Copolymerized polyester and metal primer coating material using same

A technology of copolyester and copolymerization, used in polyester coatings, primers, coatings, etc., can solve the problems of difficult operation, difficulty in increasing the thickness of the coating film, and high solution viscosity, and achieve excellent chemical resistance and high corrosion resistance. The effect of stability and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] Hereinafter, examples are given and the present invention will be specifically described. In addition, in this Example and a comparative example, a part shows a mass part.

[0072] (1) Determination of the composition of the copolyester (A)

[0073] Use 400MHz 1 An H-nuclear magnetic resonance spectrometer (hereinafter sometimes abbreviated as NMR) quantifies the molar ratio of the polyvalent carboxylic acid component and the polyhydric alcohol component constituting the copolyester (A). As a solvent, deuterated chloroform was used. In addition, when the acid value of the copolyester is increased by post-addition of acid (Japanese: acid post-addition), the total amount of acid components other than the acid component used in the post-addition of acid is assumed to be 100 mol%, and each value is calculated. The molar ratio of the ingredients.

[0074] (2) Determination of the number average molecular weight of copolyester (A)

[0075] After dissolving 4 mg of the sa...

manufacture example

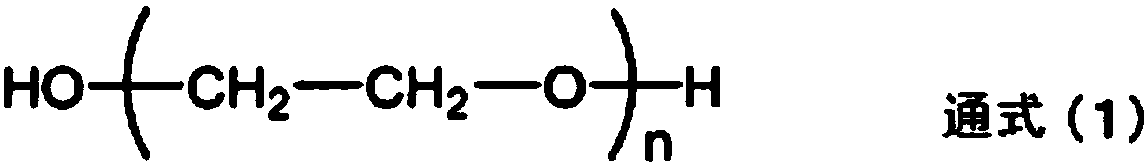

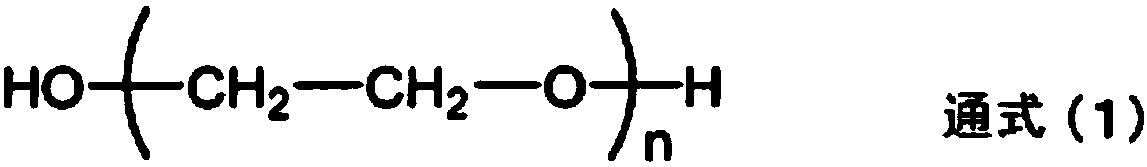

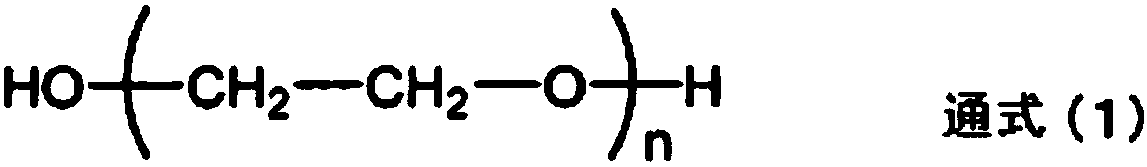

[0084] 809 parts of dimethyl terephthalate, 793 parts of dimethyl isophthalate, 19 parts of trimellitic anhydride, 407 parts of ethylene glycol, 540 parts of neopentyl glycol, 287 parts of triethylene glycol and 0.03 mol% of tetrabutyl orthotitanate relative to all acid components was charged into a reaction vessel equipped with a stirrer, a condenser, and a thermometer, and the temperature was raised from 160°C to 220°C over 4 hours, while going through the methanol removal process. transesterification reaction. Next, in the polycondensation reaction process, the pressure in the reaction system was reduced to 5 mmHg over 20 minutes, and then the temperature was raised to 250°C. Next, the pressure was reduced to 0.3 mmHg or less, the polycondensation reaction was performed for 60 minutes, and this was taken out. As a result of the compositional analysis by NMR, the mol ratio of the copolyester (a1) obtained is: terephthalic acid / isophthalic acid / trimellitic acid / ethylene glyc...

Embodiment 1

[0090] Preparation of metallic primer paint (A1)

[0091] 80 parts of copolyester (a1) were dissolved in the mixed solvent of 100 parts of cyclohexanone and 100 parts of Solvesso 150. 50 parts of calcium silicate, 13 parts of aluminum tripolyphosphate, and 37 parts of titanium oxide were added thereto, and dispersed for 6 hours using a shaker. Next, 20 parts of CYMEL 303 (manufactured by Allnex, melamine curing agent) as a crosslinking agent and 0.2 part of dodecylbenzenesulfonic acid as a curing catalyst were added to prepare the metal primer paint (Al) of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com