Rust conversion water-based metal primer and preparation method thereof

A rust water, metal technology, applied in the field of rust-to-rust water-based metal primer and its preparation, can solve problems such as carcinogenicity and adverse human health, and achieve the effects of delaying corrosion, excellent moisture and heat resistance, and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

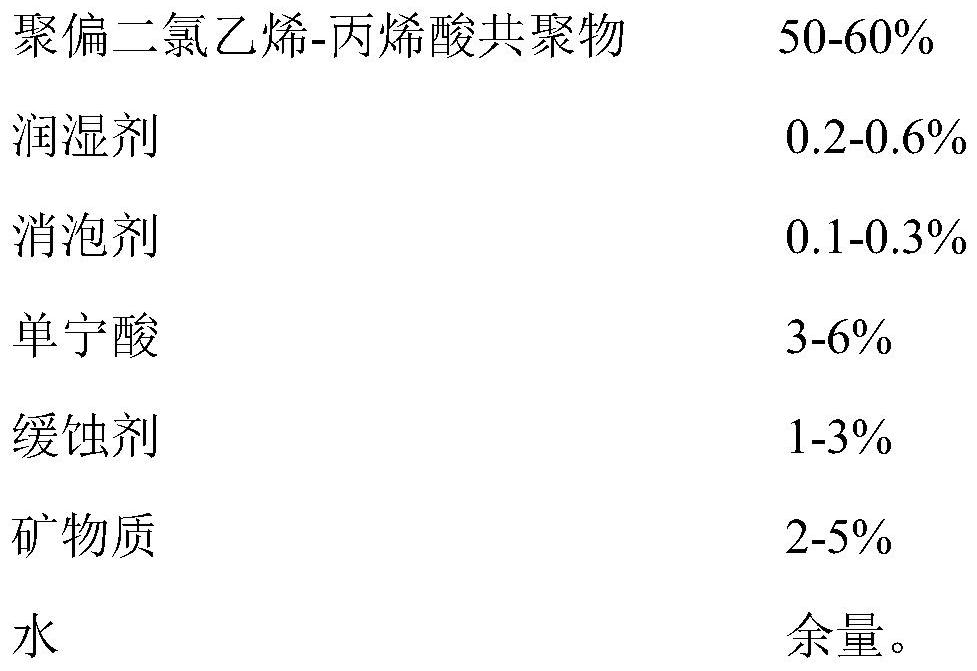

[0034] A water-based metal primer for turning rust with rust comprises the following components in mass fraction:

[0035]

[0036] The preparation method of described band rust turning rust water-based metal primer, comprises the steps:

[0037] S1. In a high-speed disperser, according to the above mass fraction, dissolve tannic acid in a part of deionized water (accounting for about 1 / 2 of the total mass of deionized water), and disperse at 40-45°C for 20 minutes to a transparent state. form a mixture;

[0038] S2. In a high-speed disperser, according to the above mass fraction, dissolve polyvinylidene chloride-acrylic acid copolymer, corrosion inhibitor, wetting agent, and defoamer in deionized water of the remaining mass and disperse for 20 minutes, and then add the Mixed solution, disperse for 15 minutes;

[0039] S3. According to the above mass fraction, add tourmaline powder to the product obtained in step S2, and continue to disperse for 30 minutes to obtain the f...

Embodiment 2

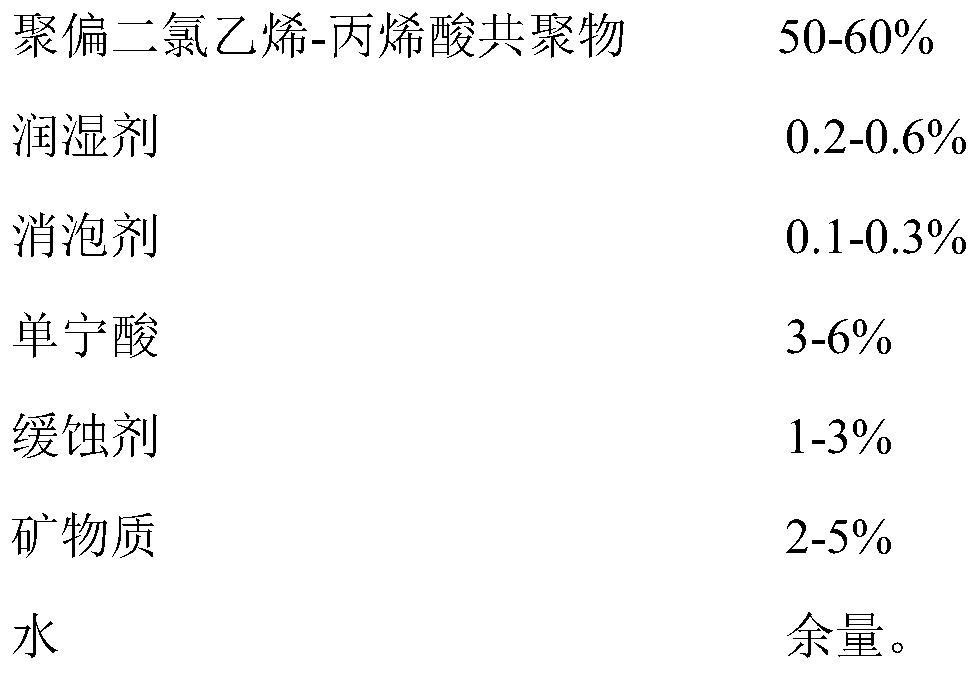

[0041] A water-based metal primer for turning rust with rust comprises the following components in mass fraction:

[0042]

[0043] The preparation method of described band rust turning rust water-based metal primer, comprises the steps:

[0044] S1. In a high-speed disperser, according to the above mass fraction, dissolve tannic acid in a part of deionized water (accounting for about 1 / 2 of the total mass of deionized water), and disperse at 40-45°C for 20 minutes to a transparent state. form a mixture;

[0045] S2. In a high-speed disperser, according to the above mass fraction, dissolve polyvinylidene chloride-acrylic acid copolymer, corrosion inhibitor, wetting agent, and defoamer in deionized water of the remaining mass and disperse for 20 minutes, and then add the Mixed solution, disperse for 15 minutes;

[0046] S3. According to the above mass fraction, add tourmaline powder to the product obtained in step S2, and continue to disperse for 30 minutes to obtain the fin...

Embodiment 3

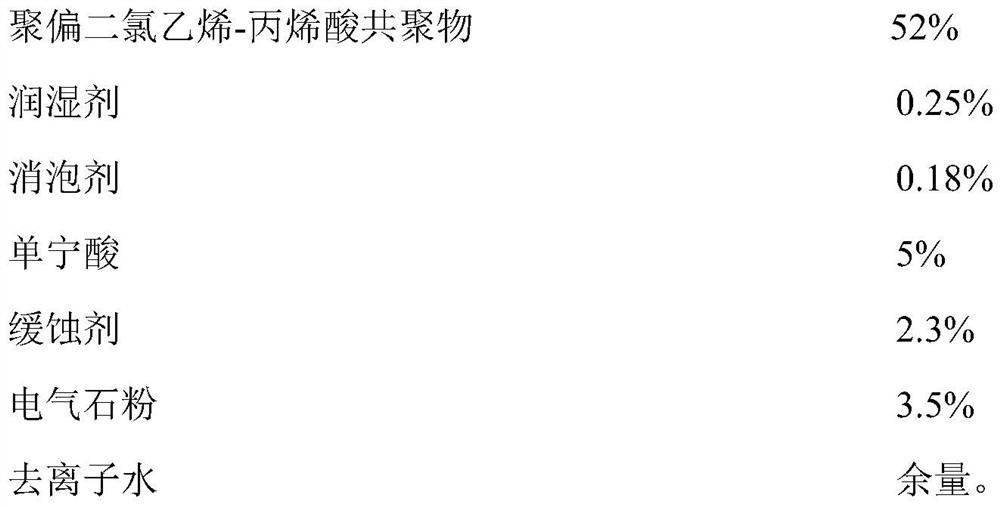

[0048] A water-based metal primer for turning rust with rust comprises the following components in mass fraction:

[0049]

[0050] The preparation method of described band rust turning rust water-based metal primer, comprises the steps:

[0051] S1. In a high-speed disperser, according to the above mass fraction, dissolve tannic acid in a part of deionized water (accounting for about 1 / 2 of the total mass of deionized water), and disperse at 40-45°C for 20 minutes to a transparent state. form a mixture;

[0052] S2. In a high-speed disperser, according to the above mass fraction, dissolve polyvinylidene chloride-acrylic acid copolymer, corrosion inhibitor, wetting agent, and defoamer in deionized water of the remaining mass and disperse for 20 minutes, and then add the Mixed solution, disperse for 15 minutes;

[0053] S3. According to the above mass fraction, add tourmaline powder to the product obtained in step S2, and continue to disperse for 30 minutes to obtain the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com