Perovskite battery based on nanometer oxide electron transfer layer

An electron transport layer, nano-oxide technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, can solve the problems of many structural and chemical defects, good results, charge recombination, etc. The effect of low growth temperature, high quality and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

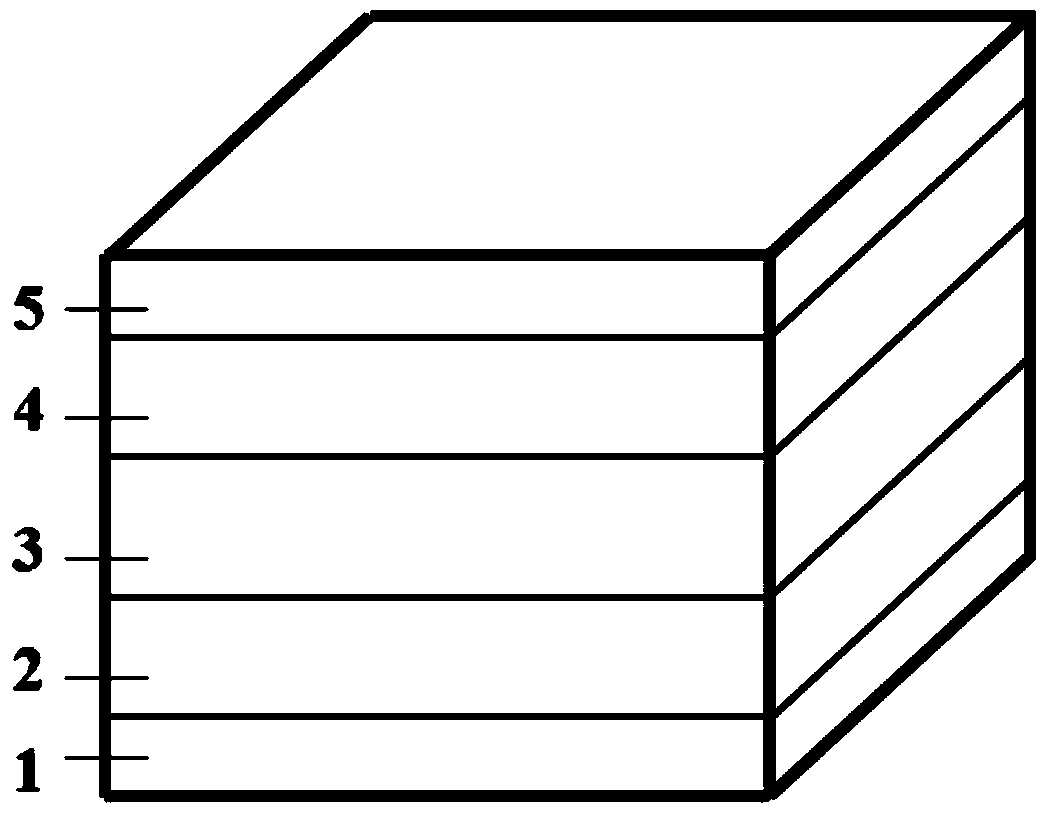

[0013] On the transparent substrate as the first electrode, a layer of zinc oxide thin film was prepared by atomic layer deposition as the electron transport layer; the light-absorbing layer of the perovskite structure was laminated on the electron transport layer; the hole transport layer was laminated on the light-absorbing layer of the perovskite structure layer; the counter electrode is stacked on the hole transport layer. That is, a perovskite battery based on a nano-oxide electron transport layer is obtained.

Embodiment 2

[0015] On the transparent substrate as the first electrode, a layer of zinc oxide thin film is prepared by atomic layer deposition, and then a layer of zinc oxide nanorods is prepared by chemical hydrothermal method at a temperature lower than 150°C, and the zinc oxide thin film and nanorods are used together as the The electron transport layer; the perovskite structure light absorption layer is stacked on the electron transport layer; the hole transport layer is stacked on the perovskite structure light absorption layer; the counter electrode is stacked on the hole transport layer. That is, a perovskite battery based on a nano-oxide electron transport layer is obtained.

Embodiment 3

[0017] On the transparent substrate as the first electrode, a layer of zinc oxide film was prepared at low temperature (below 160°C) by atomic layer deposition, and then a layer of zinc oxide nanorods were prepared by chemical method at a temperature below 150°C, and then used A layer of titanium dioxide film is coated on the surface of zinc oxide nanorods by atomic layer deposition, and the zinc oxide film and zinc oxide nanorods coated with titanium oxide are used as the electron transport layer; the perovskite structure light-absorbing layer is laminated on the electron transport layer; The hole transport layer is stacked on the perovskite structure light absorbing layer; the counter electrode is stacked on the hole transport layer. That is, a perovskite battery based on a nano-oxide electron transport layer is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com