Patents

Literature

54 results about "Metal Primer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

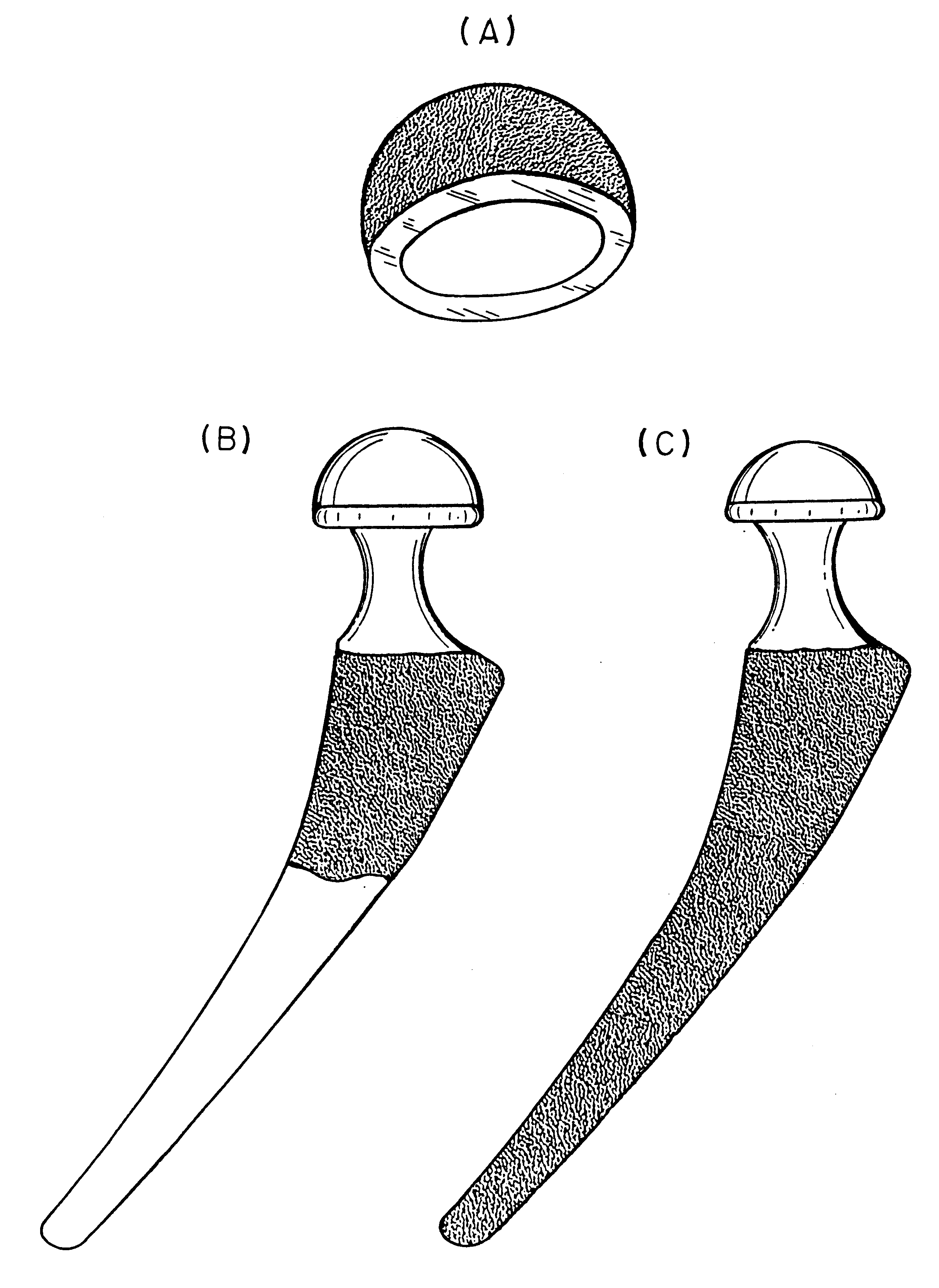

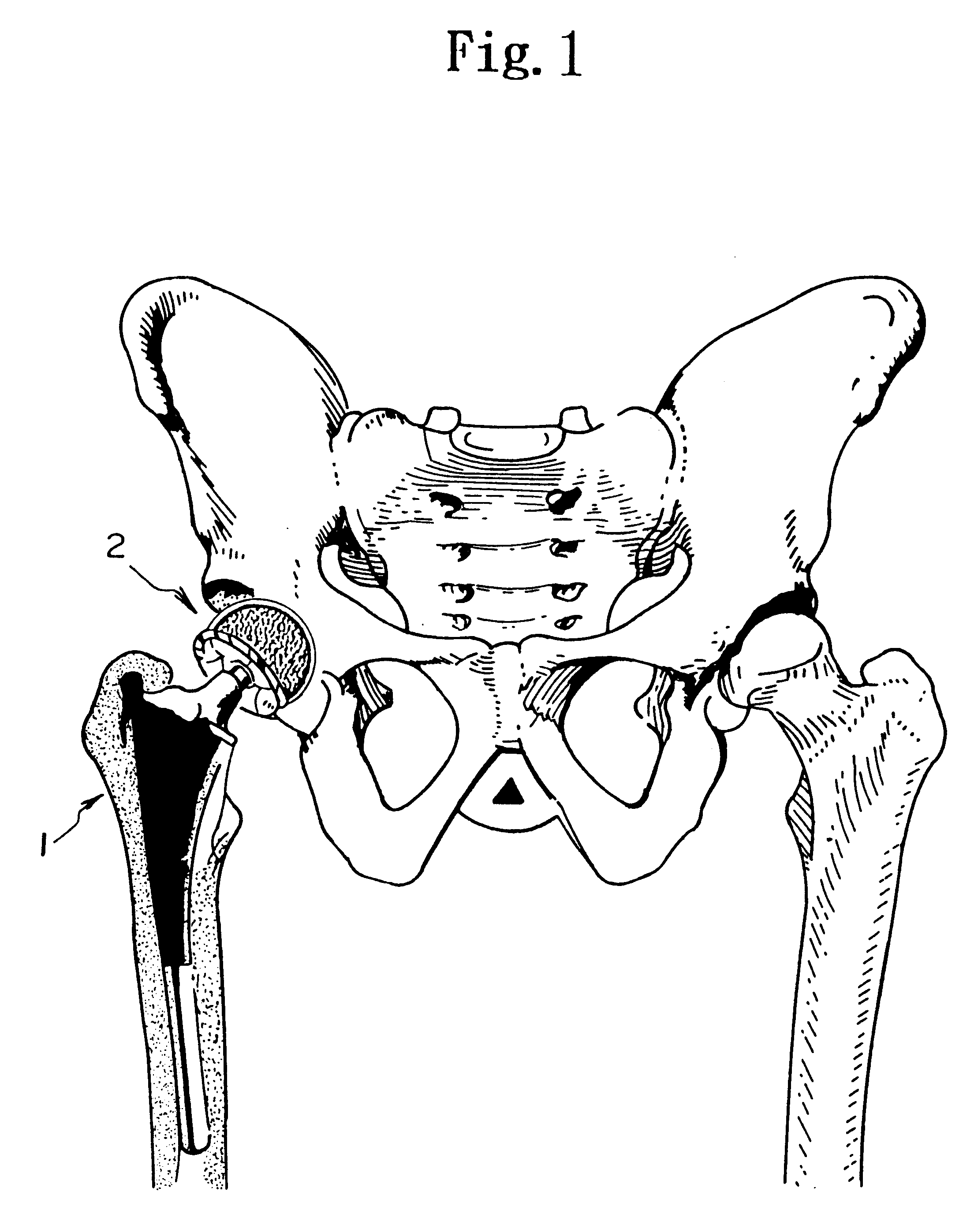

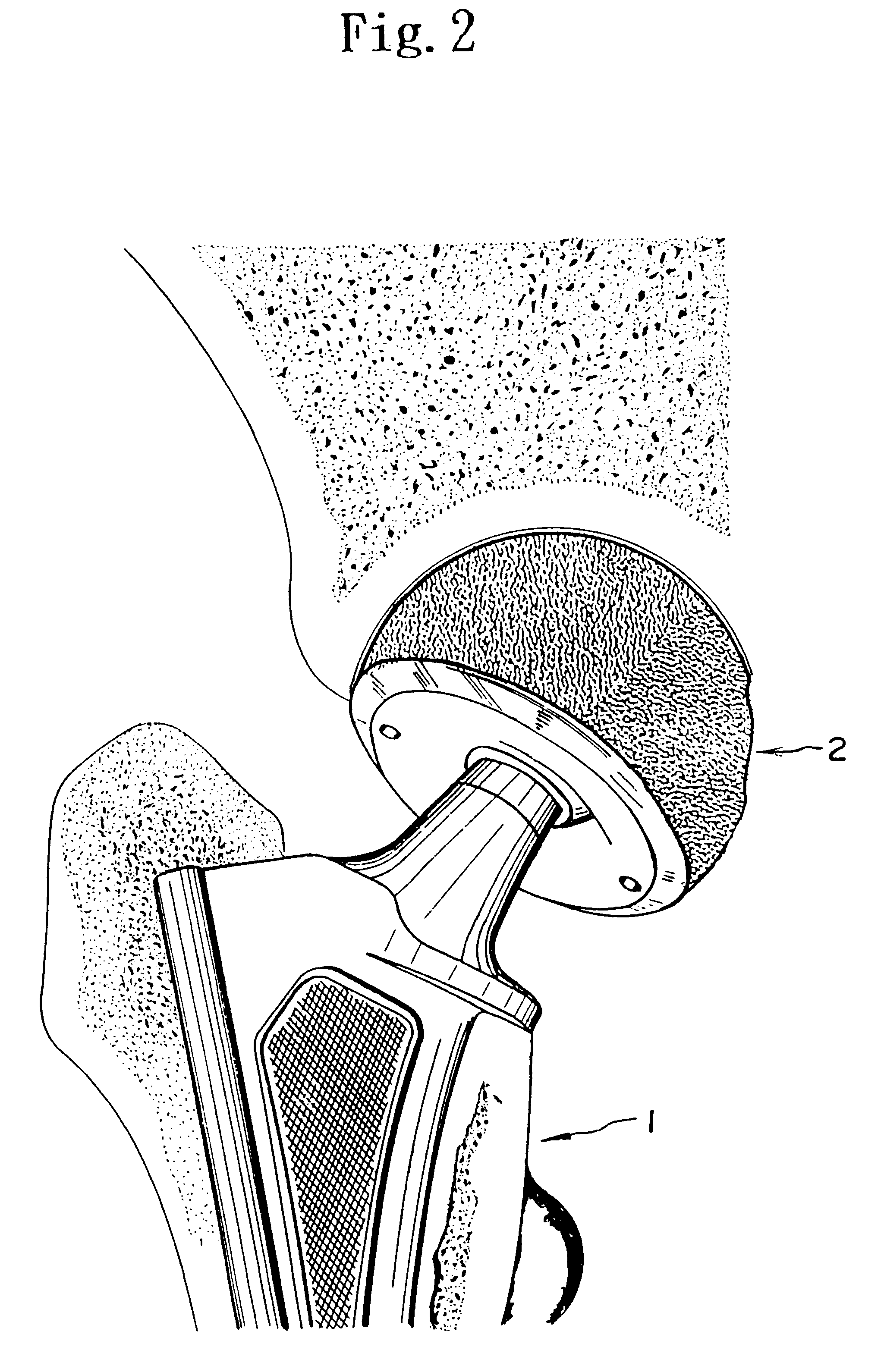

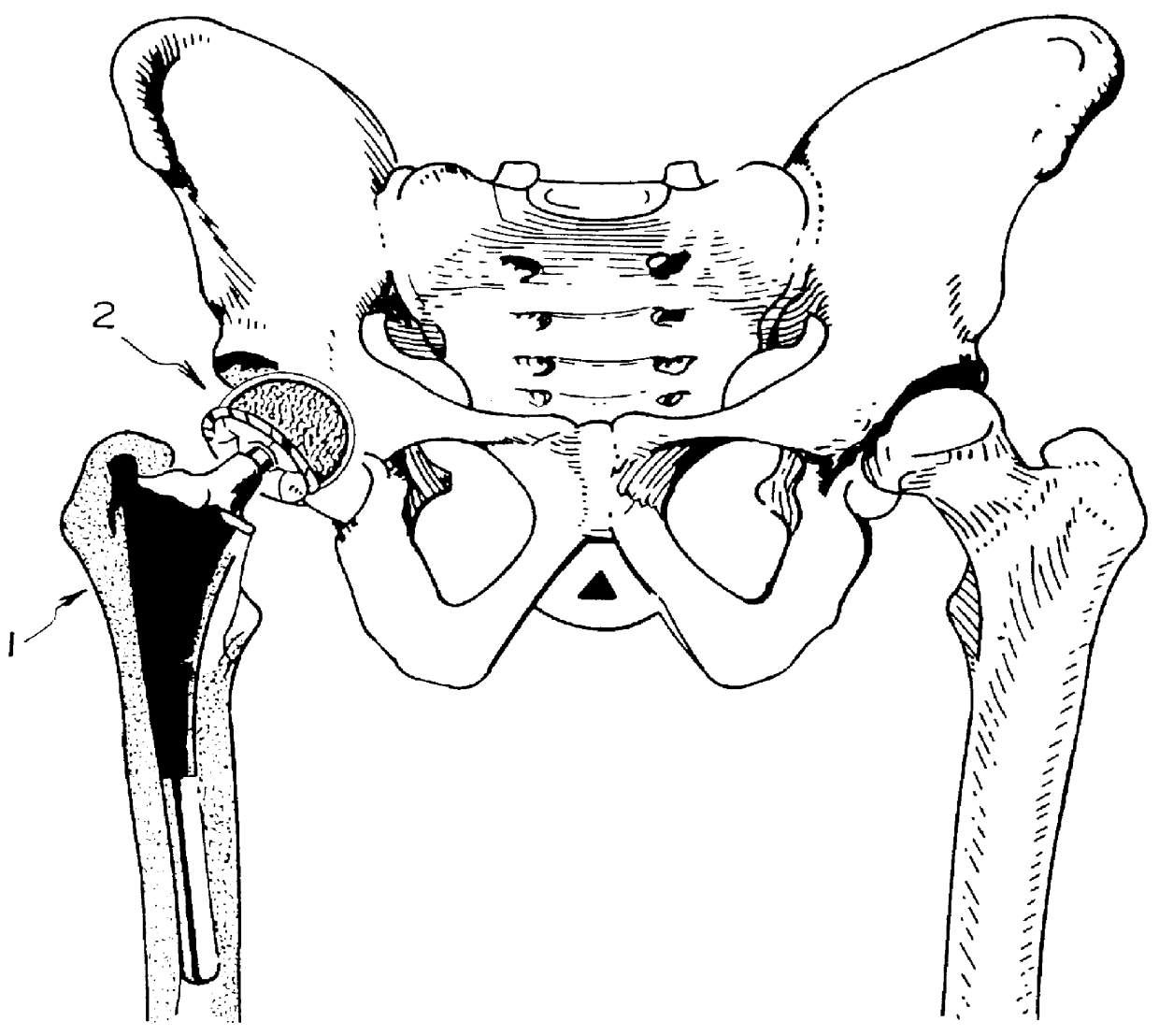

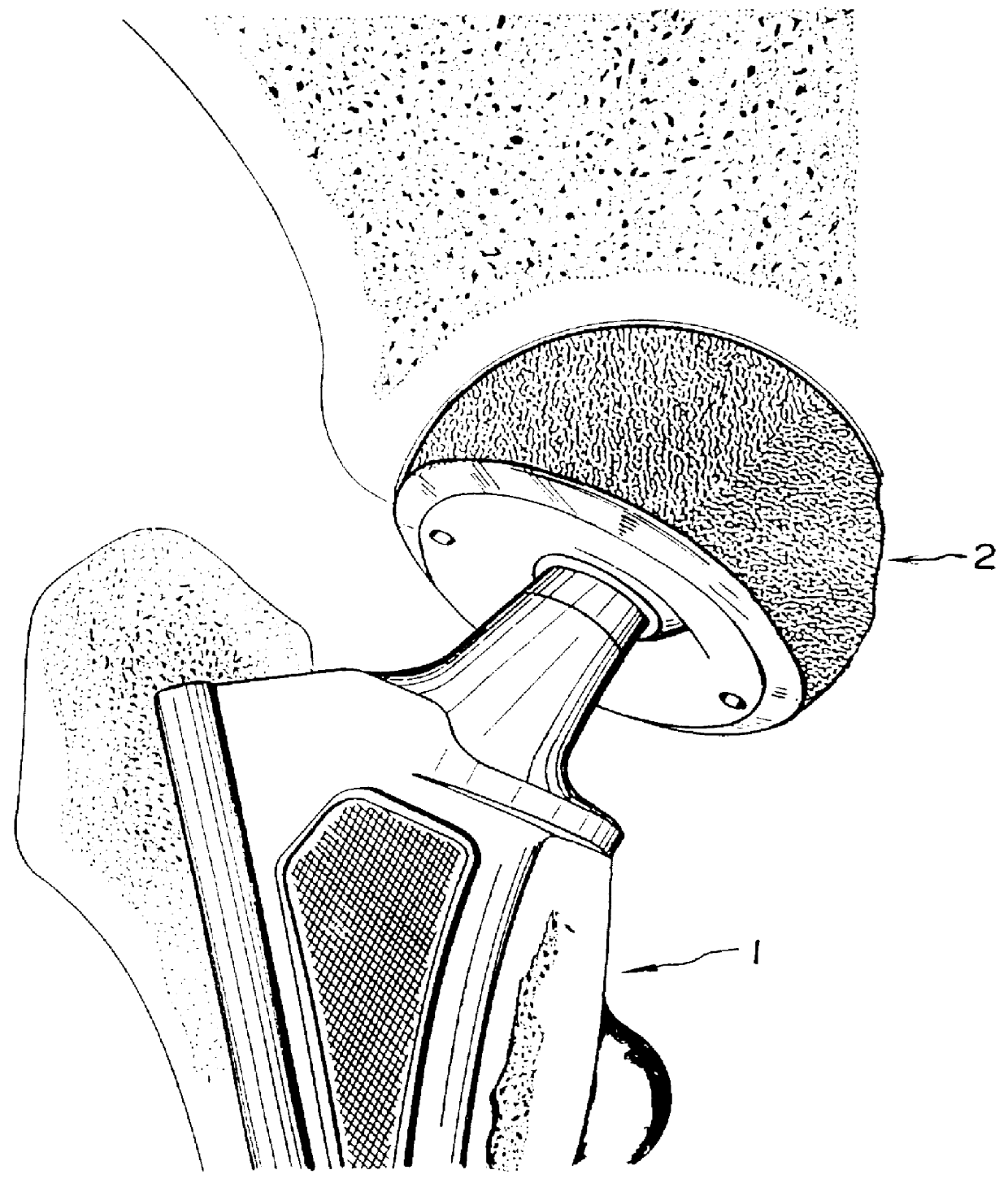

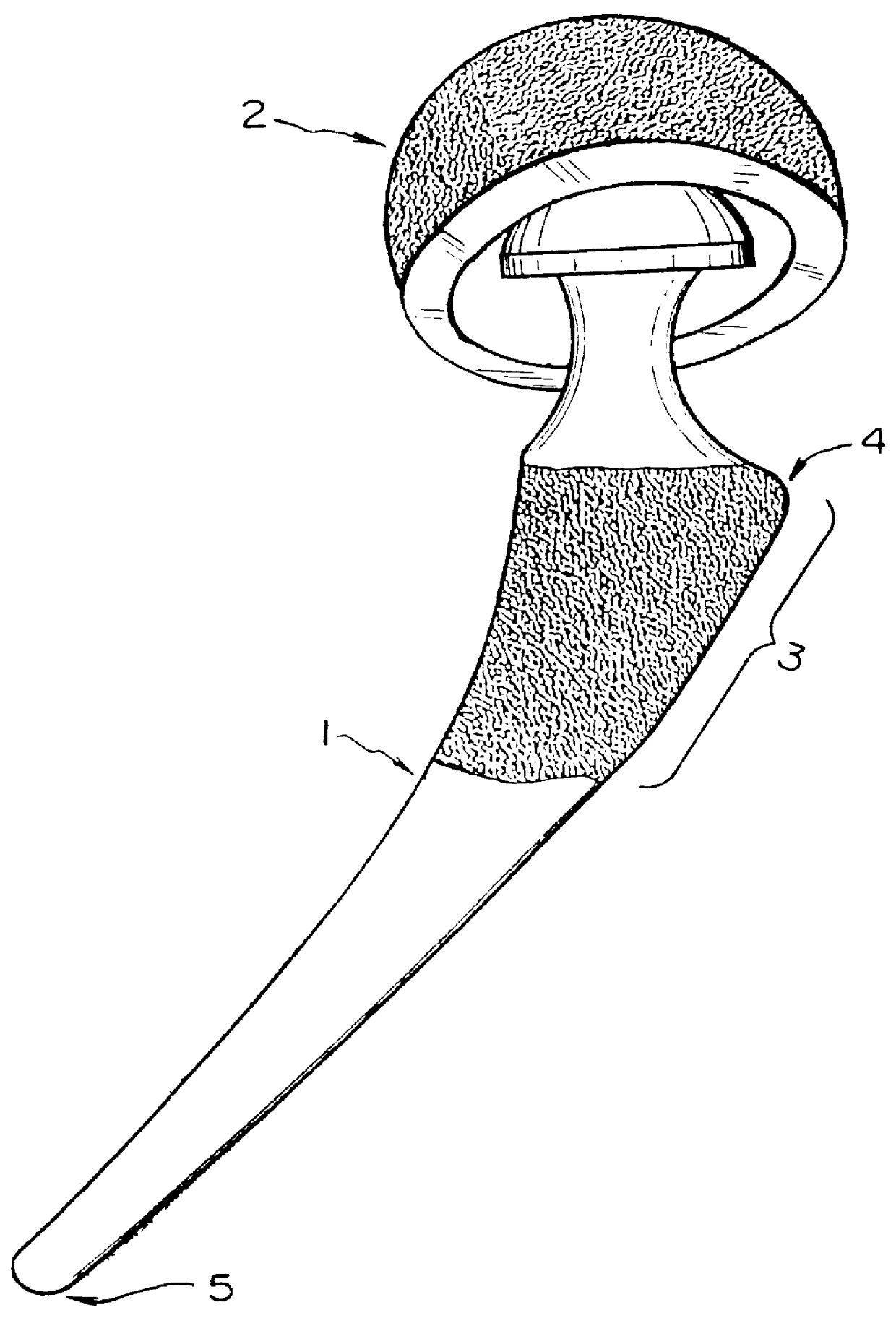

Orthopedic implant system

InactiveUS6312473B1Easy to fixAvoid excessive temperatureSurgical adhesivesBone implantFemoral stemPolymethyl methacrylate

It is an object of the present invention to provide an improved orthopedic implant system with satisfied biological, mechanical and morphological compatibilities.Solid metal femoral stem and solid metal acetabular head are covered with diffusion-bonded foamed-shaped sheet made of commercially pure titanium or titanium alloy(s). The open-cells in said foamed metal sheet are impregnated with biocompatible polymethyl methacrylate resin cement, which is reinforced with selected oxides including alumina, magnesia, zirconia, or a combination of these oxides along with an application of a small amount of a metal primer agent.

Owner:OSHIDA YOSHIKI

Orthopedic implant system

InactiveUS6066176AStrong interlocking fixationEasy to fixSurgical adhesivesBone implantPolymethyl methacrylateFemoral stem

It is an object of the present invention to provide an improved orthopedic implant system with satisfied biological, mechanical and morphological compatibilities. Solid metal femoral stem (entirely or partially) and solid metal acetabular head (entirely or partially) are covered with diffusion-bonded foamed-shaped sheet made of commercially pure titanium or titanium alloy(s). The open-cells in said foamed metal sheet are impregnated with biocompatible polymethyl methacrylate resin cement, which is reinforced with selected oxides (e.g., alumina, magnesia, zirconia, or a combination of these oxides) along with an application of a small amount of a metal primer agent.

Owner:OSHIDA YOSHIKI

Protective layers for sputter coated article

InactiveUS6833194B1Improve throughputTendency increaseVacuum evaporation coatingSputtering coatingLow emissivityMetal Primer

Owner:VITRO FLAT GLASS LLC

Biaxially oriented polylactic acid film with high barrier

ActiveUS20100040904A1Good metal adhesionImproves the gas barrier of the metallized PLA filmSynthetic resin layered productsVacuum evaporation coatingMoisture barrierFood packaging

A multilayer film including a first layer including a polylactic acid polymer, a second layer of a metal primer, deposited upon one surface of the first polylactic acid polymer layer, and a third metal layer deposited on the second metal primer layer. This metal-primed and metallized polylactic acid film exhibits improved moisture barrier properties versus a non-metal-primed and metallized polylactic acid film and can be used as part of a lamination structure for food packaging applications.

Owner:TORAY PLASTICS AMERICA

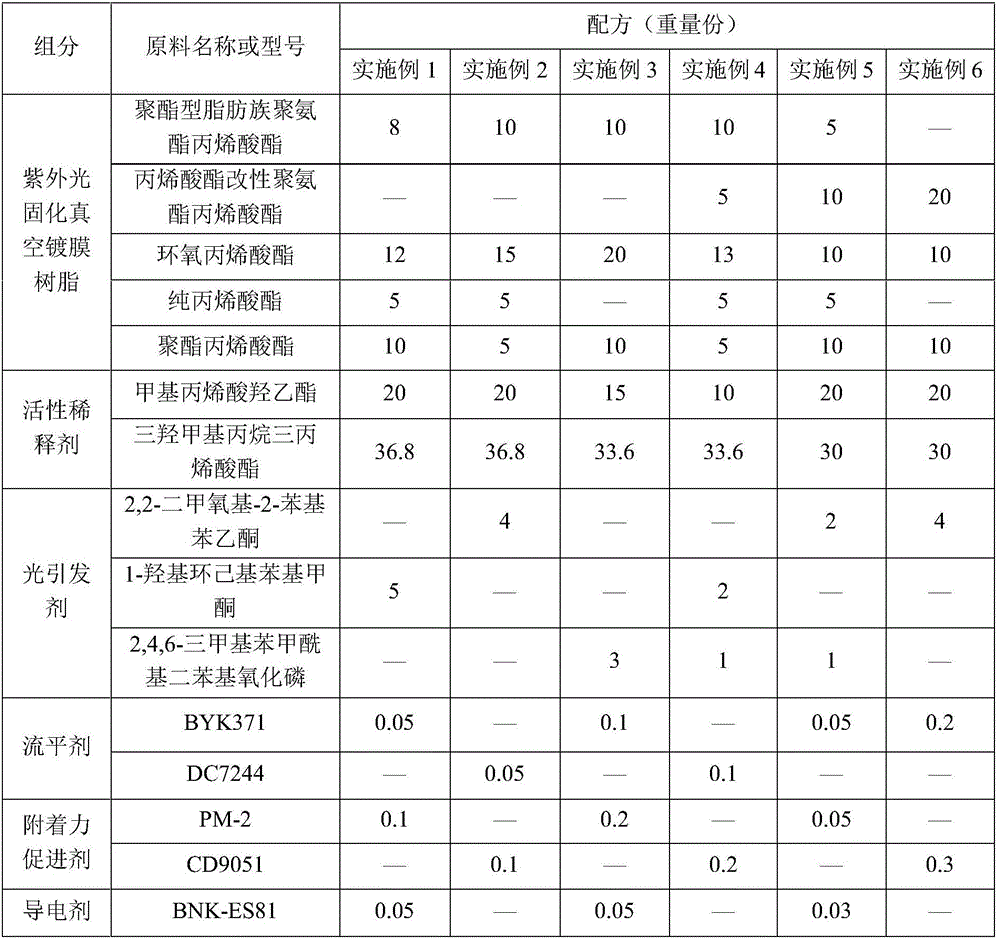

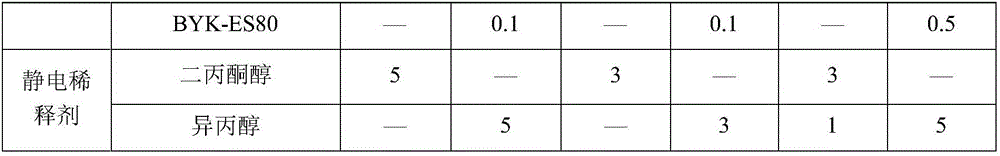

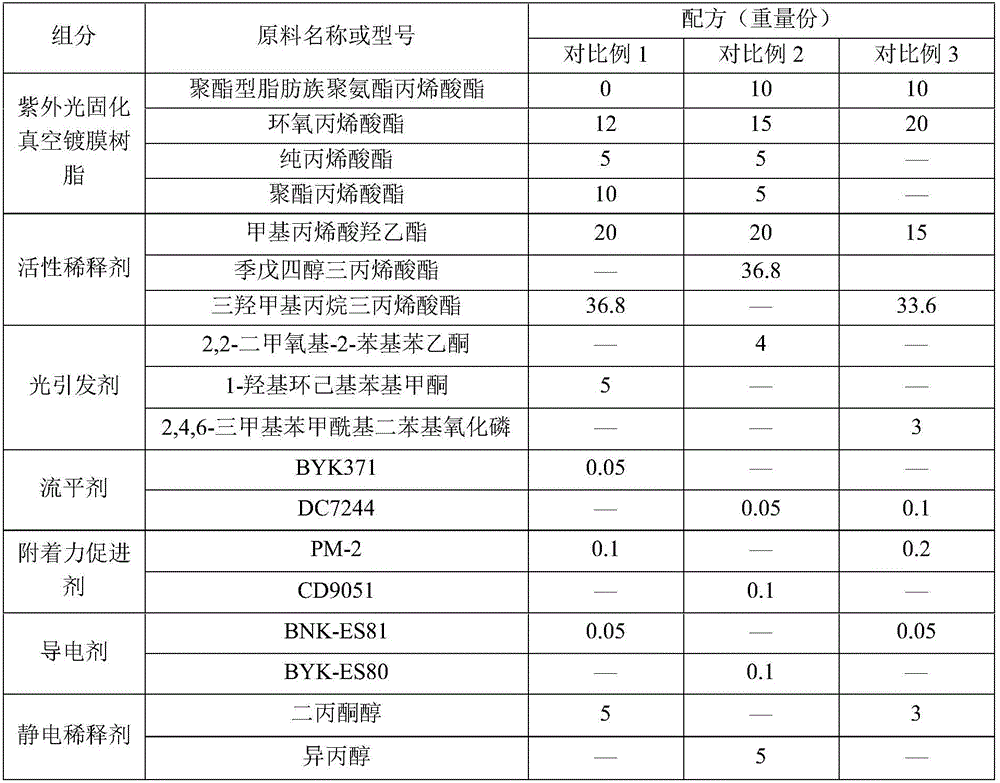

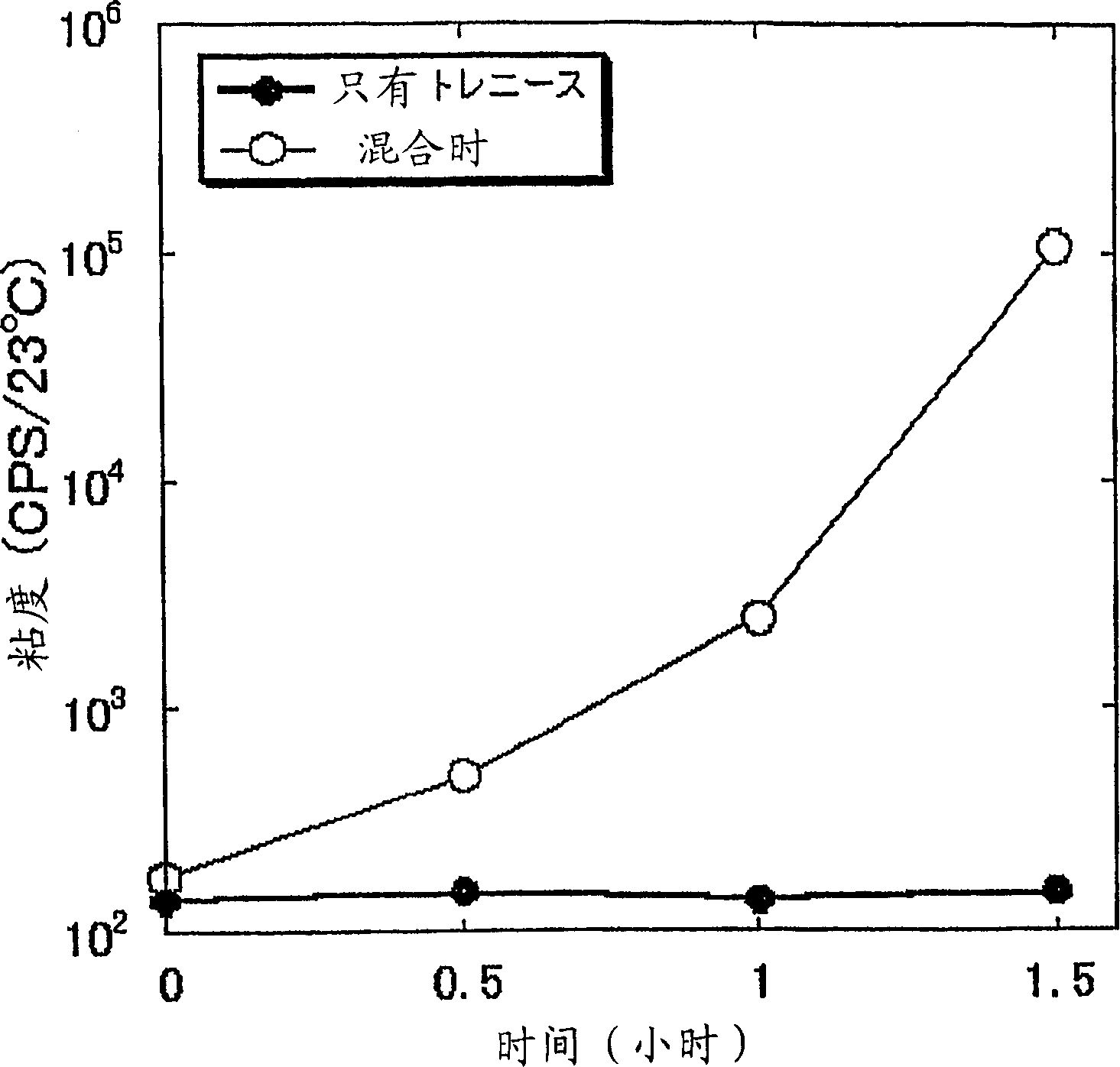

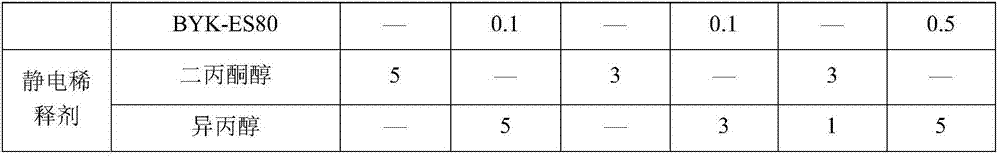

Ultraviolet curing vacuum coating metal primer capable of achieving electrostatic spraying

ActiveCN105670463ALow priceHigh viscosityPolyurea/polyurethane coatingsPowdery paintsUltravioletUrethane acrylate

The invention discloses ultraviolet curing vacuum coating metal primer capable of achieving electrostatic spraying and a preparation method thereof.The ultraviolet curing vacuum coating metal primer capable of achieving electrostatic spraying is prepared from, by weight, 5-20 parts of urethane acrylate, 10-20 parts of epoxy acrylate, 0-5 parts of pure acrylate, 5-10 parts of polyesteracrylate, 30-40 parts of trimethylolpropane triacrylate, 10-20 parts of low-functionality active diluted monomers, 2-5 parts of photoinitiator, 0.05-0.1 part of a flatting agent, 0.05-0.5 part of adhesion promoter, 0.01-0.5 part of a conductive agent and 3-5 parts of electrostatic thinner.The ultraviolet curing vacuum coating metal primer prepared through the method can be used for electrostatic spraying, has the advantages of being good in coating performance, good in adhesion, high in salt fog resistance, high in production efficiency, high in paint utilization rate and the like, and has wide market prospects.

Owner:GUANGDONG SHEN ZHAN IND CO LTD

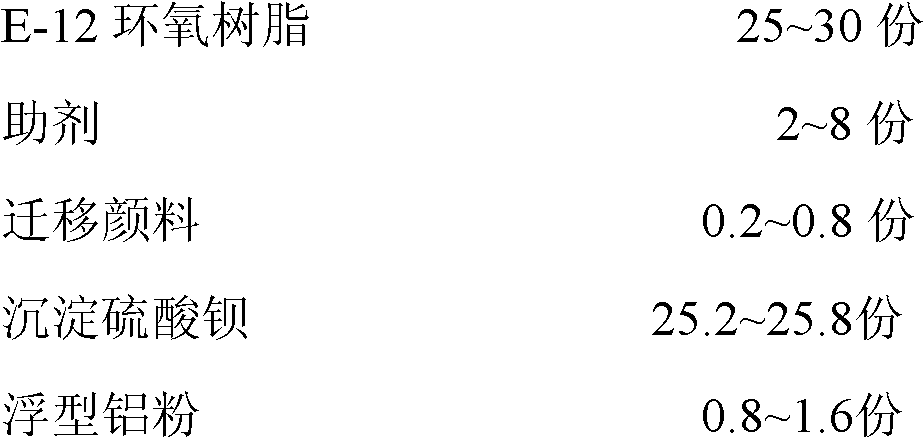

High-decoration color alloy powder coating

InactiveCN102250532ATo cover upPlay a bearing rolePowdery paintsPaints with free metalsPolyesterAlloy

The invention relates to a high-decoration color alloy powder coating which is divided into a silver powder layer and a transparent powder layer. The high-decoration color alloy powder coating comprises a silver powder layer and a transparent powder layer, wherein the silver powder layer comprises 6:4 type polyester, E-12 epoxy resin, accessory ingredients, migration pigment and precipitated barium sulphate, and the transparent powder layer comprises TGIC (1,3,5-Triglycidyl Isocyanurate) type polyester, TGIC, crylic acid flatting agent and benzoin. The coating is divided into the silver powder layer and the transparent powder layer on the basis of the pigment migration principle, and the effect of covering metal primer with transparent colored paint can be obtained by coating twice. According to the invention, the final coating effect of the color alloy powder coating is obtained by coating twice. The bottom layer is the silver powder layer which is mainly used for covering and bearing pigment; after the bottom layer is coated, transparent powder is covered on the surface of the bottom layer; and when the transparent powder is solidified, pigment migration driving force is generated so that the pigment migrates to the transparent powder layer, and thus the effect of silver-based high-lustre colored paint is achieved.

Owner:TIANJIN XIANGSHENG NEW MATERIALS CO LTD

Protective layers for sputter coated article and method for making sputter coated articles

InactiveUS20050129863A1Reduce smogReduce heatVacuum evaporation coatingSputtering coatingInfraredOptoelectronics

The present invention provides is a method of making an infrared reflective coated article, including the steps of: providing a substrate; depositing a first dielectric layer over at least a portion of the substrate, the layer comprising a first zinc stannate film deposited over the substrate, and an electrical enhancing film deposited over the first zinc stannate film, the electrical enhancing film selected from zinc oxide-tin oxide film and a second zinc stannate film; forming an infrared reflective layer on the first dielectric layer; forming a metal primer layer over the infrared reflective layer; forming a second dielectric layer over the primer layer; and forming a protective layer of at least two films in a position where it can provide durability to the dielectric layer, infrared reflective layer, metal primer layer, and second dielectric layer.

Owner:VITRO FLAT GLASS LLC

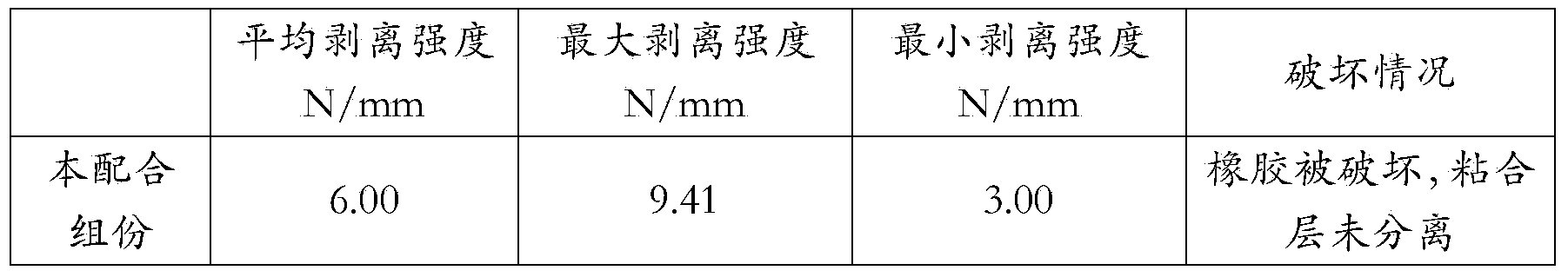

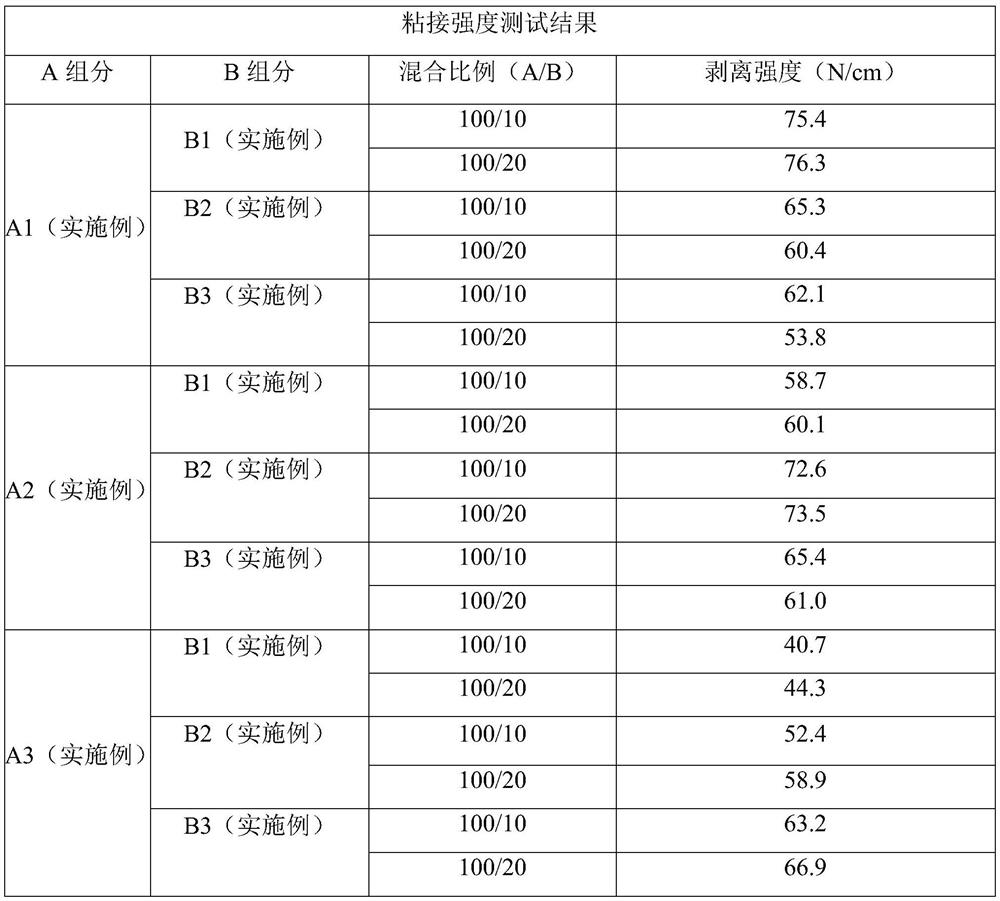

Room-temperature curing efficient adhesive and preparation method thereof

ActiveCN104388012AHigh affinityImprove heat resistanceRubber derivative coatingsNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention relates to a room-temperature curing efficient adhesive and a preparation method thereof. The room-temperature curing efficient adhesive is composed of a metal primer and a chloroprene rubber adhesive, wherein a base formula of the metal primer comprises the following raw materials by weight: 1200-1500g of chlorinated rubber CR20, 100-200g of general chloroprene rubber CR2321, 1-3g of an anti-aging agent BHT, 200-300g of light magnesium oxide and 3,000-4,000g of industrial methylbenzene; and the chloroprene rubber adhesive comprises the following raw materials by weight: 50-70g of chloroprene rubber A-90, 30-50g of chloroprene rubber M-40, 1-3g of an anti-aging agent WSL, 0.1-0.6g of a red iron oxide pigment, 10-30g of chlorinated rubber R20, 10-50g of fumed silica, 6-8g of light magnesium oxide, 10-40g of terpene-phenolic resin, and 500-800g of a mixed solvent which is composed of methylbenzene and butanone according to the mass ratio of 3 to 2. The room-temperature curing efficient adhesive provided by the invention is high in adhesive strength, stable in quality and good in heat resistance, has good adaptability on metal materials and non-metal materials, and is suitable for large-scale bonding work.

Owner:YANTAI XINHAI MINING MACHINERY

Method of preparing a metal-silicone rubber composite

InactiveUS20070003702A1Reduce crackingReduce wrinklesVacuum evaporation coatingSputtering coatingPolymer scienceTitanium

A method of preparing a metal-silicone rubber composite, the method comprising the steps of (i) depositing a layer of gold on a surface of a mold; (ii) depositing a primer layer of a metal on the layer of gold, wherein the metal is selected from aluminum, chromium, titanium, and copper, (iii) applying a radiation-curable silicone composition on the primer layer, (iv) curing the silicone composition with radiation to form a silicone rubber, and (v) removing the silicone rubber from the mold, whereby the layer of gold and the primer layer are transferred to the silicone rubber.

Owner:DOW CORNING CORP

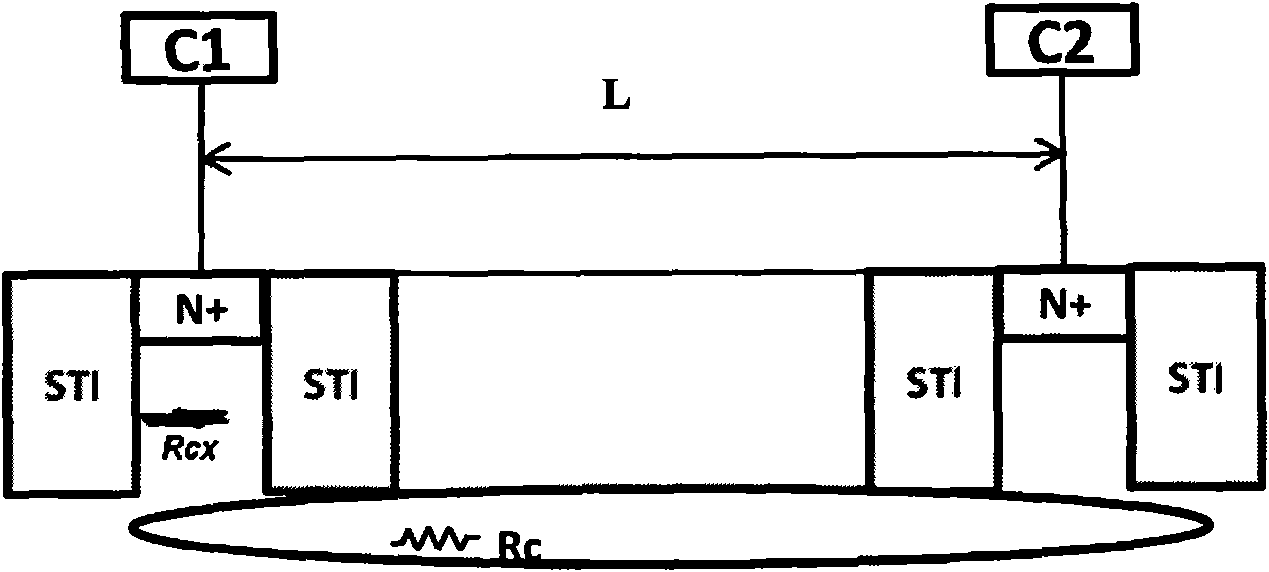

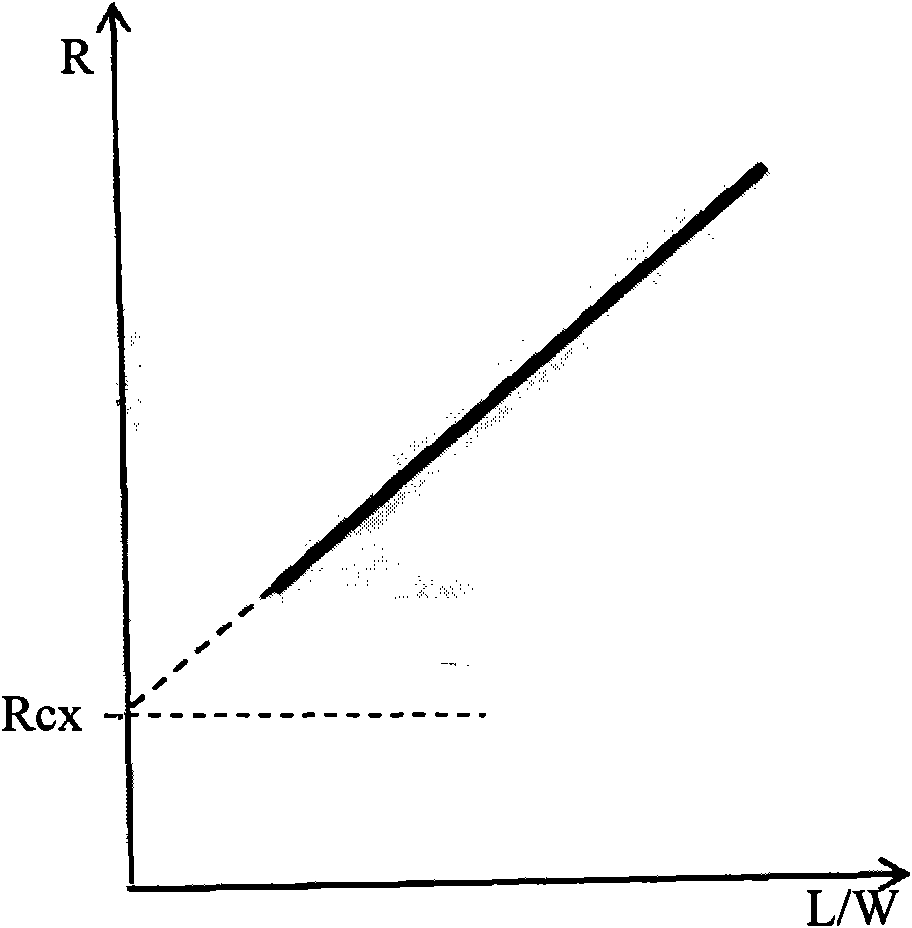

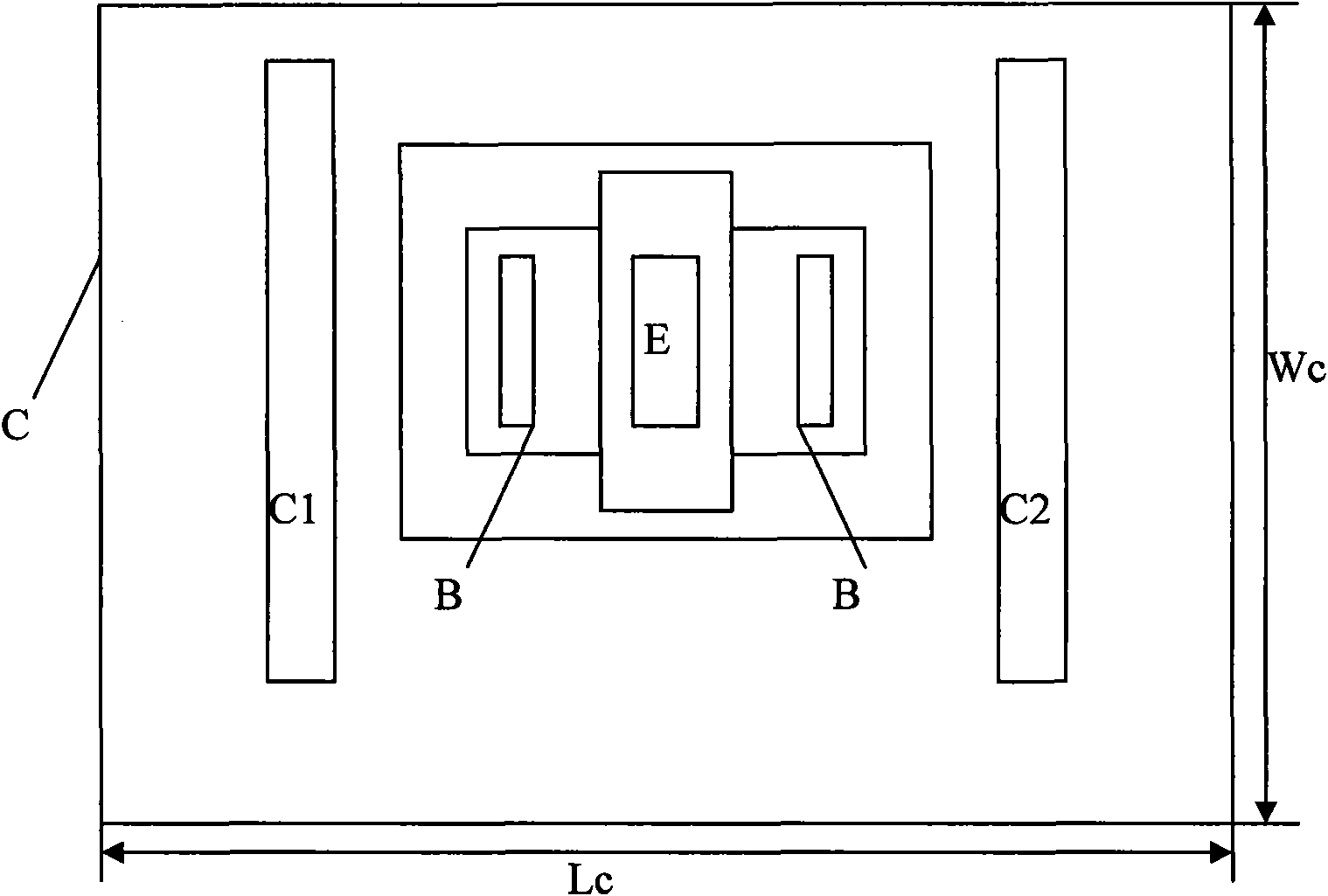

Method for measuring collector area intrinsic square resistance of bipolar transistor

The invention provides a method for measuring collector area intrinsic square resistance of a bipolar transistor. The bipolar transistor comprises a launch area, a base area and a collector area; wherein the launch area comprises the launch area metal primer, the base area comprises the base area metal primer, and the collector area comprises two collector area metal primers. When measuring, keeping zero voltage bias by the launch area, applying a first voltage Vbe to the base area; respectively applying a second voltage Vce+DeltaV and a third voltage Vce-DeltaV to the two collector metal primers of the the collector area, and measuring the electric current I which passes through the collector area; repeating the step a and the step b at a plurality of bipolar transistors of the collectorarea with the same length LC and the different widths Wc; according to the values of the length LC, the width Wc and the electric current I of the collector area, based on a formula 2DeltaV / DeltaI=Rsh*Lc / DeltaWc+Rx, fitting a curve by taking Lc / DeltaWc as horizontal ordinate and 2DeltaV / DeltaI as longitudinal coordinate, wherein the gradient of the curve is the collector area intrinsic square resistance Rsh, and the intercept distance is the extrinsic resistance Rx of the collector area.

Owner:GRACE SEMICON MFG CORP

Novel preparation method of imitation electroplating powder paint

InactiveCN108467663AImprove corrosion resistanceImprove adhesionAnti-corrosive paintsPowdery paintsMetal coatingWax

The invention discloses a novel preparation method of imitation electroplating powder paint. The preparation method comprises the steps of allowing a construction party to uniformly spray metal primerpowder onto the surface of a metal workpiece via an electrostatic spraying and high-temperature solidification technology, allowing the powder to be solidified on the surface of the workpiece to forma 80-100um coating with a metal light texture, and after complete solidification and cooling of the coating, uniformly spraying transparent resin powder onto the surface of the workpiece for solidification on the surface of the metal coating to form a 60-80um transparent protective coating. The metal primer powder and transparent finish powder are coated to form a surface coating of the coated workpiece; the surface of the workpiece has a metal luster; a sensitizer and high-gloss wax allows the metal luster of the surface of the workpiece to be more obvious; at the same time, due to double-layer application, the workpiece has high corrosion resistance, adhesion, rigidity and impact resistance; and the transparent finish powder exerts a good protection effect on the metal powder coating and further improves glossiness of the metal coating.

Owner:浙江绿环新材料科技有限公司

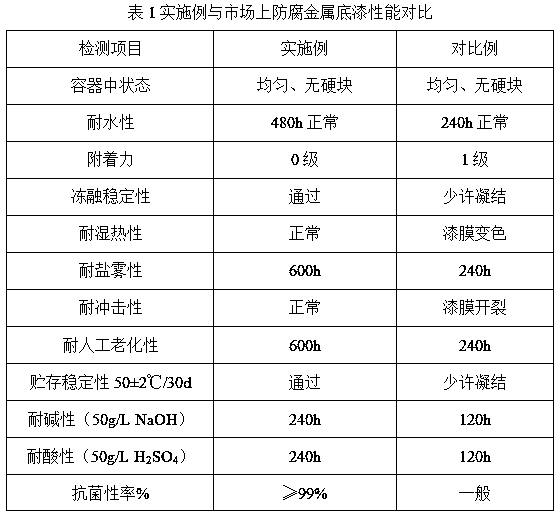

Aqueous polyurethane anticorrosive metal primer paint and preparation method thereof

InactiveCN109517515AGood and long-lasting anti-corrosion effectStrong adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsPolyolAcrylic resin

The invention relates to aqueous polyurethane anticorrosive metal primer paint. A basic formula of the aqueous polyurethane anticorrosive metal primer paint comprises the components in part by weight:35.0-55.0 parts of schiff base structure-containing polyurethane aqueous resin, 15.0-25.0 parts of nano aqueous acrylic resin, 10.0-30.0 parts of nanofiller, 1.5-4.0 parts of triethylamine, 4.0-10.0parts of auxiliary agent and 10.0-25.0 parts of deionized water, wherein the schiff base structure-containing polyurethane aqueous resin is prepared by reacting polyisocyanate, polyol, a salicylaldehyde schiff base, oligomer polyol, dimethylolpropionic acid, and a neutralizing agent. The aqueous polyurethane anticorrosive metal primer paint prepared by the invention combines the characteristics ofthe schiff base structure and polyurethane resin, the anticorrosive agent and the bactericide do not need to be added, the anti-corrosive effect is excellent, the primer paint can adapt to various different environments, the nano-aqueous acrylic resin and the nano-filler are added so that the anticorrosive coating have good self-repairing capability.

Owner:SHAOGUAN HEZHONG CHEM CO LTD +1

Environmentally-friendly metal primer

InactiveCN108795240AImprove acid resistanceAccelerated corrosionFireproof paintsAnti-corrosive paintsEpoxyDispersion stability

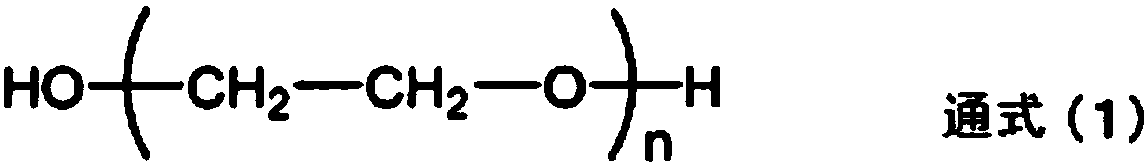

The invention discloses an environmentally-friendly metal primer. A preparation method of the metal primer includes: (1) adding graphite to water, stirring at 1200-1500r / min, adding sodium carboxymethyl cellulose and continuing to stir to prepare a graphite solution A; (2) adding epoxy resin, polyethylene glycol modified amino resin and polyacrylic acid polydimethylsiloxane to ethanol, stirring at1000r / min till the solid dissolves, then adding zinc yellow, carbon black and fumed silica and continuing stirring evenly to prepare a solution B; (3) adding the solution A slowly to the solution B under the stirring condition of 1500r / min and stirring uniformly to prepare slurry; (4) grinding and filtering the slurry to obtain the primer. The primer has simple process, the adopted solvents are environmentally friendly, the graphite and the zinc yellow in the process formula achieve an anti-corrosive effect, and the graphite has good dispersion stability. The prepared primer is an effective anti-corrosive primer, and can be widely applied to the field of metal corrosion prevention.

Owner:合肥炫升环保材料科技有限公司

Biaxially oriented polylactic acid film with high barrier

ActiveUS9314999B2Good metal adhesionImproves the gas barrier of the metallized PLA filmSynthetic resin layered productsVacuum evaporation coatingMoisture barrierMetal Primer

A multilayer film including a first layer including a polylactic acid polymer, a second layer of a metal primer, deposited upon one surface of the first polylactic acid polymer layer, and a third metal layer deposited on the second metal primer layer. This metal-primed and metallized polylactic acid film exhibits improved moisture barrier properties versus a non-metal-primed and metallized polylactic acid film and can be used as part of a lamination structure for food packaging applications.

Owner:TORAY PLASTICS (AMERICA) INC

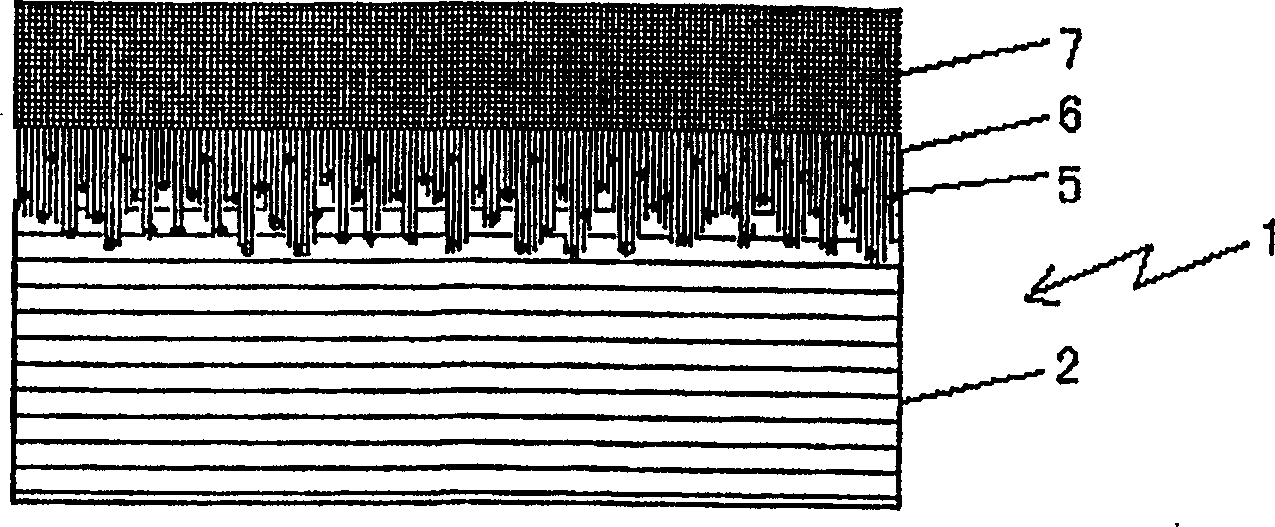

Preparation method of resin-based composite material flow guide blade erosion-resistant coating

ActiveCN110257752AExtended service lifeHigh bonding strengthLiquid surface applicatorsMolten spray coatingThermal sprayingThermal expansion

The invention belongs to the field of resin-based composite material protective coatings, and particularly relates to a preparation method of a resin-based composite material flow guide blade erosion-resistant coating. According to the preparation method, structures of a resin / metal primer layer and a metal intermediate layer are added in a traditional anti-scouring coating, so that the problem of excessive interface stress caused by mismatching of thermal expansion coefficients of the coating is effectively solved, the coating can be continuously used 3000 times in a thermal cycle test of 300 DEG C without failure, and the method is suitable for preparing the anti-scouring coatings of resin-based composite material flow guide blades and stator blades. The resin base / metal primer layer structure is prepared through a room-temperature gas spraying and curing treatment process, so that the interface compatibility of the coating and a resin-base body is improved, and the interface bonding strength is improved; on the other hand, the pretreatment of spraying to blade bodies is not needed, so that the damage of the pretreatment to blade body matrix resin and fibers is reduced. The metal intermediate layer and the anti-scouring surface layer are prepared on the surface of the primer layer by adopting a thermal spraying process, and the method has the advantages of strong controllability in the process, low cost, high spraying efficiency and good coating performance.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

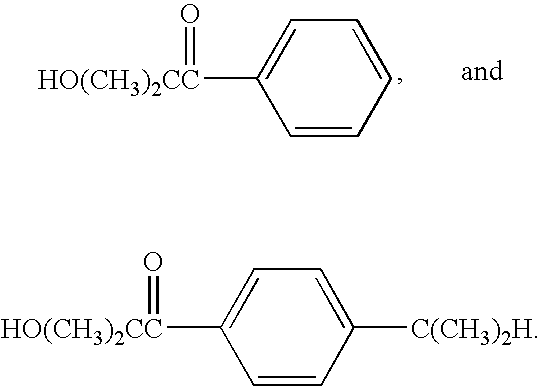

Anticorrosive metal primer

InactiveCN105440876APrevent surface discolorationHigh peel strengthAnti-corrosive paintsPolyester coatingsDiacetone alcoholCis-Butenedioic Acid

The invention discloses an anticorrosive metal primer. The anticorrosive metal primer is prepared from, by weight, 10-23 parts of amino resin, 14-42 parts of polyester resin, 10-18 parts of 1,2-propylene glycol-1-monobutyl ether, 11-28 parts of diethyl carbonate, 35-52 parts of 2,2-di(4-hydroxyphenyl)propane, 9-21 parts of cethyl trimethyl ammonium bromide, 13-27 parts of isoprene, 2-13 parts of ammonium stearate, 8-20 parts of triethyl acetocitrate, 5-10 parts of tetraethylenepentamine, 5-15 parts of maleic anhydride, 14-22 parts of diacetone alcohol, and 8-27 parts of ethyl alcohol. The paint prepared from the metal primer is environmentally friendly, free of toxicity, harmless to people, capable of being well combined with the metal primer and a finishing coat, high in water resistance, capable of preventing color change of a metal surface, improving the peel strength of a paintcoat and guaranteeing the anticorrosive effect, and long in anticorrosive time.

Owner:TONGLING MINGCHENG FOUNDRY

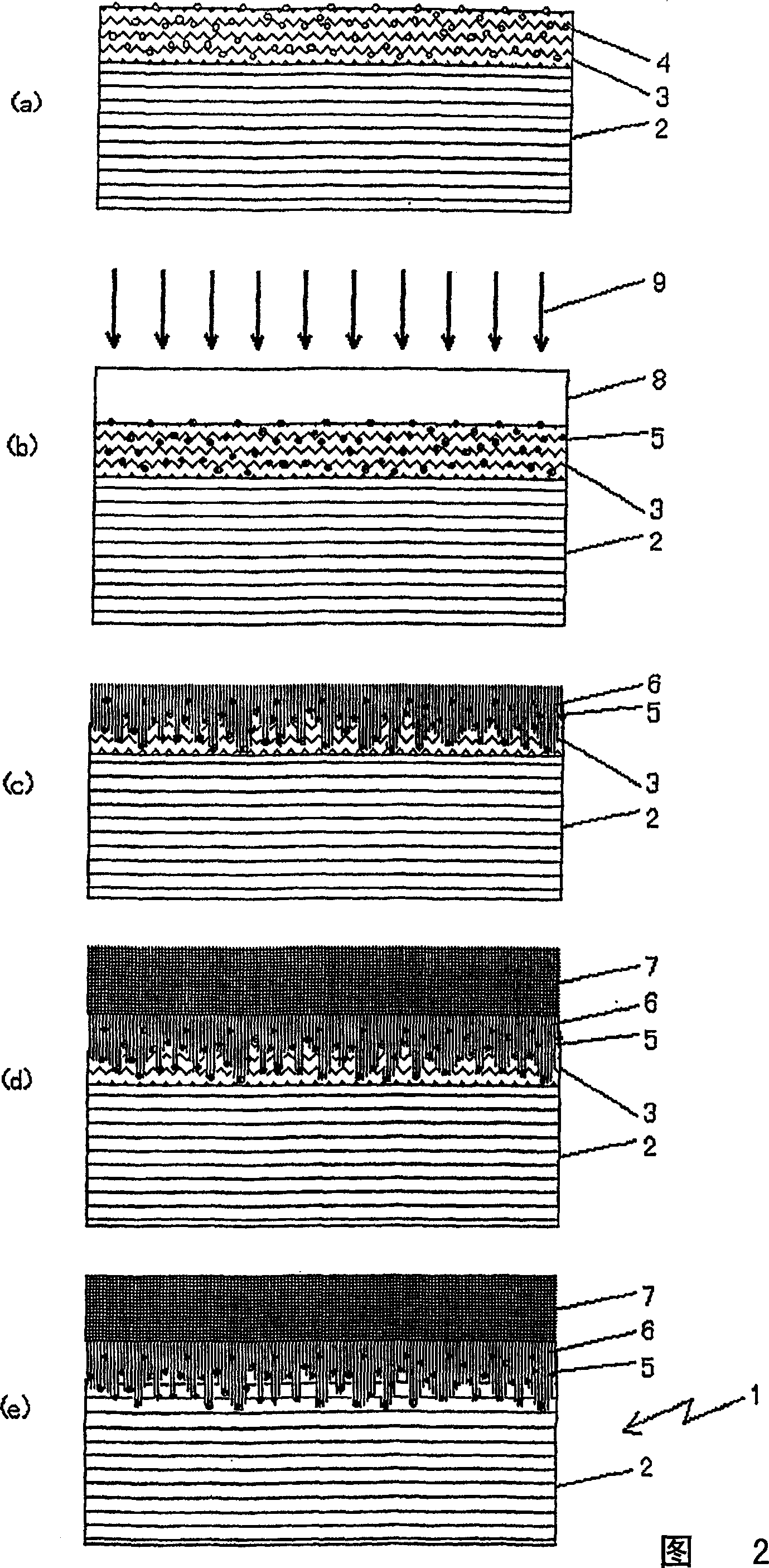

Polyimide resin precursor solution, laminates for electronic components made by using the solution and process for production of the laminates

InactiveCN1487978AImprove adhesion strengthConductive layers on insulating-supportsLiquid/solution decomposition chemical coatingPolyimide substrateHydrogen

Laminates for electronic components are produced by applying a polyimide resin precursor solution containing a palladium compound on a polyimide substrate, drying the resulting coating to form a polyimide resin precursor layer, irradiating this layer with ultraviolet rays in the presence of a hydrogen donor to form nuclei for primer plating, forming a metal primer layer by electroless plating, and converting the polyimide resin precursor layer into a polyimide resin layer through imidation by heating either after or before the formation of a surface plating layer. The invention provides laminates for electronic components which are extremely improved in adhesion to metal layers without impairing the characteristics inherent in the substrate and are excellent in insulating properties, and polyimide resin precursor resin solution to be used in the production of the laminates.

Owner:TORAY ENG CO LTD

Normal-temperature curing type metal primer and preparation method thereof

The invention provides a normal-temperature curing type metal primer and a preparation method thereof. The preparation method comprises the following steps: dissolving high-molecular-weight epoxy resin and thermoplastic TPU resin in a mixed solvent to obtain a component A of the metal primer; dissolving polyisocyanate in ethyl acetate to obtain a first mixture; dissolving a silane coupling agent in ethyl acetate to obtain a second mixture; under a stirring state, dropwise adding the second mixture into the first mixture, and fully reacting to obtain a component B of the metal primer; and mixing the metal primer component A with the metal primer component B to obtain the normal-temperature curing type metal primer. The normal-temperature curing type metal primer prepared by the preparation method is uniformly brushed on the metal surface subjected to oil removal and rust removal, natural drying is performed for 6 hours, and pretreatment is not needed.

Owner:苏州市陆氏新材料有限公司

An electrostatic sprayable UV-curable vacuum coating metal primer

ActiveCN105670463BLow priceHigh viscosityPolyurea/polyurethane coatingsPowdery paintsUrethane acrylateMetal Primer

Owner:GUANGDONG SHEN ZHAN IND CO LTD

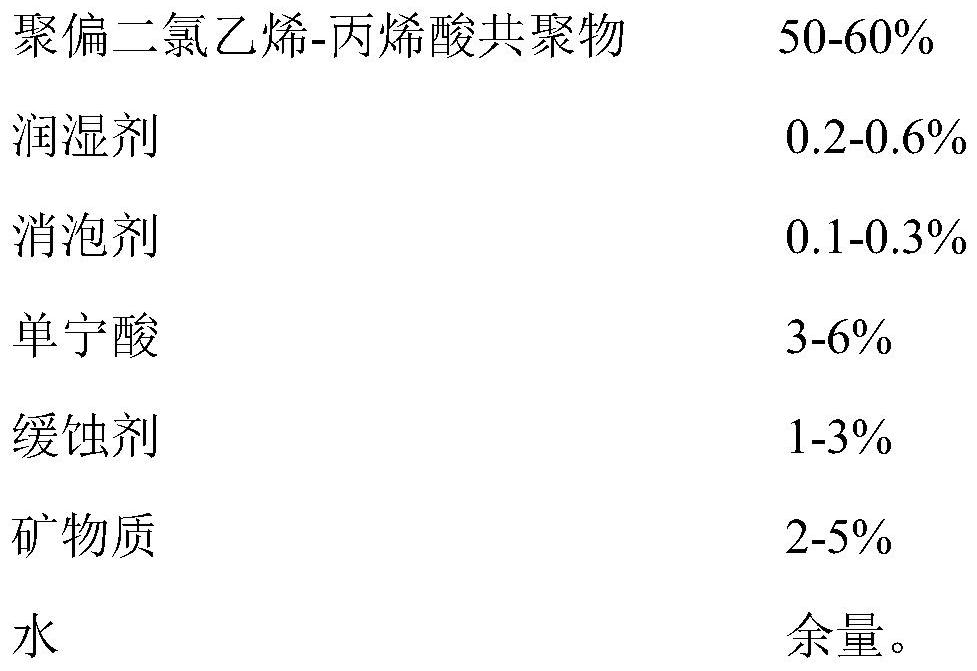

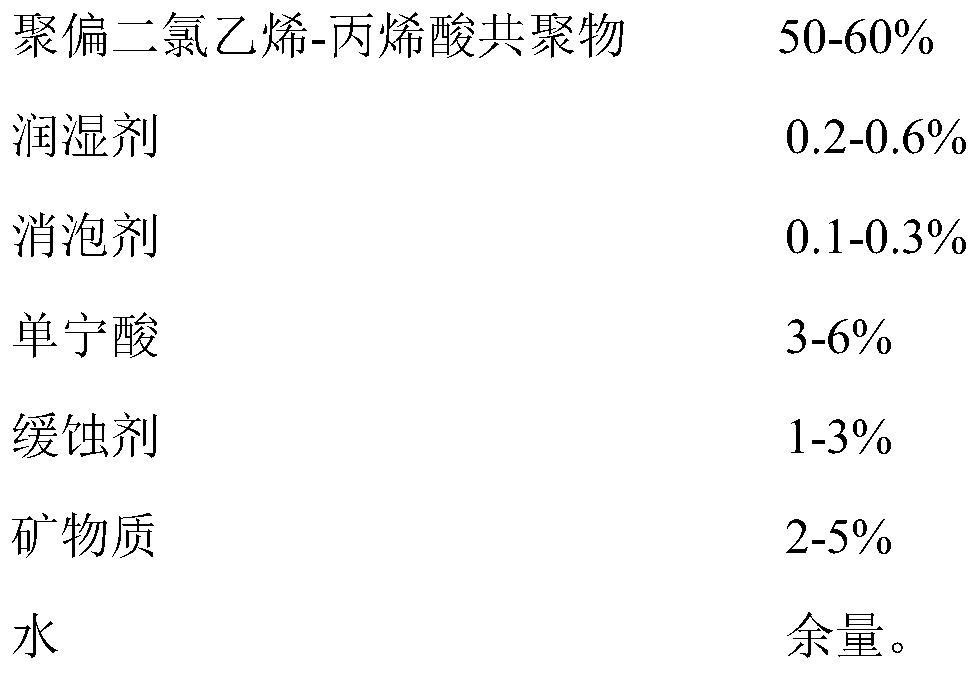

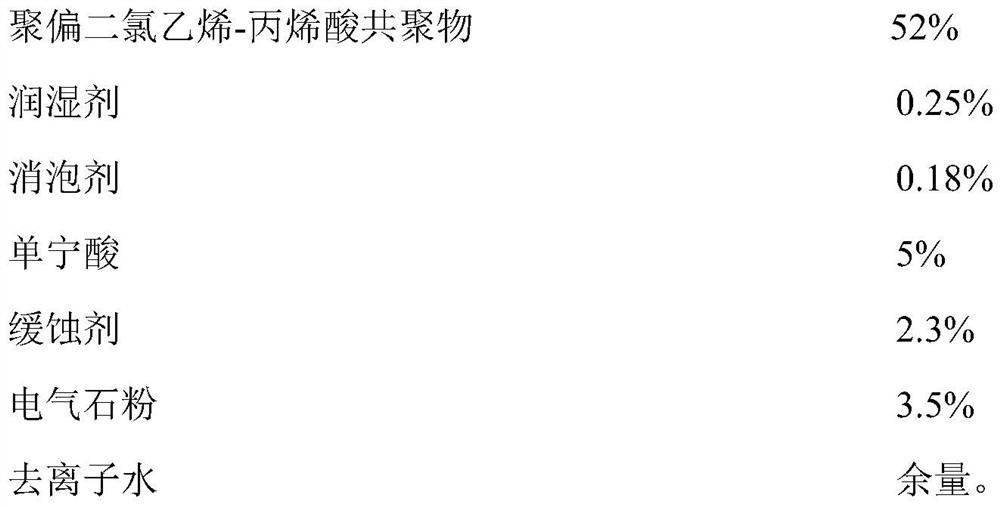

Rust conversion water-based metal primer and preparation method thereof

The invention relates to a rust conversion water-based metal primer. The rust conversion water-based metal primer comprises a polyvinylidene chloride-acrylic acid copolymer, tannic acid and a corrosion inhibitor, wherein the corrosion inhibitor is at least one selected from phosphonohydroxyacetic acid and ethylene diamine tetra (methylene phosphonic acid). The rust conversion water-based metal primer product disclosed by the invention does not contain alkylphenol polyoxyethylene ether, is low in VOC (Volatile Organic Compounds) and is environment-friendly. Through the synergistic effect of the polyvinylidene chloride-acrylic acid copolymer, a rust conversion auxiliary agent and the corrosion inhibitor, corrosion of metal is delayed, the heat and humidity resistance is excellent, the contact area between the primer and the metal surface can be effectively increased, and the adhesive capacity of the primer is enhanced. A rust layer on the metal surface treated by the rust conversion water-based metal primer can be directly coated under the condition of rust without being subjected to rust removal treatment.

Owner:SHANGHAI CARPOLY PAINT

Coating Formation Method

Owner:KANSAI PAINT CO LTD

Corrosion-resistant metal primer

InactiveCN104341941AImprove protectionImprove high temperature resistanceAnti-corrosive paintsCyclohexanoneXylylene

The invention relates to a corrosion-resistant metal primer which is prepared from the following raw materials in parts by weight: 9-15 parts of carbon black, 3-8 parts of xylene, 4-10 parts of cyclohexanone, 8-15 parts of amino resin, 4-8 parts of leveling agent, 4-6 parts of organic solvent, 3-8 parts of zinc stearate, 4-7 parts of ethylene glycol monobutyl ether, 4-8 parts of cellulose acetate butyrate, 2-6 parts of m-cresol, 5-8 parts of n-butyl etherified urea-formaldehyde resin and 5-9 parts of siloxane. The corrosion-resistant metal primer can well protect the metal and prevent the metal from rusting, has favorable high temperature resistance and tolerance, and is convenient to use.

Owner:QINGDAO KANGTAIXIN ENVIRONMENTAL PROTECTION TECH

Copolymerized polyester and metal primer coating material using same

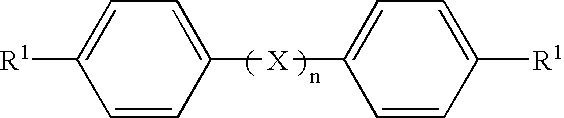

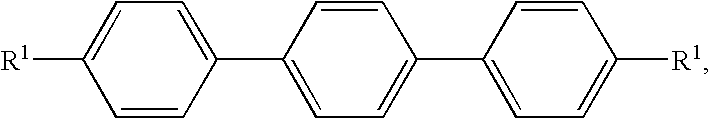

ActiveCN107849230AHigh solid contentHigh hardnessLiquid surface applicatorsPolyester coatingsPolyesterCarboxylic acid

To provide a copolymerized polyester which is effective as a binder component for a metal primer coating material for coil coating. Additionally, to provide a metal primer coating material which has acoating material composition using the copolymerized polyester, and which has excellent surface hardness, bendability, corrosion resistance and chemical resistance. A copolymerized polyester (A) which has, as copolymerization components, a polyvalent carboxylic acid component and a polyhydric alcohol component, and wherein: if the total polyvalent carboxylic acid component is taken as 100% by mole, an aromatic dicarboxylic acid component is contained in an amount of 95-100% by mole and an aliphatic dicarboxylic acid component is contained in an amount of 0-5% by mole; and if the total polyhydric alcohol component is taken as 100% by mole, a glycol component having a specific structure is contained in an amount of 1-30% by mole. This copolymerized polyester (A) has a glass transition temperature within the range of 25-50 DEG C.

Owner:TOYO TOYOBO CO LTD

Metal primer

The invention discloses a metal primer and relates to the technical field of paint. The metal primer includes a first component and a second component, wherein the first component includes following components, by weight, 30-50 parts of synthetic fatty acid modified alkyd resin, 5-10 parts of butanol, 10-20 parts of talcum powder, 0.5-1 part of a modified polyurethane dispersing agent, 30-40 parts of calcium carbonate, 30-40 parts of titanium dioxide and 5-10 parts of dimethylbenzene; and the second component includes following components, by weight, 30-50 parts of isocyanate and 15-35 parts of dimethylbenzene. The metal primer can be dried quickly, is strong in adhesive force, is good in mechanical performances and protective performances, is strong in filling capability, is good in a matching performance, can be matched with various strong solvent finishes and is suitable for being used in coating and priming of various metal products and wood surfaces.

Owner:DRAGON FISH PAINT

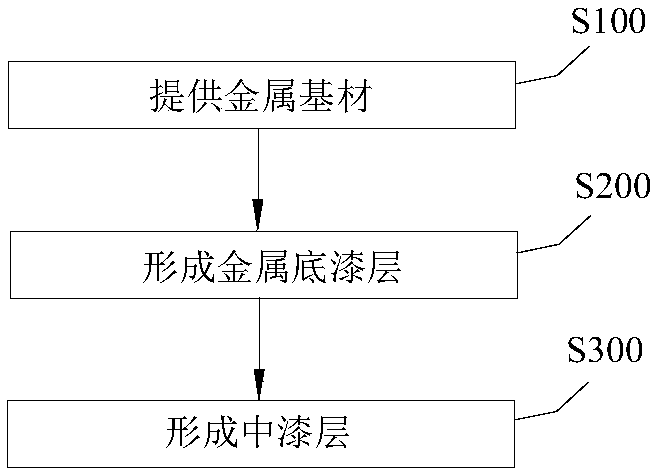

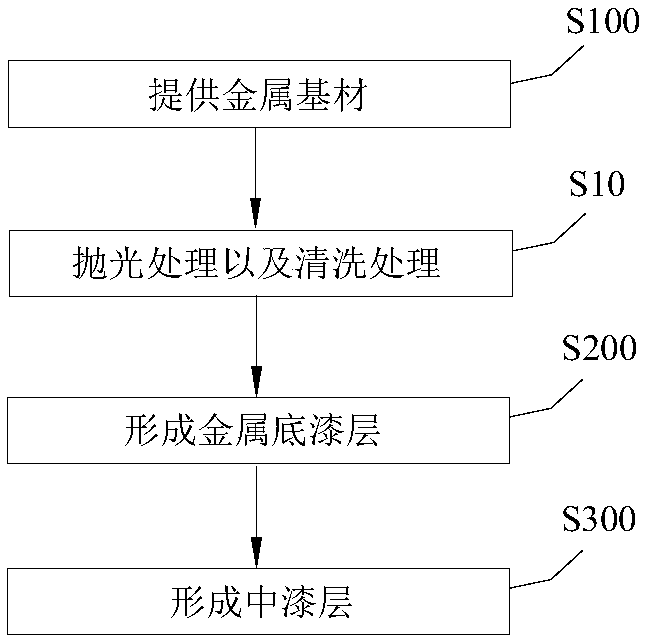

Board, manufacturing method thereof, shell and mobile terminal

ActiveCN108559938AImprove performancePrevent orange peelMolten spray coatingCasings/cabinets/drawers detailsEpoxyLacquer

The invention discloses a board, a manufacturing method thereof, a shell and a mobile terminal. According to the embodiment of the invention, the method comprises the steps that a metal base materialis provided, and an epoxy resin layer is arranged on the partial surface of the metal base material; a metal priming paint layer is formed on the side, away from the metal base material, of the epoxyresin layer; and a middle paint layer is formed in the side, away from the epoxy resin layer, of the metal priming paint layer. Accordingly, for the board prepared through the method, the metal priming paint layer and the middle paint layer can improve the metal texture and the hue brightness degree of the epoxy resin layer, the surface evenness and appearance delicacy are improved, the matching consistence of the epoxy resin layer and the metal base material is improved remarkably, and the appearance effect is improved. Meanwhile, the method can effectively avoid the problems of orange peel and oil accumulation balance.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Metal primer with good mechanical property

The invention discloses metal primer with a good mechanical property. The metal primer mainly comprises aqueous silicate minerals and is characterized in that 15-20 parts of sodium phosphate, 5-15 parts of modified polyurethane dispersing agents, 15-20 parts of sodium hydroxide and 5-10 parts of nano-silver oxide are added. Compared with the prior art, the metal primer has the advantage of excellent effects achieved by adding the sodium phosphate, the modified polyurethane dispersing agents, the sodium hydroxide and the nano-silver oxide.

Owner:SHENYANG CHUANGDA TECH TRADE MARKET

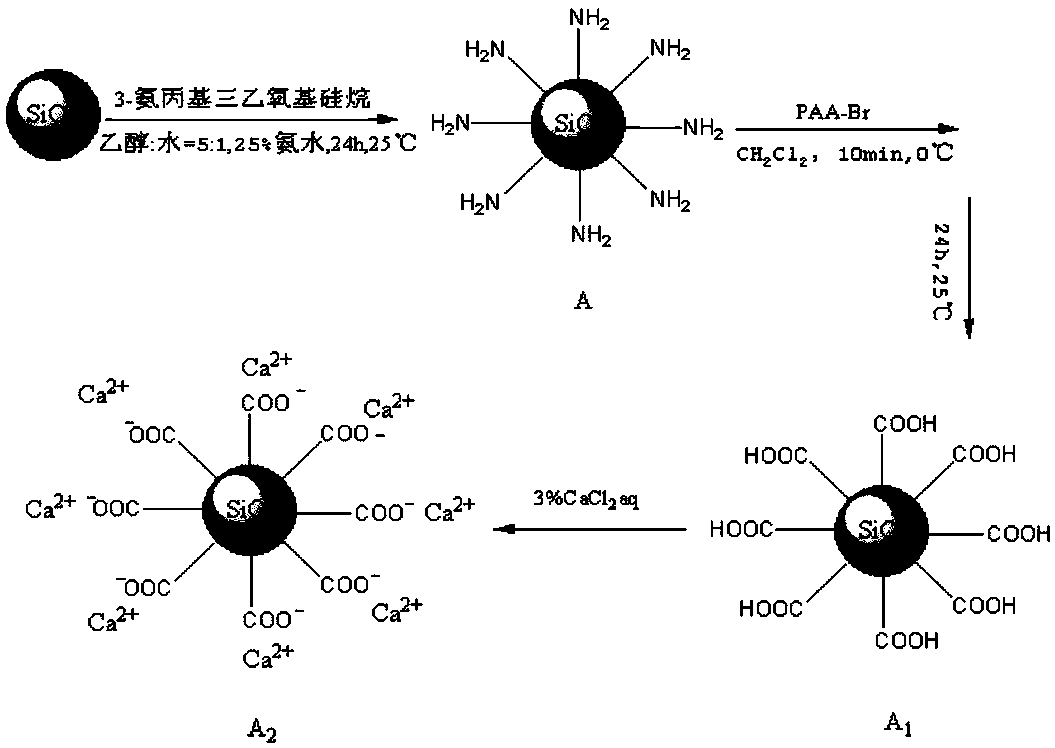

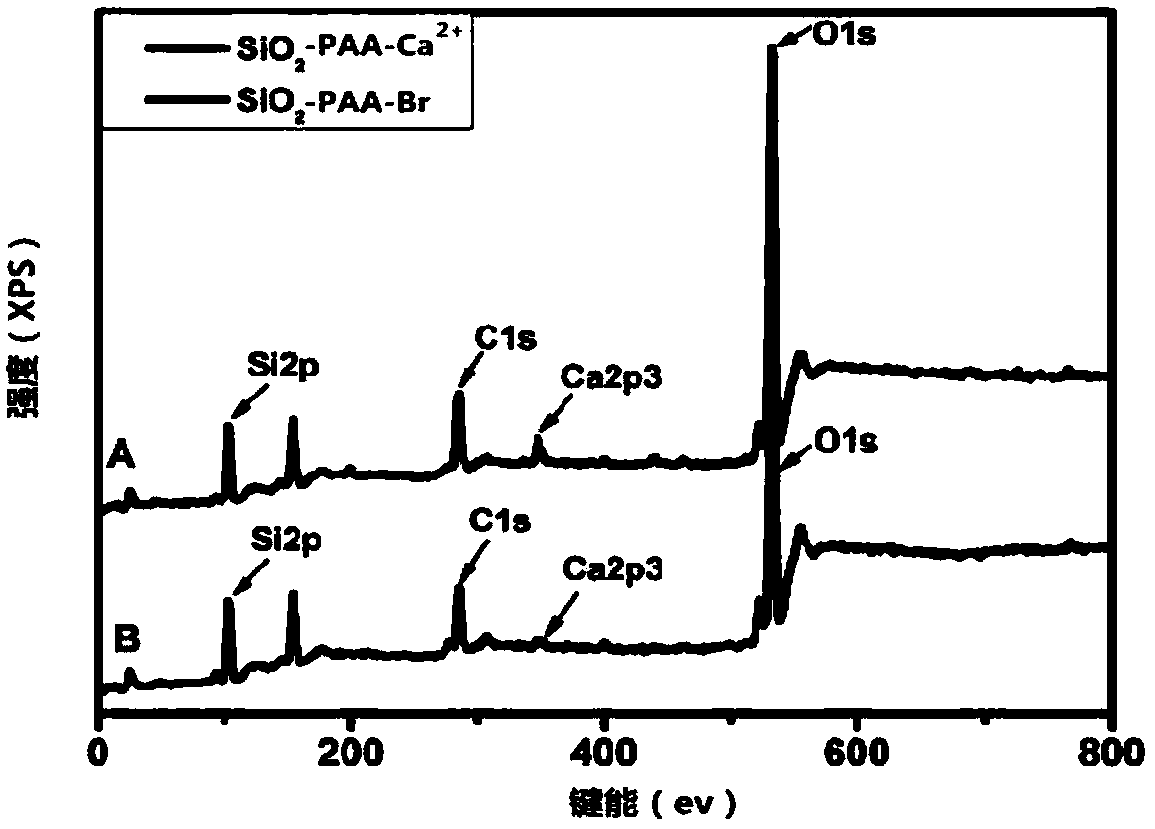

Microspheric ion exchange flash-rust-resistant anti-rust metal primer and preparation method thereof

The invention provides aqueous anti-rust metal primers, and in particular relates to microspheric ion exchange flash-rust-resistant anti-rust metal primer and a preparation method thereof. The primeris prepared from polyacrylic emulsion, polymer emulsion of a hollow structure, a coalescing agent, a thickening agent, a pH regulator, a flash-rust-resistant agent, a body filler, microspheric calcium-ion-containing silica gel, strontium phosphate, bentonite and water. The environmentally friendly anti-rust metal primer provided by the invention has excellent salt fog resistance and flash rust resistance; the film density is excellent, and the dry film of 0.5 mm can bear a water pressure of 0.3MPa for 30 minutes; the adhesive force is extremely high, and the national standard of automotive anti-rust primers can be reached; the content of prohibited substances is far lower than the content required in relevant laws and regulations.

Owner:哈尔滨雨阳佳泰环保新材料有限公司

Water-based metal primer-finish combined paint and preparation method thereof

The invention discloses water-based metal primer-finish combined paint. The water-based metal primer-finish combined paint comprises, by weight, 5-6% of water, 0.1-0.4% of magnesium aluminum silicate,0.5-0.6% of a dispersant, 0.1-0.2% of a wetting agent, 0.1-0.3% of a defoamer, 0.2-0.5% of a pH regulator AMP-95, 12-18% of R-760 titanium dioxide, 2-5% of zinc phosphate, 3-5% of barium sulfate of 1000 meshes, 1-3% of mica powder of 1000 meshes, 50-55% of an water-based acrylic industrial emulsion, 2-3% of a film former Texanol, 0.5-1% of an anti-flash rust agent, 0.1-0.5% of a preservative, 0.1-0.5% of a polyurethane thickener, 0.1-0.2% of a substrate wetting agent and the balance of water.

Owner:CHUZHOU MAISITE NEW BUILDING MATERIAL

A kind of primer and preparation method thereof

ActiveCN103897467BRestore toStrong adhesionPolyurea/polyurethane coatingsPaints with free metalsMetal coatingChemical plating

Owner:广东顺德三阳化学有限公司

Metal primer with good filling ability

The technical scheme of the invention is a metal primer with good filling ability, wherein the main component is a water-containing silicate mineral, and the metal primer is characterized in that 15-20 parts of stearyl betaine, 5-15 parts of a modified polyurethane dispersant, 15-20 parts of zirconium butyl acetate and 5-10 parts of dibutyl maleate are added. Compared to the metal primer in the prior art, the metal primer of the present invention has the following beneficial effect that stearyl betaine, the modified polyurethane dispersant, zirconium butyl acetate and dibutyl maleate added, such that the metal primer has the good effect.

Owner:SHENYANG CHUANGDA TECH TRADE MARKET

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com