Microspheric ion exchange flash-rust-resistant anti-rust metal primer and preparation method thereof

An ion exchange and anti-flash rust technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of poor paint film compactness, poor anti-rust effect, poor flash rust resistance, etc., and achieve uniform paint film and excellent paint film compactness. , the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

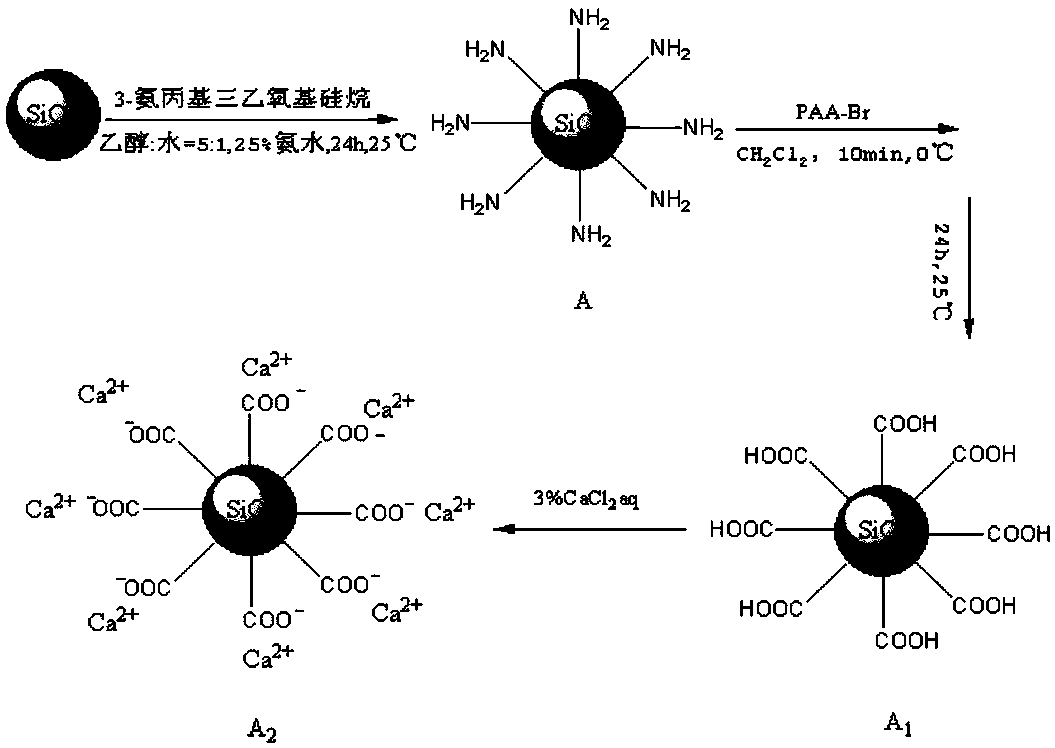

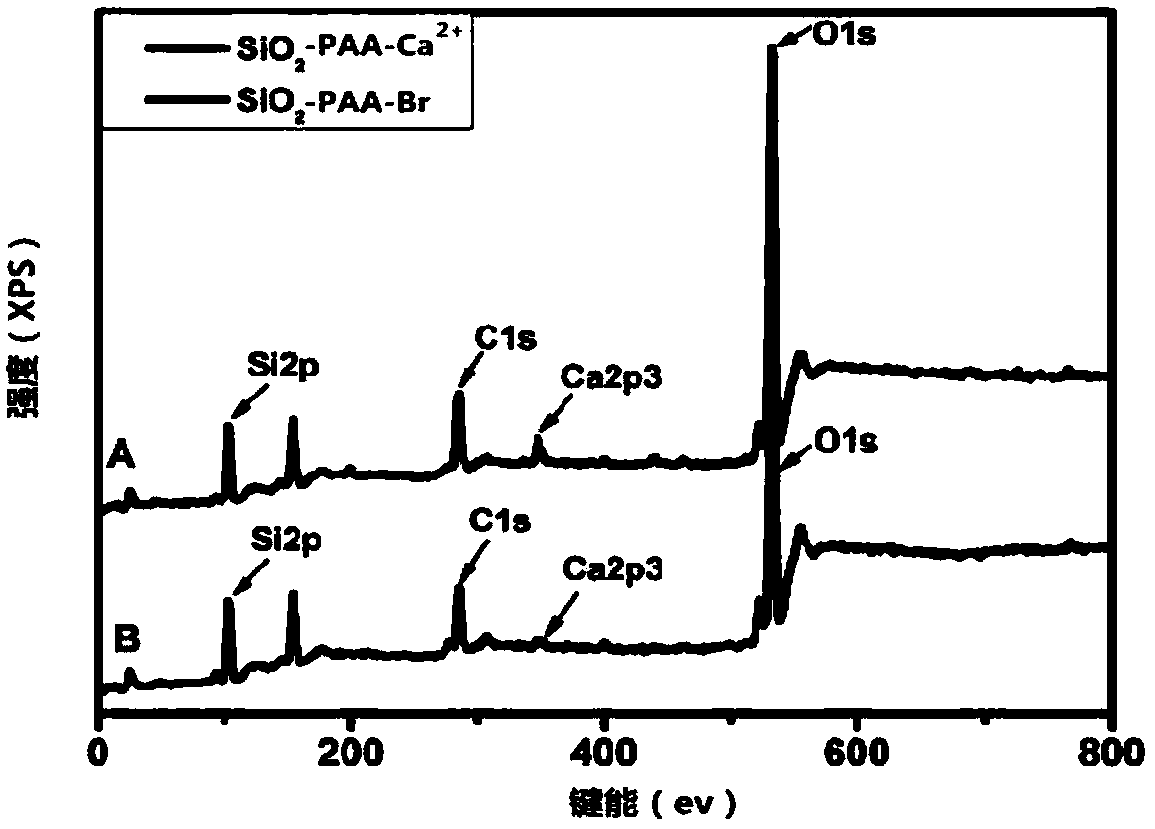

[0049] Embodiment A: Preparation of microspherical silica gel containing calcium ions

[0050] Prepare 3-aminopropyltriethoxysilane, ethanol, deionized water, 25% ammonia water, anhydrous calcium chloride, PAA-Br, dichloromethane and other raw materials, and prepare them according to the following steps:

[0051] Disperse a certain amount of silicon dioxide in a mixed solution of ethanol: water = 5: 1 by ultrasonic waves, then add 25% ammonia water and 3-aminopropyltriethoxysilane, stir at 25°C for 24h, filter, wash, Vacuum drying for 10 hours to obtain A;

[0052] Disperse A in dichloromethane and NaHPO 4 -NaH 2 PO 4 (pH=6) into the mixed solution, add PAA-Br, 0°C, 10min, then warm up to 25°C, stir for 24h, centrifuge, wash, and vacuum dry for 10h to obtain A 1 ;

[0053] Will A 1 Disperse in deionized water, add 3% CaCl2, stir for 24h, centrifuge, wash, and vacuum dry for 10h to obtain the surface calcium ionized silica A 2 .

[0054] figure 1 It is a schematic flow...

Embodiment B

[0055] Example B: Formulation of a mixture of hydroxyethyl cellulose ether and non-associative polyurethane

[0056] Prepare Dow Chemical's 250MBR (hydroxymethyl cellulose ether with a number average molecular weight of 25,000-30,000) and Names Deqian's HX6008 (non-associative polyurethane), according to m (250MBR): m ( HX6008) = 1:9 for preparation, using a rotational viscometer (No. 3 rotor) to measure the viscosity of the mixture, which is 30000pa.s.

Embodiment 1

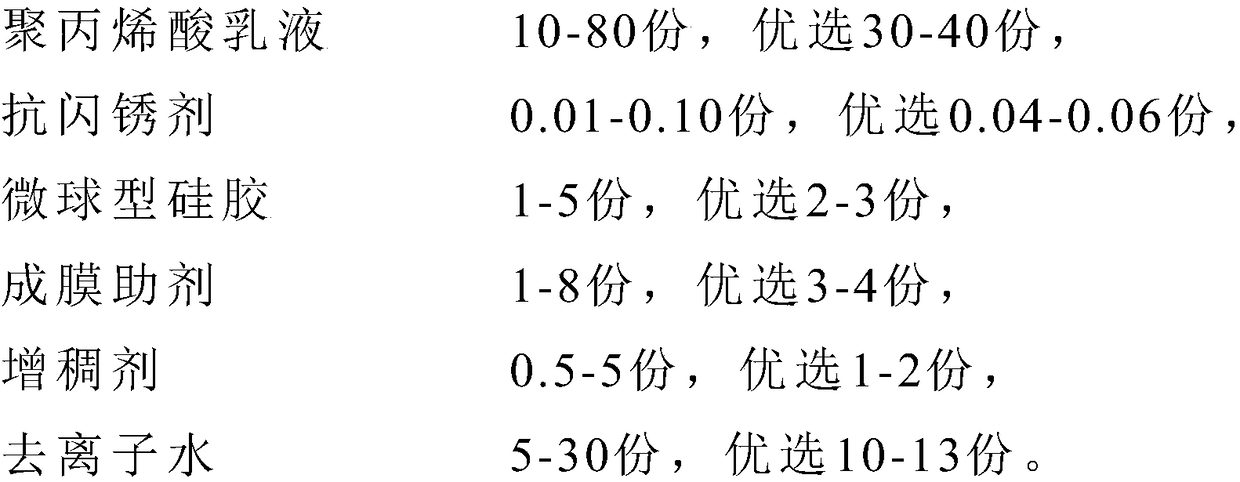

[0057] Embodiment 1: preparation is applicable to the waterborne antirust primer of metal substrate

[0058] Prepare each raw material: 120g deionized water, 350g polyacrylic acid emulsion (AS9519 of Dow Chemical Company), 80g hollow structure polymer emulsion (excellent creation E of Dow Chemical Company), 30g film-forming aid (Eastman Company's Alcohol ester 12), 15g thickening agent (250MBR of Dow Chemical Company and the HX6008), 0.5g pH adjuster (DMAE of Hai Mingsi Company), 0.5g anti-flash rust agent (dimension of Hai Mingsi Company FA 179), 250g body filler (1250 mesh heavy calcium carbonate of Linkou Omiya Company), 25g microspherical calcium ion-containing silica gel (AC3 of Grace Company), 15g strontium phosphate (SZP-391 of Halox Company), 0.5g Bentonite (Hemingsi company's LT).

[0059] Then proceed as follows to prepare:

[0060] Put deionized water into the mixer, and stir for 10 minutes at 600 rpm;

[0061] Under stirring conditions, add film-forming aid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com