Method for preparing dye-sensitized solar cell compound light anode with zinc oxide nanometer structure

A zinc oxide nanometer, solar cell technology, applied in photosensitive devices, circuits, capacitors, etc., can solve problems such as low photoelectric conversion efficiency, and achieve the effects of low synthesis cost, simple process requirements, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

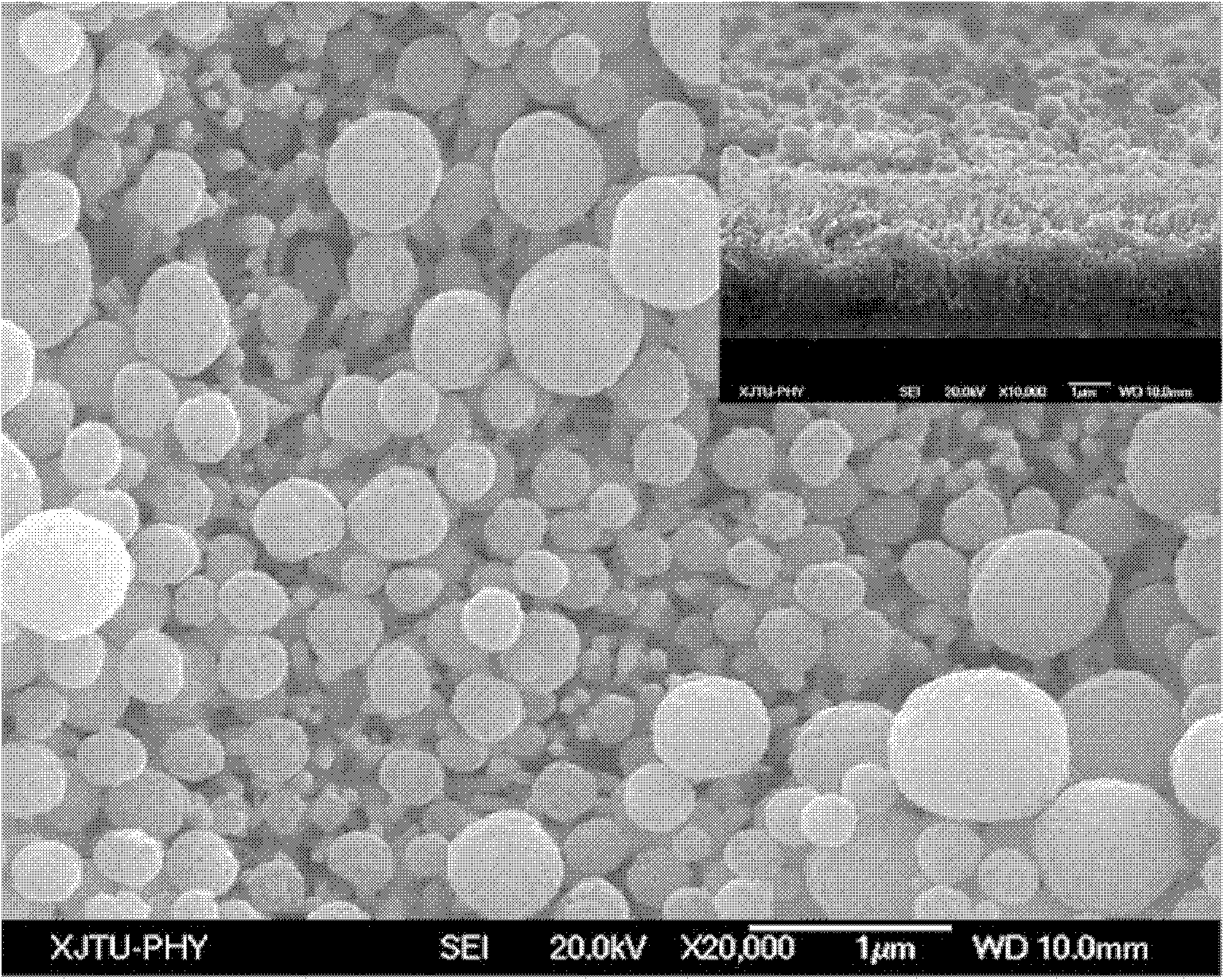

[0011] Embodiment 1, 1) zinc acetate dihydrate, monoethanol ammonia and deionized water are dissolved in ethylene glycol methyl ether at a molar ratio of 1: 1: 0.5 and the concentration of zinc acetate dihydrate made is 0.1mol / L Mix the solution, then seal the mixed solution and put it into a constant temperature water bath, and magnetically stir at a constant temperature of 60°C to obtain a transparent and uniform sol; 2) Use the spin coating process to deposit the above sol on the cleaned FTO Put the spin-coated substrate into a 200°C drying oven to dry, and finally anneal at 350°C for 2 hours to obtain a zinc oxide seed layer; 3) Dissolve zinc nitrate hexahydrate and sodium hydroxide in water to prepare Form a growth solution, the concentration of zinc nitrate hexahydrate in the growth solution is 0.02mol / L, the concentration of sodium hydroxide is 0.4mol / L, put the substrate coated with the zinc oxide seed crystal layer into the growth solution, and heat it at 60°C Treat a...

Embodiment 2

[0012] Embodiment 2, 1) zinc acetate dihydrate, monoethanol ammonia and deionized water are dissolved in ethylene glycol methyl ether at a molar ratio of 1: 1: 0.5 and the concentration of zinc acetate dihydrate is 0.5mol / L Mix the solution, then seal the mixed solution and put it into a constant temperature water bath, and magnetically stir at a constant temperature of 60°C to obtain a transparent and uniform sol; 2) Use the spin coating process to deposit the above sol on the cleaned FTO Put the spin-coated substrate into a drying oven at 250°C for drying, and finally anneal at 400°C for 1.5 hours to obtain a zinc oxide seed layer; 3) Dissolve zinc nitrate hexahydrate and sodium hydroxide in water to prepare Form a growth solution, the concentration of zinc nitrate hexahydrate in the growth solution is 0.02mol / L, the concentration of sodium hydroxide is 0.5mol / L, put the substrate coated with the zinc oxide seed crystal layer into the growth solution, and heat it at 70°C Tre...

Embodiment 3

[0013] Embodiment 3, 1) zinc acetate dihydrate, monoethanol ammonia and deionized water are dissolved in ethylene glycol methyl ether in the molar ratio of 1: 1: 0.5 and the concentration that makes zinc acetate dihydrate is 0.8mol / L Mix the solution, then seal the mixed solution and put it into a constant temperature water bath, and magnetically stir at a constant temperature of 60°C to obtain a transparent and uniform sol; 2) Use the spin coating process to deposit the above sol on the cleaned FTO Put the spin-coated substrate into a drying oven at 230°C for drying, and finally anneal at 380°C for 1 hour to obtain a zinc oxide seed layer; 3) Dissolve zinc nitrate hexahydrate and sodium hydroxide in water to prepare Form a growth solution, the concentration of zinc nitrate hexahydrate in the growth solution is 0.03mol / L, the concentration of sodium hydroxide is 0.6mol / L, put the substrate coated with the zinc oxide seed crystal layer into the growth solution, at 80 ℃ Treat at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com