Aqueous polyurethane anticorrosive metal primer paint and preparation method thereof

A water-based polyurethane and polyurethane technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve problems such as lack of self-healing ability, uneven dispersion of anti-corrosion agents, anti-corrosion failure, etc., to achieve good self-healing ability, Good and long-lasting anti-corrosion effect, long-lasting effect of anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

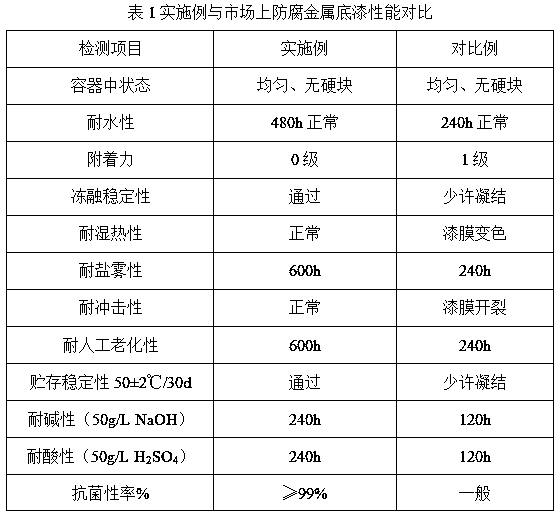

Examples

Embodiment 1

[0034] A kind of polyurethane aqueous resin X containing Schiff base structure, its preparation process is as follows:

[0035] a. In a four-port reaction kettle equipped with a thermometer and an agitator, add 1.8 parts of butanediol, 2.0 parts of trimethylolpropane, 8.2 parts of polytetrahydrofuran polyol and dimethylol propionic acid in order according to the weight of the formula 2.5 parts, heat up to 90-105°C for vacuum dehydration for 1.5-2.0 hours;

[0036] b. Cool down to 65-70°C, install a condenser tube, add 10.4 parts of isophorone diisocyanate and 0.4 parts of dibutyltin dilaurate in the formula, feed nitrogen, keep warm for 1.0h, and then heat up to 80-82°C React for 2.0-2.5 hours, add 11.0 parts of acetone to adjust the viscosity, then raise the temperature to 85-88 ° C, slowly add 3.6 parts of salicylaldehyde Schiff base, add for 3-3.5 hours, then continue the heat preservation reaction for 1-1.5 hours, and detect , when the NCO value is consistent with the des...

Embodiment 2

[0039] A kind of polyurethane aqueous resin Y containing Schiff base structure, its preparation process is as follows:

[0040]a. In a four-port reaction kettle equipped with a thermometer and an agitator, add 2.2 parts of neopentyl glycol, 1.3 parts of glycerin, 10.0 parts of polyether glycol and 2.8 parts of dimethylol propionic acid in sequence according to the weight of the formula , heated to 90-105°C for vacuum dehydration for 1.5-2.0 hours;

[0041] b. Cool down to 65-70°C, install a condenser tube, add 13.5 parts of isophorone diisocyanate and 0.5 part of dibutyltin dilaurate in the formula, feed nitrogen, keep warm for 1.0h, and then heat up to 80-82°C React for 2.0-2.5 hours, add 12.0 parts of acetone to adjust the viscosity, then raise the temperature to 85-88 ° C, slowly add 4.2 parts of salicylaldehyde Schiff base, the addition time is 3-3.5 hours, and then continue the heat preservation reaction for 1-1.5 hours, Detection, when the NCO value is consistent with t...

Embodiment 3

[0044] A kind of waterborne polyurethane anticorrosion metal primer, its preparation steps are as follows:

[0045] A. According to the set weight parts, mix and stir 8.5 parts of deionized water, 0.3 parts of wetting agent, 0.8 parts of dispersant, and 0.2 parts of defoamer evenly, add 6.0 parts of fumed silica, 12.0 parts of mica powder, and use 1500 ~2000rpm high-speed stirring and dispersing for 0.5h to obtain a uniform aqueous dispersion;

[0046] B. Add 40.0 parts of polyurethane antibacterial water-based resin containing Schiff base structure X and 20.0 parts of nanometer water-based acrylic resin to the above-mentioned water-based dispersion under stirring at 600-800 rpm, and then add 3.5 parts of film-forming aids and 0.3 parts of leveling agent 0.1 part of defoaming agent, 0.2 part of thickening and anti-settling agent, 0.3 part of pH regulator, stir and disperse evenly;

[0047] C. Add 5.8 parts of deionized water and 2.0 parts of triethylamine, and stir evenly to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com