Reaction type flame retardant for soft polyurethane foam and application

A reactive flame retardant, polyurethane soft foam technology, applied in the field of flame retardants, can solve the problems of soft foam mist value and VOC unqualified, flame retardant migration, easy migration of plasticizers, etc., to achieve excellent flame compounding Performance, long-lasting flame retardant effect, and high peel strength

Inactive Publication Date: 2011-08-31

北京万博汇佳科贸有限公司

View PDF5 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] This technology of using additive flame retardant has the following disadvantages: ①. During the use of polyurethane foam, the flame retardant may migrate, resulting in a reduction in the flame retardant effect; the migrated small molecule flame retardant will make The fog value and VOC of the soft foam are unqualified, and these characteristics are especially required for applications in automobiles

② Added flame retardants have a greater impact on the mechanical properties and performance of polyurethane foam, mainly in the decline in tensile and rebound properties to a large extent

Although the use of plasticizers can temporarily improve the performance of foams, plasticizers are toxic and have been gradually restricted in use

And the plasticizer is easy to move out, which will cause the fog value and VOC of the foam to be unqualified

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

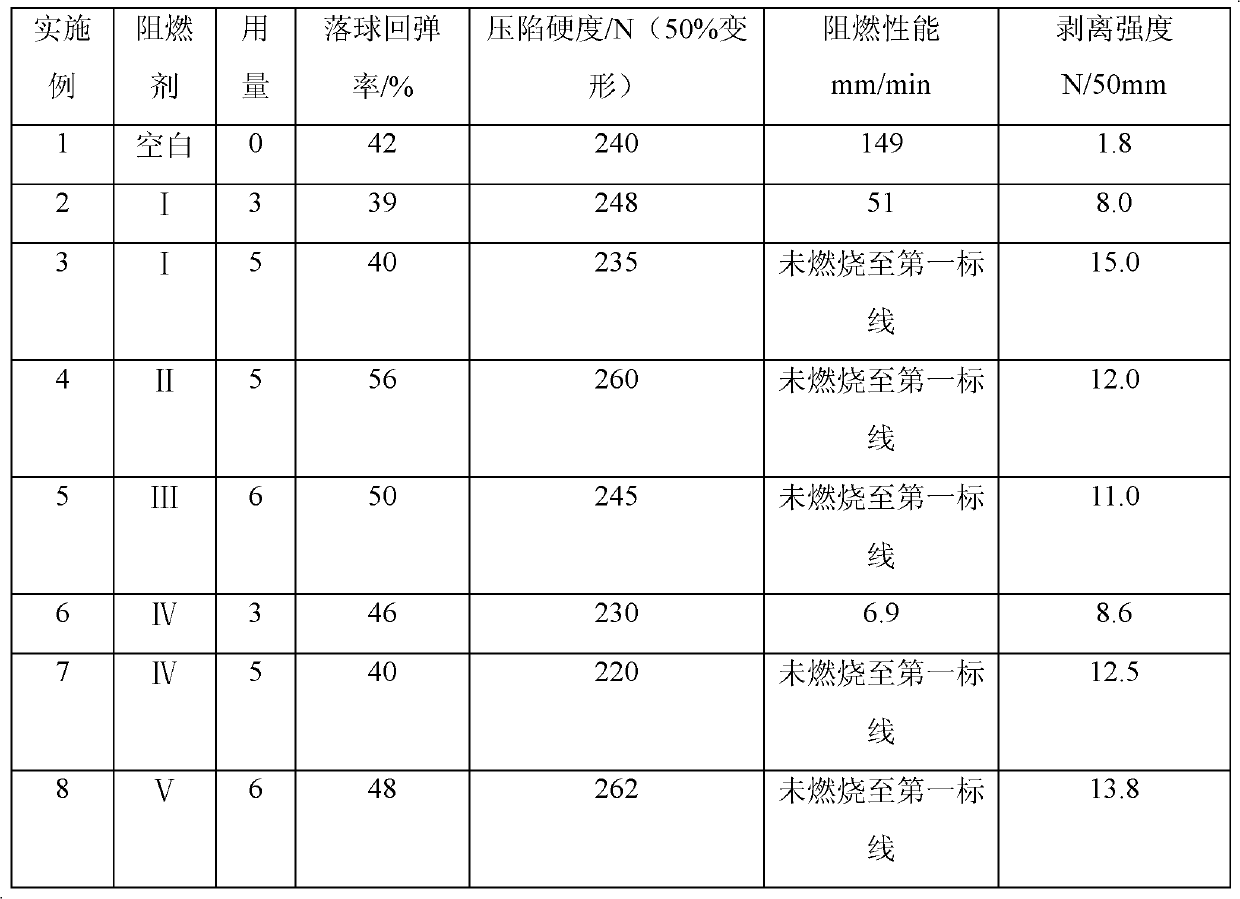

[0014] The following further illustrates the present invention in conjunction with the foaming and detection results of the flexible polyurethane foam, rather than limiting the scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a reaction type flame retardant for soft polyurethane foam and an application, belonging to the technical field of the flame retardants. The reaction type flame retardant contains three components, namely a phosphorus-containing polyhydroxy compound, a halogen-containing polylol and a chain extender with two degrees of functionality. When the flame retardant is in use, the reaction type flame retardant can be directly added into polyether polylol and is good in compatibility with the polyether polylol, and the precipitation can be avoided. The polyurethane foam prepared by the reaction type flame retardant is lasting in flame retarding effect and further has the characteristics of low VOC (volatile organic compounds) and low atomization, the flame retarding effect can not be reduced after aging, and adverse impacts on physical properties of the foam can be avoided. The soft foam using the flame retardant has excellent flame laminating performance and great peeling strength, and is suitable for being used as an interior trimming material for automobiles and airplanes.

Description

technical field [0001] The invention relates to a reactive flame retardant and its application in flexible polyurethane foam plastics, belonging to the technical field of flame retardants. Background technique [0002] Flexible polyurethane foam has excellent properties such as light weight, softness, insulation, and breathability, and is widely used in many industries such as aircraft, automobiles, ships, and furniture. However, the polyurethane foam base material has the defects of being extremely easy to catch fire, dripping, spreading rapidly, and being extremely difficult to extinguish. The most commonly used method to solve this problem is to add flame retardants in the polyurethane foaming process. There are many documents related to flame retardants and improving the physical properties of polyurethane foams. For example, U.S. Patent USP6855741 discloses a kind of improved flexible polyurethane foam plastics, and its flame retardant adopts alkyl benzyl phthalate and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G18/32C08G18/66C08G18/48C08G18/42C08J9/12C08G101/00

Inventor 王建荣

Owner 北京万博汇佳科贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com