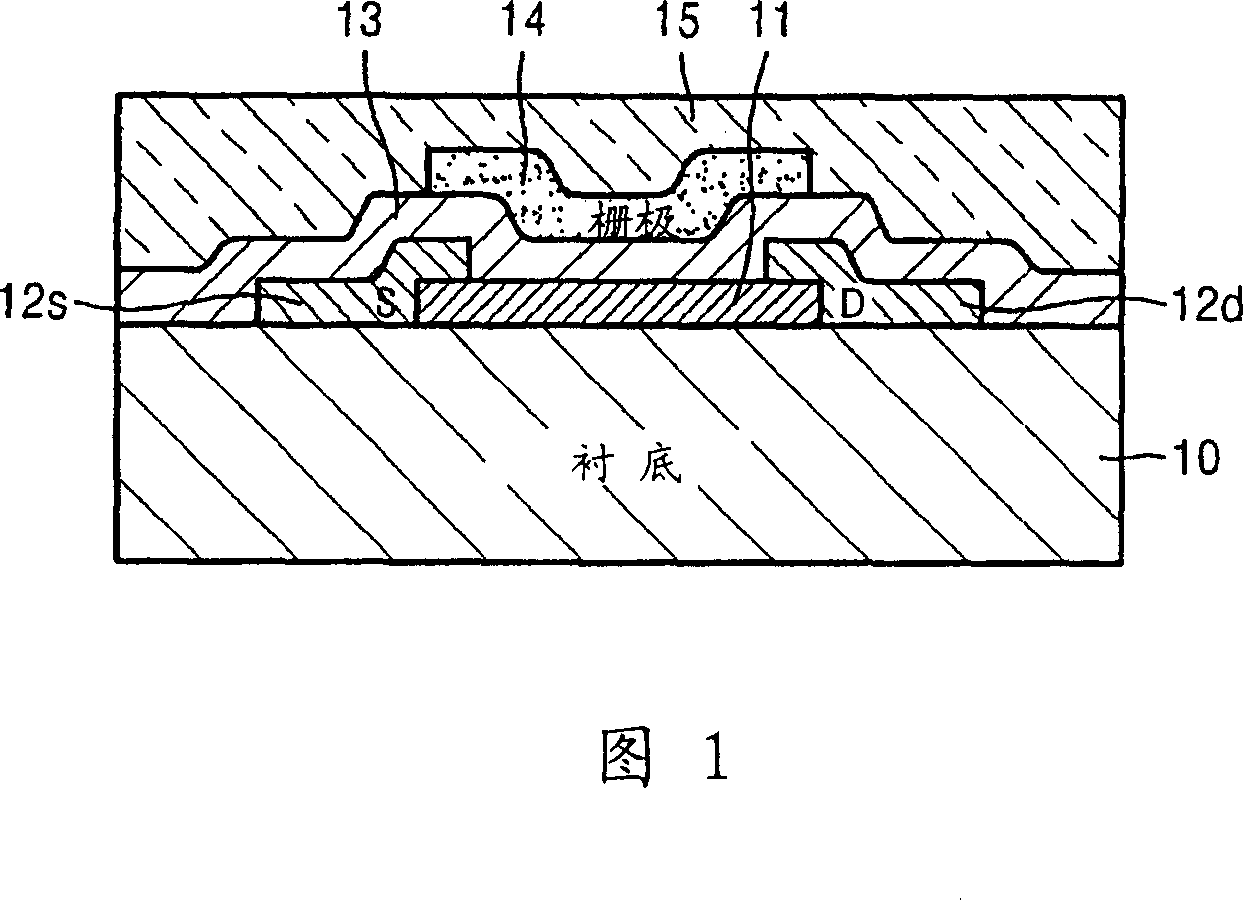

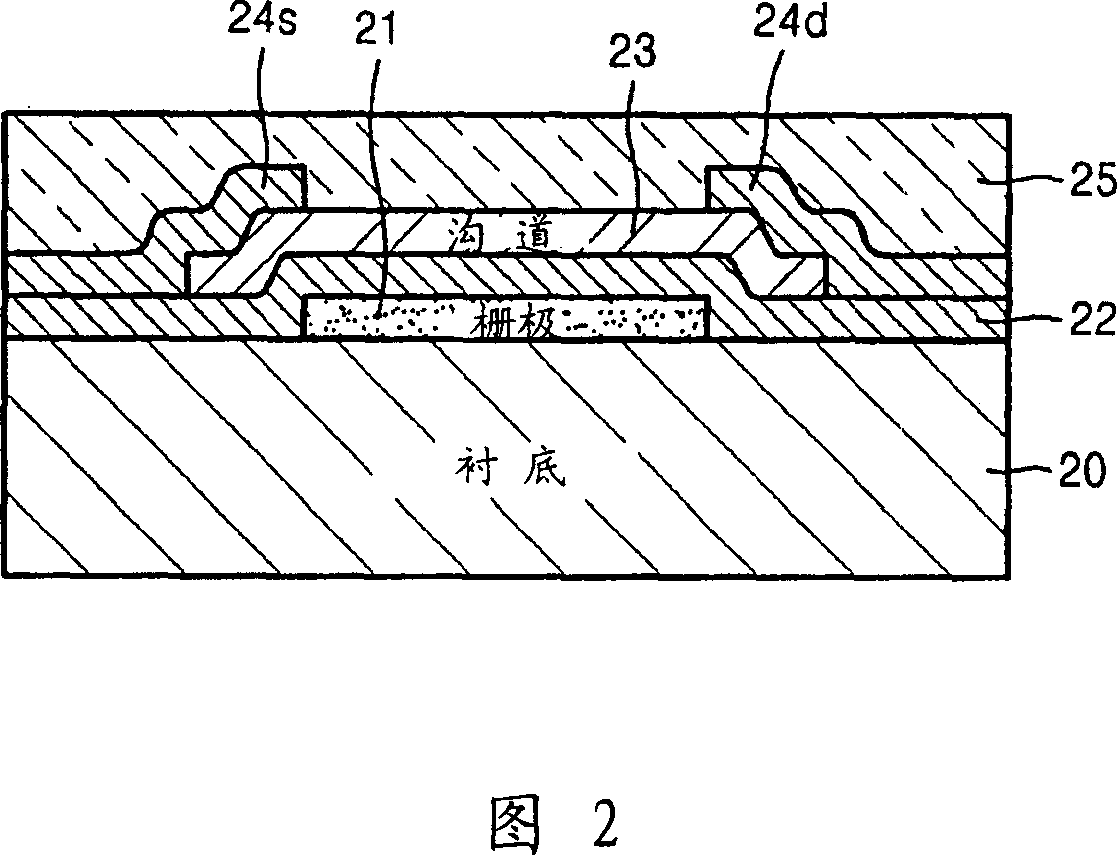

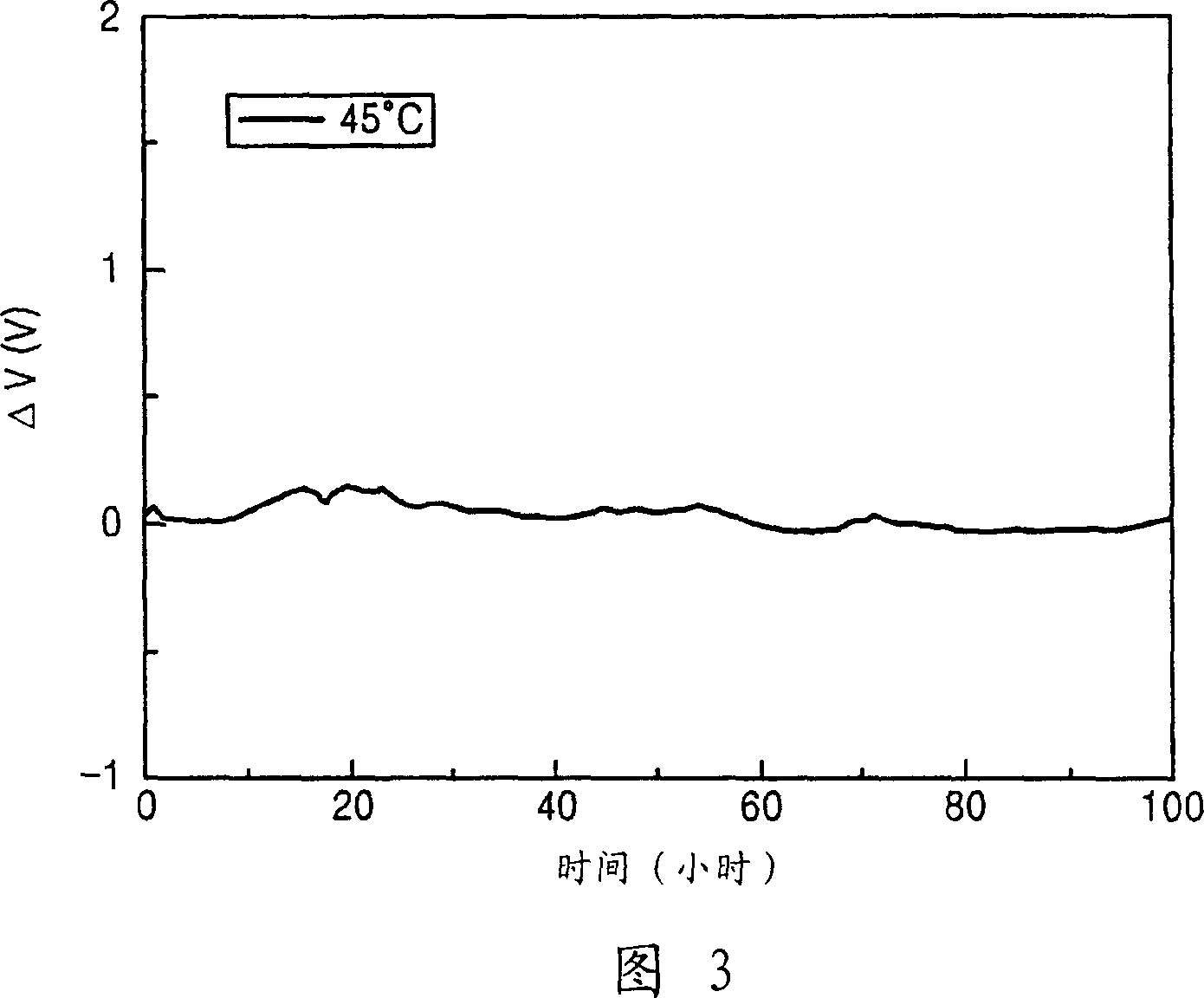

InactiveCN101060139ATransistorSemiconductor/solid-state device manufacturingGate insulatorElectric field

The invention provides an amorphous zinc oxide (ZnO) thin-film transistor (TFT) and a manufacturing method thereof. The amorphous zinc oxide thin-film transistor comprises an underlay, a semiconductor channel, a source electrode, a drain electrode, a grid electrode and a grid electrode insulator, wherein, the underlay is formed by amorphous zinc oxide compound semiconducting material containing n (Gao3), m (InO3) and (ZnO) k; the source electrode and the drain electrode are electrically contacted with the two ends of the semiconductor channel; the grid electrode forms an electric field surrounding the semiconductor channel; the grid electrode insulator is arranged between the grid electrode and the semiconductor channel. The conditions of inequality that n is more than or equal to 1.5, m is more than or equal to 1.5 and k is more than zero are met.

Owner:SAMSUNG ELECTRONICS CO LTD

Zinc oxide thin film, transparent conductive film and display device using the same

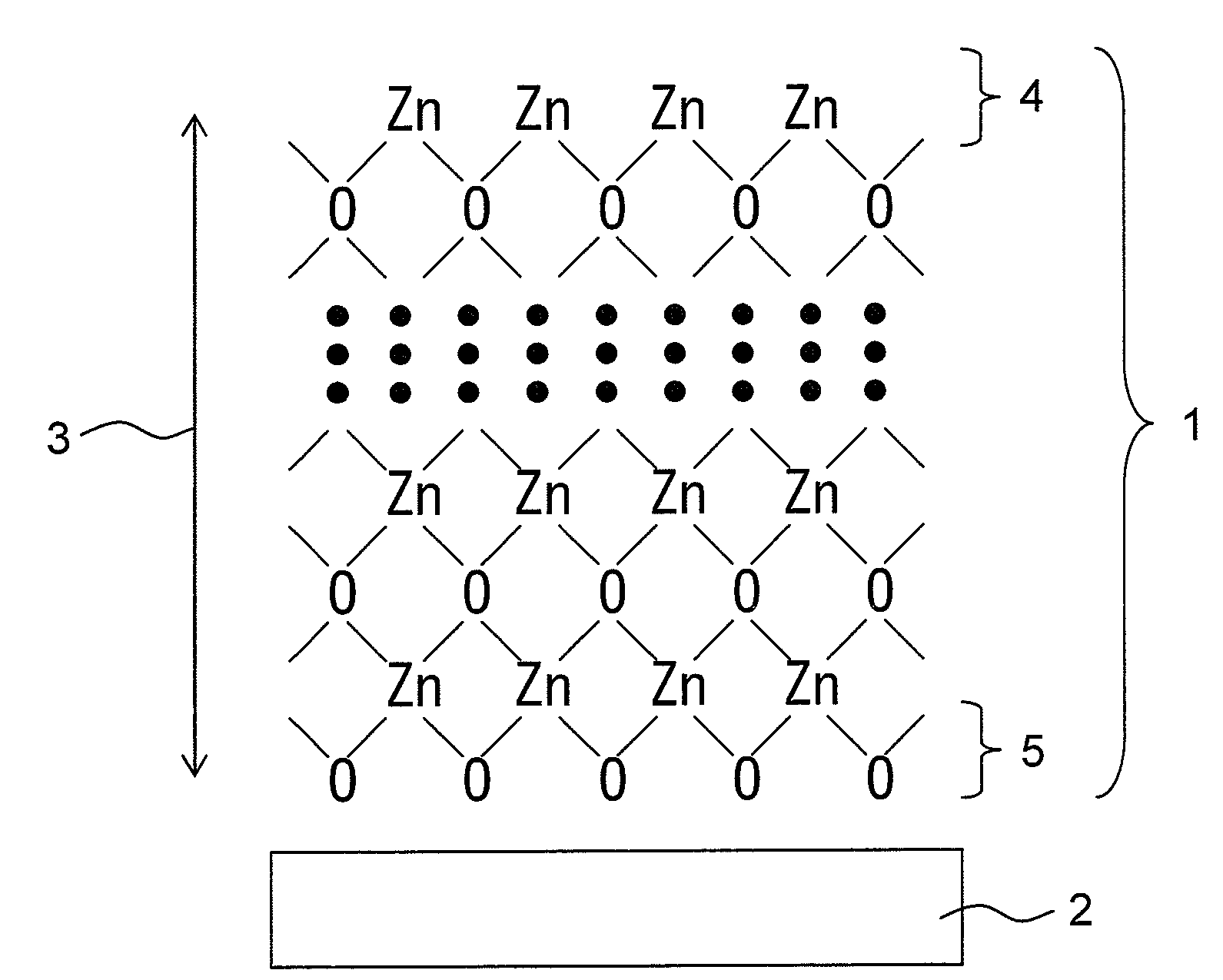

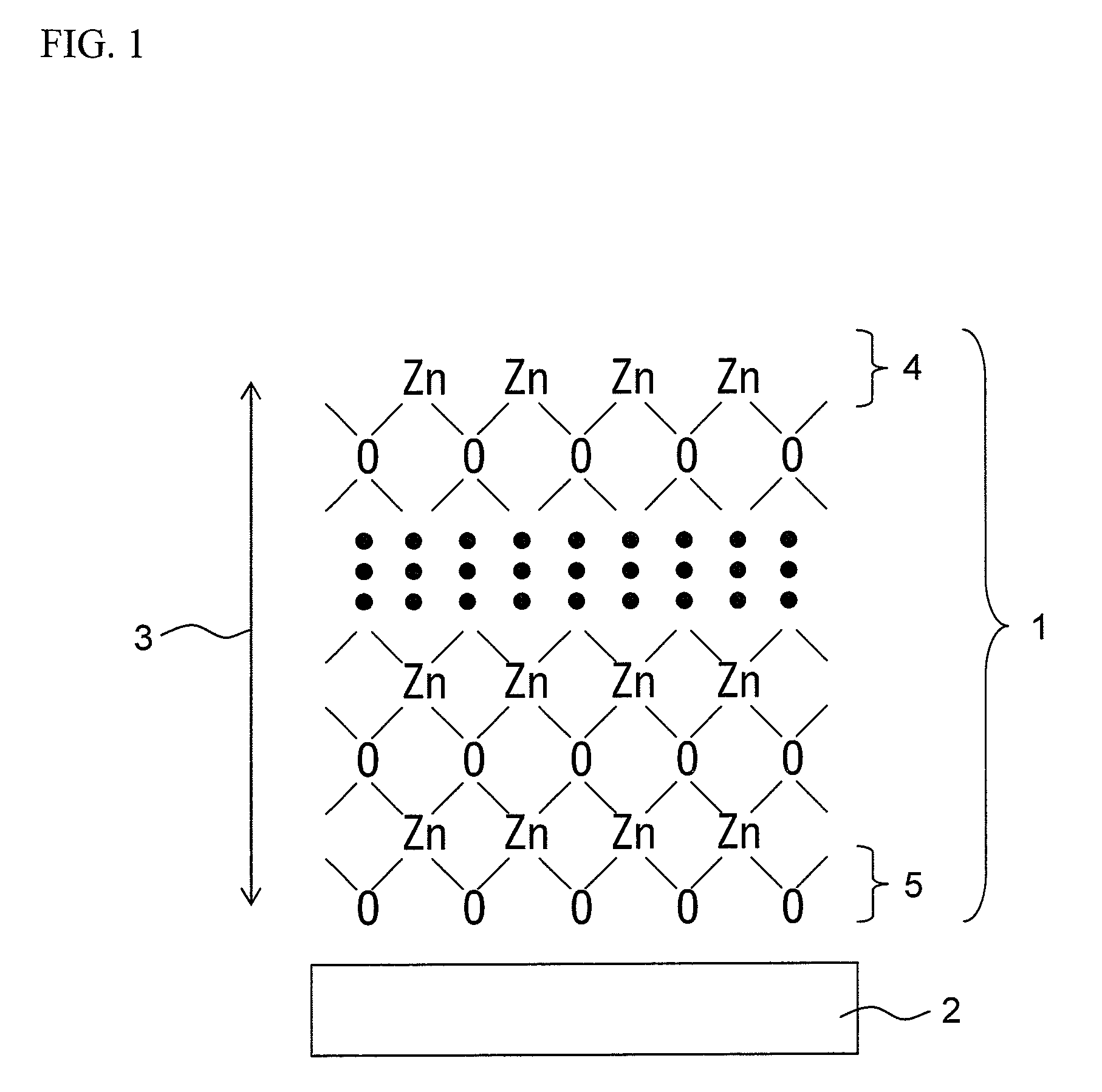

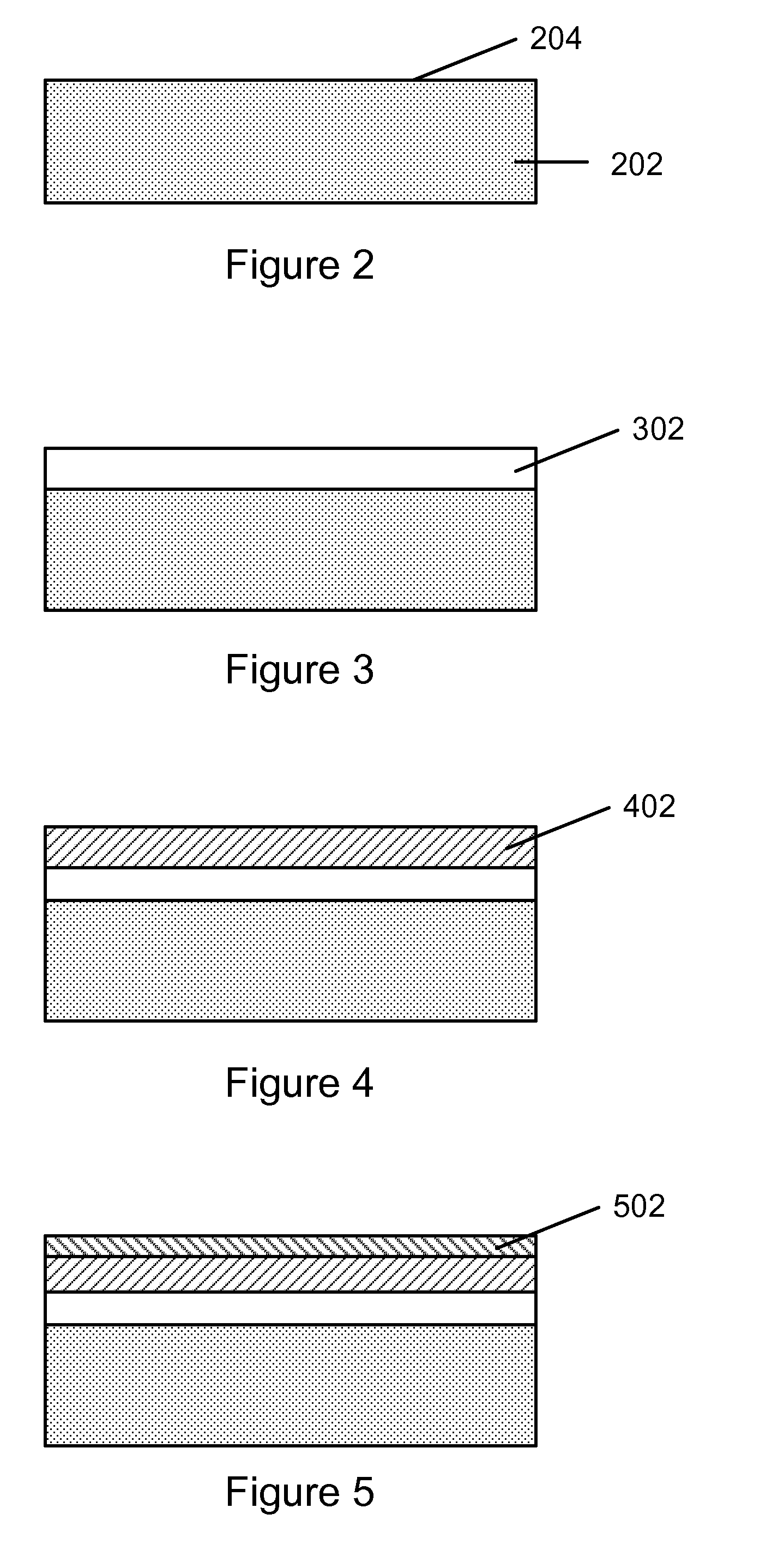

InactiveUS8137594B2Excellent in electric characteristicDenser and less defectiveConductive materialVacuum evaporation coatingDisplay deviceTransparent conducting film

A zinc oxide thin film having desired crystallinity is fabricated. The present invention provides a zinc oxide thin film which laminated on a substrate, and which is a crystalline thin film of a wurtzite form. The c-axis of the crystalline thin film is oriented in a direction substantially perpendicular to the substrate. A zinc surface of being one polar surface of the crystalline thin film in the c-axis direction is formed in the uppermost layer. In addition, the invention also provides a zinc oxide thin film which is laminated on a substrate, and which is a crystalline thin film of a wurtzite form. The zinc oxide thin film is formed on a metal thin film layer by a thin film fabricating technique.

Owner:HITACHI LTD

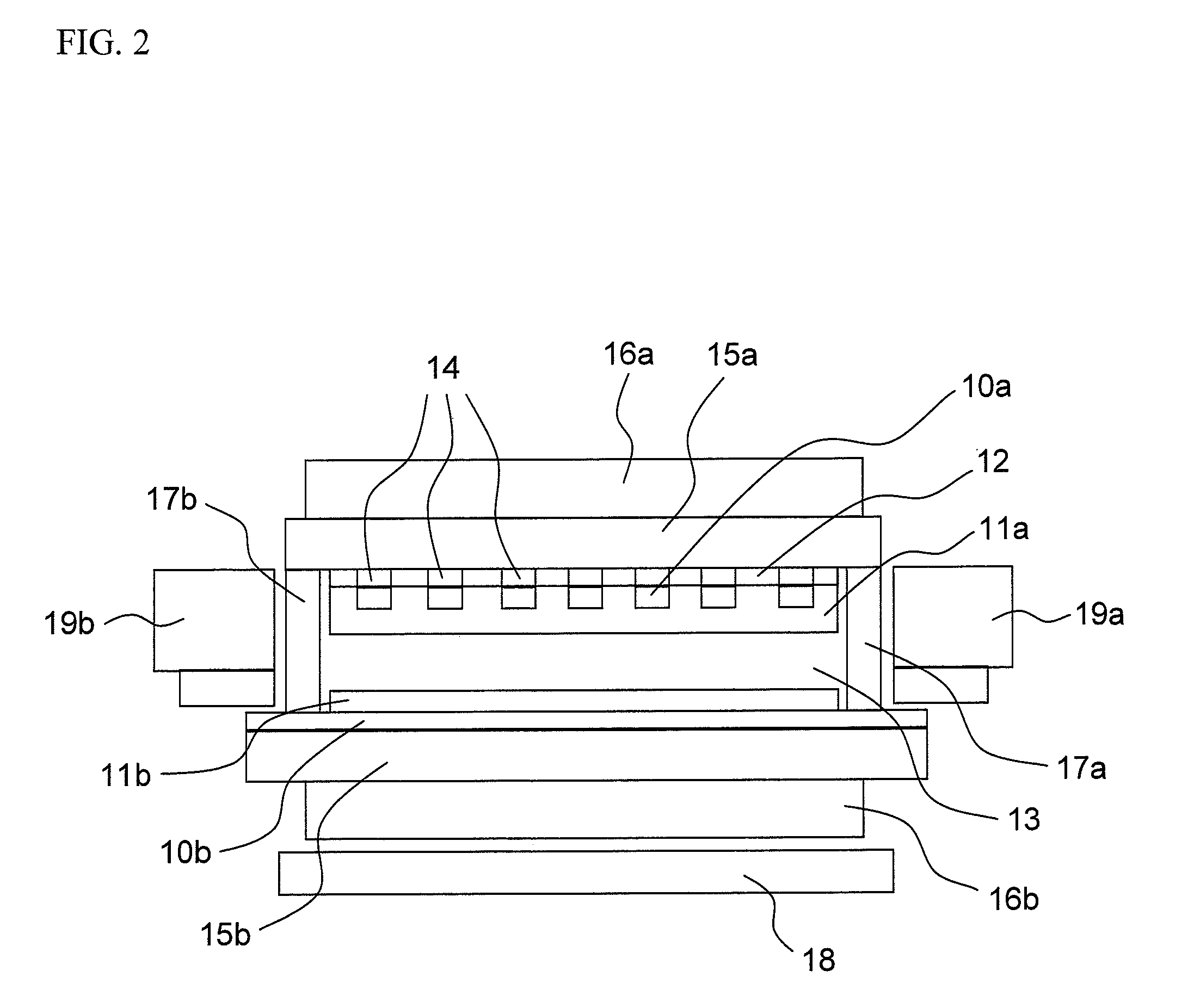

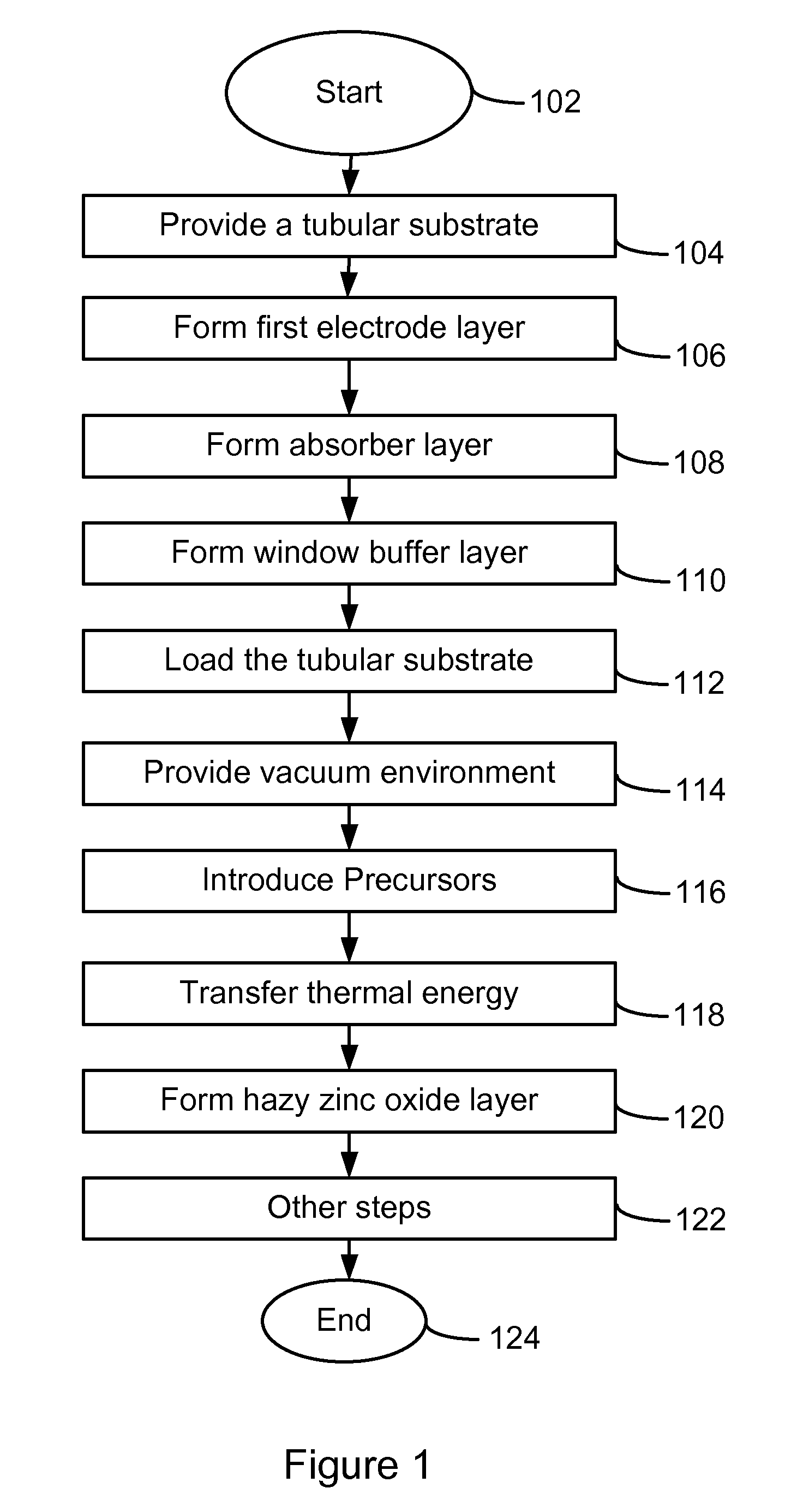

Hazy Zinc Oxide Film for Shaped CIGS/CIS Solar Cells

InactiveUS20110259413A1Improve conversion efficiencySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSolar cellTorr

A method for fabricating a shaped thin film photovoltaic device includes providing a length of tubular glass substrate having an inner diameter, an outer diameter, a circumferential outer surface region covered by an absorber layer and a window buffer layer overlying the absorber layer. The substrate is placed in a vacuum of between about 0.1 Torr to about 0.02 Torr and a mixture of reactant species derived from diethylzinc species, water species, and a carrier gas are introduced, as well as a diborane species. The substrate is heated to form a zinc oxide film with a thickness of 0.75-3 μm, a haziness of at least 5%, and an electrical resistivity of less than about 2.5 milliohm-cm.

Owner:CM MFG

Autombobile windshield glass possessing infrared reflection performance and its preparation method

InactiveCN1555989AImprove transmittanceWith thermal insulation performanceWindowsWindscreensIndiumSilicon oxide

An anti-fogging insulating windshield with high infrared reflectivity (more than 70%) features that a semiconductor oxide film, which may be the indium oxide film doped by tin oxide or the zinc oxide film doped by at least one of aluminium oxide, silicon oxide, boron oxide, dysprosium oxide and gallium oxide, is arranged between PVB film and the internal or external surface of glass. Its preparing processis also disclosed.

Owner:TSINGHUA UNIV

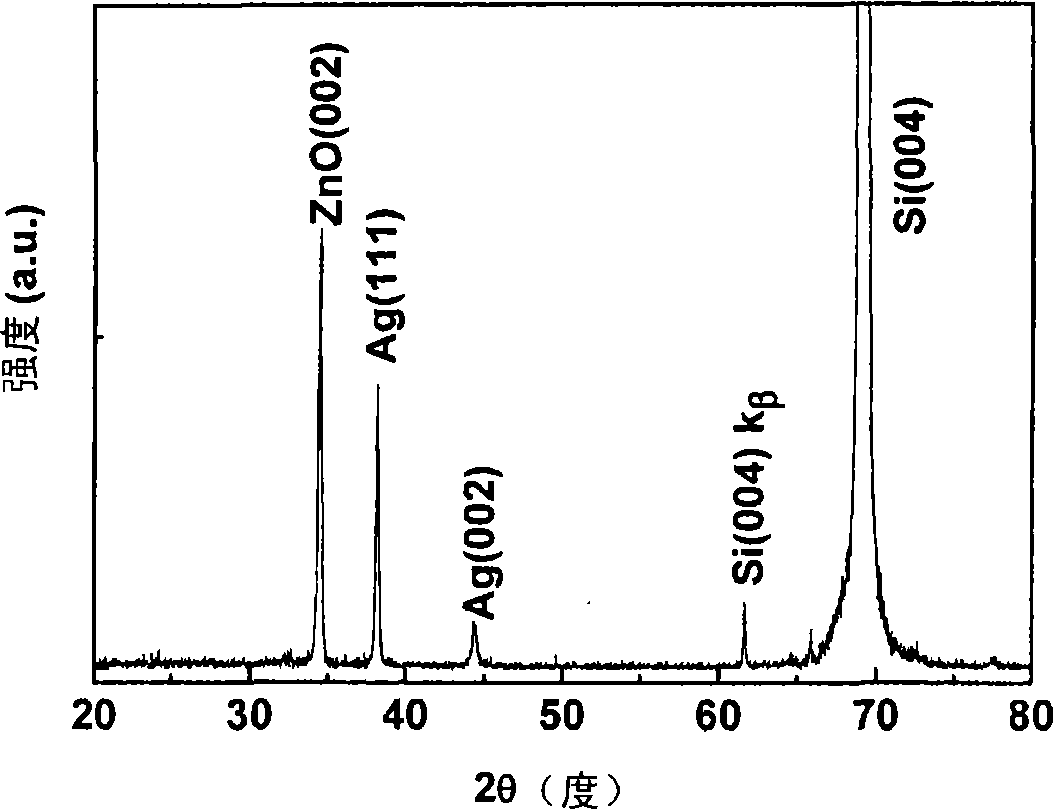

Method for reinforcing zinc oxide film blue light emission

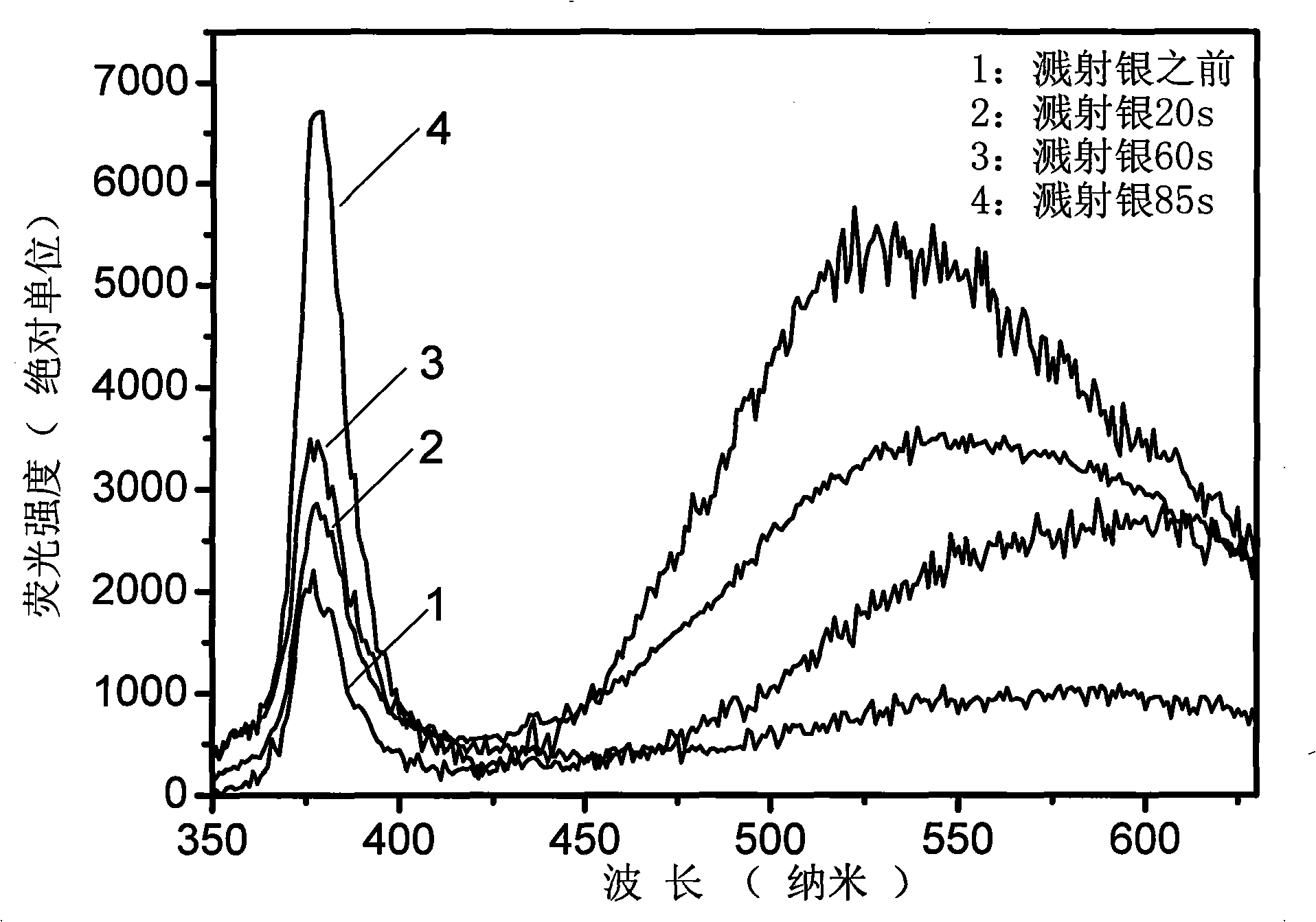

InactiveCN101442089APracticalIncreased intensity of blue light emissionSemiconductor devicesComposite filmPhotoluminescence

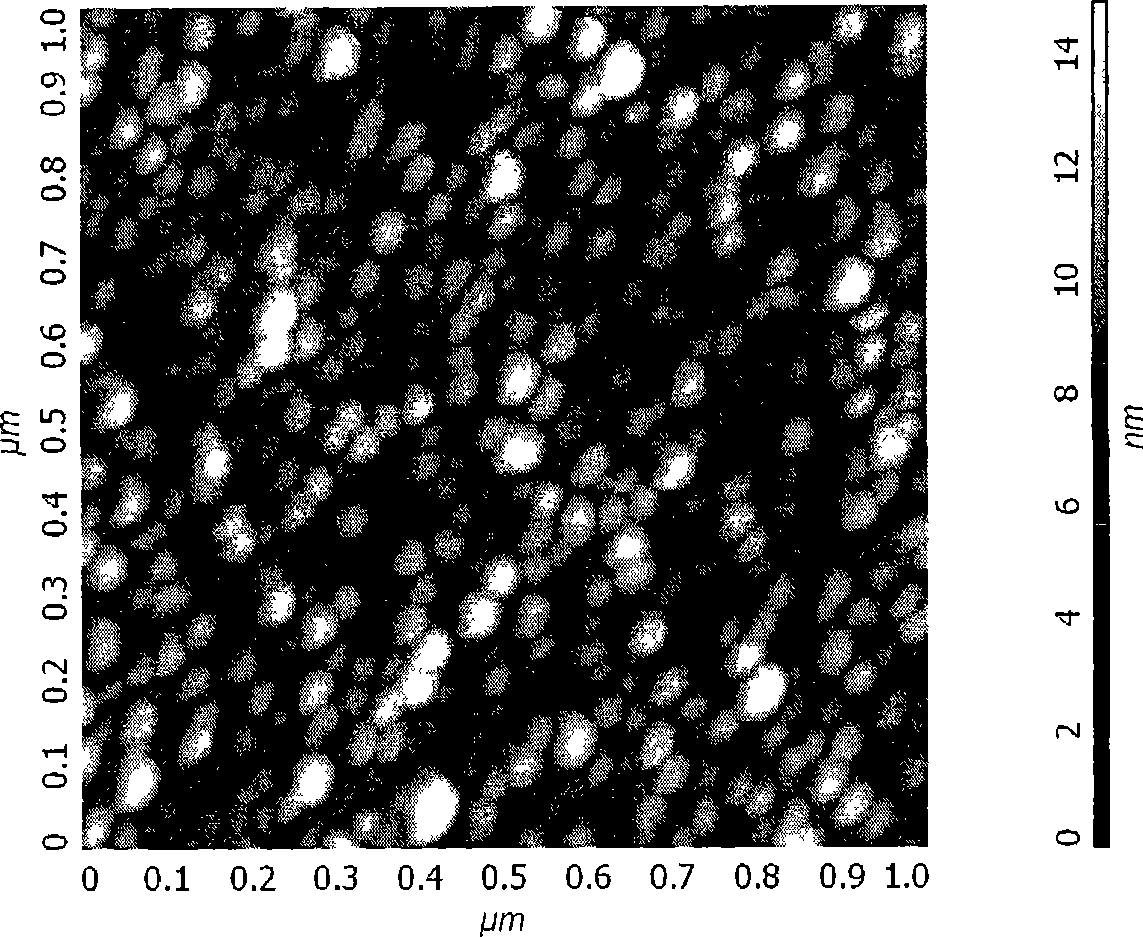

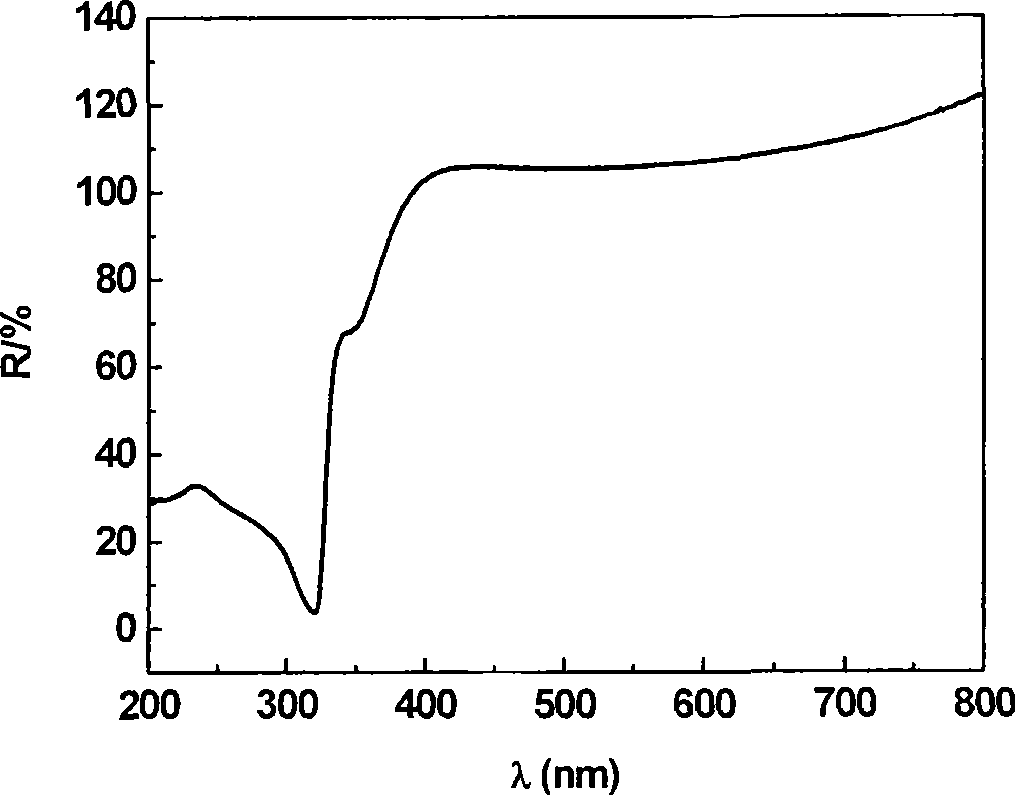

The invention discloses a method for enhancing ZnO film blue-ray emission. The method relates to semiconductor technology, and comprises the following steps: preparing a ZnO / Ag composite thin-film; accelerating recombination of interband emission of ZnO by using resonant coupling between plasmon on the surface of Ag and interband emission of the ZnO; and coupling plasmon into light by using the film surface of Ag with certain roughness to achieve the aim of enhancing the ZnO film blue-ray emission. Comparing photoluminescence performance of the ZnO / Ag composite thin-film with that of a ZnO film, a discovery that the participation of the plasmon on the surface of the Ag can improve intensity of the interband emission of the ZnO by 50 times is made; at the same time, the method can effectively suppress green light emission caused by the flaw on the ZnO film. The method not only can enhance the ZnO blue light emission, but also can be extensively applied to other semiconductor luminous materials and other types of luminophors.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Zinc oxide film and method for making

InactiveUS20080299411A1Pretreated surfacesSemiconductor/solid-state device manufacturingOptical propertyNucleation

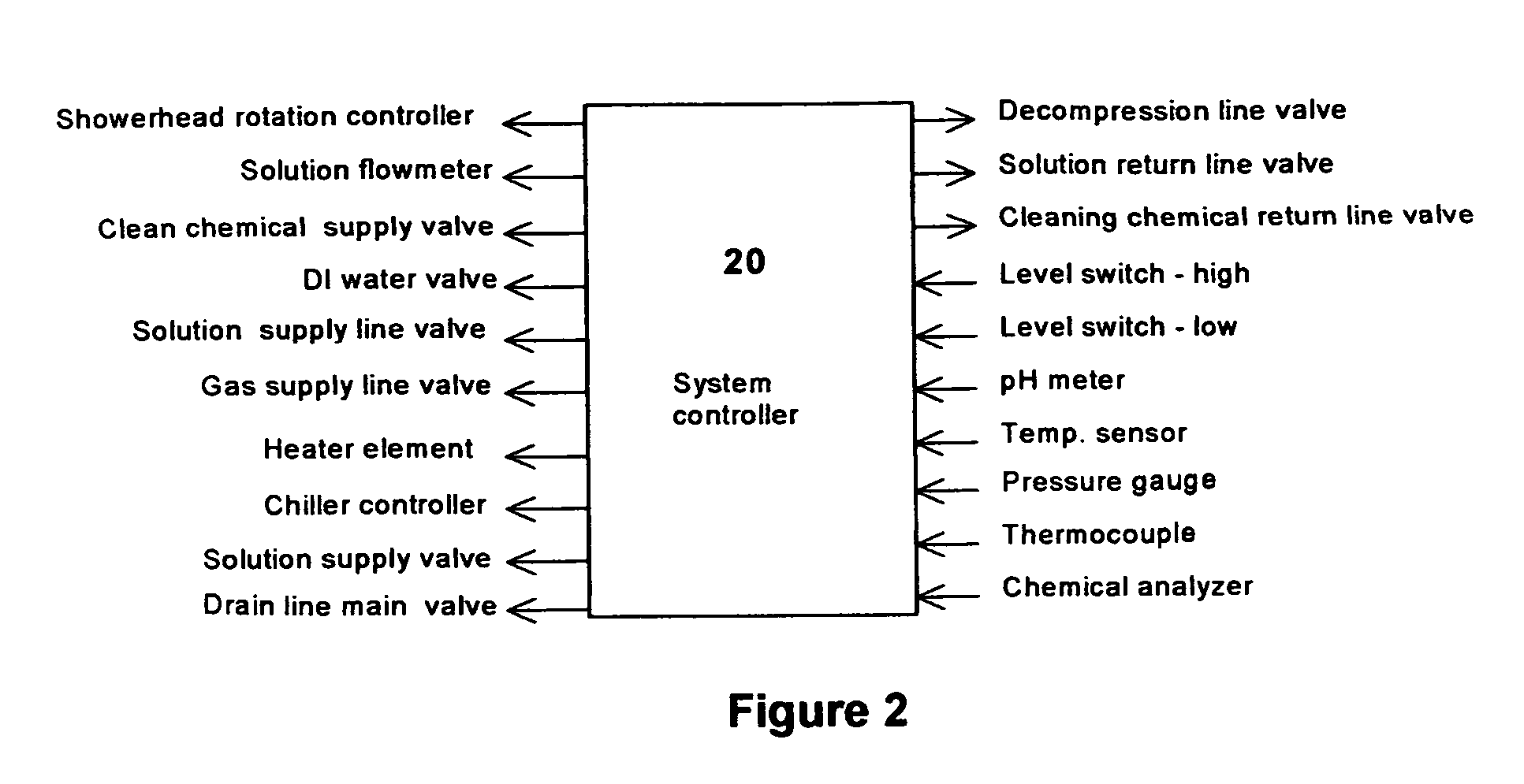

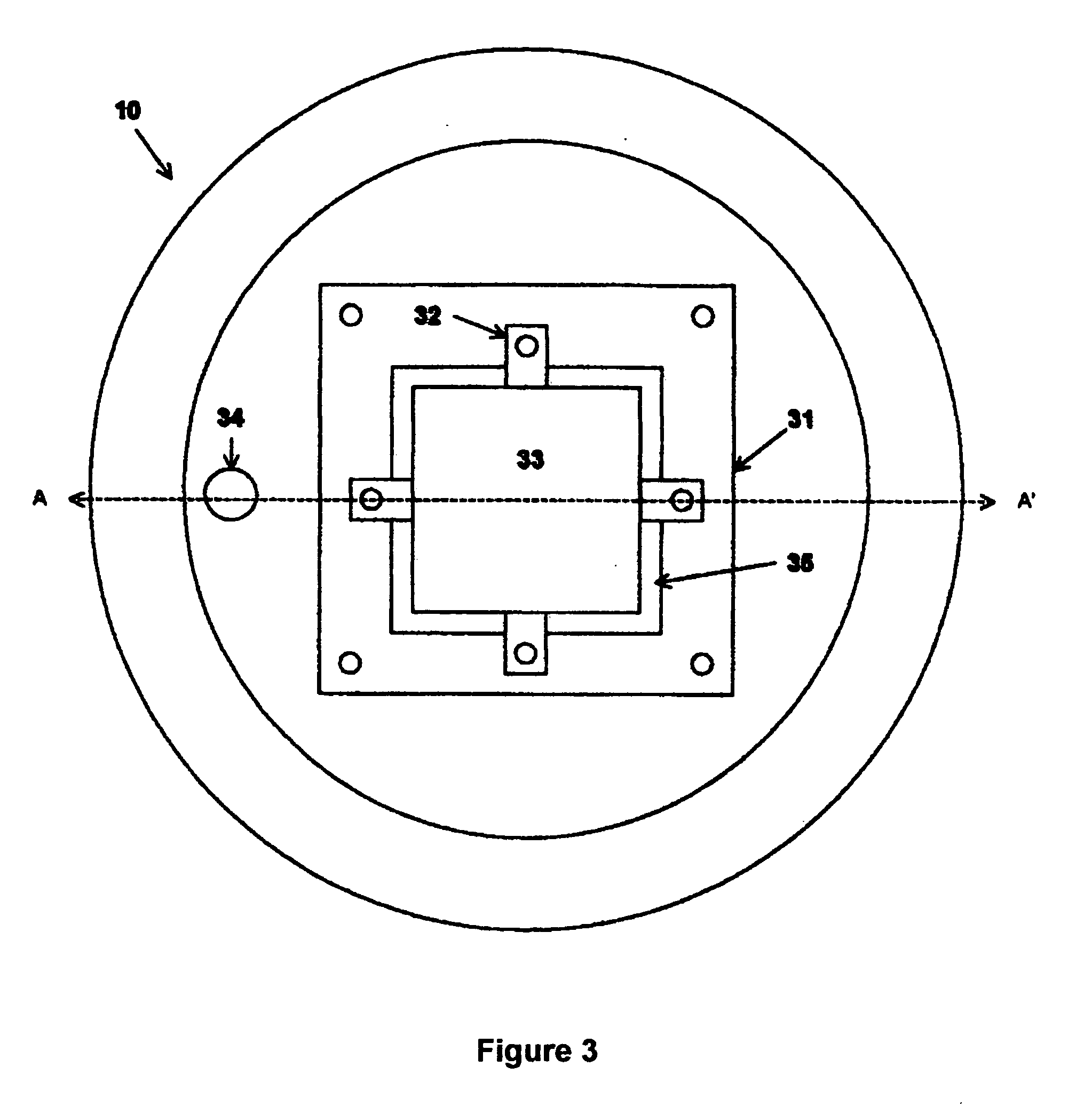

A method for depositing a solid film of ZnO onto a substrate from a reagent solution includes a reservoir of reagent solution maintained at a sufficiently low temperature to inhibit homogeneous reactions within the reagent solution. The reagent solution contains a source of Zn, a source of O, and multiple ligands to further control solution stability and shelf life. The chilled solution is dispensed through a showerhead onto a substrate. The substrate is positioned in a holder that has a raised structure peripheral to the substrate to retain or impound a controlled volume (or depth) of reagent solution over the exposed surface of the substrate. The reagent solution is periodically or continuously replenished from the showerhead so that only the part of the solution directly adjacent to the substrate is heated. A heater is disposed beneath the substrate and maintains the substrate at an elevated temperature at which the deposition of a desired solid phase from the reagent solution may be initiated. The showerhead may also dispense excess chilled reagent solution to cool various components within the apparatus and minimize nucleation of solids in areas other than on the substrate. The deposited film may be annealed after deposition and may be doped to enhance selected characteristics. The ZnO films made by the process have distinctive electrical and optical properties and are suitable for a variety of electronic and optical devices.

Owner:QUANTUMSCAPE CORP

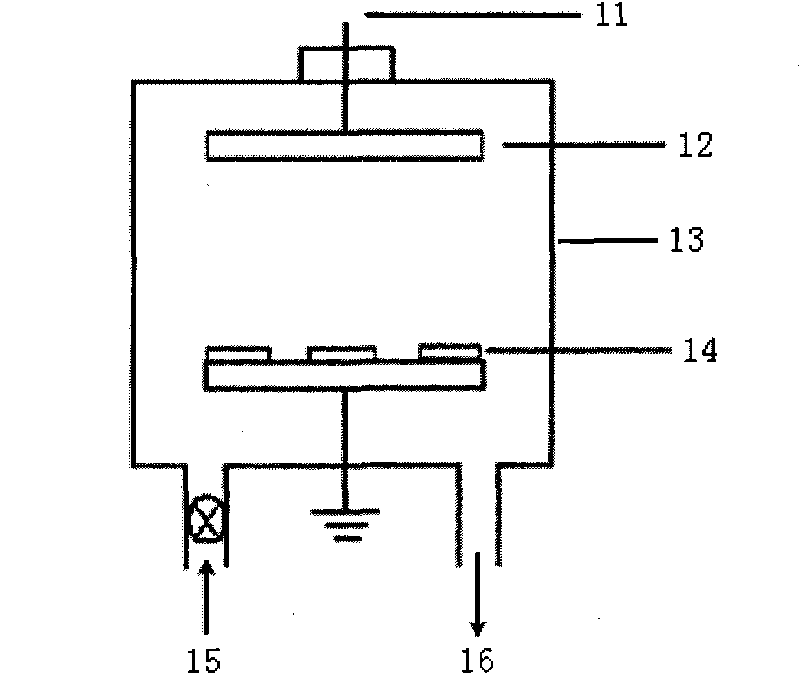

Preparation method of zinc oxide UV photodetector prototype device

InactiveCN1400674AWon't fall offTightly boundFinal product manufacturePhotometryPhotodetectorPhotoresist

A preparation method of this invented Zno UV-light electric detector prototype device contains the following steps 1) spinly coating a photoresist to photolithograph an electrode pattern and remaining part is covered by the photoresist 2) depositing a metal layer on Zno surface with magnet control spurt method and thickness of the metal layer is smaller than that of the photoresist 3). putting the metal covered Zno film into acetone solution dissolving the photoresist for ultrasonic cleaning removing the photoresist and the metal layer on the photoresist surface 4) annealing under protection,removing organic dirt on the electrode surface and increasing Ohmic contact character to effectively prevent performance from turning bad due to erosion to the Zno surface.

Owner:ZHEJIANG UNIV

Method for preparing p-type zinc oxide film

InactiveCN1461044AConcentration control is convenientThe principle is simpleFinal product manufactureVacuum evaporation coatingAtmospheric airNitrogen gas

The method for preparing p-type zinc oxide film by using magnetron sputtering process is characterized by that it uses metal zinc as target for magnetron sputtering, and introduces nitrogen gas or nitrogen gas and oxygen gas into working gas argon gas as reactant gas, makes the pressure of magnetron sputtering vacuum chamber be 10(-1)Pa-10(o)Pa, the ratio of nitrogen flow and argon flow be in the range of 1:10-1:1, and the ratio of oxygen flow anjd argon flow be in the range of 0:1-1:1, then makes the obtained nitrogen-oxygen-zinc film undergo the process of heat treatment in atmosphere or oxygen atmosphere, its heat treatment temp. is 300-500 deg.c and treatment time is 0.5-5 hr. so as to obtain the invented product.

Owner:ZHEJIANG UNIV

Cadmium-free CuInGaSe thin film solar cell assembly and preparing method of zinc sulfide buffer layer thin film thereof

ActiveCN102254998AImprove crystal qualityImprove uniformityFinal product manufactureVacuum evaporation coatingElectrical batteryCadmium Cation

The invention discloses a preparing method of a cadmium-free CuInGaSe thin film solar cell assembly. The preparing method comprises the following steps of: step one, forming a back electrode and a CuInGaSe light absorption layer on a substrate in sequence, and forming a sample sheet; step two, sputtering a zinc oxide thin film on the surface of the sheet; step three, putting the sample sheet in aselenization chamber to anneal in hydrogen sulfide atmosphere, and converting the zinc oxide thin film into a zinc sulfide buffer layer thin film; and step four, forming a baffle layer and a window later on the zinc sulfide buffer layer thin film in sequence, thus obtaining the cadmium-free CuInGaSe thin film solar cell assembly. The preparing method is relatively high in temperature during the annealing progress, so that crystallization quality of the thin film can be increased. The invention further provides a preparing method of the zinc sulfide buffer layer thin film.

Owner:汉摩尼(江苏)光电科技有限公司

Electrode material of C@MnO2 nanotube super capacitor and preparation method and application of electrode material

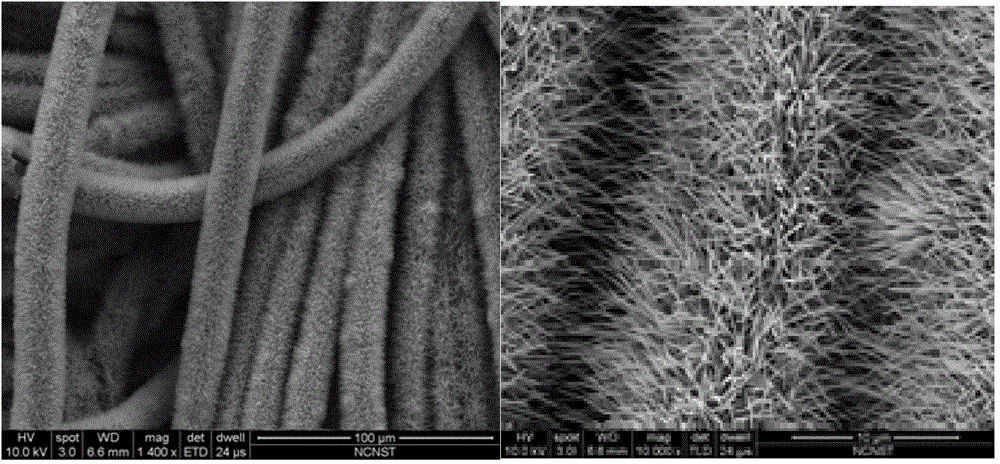

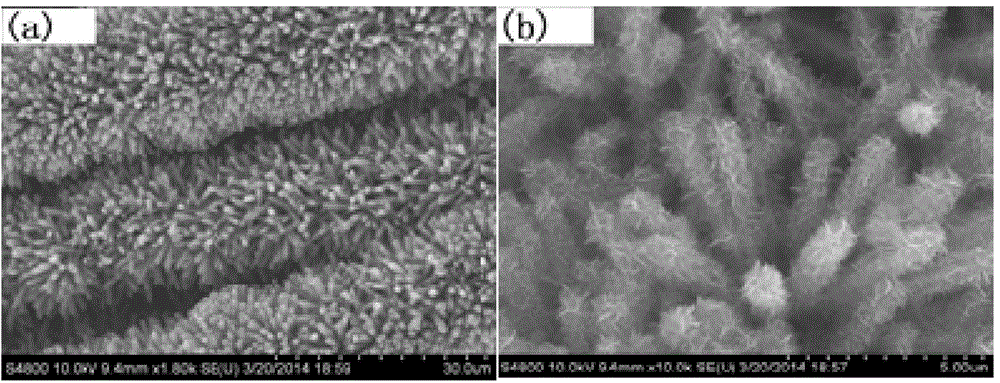

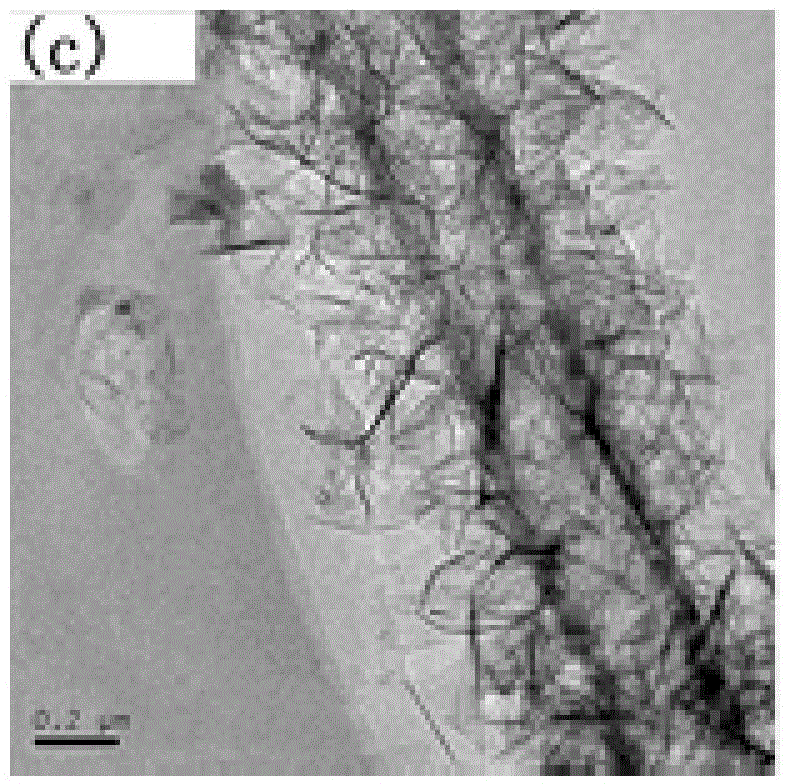

ActiveCN104465123AImproved magnification performanceImprove electronic conductivityHybrid capacitor electrodesHybrid/EDL manufactureCarbon layerFiber

The invention provides an electrode material of a three-dimensional C@MnO2 composite nanotube array super capacitor and a preparation method and application of the electrode material. A nanotube-shaped carbon layer is arranged inside the material, and a MnO2 material is arranged outside the material. The preparation method includes the steps that (1) a flexible carbon fiber cloth is subjected to pretreatment and magnetron sputtering to deposit a zinc oxide thin film; (2) zinc oxide nanorod array growth is conducted; (3) a zinc oxide nanorod array carbon cloth with the surface being coated with thin-layer carbon is prepared; (4) the carbon cloth obtained in the step (3) is used as a working electrode, and a three-electrode electrodeposition system is used for conducting manganese dioxide electrochemical deposition, flushing and drying to obtain the super capacitor electrode material which is of a three-dimensional C@MnO2 nanotube-shaped array structure. According to the material, the carbon material with good electrical conductivity and the MnO2 material with high specific capacitance and poor electrical conductivity are compounded, the advantages of the carbon material and the advantages of the MnO2 material are fully performed, due to hollow nanotubes, electrolyte solution ions can better enter and exit, and thus the rate capability of the capacitor can be greatly improved.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

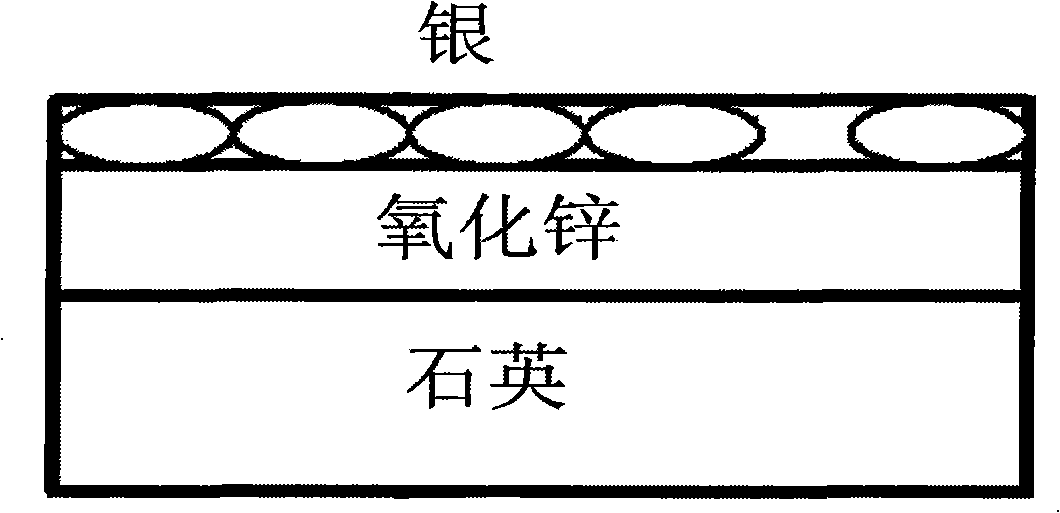

Method for reinforcing zinc oxide thin membrane luminescence

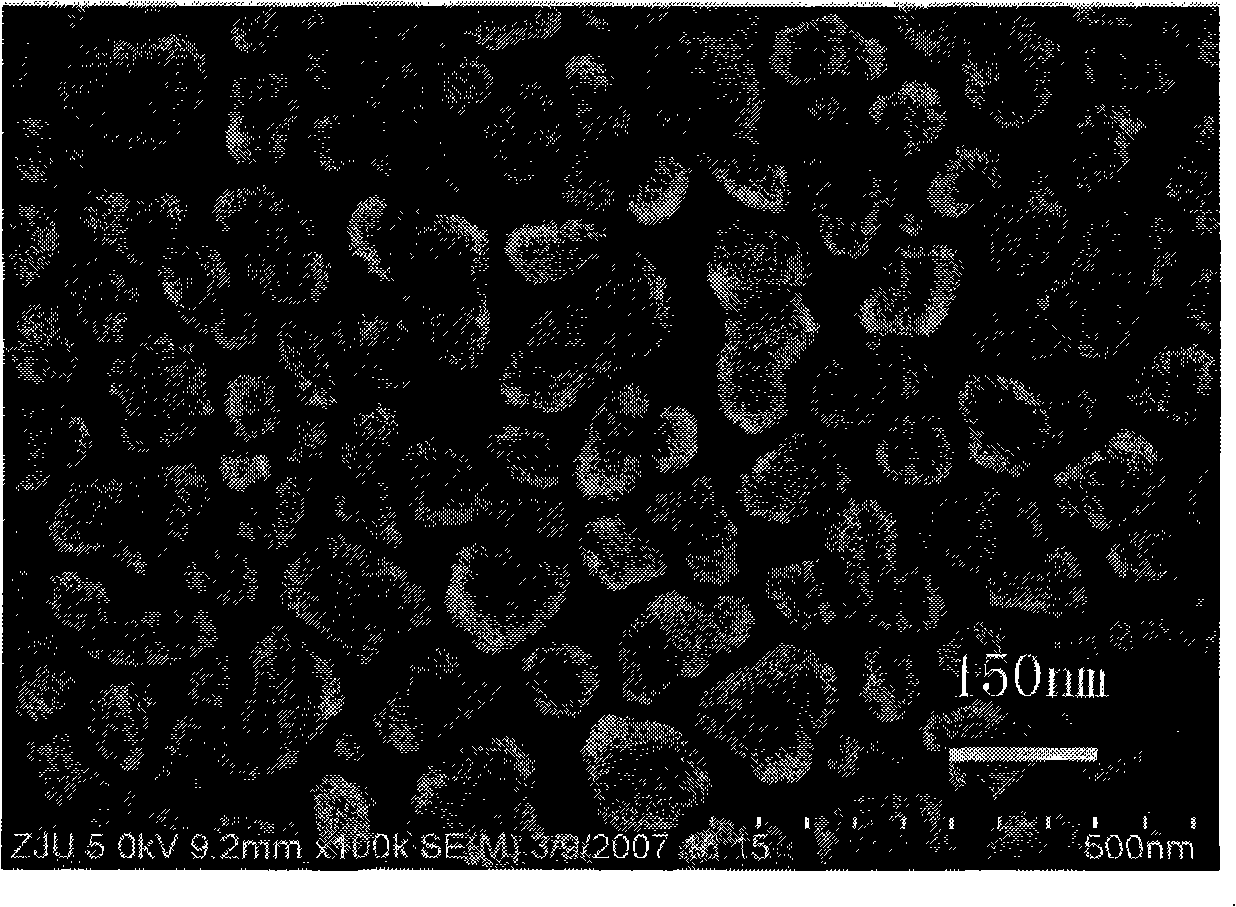

InactiveCN101270468AImprove luminous efficiencyHigh luminous intensityVacuum evaporation coatingSputtering coatingSputteringLuminescence

The invention discloses a method for enhancing a zinc oxide film to shine which adopts magnetron sputtering to grow silver nanoparticles on the zinc oxide film. The preparation of the invention relates to: putting a quartz floor with a grown zinc oxide film into the reaction chamber of a DC reaction magnetron sputtering device; depositing the silver nanoparticles on the zinc oxide film by DC magnetron sputtering. The invention can be adopted to enhance the shining efficiency of the zinc oxide film. The method is simple, the structure of the whole shining system is easy; the shining enhancing can be controlled by the sputtering time; besides, interband shining enhancing and defect shining quenching can be realized simultaneously; the method can be used for enhancing the shining intensity of the shining materials like zinc oxide, etc.

Owner:ZHEJIANG UNIV

P-zinc oxide/N- nickel oxide heterogeneous PN junction ultraviolet laser diode and method for production

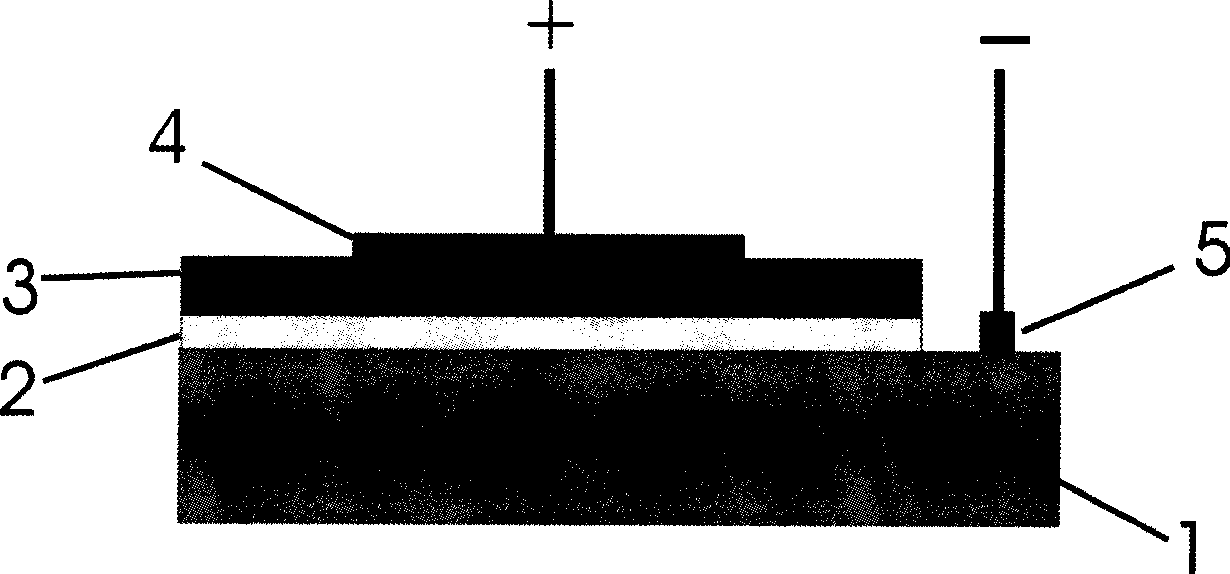

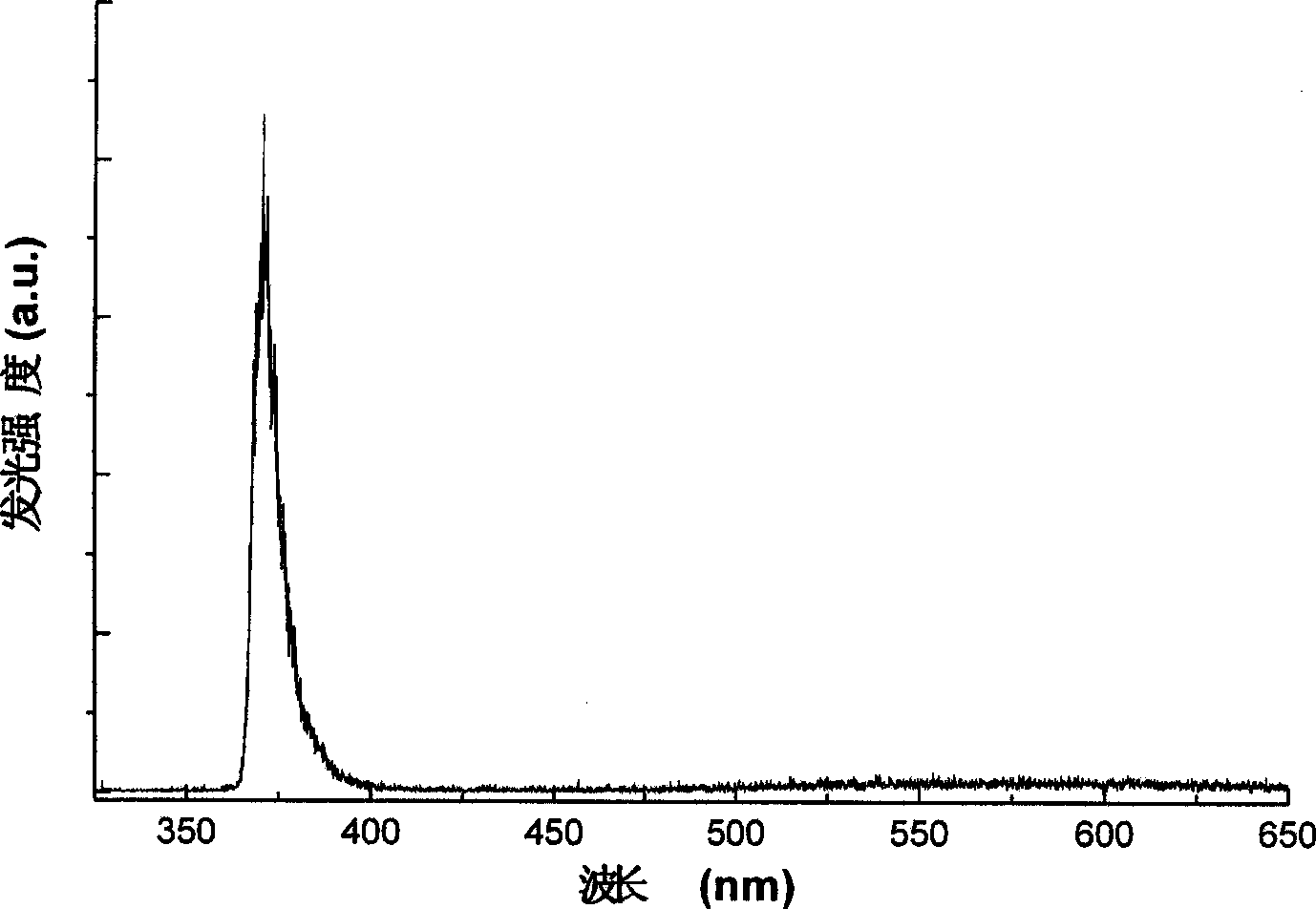

ActiveCN101505035AGood electro-ultraviolet lasing luminescence propertiesImprove performanceLaser detailsLaser active region structureIndiumRadio frequency magnetron sputtering

The invention discloses an n -zinc oxide / p- nickel oxide heterogeneous pn junction ultraviolet laser diode and a preparation method thereof. The heterogeneous pn junction diode at least comprises a pn junction, a substrate and an ohm contacting electrode, wherein the pn junction is the heterogeneous pn junction by plating a p-type nickel oxide film on an n-type zinc oxide film; and the substrate is a sapphire plated with n-type GaN. The preparation method comprises the following steps: firstly preparing the n-type ZnO film layer on the substrate by the radio frequency magnetron sputtering technology; then sputtering a p-type NiO film layer on the n-type ZnO film layer to form the heterogeneity pn junction; finally manufacturing a pn junction electrode by a sputtering method or a thermal evaporation method; sputtering gold electrodes or platinum electrodes or nickel platinum electrodes or ITO electrodes on the NiO surface; plating indium electrodes or aluminum electrodes or gold electrodes on the GaN or the edge of ZnO; and making the electrodes form ohm contact after annealing alloying. The heterogeneous pn junction diode has the advantages of better electro-ultraviolet lasing luminescence characteristic, peak luminous wavelength of about 375 nm, simple preparation process and low cost.

Owner:常熟紫金知识产权服务有限公司

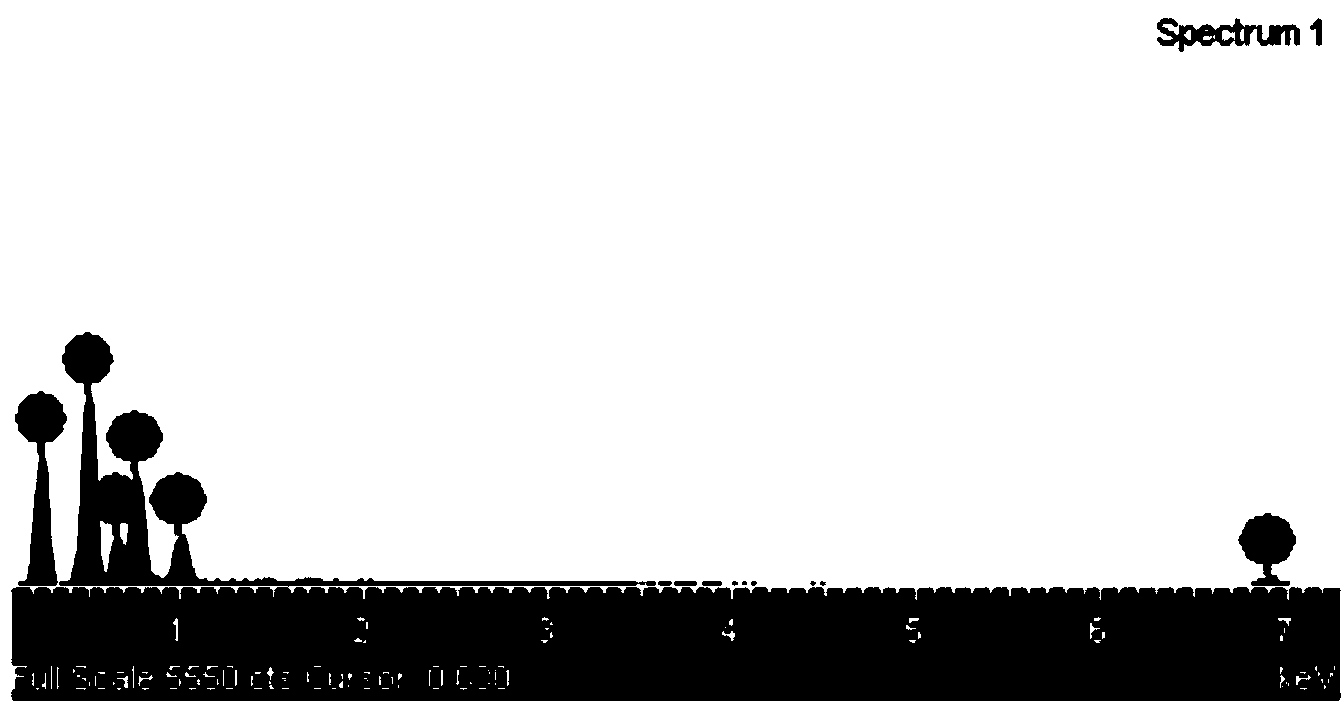

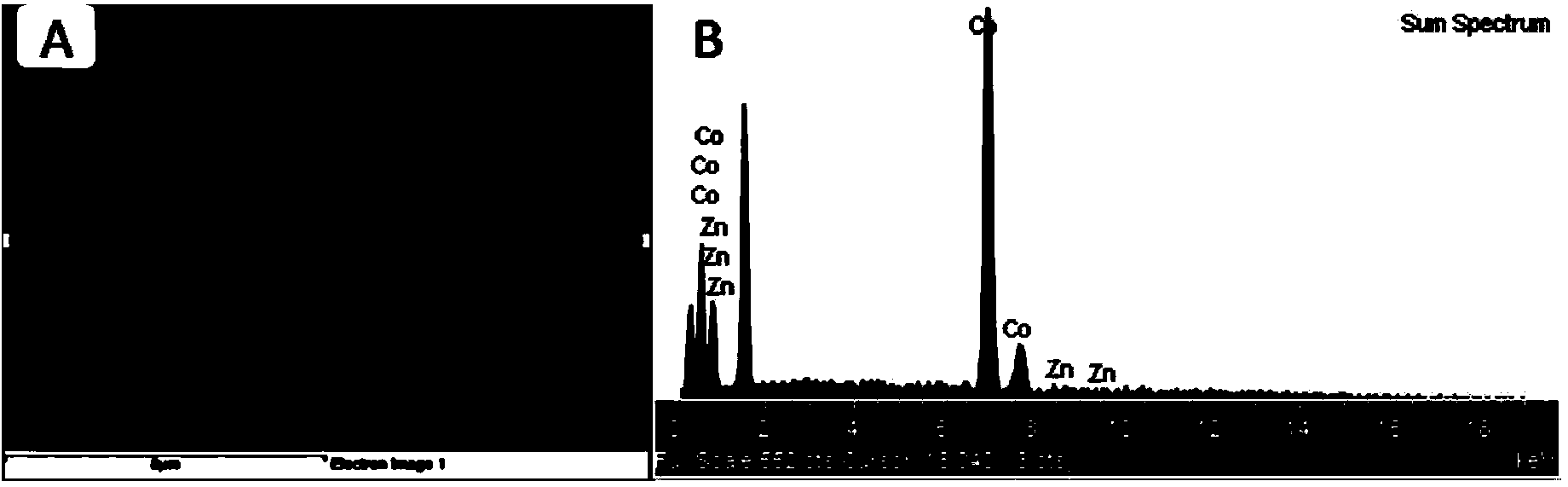

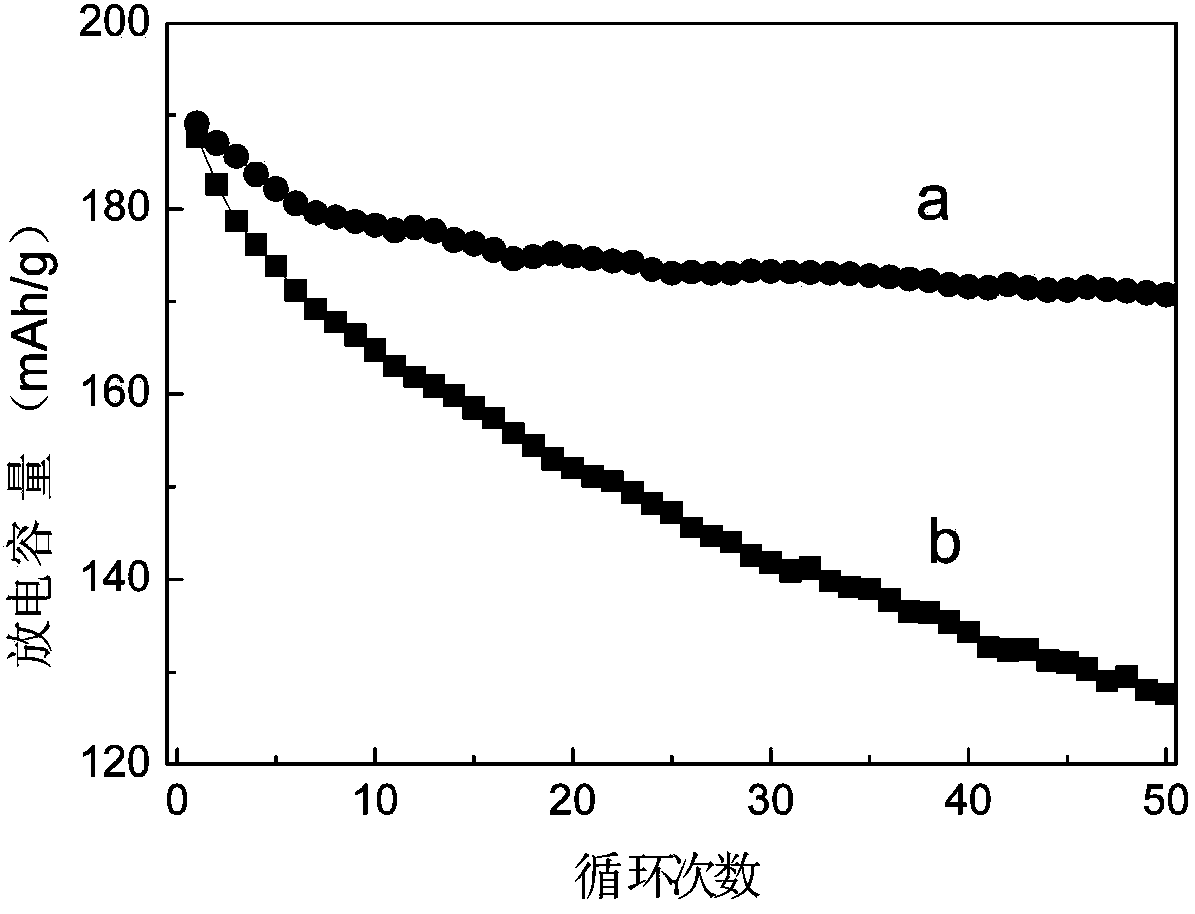

Making method of zinc oxide or aluminum-doped zinc oxide coated lithium cobaltate electrode

InactiveCN103594684AAvoid affecting transport performanceInhibition of dissolutionCell electrodesAluminum doped zinc oxideRadio frequency magnetron sputtering

A making method of a zinc oxide or aluminum-doped zinc oxide coated lithium cobaltate electrode belongs to the technical field of batteries. In the invention, zinc oxide or aluminum-doped zinc oxide deposited on a routine lithium cobaltate electrode through a radio frequency magnetron sputtering technology as a coating material to obtain the coated and modified lithium cobaltate electrode. The method concretely comprises the following steps: mixing lithium cobaltate powder with a conductive additive, a binder and a solvent, grinding to prepare a slurry, coating a current collector with the slurry, drying the coated current collector to make the routine sheet lithium cobaltate electrode, and depositing the coating layer of zinc oxide or aluminum-doped zinc oxide by adopting the radio frequency magnetron sputtering technology to realize the coating modification of the lithium cobaltate electrode. The method improves the electrode interface situation, effectively inhibit the secondary reactions on the high-potential interval electrode surface, reduces the capacity loss and improves the structural stability of an active material, so the working voltages of the batteries are widened, and the energy density, the power density and the cycle performance of the batteries are improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

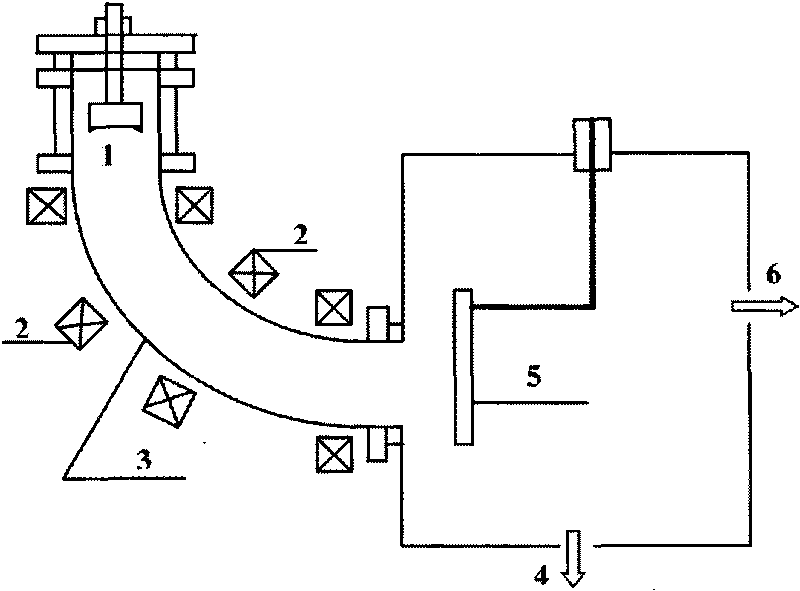

Method of zinc oxide film grown on the epitaxial lateral overgrowth gallium nitride template

ActiveUS20100102307A1Polycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseLateral overgrowth

A growth method is proposed for high quality zinc oxide comprising the following steps: (1) growing a gallium nitride layer on a sapphire substrate around a temperature of 1000° C.; (2) patterning a SiO2 mask into stripes oriented in the gallium nitride <1 100> or <11 20> direction; (3) growing epitaxial lateral overgrowth of (ELO) gallium nitride layers by controlling the facet planes via choosing the growth temperature and the reactor; (4) depositing zinc oxide films on facets ELO gallium nitride templates by chemical vapor deposition (CVD). Zinc oxide crystal of high quality with a reduced number of crystal defects can be grown on a gallium nitride template. This method can be used to fabricate zinc oxide films with low dislocation density lower than 104 / cm−2, which will find important applications in future electronic and optoelectronic devices.

Owner:NAT UNIV OF SINGAPORE

Prepn of P-type zinc oxide film

InactiveCN1453840ASimple processLow costSemiconductor/solid-state device manufacturingRadio frequency magnetron sputteringSource material

The present invention relates to the preparation of P-type zinc oxide film in semiconductor photoelectronic material and device field. By using sapphire or silicon as substrate material and sinteredZnO ceramic target with mixed P2O5 in 5 wt% and Ga2O3 in 0.2 wt% as source material and under proper sputtering gas pressures, sputtering power and higher substrate temperature, RF magnetically controlled sputtering process is adopted to prepare ZnO film with mixed P and Ga.Then, through annealing in vacuum at 800 deg.c and light irradiation for 40 min, P-type ZnO film is prepared. The preparation process of the present invention is simple, low in cost and high in product stability, and the film product has resistivity of 0.1 ohm. Cm and hole density of 10E18 each cu cm.

Owner:SHANDONG UNIV

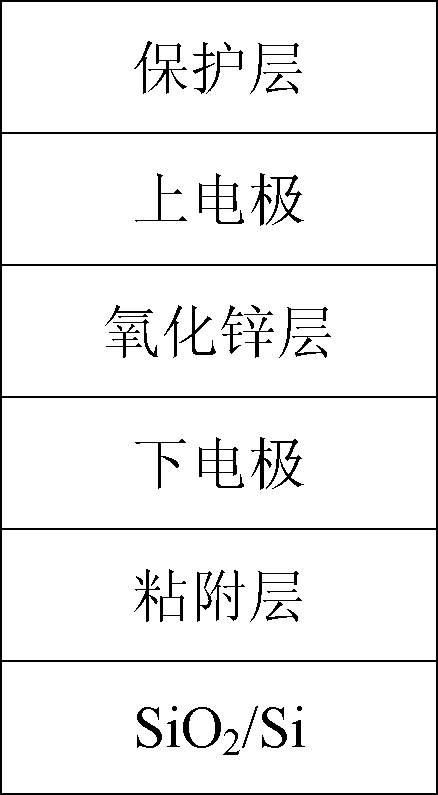

Zinc-oxide-based polarity-controlled resistive random-access memory (RRAM) and manufacturing method thereof

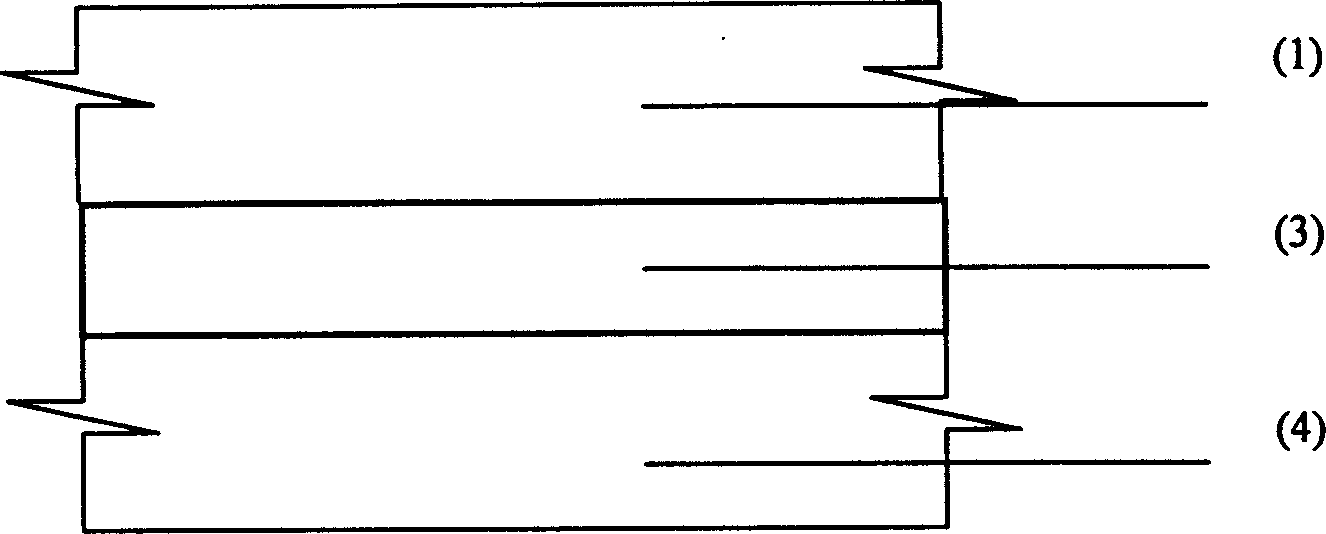

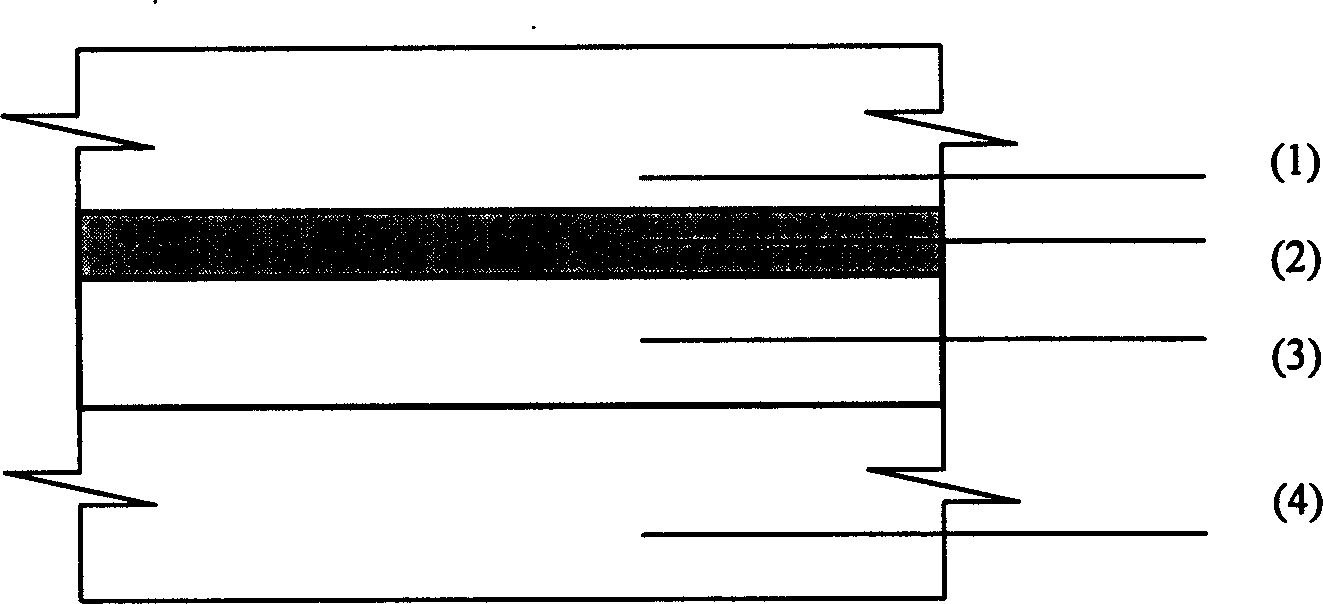

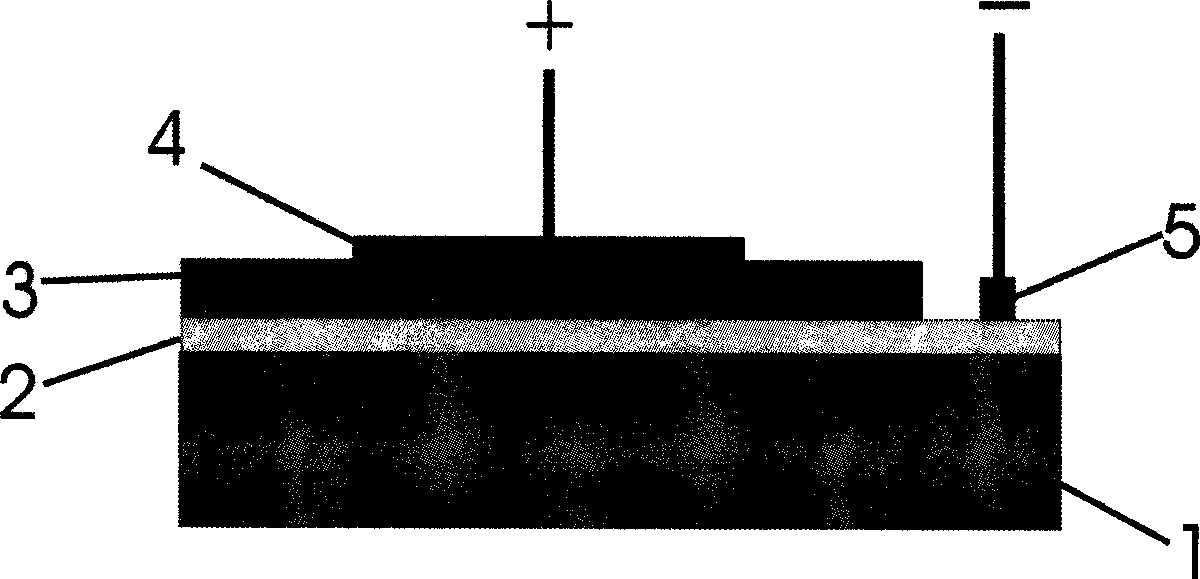

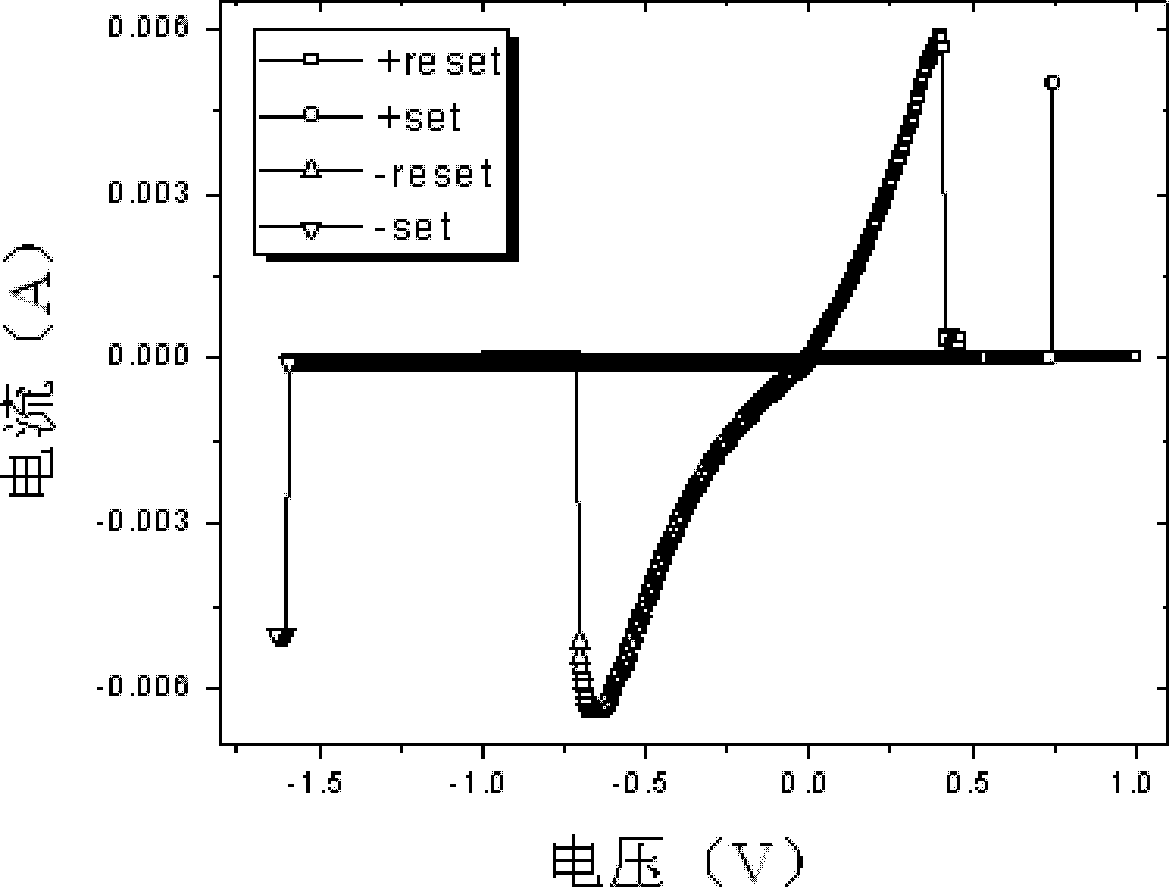

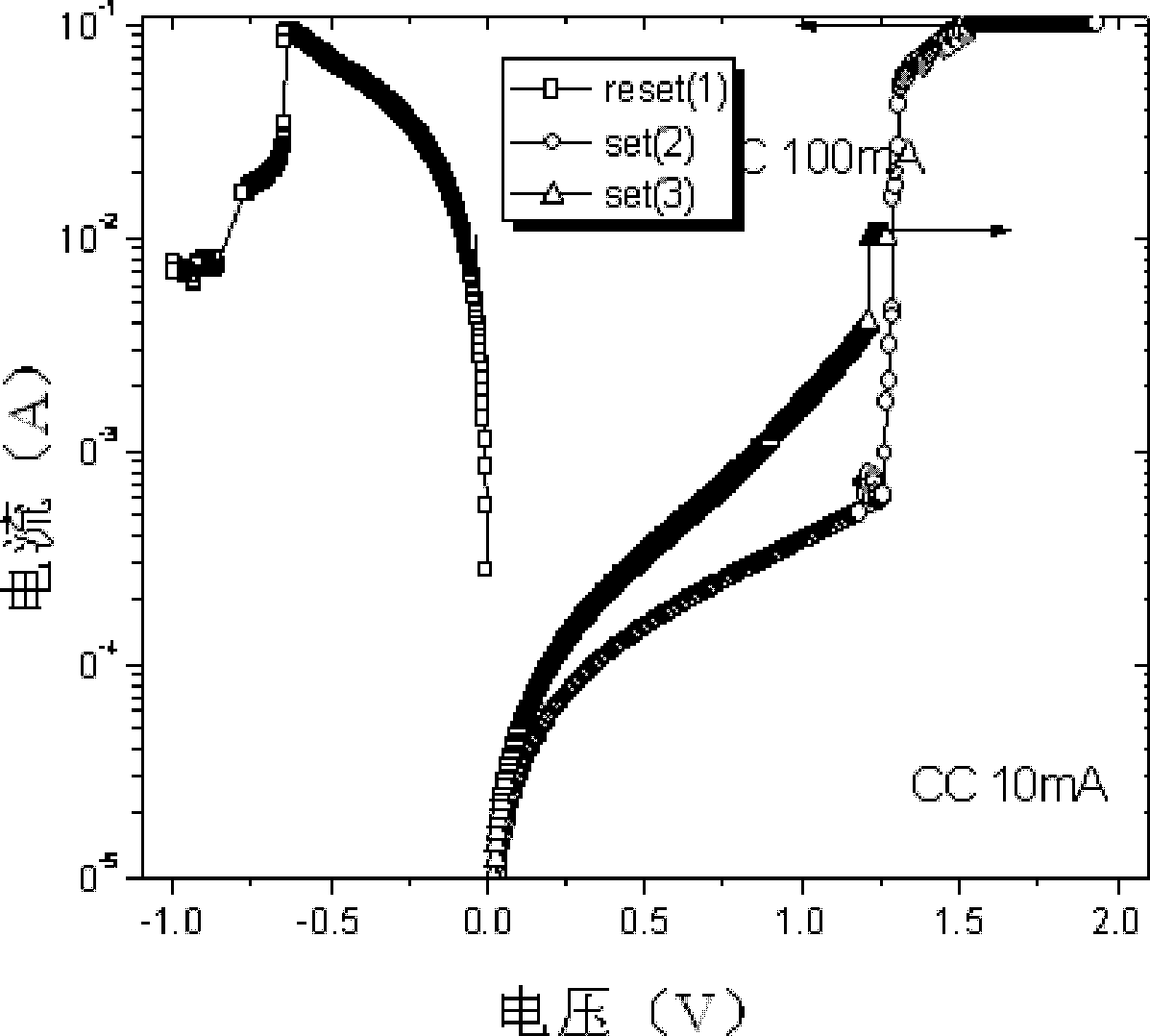

The invention discloses a zinc-oxide-based polarity-controlled resistive random-access memory (RRAM) based on which is composed of a SiO2 / Si substrate, an adhesive layer, a lower electrode, a zinc oxide thin film with a resistance conversion characteristic, an upper electrode and a protective layer, wherein, the thickness of the adhesive layer is 5-20nm, the thickness of the lower electrode is 5-100nm, the thickness of the zinc oxide thin film with characteristics of conversion is 5-200nm, the thickness of the upper electrode is 5-100nm, and the thickness of the protective layer is 5-100nm. The polarity-controlled RRAM provided by the invention has the advantages that the influence of the characteristics of resistance conversion based on a zinc oxide thin film resistance changing device is shown into unipolarity, bipolarity and nonpolarity through depositing different upper electrode materials; according to the characteristics of different polarity resistance changing properties, the application prospects of the RRAM can be expanded, the importance of academics and practical application of the RRAM is highlighted; and a polarity-controlled resistance changing device can be prepared through preparing different upper electrodes of the resistance changing device, thus the RRAM has great significance in the aspects of mass production and actual promotion of the RRAM production process.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

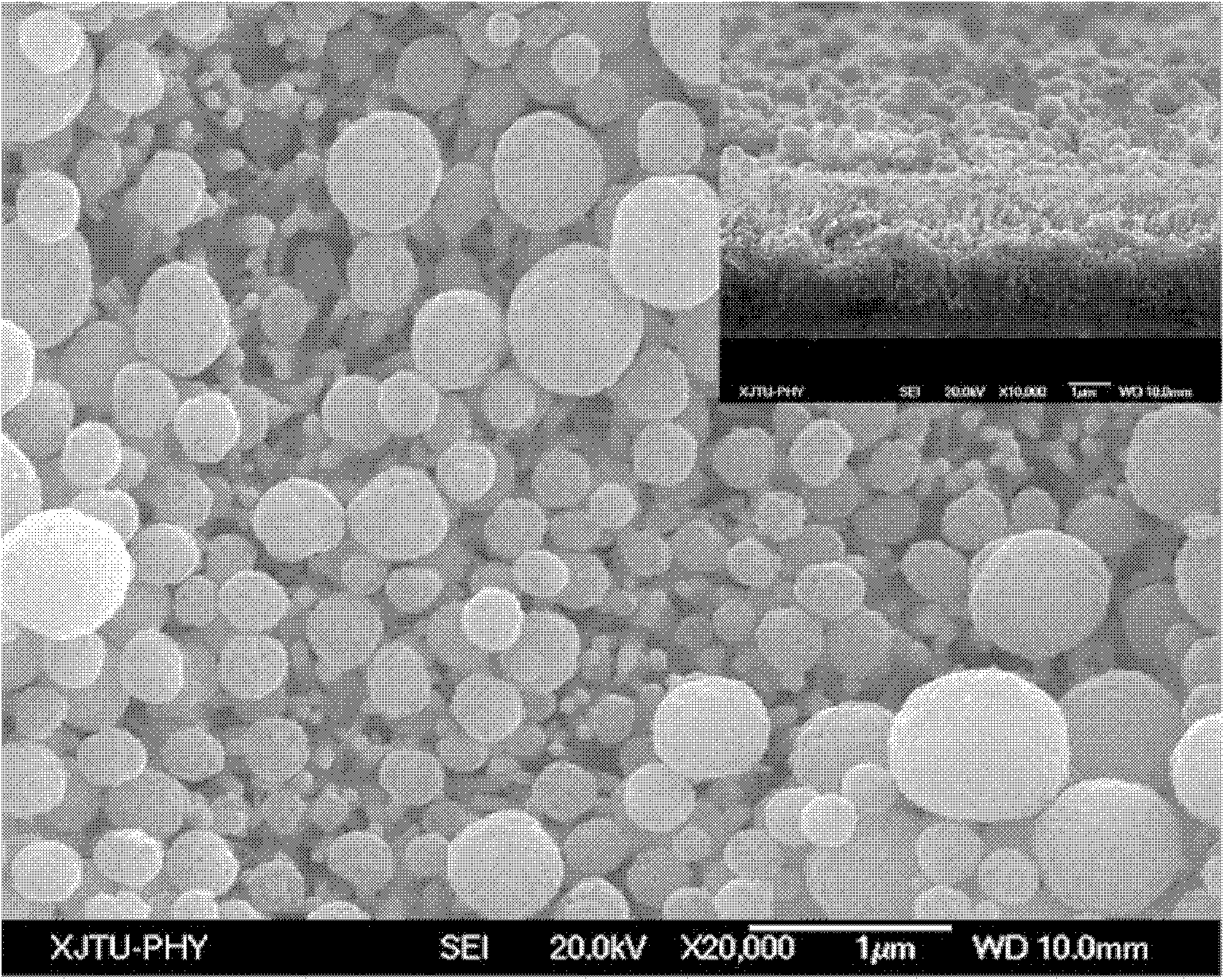

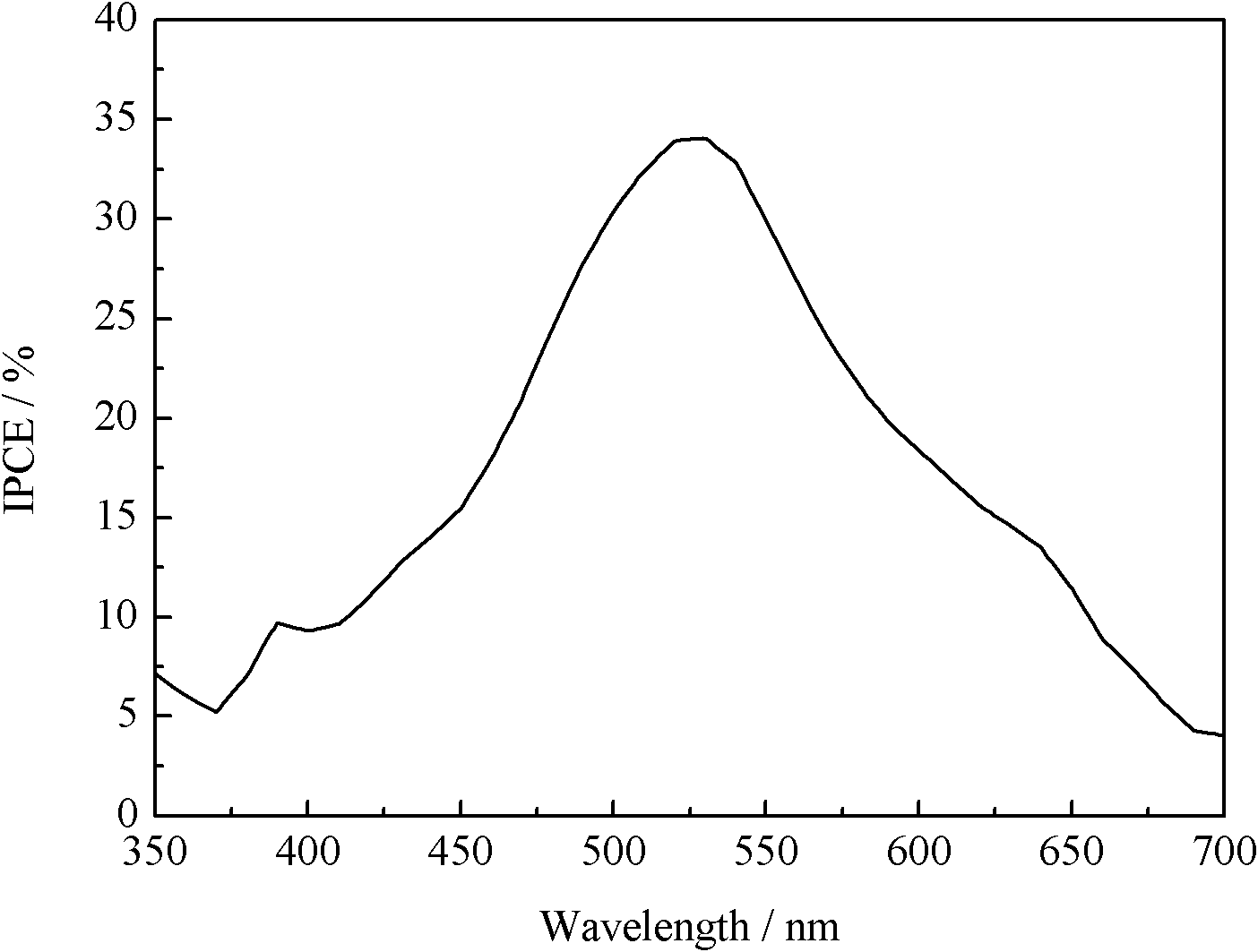

Method for preparing dye-sensitized solar cell compound light anode with zinc oxide nanometer structure

InactiveCN101800130ALower synthesis costSimple process requirementsLight-sensitive devicesFinal product manufactureDye absorptionMicrosphere

The invention relates to a method for preparing a dye-sensitized solar cell compound light anode with a zinc oxide nanometer structure, which adopts a one-dimensional zinc oxide nanowire array as an electronic transport layer, and a layer of multi-dispersed system zinc oxide microspheres is coated on the electronic transport layer and is used as a dye absorption and light scattering layer. The method comprises the following steps of: firstly, depositing a zinc oxide film on a FTO glass sheet by utilizing the sol-gel technology; secondly, growing a zinc oxide nanowire array on the zinc oxide film by adopting the hydrothermal self-assembly growth technology; and finally, coating a layer of multi-dispersed system zinc oxide microspheres grown by collochemistry self-assembly on the zinc oxide nanowire array to prepare the compound light anode with the zinc oxide nanometer structure, which has the advantages of low cost, simple process requirement, good repeatability, capability of performing large-scale preparation and high specific surface and light scattering properties.

Owner:XI AN JIAOTONG UNIV

High purity zinc oxide powder and method for production thereof, and high purity zinc oxide target and thin film of high purity zinc oxide

Owner:JX NIPPON MINING & METALS CORP

Perovskite battery based on nanometer oxide electron transfer layer

InactiveCN103904147AEasy to makeLow growth temperatureMaterial nanotechnologyPhotovoltaic energy generationFilm baseHole transport layer

The invention discloses a perovskite battery based on a nanometer oxide electron transfer layer. According to the structure, the perovskite battery comprises a first electrode, the nanometer oxide electron transfer layer, a perovskite structure light absorption layer, a hole transporting layer and a counter electrode. A two-dimension nanometer structure is a nanoscale titanium dioxide film and a zinc oxide film or a multiple-layer film based on titanium dioxide, zinc oxide and aluminum oxide. A one-dimension nanometer structure is nanoscale titanium dioxide and zinc oxide which are in the shape of a tube or a wire or a rod or a composite nanoscale structure which is in the shape of a tube or a wire or a rod and based on titanium dioxide, zinc oxide and aluminum oxide. The perovskite battery based on the nanometer oxide electron transfer layer has the advantages that the manufacturing process is simple, the growth temperature of the nanometer oxide electron transfer layer is low, and the quality of the nanometer oxide electron transfer layer is high; in addition, the perovskite battery based on the nanometer oxide electron transfer layer can be used in not only a hard substrate but also a flexible substrate.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

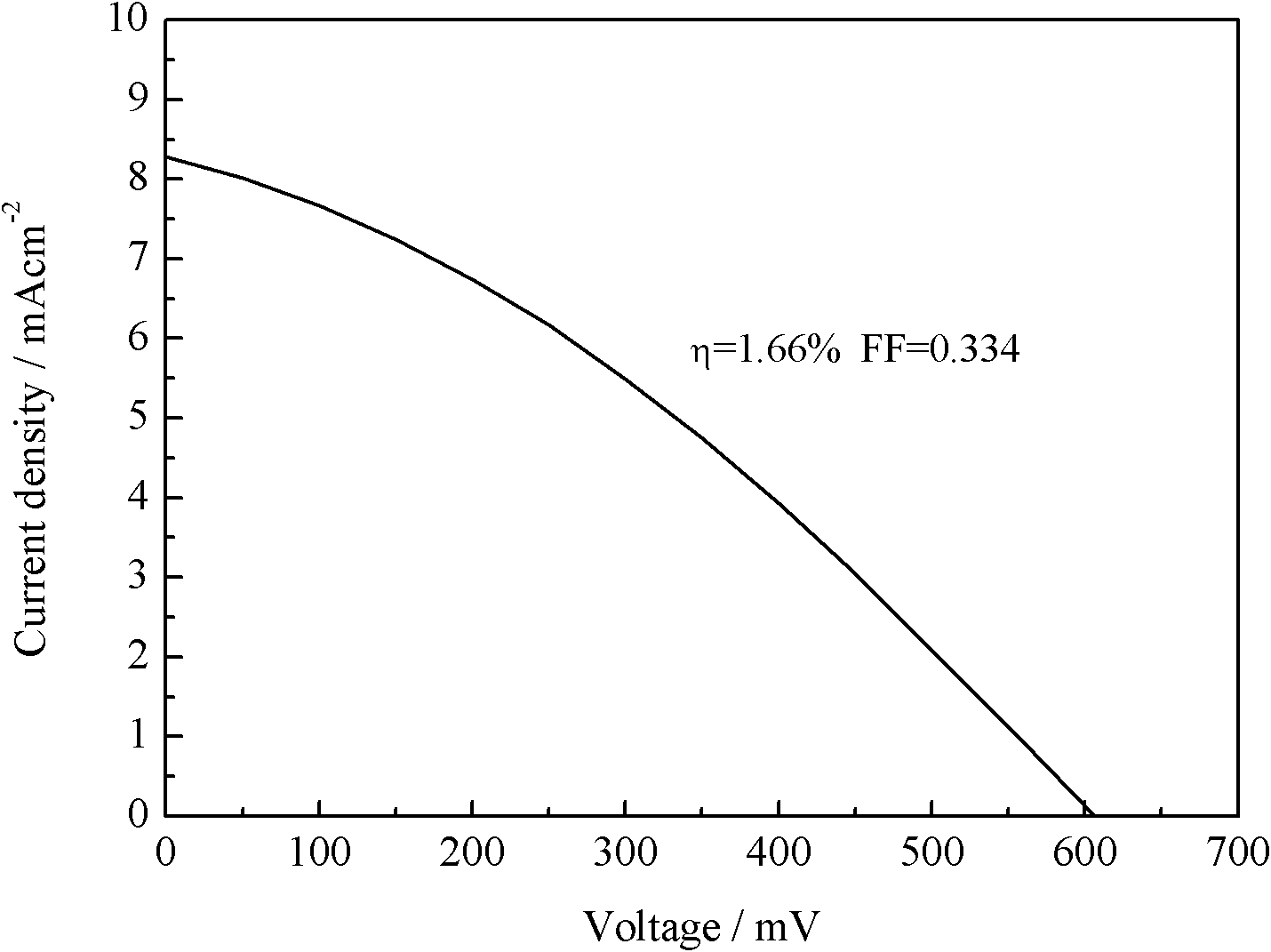

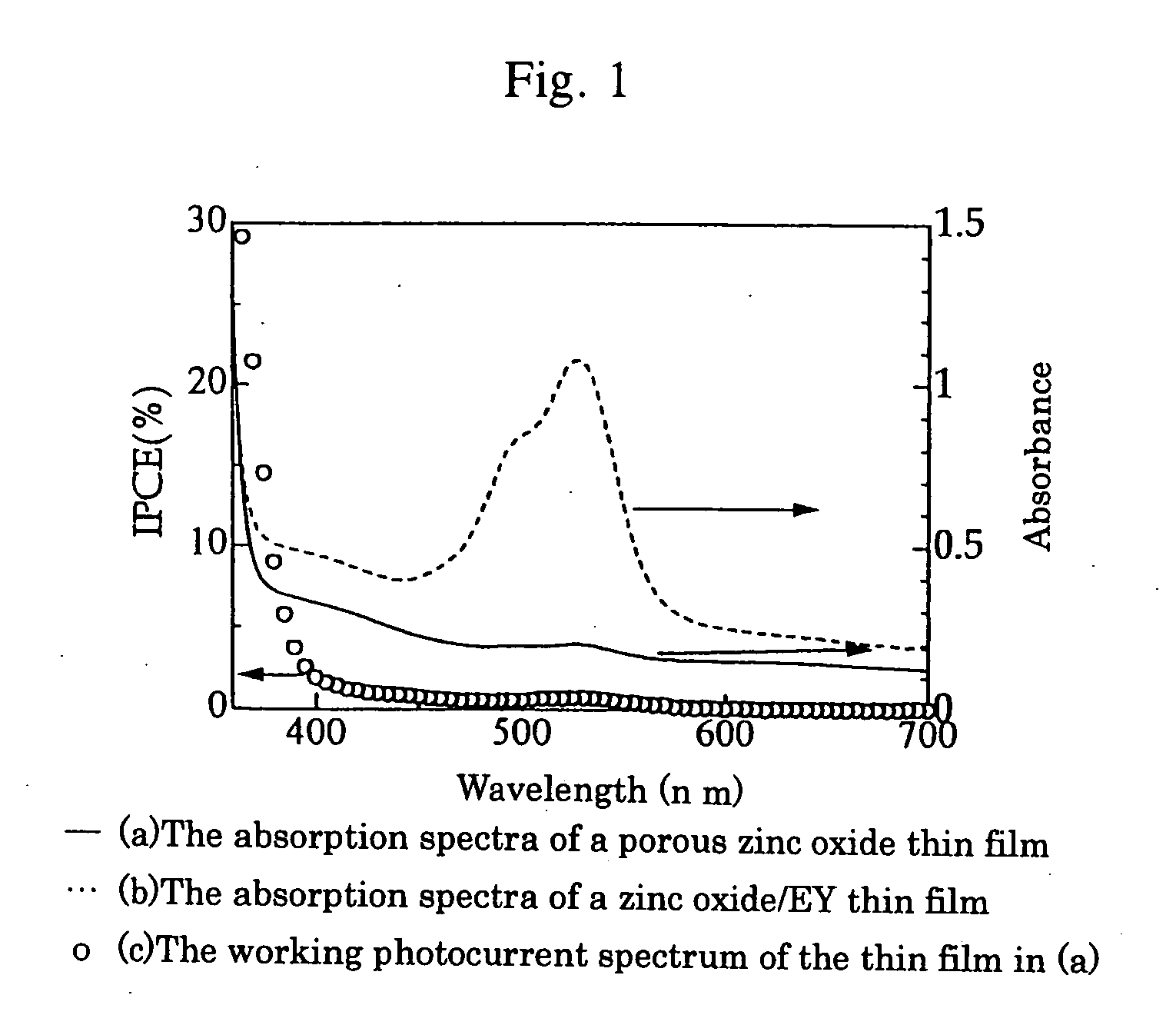

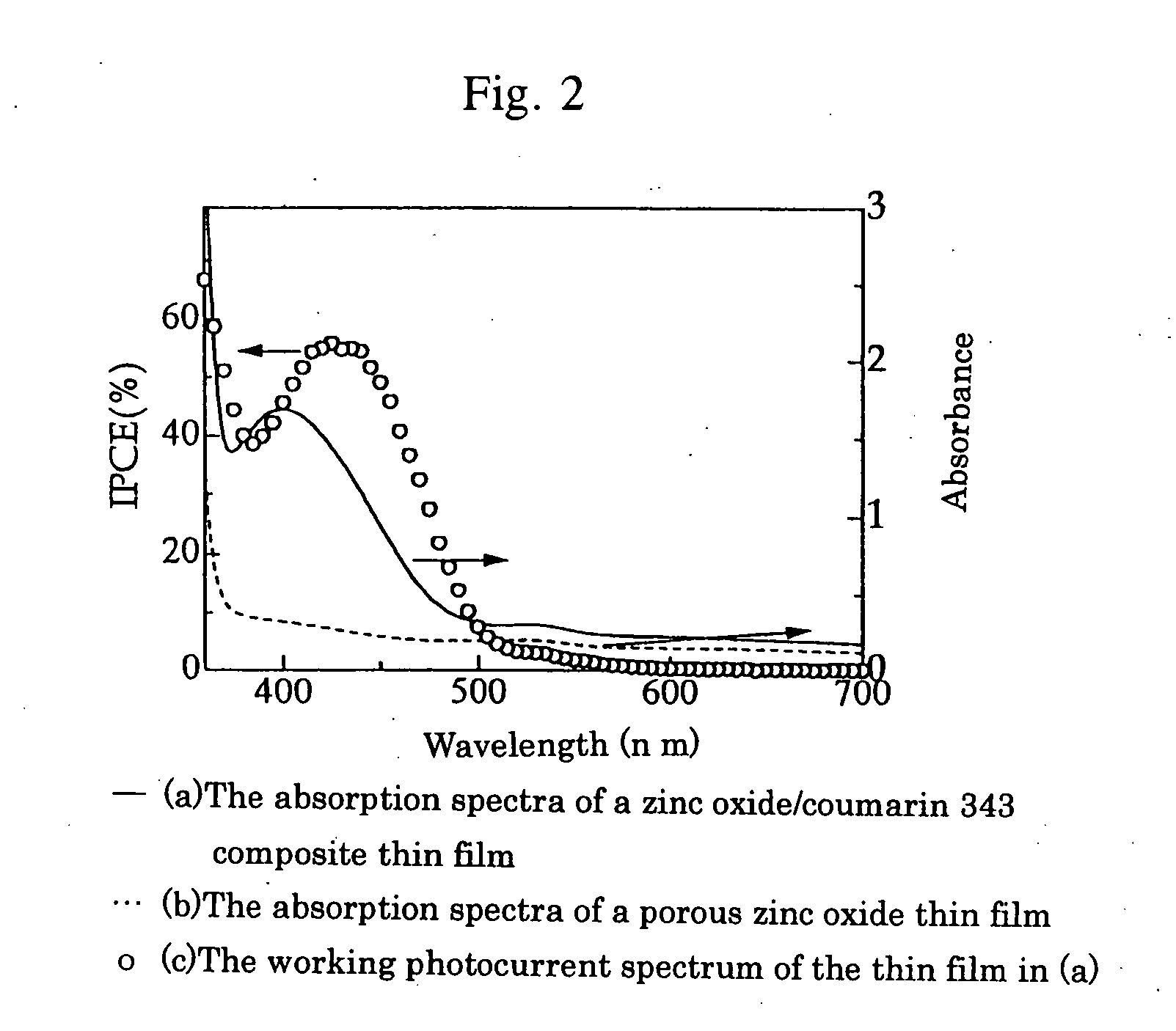

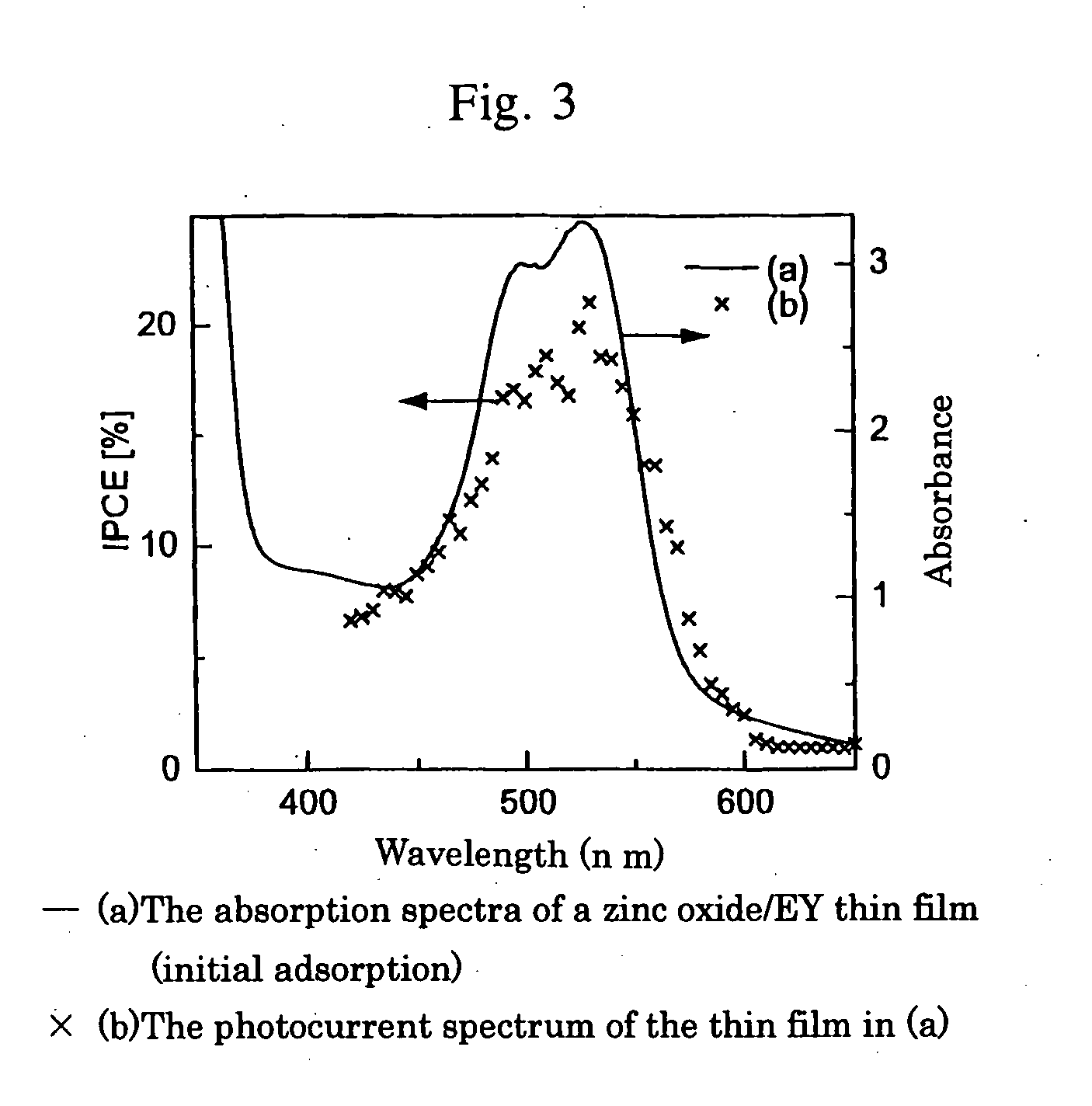

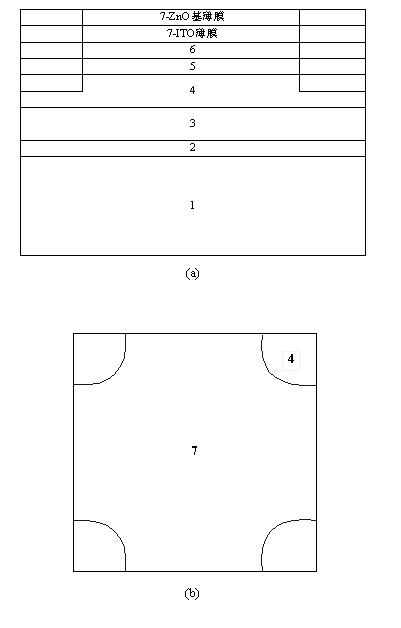

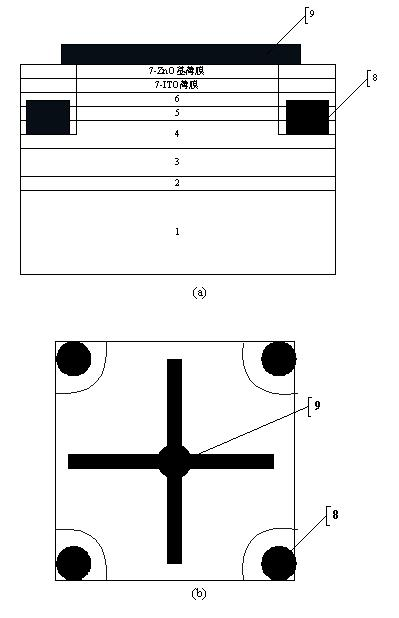

Porous zinc oxide thin-film for substrate of dye-sensitized solar cell, zinc oxide/dye composite thin-film for photoelectrode and dye-sensitized solar cell

InactiveUS20060162765A1Increase surface areaImprove featuresLight-sensitive devicesElectrolytic inorganic material coatingOptoelectronicsZinc salts

The invention provides a porous zinc oxide thin film for a substrate of a dye-sensitized solar cell having pores formed by mixing an electrolytic solution containing a zinc salt with a template compound in advance in the presence of a desired substrate, applying cathodic electrodeposition for uniform and forcible material transport on the surface of the substrate, forming a zinc oxide thin film comprising the template compound adsorbed on the inner surface of the thin film on the substrate, and applying means for desorbing the template compound from the zinc oxide thin film; a zinc oxide / dye composite thin film for a photoelectrode prepared by adsorbing the dye in the pores; and a dye-sensitized solar cell using the zinc oxide / dye composite thin film as the photoelectrode material.

Owner:NAGOYA INDUSTRIAL SCIENCE RESEARCH INST

Light-emitting diode (LED) with indium tin oxide (ITO)/zinc oxide based composite transparent electrode and preparation method of LED

InactiveCN102169943AReduce contact resistanceSpread evenlySemiconductor devicesEvaporationIndium zinc oxide

The invention relates to a light-emitting diode (LED) with an indium tin oxide (ITO) / zinc oxide based composite transparent electrode and a manufacturing process of the LED. The LED comprises a buffer layer, an intrinsic layer, an n-gallium nitride (GaN), a quantum well, a p-GaN and an ITO / zinc oxide based composite current expansion layer which are arranged on a sapphire substrate; an n-metal electrode (PAD) is connected with the n-GaN; and a p-metal electrode (PAD) is connected with the ITO / zinc oxide based composite current expansion layer. The manufacturing process comprises the following steps of: finishing sequential growth of the buffer layer, the intrinsic layer, the n-GaN, the quantum well and the p-GaN in metal organic chemical vapour deposition (MOCVD) equipment; sequentially depositing an ITO film and a zinc oxide film on a surface of the p-GaN by electron beam evaporation and magnetron sputtering to form the ITO / zinc oxide based composite current expansion layer; exposing the n-GaN by dry etching; and growing the metal electrodes by thermal evaporation after annealing. The size of a chip is 1mm*1mm. The composite transparent electrode improves contact between the p-GaN and an electrode layer, improves the light extraction efficiency of an LED chip and improves the reliability of the LED chip.

Owner:SHANGHAI UNIV

Zinc oxide coating modified in vivo implanted artificial organ and preparation method thereof

InactiveCN101745147AGood blood compatibilityHigh puritySurgeryVacuum evaporation coatingRare-earth elementRadio frequency magnetron sputtering

The invention discloses an artificial organ used for in vivo implantation, which comprises an artificial organ matrix and an artificial organ surface modified layer, wherein the surface modified layer is a zinc oxide thin film the thickness of which is 10nm to 700nm, preferably a zinc oxide thin film the thickness of which is 200nm to 400nm. The zinc oxide thin film is doped preferably by light rare earth elements. The invention also discloses two methods for preparing the artificial organ the surface of which is modified by the zinc oxide coating, wherein in one method, a layer of pure or light rare earth-doped transparent zinc oxide thin film is prepared on the surface of the in vivo implanted artificial organ by adopting a radio frequency magnetic control sputtering technology to serve as a biological coating for improving an implant anticoagulant property; in the other method, the transparent zinc oxide thin film is deposited by adopting a method of magnetic filtration arc ion plating. The anticoagulant property and the mechanical property of the in vivo implanted artificial organ are improved.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com