Patents

Literature

43 results about "Commercially pure titanium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grade 1 Commercially Pure Titanium Titanium is classified in two categories: commercially pure titanium (Ti) which is used in the chemical process industries and titanium alloys having such additives as aluminum (Al) and vanadium (V) and which are used for jet aircraft engines, airframes and other components. Unalloyed...

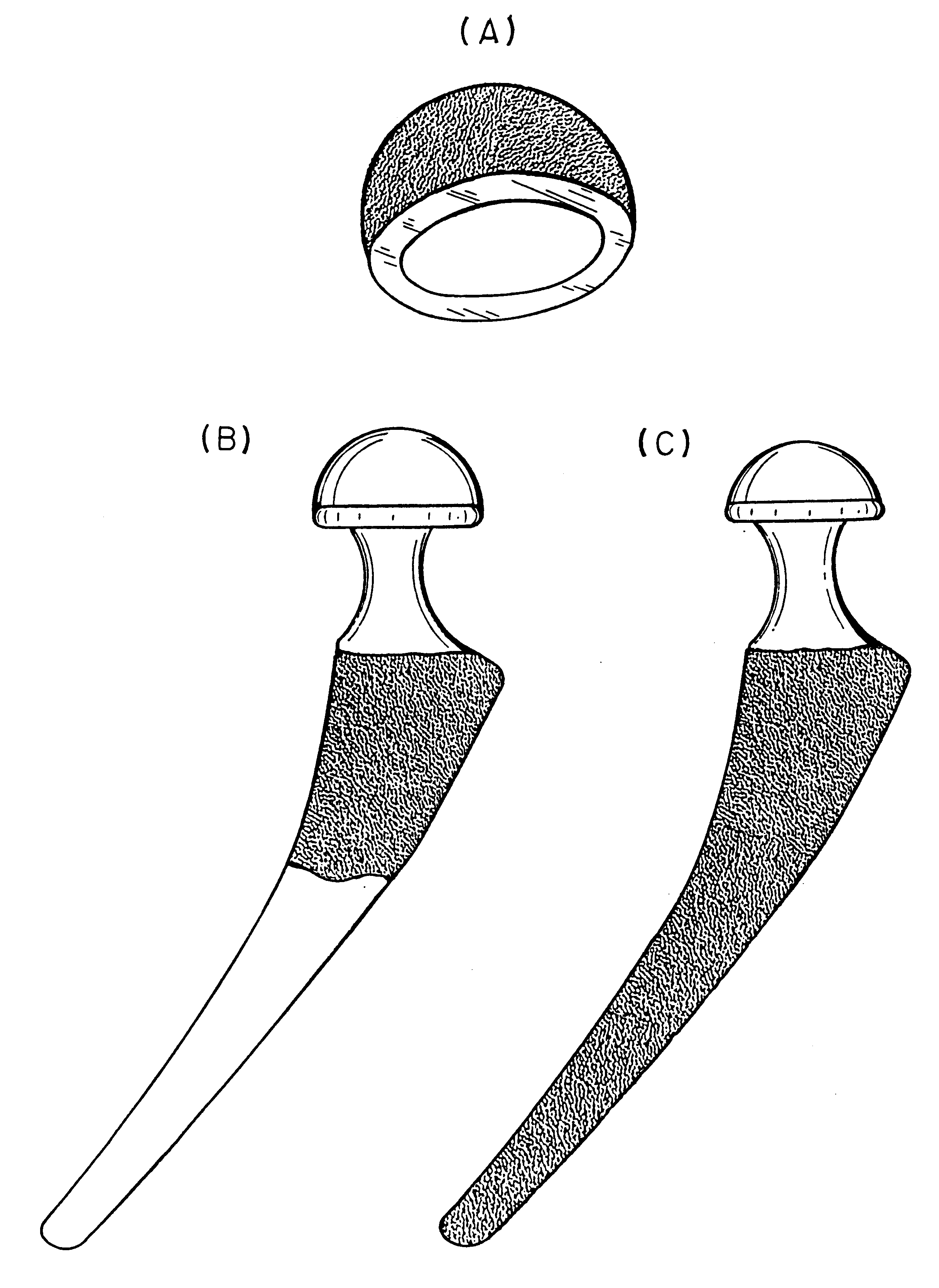

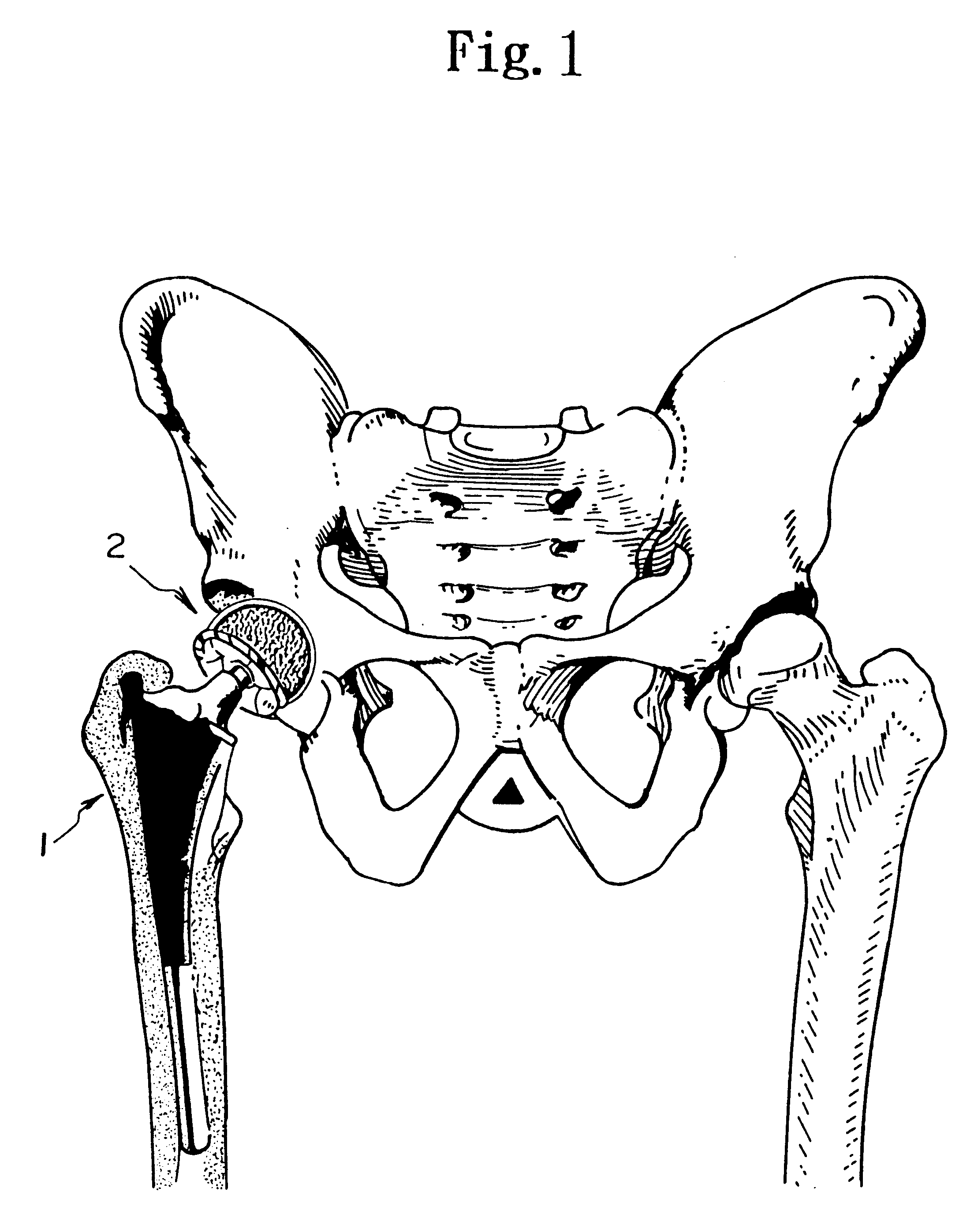

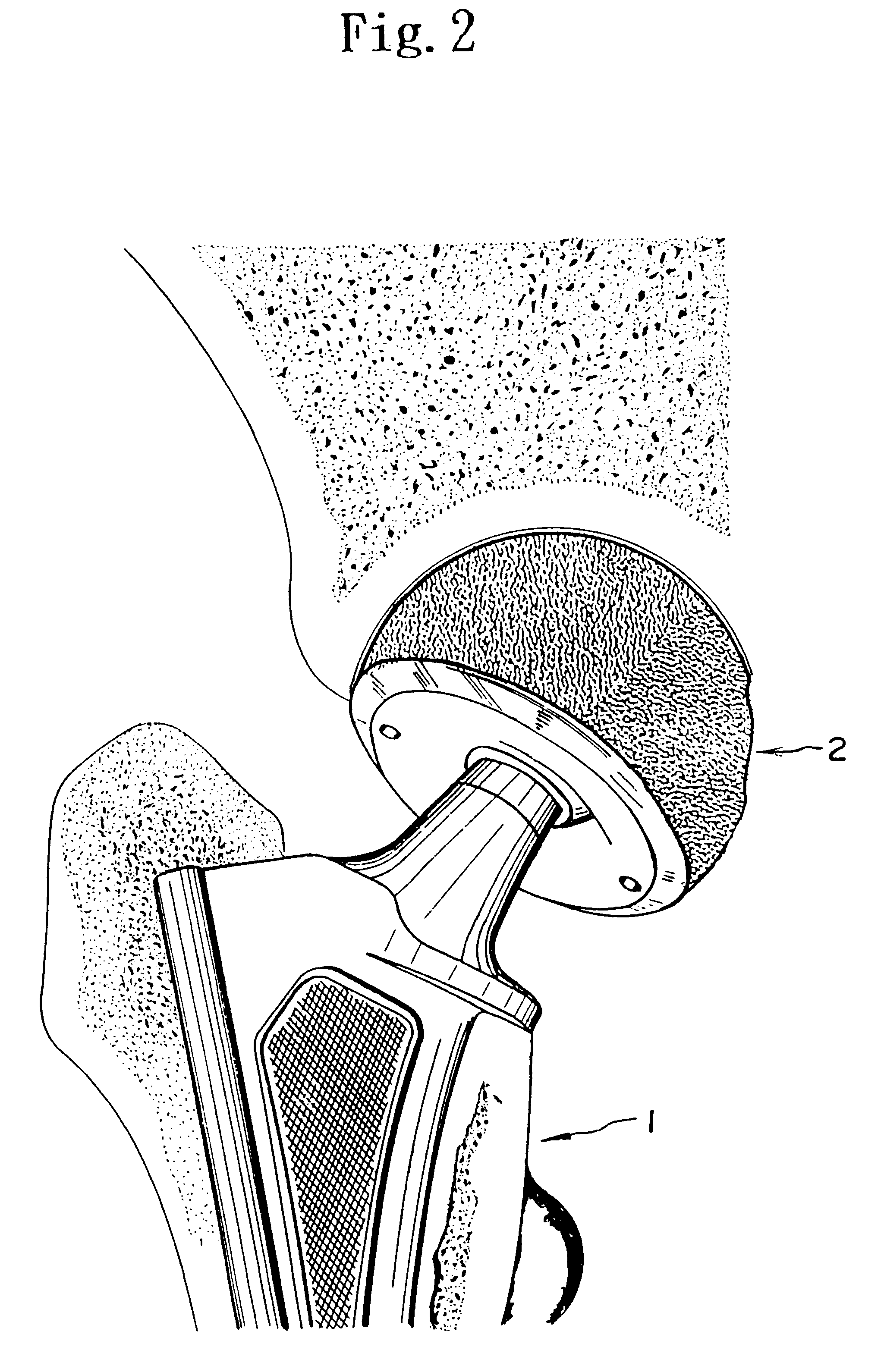

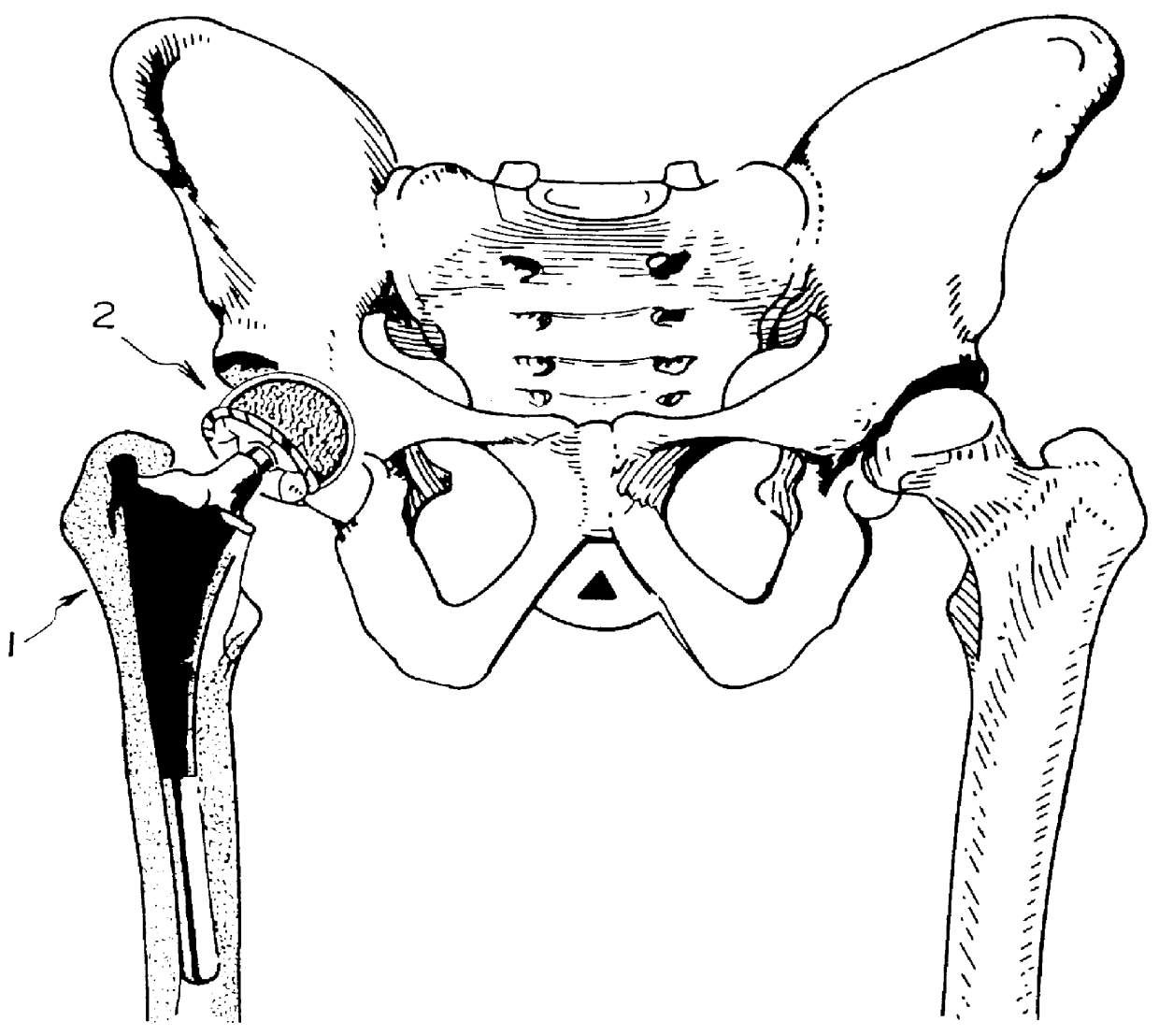

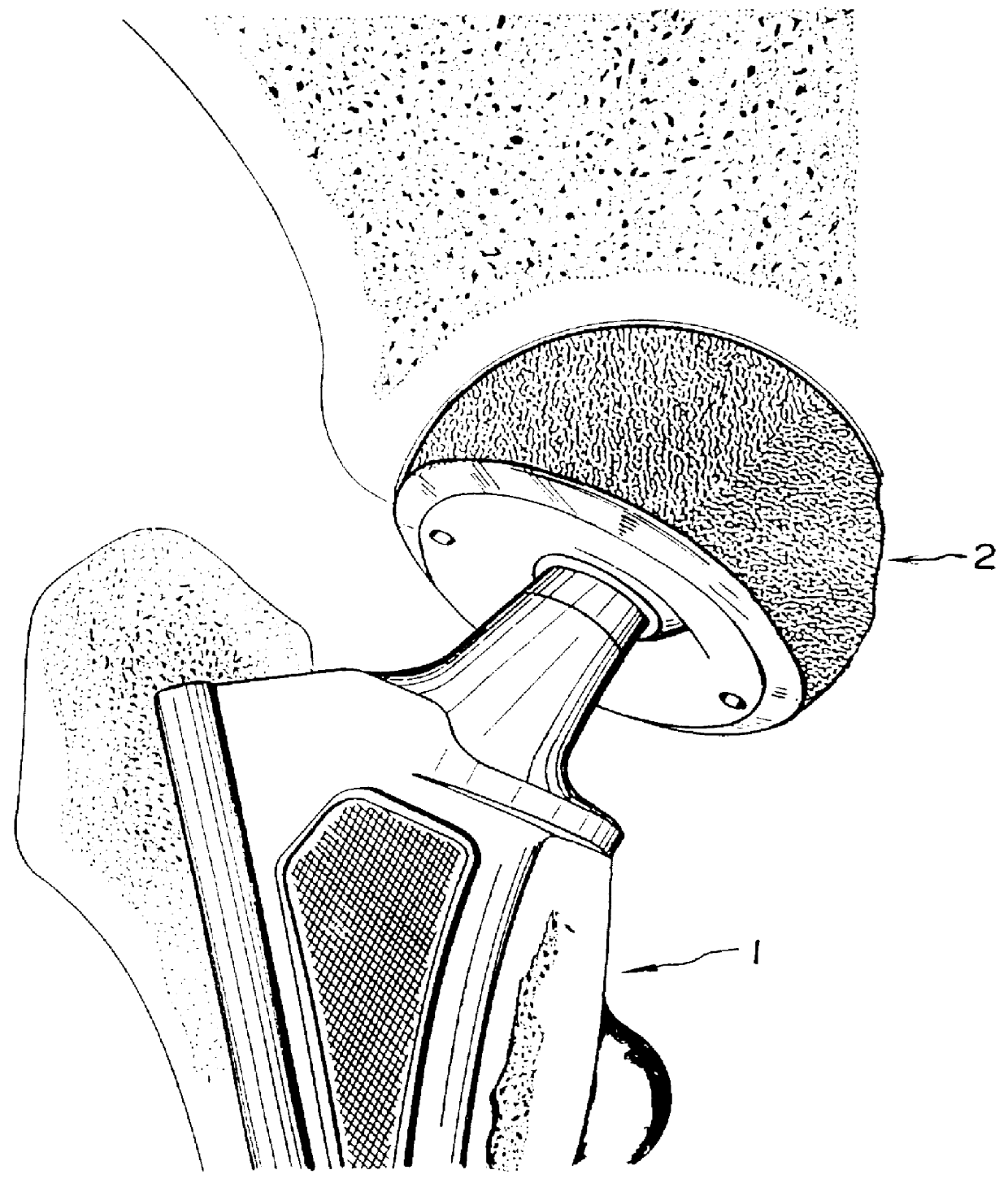

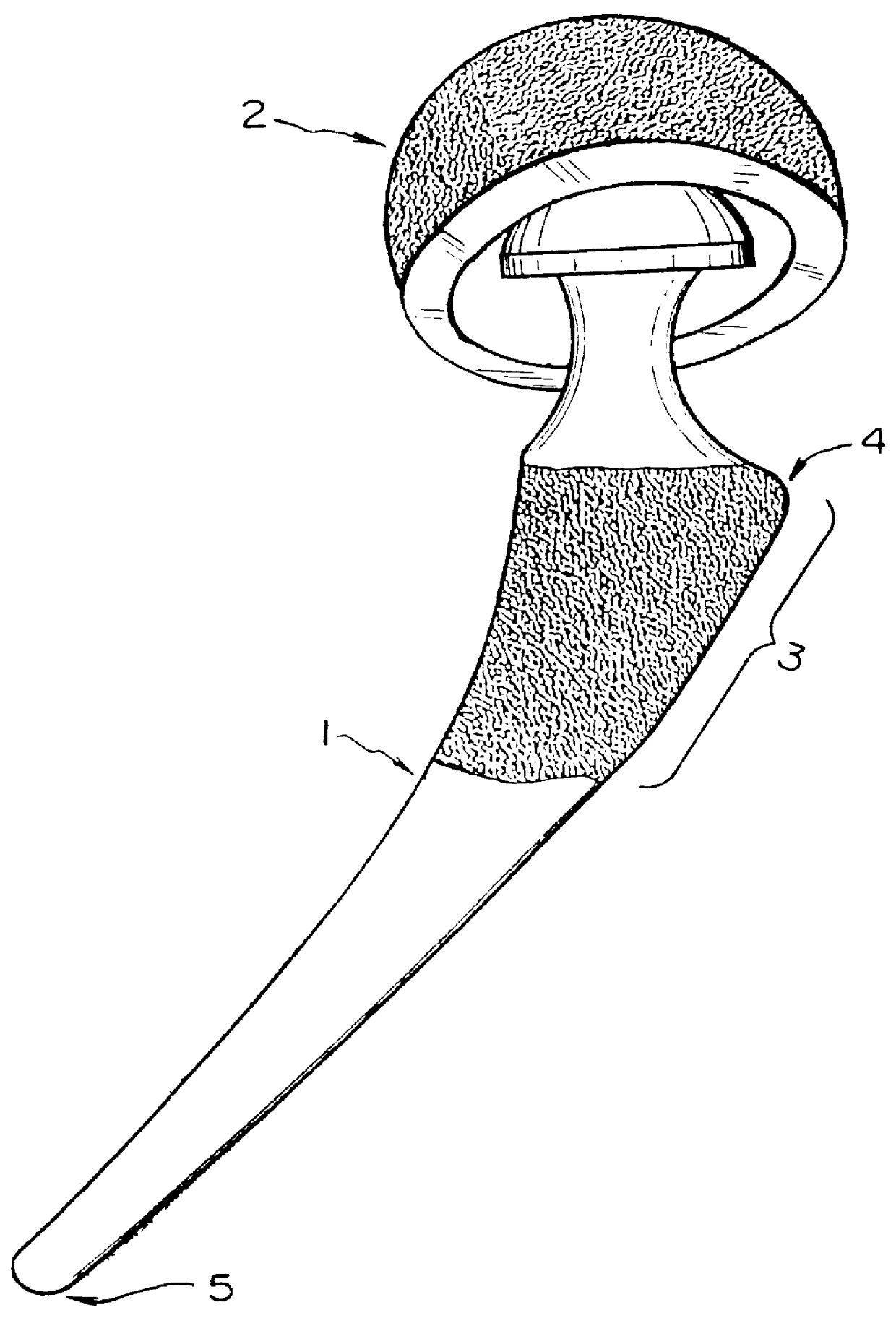

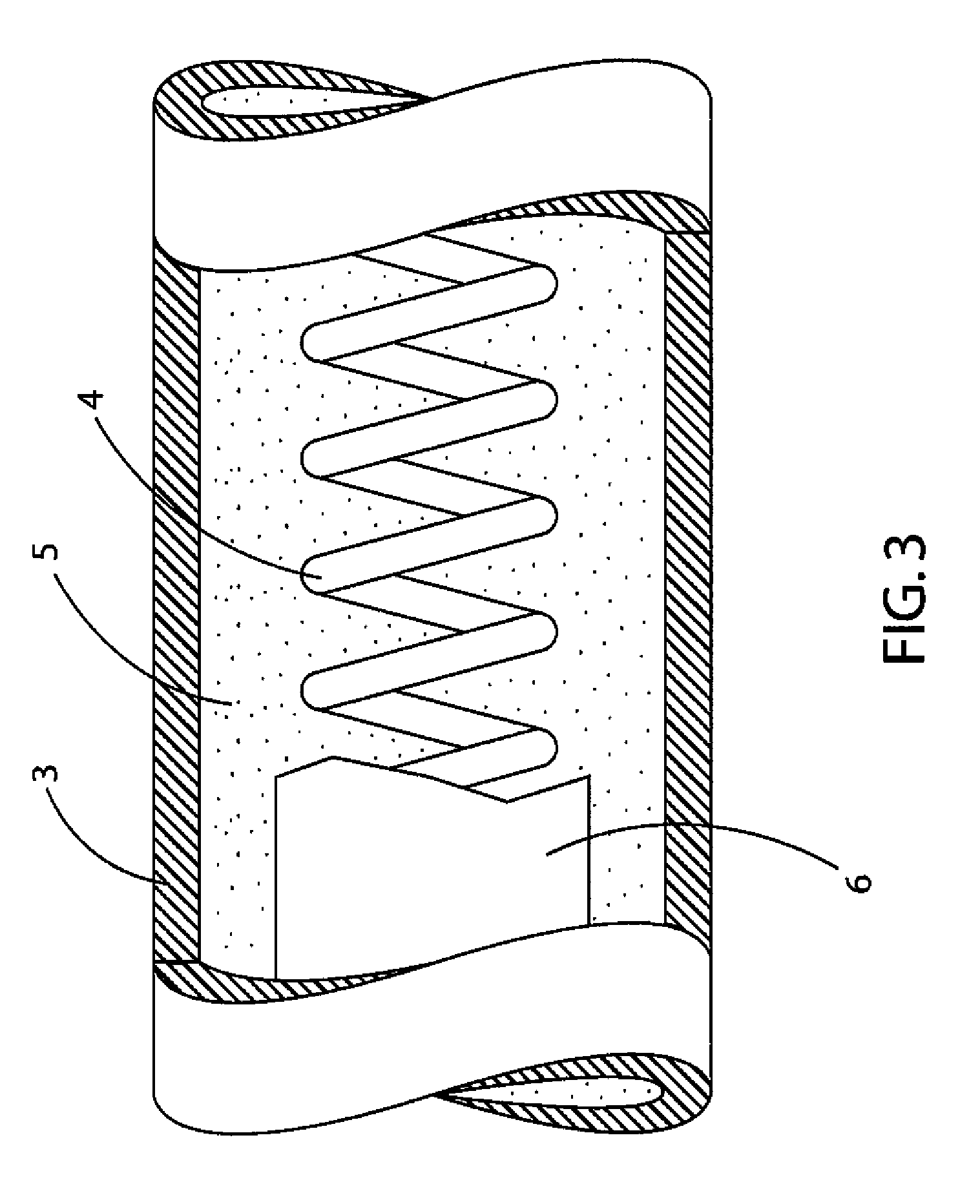

Orthopedic implant system

InactiveUS6312473B1Easy to fixAvoid excessive temperatureSurgical adhesivesBone implantFemoral stemPolymethyl methacrylate

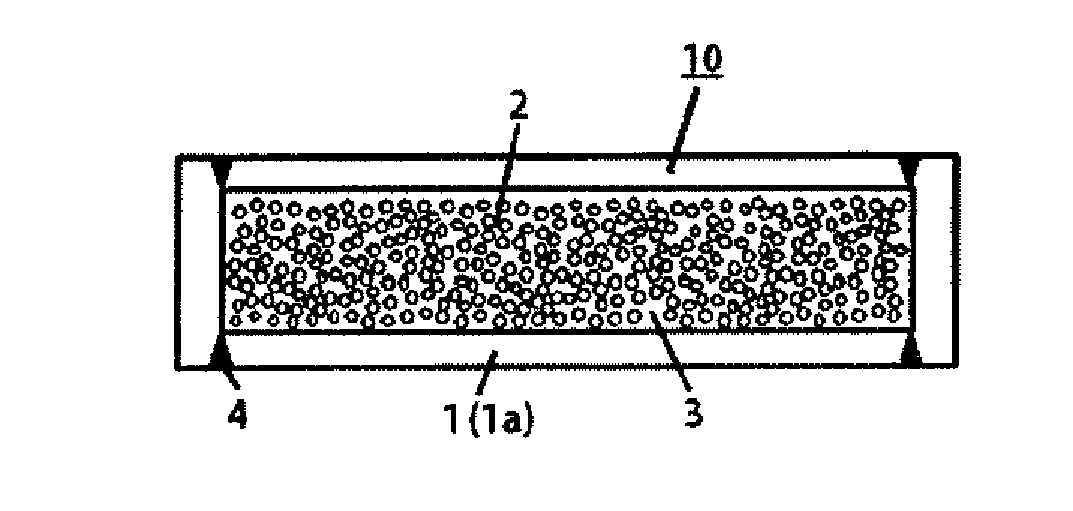

It is an object of the present invention to provide an improved orthopedic implant system with satisfied biological, mechanical and morphological compatibilities.Solid metal femoral stem and solid metal acetabular head are covered with diffusion-bonded foamed-shaped sheet made of commercially pure titanium or titanium alloy(s). The open-cells in said foamed metal sheet are impregnated with biocompatible polymethyl methacrylate resin cement, which is reinforced with selected oxides including alumina, magnesia, zirconia, or a combination of these oxides along with an application of a small amount of a metal primer agent.

Owner:OSHIDA YOSHIKI

Orthopedic implant system

InactiveUS6066176AStrong interlocking fixationEasy to fixSurgical adhesivesBone implantPolymethyl methacrylateFemoral stem

It is an object of the present invention to provide an improved orthopedic implant system with satisfied biological, mechanical and morphological compatibilities. Solid metal femoral stem (entirely or partially) and solid metal acetabular head (entirely or partially) are covered with diffusion-bonded foamed-shaped sheet made of commercially pure titanium or titanium alloy(s). The open-cells in said foamed metal sheet are impregnated with biocompatible polymethyl methacrylate resin cement, which is reinforced with selected oxides (e.g., alumina, magnesia, zirconia, or a combination of these oxides) along with an application of a small amount of a metal primer agent.

Owner:OSHIDA YOSHIKI

Nanostructured commercially pure titanium for biomedicine and a method for producing a rod therefrom

ActiveUS20110179848A1Improve failureImprove propertiesNanostructure manufactureMetal-working apparatusEqual channel angular extrusionCommercially pure titanium

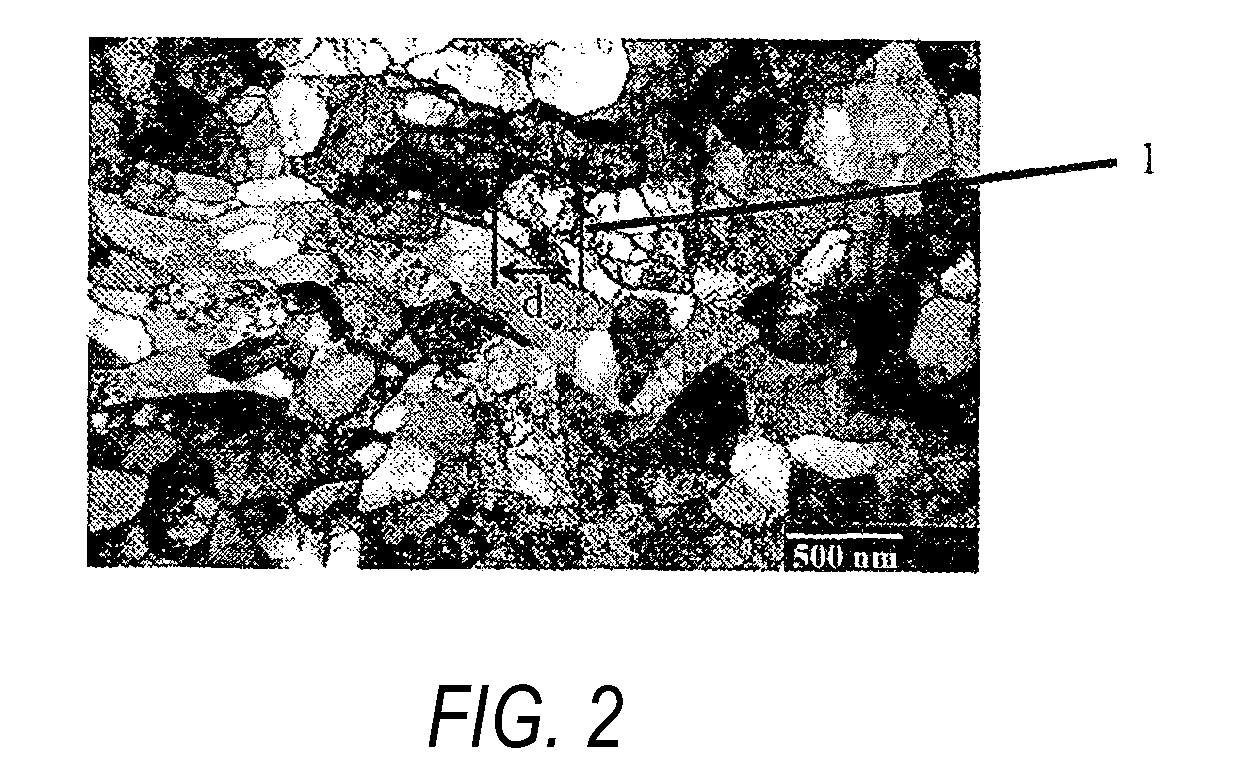

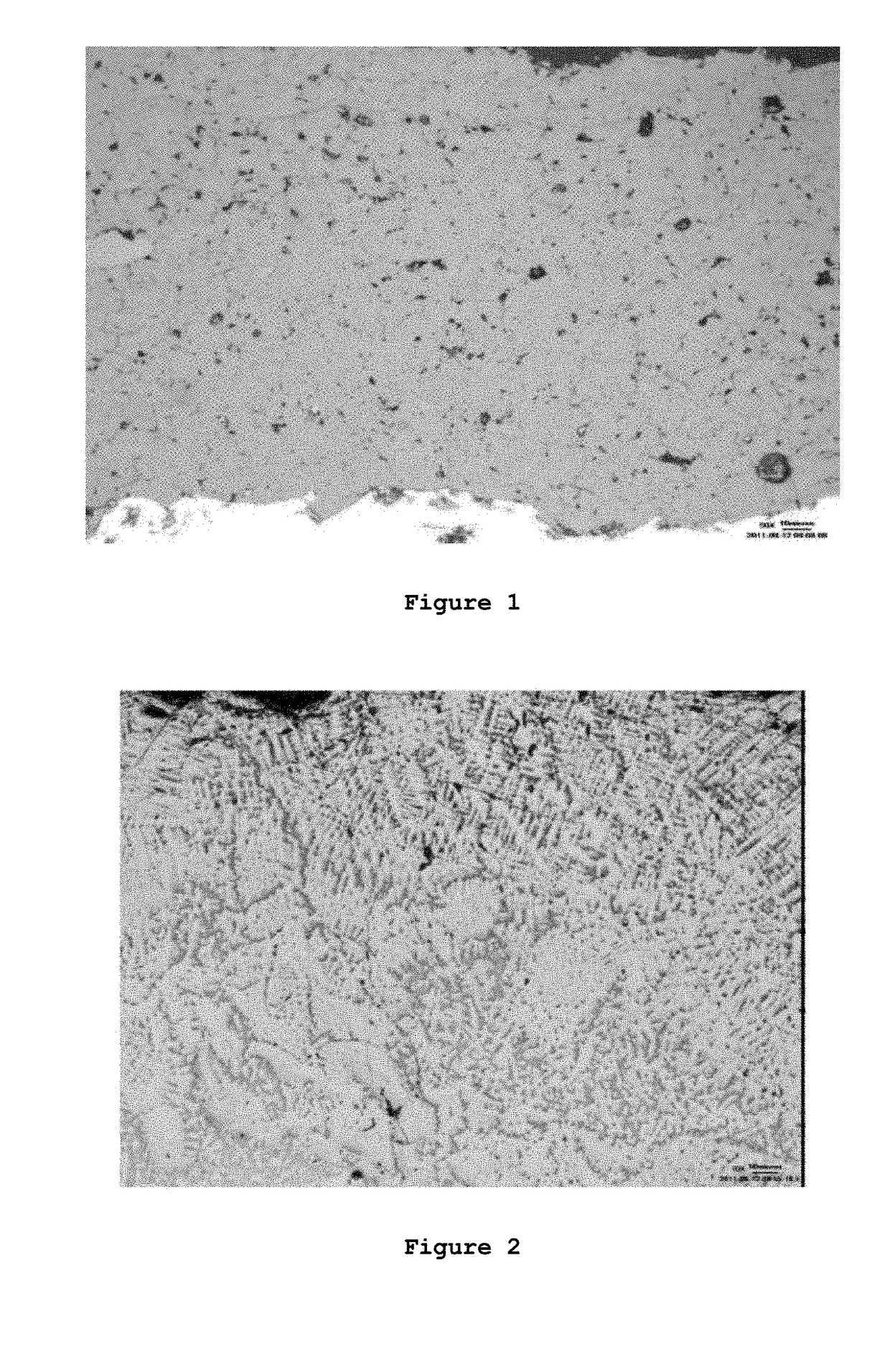

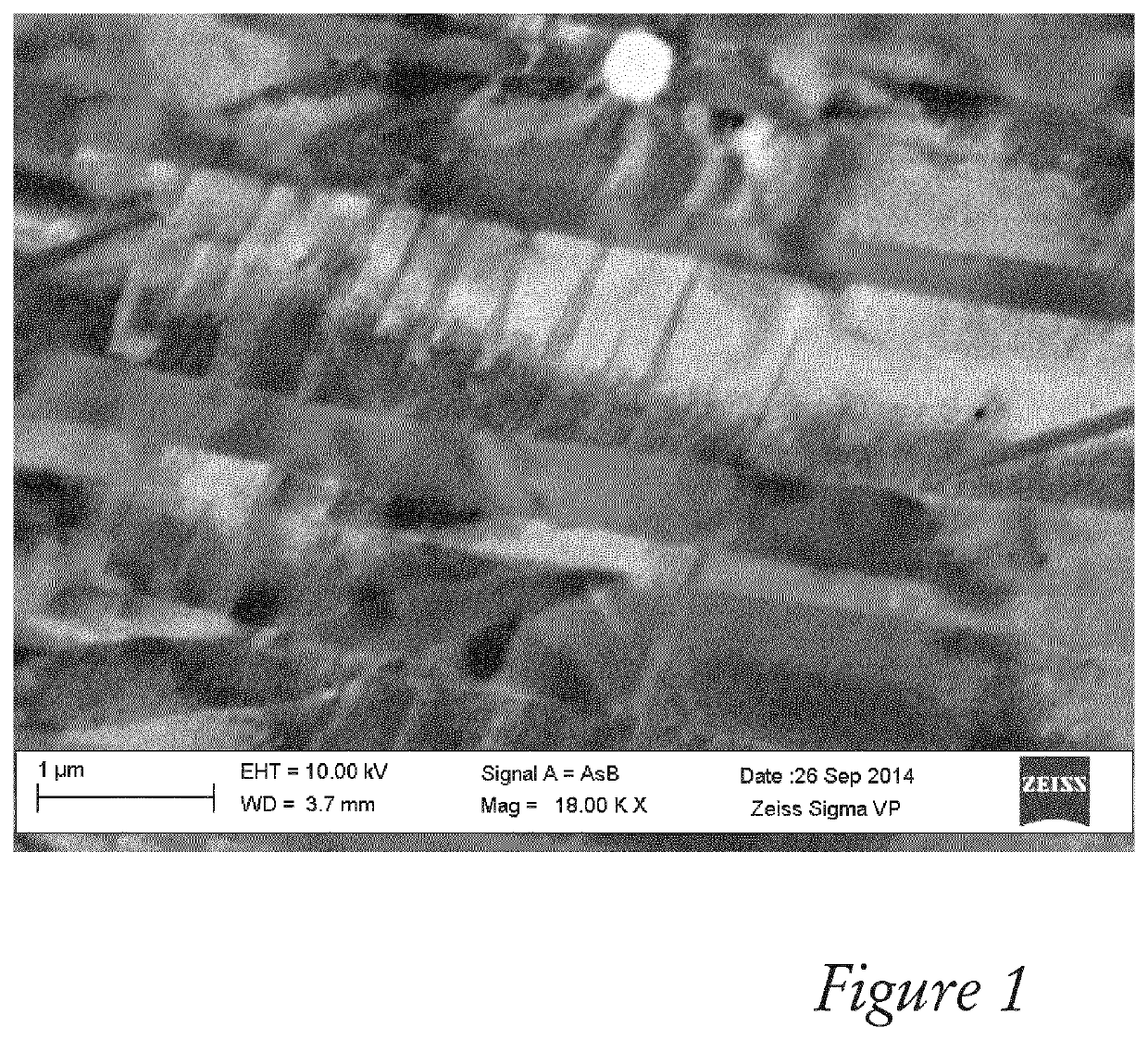

Commercially pure titanium having UFG structure and enhanced mechanical and biomedical characteristics has nanocrystalline alpha-phase grains with a hexagonal close-packed lattice, in which the share of grains with a size of 0.1 . . . 0.5 μm and a grain shape coefficient of no more than 2 in the mutually perpendicular planes makes no less than 90%, over 60% of the grains having high-angle boundaries disoriented in relation to the adjacent grains by the angles from 15 to 90°.The method for making a rod of the material provides for equal-channel angular pressing of a billet at T≦450° C. with the total accumulated true strain e≧4 to effect severe plastic deformation of the billet and subsequent thermomechanical treatment with a gradual decrease of the temperature in the range of 450 . . . 350° C. and the strain rate of 10−2 . . . 10−4 s−1 with the strain degree from 40 to 80% to effect additional plastic deformation.

Owner:FSBFEI HPE USATU 50 +1

Nanostructured commercially pure titanium for biomedicine and a method for producing a rod therefrom

ActiveUS8919168B2Improve failureImprove propertiesNanostructure manufacturePig casting plantsEqual channel angular extrusionCommercially pure titanium

Commercially pure titanium having UFG structure and enhanced mechanical and biomedical characteristics has nanocrystalline alpha-phase grains with a hexagonal close-packed lattice, in which the share of grains with a size of 0.1 . . . 0.5 μm and a grain shape coefficient of no more than 2 in the mutually perpendicular planes makes no less than 90%, over 60% of the grains having high-angle boundaries disoriented in relation to the adjacent grains by the angles from 15 to 90°.The method for making a rod of the material provides for equal-channel angular pressing of a billet at T≦450° C. with the total accumulated true strain e≧4 to effect severe plastic deformation of the billet and subsequent thermomechanical treatment with a gradual decrease of the temperature in the range of 450 . . . 350° C. and the strain rate of 10−2 . . . 10−4 s−1 with the strain degree from 40 to 80% to effect additional plastic deformation.

Owner:FSBFEI HPE USATU 50 +1

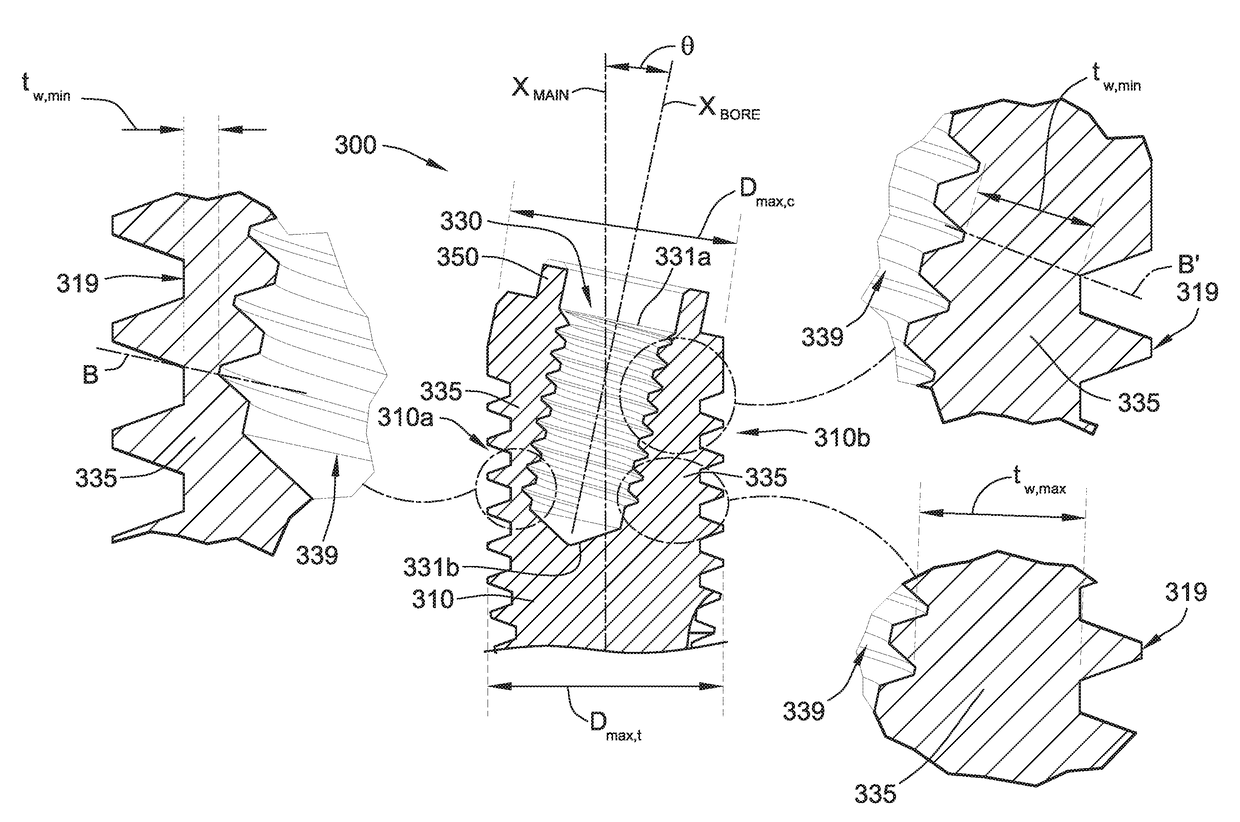

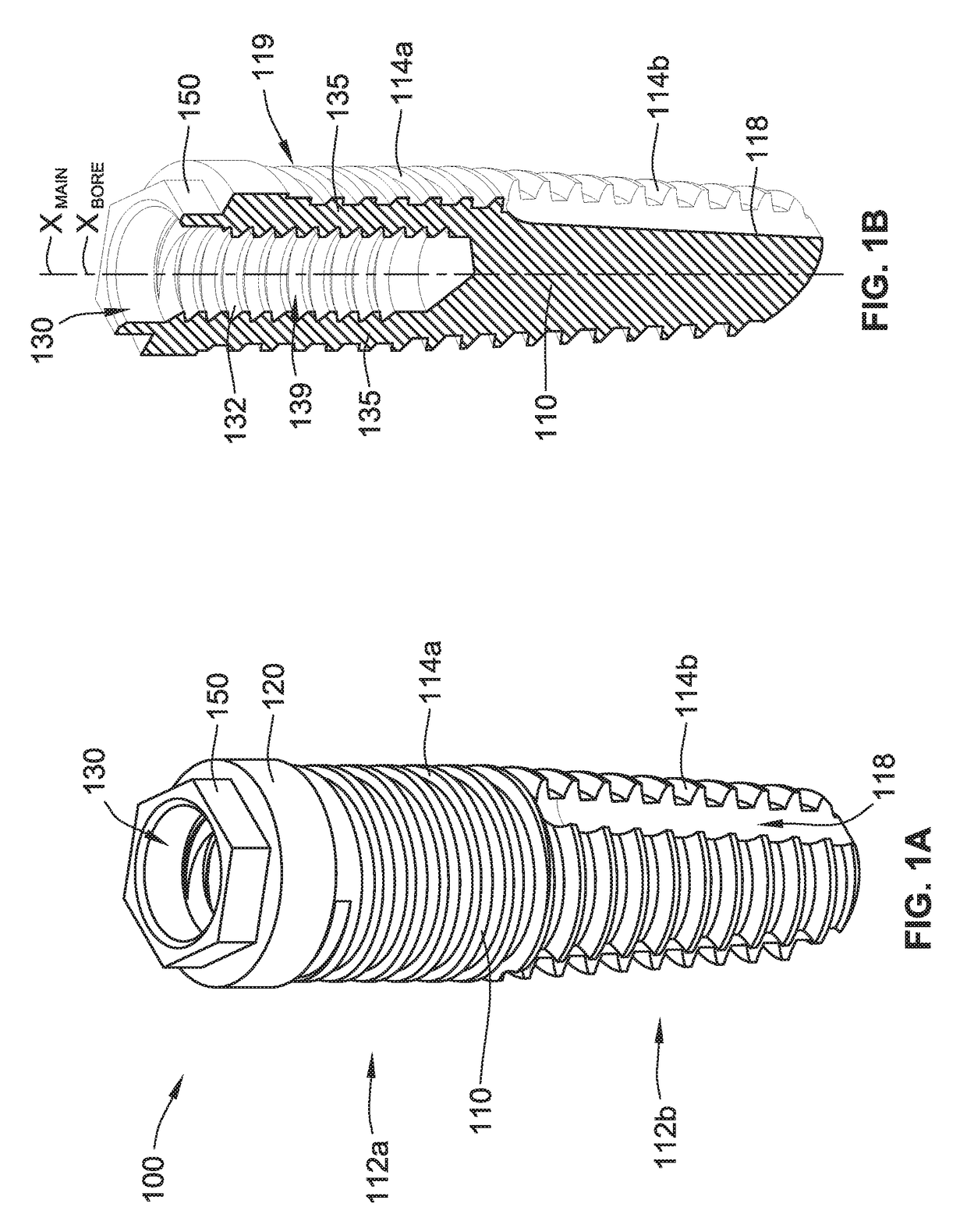

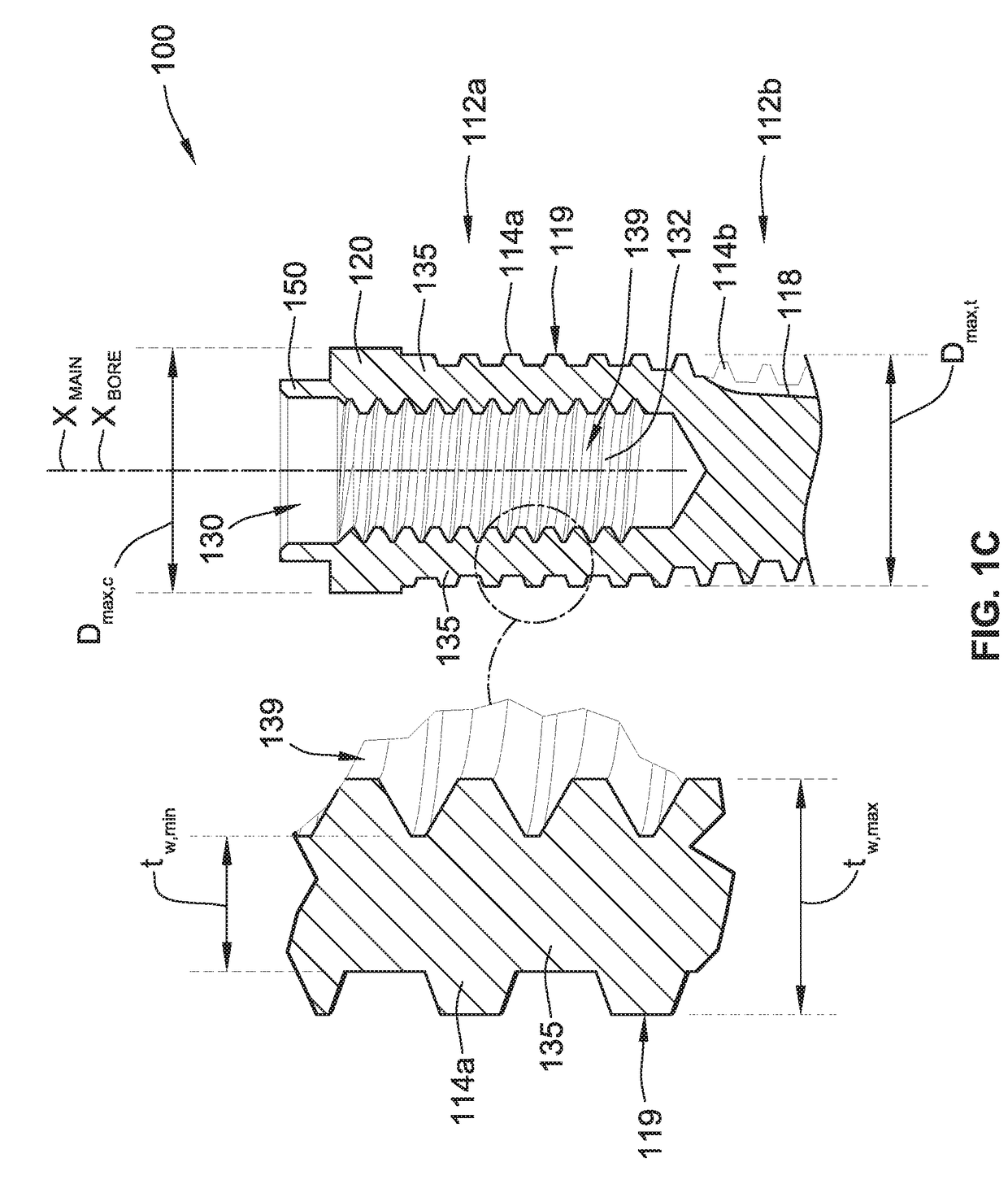

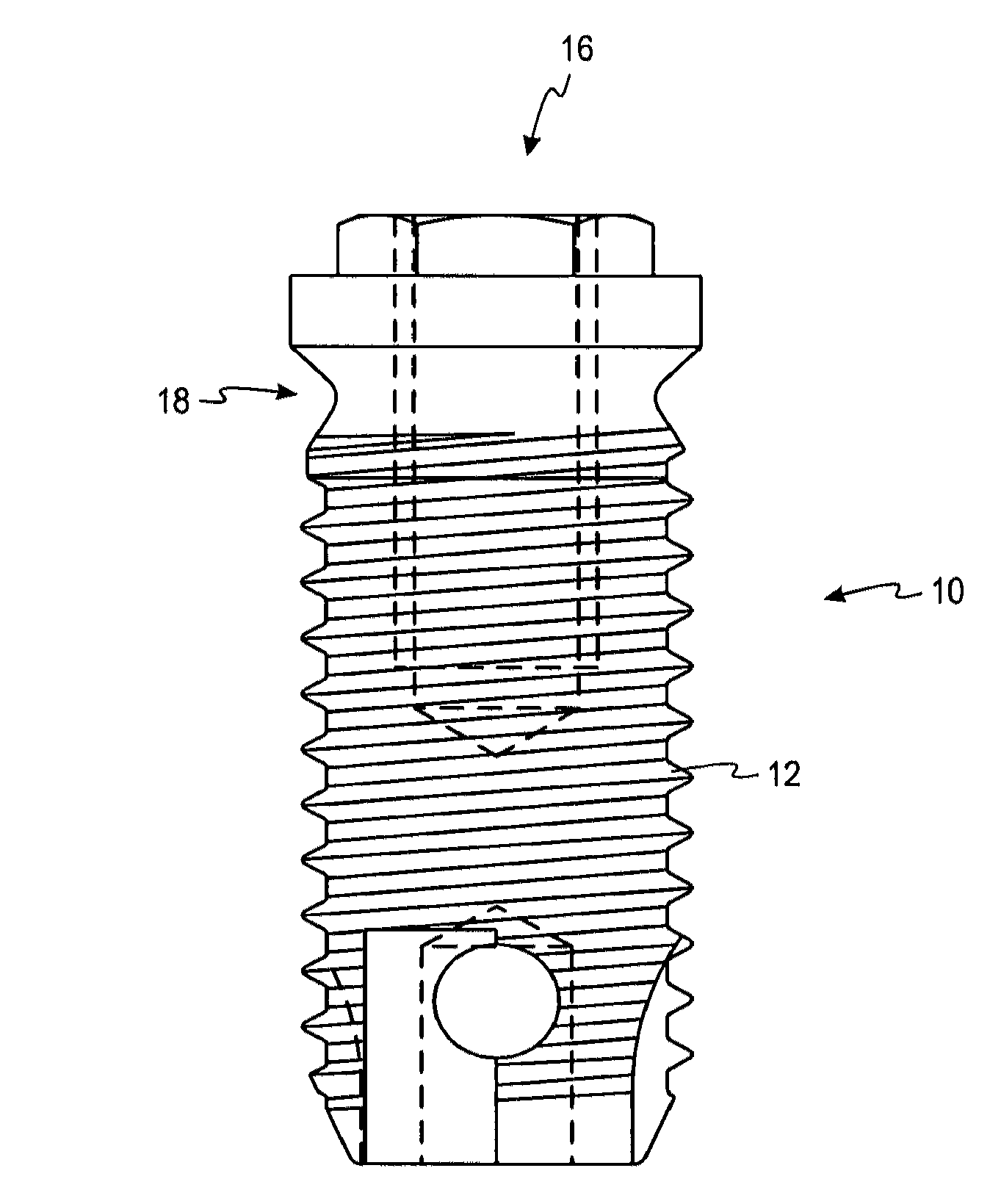

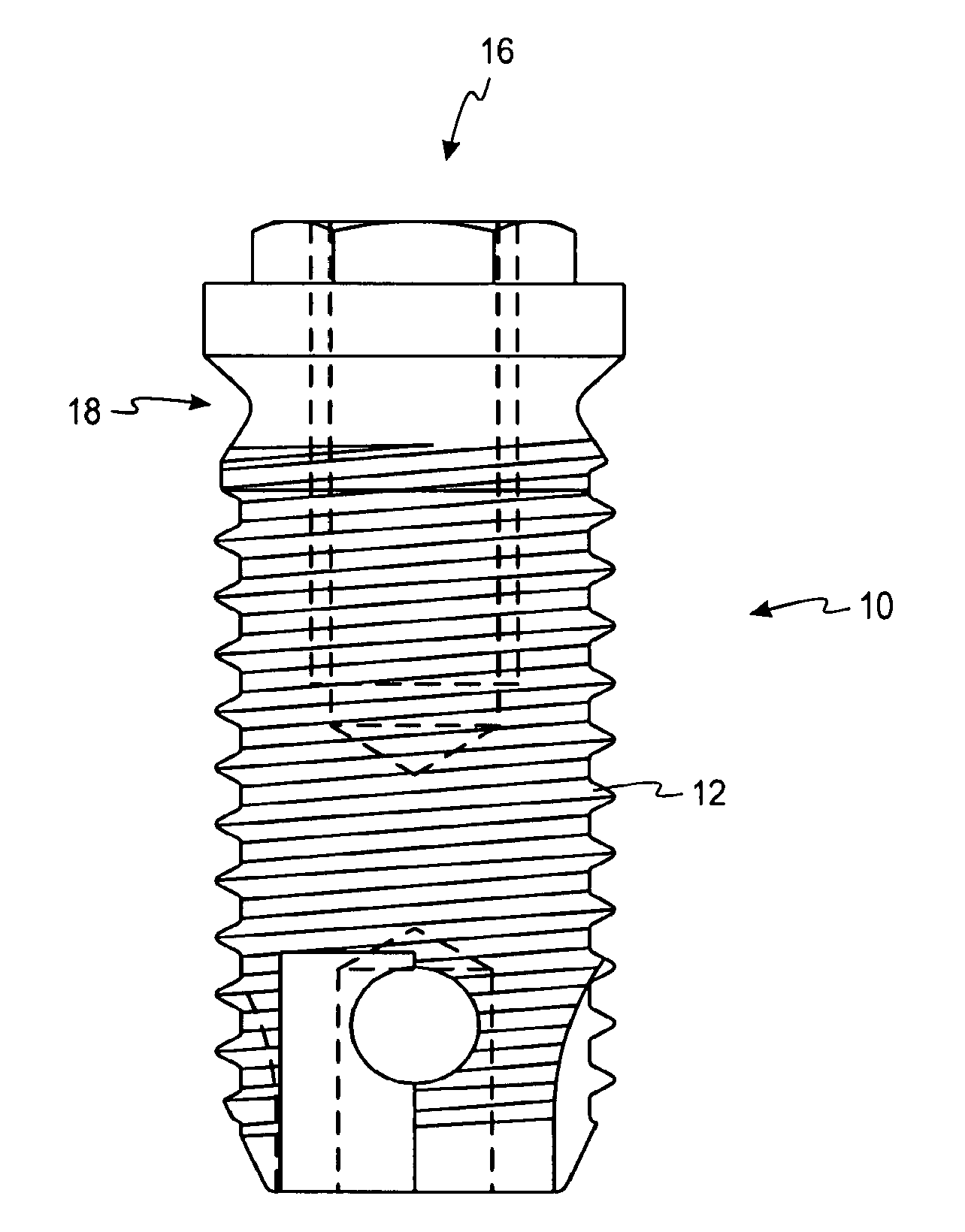

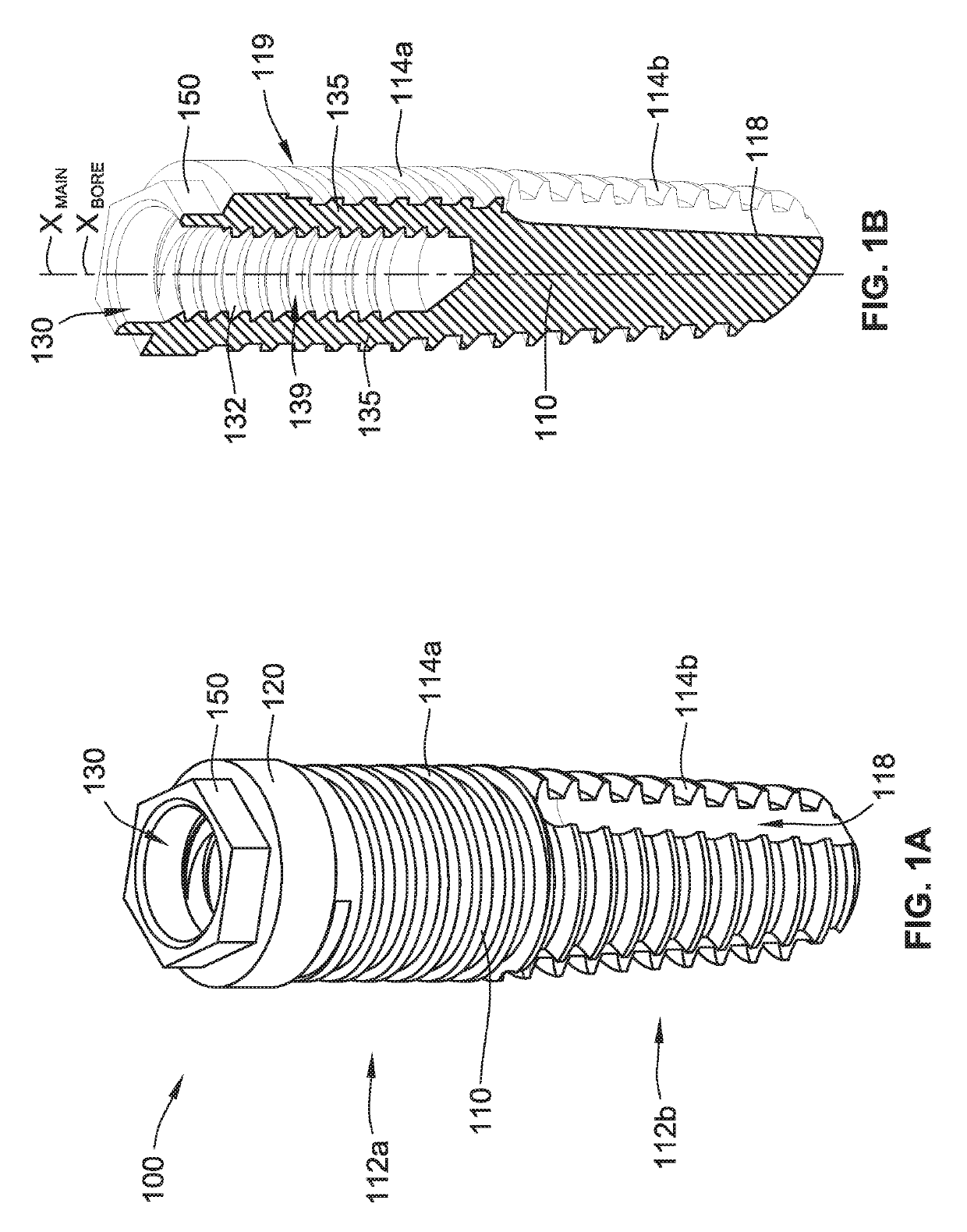

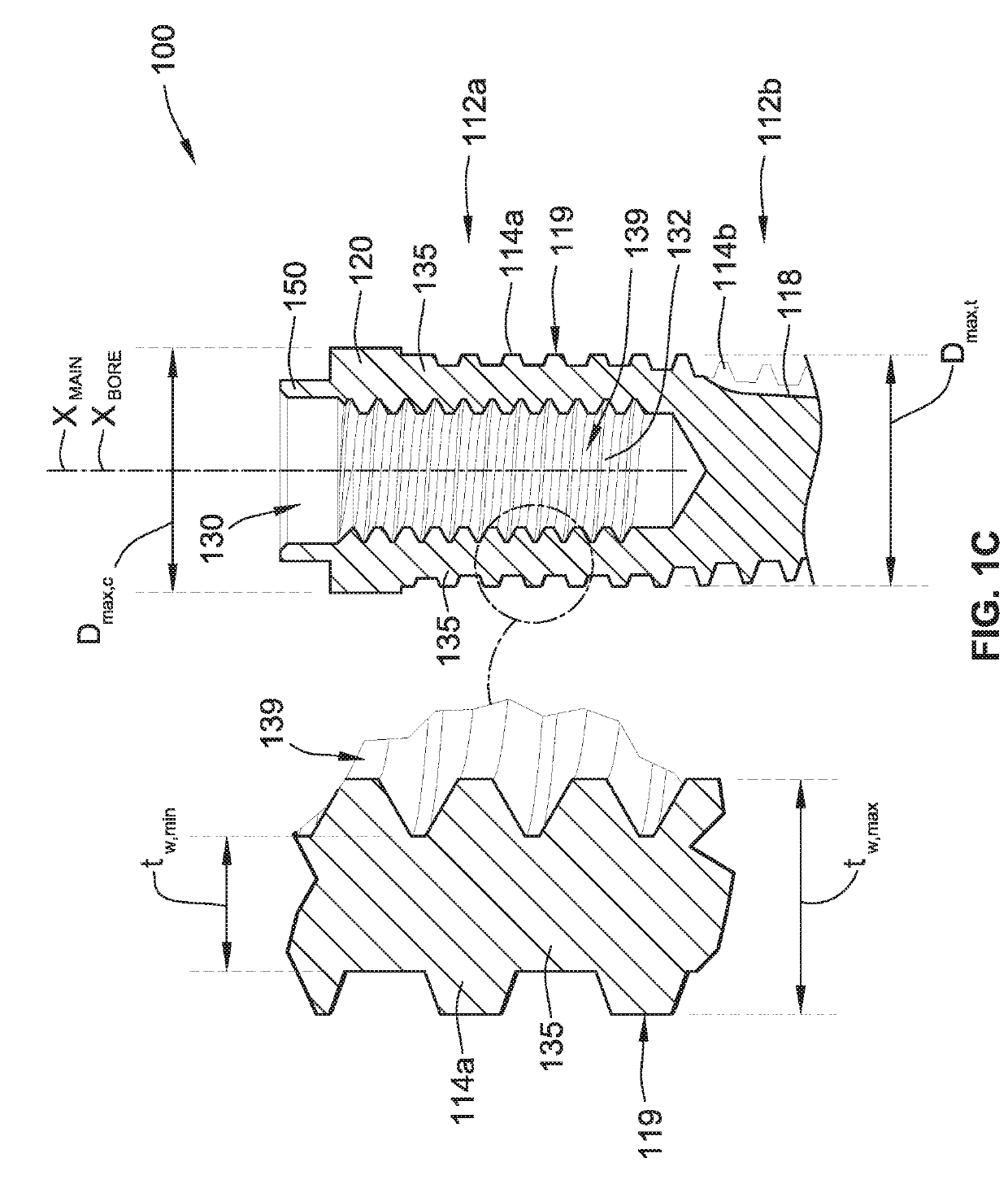

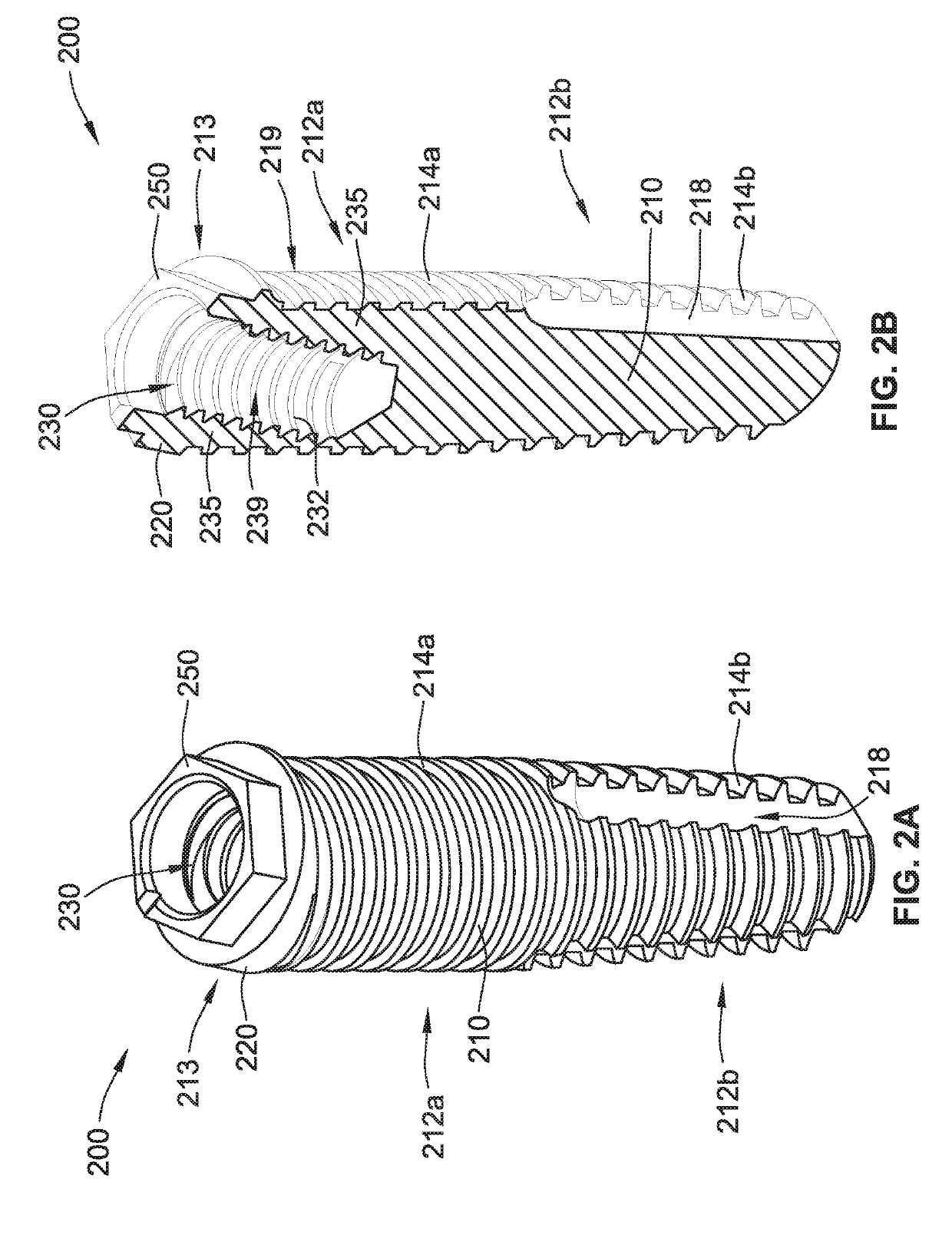

Angulated dental implant

A dental implant includes a generally cylindrical body, an interior bore, and a non-rotational feature. The generally cylindrical body has a main-central axis and is formed from cold-worked, high strength, commercially pure titanium having an ultimate tensile strength of at least about 900 MPa. The generally cylindrical body has a proximal portion and an opposing distal portion for anchoring the dental implant in bone of a patient. The interior bore is formed in the generally cylindrical body and has (i) a bore-central axis and (ii) a threaded portion for receiving a screw that is configured to removable hold an abutment in engagement with the dental implant. The non-rotational feature is configured to engage the abutment in a non-rotational fashion.

Owner:SOUTHERN IMPLATS (PTY) LTD

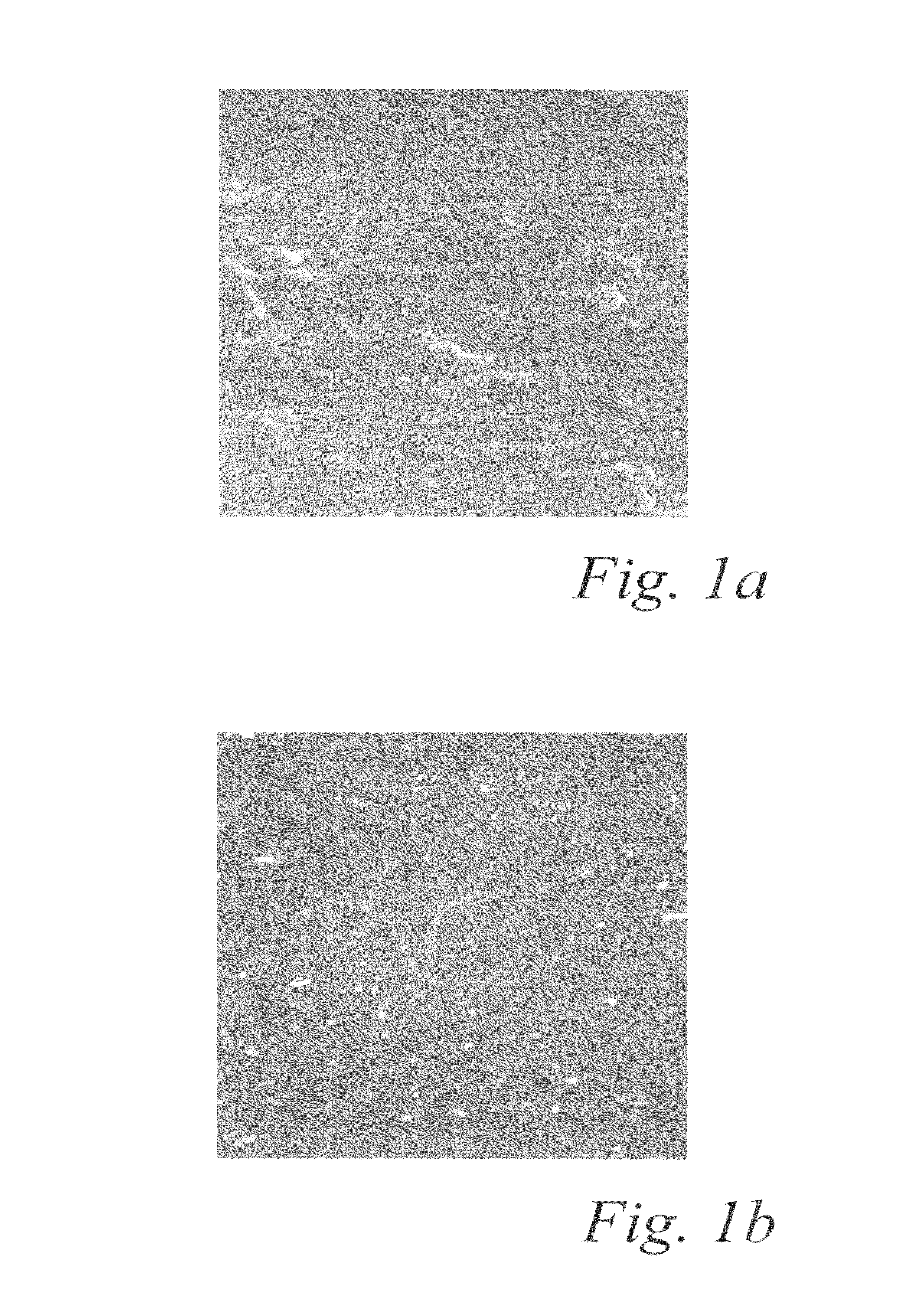

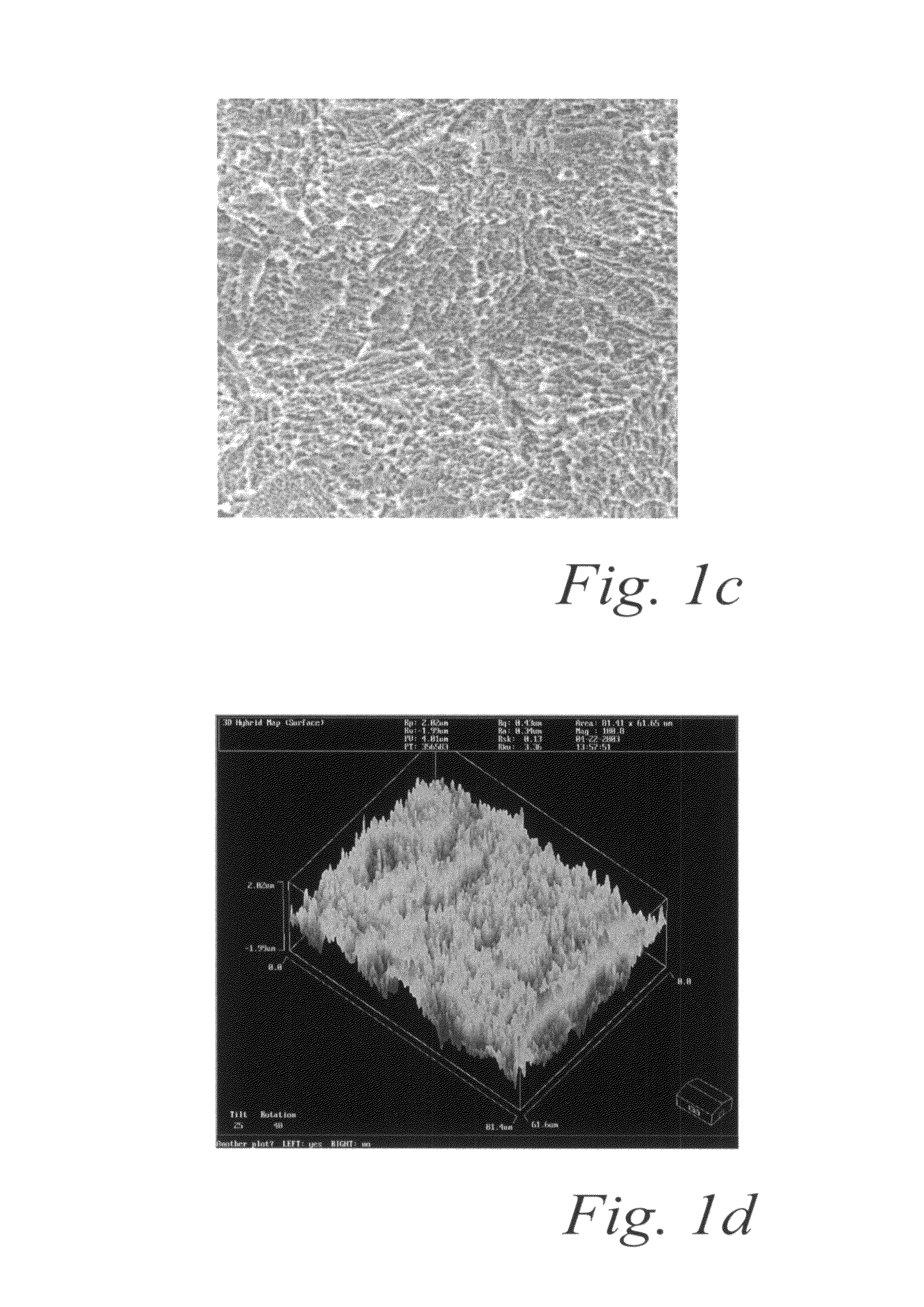

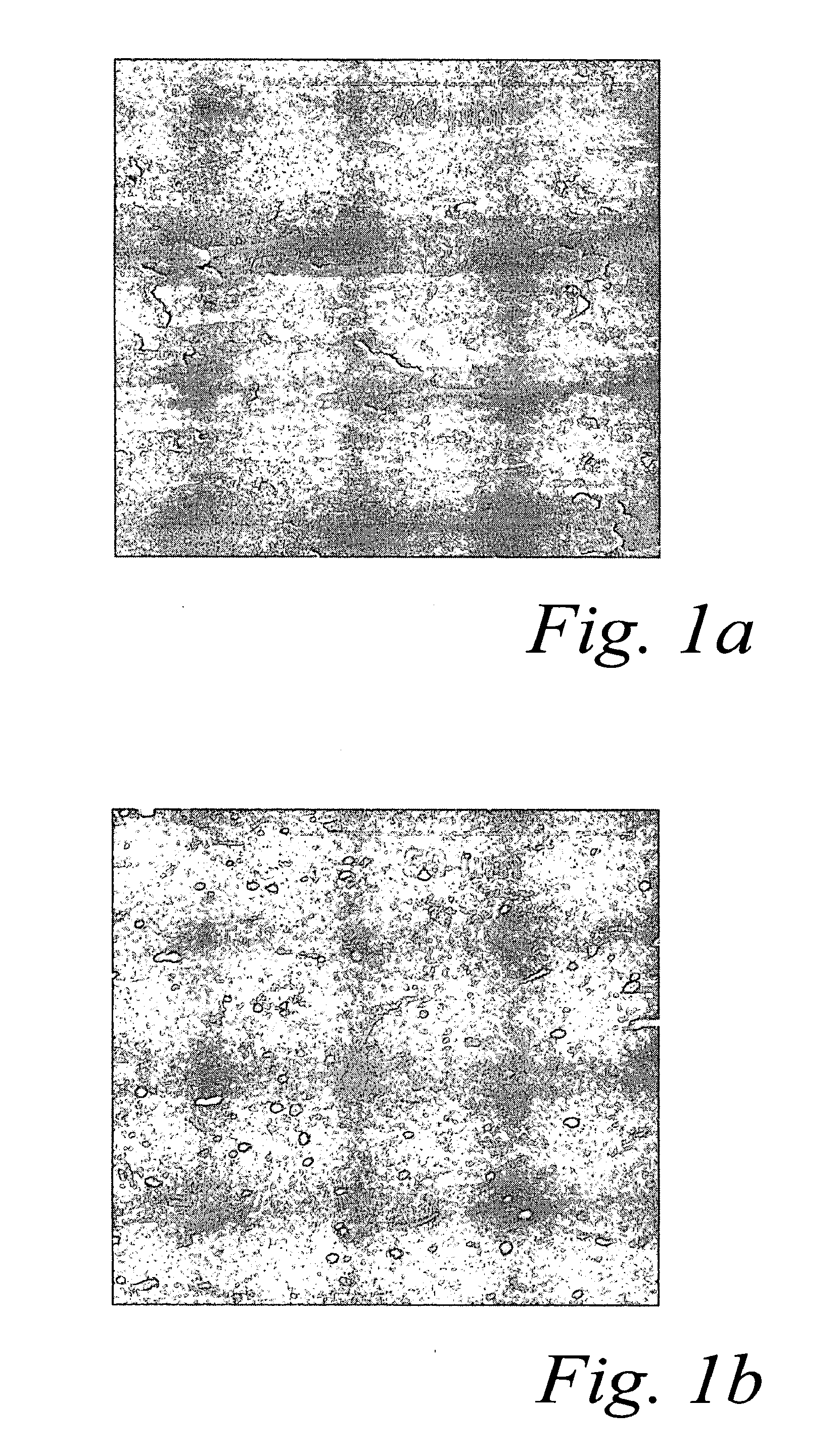

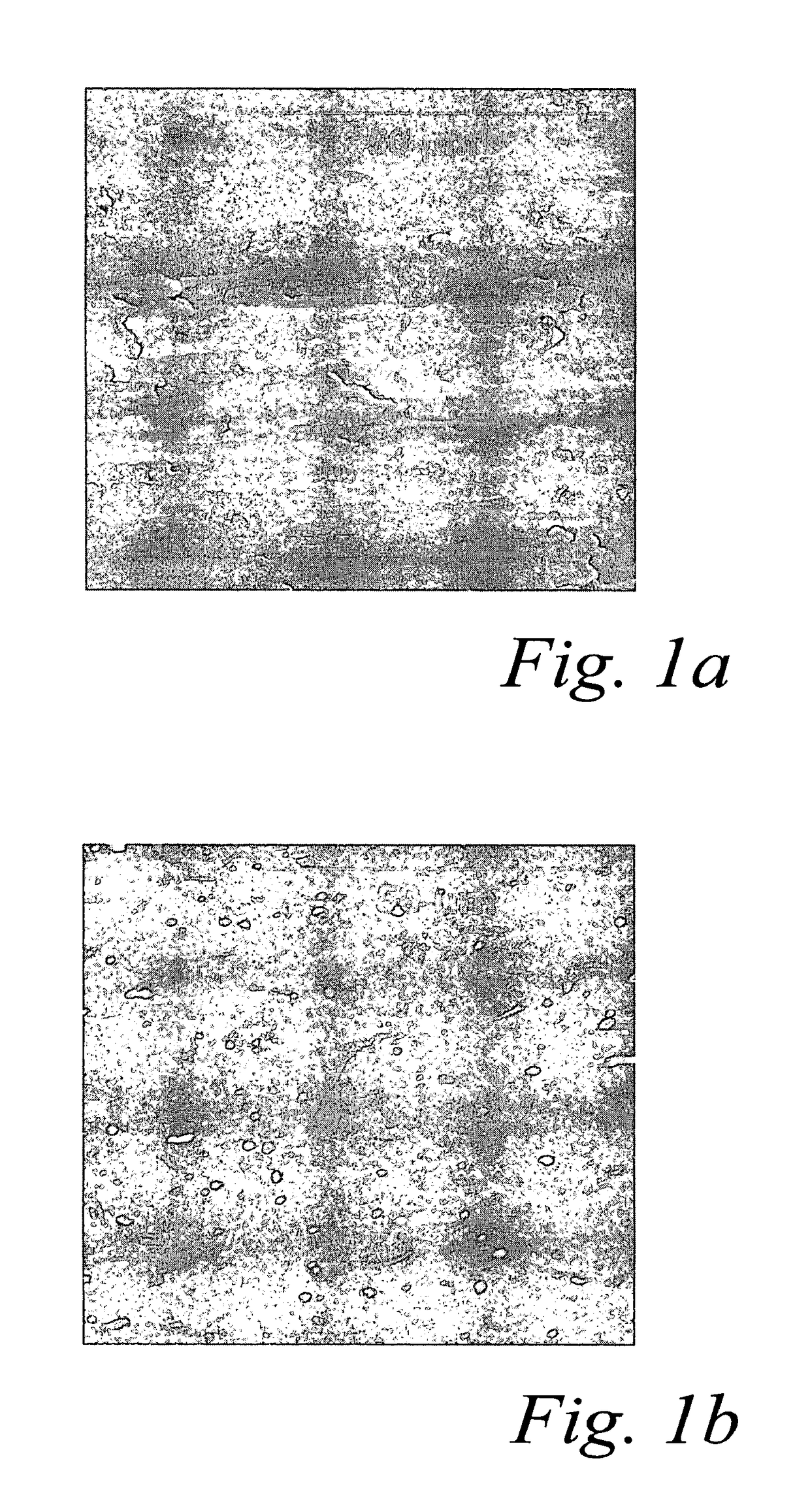

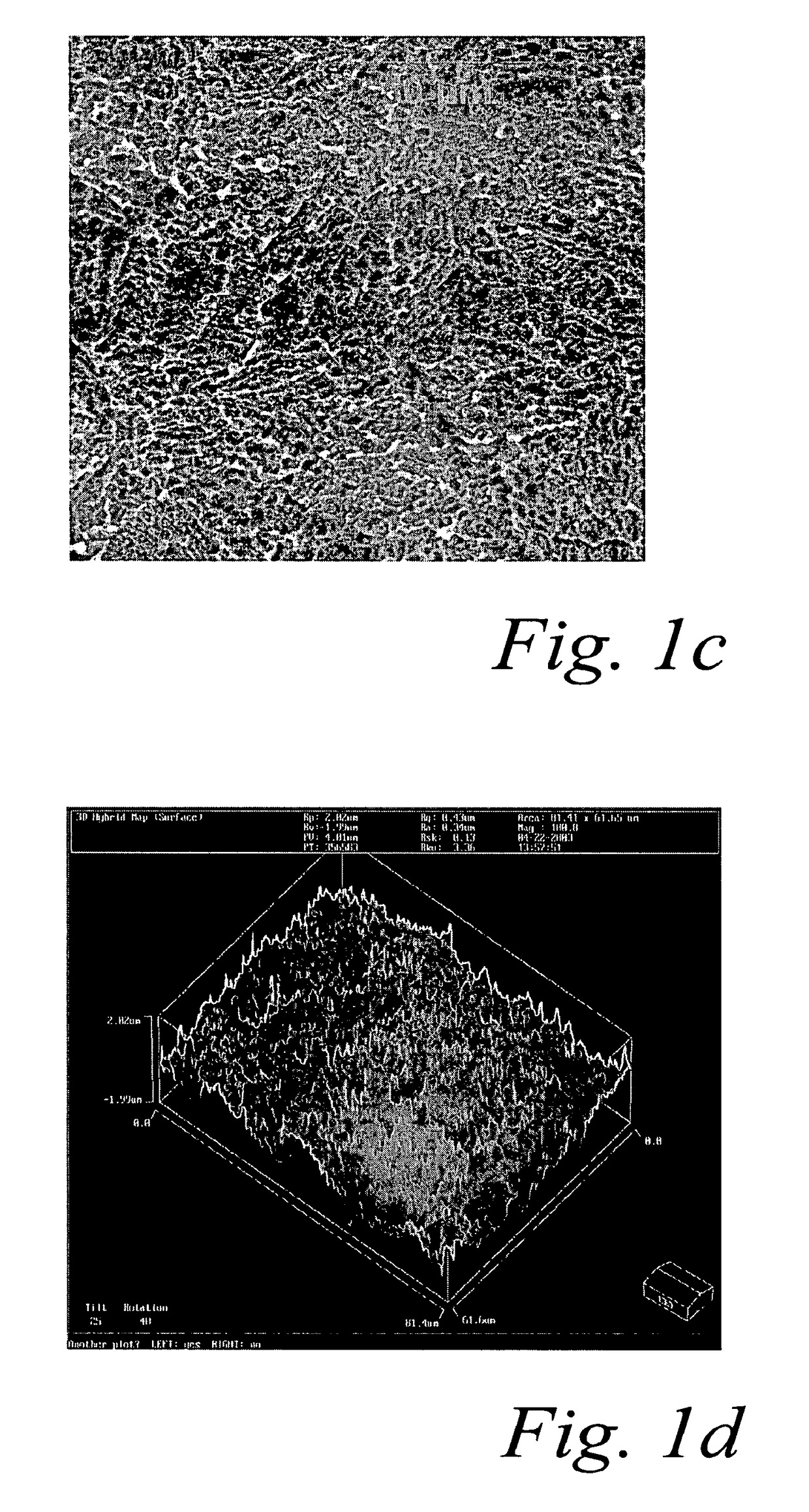

Surface treatment process for implants made of titanium alloy

ActiveUS8251700B2Reduce lossesDental implantsImpression capsHydrofluoric acidCommercially pure titanium

A titanium 6 A1 / 4V alloy is provided with a surface topography that is similar to the Osseotite® surface produced on commercially pure titanium. Native oxide is removed from the Ti 6A1 / 4V alloy, followed by contacting the metal at ambient temperature with an aqueous hydrochloric acid solution containing a relatively small amount of hydrofluoric acid.

Owner:BIOMET 3I LLC

Surface treatment process for implants made of titanium alloy

ActiveUS20120288828A1Reduce lossesDental implantsImpression capsCommercially pure titaniumTitanium alloy

A titanium 6 Al / 4V alloy is provided with a surface topography that is similar to the Osseotite® surface produced on commercially pure titanium. Native oxide is removed from the Ti 6Al / 4V alloy, followed by contacting the metal at ambient temperature with an aqueous hydrochloric acid solution containing a relatively small amount of hydrofluoric acid.

Owner:BIOMET 3I LLC

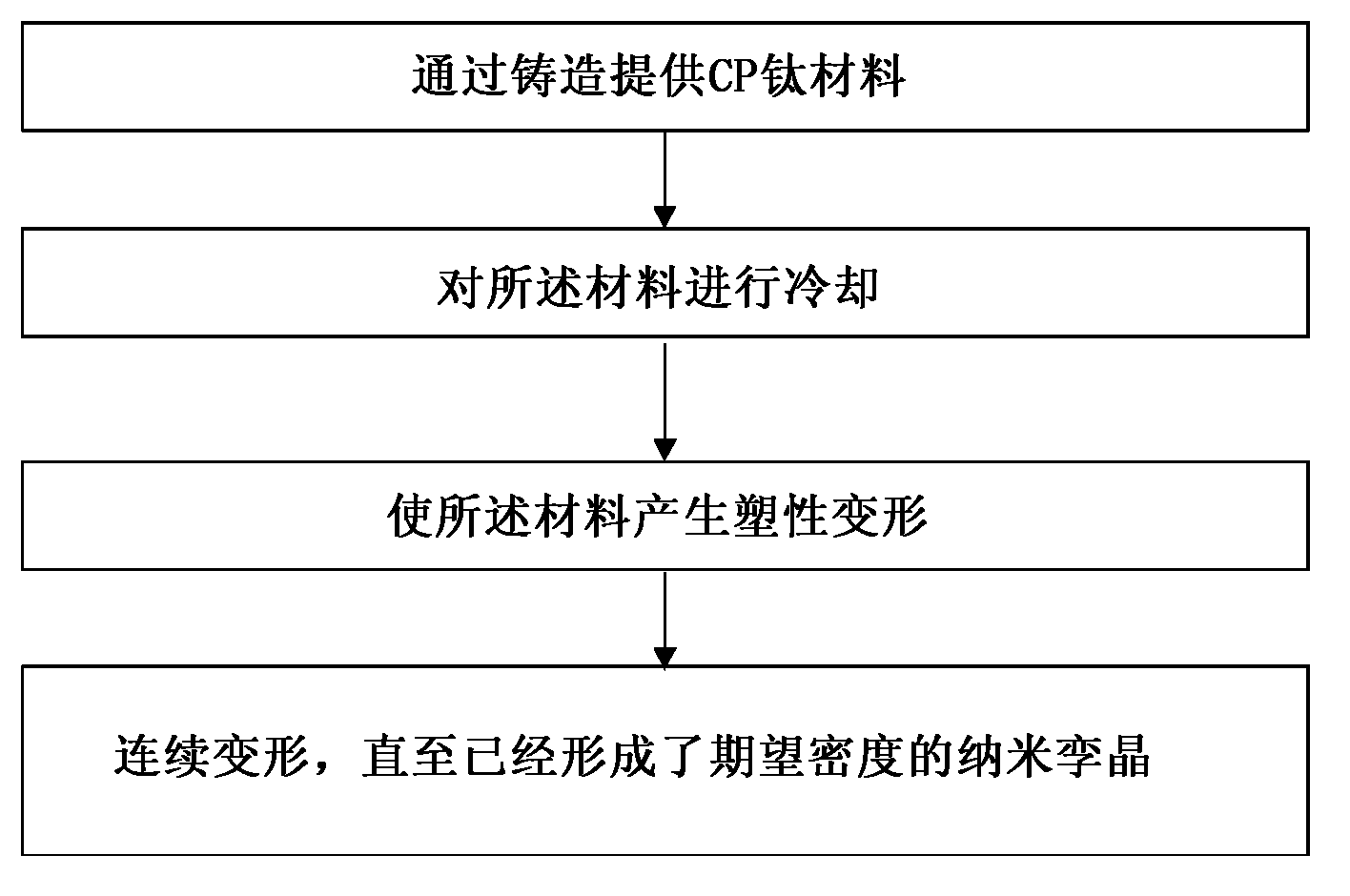

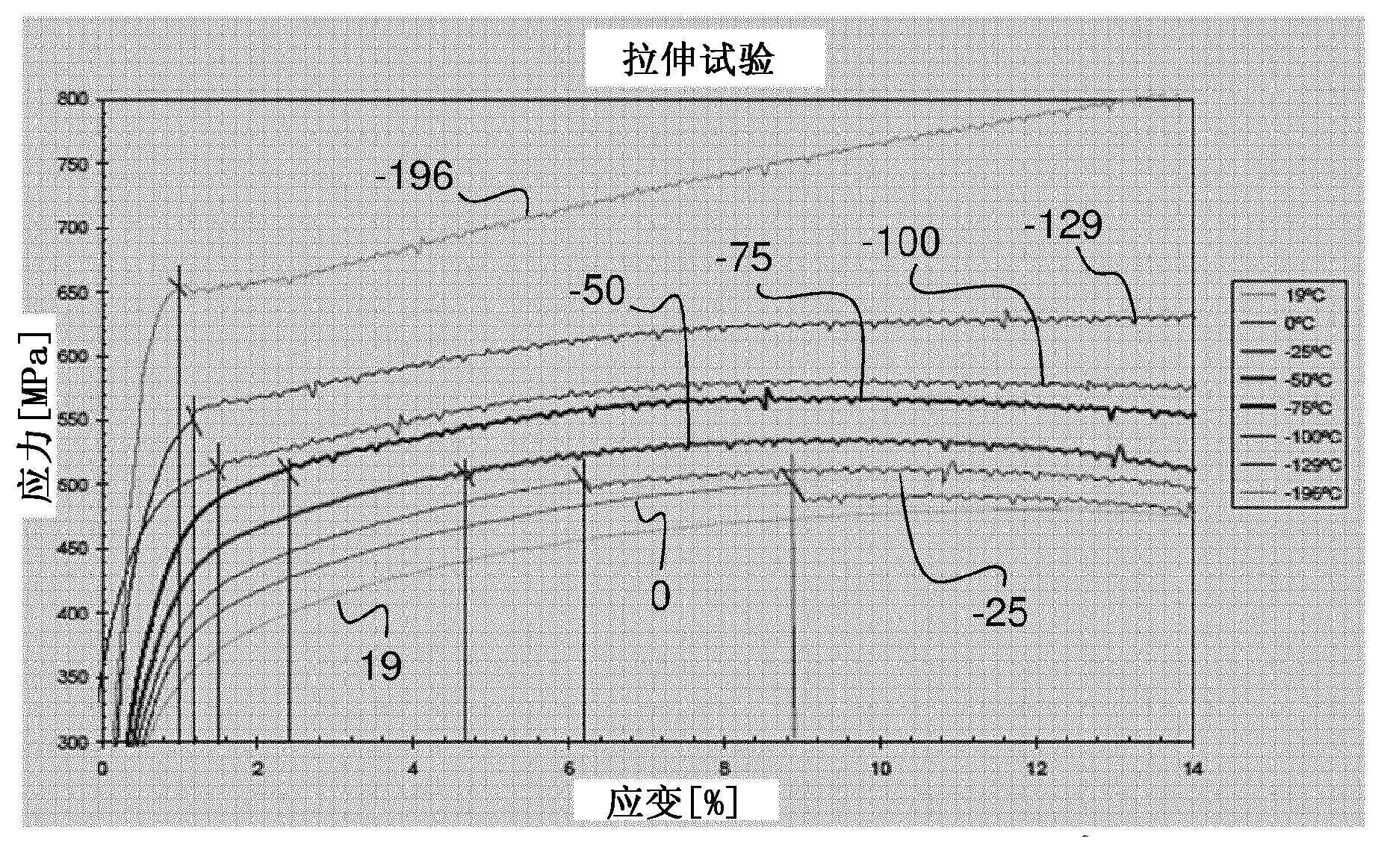

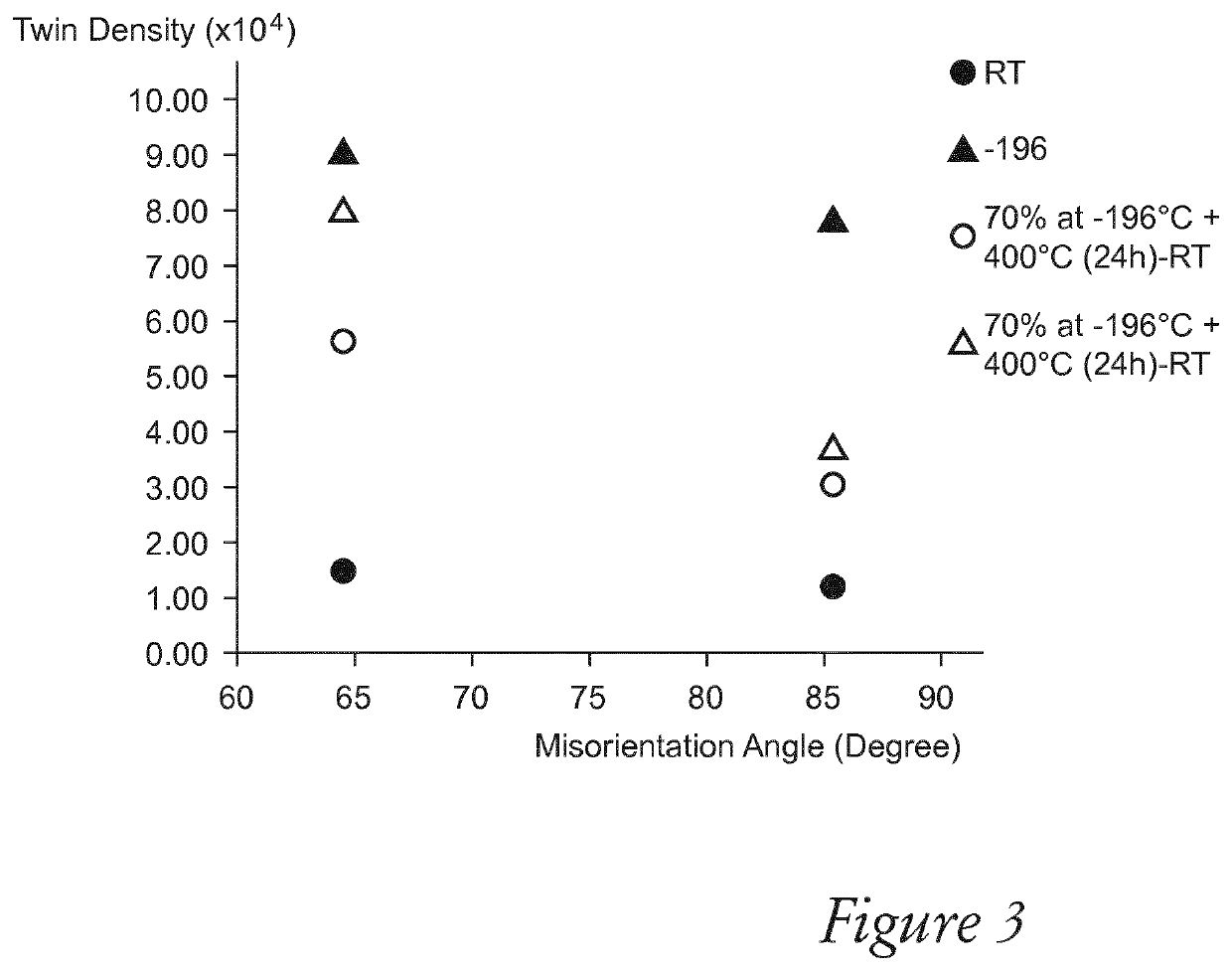

Method of producing a nano-winned titanium material by casting

The invention relates to a method of producing a nano twinned commercially pure titanium material comprising the steps of: - casting a commercially pure titanium material that apart from titanium contains not more than 0.05 wt% N, not more than 0.08 wt% C, not more than 0.015 wt% H, not more than 0.50 wt% Fe, not more than 0.40 wt% O, and not more than 0.40 wt% residuals, - bringing the material to a temperature at or below 0 DEG C, and - imparting plastic deformation to the material at that temperature to such a degree that nano twins are formed in the material.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Preparation method of titanium modified layer on surface of magnesium and lithium alloy

InactiveCN102345103AVacuum evaporation coatingSputtering coatingHigh pressureCommercially pure titanium

The invention discloses a preparation method of a titanium modified layer on the surface of a magnesium and lithium alloy, and relates to a preparation method of an alloy titanium modified layer. The invention aims to solve the technical problem of poor corrosion resistance of the traditional magnesium and lithium alloy. The preparation method comprises the steps of: firstly, grinding the surface of the magnesium and lithium alloy by waterproof abrasive paper, then polishing, ultrasonically cleaning in acetone (analytically pure), ultrasonically cleaning in absolute ethyl alcohol, and drying; and secondly, placing a sample table in a vacuum chamber and connecting to the high-voltage pulse output end of a high-voltage pulse power supply, using a commercially pure titanium target as a magnetic control sputtering target material and connecting to the high-power pulse output end of a magnetic control sputtering power supply, then vacuumizing in the vacuum chamber, introducing high-purity argon when the vacuum degree is 4.0*10<-3>Pa, starting the high-voltage pulse power supply, then starting the magnetic control sputtering power supply, building in luminance and pre-ionizing through direct current, regulating working parameters, and carrying out ion injection and deposition, thereby obtaining the titanium modified layer on the surface of the magnesium and lithium alloy. According to the method disclosed by the invention, the titanium layer is formed on the surface of the magnesium alloy, and the surface hardness of the magnesium alloy is improved by about 40%.

Owner:JIAMUSI UNIVERSITY

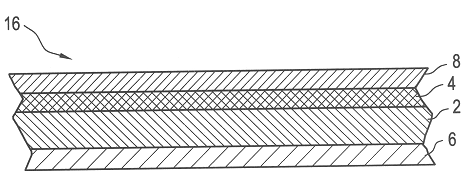

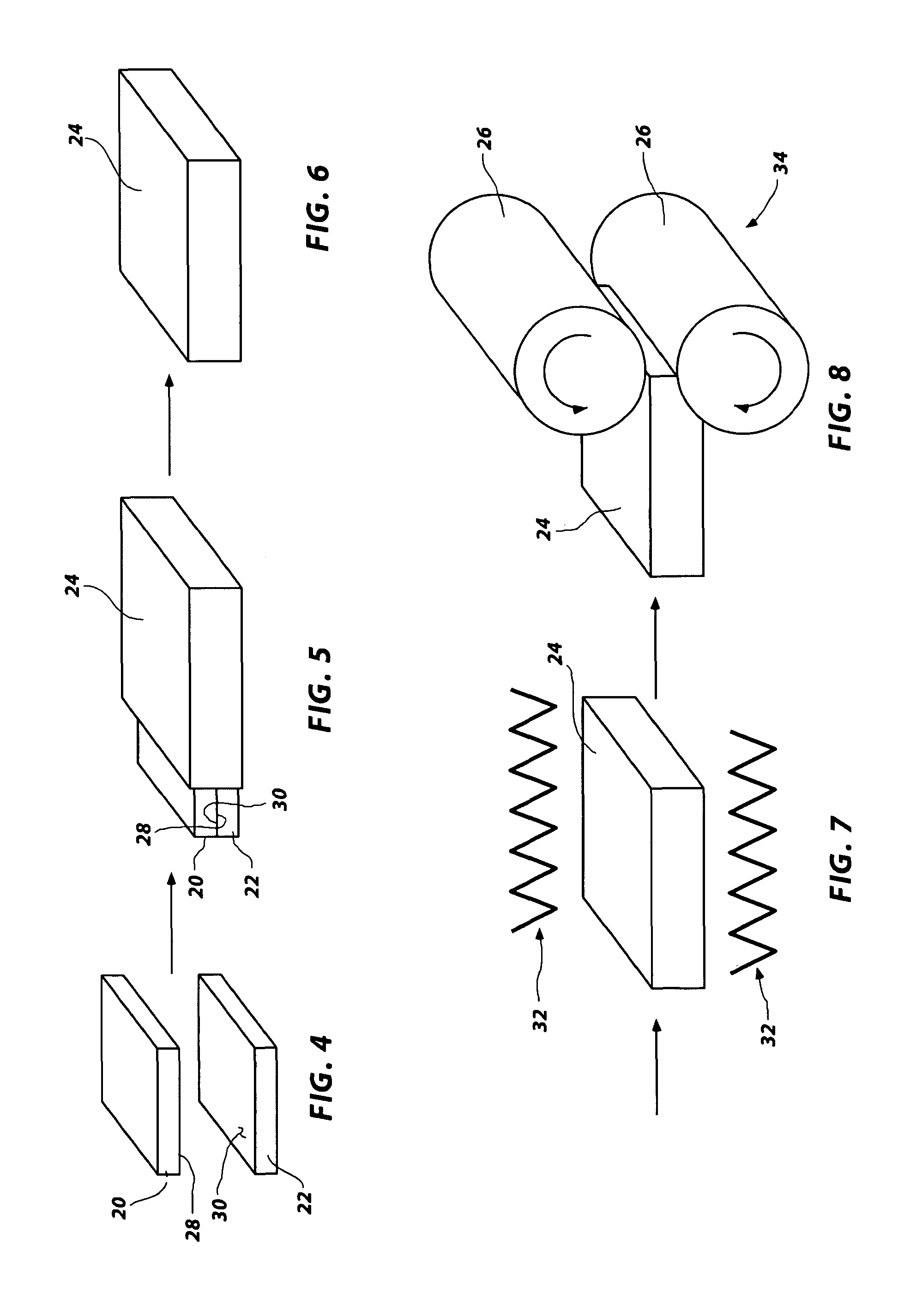

Method of making clad materials using lead alloys and composite strips made by such method

InactiveUS6475675B1Yield strength is minimizedDifference in physical propertyElectrode carriers/collectorsBearing componentsAlloyCommercially pure titanium

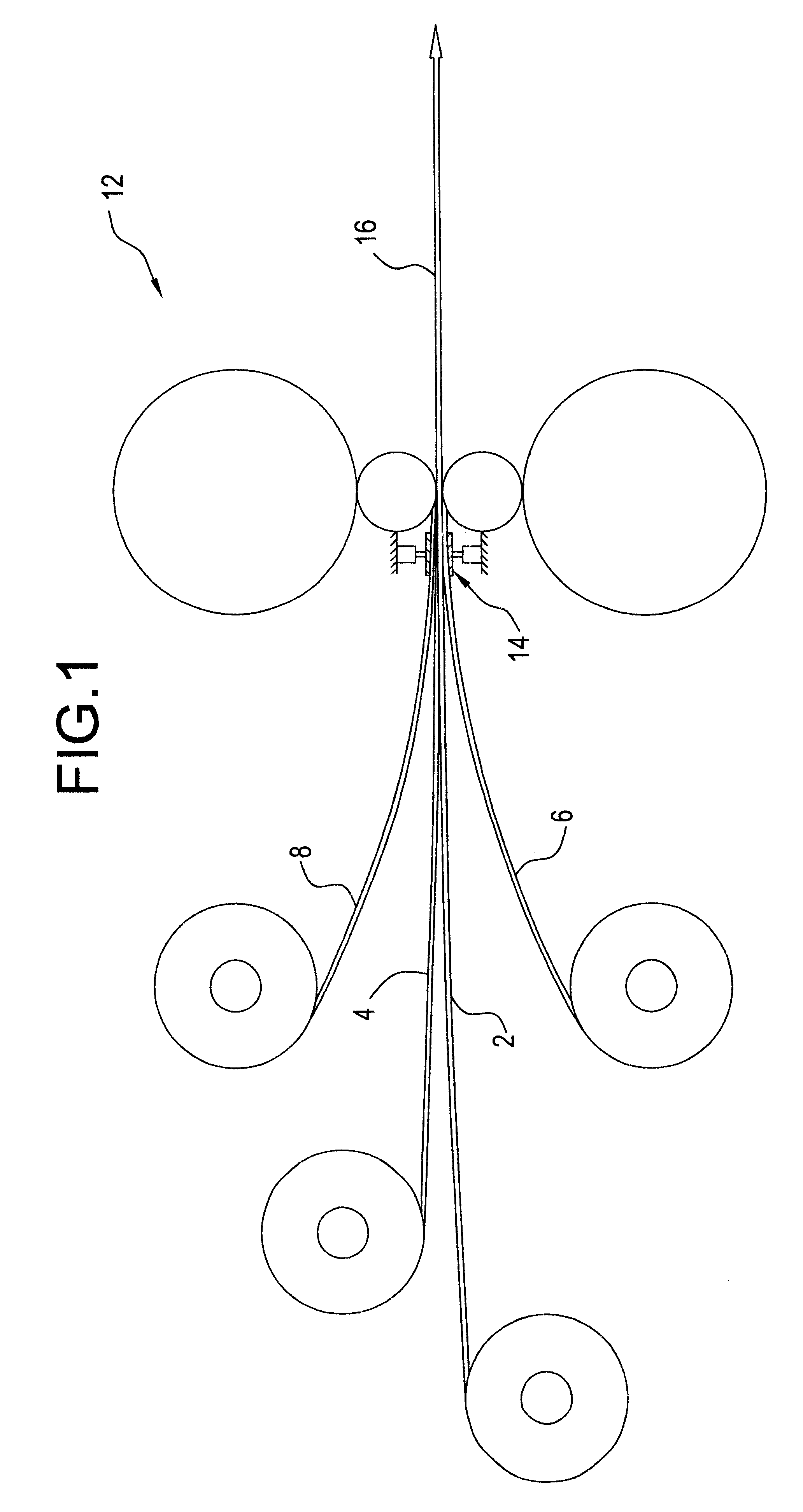

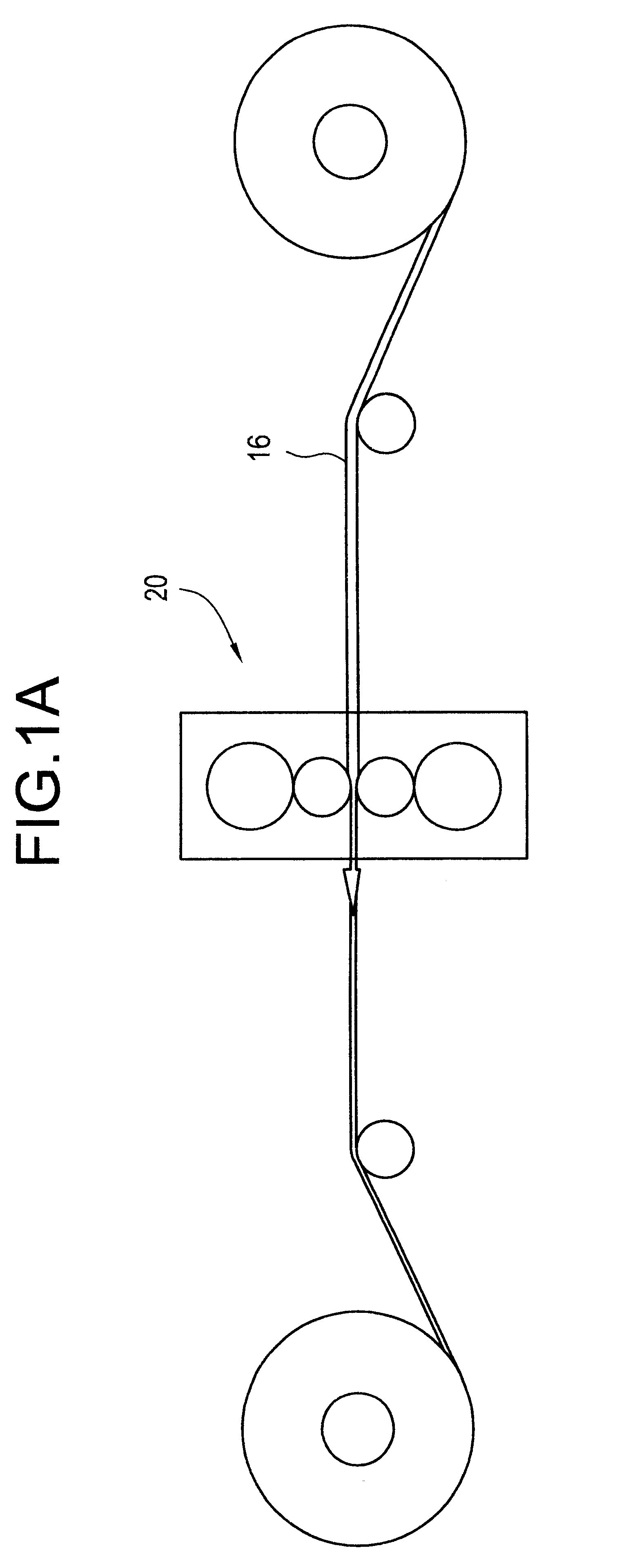

Lead alloy strip material (4, 6, 8) is roll bonded on one or both opposite face surfaces of a core strip material (2). The core material can be commercially pure titanium, austenitic stainless steel, low carbon steel, copper, aluminum, alloys thereof or other suitable metal that has sufficient ductility and that can provide desired attributes of stiffness and corrosion resistance to the composite. The lead alloy material is strengthened by the addition of less than approximately 1% of calcium or antimony and the core material is softened by fully annealing it prior to bonding. The several strips are reduced in thickness, preferably in approximately the same proportion, by at least 40% in the bonding pass to create a solid phase bond among the strips. The bonded composite is then rolled to final gauge and, for selected applications, is corrugated and cut to form panels (20, 22, 24) and etched to form pockets (8b) for pasting of active materials such as lead oxide for battery plates.

Owner:EMS ENGINEERED MATERIALS SOLUTIONS LLC

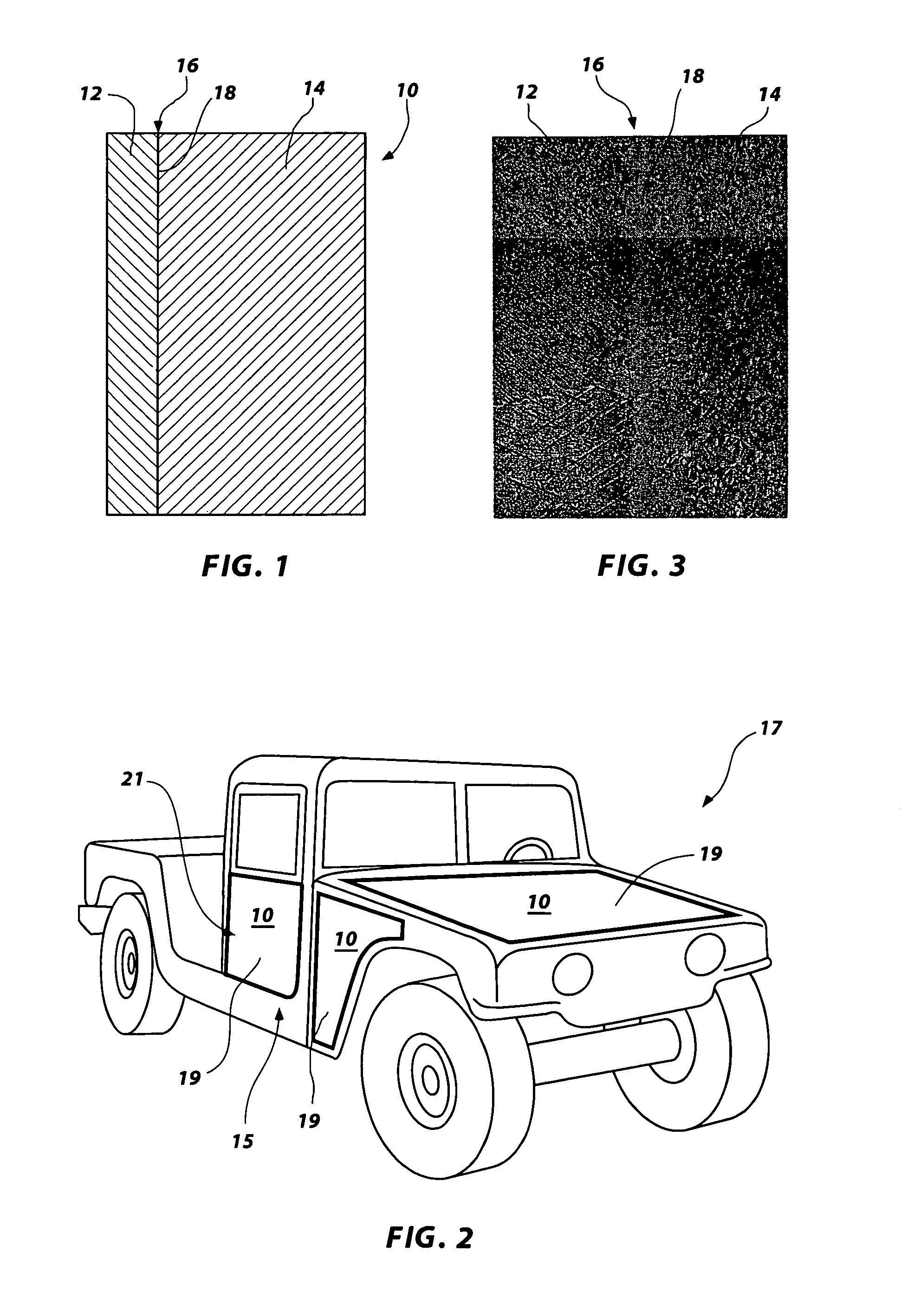

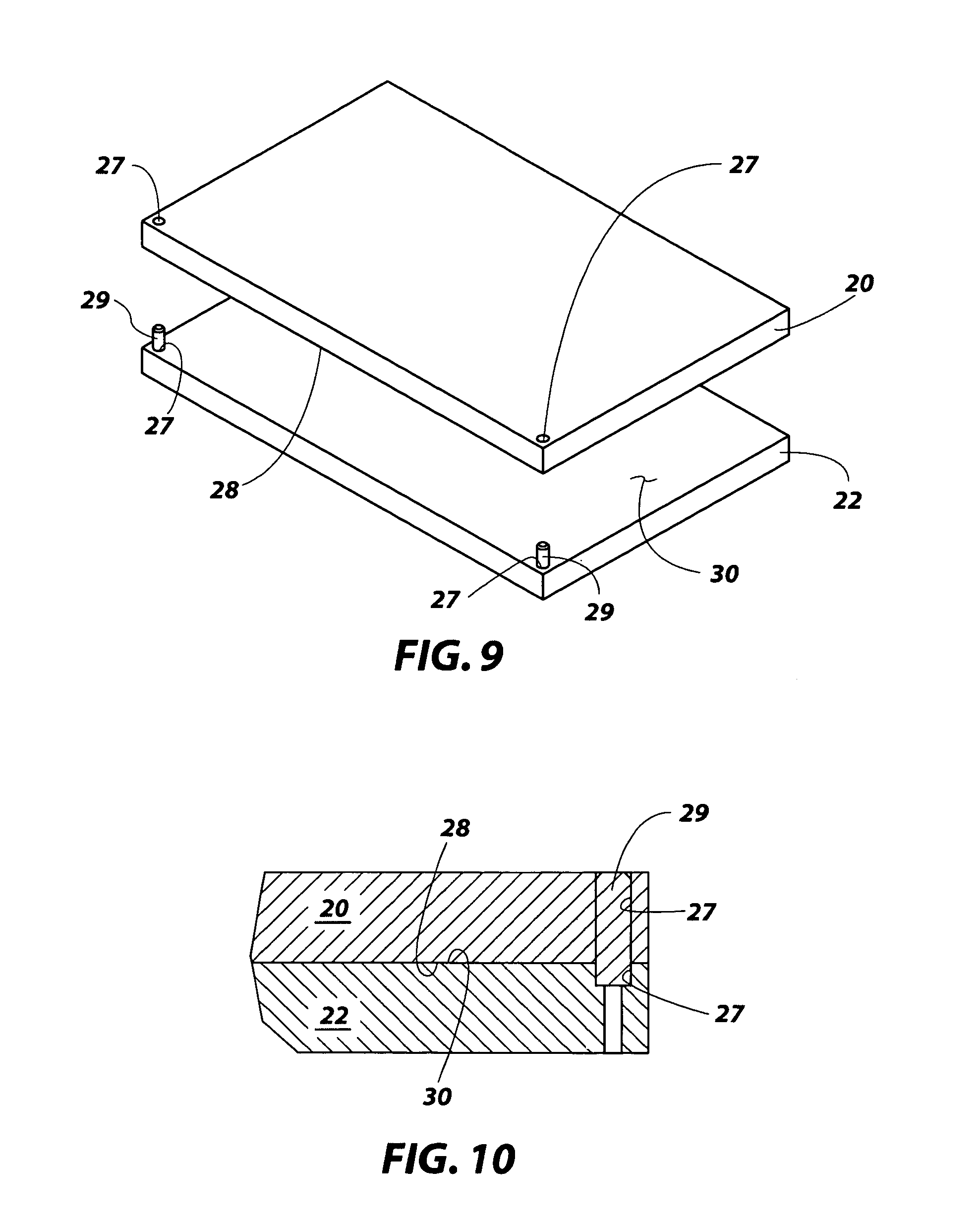

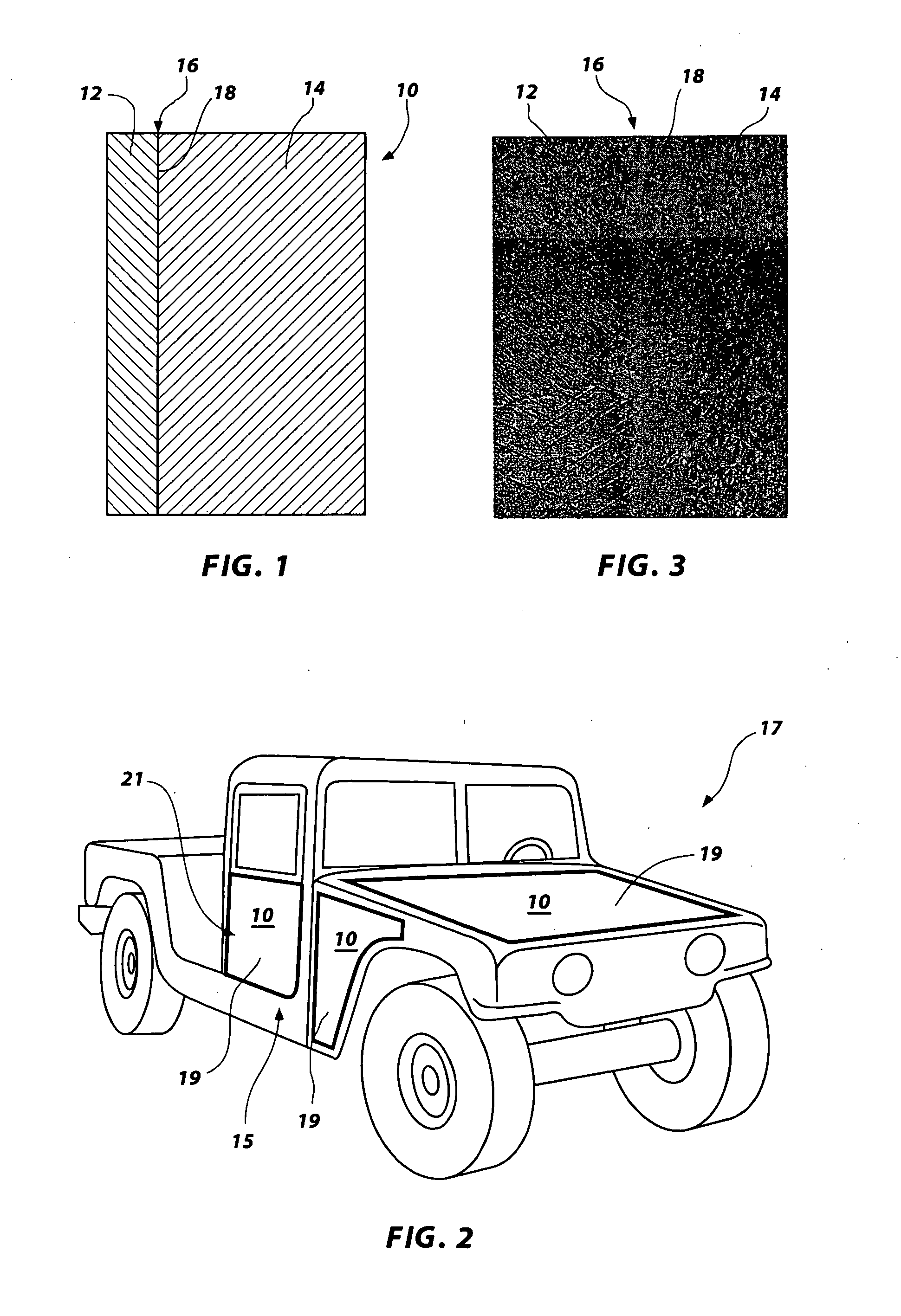

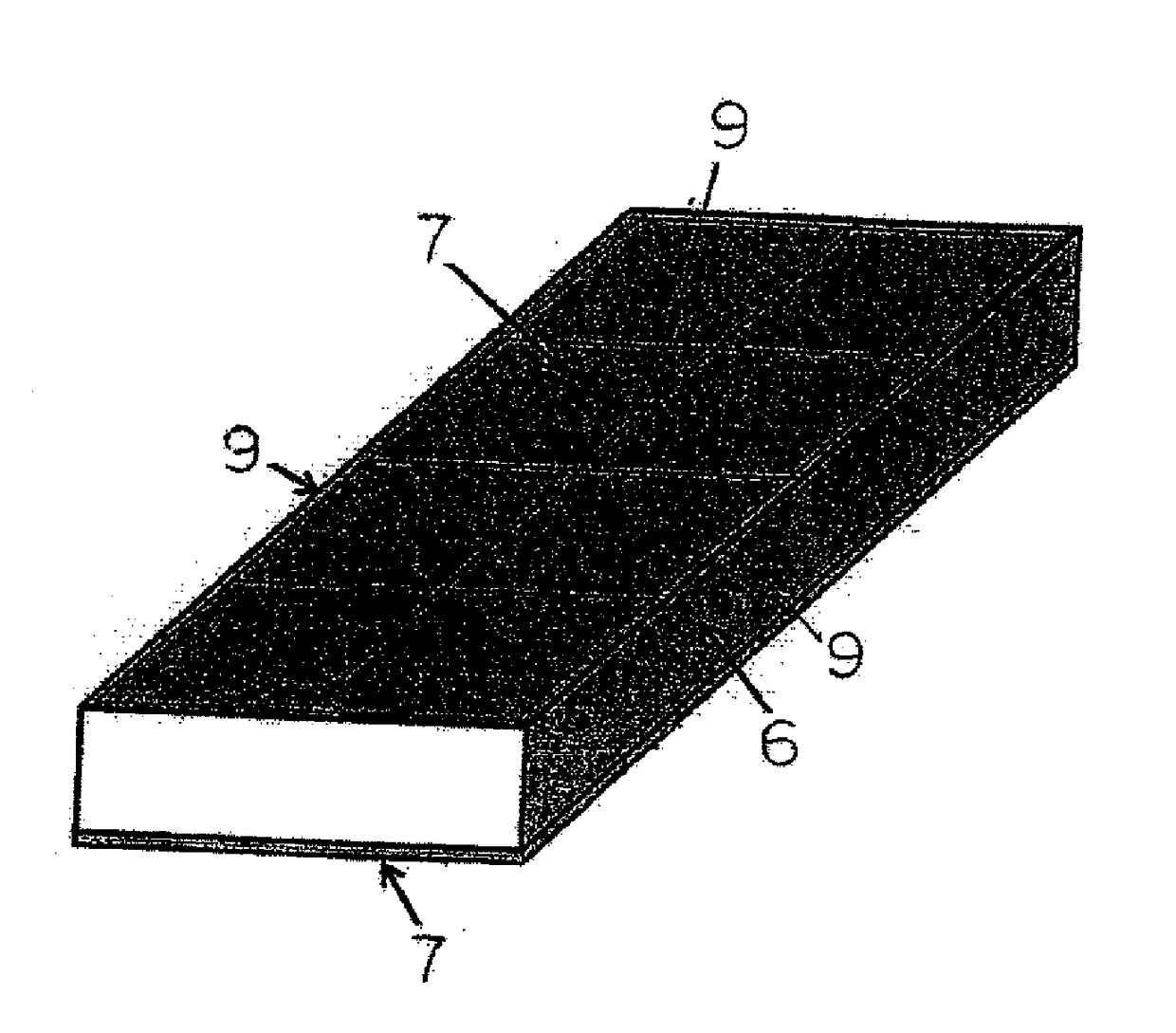

Laminate armor and related methods

InactiveUS8381631B2Electron beam welding apparatusWelding/cutting media/materialsCommercially pure titaniumTitanium alloy

Owner:BATTELLE ENERGY ALLIANCE LLC

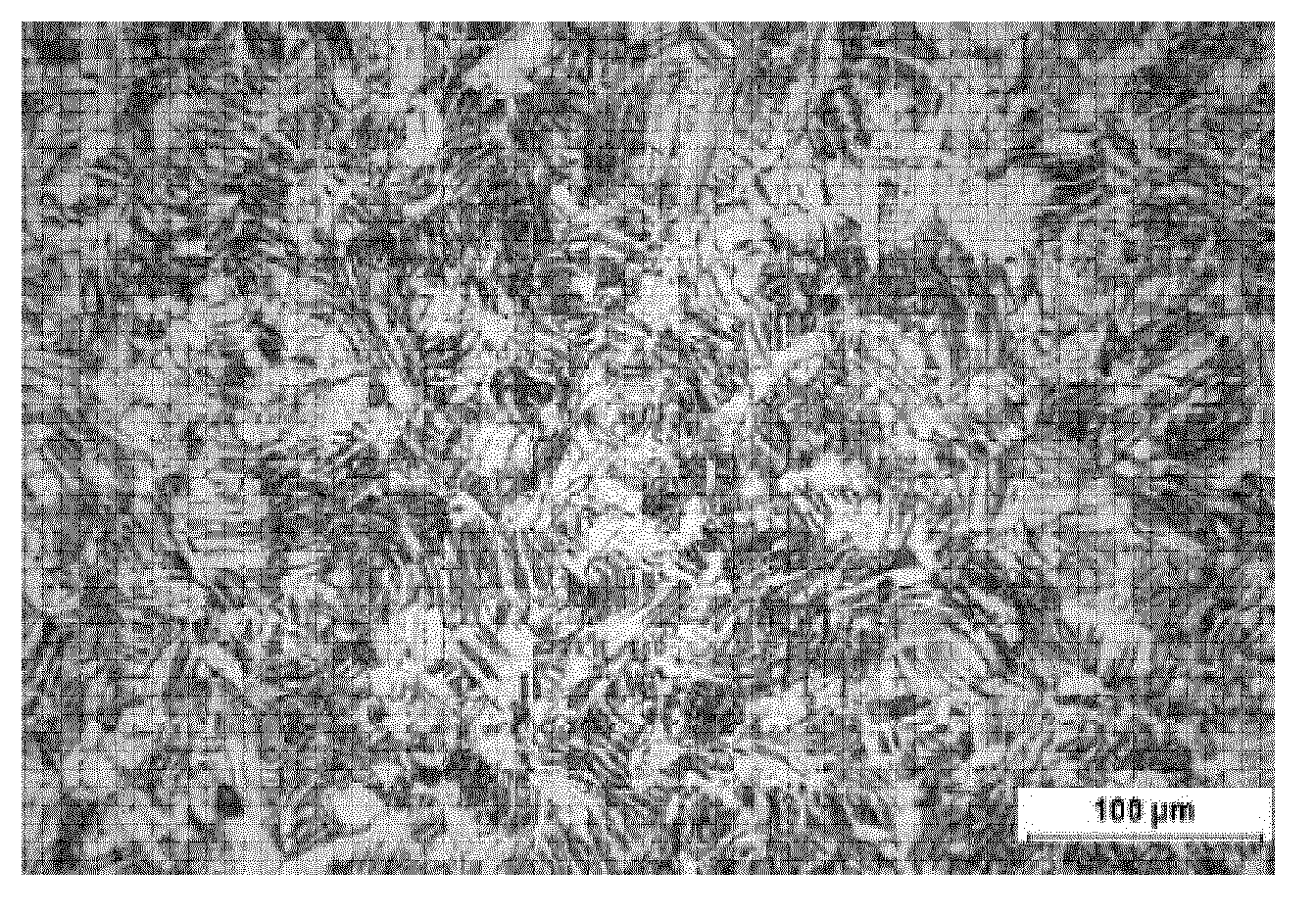

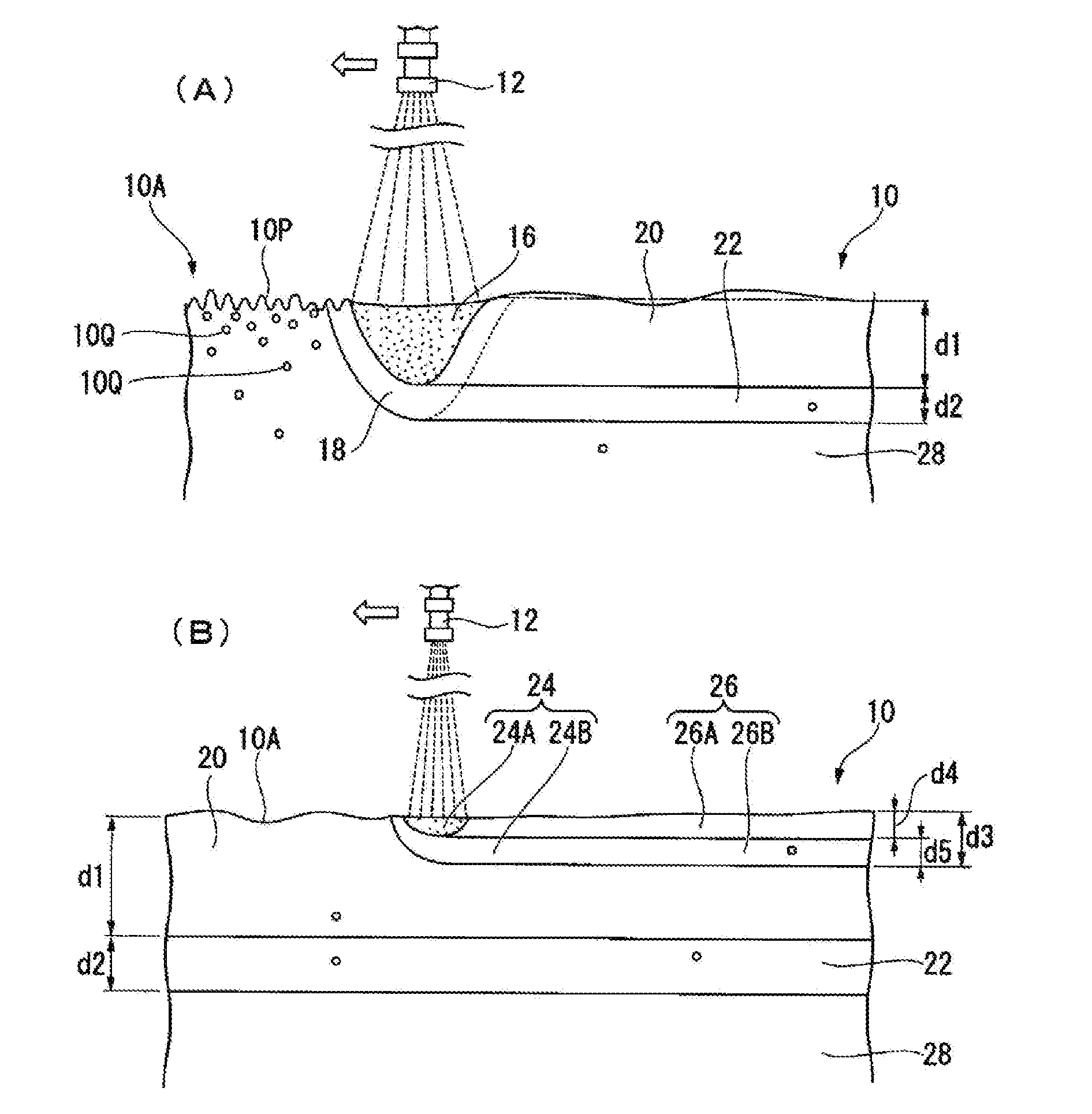

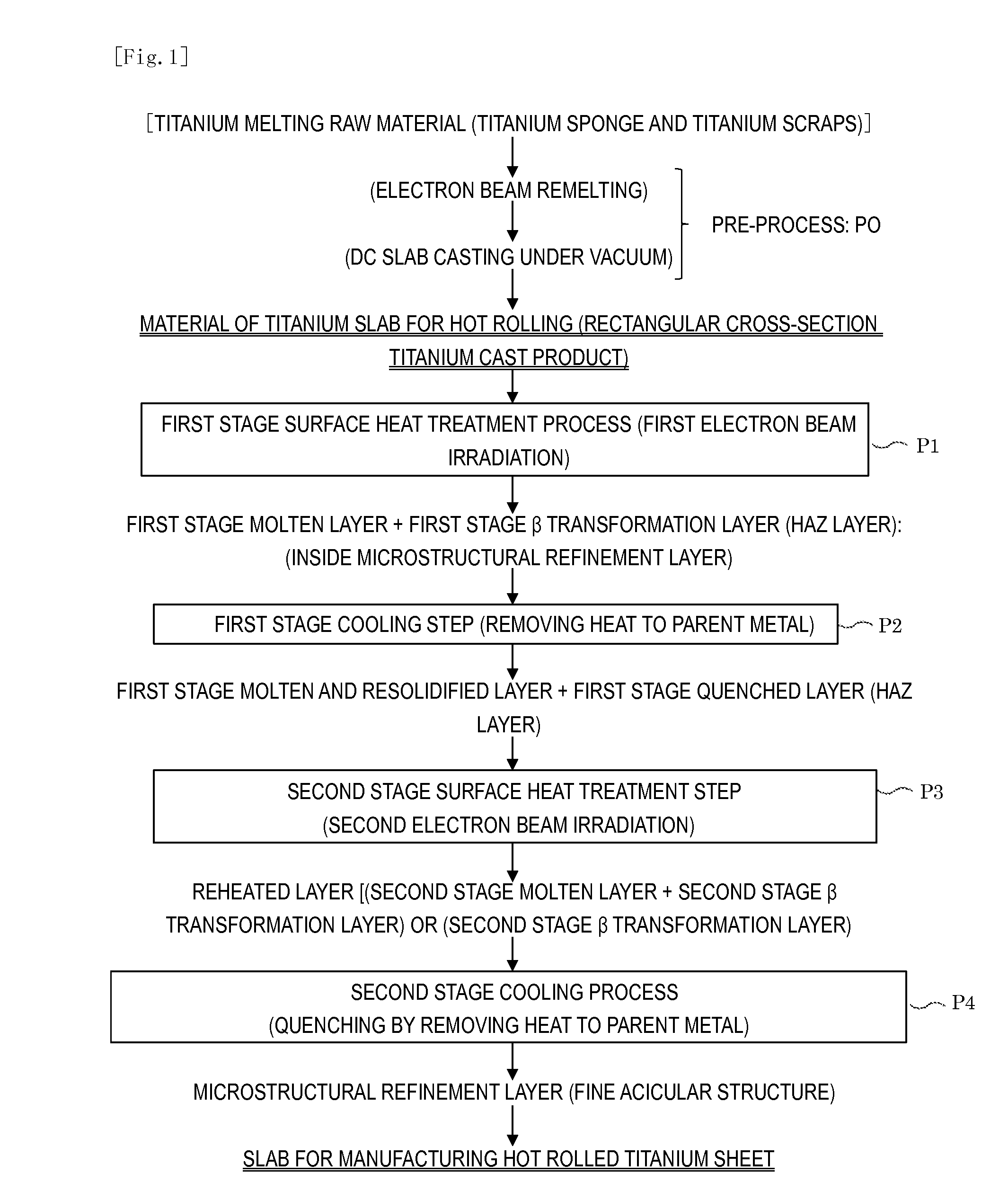

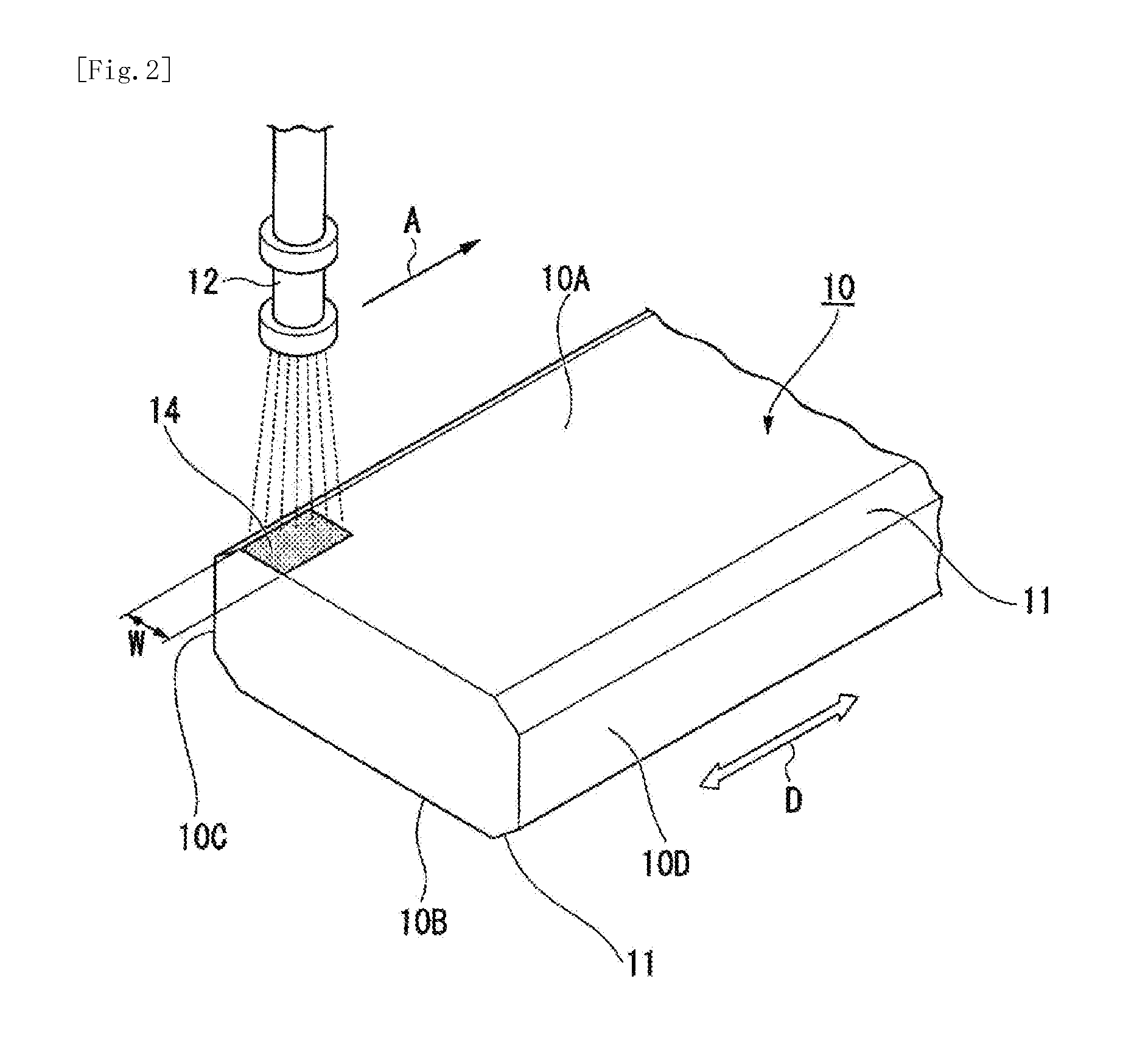

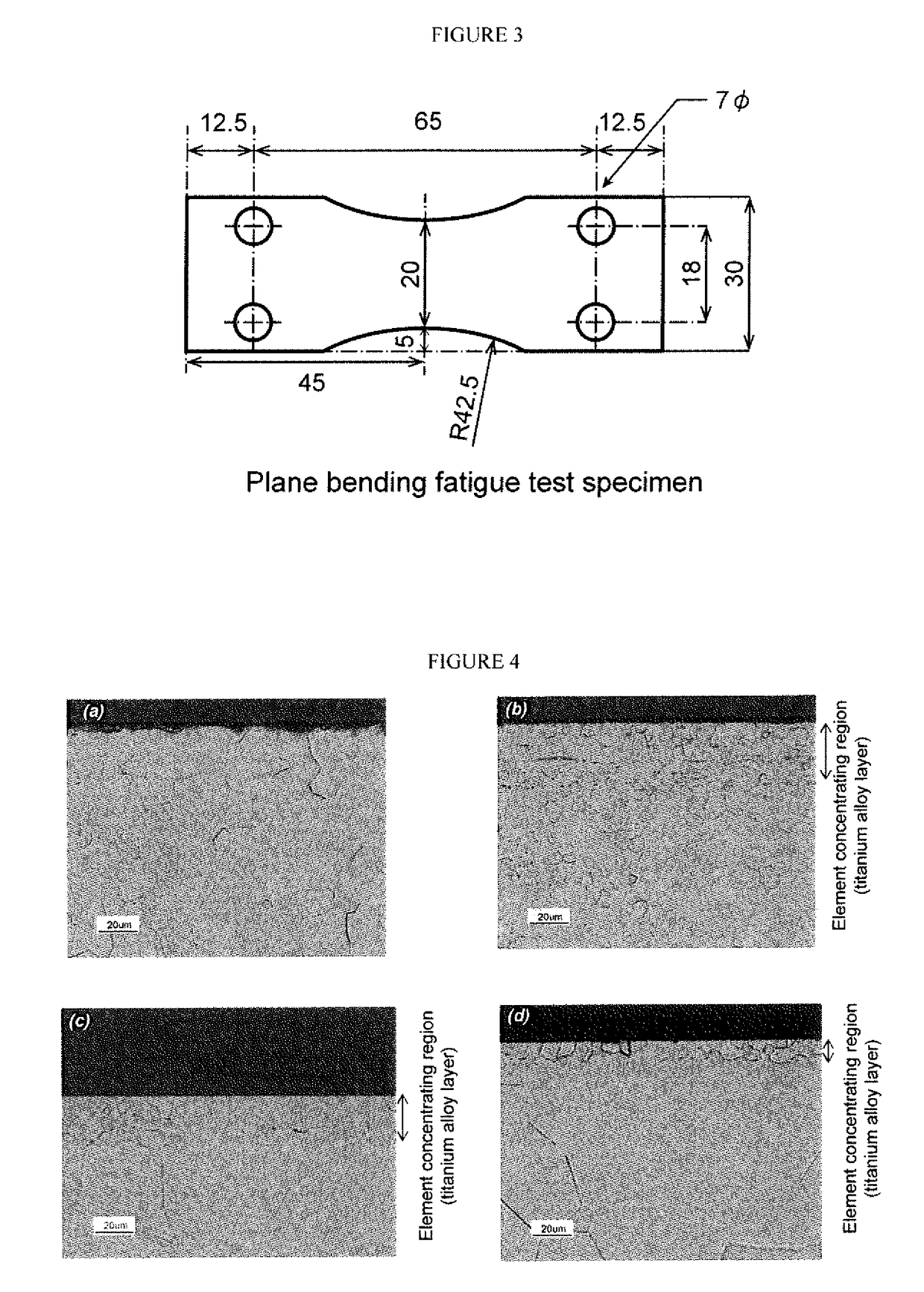

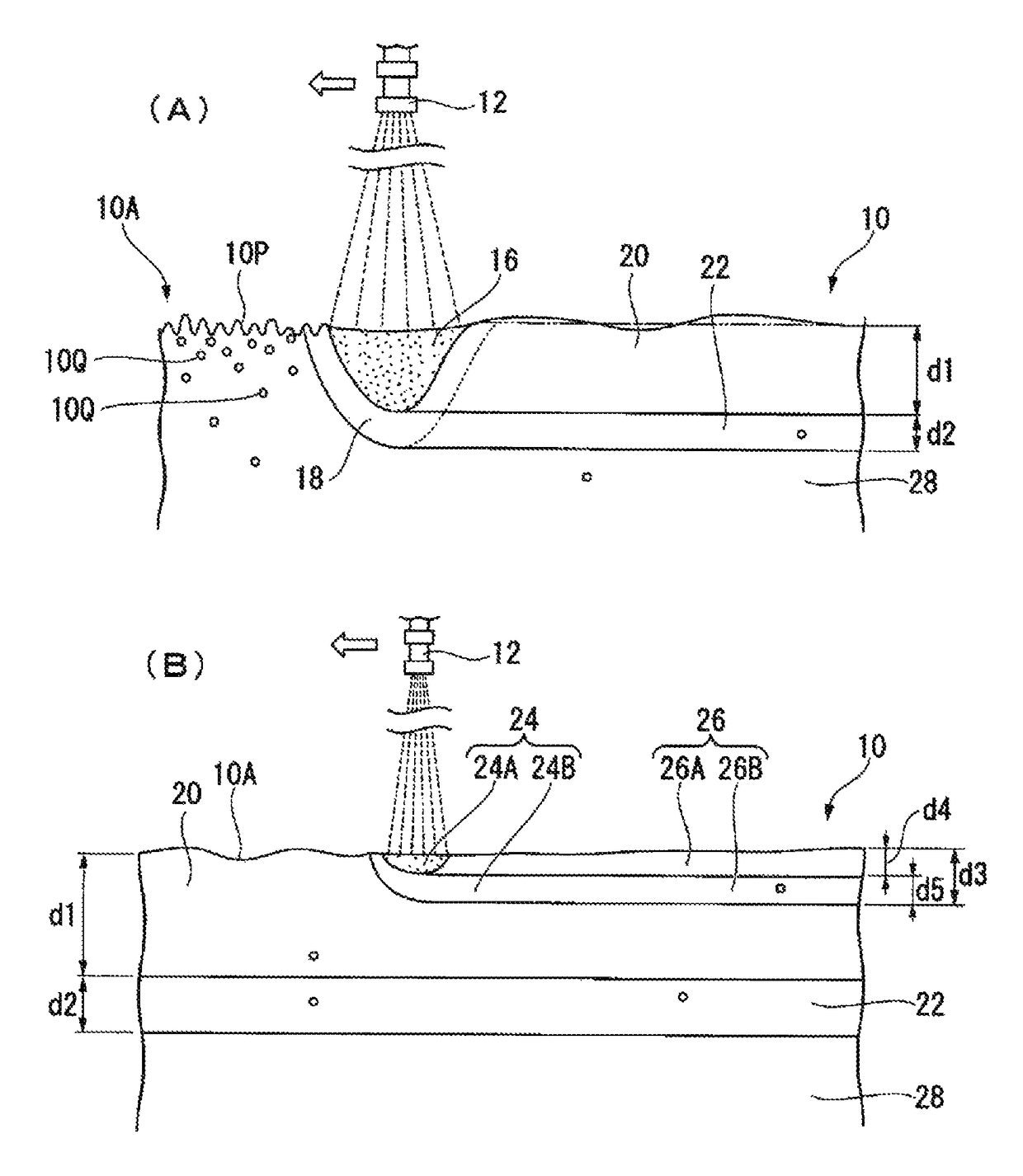

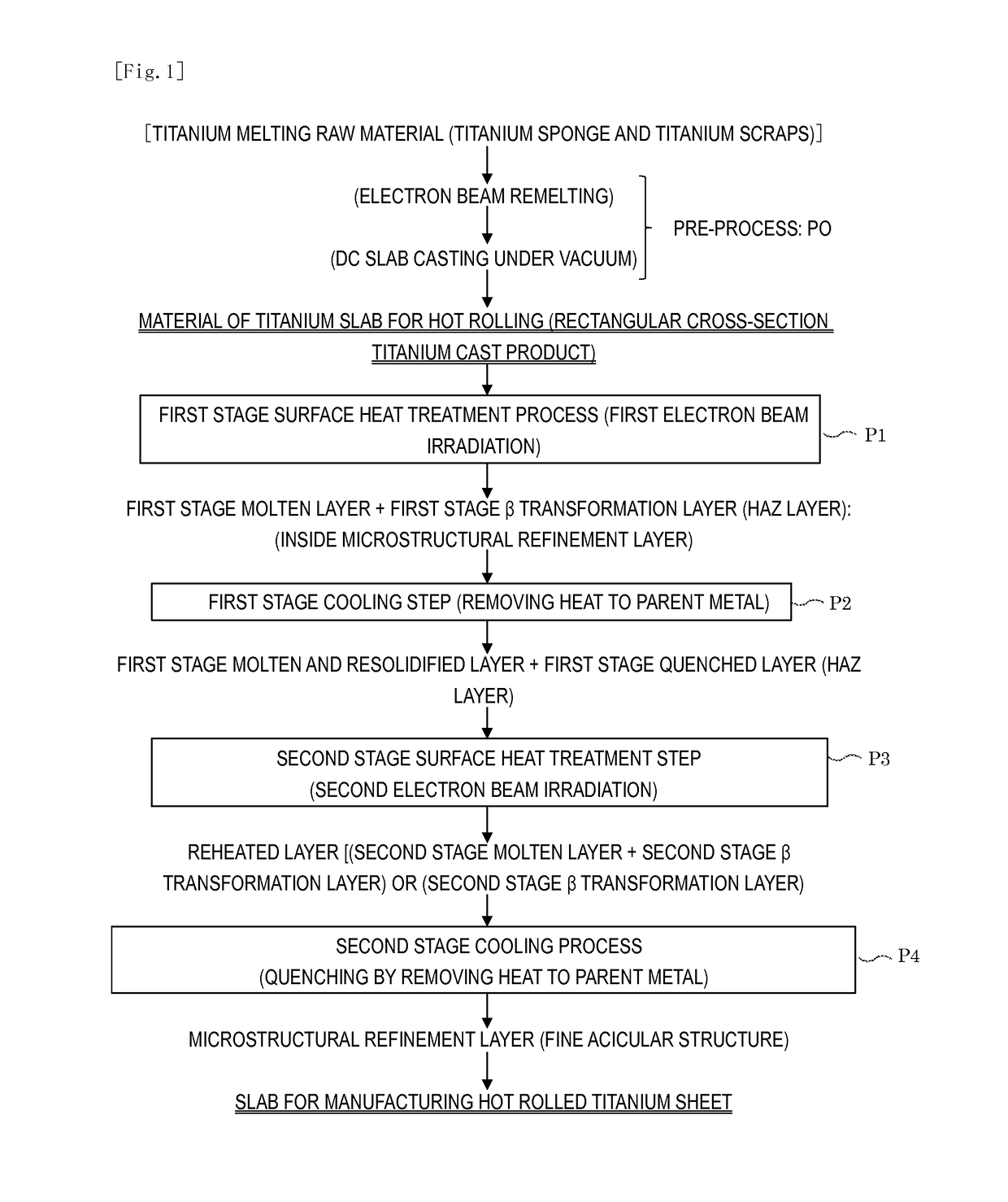

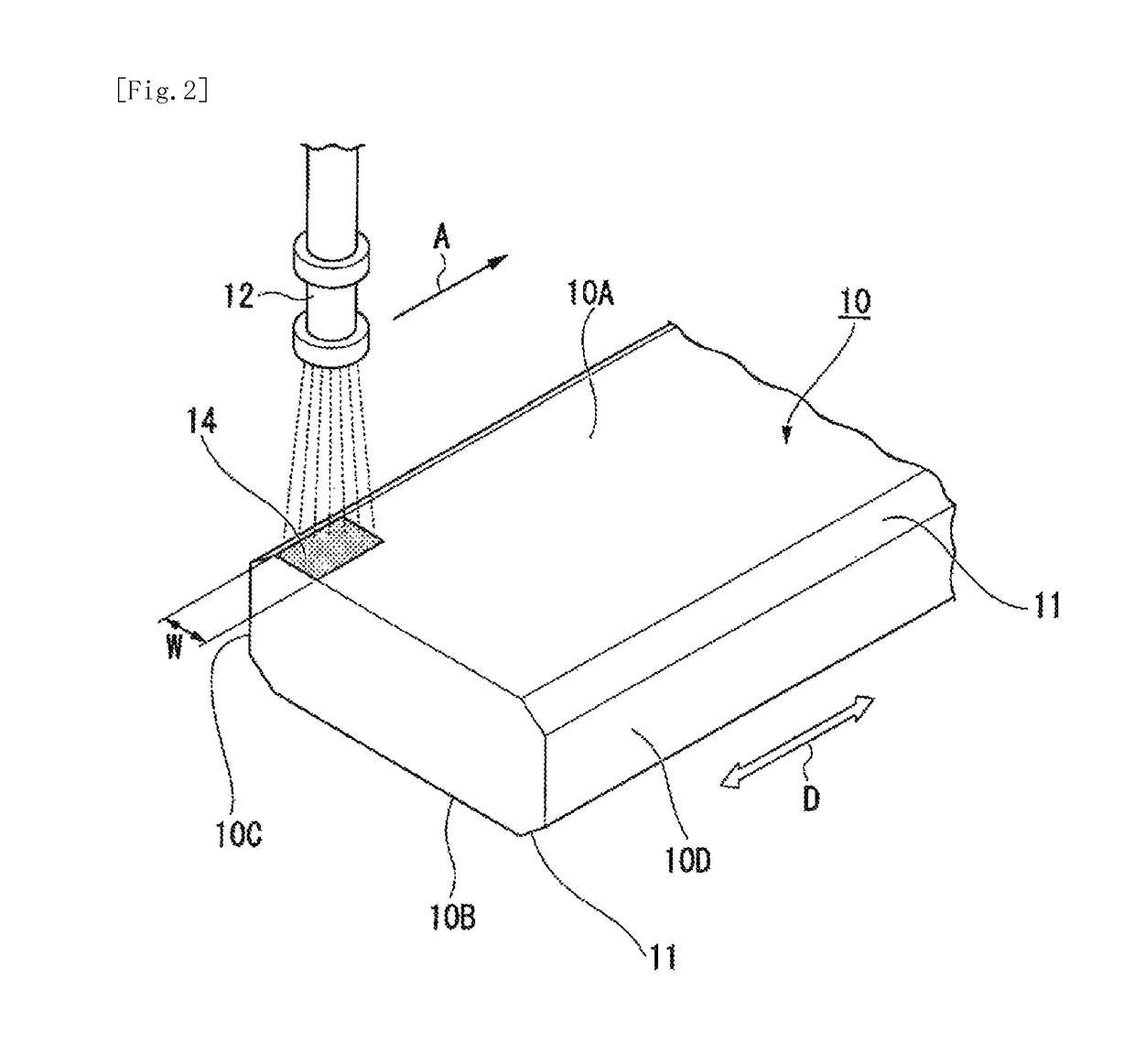

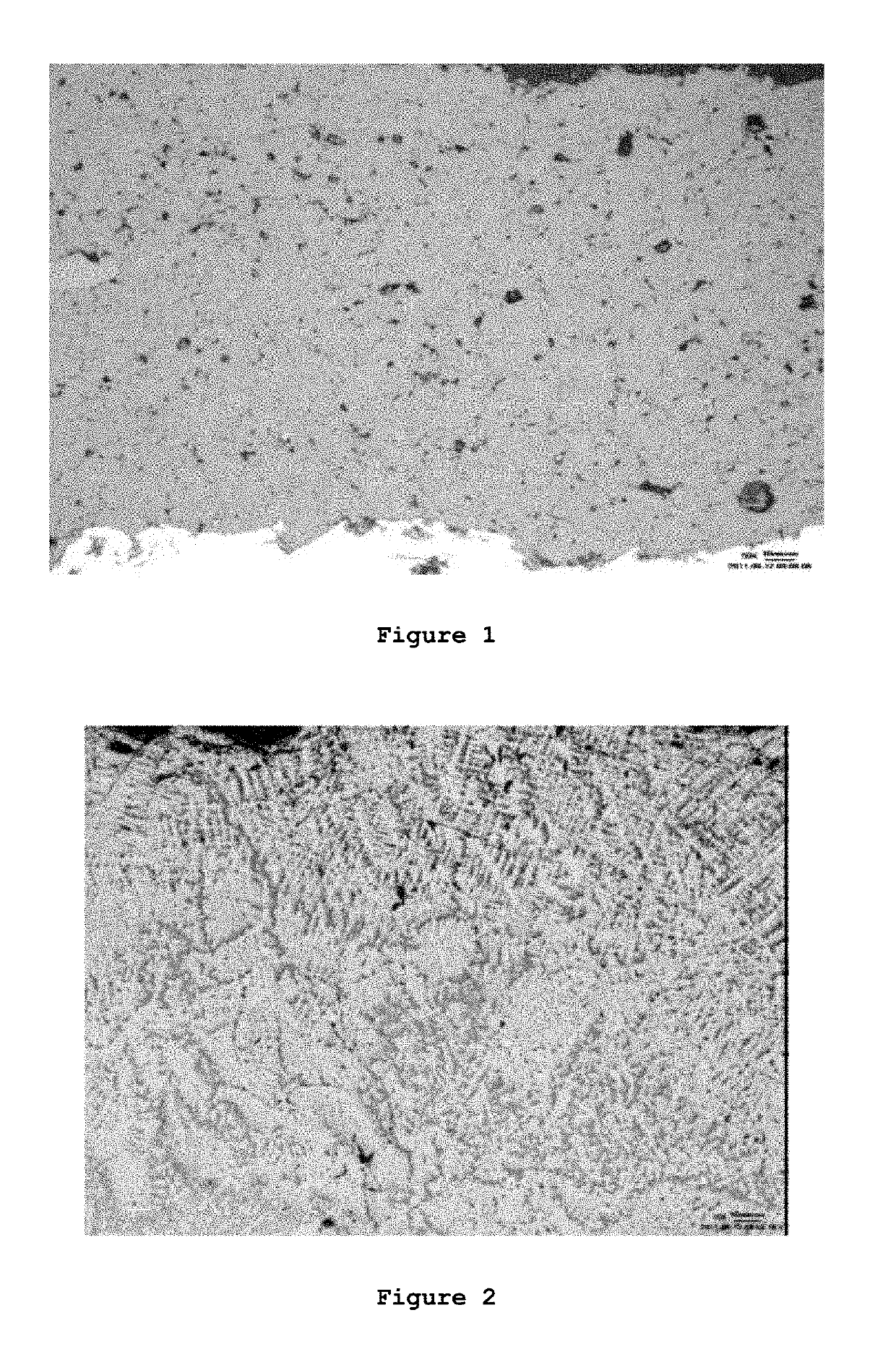

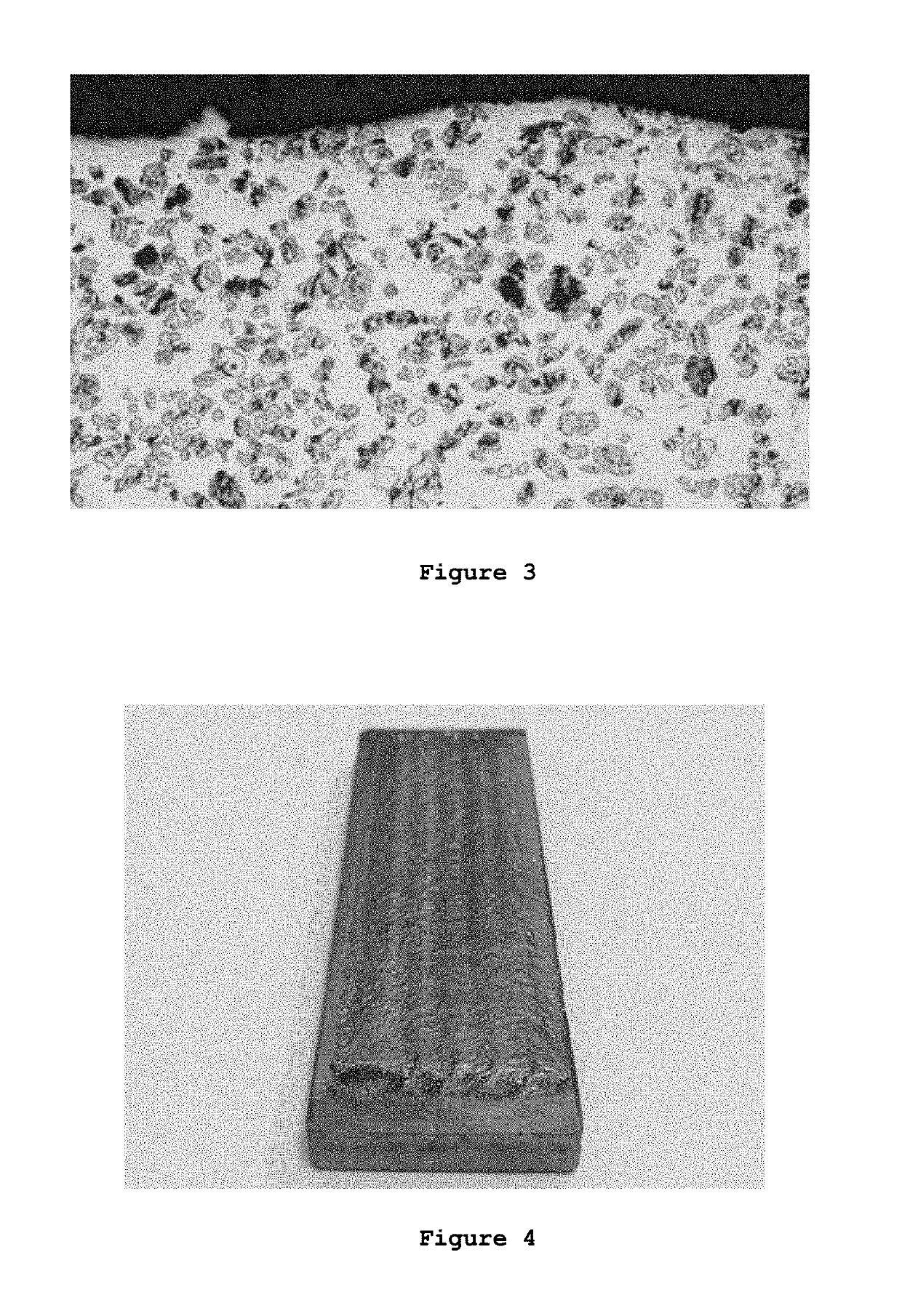

Titanium cast product for hot rolling and method for manufacturing same

ActiveUS20160038983A1Surely and stably be preventedLow costWork manipulationMetal rolling arrangementsSurface layerCommercially pure titanium

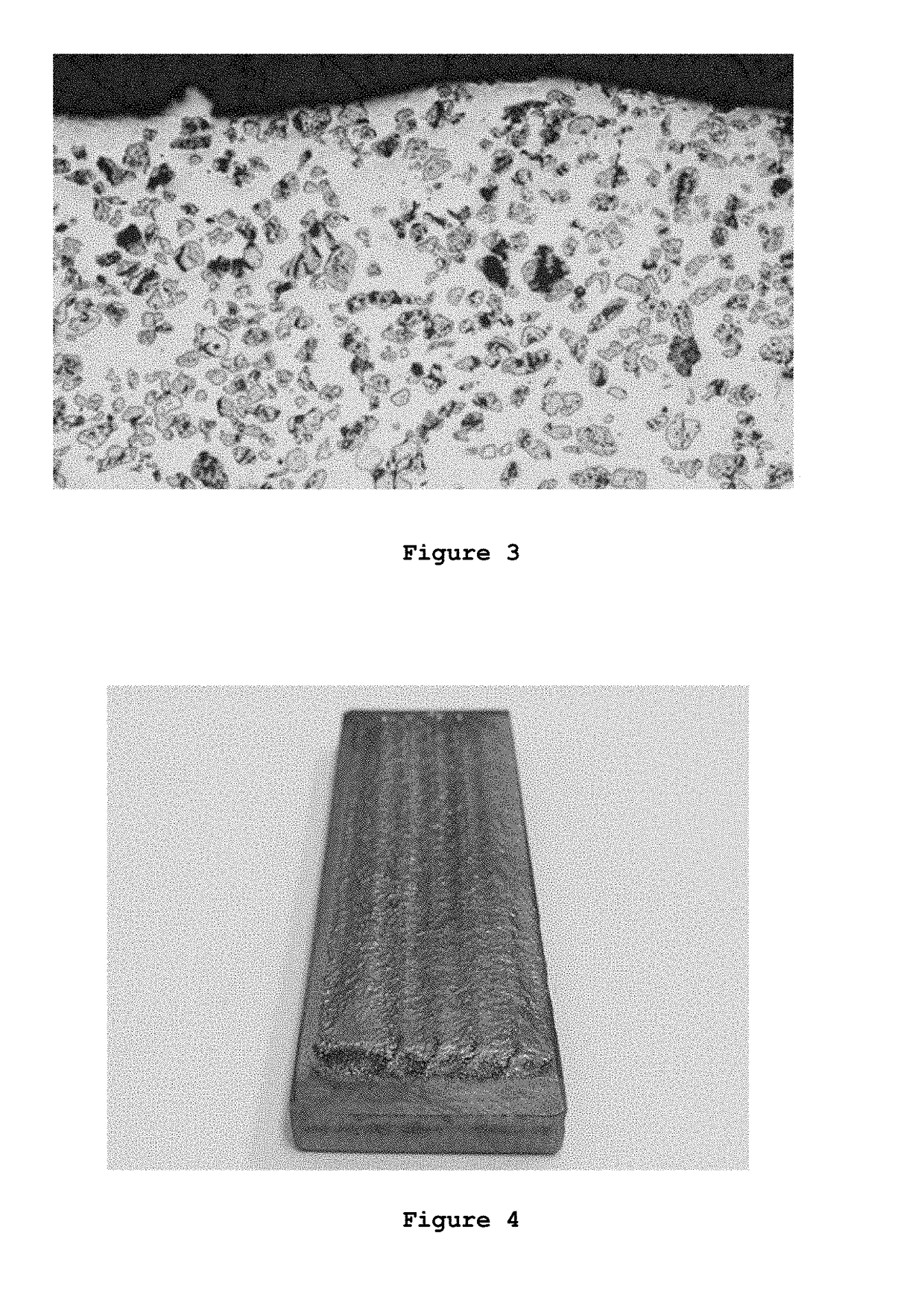

There is provided a titanium cast product for hot rolling composed of commercially pure titanium, the titanium cast product including: a microstructural refinement layer having acicular microstructure on an outermost layer of a surface layer to be rolled; and an inside microstructural refinement layer having acicular microstructure provided in an inside of the microstructural refinement layer. Cast solidification microstructure is present more inward than the inside microstructural refinement layer. The microstructural refinement layer has finer microstructure than the inside microstructural refinement layer. The microstructural refinement layer is present in a range of a depth of 1 mm or more and less than 6 mm from the surface. The inside microstructural refinement layer is present in an inside of the microstructural refinement layer in a range of a depth of 3 mm or more and 20 mm or less from the surface.

Owner:NIPPON STEEL CORP

Surface-treated titanium material excellent in oxidation resistance, production method thereof, and engine exhaust system

InactiveUS20050284544A1Improve antioxidant capacityImprove the immunityHot-dipping/immersion processesExhaust apparatusChemical compoundAlloy

Disclosed are a surface-treated titanium material that is excellent in oxidation resistance and allows the excellent oxidation resistance to last for a long period of time and the surface treatment itself to be applied safely at a low cost; the production method thereof; and an exhaust system thereof. A surface-treated titanium material produced by forming an oxidation-resistant baked film 5 μm or more in thickness on a substrate comprising commercially pure titanium or titanium-base alloy, and said baked film is formed by filling the gaps among particles comprising Al alloy containing Si by 10 at % or less or commercially pure aluminum with chemical compounds comprising a metallic element M (M represents one or more of Ti, Zr, Cr, Si and Al) and C and / or O.

Owner:KOBE STEEL LTD

Wear resistant coating

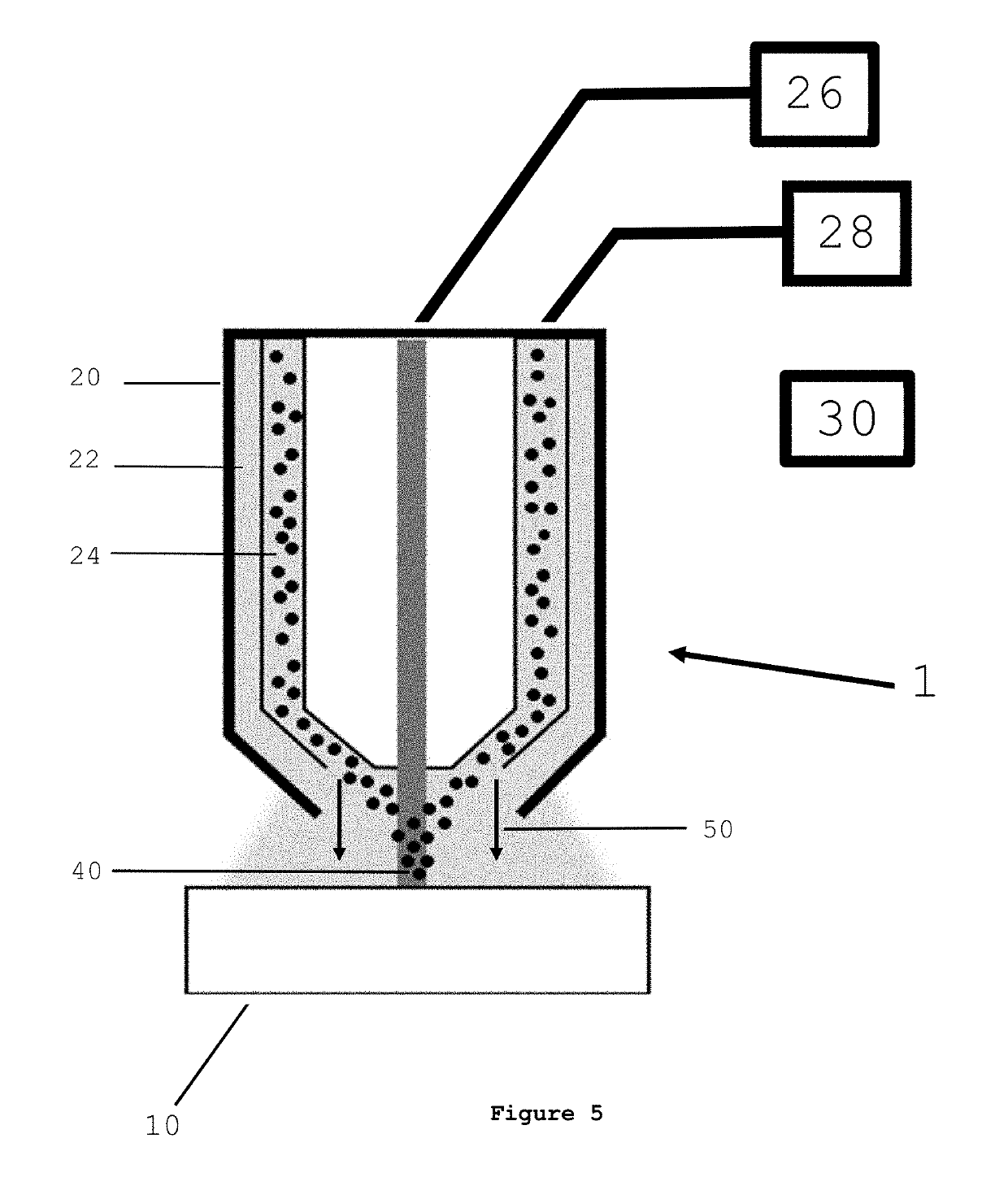

ActiveUS20180030585A1Affect susceptibilityReduced likelihood of wearMolten spray coatingArc welding apparatusMelting tankWear resistant

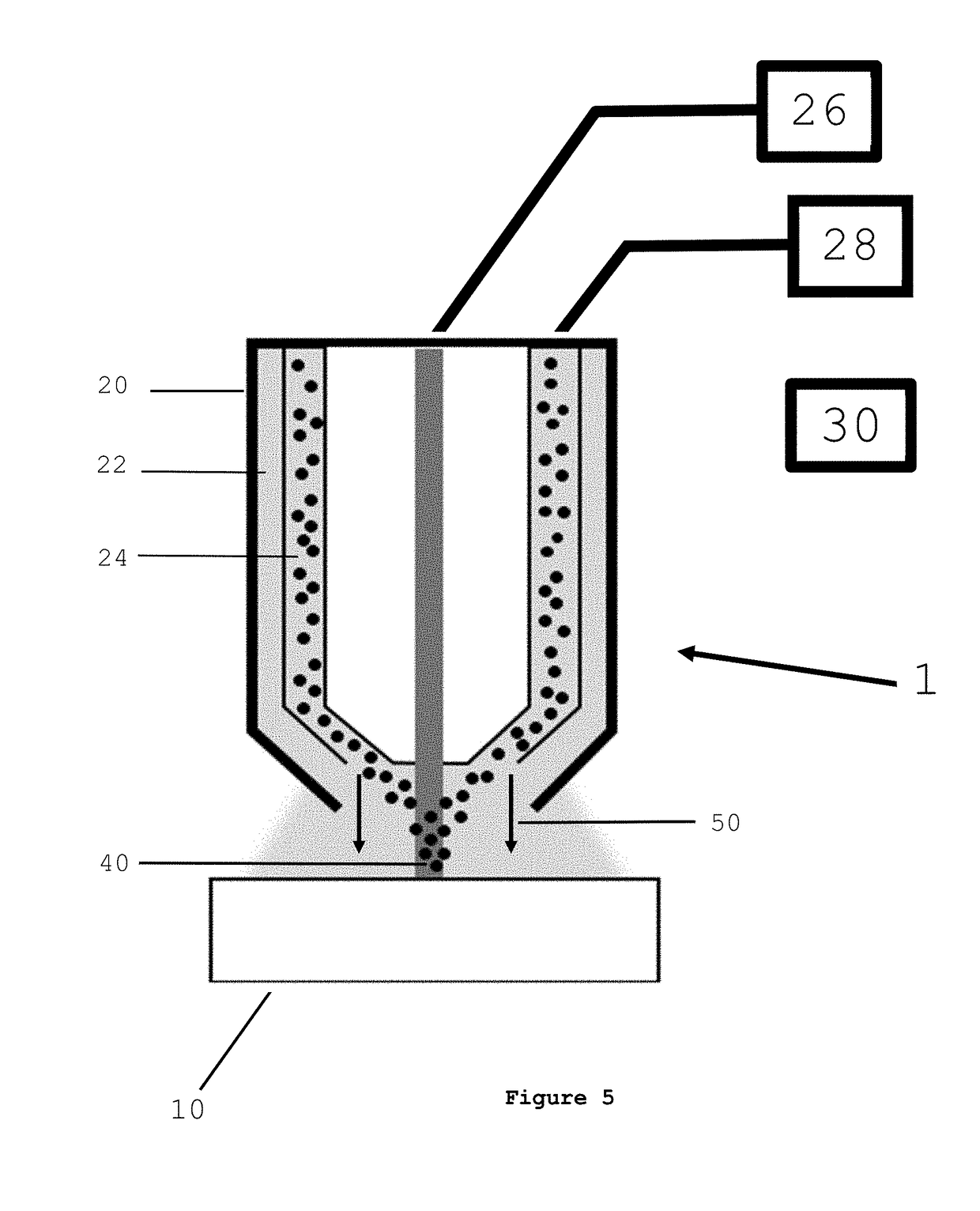

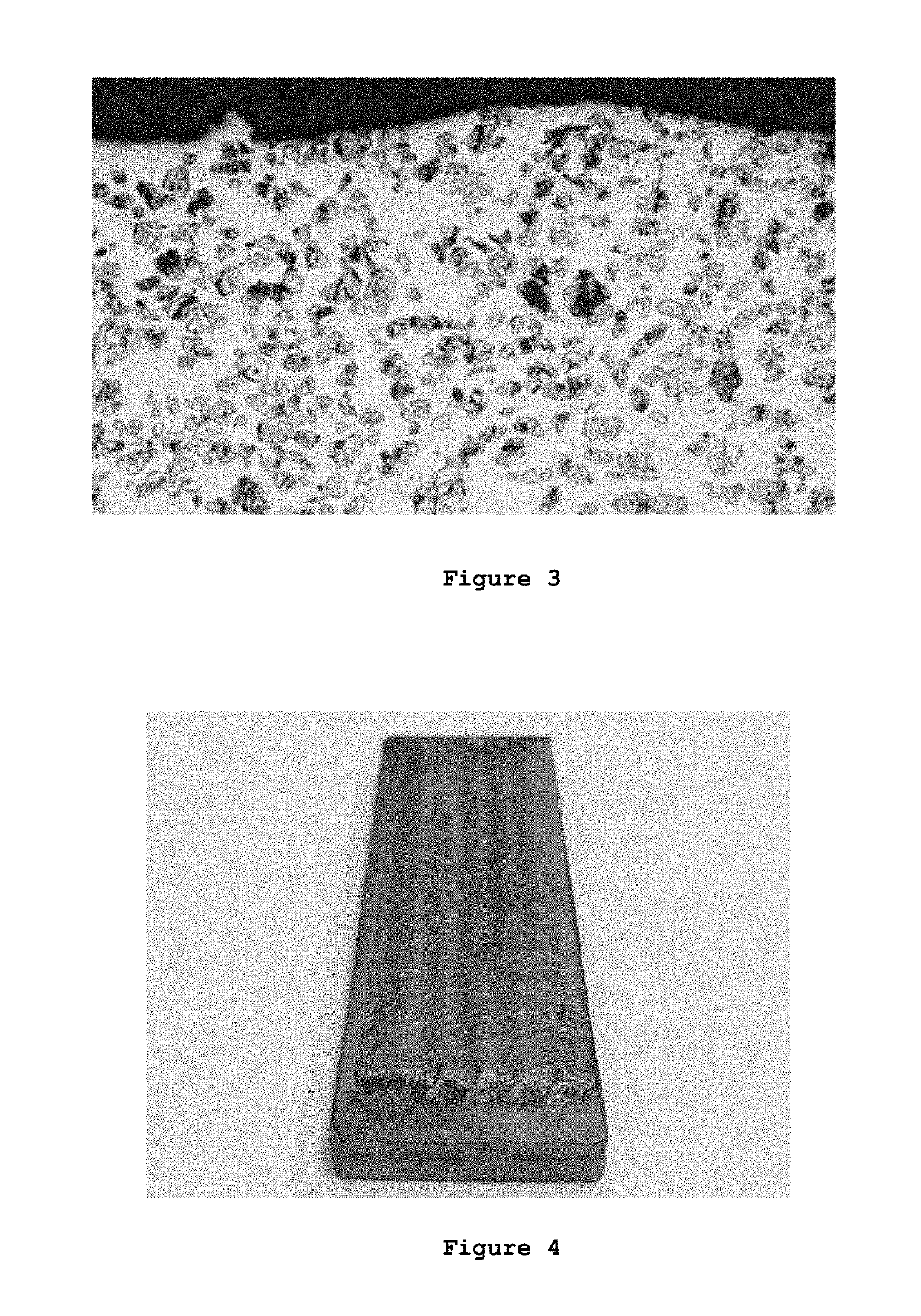

A method of forming a wear resistant and galling resistant coating for abrasive environments and a feed material for the method are disclosed. The feed material is for forming a wear resistant and galling resistant coating on a substrate by a welding process that heats the feed and the substrate. The feed material comprises 35 to 50 wt % titanium nitride particles and a balance of commercially pure titanium or titanium alloy particles and incidental impurities. The method involves delivering the feed material to a surface of a substrate and exposing the feed material and the substrate to sufficient energy to cause at least the commercially pure titanium or titanium alloy particles in the feed to melt and at least some of the titanium nitride particles in the feed to melt, thereby forming a melt pool. On solidification of the melt pool, at least some of the titanium nitride particles are embedded in a matrix formed from melt pool, thereby forming a wear resistant and galling resistant coating on the substrate. A wear resistant and galling resistant coating formed of the feed material is also disclosed.

Owner:BRENCO SURFACE ENG

Angulated dental implant

A dental implant includes a generally cylindrical body, an interior bore, and a non-rotational feature. The generally cylindrical body has a main-central axis and is formed from cold-worked, high strength, commercially pure titanium having an ultimate tensile strength of at least about 900 MPa. The generally cylindrical body has a proximal portion and an opposing distal portion for anchoring the dental implant in bone of a patient. The interior bore is formed in the generally cylindrical body and has (i) a bore-central axis and (ii) a threaded portion for receiving a screw that is configured to removable hold an abutment in engagement with the dental implant. The non-rotational feature is configured to engage the abutment in a non-rotational fashion.

Owner:SOUTHERN IMPLATS (PTY) LTD

Laminate armor and related methods

InactiveUS20120180630A1Electron beam welding apparatusWelding/cutting media/materialsTitanium alloyCommercially pure titanium

Laminate armor and methods of manufacturing laminate armor are disclosed. Specifically, laminate armor plates comprising a commercially pure titanium layer and a titanium alloy layer bonded to the commercially pure titanium outer layer are disclosed, wherein an average thickness of the titanium alloy inner layer is about four times an average thickness of the commercially pure titanium outer layer. In use, the titanium alloy layer is positioned facing an area to be protected. Additionally, roll-bonding methods for manufacturing laminate armor plates are disclosed.

Owner:BATTELLE ENERGY ALLIANCE LLC

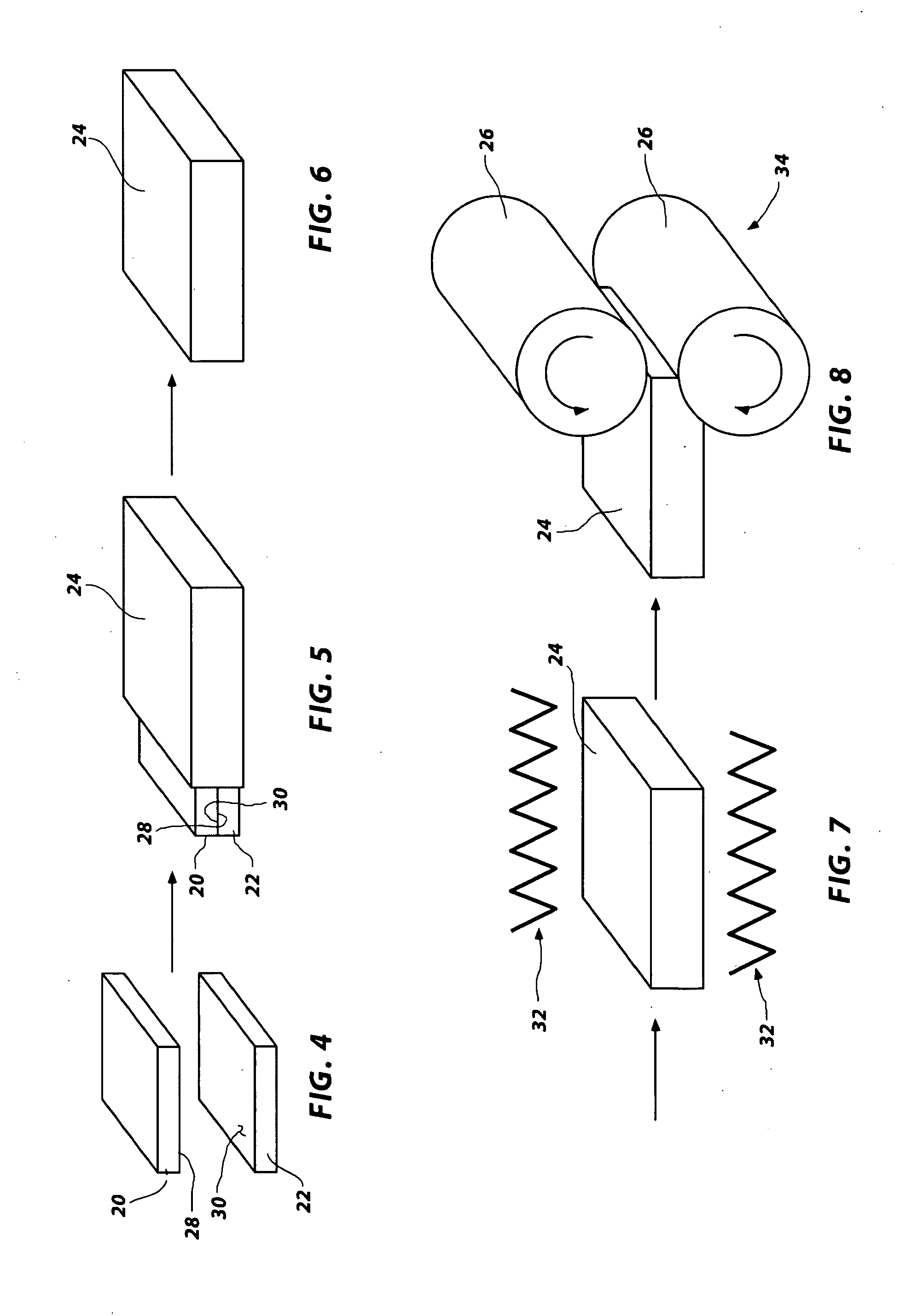

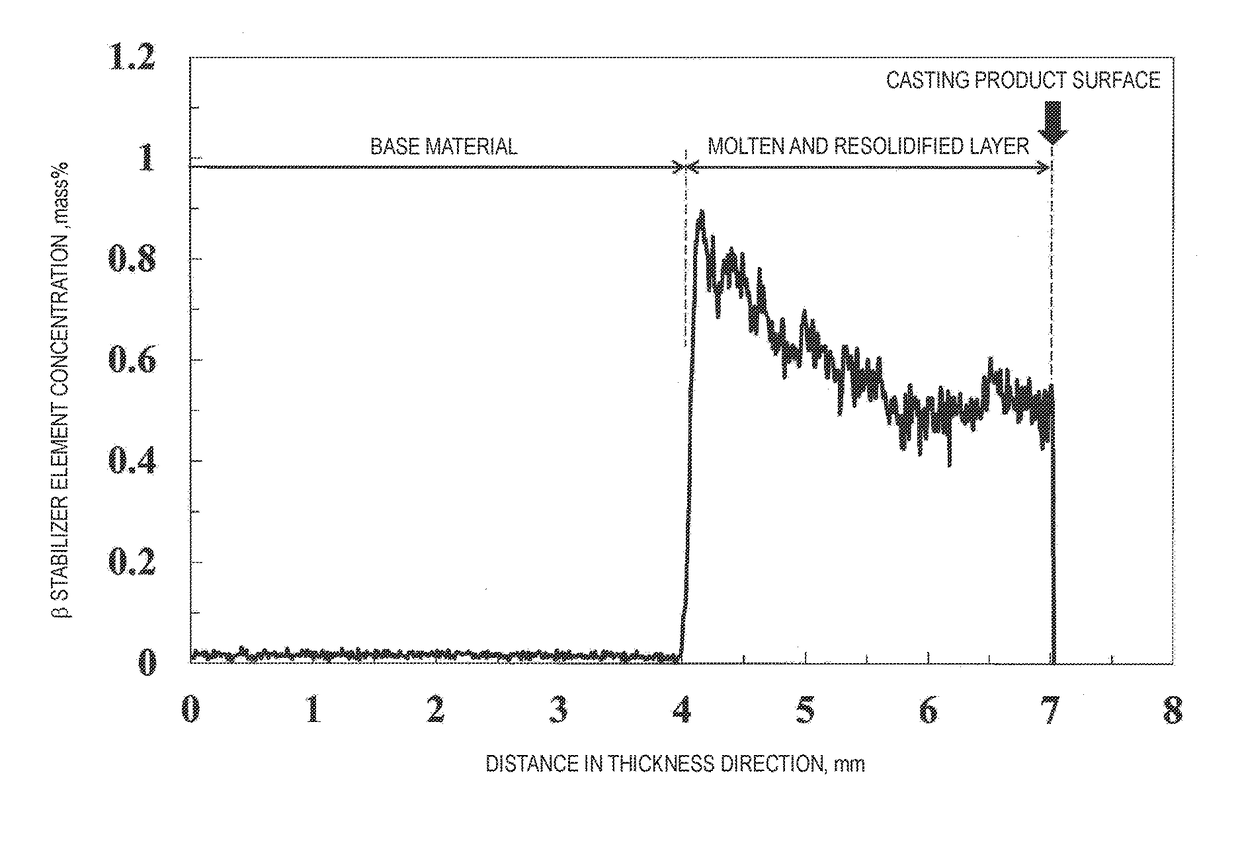

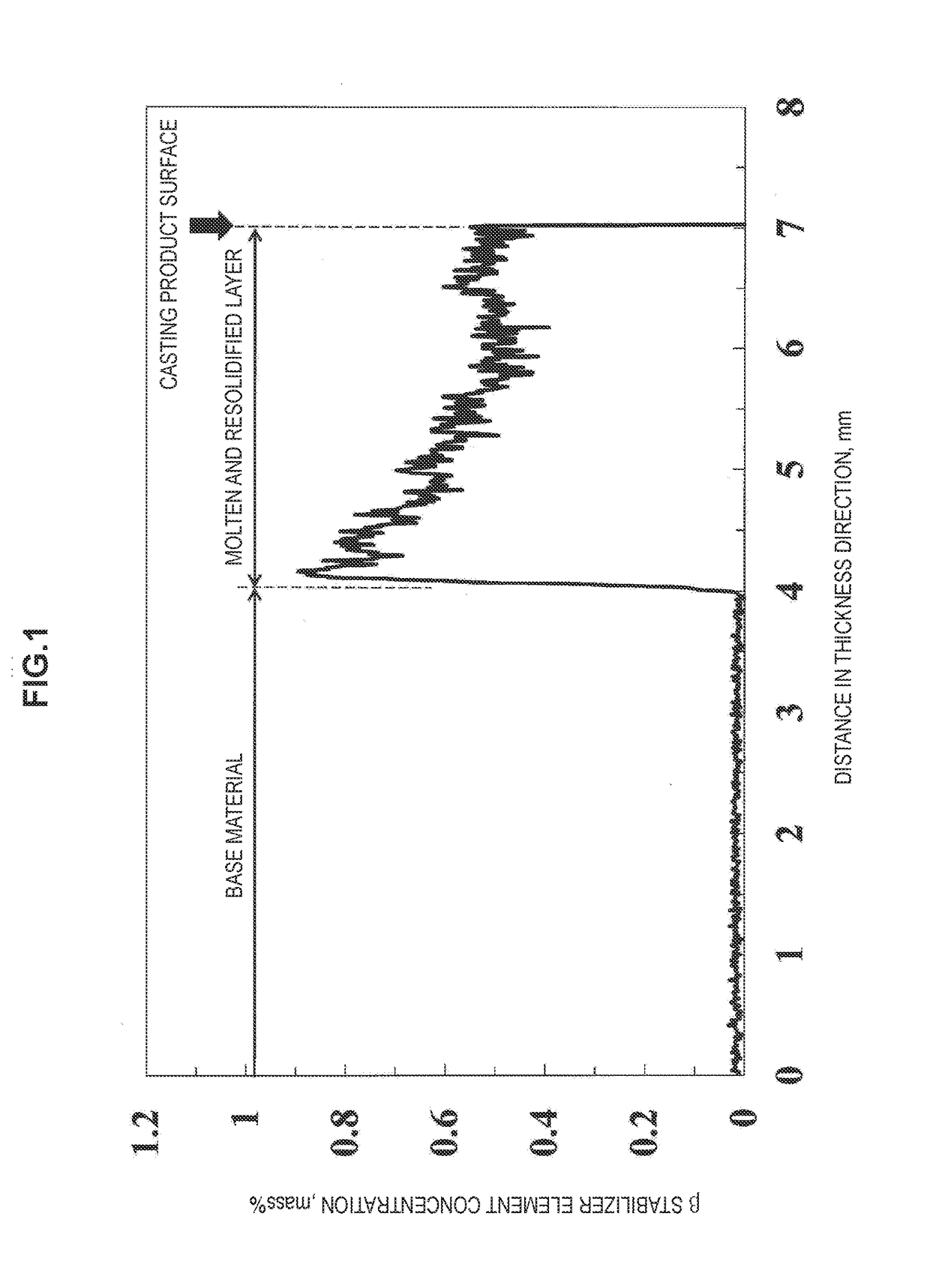

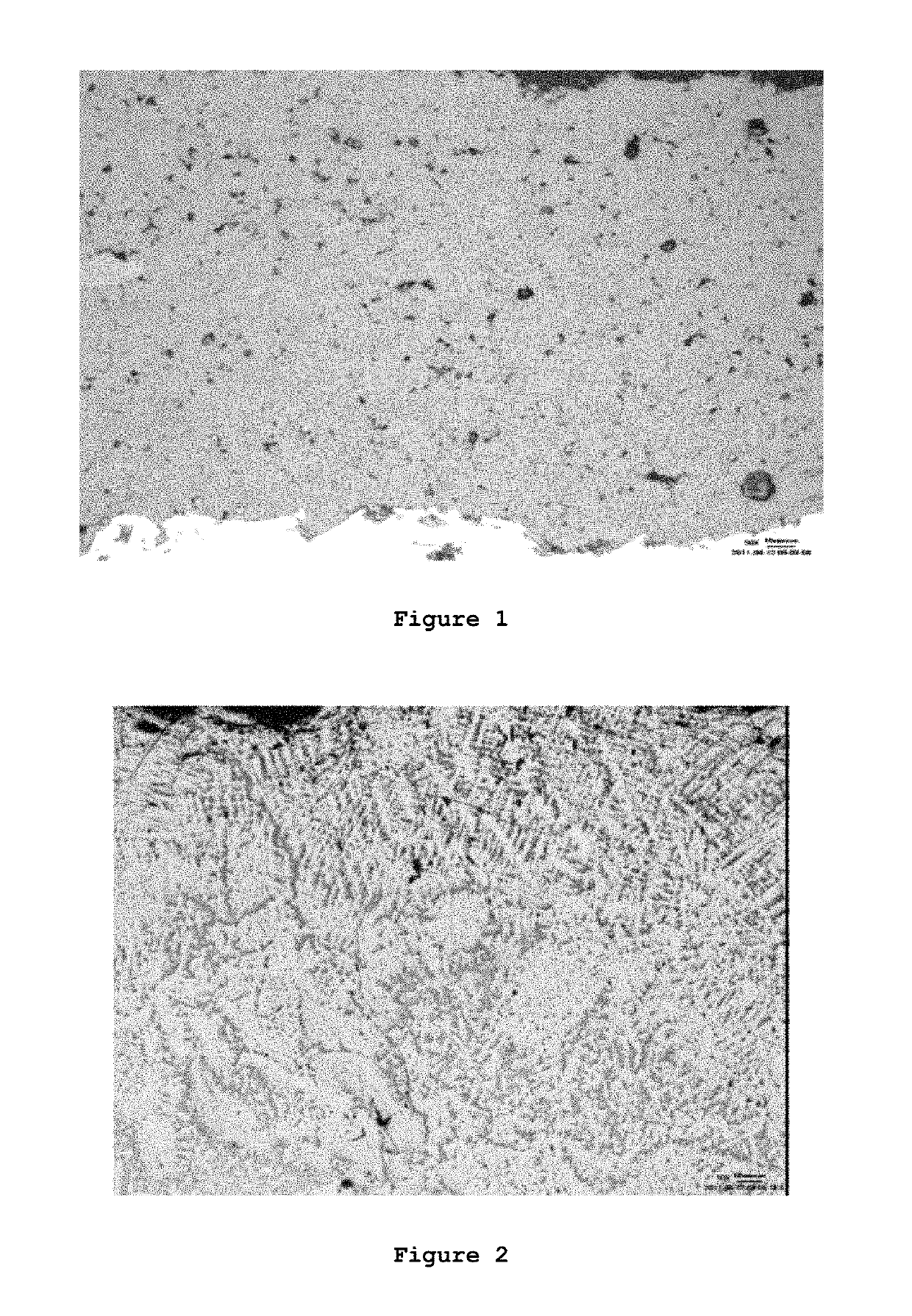

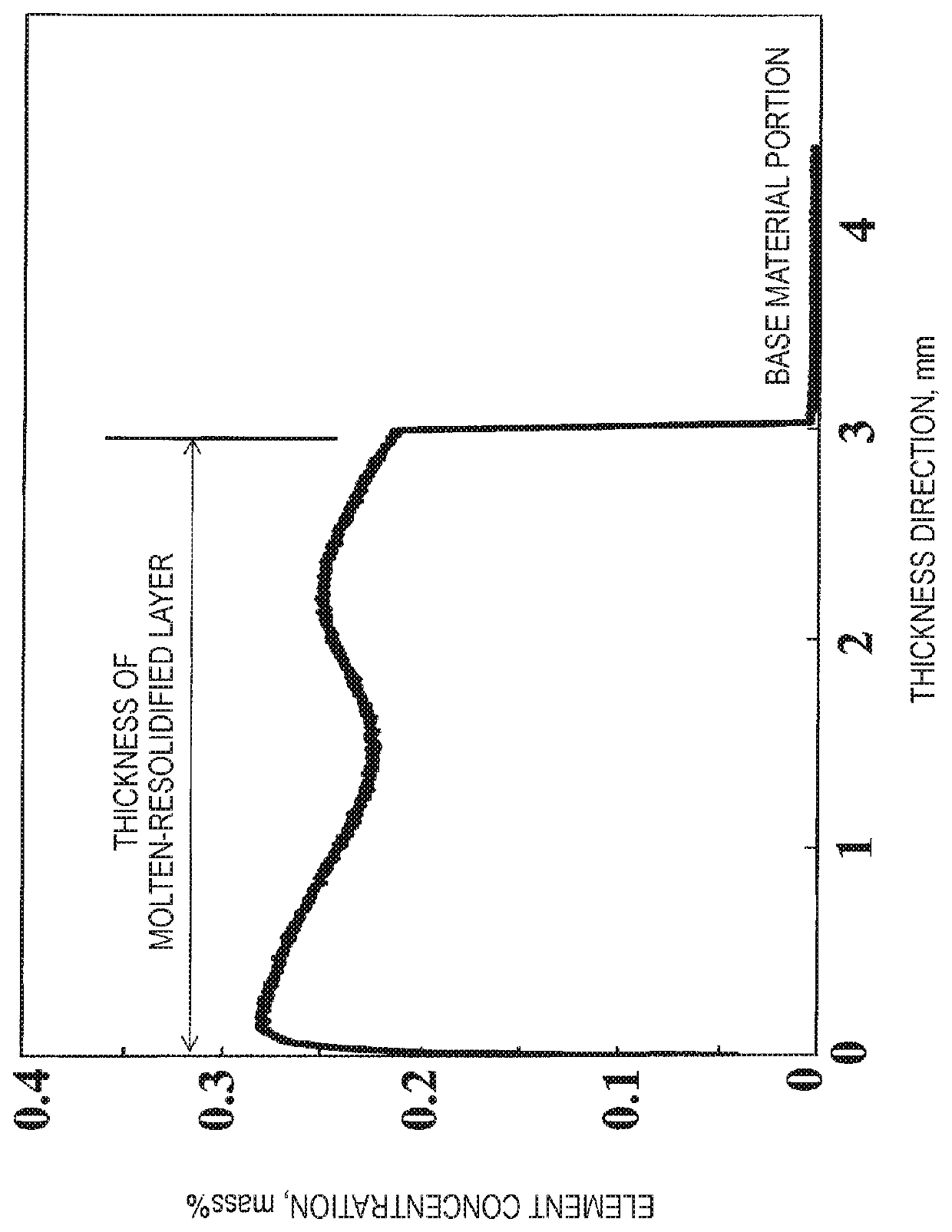

Titanium casting product for hot rolling and method for producing the same

ActiveUS20170282231A1Shorten heating timeReducing treatmentMolten casting coatingSolid state diffusion coatingSurface layerCommercially pure titanium

Provided is a titanium cast product made of commercially pure titanium, the titanium cast product being produced by electron-beam remelting or plasma arc melting, comprising: a melted and resolidified layer in a range of 1 mm or more in depth at a surface serving as a surface to be rolled, the melted and resolidified layer being obtained by adding one or more kinds of β stabilizer elements to the surface and melting and resolidifying the surface. An average value of β stabilizer element(s) concentration in a range of within 1 mm in depth is higher than β stabilizer element(s) concentration in a base material by, in mass %, equal to or more than 0.08 mass % and equal to or less than 1.50 mass %. As the material containing the β stabilizer element, powder, a chip, wire, or foil is used. As means for melting a surface layer, electron-beam heating and plasma arc heating are used.

Owner:NIPPON STEEL CORP

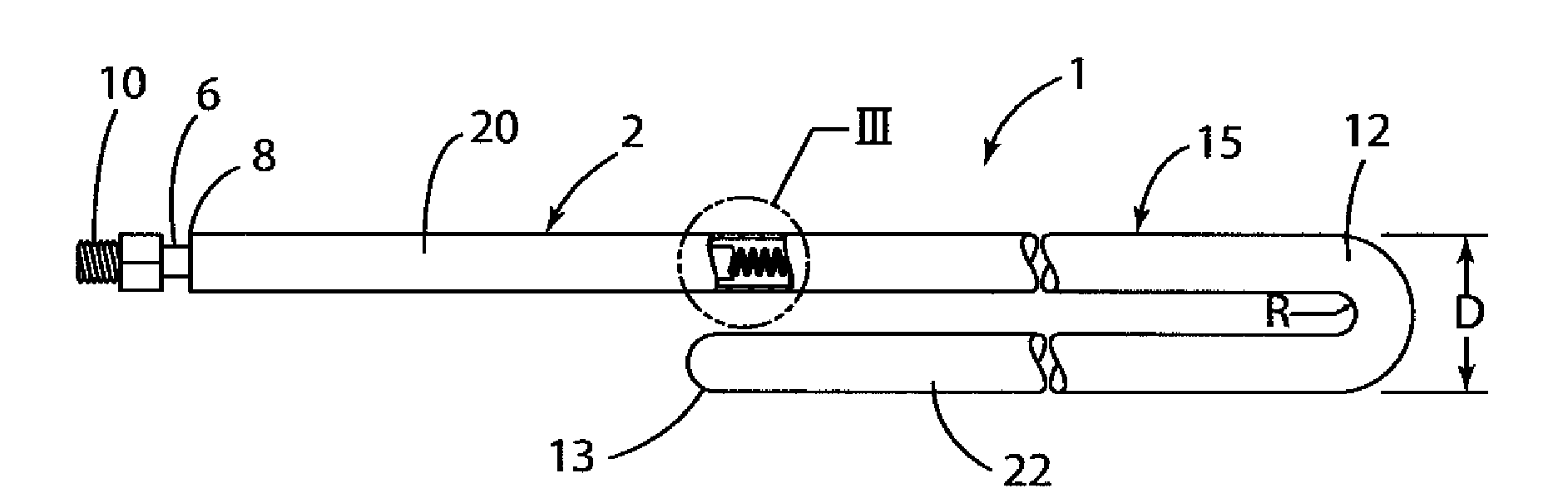

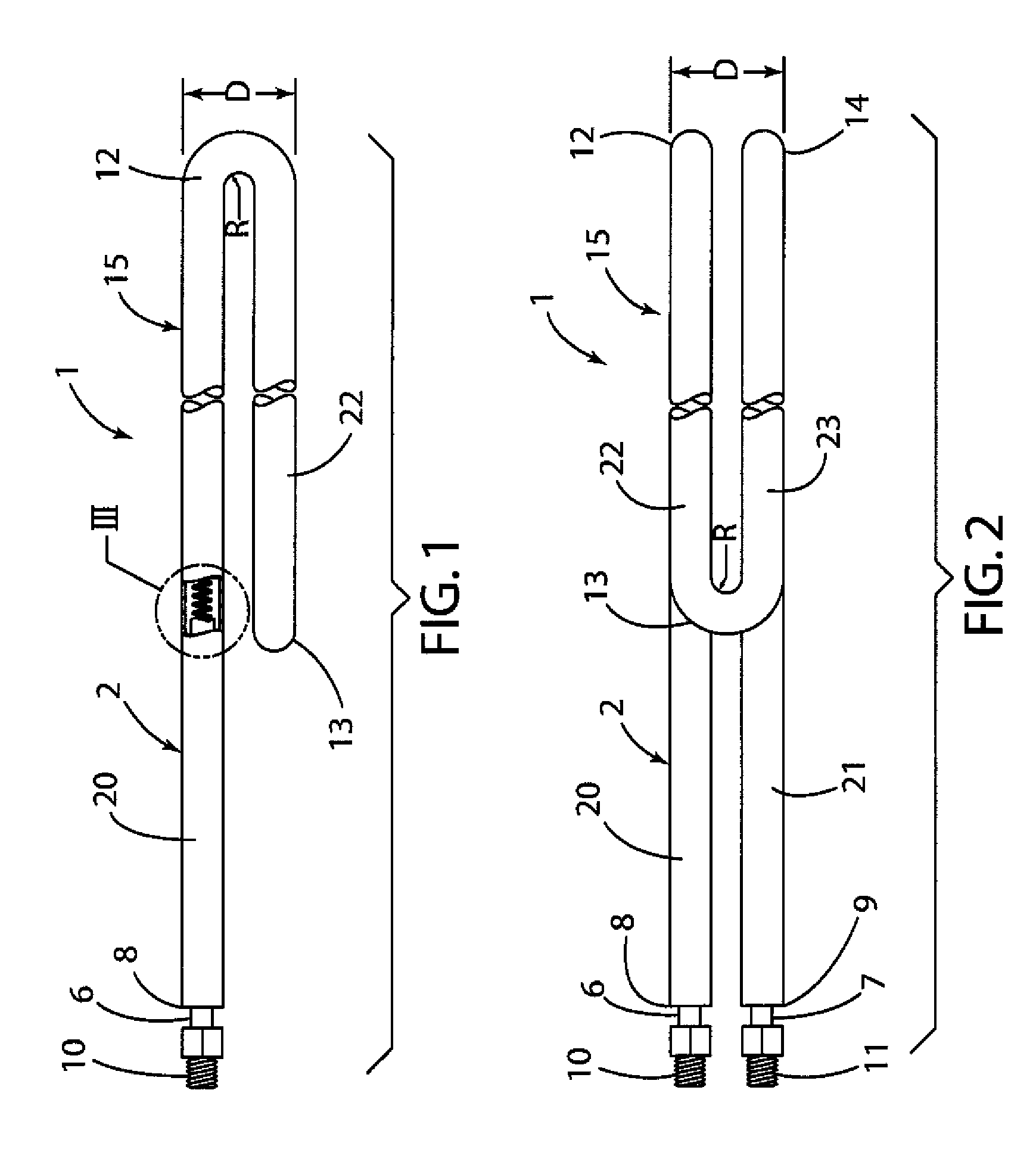

Method of forming a titanium heating element

InactiveUS7954229B1Envelope/housing resistor manufactureHeating element shapesTitanium nitrideThermal water

A method of making a titanium heating element for electric water heaters includes heating commercially pure titanium tubing to a specified temperature for a predetermined period of time. A resistance wire and magnesium dioxide powder may be positioned in the tubing prior to the annealing process. The outer surfaces of the titanium tube are exposed to the air during at least a portion of the annealing process, such that a layer of titanium dioxide develops on the outer surface of the titanium. The heating element is then formed into a loop or other suitable shape, and it is positioned inside a housing. The housing may include fittings to connect the water heater to the tubing of a pool, jetted tub, spa, hot tub or the like.

Owner:BLUE DESERT INT INC

Surface treatment process for implants made of titanium alloy

ActiveUS10227697B2Reduce lossesDental implantsImpression capsHydrofluoric acidCommercially pure titanium

A titanium 6 A1 / 4V alloy is provided with a surface topography that is similar to the Osseotite® surface produced on commercially pure titanium. Native oxide is removed from the Ti 6A1 / 4V alloy, followed by contacting the metal at ambient temperature with an aqueous hydrochloric acid solution containing a relatively small amount of hydrofluoric acid.

Owner:BIOMET 3I LLC

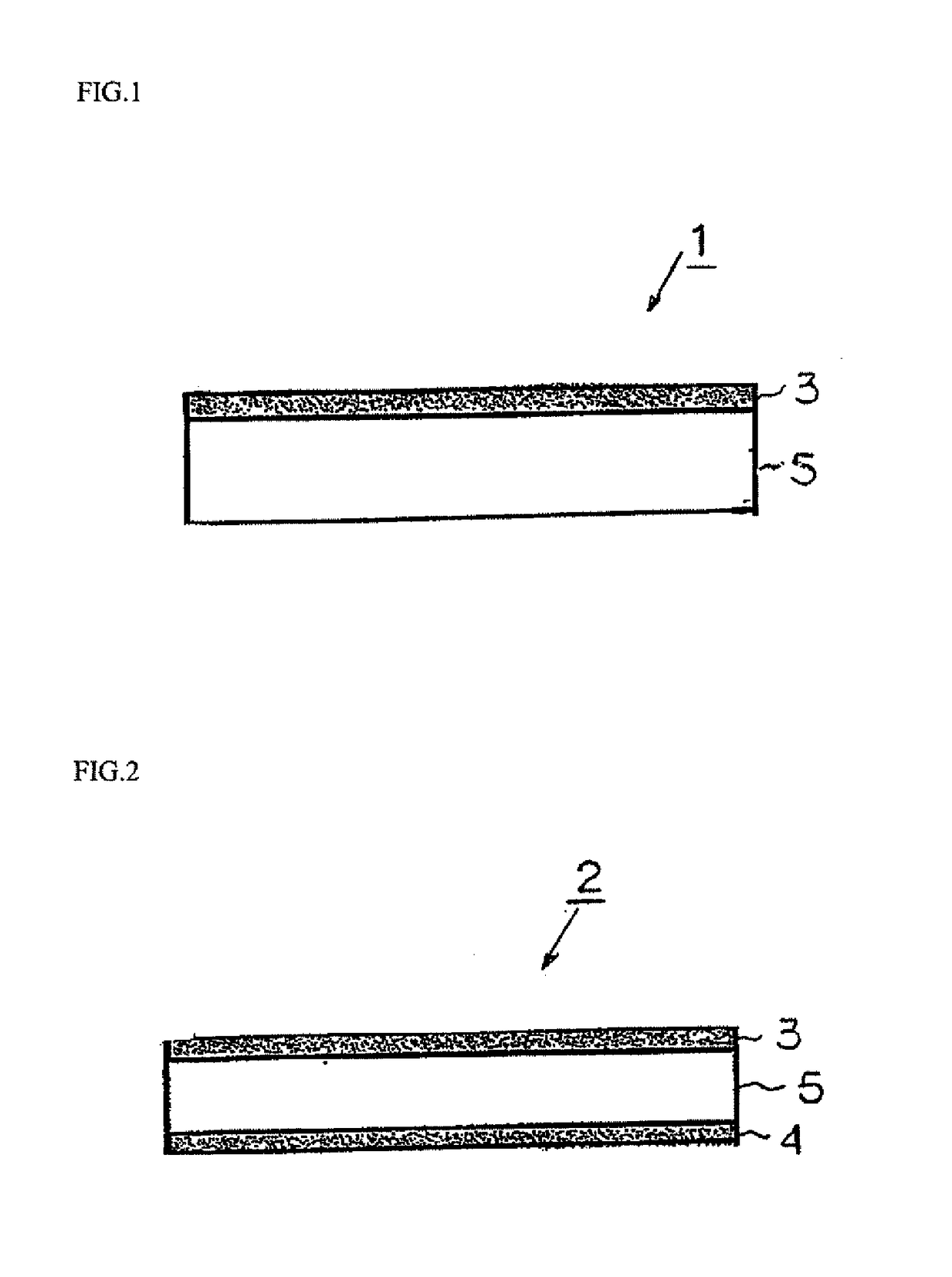

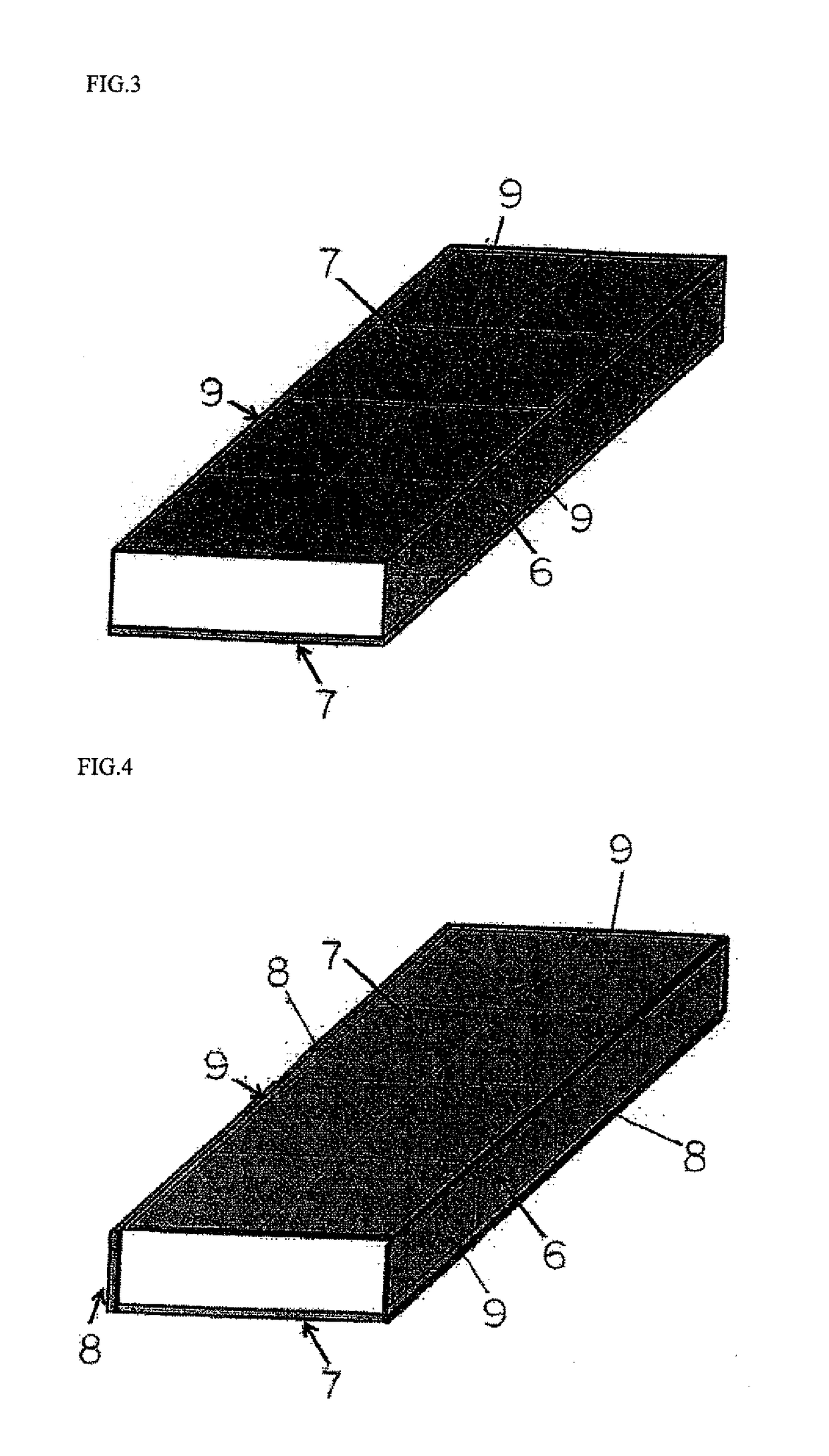

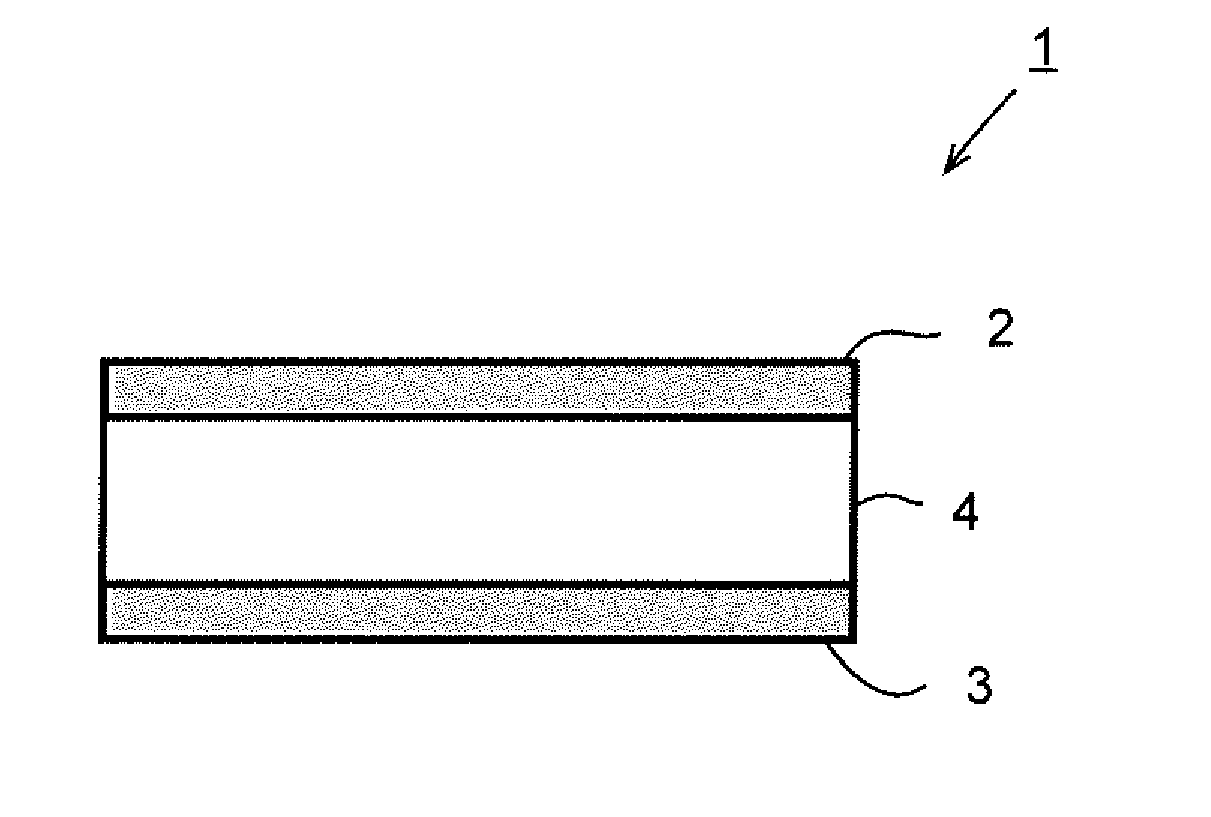

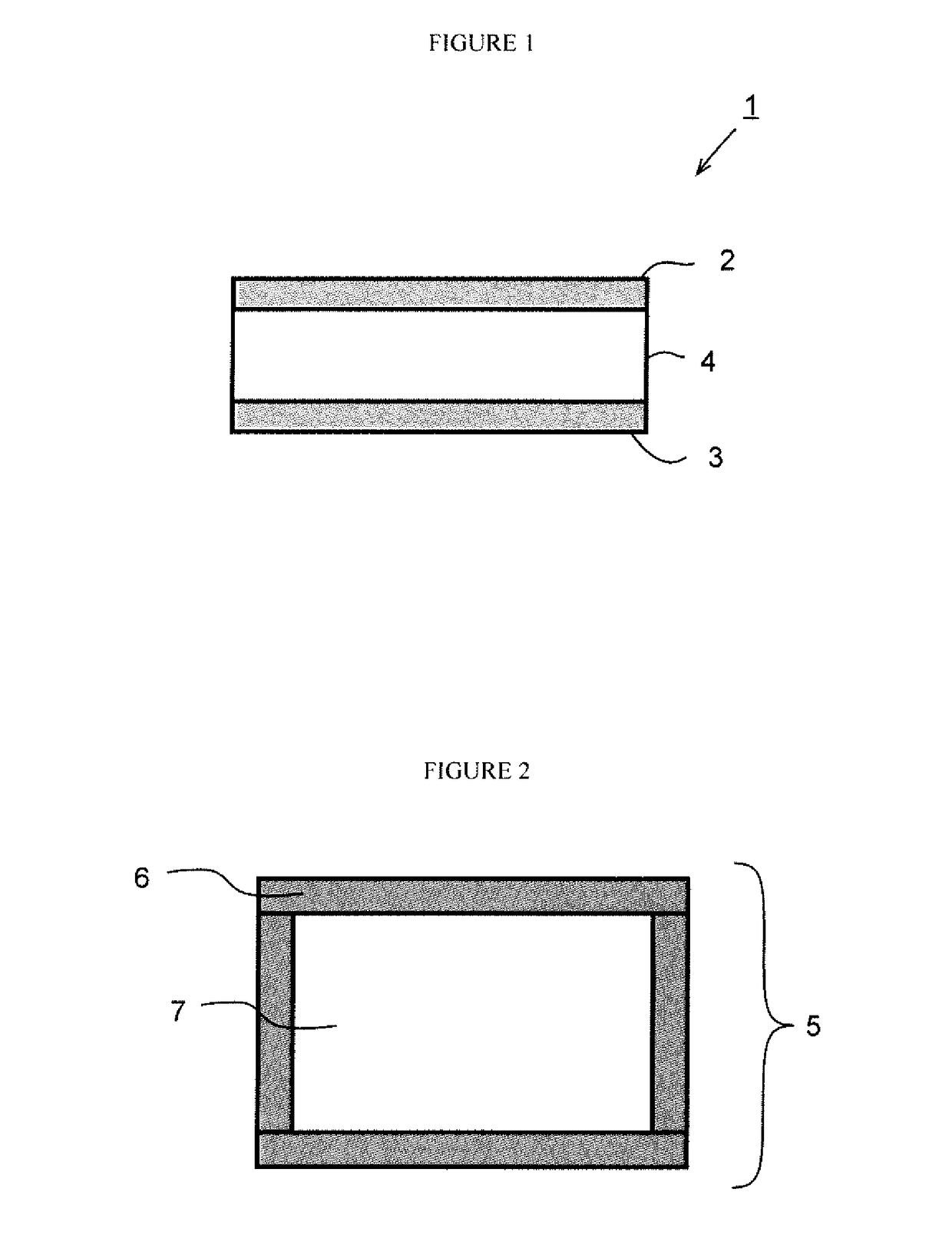

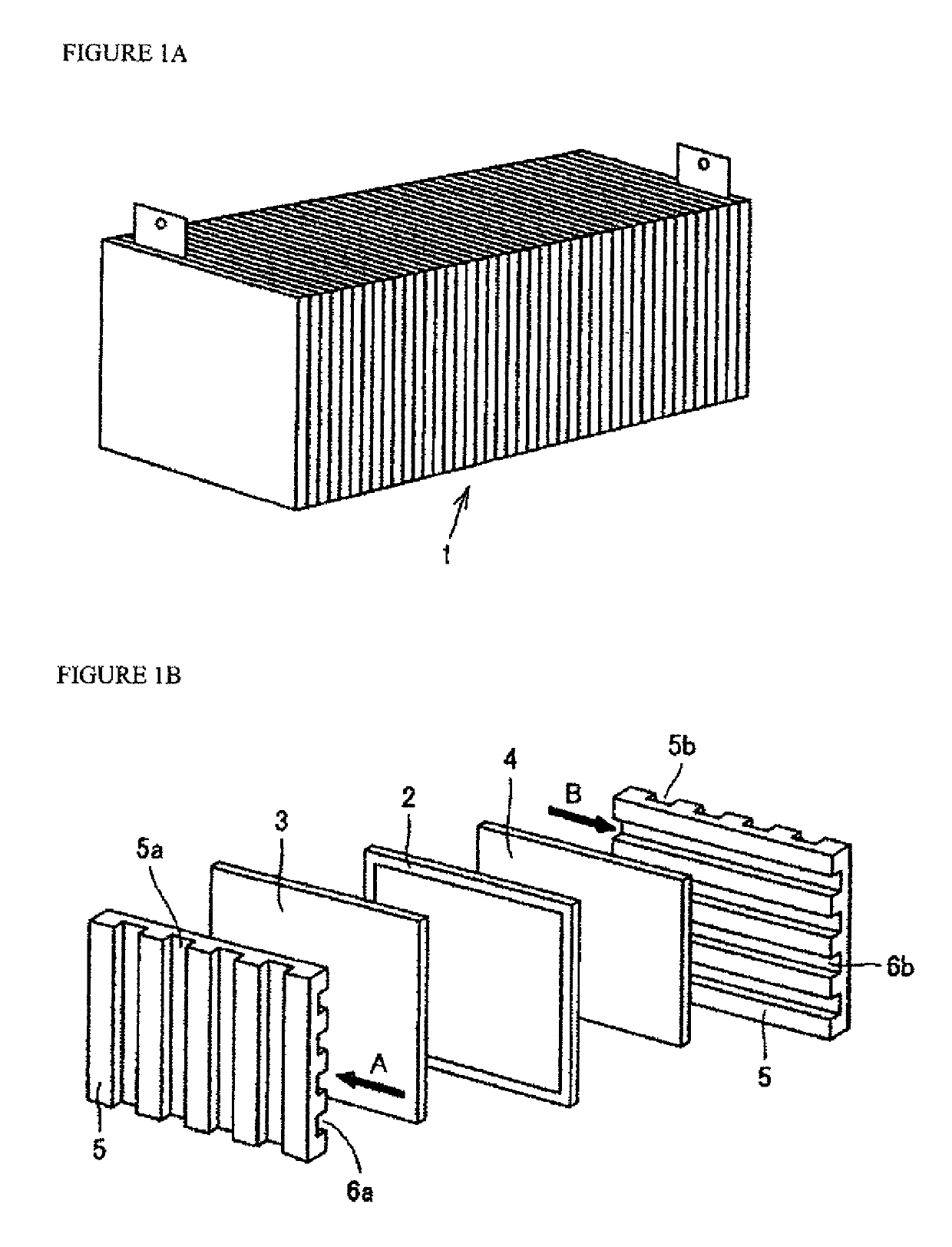

Titanium composite material and titanium material for hot rolling

ActiveUS20180216211A1Low production costElectron beam welding apparatusThin material handlingChemical compositionTitanium alloy

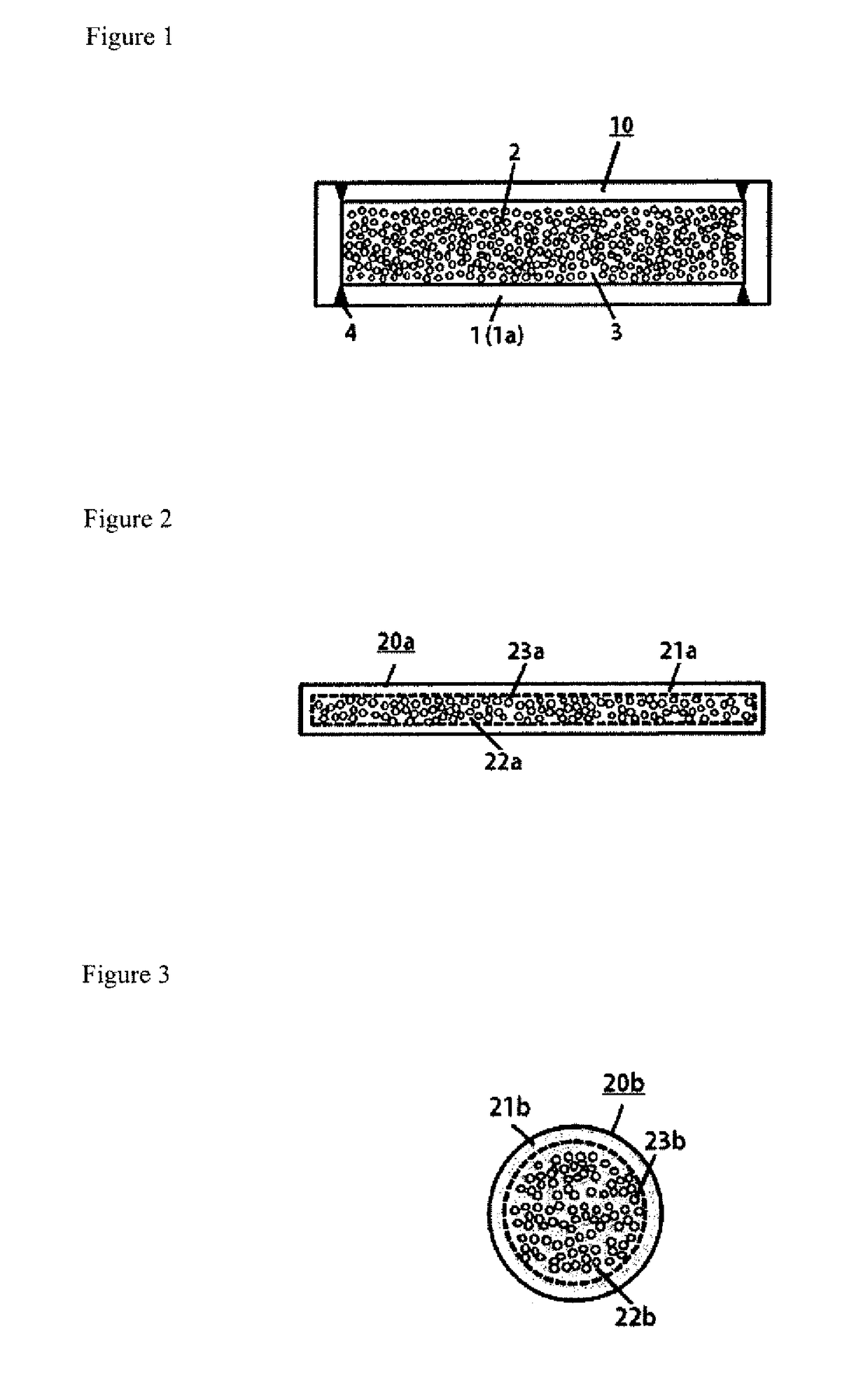

A titanium composite material 1 is provided that includes: an inner layer 5 consisting of a commercially pure titanium or a titanium alloy; an outer layer 3 formed on at least one surface of the inner layer 5 and having a chemical composition that is different from a chemical composition of the inner layer 5; and an intermediate layer formed between the inner layer 5 and the outer layer 3 and having a chemical composition that is different from the chemical composition of the inner layer 5. The thickness of the outer layer 3 is 2 μm or more, and occupies no more than 40% of the overall thickness per side. The thickness of the intermediate layer is 0.5 μm or more. Despite being inexpensive, this titanium composite material has desired characteristics.

Owner:NIPPON STEEL CORP

Titanium composite material and titanium material for hot working

ActiveUS20180216210A1Low production costThin material handlingMetal rolling arrangementsPorositySurface layer

Provided is a titanium composite material 1 including: a first surface layer portion 2; an inner layer portion 4; and a second surface layer portion 3; wherein: the first surface layer portion 2 and the second surface layer portion 3 are composed of a titanium alloy; the inner layer portion 4 is composed of a commercially pure titanium including pores; a thickness of at least one of the first surface layer portion 2 and the second surface layer portion 3 is 2 μm or more, and a proportion of the thickness with respect to an overall thickness of the titanium composite material 1 is 40% or less; and a porosity in a cross section perpendicular to a sheet thickness direction is more than 0% and 30% or less.

Owner:NIPPON STEEL CORP

Wear resistant coating

ActiveUS10358710B2Lower requirementEasy to useMolten spray coatingArc welding apparatusMelting tankWear resistant

Owner:MOGAS IND PTY LTD

Process for manufacturing a product of commercially pure titanium

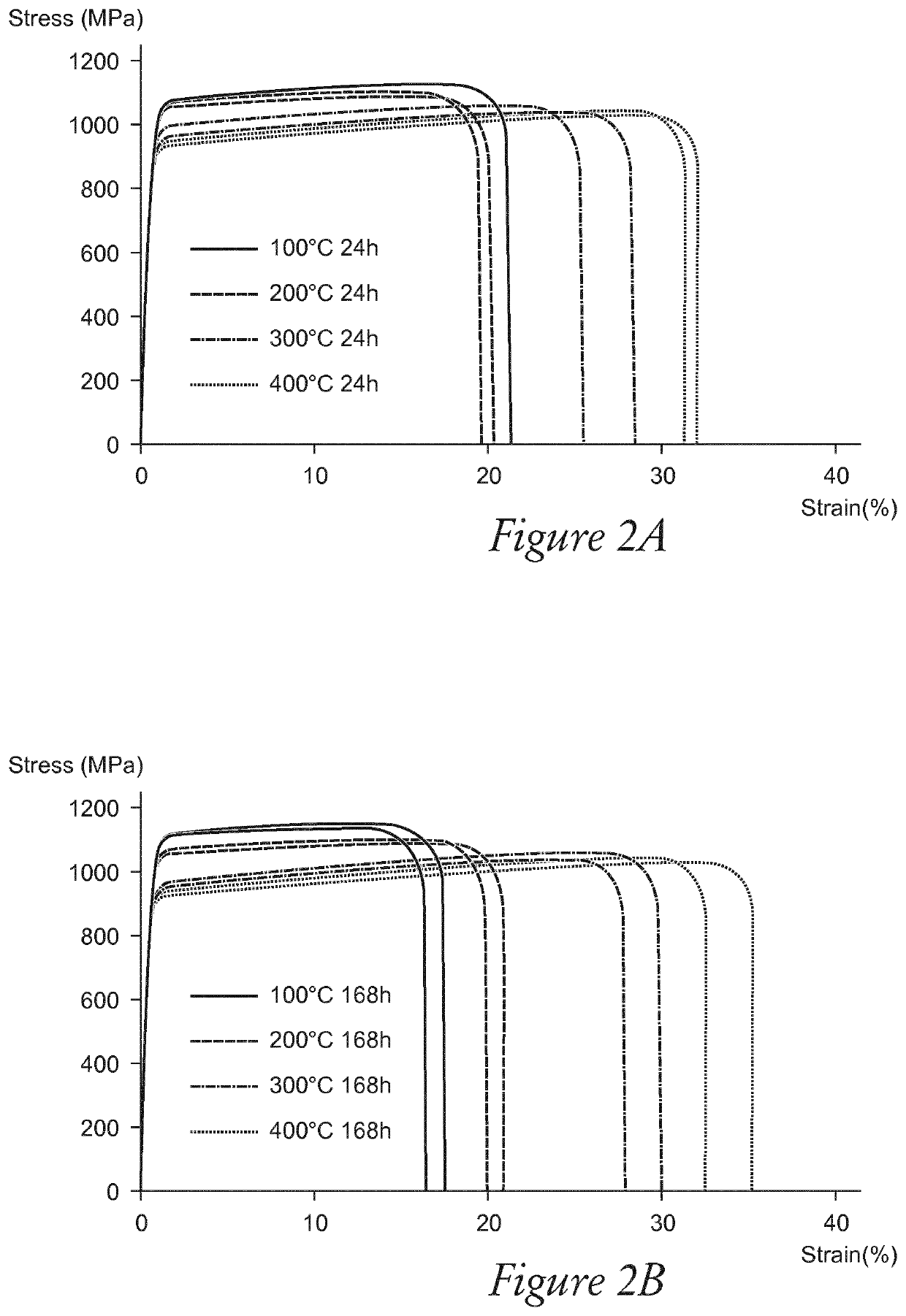

The present disclosure relates to a process for manufacturing a product of commercially pure titanium, wherein the process includes the steps of mechanically deforming an object of commercially pure titanium in a temperature below −80° C. until the product is formed, and heat-treating the formed product in a temperature range of from 300 to below 450° C. during a treatment time from 10 minutes to 168 hours.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Titanium-containing structure and titanium product

ActiveUS20170233850A1Low production costImprove production yieldMetal rolling arrangementsInternal pressureChemical composition

A titanium-containing structure made of a titanium material includes: a package made of a commercially pure titanium material; and a filler packed into the package, wherein an internal pressure of the package is 10 Pa or less, the pressure being an absolute pressure, and wherein the filler includes at least one selected from titanium sponge, titanium briquet, and titanium scrap, and the filler has the same type of a chemical composition of the commercially pure titanium material. This titanium-containing structure enables production of a titanium product by performing hot working and eliminating the conventional melting step and forging step.

Owner:NIPPON STEEL CORP

Titanium cast product for hot rolling and method for manufacturing same

ActiveUS10046373B2Surely and stably be preventedLow costMetal rolling arrangementsSurface layerCommercially pure titanium

There is provided a titanium cast product for hot rolling composed of commercially pure titanium, the titanium cast product including: a microstructural refinement layer having acicular microstructure on an outermost layer of a surface layer to be rolled; and an inside microstructural refinement layer having acicular microstructure provided in an inside of the microstructural refinement layer. Cast solidification microstructure is present more inward than the inside microstructural refinement layer. The microstructural refinement layer has finer microstructure than the inside microstructural refinement layer. The microstructural refinement layer is present in a range of a depth of 1 mm or more and less than 6 mm from the surface. The inside microstructural refinement layer is present in an inside of the microstructural refinement layer in a range of a depth of 3 mm or more and 20 mm or less from the surface.

Owner:NIPPON STEEL CORP

Vacuum Annealing Process of Cold Rolled Industrial Pure Titanium Coil

The present invention discloses a vacuum annealing technology of cold rolled commercial pure titanium coils, the technology comprising the following steps: putting 3 cold rolled commercial pure titanium coils of which the surface has been cleaned into a vacuum annealing furnace, and pre-vacuumizing the vacuum furnace until the vacuum degree is not higher than 2.0*10-3Pa; heating the furnace at a heating rate of 40~90 DEG C / h until the temperature of the furnace reaches 450~500 DEG C, and maintaining this temperature for 3~6 hours; keeping heating the furnace at a heating rate of 50~100 DEG C / h until the temperature of the furnace reaches 600~680 DEG C, adding inert gas of which the purity is not less than 99.99% into the furnace until the pressure reaches 2.0~8.0 kPa, and maintaining this temperature for 4~8 hours; closing the heating system, cooling the furnace at a cooling rate of 50~100 DEG C / h until the temperature of the furnace drops to 330~370 DEG C, starting a forced cooling system, and taking out the titanium coils when the temperature of the furnace is not higher than 150 DEG C. The smooth finish of annealed titanium coils is even. Through test, it is found that both the inner and external coils are of homogeneous structure, and the mechanical property is good, so that the requirements are fully met.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Wear resistant coating

InactiveUS20190284674A1Improve wear resistanceImprove suppression propertiesMolten spray coatingArc welding apparatusWear resistantTitanium nitride

Owner:BRENCO SURFACE ENG PTY LTD

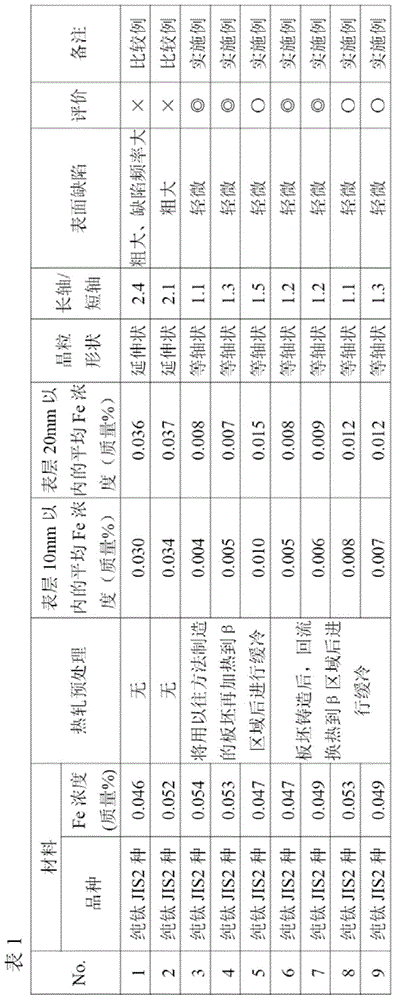

Titanium slab for hot rolling and process for producing same

The present invention provides a titanium slab for hot rolling with good surface properties of a hot-rolled strip-shaped coil even if the preliminary rolling process is omitted in the titanium slab obtained by smelting industrial pure titanium, and the titanium slab Smelting method. The titanium slab of the present invention is a titanium slab for hot rolling obtained by smelting commercially pure titanium containing Fe as a β-phase stabilizing element. A titanium slab in which the average Fe concentration from the surface layer to 10 mm is specified to be 0.01% by mass or less to suppress the formation of coarse β phases. It can be obtained by cooling the titanium slab obtained by smelting industrial pure titanium until the surface reaches below the β transformation point, and then heating it above the β transformation point, and slowly cooling from the surface layer of the slab.

Owner:NIPPON STEEL CORP

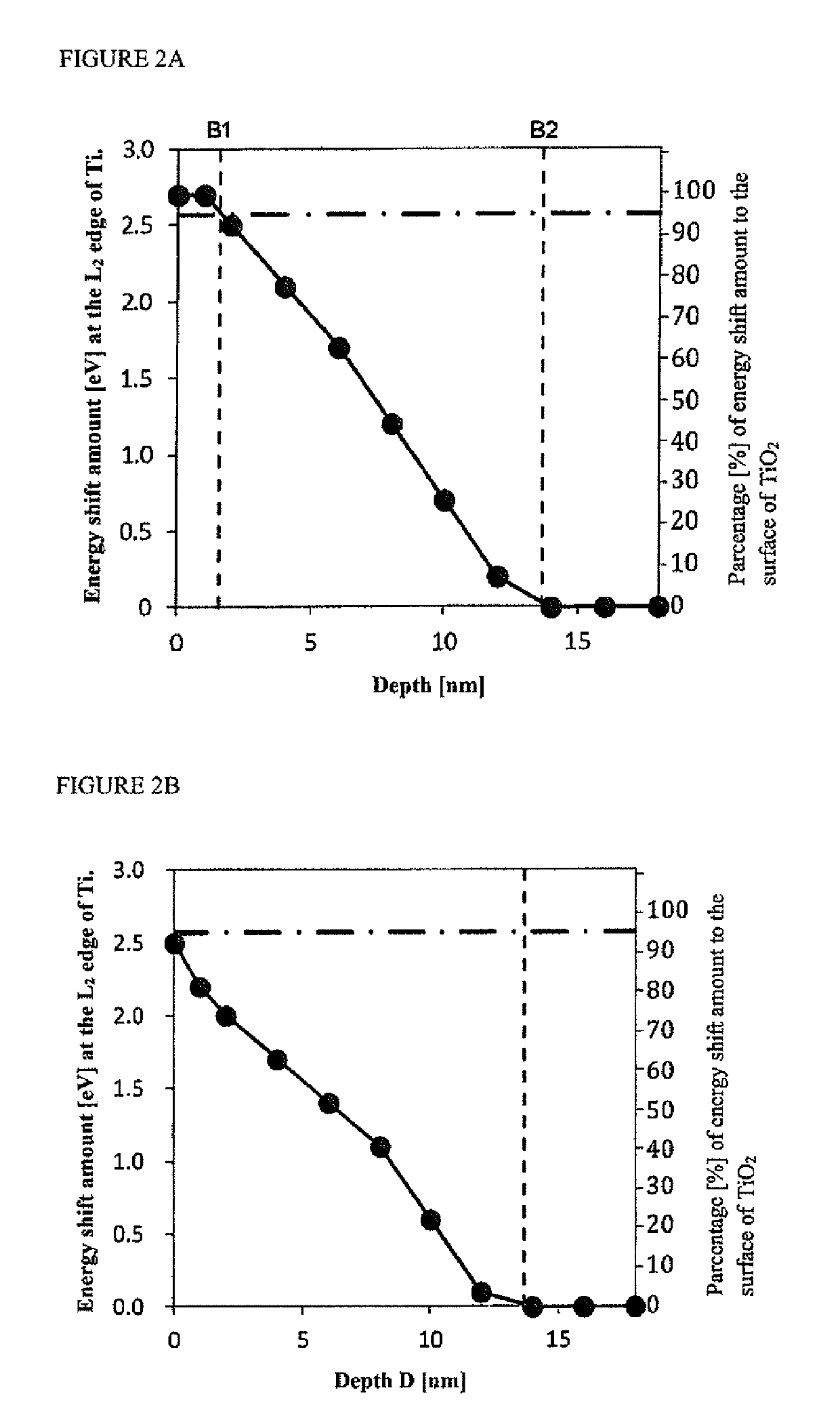

Titanium product, separator, and proton exchange membrane fuel cell, and method for producing titanium product

ActiveUS10505205B2Contact resistanceReduce contact resistanceSolid state diffusion coatingSolid electrolyte fuel cellsFiberElectrical resistance and conductance

A titanium product for a separator of a proton exchange membrane fuel cell according to the present invention includes: a base material that consists of commercially pure titanium; a first oxide layer that is formed in a surface layer of the titanium product, consists of TiO2 of a rutile crystallinity, and has a thickness of 0.1 to 1.5 nm; and a second oxide layer that is formed between the base material and the first oxide layer, consists of TiOx (1<x<2), and has a thickness of 3 to 20 nm. This titanium product is suitable to be used as a separator of a proton exchange membrane fuel cell that has a high corrosion resistance in an environment in a fuel cell, is capable of keeping a low contact resistance with an electrode consisting of carbon fiber and the like, and is inexpensive.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com