Normal-temperature curing type metal primer and preparation method thereof

A room temperature curing, metal bottom technology, applied in coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of difficult pre-treatment production lines, time-consuming and energy-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

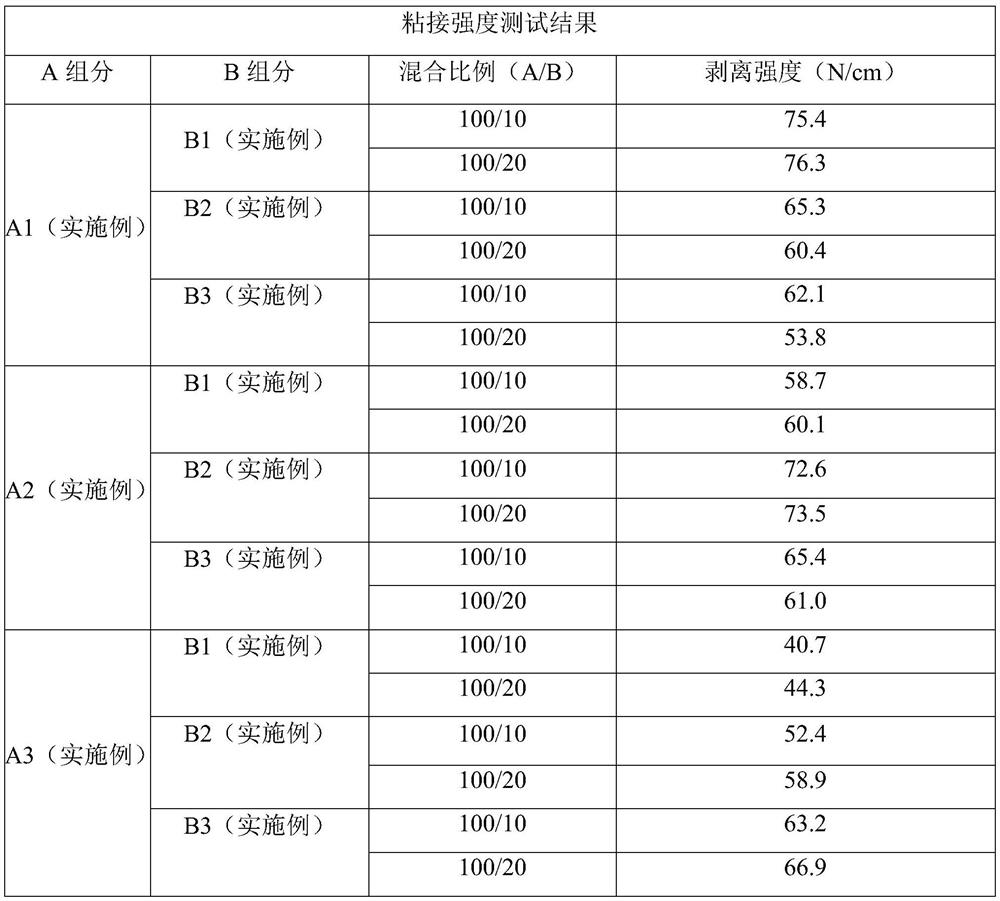

Embodiment 1

[0025] This embodiment provides a solvent-based metal primer, which is prepared through the following steps:

[0026] (a) 100 parts by weight of high molecular weight epoxy resin (usually bisphenol A type, with a softening point of 140°C-155°C) and 20 parts by weight of heat-activated TPU resin (heat activation temperature of 50°C-60°C) are dissolved In 680 parts by weight of a mixed solvent (butanone: ethyl acetate: butyl acetate = 2:1:1, volume ratio), stir and dissolve to obtain component A, with a solid content of 15%, marked as: A1 (Example);

[0027] (b) Dissolve 100 parts by weight of polyisocyanate (polyphenyl polyisocyanate) in 100 parts by weight of ethyl acetate to obtain the first mixture; dissolve 10 parts by weight of silane coupling agent (aminosilane) in 40 parts by weight of ethyl acetate The second mixture was obtained in the ester; under the high-speed stirring state, the second mixture was added dropwise to the first mixture, and the B component was obtaine...

Embodiment 2

[0029] This embodiment provides a solvent-based metal primer, which is prepared through the following steps:

[0030] Basically consistent with that in Example 1, the difference is: in A2 (embodiment), the ratio of macromolecular epoxy resin and TPU is 100:30; Among the B2 (embodiment), the ratio of isocyanate and silane coupling agent is 100 :20.

Embodiment 3

[0032] This embodiment provides a solvent-based metal primer, which is prepared through the following steps:

[0033] Basically consistent with that in Example 1, the difference is: in A3 (embodiment), the ratio of polymer epoxy resin and TPU is 100:40; among the B3 (embodiment), the ratio of isocyanate and silane coupling agent is 100 :30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com