Coating Formation Method

A technology of coating film and transparent coating film, applied in the direction of coating, device for coating liquid on the surface, special surface, etc., can solve the problem of insufficient chroma, and achieve the effect of high chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0069] Preparation of acrylic resins containing hydroxyl groups

[0070] 50 parts of ethylene glycol monoethyl ether acetate were placed in a reaction vessel equipped with a thermometer, a thermostat, a stirrer, a reflux condenser and a dropping funnel, stirred and mixed. The mixture was heated to 135°C. Subsequently, the monomer / polymerization initiator mixture described below was added dropwise to the reaction vessel kept at the same temperature over 3 hours. After the dropwise addition was complete, the mixture was aged for 1 hour. Thereafter, a mixture comprising 10 parts of ethylene glycol monoethyl ether acetate and 0.6 parts of 2,2'-azobis(2-methylpropionitrile) was added dropwise to the reaction product within 1 hour and 30 minutes and While maintaining the same temperature, the resulting product was aged for another 2 hours. Then, ethylene glycol monoethyl ether acetate was distilled off under reduced pressure, thereby obtaining a hydroxyl group-containing acrylic ...

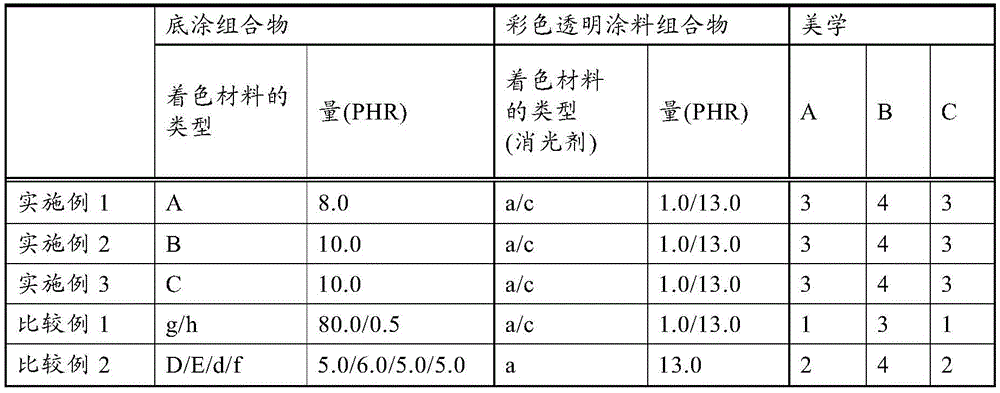

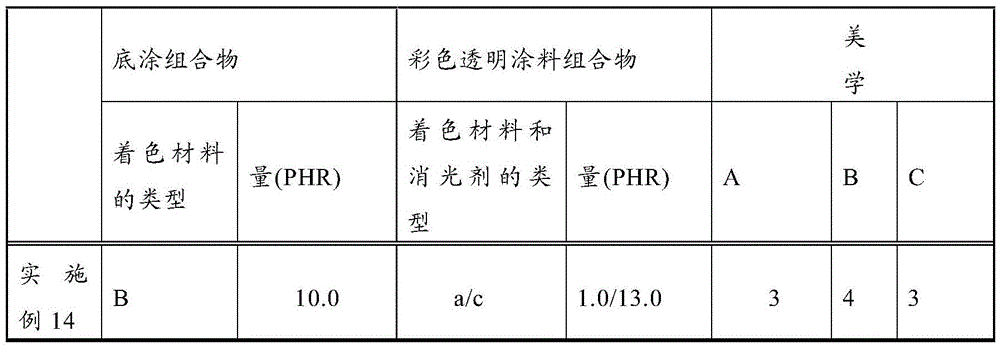

Embodiment 1 to 3 and comparative example 1 and 2

[0078] With respect to the resin component of 100 parts (solid content), this resin component comprises the acrylic resin containing the hydroxyl group that obtains in the preparation example 1 of 75 parts and the U-Van 28-60 of 25 parts (trade name, butyl ether melamine resin; produced by Mitsui Chemicals, Inc.), a coloring material was added in the ratio shown in Table 1, and the mixture was stirred and mixed to prepare a primer composition containing the coloring material. The primer composition was diluted to a viscosity suitable for painting to form an organosolvent coating composition having a solids content of about 25%. The coating composition was applied to the substrate to be coated by air spraying to a film thickness of 15 μm when cured. After painting, the resulting product was allowed to stand in the laboratory for about 15 minutes at a room temperature of about 20°C. Thereafter, by air spraying, with respect to 100 parts by mass of the resin component (LUGABAKE ...

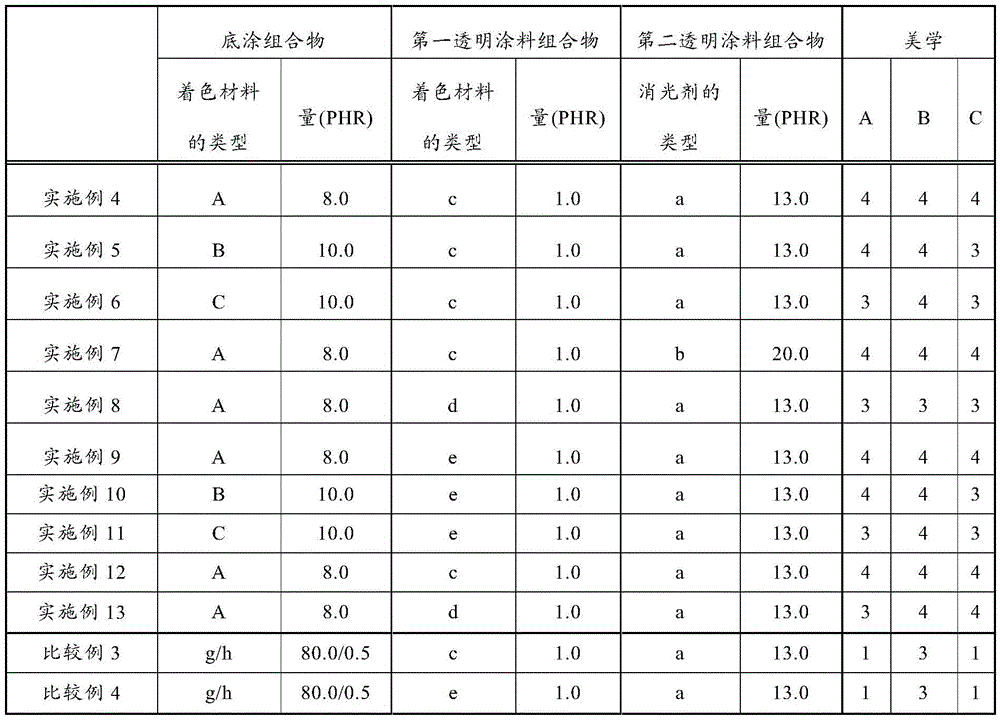

Embodiment 4-11 and comparative example 3 and 4

[0080] With respect to the resin component of 100 parts (solid content), this resin component comprises the acrylic resin containing the hydroxyl group that obtains in the preparation example 1 of 75 parts and the U-Van 28-60 of 25 parts (trade name, butyl ether melamine resin; manufactured by Mitsui Chemicals, Inc.), a coloring material was added in the ratio shown in Table 2, and the mixture was stirred and mixed to prepare a primer composition containing the coloring material. The primer composition was diluted to a viscosity suitable for painting to form an organosolvent coating composition having a solids content of about 25%. The coating composition was applied to the substrate to be coated by air spraying to a film thickness of 15 μm when cured. After painting, the resulting product was allowed to stand in the laboratory for about 15 minutes at a room temperature of about 20°C. Thereafter, by air spraying, with respect to 100 parts by mass of the resin component (LUGAB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com