Method of producing a nano-winned titanium material by casting

A nano-twin, pure titanium technology, applied in the field of manufacturing commercial pure titanium materials containing nano-twins, can solve the problem of unknown strength of titanium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

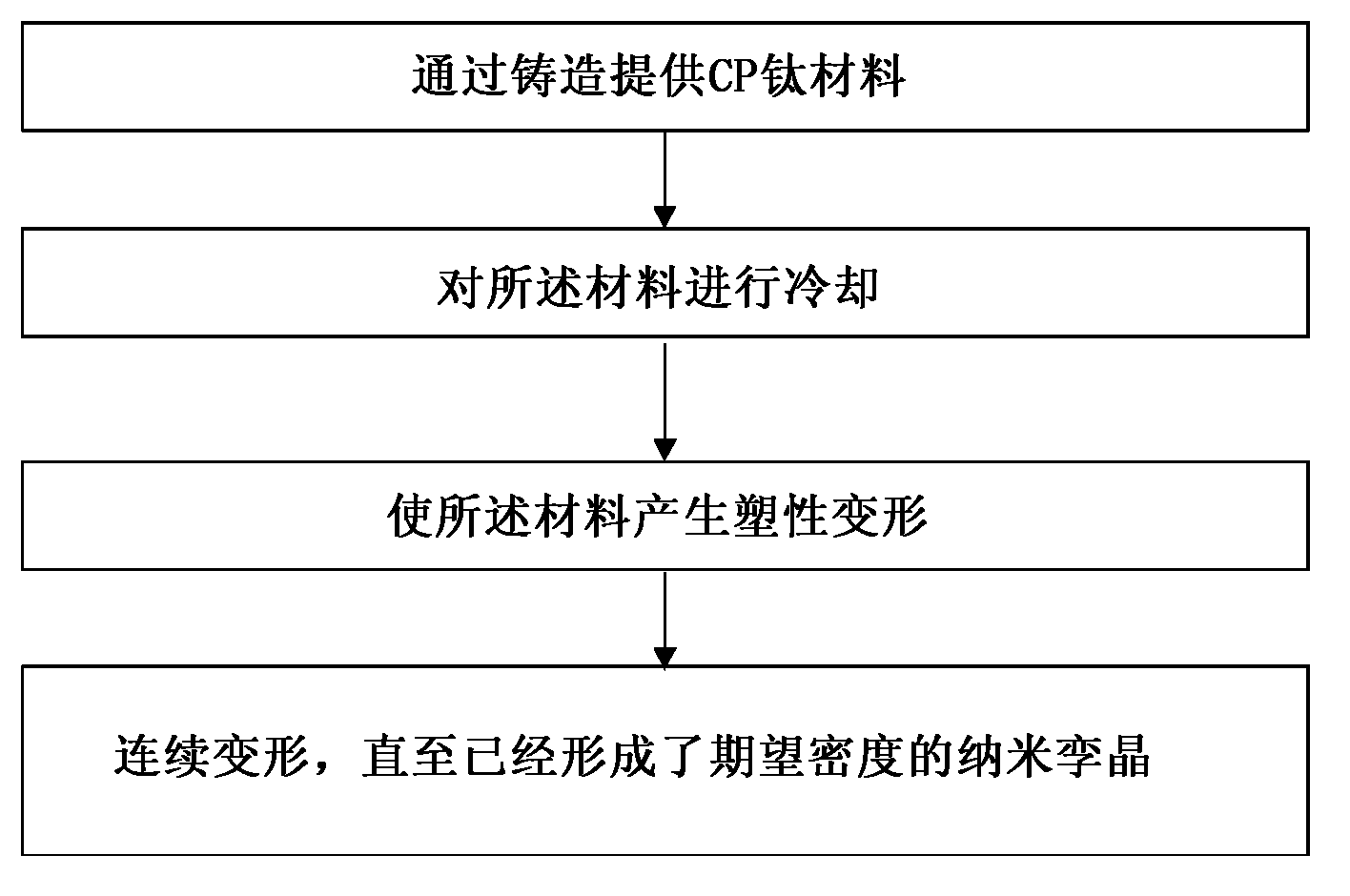

Method used

Image

Examples

Embodiment 1

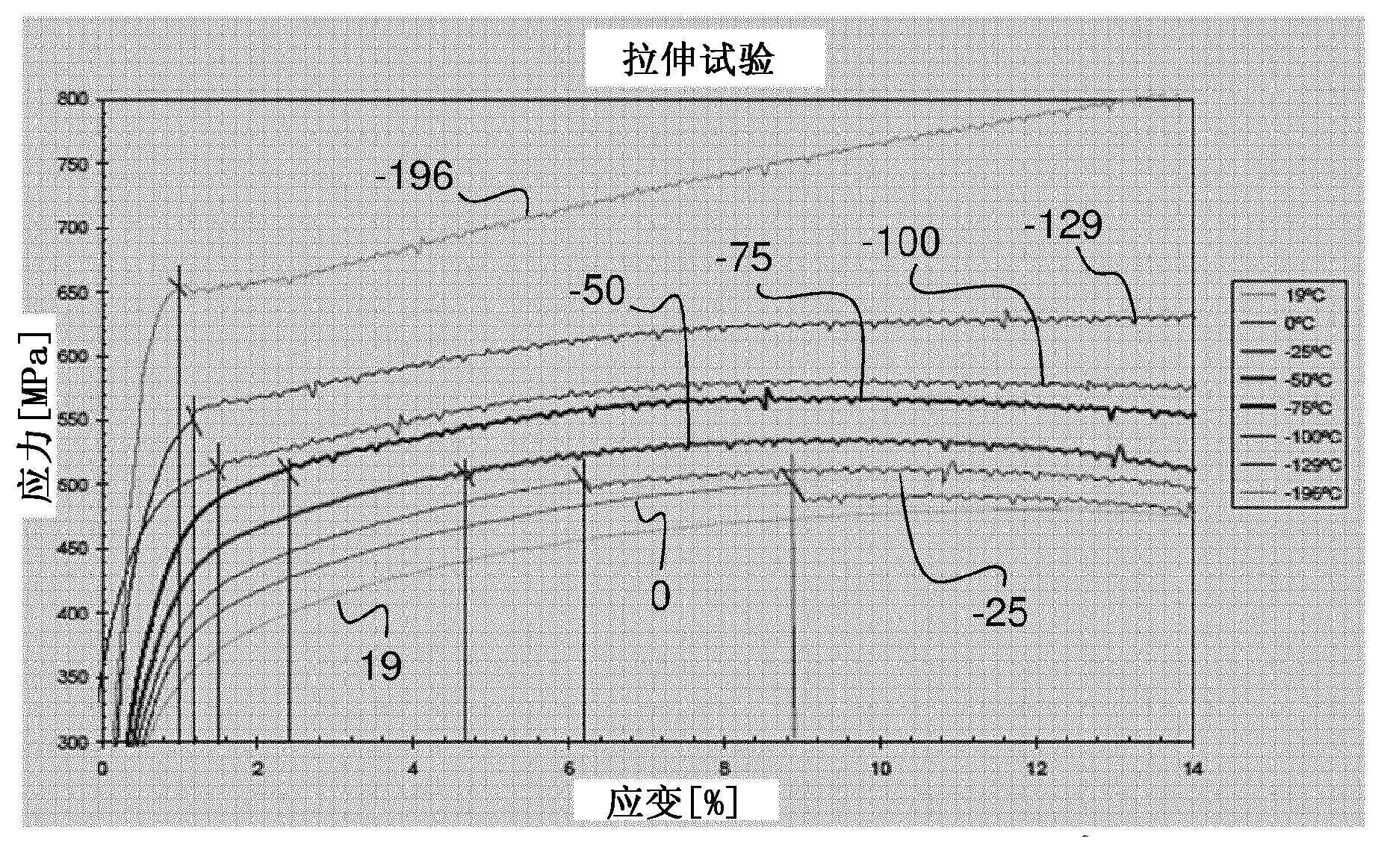

[0059] In Example 1, sample CP Ti#1 was cooled to a temperature below -100°C and then plastically deformed at that temperature.

[0060] A sample with an initial total length of 50 mm was plastically deformed by stretching at a rate of 20 mm / min (0.67% per second) until the total deformation rate was 35%. The deformation is done at 2% intervals.

Embodiment 2

[0062] In Example 2, sample CP Ti#2 was cooled to a temperature below -100°C and then plastically deformed at that temperature.

[0063] A specimen having an initial total length of 50 mm was plastically deformed by stretching at a rate of 30 mm / min (1% per second) until the total deformation rate was 35%. The deformation is done at 2% intervals.

Embodiment 3

[0065] In Example 3, sample CP Ti#3 was cooled to a temperature below -100°C and then plastically deformed at that temperature.

[0066] A sample with an initial total length of 50 mm was plastically deformed by stretching at a rate of 20 mm / min (0.67% per second) until the total deformation rate was 40%. The deformation is done at 2% intervals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com