High-decoration color alloy powder coating

An alloy powder and decorative technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problem of lower leveling of surface paint, inability to fully wet the pigment, and different shades of coating color and other issues, to achieve the effect of large economic and social benefits, large market development and application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A high-decorative color alloy powder coating, which utilizes the principle of pigment migration to successfully prepare a brightly colored and uniform powder coating transparent paint coating. The effect of metallic primer outer transparent paint can be obtained through two coatings. Its raw material components and parts by weight are respectively:

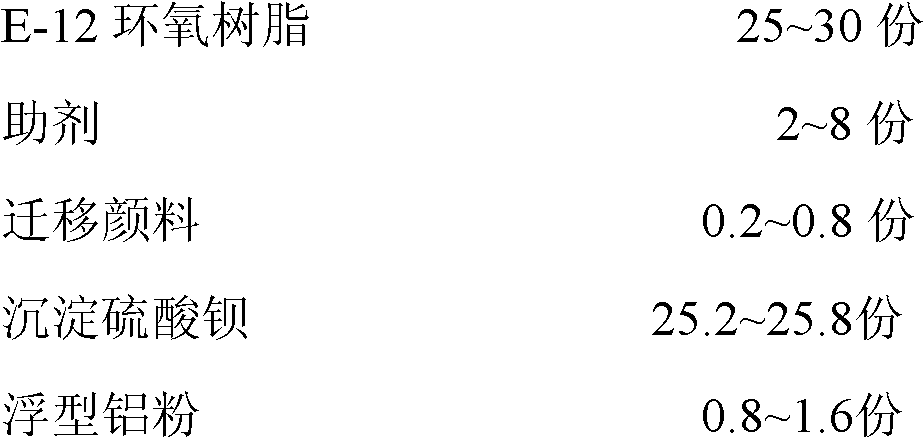

[0031] (1) Silver powder layer (bottom layer):

[0032]

[0033] (2) Transparent powder layer:

[0034]

[0035]

[0036] Among them, the acid value of the 6:4 type polyester is 45-60mg KOH / g, and the polyester viscosity index requirement is ICI viscosity (175°C) 50-60Po, and 6055 of Hangzhou Zhongfa Company is used in this embodiment;

[0037] E-12 epoxy resin uses grade E-12 epoxy, its epoxy equivalent is 710-875g / eq, and the glass transition temperature requirement is 88-92°C. In this embodiment, CYD-014U of Baling Petrochemical is used;

[0038] Auxiliaries include leveling agents (polyacrylate type leveling ...

Embodiment 2

[0056] (1) Silver powder layer (bottom layer):

[0057]

[0058] (2) Transparent powder layer:

[0059]

[0060] Wherein, 6:4 type polyester is with embodiment 1;

[0061] E-12 epoxy resin is Guodu Chemical 242;

[0062] Auxiliary agent is with embodiment 1;

[0063] Leaving aluminum powder is PC100 of Aika Company;

[0064] TGIC type polyester is with embodiment 1;

[0065] Migrating pigment is with embodiment 1.

[0066] Each coating preparation method is the same as in Example 1.

[0067] Through the above formula and preparation method, high decorative color alloy powder coating 2 can be obtained.

[0068] It should be noted that in Example 1 and Example 2, a certain amount of floating aluminum powder was added to the bottom layer, so the final coating effect of the bottom layer depends on the silver powder used, and the resulting effect is electroplated silver or super silver, wherein, according to the implementation The content ratio of the content of the le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com