Method for reinforcing zinc oxide film blue light emission

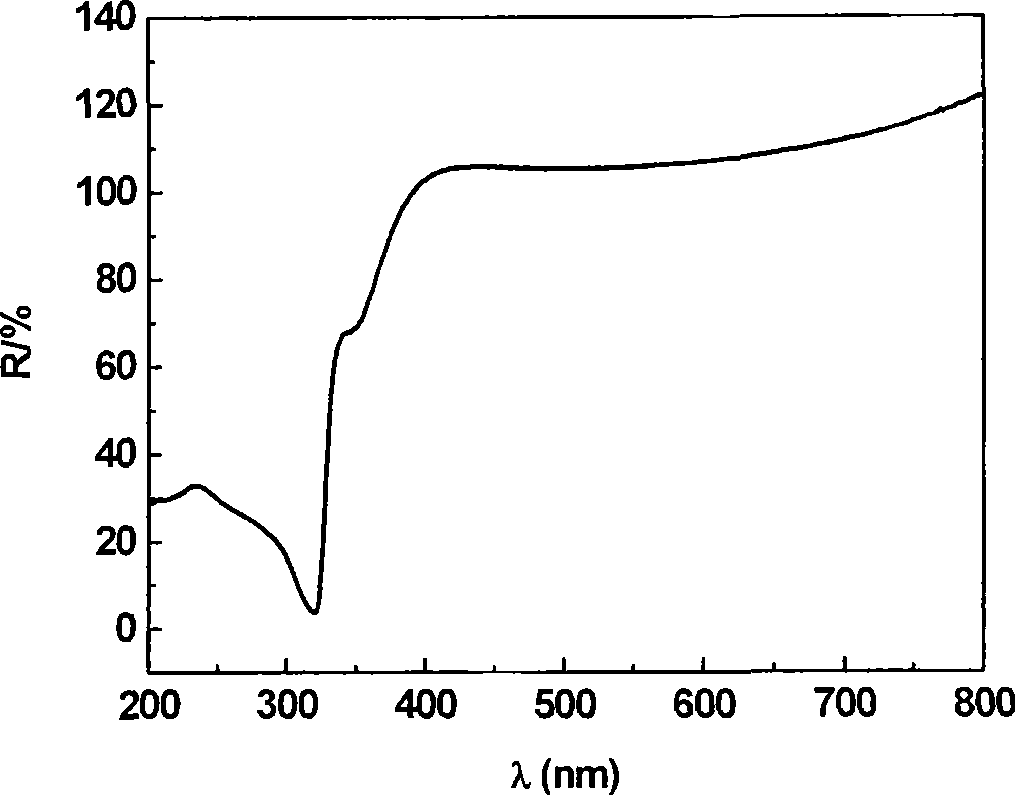

A zinc oxide film, blue light technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low blue light emission efficiency and many defects in ZnO film, and achieve the effect of wide application, enhanced blue light emission of ZnO, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

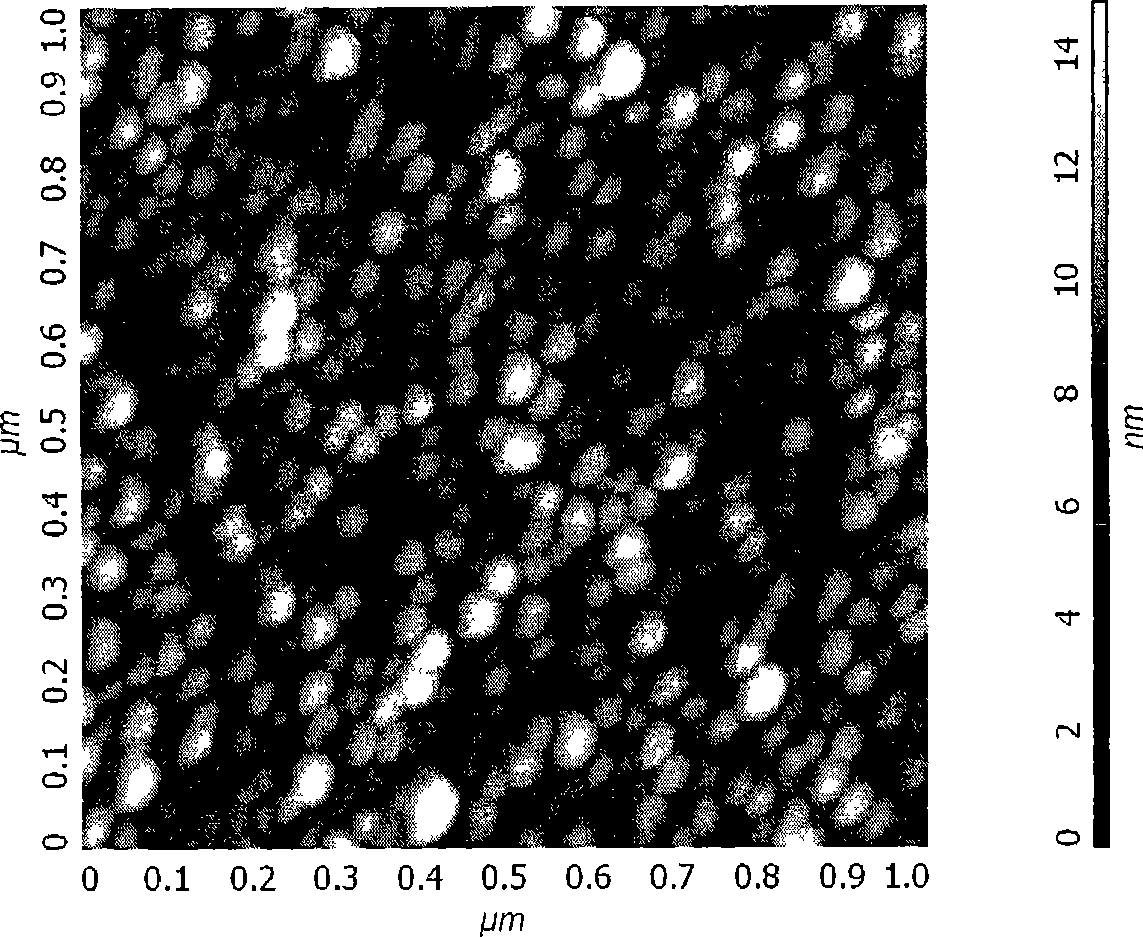

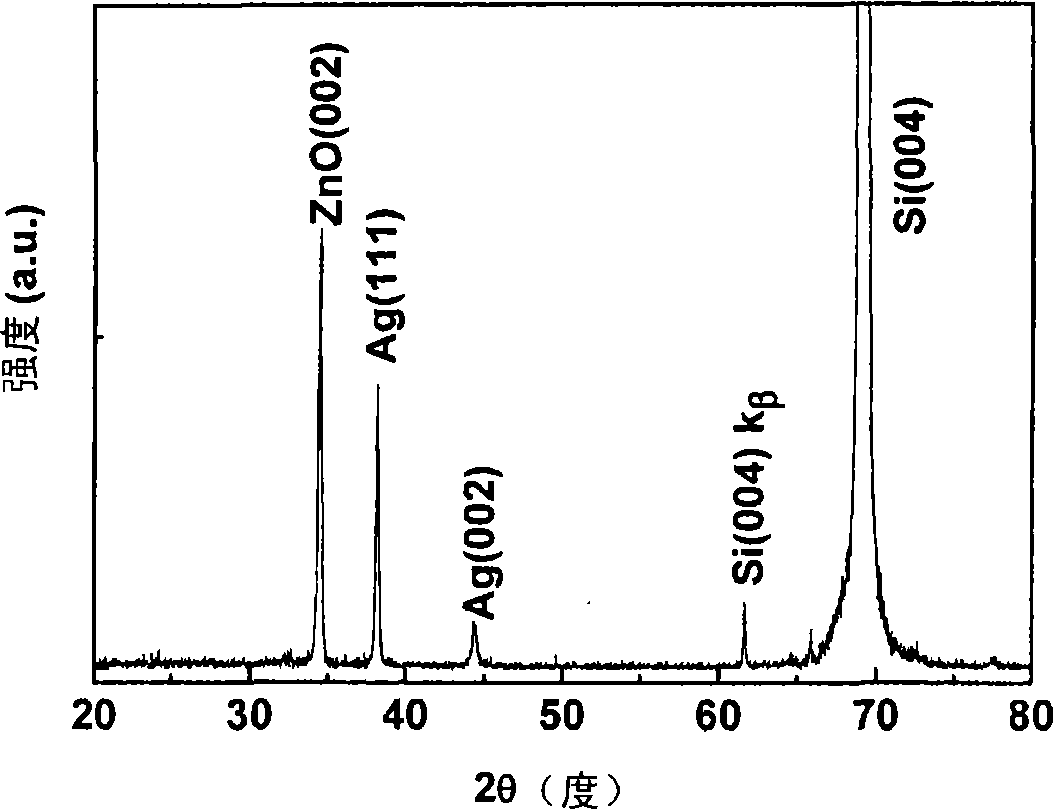

[0022] Growth process:

[0023] 1) The equipment used for growth is a three-target radio frequency magnetron sputtering system, including a sample chamber, a deposition chamber, a vacuum system, a radio frequency power supply and a matching system, a substrate heating and temperature control system, a sample rotation system, etc.;

[0024] 2) Using 99.99% high-purity metal Ag target and 99.99% high-purity ZnO ceramic target as sputtering target;

[0025] 3) loading the above-mentioned target material on the radio frequency target platform in the deposition chamber;

[0026] 4) Place the Si(001) substrate on the sample holder, and adjust the distance between the target and the substrate to be 80mm;

[0027] 5) The background vacuum of the sample chamber is 1×10 -5 Pa;

[0028] 6) First grow the Ag film, the process conditions are: the working gas is high-purity argon (Ar) gas, the working pressure is 1.0-2.0Pa, the radio frequency sputtering power is 20-80W, the substrate te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com