Amorphous zinc oxide thin film transistor and method of manufacturing the same

A thin-film transistor and amorphous technology, which is applied in the field of low-temperature ZnO TFT and its manufacturing, can solve the problems of being unsuitable for mass production and unfavorable for large-screen displays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] To briefly describe the present invention, a semiconductor channel is formed using a low temperature process at or below 350°C, and the semiconductor channel has n(GaO 3 )·m(InO 3 )·(ZnO)k composition, wherein the inequality conditions n≥1.5, m≥1.5, k>0 are satisfied. Here, k in the inequality has a different value from at least one of m and n.

[0020] According to an embodiment of the present invention, using a sputtering process which is a low-temperature process, specifically a radio frequency (RF) magnetron sputtering method, a ZnO TFT is formed, which has a GaO 3 -InO 3 -Amorphous semiconductor channel formed of ZnO semiconductor material.

[0021] Hereinafter, the present invention will be described more fully with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown.

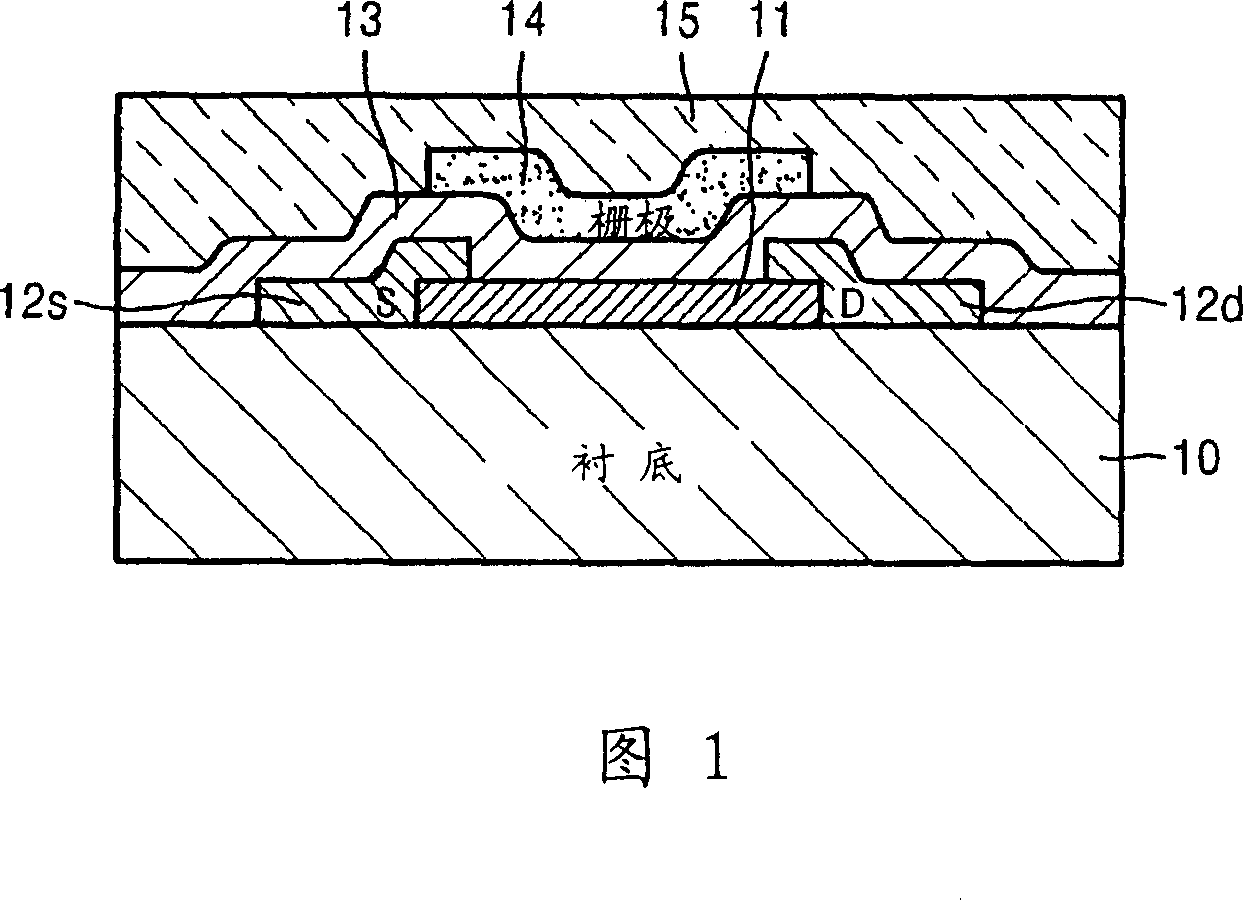

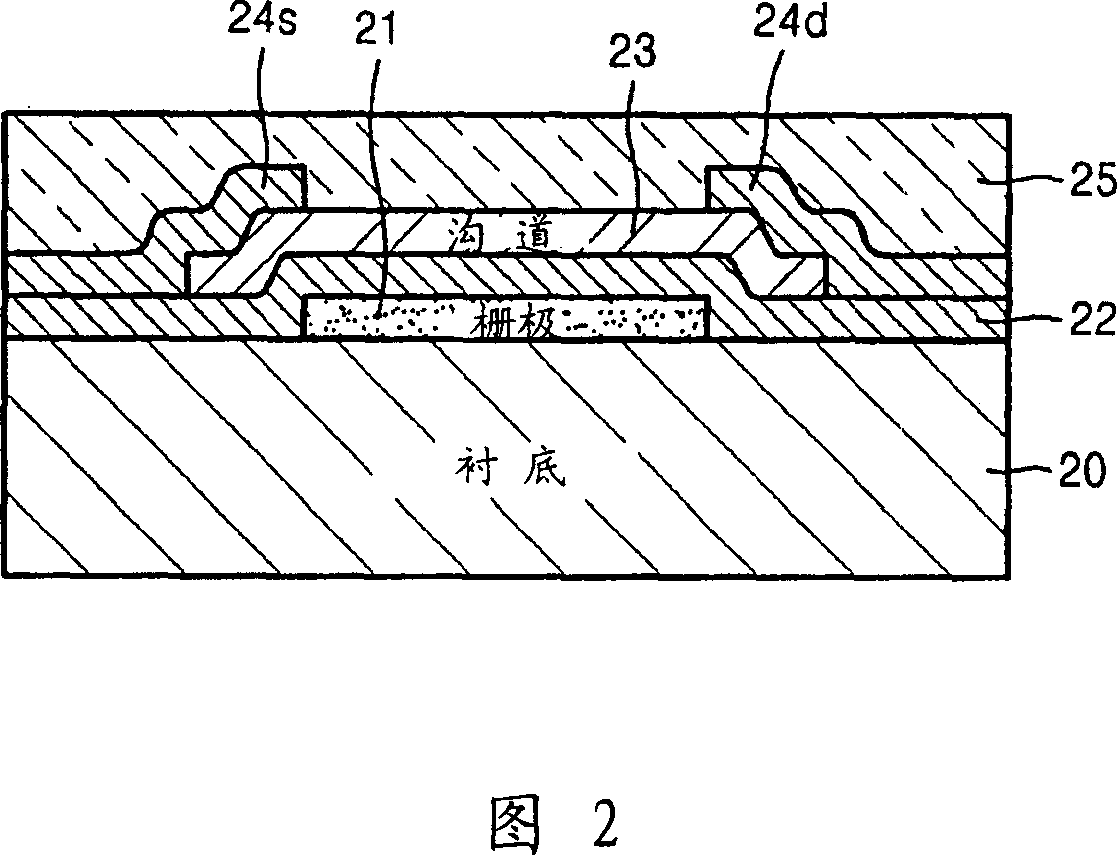

[0022] 1 is a schematic cross-sectional view of a top-gate ZnO TFT according to an embodiment of the present invention, and FIG. 2 is a schematic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com