Room-temperature curing efficient adhesive and preparation method thereof

A room temperature curing and adhesive technology, applied in the chemical field, can solve the problems of high cost of flat vulcanizing machines and vulcanizing tanks, unrealistic mold opening, low bonding strength, etc., to improve heat resistance, improve bonding strength, The effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

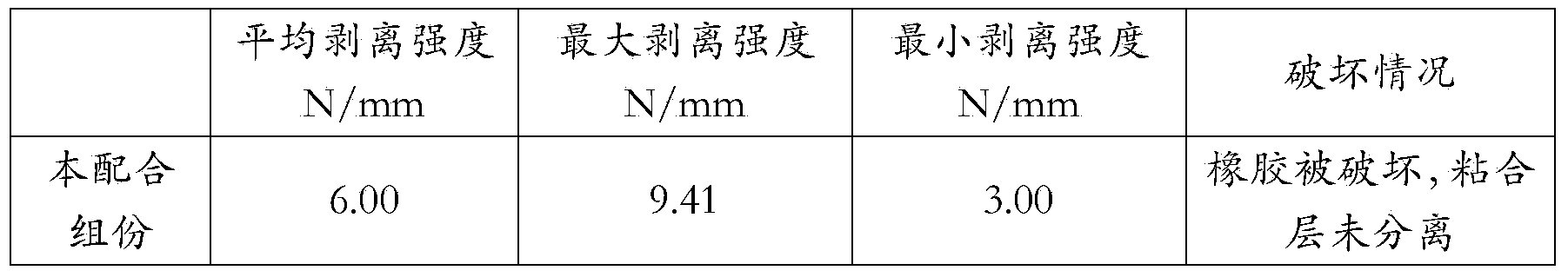

Examples

Embodiment 1

[0037] Preparation of metal primer:

[0038] 1) Add 150g of general-purpose neoprene rubber CR2321 (Changshou Chemical Industry) into the open mill, the roll distance is 4-5mm, add 1.5g of anti-aging agent BHT (Anhui Haihua Technology) after wrapping the rolls, and make a triangle after the material is eaten. Knead for 2 minutes, then adjust the roller distance to 1mm to produce a film to obtain a film;

[0039] 2) Take 800g of industrial toluene (Qingdao Jinpeng Chemical Industry Co., Ltd.) and pour it into a double-layer stainless steel closed reaction kettle with agitator, cut the film obtained in 1) into 30mm*30mm rubber blocks and add it to the reaction kettle, and the stirring speed is 600r / min, stir until the glue block dissolves evenly;

[0040] 3) Pour 3200g of industrial toluene into the reactor, add 1500g of chlorinated rubber CR20 (Dongxin Chemical) and 200g of light magnesium oxide (purity 99.5%) (Yantai Aifer Chemical), and stir for 16 hours. The temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com