Zinc-oxide-based polarity-controlled resistive random-access memory (RRAM) and manufacturing method thereof

A technology of resistive memory and zinc oxide, applied in electrical components and other directions, can solve the problem that the physical mechanism of the resistive switching mechanism is not completely clear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

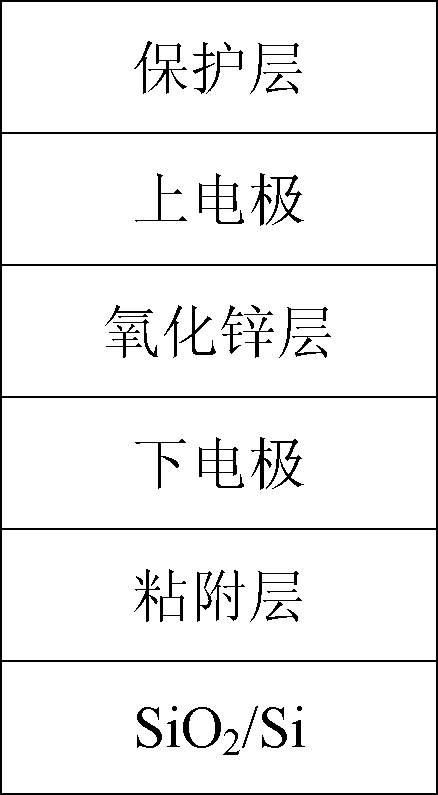

[0034] A ZnO-based polarity controllable resistive variable memory made of SiO 2 / Si substrate, adhesion layer, lower electrode, zinc oxide film with resistance switching characteristics, upper electrode and protective layer, such as figure 1 As shown, the specific preparation process is as follows:

[0035] 1) On SiO by ion beam sputtering 2 Prepare the adhesion layer Ti film on the Si substrate, the thickness of the Ti film is 5nm;

[0036] 2) Prepare the lower electrode Cu on the adhesion layer by DC magnetron sputtering method, the background vacuum degree: 1×10 -4 Pa, substrate temperature: room temperature, working pressure: 1.5Pa, Ar=30sccm, sputtering power: 85W; film thickness 20nm;

[0037] 3) Prepare a zinc oxide film with resistive switching properties on the lower electrode by radio frequency magnetron sputtering, the background vacuum degree: 1×10 -4 Pa, substrate temperature: 250°C, working pressure: 1.0Pa, O in sputtering 2 =8sccm, Ar=32sccm, sputtering po...

Embodiment 2

[0042] A ZnO-based polarity controllable resistive variable memory made of SiO 2 / Si substrate, adhesion layer, lower electrode, zinc oxide film with resistance transition characteristics, upper electrode and protective layer, the specific preparation process is as follows:

[0043] 1) Prepare an adhesion layer Ti film on a SiO2 / Si substrate by ion beam sputtering, the thickness of the Ti film is 5nm;

[0044] 2) Prepare the lower electrode Cu on the Ti film by DC magnetron sputtering method, the background vacuum degree: 1×10 -4 Pa, substrate temperature: room temperature, working pressure: 1.5Pa, Ar=30sccm, sputtering power: 85W; film thickness 20nm;

[0045] 3) Prepare a zinc oxide film with resistive switching properties on the lower electrode by radio frequency magnetron sputtering, the background vacuum degree: 1×10 -4 Pa, substrate temperature: 250°C, working pressure: 1.0Pa, O in sputtering 2 =8sccm, Ar=32sccm, sputtering power: 100W; film thickness 100nm;

[0046]...

Embodiment 3

[0050] A ZnO-based polarity controllable resistive variable memory made of SiO 2 / Si substrate, adhesion layer, lower electrode, zinc oxide film with resistance transition characteristics, upper electrode and protective layer, the specific preparation process is as follows:

[0051] 1) Prepare an adhesion layer Ti film on a SiO2 / Si substrate by ion beam sputtering, the thickness of the Ti film is 5nm;

[0052] 2) Prepare the lower electrode Cu on the adhesion layer by DC magnetron sputtering method, the background vacuum degree: 1×10 -4 Pa, substrate temperature: room temperature, working pressure: 1.5Pa, Ar=30sccm, sputtering power: 85W; film thickness 20nm;

[0053] 3) A zinc oxide film was prepared on the lower electrode by radio frequency sputtering, the oxygen partial pressure in sputtering was 25%, the sputtering power was 250W, and the film thickness was 100nm;

[0054] 4) The upper electrode Ag is prepared on the zinc oxide film by DC magnetron sputtering method, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com