Electrode material of C@MnO2 nanotube super capacitor and preparation method and application of electrode material

A supercapacitor electrode and supercapacitor technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of no contribution to capacitance, easy lodging, and no contribution to capacitor capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] CMnO 2 Preparation of electrode materials:

[0070] (1) The flexible carbon fiber cloth was ultrasonically cleaned with acetone and alcohol for 2 minutes, and then baked at 110°C for 1 hour; using magnetron sputtering, a 50nm ZnO film was deposited on the pretreated carbon cloth by sputtering, as Growth seed layer of zinc oxide nanorods;

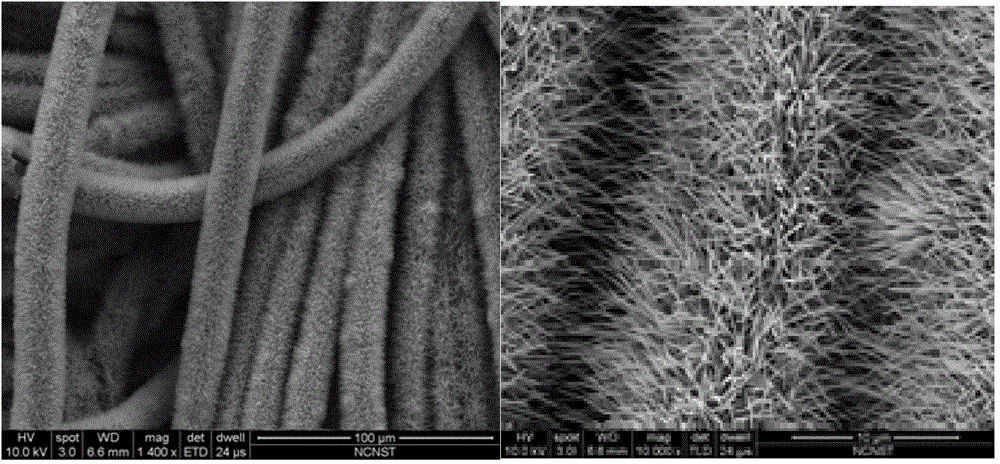

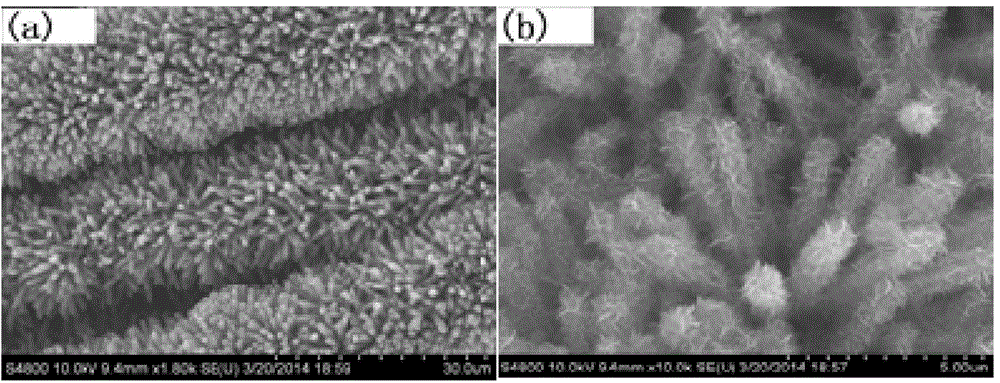

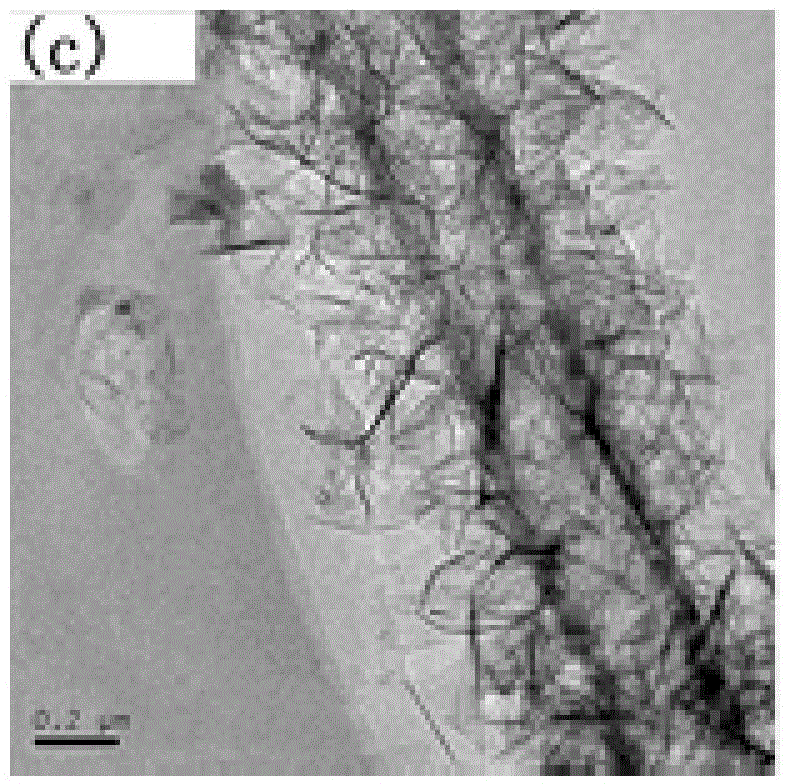

[0071] (2) ZnO nanorod array growth: put the carbon cloth sample prepared in the above step (1) into a sealable container, add deionized water, 0.5 mol / L zinc nitrate solution, 0.1mol / L polyvinylimine solution, 0.25mol / L hexamethylenetetramine solution and 75% ammonia water. After fully stirring, seal it, and then heat it in a water bath at 65°C for 10 hours to obtain a zinc oxide nanorod array of about 6 microns, which is evenly distributed around the carbon cloth fiber, as figure 1 shown.

[0072] (3) Rinse the carbon cloth with ZnO nanowire arrays grown in step (2) with absolute ethanol and deionized water in turn to make the s...

Embodiment 2

[0077] CMnO 2 Preparation of electrode materials:

[0078] (1) Except for ultrasonic cleaning time of 1 min, drying at 105° C. for 2 h, and sputtering deposition of a 55 nm ZnO thin film, other processes are the same as step (1) in Example 1.

[0079] (2) In addition to adding deionized water, 0.3mol / L zinc nitrate solution, 0.05mol / L phenol solution, and 0.2mol / L ethylenediaminetetrapropionic acid in a volume ratio of 30:5:5:2:1 The solution and 70% ammonia water were washed with water at 60° C. for 12 hours, and the other processes were the same as step (2) in Example 1.

[0080] (3) In addition to immersing the carbon cloth in a 1.5mol / L sucrose solution for 4 hours, drying in an oven at 85°C for 4 hours, and annealing at 500°C for 6 hours under the protection of 55 sccm of nitrogen, other processes are the same as those in Example 1 (3) same.

[0081] (4) Divided by the mixed solution of manganese acetate of 0.03mol / L and sodium acetate of 0.15mol / L as the electrolyte, ...

Embodiment 3

[0084] CMnO 2 Preparation of electrode materials:

[0085] (1) Except that the ultrasonic cleaning time is 5 minutes, drying at 115° C. for 3 hours, and a 60 nm ZnO thin film deposited by sputtering, other processes are the same as step (1) in Example 1.

[0086] (2) In addition to adding deionized water, 0.7mol / L zinc chloride solution, 0.15mol / L dimethyl malonate solution, 0.3mol / L Triethylenetetramine solution and 80% ammonia water were washed with water at 70° C. for 8 hours, and the other processes were the same as step (2) in Example 1.

[0087] (3) In addition to immersing the carbon cloth in a 0.5mol / L fructose solution for 7 hours, drying in an oven at 75°C for 6 hours, and annealing at 700°C for 4 hours under the protection of 45 sccm of nitrogen, other processes are the same as those in Example 1 (3) same.

[0088] (4) Divided by the mixed solution of 0.01mol / L manganese chloride and 0.05mol / L sodium chloride as the electrolyte, at 1mA / cm 2 Under the current den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com