Patents

Literature

1685 results about "Barium sulphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

UV PTFE diffuser technology

InactiveUS20120168641A1Scattering properties measurementsWater/sewage treatment apparatusUltravioletUltraviolet radiation

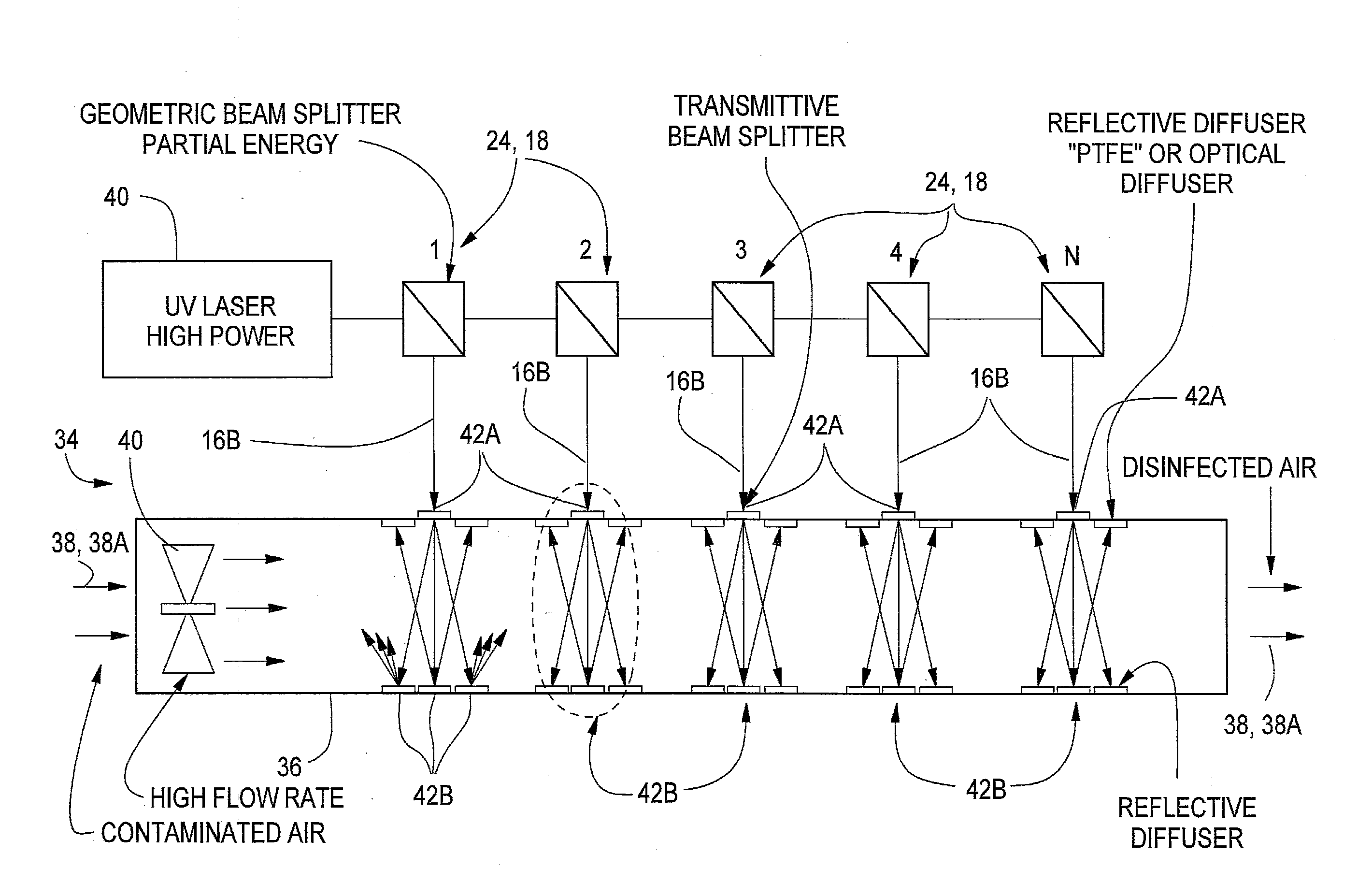

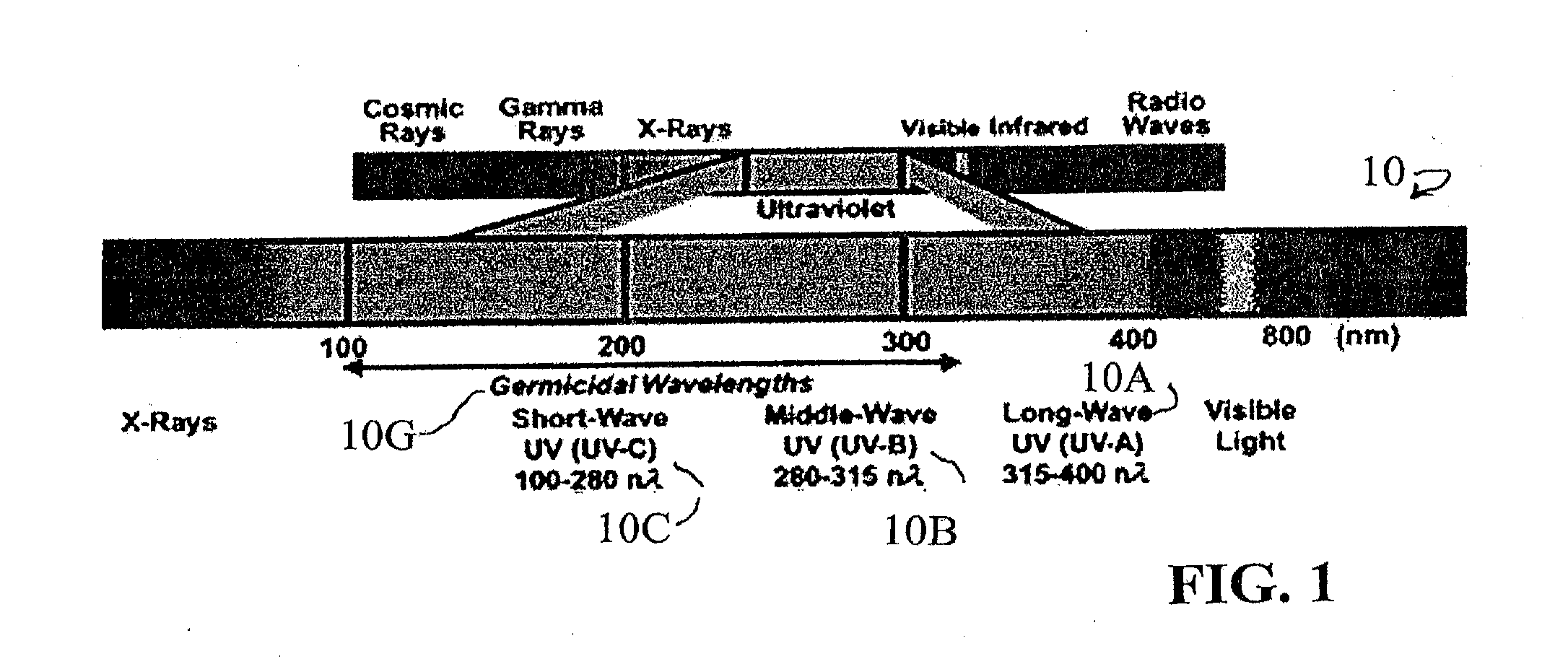

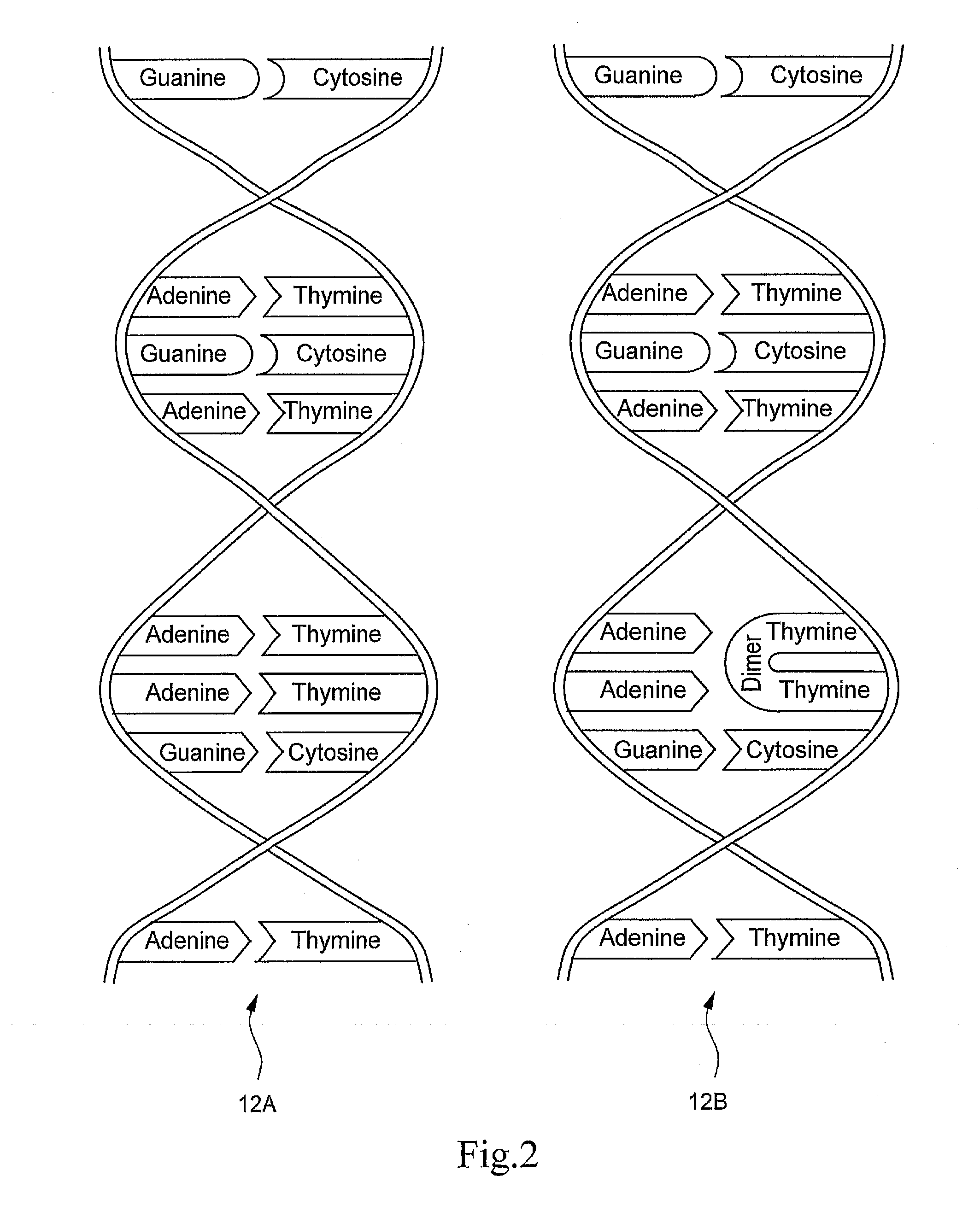

A system for emitting diffused ultraviolet radiation for the disinfection of air, water, food or other surfaces includes a laser for generating a laser beam in a desired wavelength range and a beam shaping system. The beam shaping system includes a beamsplitting optical element for splitting the laser beam into a plurality of beamlets and at least one diffusive reflective element for reflecting at least one beamlet with a diffused radiation profile wherein the at least one diffusive reflective element comprises one of polytetrafluoroethylene (PTFE) and barium sulphate.

Owner:LIZOTTE TODD E

Ink-jet recording material comprising pigment layers

InactiveUS6502935B1Shorten drying timeImprove image qualityDuplicating/marking methodsCoatingsPigmentChemistry

Owner:FELIX SCHOELLER JR FOTO & SPEZIALPAPIERE

Electrically insulative powder coatings and compositions and methods for making them

InactiveUS20050065294A1Increased TgImprove adhesionPlastic/resin/waxes insulatorsInsulated cablesEpoxyAcrylic resin

The present invention provides powder compositions comprising from 20 to 90 phr of one or more than one silicone resin having a glass transition temperature (Tg) of at least 40° C., from 10 to 80 phr of one or more than one resin chosen from glycidyl functional acrylic resin, mixtures of aromatic epoxy resin or novolac resin with carboxyl functional acrylic resin carboxyl functional polyester resin or glycidyl functional acrylic resin, and one or more than one filler, such as wollastonite, barium sulfate, mica, talc, alumina, layered silicates like montmorillonite, and mixtures thereof. The one or more than one silicone resin may or may not be flaked and may or may not contain silanol groups. The compositions of the present invention provide single layer or multilayer powder coatings that are free of voids larger than 30 μm in diameter, and which may meet the UL Class H (180° C.) certification for electrical insulation applications. Further, the compositions may be used to provide powder coatings, films, moldings, electrical potting compounds and electrical encapsulation compounds.

Owner:CRAMER MICHELE LE +2

Polymer cement for percutaneous vertebroplasty and methods of using and making same

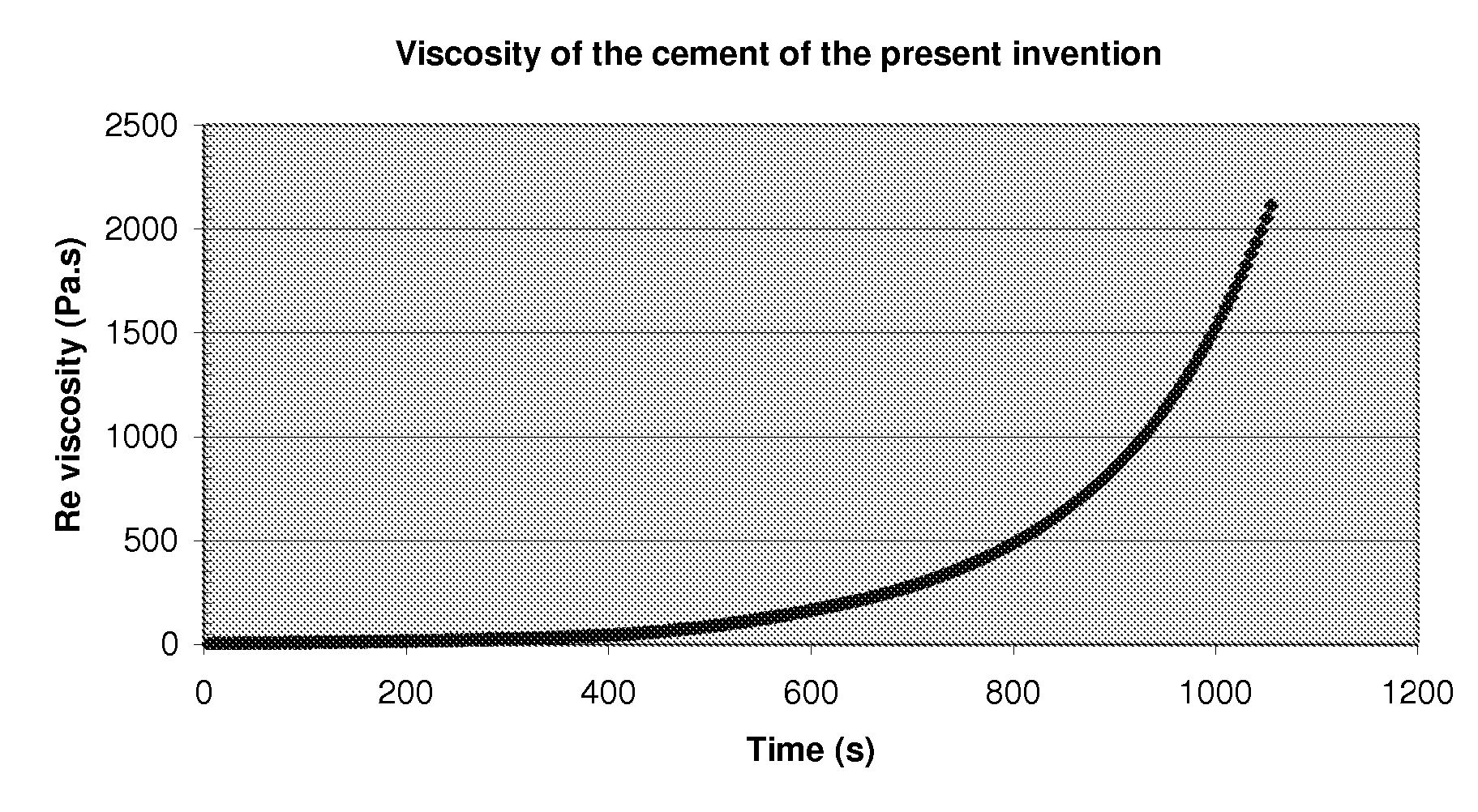

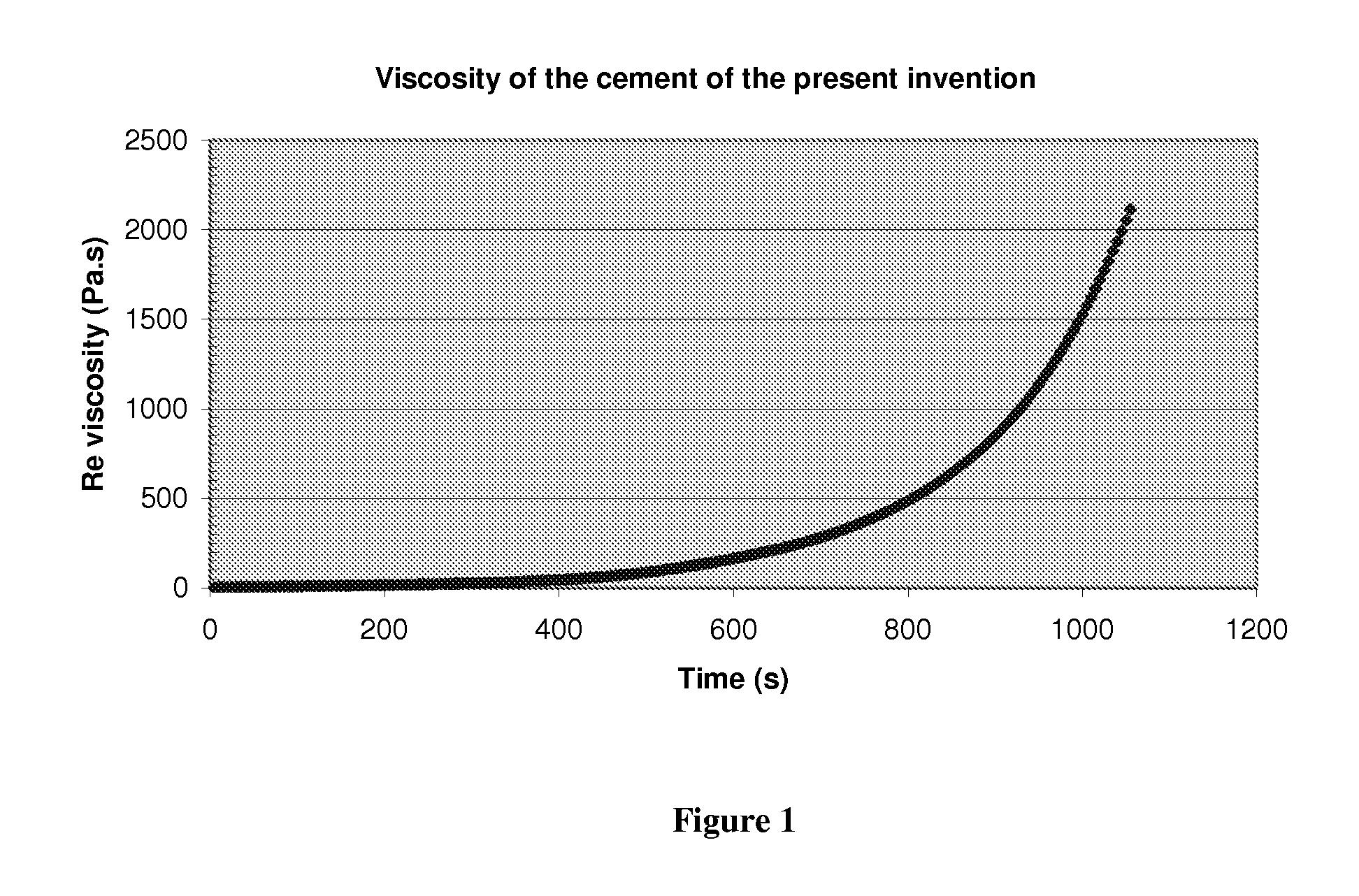

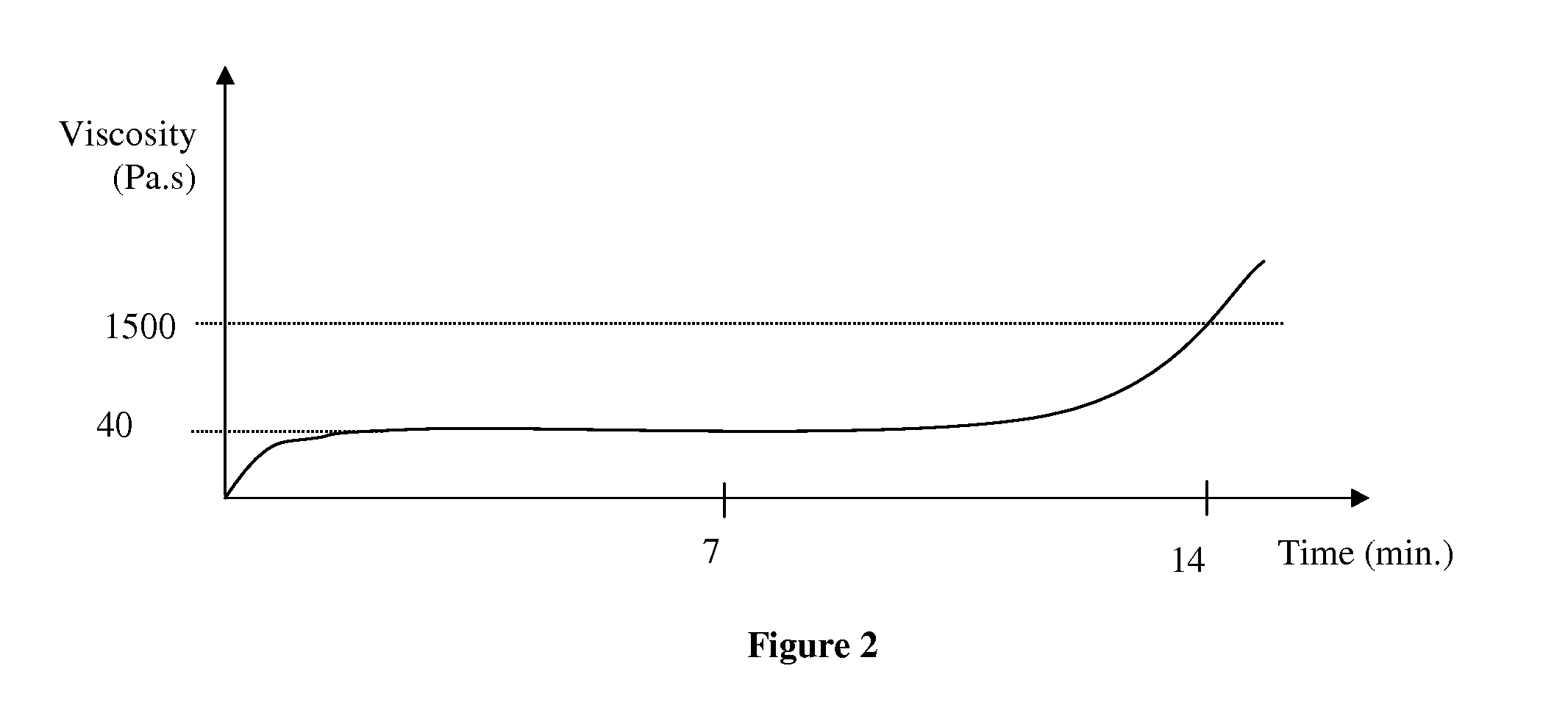

The invention provides a fluid cement for medical use for bone reconstruction, in particular for filling the vertebral body, and a binary composition which is intended for the preparation of such a cement. The invention also provides a device for conditioning the binary composition, and a method of preparing a bone cement from a binary composition. The fluid cement according to the invention comprises: a) approximately 60% to 85% by weight of a polymer comprising a polymethylmethacrylate and a methylmethacrylate monomer and b) approximately from 15 to 40% by weight of a radio-opaque composition. Preferably, the radio-opaque composition comprises a radio-opacifier, such as barium sulfate and zirconium dioxide, in a mixture with a calcium phosphate, for example apatite hydroxide.

Owner:TEKNIMED SAS

Resin bendable grinding wheel and preparation method and device

InactiveCN101804602AAvoid carbonizationIncrease contentFlexible-parts wheelsGrinding devicesFiberglass meshCarbide silicon

The invention discloses a resin bendable grinding wheel and a preparation method and a device thereof. The resin bendable grinding wheel consists of brown aluminium oxide, calcined alumina, white alundum, black silicon carbide, phenolic resin powder, phenolic resin liquid, cryolite, barium sulphate, pyretic, iron oxide red, Hunori gel, alkali-free high tensile glass fiber mesh and non-woven black cloth. Compared with the prior art, through the optimization configuration on the aspect of the material selection and working procedures, the strength, the flexibility and the aging resistance of the grinding wheel are greatly improved, and at the same time, the resource and the energy are saved; and the strength of the grinding wheel is more than 80m / s, the grinding ratio is more than or equal to 1:15, the maximum bendable angle can reach 40 degrees, the tensile strength is greatly improved, the service life is prolonged by two times, the energy consumption is reduced by 5 to 10 percent, and the yield of the finished product can reach more than 99 percent.

Owner:GUIZHOU FUSUN INDAL

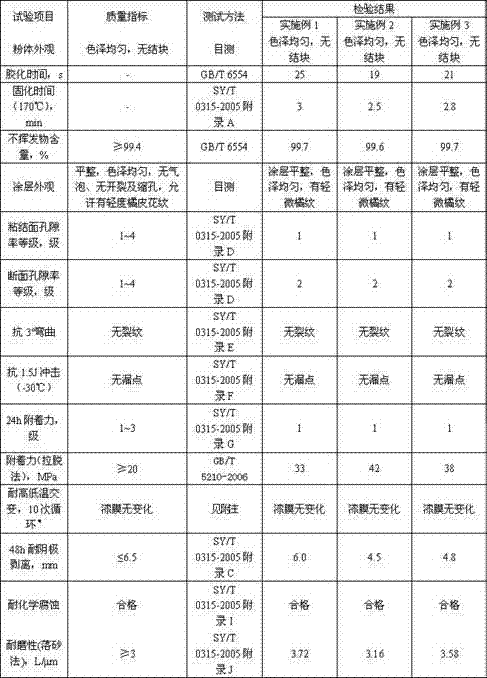

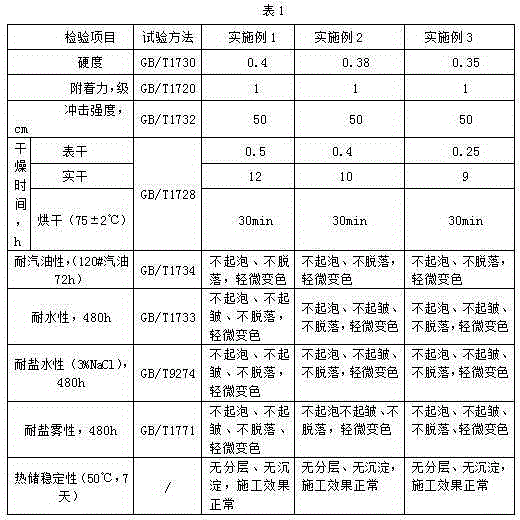

Waterborne residual rust antirust coating and preparation method thereof

ActiveCN103897510AExcellent physical and chemical anti-rustFunction increaseAnti-corrosive paintsEpoxy resin coatingsAcrylic resinMechanical equipment

The invention discloses a waterborne residual rust antirust coating and a preparation method thereof. The waterborne residual rust antirust coating is prepared from styrene-acrylic emulsion, water soluble epoxy resin, water soluble acrylic resin, iron oxide red, graphene, zinc oxide, barium sulphate, transforming agents, a transformation accelerator, a levelling agent, a defoaming agent, a dispersing agent, a thickening agent and water. The waterborne residual rust antirust coating contains no organic solvent, is environment-friendly and pollution-free, has the characteristic that bottom and surface are combined and has an excellent physical and chemical antirust and rust transforming function, is applicable to rust protection of the surface of steel with rust, a hard oxidation skin layer or an oil paint film and is also applicable to rust protection of the surface of rust-free steel, the preparation method is simple, construction is easy, two transforming agents are complexed in the waterborne residual rust antirust coating, so that a binding force between the waterborne residual rust antirust coating and rust is increased, the waterborne residual rust antirust coating can be directly brushed and coated on the surface of rusty steel and is applicable to multiple construction ways such as spraying, brushing and showering, the coating cost is low, and the rust protection requirements of urban road facilities, bridges, oil and gas pipelines, engineering mechanical equipment, ships and the like can be met.

Owner:重庆南方漆业有限公司

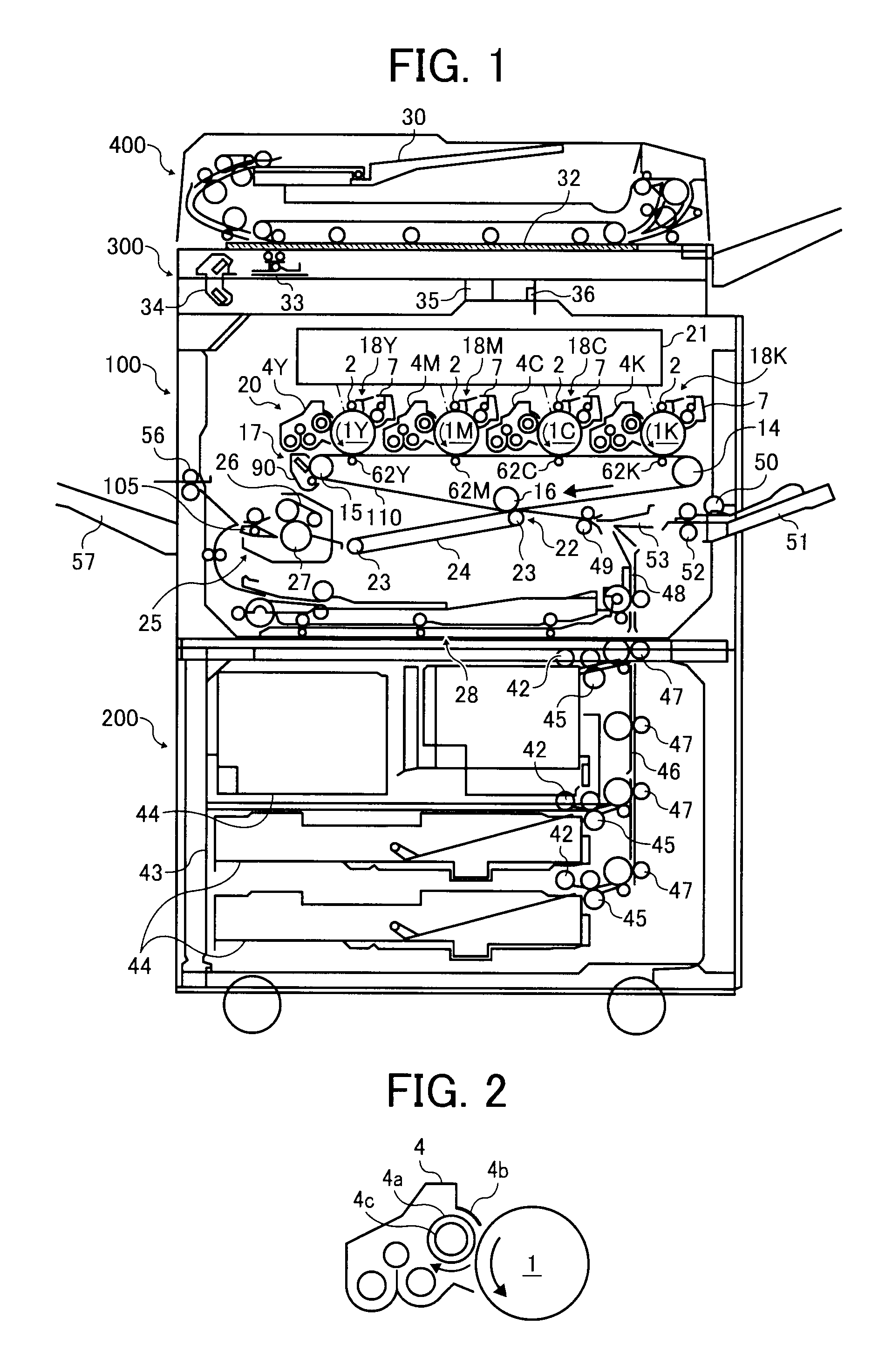

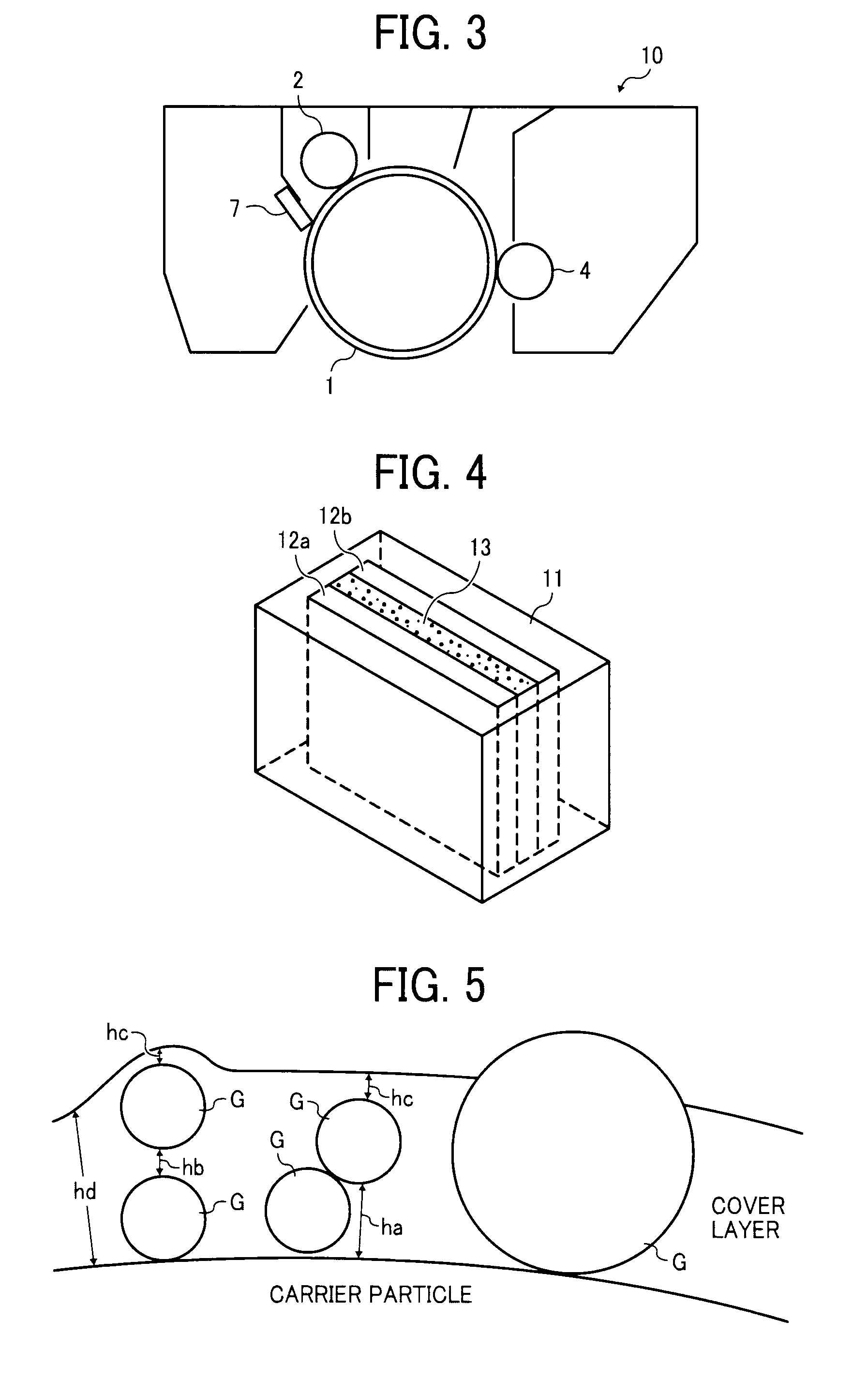

Carrier, developer using the carrier, and developing device, image forming method, image forming apparatus and process cartridge using the developer

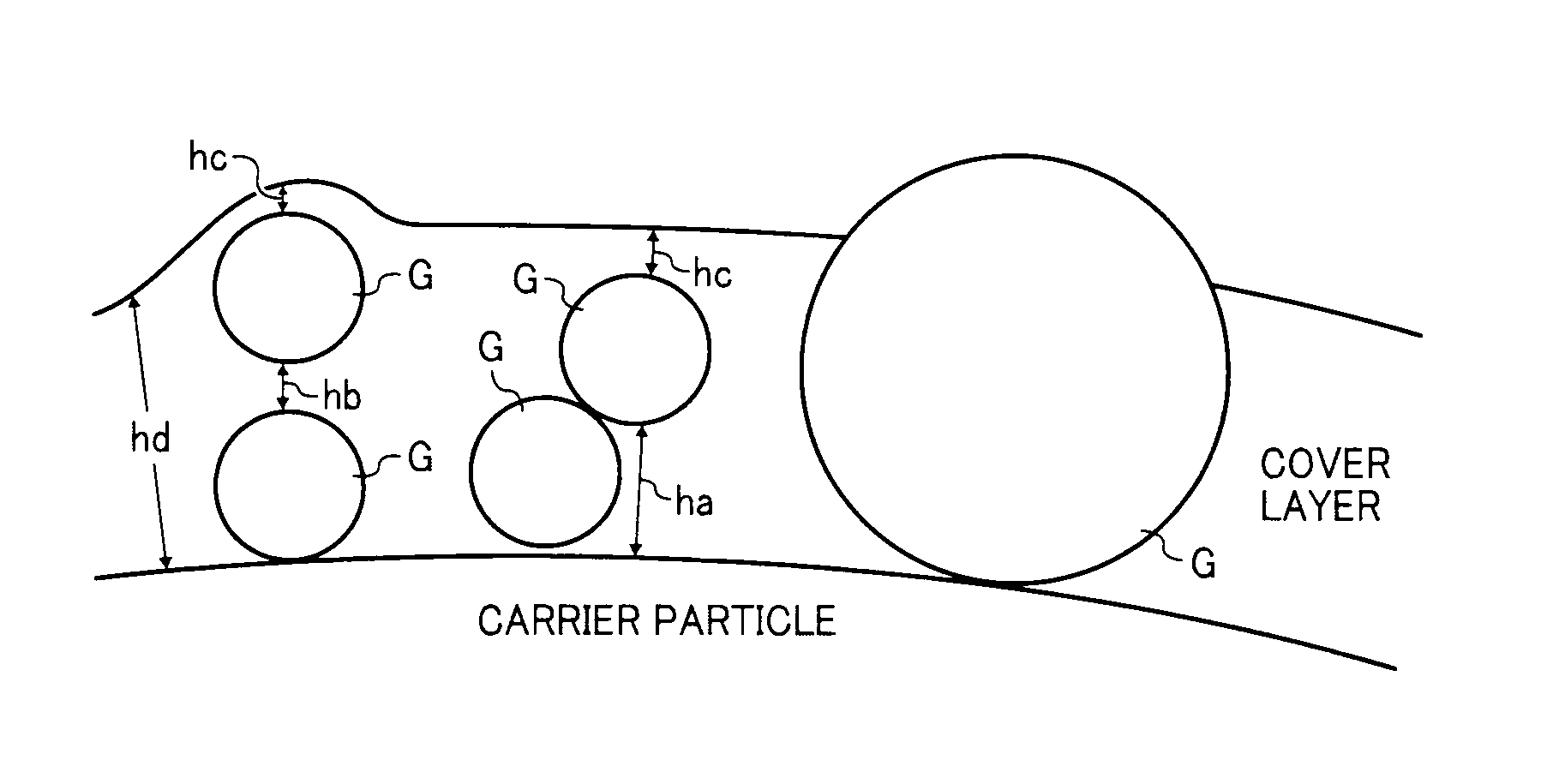

A carrier for use in a two component developer for developing an electrostatic latent image is provided. The carrier includes a particulate core material; and a cover layer located on a surface of the core material and including a silicone resin and barium sulfate. The cover layer includes Ba and Si at an atomic ratio of from 0.01 to 0.08 as determined by X-ray photoelectron spectroscopy.

Owner:RICOH KK

Super battery plate

ActiveCN101556997AIncrease specific energyHigh specific powerElectrolytic capacitorsHybrid capacitor electrodesFiberCarbon fibers

The invention discloses a super battery plate which comprises a positive plate and a negative plate; the raw materials of the positive plate consist of lead powder, carbon fibers, carbon materials, short fibers and sulfuric acid solution; the raw materials of the negative plate consist of lead powder, PTFE, barium sulphate, humic acid, lignin sodium sulplate, carbon fibers, carbon materials, short fibers and dilute sulfuric acid; the super battery prepared by the super battery plate has the advantages of high specific power and specific energy as well as long charge and discharge service life of a large pulse current. Moreover, the discharge of a low-temperature large current is batter than that of a common battery.

Owner:CHISEN POWER JIANGSU CO LTD

Method for preparing anti-dazzle glass

The method relates to a method for preparing antiglare glass. The method comprises the following steps that: (1) an etching solution comprises the following compositions in portion by weight according to a formula: 10 to 15 portions of ammonium bifluoride, 20 to 30 portions of ammonium fluoride, 5 to 7.5 portions of calcium fluoride, 10 to 15 portions of barium sulphate, 5 to 7.5 portions of ammonium sulphate, 5 to 10 portions of sodium fluosilicate or 5 to 10 portions of sodium fluoborate, 5 to 10 portions of zinc chloride, 10 to 20 portions of concentrated sulphuric acid and 70 to 100 portions of water; raw materials are weighed, mixed, evenly stirred and matured for 6 to 10 hours at room temperature to prepare the etching solution; (2) the surface of a glass sample is cleaned and dried by absolute ethyl alcohol; (3) one surface of the glass sample which does not need to be etched is covered; and (4) the glass sample is put into the etching solution, marinated, taken out, washed by clean water and dried to produce a finished product of the antiglare glass. The method has simple process and easy operation; the prepared glass sample has the advantages of small particles on the surface and even distribution of the particles, high light transmissivity, good antiglare effect, etc.

Owner:DONGHUA UNIV

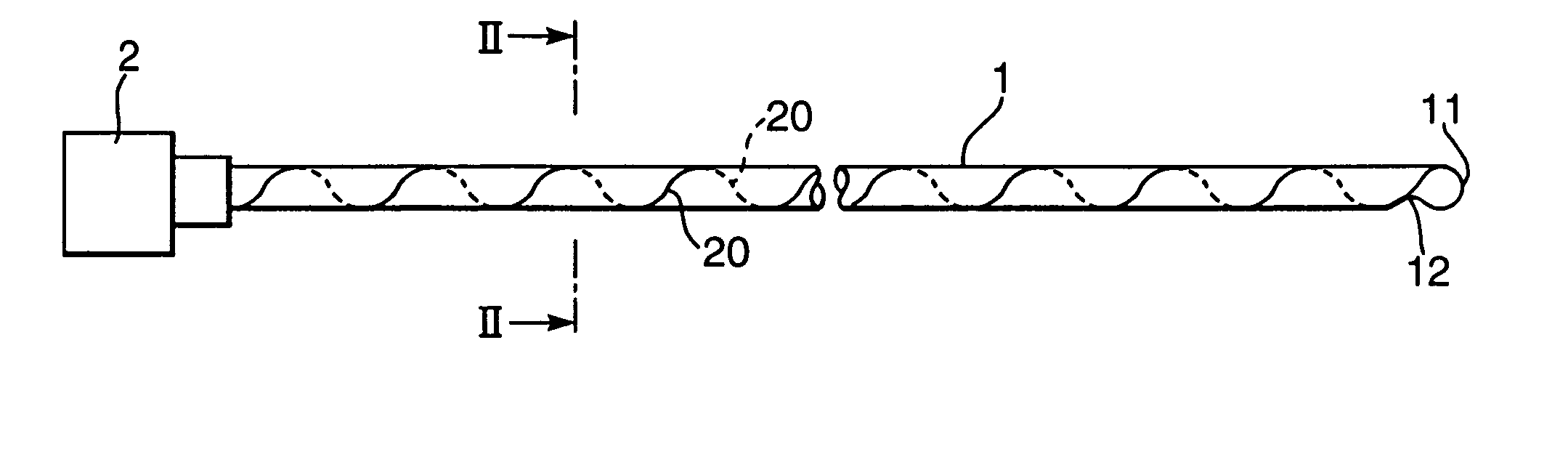

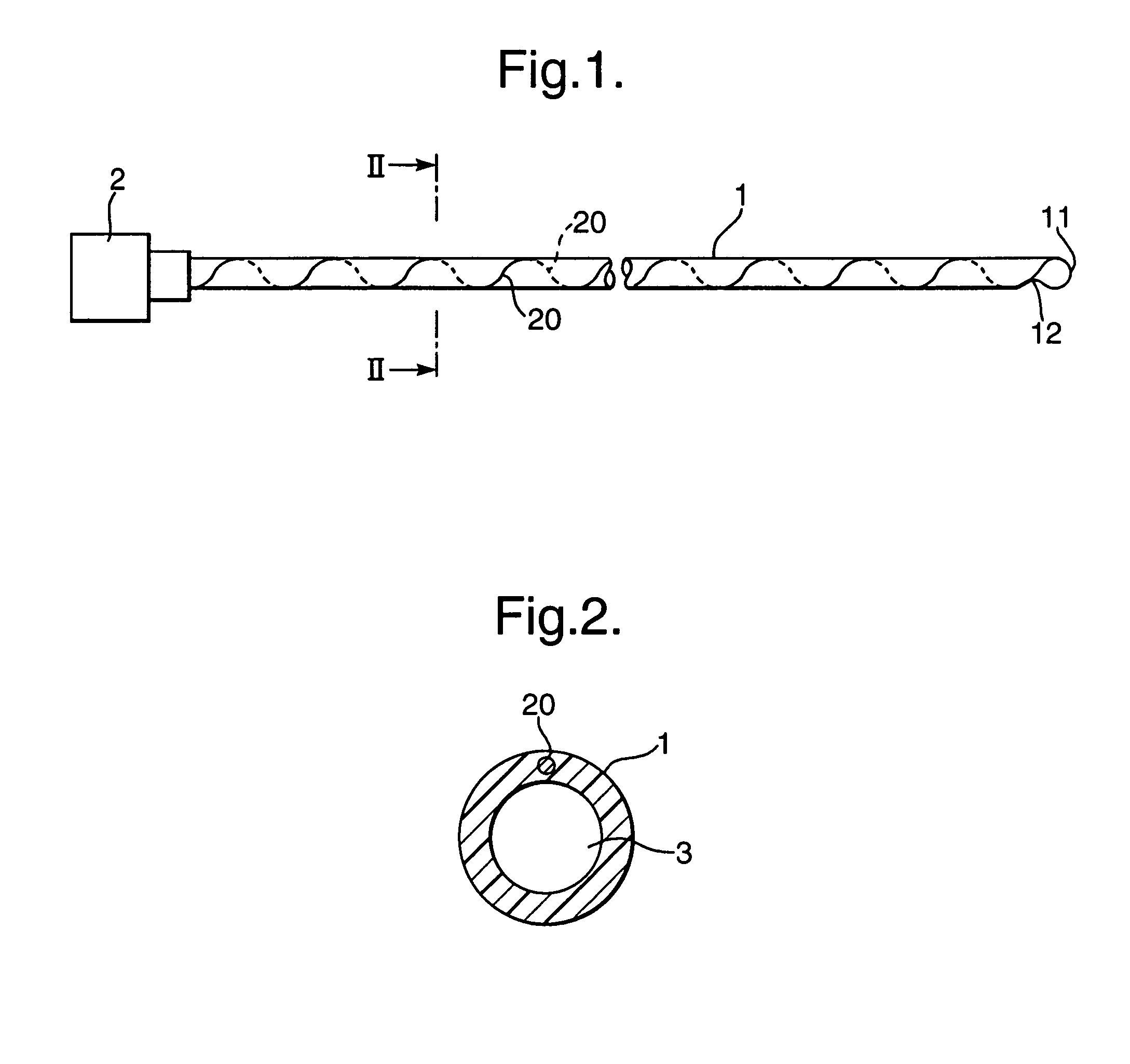

Medico-surgical devices

ActiveUS7258669B2Low ultrasound reflectionHigh ultrasound reflectionUltrasonic/sonic/infrasonic diagnosticsDiagnostic markersMedical treatmentSurgical device

An embryo-transfer catheter has an extruded shaft with a gas-filled lumen that extends helically along the catheter to provide an ultrasound marker. The catheter has a side opening close to a closed rounded patient end. The catheter could be completely transparent to x-rays or the plastics from which it is formed could incorporate an x-ray opaque filler, such as barium sulphate.

Owner:THE COOPER CO GLOBAL HLDG LP

High-energy lead-acid storage battery cathode plate diachylon and preparation method thereof

ActiveCN101937991ALow conductivityImprove the utilization rate of active substancesLead-acid accumulator electrodesPolyesterFiber

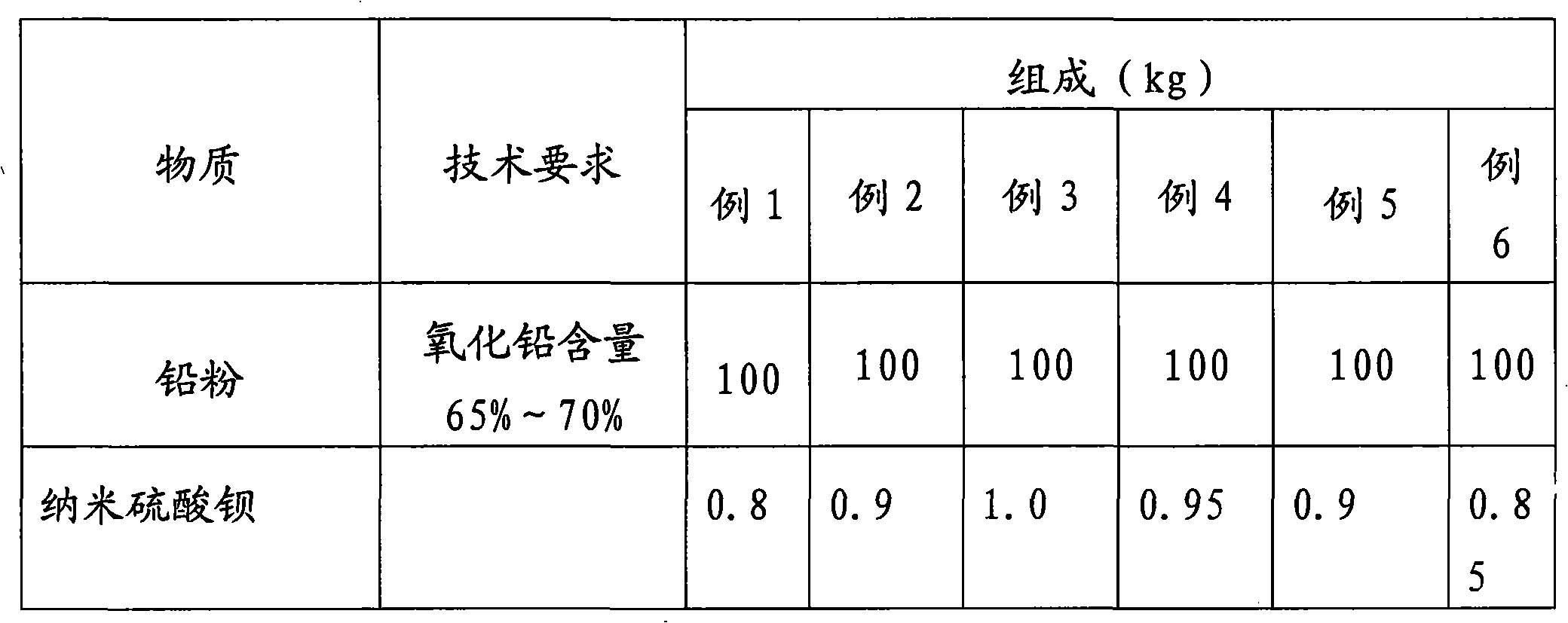

The invention provides a high-energy lead-acid storage battery cathode plate diachylon and a preparation method thereof. The diachylon comprises lead powder, pure water, analytical pure sulfuric acid and an auxiliary material, wherein the lead powder comprises 65-70 percent of lead oxide, the density of the analytical pure sulfuric acid is 1.400g / cm<3>, and the pure water has the conductivity of smaller than 0.3 mus / cm; and the auxiliary material comprises the following components based on the weight proportion of the lead powder: 0.8-1 percent of nano barium sulphate, 0.1-0.3 percent of modified sodium lignosulphonate, 0.1-0.3 percent of tannin, 0.08-0.1 percent of polyester short fiber, 0.2-0.3 percent of carbon black and 0.3-1 percent of poly-alpha-olefin base oil. When diachylon is mixed, 10-15kg of water, 8-12kg of analytical pure sulfuric acid and the auxiliary material based on the weight proportion of the lead powder are added into 100kg of lead powder. The invention provides the high-energy lead-acid storage battery cathode plate diachylon and the preparation method thereof.

Owner:张家口保胜新能源科技有限公司

Lead carbon mixed negative lead paste and preparation method thereof

ActiveCN102881867AEvenly dispersedGood dispersionLead-acid accumulator electrodesFiberActivated carbon

The invention discloses a lead carbon mixed negative lead paste and a preparation method thereof. The lead paste is prepared by the following raw materials of, according to weight part proportions, 100 of lead powder, 0.01-2 of gas phase grown carbon fibers, 0.01-2 of high specific surface carbon black, 0.01-5 of activated carbon, 0.01-2 of a hydrogen evolution inhibitor, 0.3-2 of barium sulfate, 0-1.2 of sodium lignosulfonate, 0.5-2 of a humic acid, 0.05-0.1 of short fibers, 5-20 of water and 4-15 of sulfuric acid (the concentration is 1.2-1.40 g / mL). Due to the addition of the gas phase grown carbon fibers, the lead carbon mixed negative lead paste can maintain stable apertures and good active interface; and the high conductive characteristic and high capacitance characteristic of the carbon materials can be fully played. The preparation method of the lead carbon mixed negative lead paste employs a mode of firstly immersing the carbon materials, and then mixing the lead powder and the carbon powder, thereby realizing the better uniform distribution of the carbon. The charging acceptance capability and HRPSoC cycle life of the battery can be significantly improved by using the lead carbon mixed negative lead paste to make a lead carbon super battery.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +2

Epoxy anticorrosive paint for underwater steel

InactiveCN102719174AStrong adhesionPromote environmental protectionAntifouling/underwater paintsPaints with biocidesSolvent freeSolvent

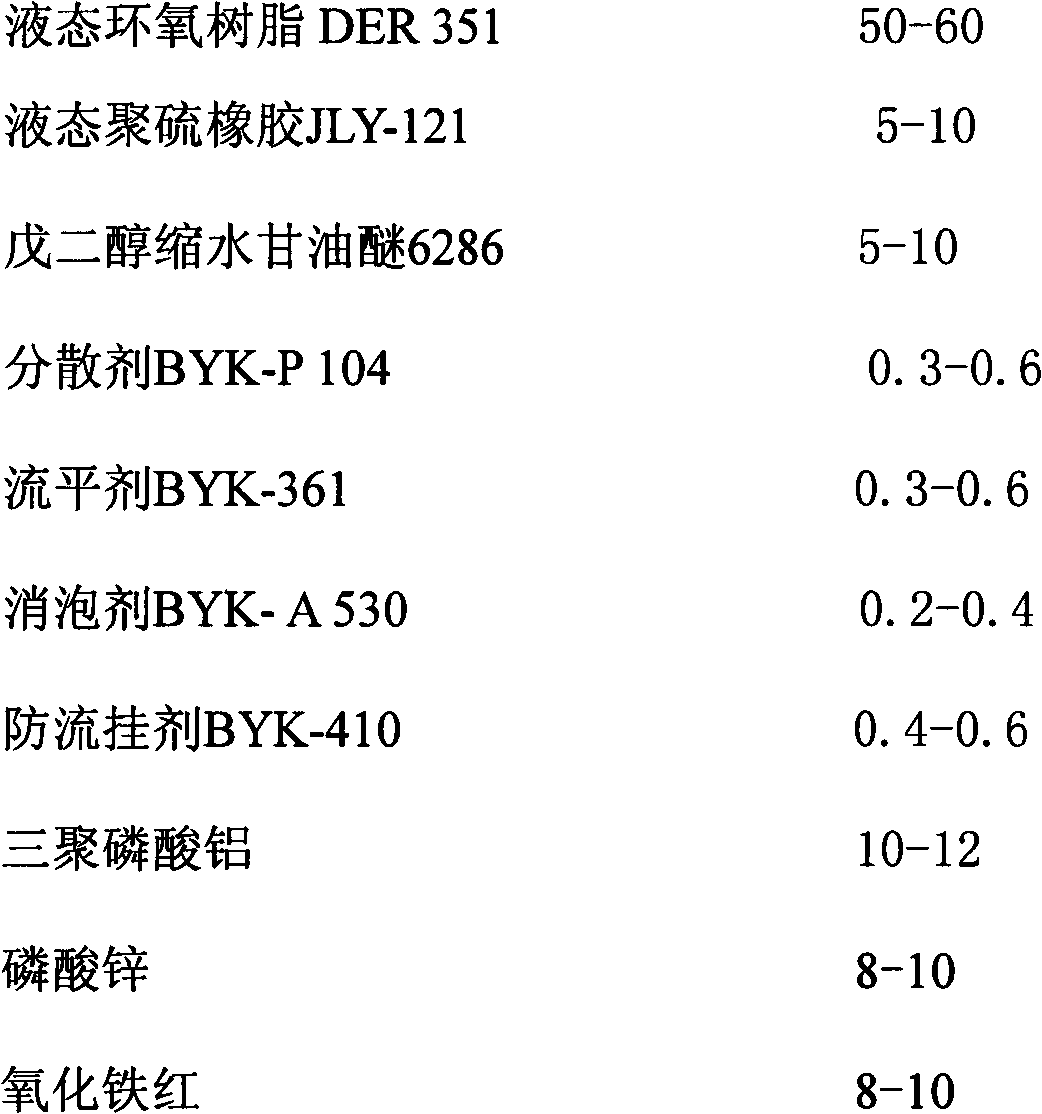

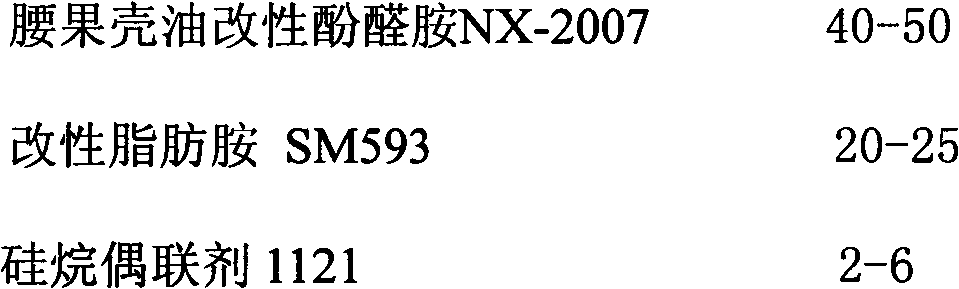

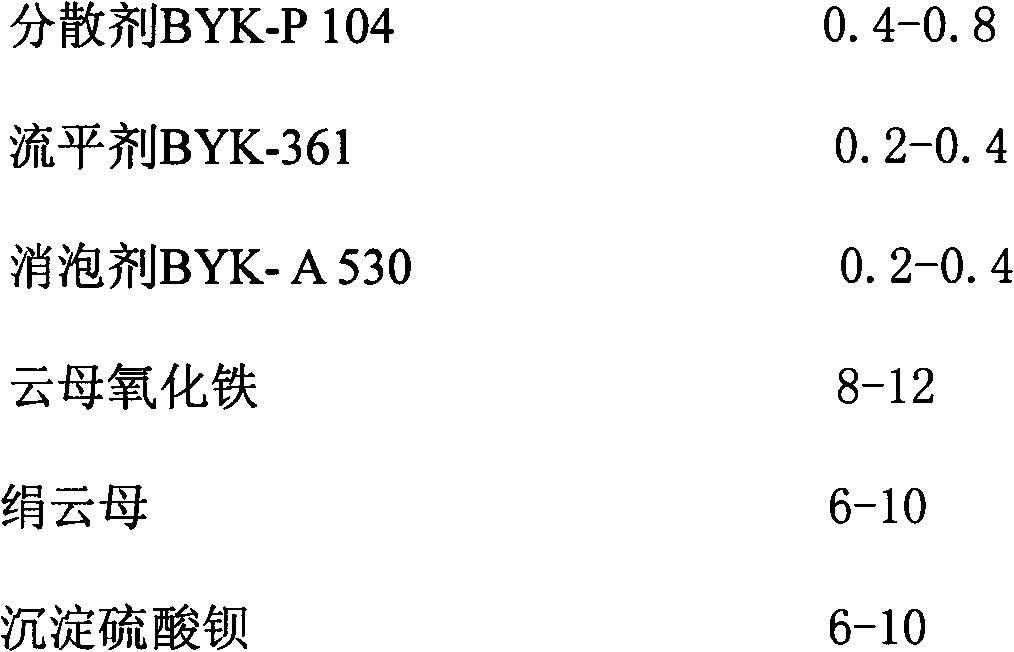

The invention discloses epoxy anticorrosive paint for underwater steel. Liquid epoxy resin DER351 is used as base materials, liquid polysulfide rubber JLY-121 is used as toughening agent, pentanediol glycidyl ether 6286 is used as diluents, aluminum tripolyphosphate, zinc phosphate and iron oxide red are used as active rustproofing pigment, micaceous iron oxide, sericite and precipitated barium sulphate are used as filler, cashew shell oil modified phenolic aldehyde and modified fatty amine are used as curing agents, silane coupling agent 1121 is used as adhesion promoter, and solvent-free bicomponent epoxy anticorrosive paint for underwater steel is prepared by the normal preparation process under the cooperation of functional auxiliaries. The epoxy anticorrosive paint for underwater steel has fine environment friendliness, can be brushed or scraped at rusted damp interfaces of underwater steel, can be quickly cured to form films, excellent in coating adhesive power, capable of removing, converting and stabilizing rusts, high in resistance to impact, abrasion and corrosion and widely applicable to corrosion resistance of various underwater steel facilities.

Owner:BEIJING GUOTAI RUIHUA DIATOMS APPL TECH

Antifouling paint for ship and marine facility

InactiveCN101805546AExcellent service lifeExcellent usabilityAntifouling/underwater paintsPaints with biocidesSodium BentoniteAcrylic resin

The invention discloses an antifouling paint for ship and marine facility, comprising the following ingredients by weight percent: 30-45wt% of scale glass, 15-25wt% of acrylic resin, 0-5wt% of rosin, 5-10wt% of asphalt, 5-15wt% of dimethylbenzene, 3-5wt% of bentonite, 0-5wt% of barium sulphate, 2-5wt% of talcum powder, 2-10wt% of ferric oxide and 5-8wt% of zinc oxide. The used scale glass can be adjusted in blending ratio thereof, or the percent content of the scale glass in the antifouling paint is adjusted, so as to control release rate of Cu+; the antifouling paint can release Cu+ chronically, slowly and stably at expected speed under the soaking of sea water; the formed paint film has obvious antifouling anti-algae capability and can prevent marine life from being adhered on the surface of ship and ocean facility, protection degree on paint film of ship and marine facility is effectively improved, and the antifouling paint is non-toxic and environmentally friendly.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

A kind of sodium-free refining agent for aluminum and aluminum alloy and production method thereof

The invention discloses a sodium-free refining agent for aluminum and aluminum alloy, which consists of the following ingredients in percentage by weight: 15 to 25 percent of potassium aluminium fluoride, 5 to 15 percent of calcium fluoride, 10 to 25 percent of potassium carbonate, 10 to 25 percent of potassium sulfate, 5 to 15 percent of barium sulfate, 15 to 30 percent of potassium chloride and3 to 5 percent of anhydrous aluminium chloride. The invention also discloses a production method of the sodium-free refining agent. Because the sodium-free refining agent does not contain sodium salts, compared with sodium-containing refining agents, the sodium-free refining agent effectively solves the problem of antimony modification and phosphor modification influence caused by more or less sodium salt contained in the existing refining agent and overcomes the defects of alloy casting performance influence, melt flowability reduction and sodium brittleness possibly caused by the sodium element in aluminum-magnesium system alloy with the magnesium content being higher than 2 percent. A better use effect can be obtained in the antimony modification and phosphor modification alloys and high-magnesium-aluminum alloy. The invention belongs to the qualitative improvement on the prior art.

Owner:HEBEI SITONG NEW METAL MATERIAL CO LTD

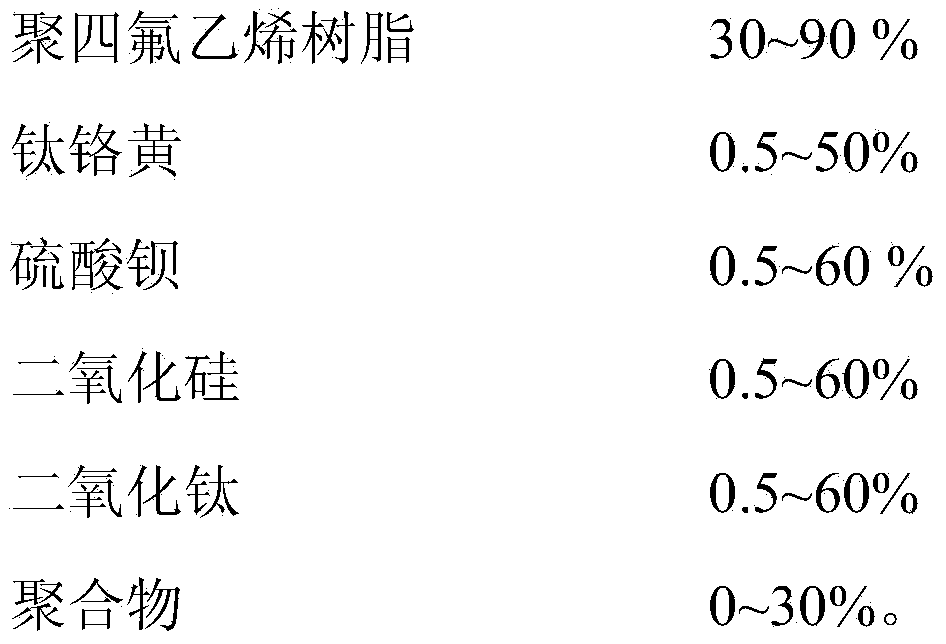

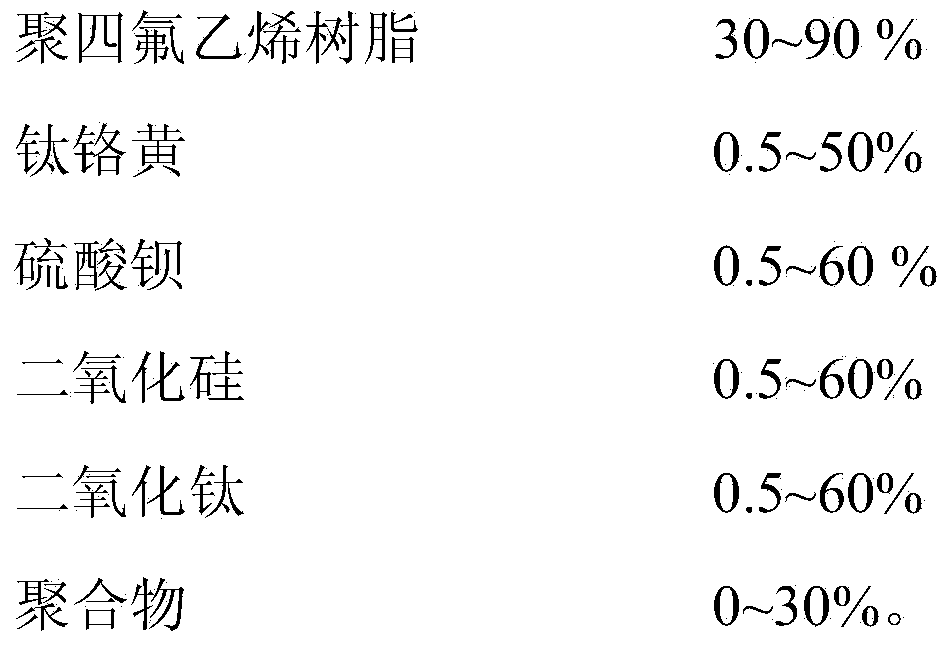

Wear-resistant low-creep polytetrafluoroethylene sealing material as well as preparation method and application thereof

The invention discloses a wear-resistant low-creep polytetrafluoroethylene sealing material as well as a preparation method and application thereof. The sealing material comprises the following components by mass percent: 30-90% of polytetrafluoroethylene resin, 0.5-50% of chrome antimony titanium buff rutile, 0.5-60% of barium sulfate, 0.5-60% of silicon dioxide, 0.5-60% of titanium dioxide and 0-30% of polymers. The preparation method comprises the steps of drying various components, mixing the components uniformly in a high-speed mixer according to the proportion, carrying out cold compression molding and sintering, insulating and cooling, thus obtaining the wear-resistant low-creep polytetrafluoroethylene sealing material. The wear-resistant low-creep polytetrafluoroethylene sealing material disclosed by the invention is resistant to wear, has low creep and long service life and can be applied to various industrial fields such as national defence, transportation, chemical industry, machinery, textiles, food and the like besides the advanced science and technology.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Rubber compositions for oil seal of rubber framework and method for manufacturing same

Owner:青岛茂林橡胶制品有限公司

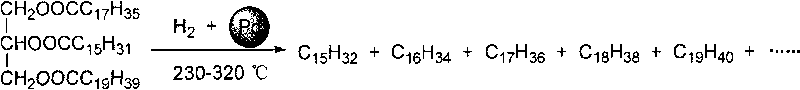

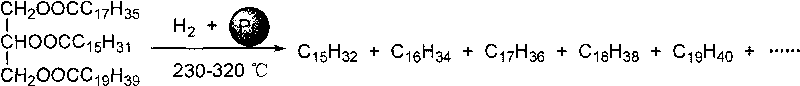

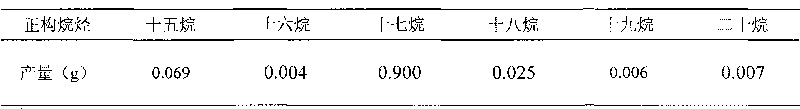

Method for preparing diesel components by catalytic hydrodeoxygenation of vegetable oil

InactiveCN101709225AHigh catalytic activityImprove catalytic selectivityBiofuelsLiquid carbonaceous fuelsRecyclable catalystLiquid product

The invention provides a method for preparing diesel components by catalytic hydrodeoxygenation of vegetable oil, which prepares high heat-value alkane by catalytic hydrodeoxygenation of the vegetable oil. The method comprises the following reaction steps: adding the vegetable oil, barium sulphate-loaded palladium serving as a catalyst, as well as a solvent selected from n-hexane, n-heptane, n-octane and dodecane to a reactor; supplying hydrogen; allowing reaction pressure to be between 1 and 10 MPa; stirring and heating at 230 to 320 DEG C; performing reaction for 3 to 12 hours and then stopping the reaction; allowing the catalyst and liquid products to automatically separate after the obtained product is cooled to room temperature; and obtaining the diesel components containing high heat-value alkane without centrifugation, filtration and other complicated post treatment. The method has the advantages of simple preparation process, low reaction temperature, low solvent consumption, no cracking of carbon chain parts of the oil, high combustion heat value of target products and recyclable catalyst.

Owner:ZHEJIANG UNIV

Diatom ooze coating and preparation method thereof

InactiveCN104877427ATo achieve the purpose of purifying the airWith sterilizationFireproof paintsAntifouling/underwater paintsMoisture absorptionFire prevention

The invention discloses a diatom ooze coating which is made of raw materials comprising, by weight, 15-25 parts of water, 0.6-2.6 parts of lignin or lignin derivatives, 10-15 parts of tourmalines, 0.1-0.3 part of silver oxide, 10-15 parts of titanium dioxide, 3-6 parts of precipitated barium sulphate, 5-15 parts of kaoline, 5-10 parts of sea-foam stone powder, 30-45 parts of nano diatomite, 0.5-1.5 parts of palladium, 5-10 parts of nanometer titania, 0.4-0.6 part of leveling agents, 1.5-4 parts of thickening agents, 0.6-1.2 parts of mildew preventives, 1-5 parts of active carbon nanoparticles, 0.5-3 parts of net-flavor emulsions, 8-15 parts of dispersible adhesive powder and 0-3 parts of pigment. The diatom ooze coating is excellent in breathability and moisture absorption, gas ion negatively charged can be released, human body synthesis and vitamin storage can be promoted, and human immune ability is improved; functions of sterilization, mold prevention, deodorization, air purification and fire prevention are achieved; the preparation method is simple, easy to operate and convenient for large-scale production.

Owner:TONGCHENG HUIQI IND & TRADE

Carbon fiber reinforced friction material and its prepn

The present invention relates to new material, and is one kind of carbon fiber reinforced friction resistance material suitable for producing automobile and train brake disc and its preparation process. The carbon fiber reinforced friction resistance material is produced with reinforcing fiber, base resin and friction performance regulator, the reinforcing fiber is the mixture of carbon fiber, metal fiber and inorganic mineral fiber; the base resin is water latex modified phenolic resin; and the friction performance regulator consists of at least two of barium sulfate, ionic oxide, triiron tetrachloride, iron trichloride, magnesia and silica. The preparation process includes the steps of mixing material, pre-stoving, pressing and post-treatment. The carbon fiber reinforced friction resistance material has excellent friction resistance performance and the preparation process has no pollution.

Owner:SHANDONG UNIV

Preparation method of polyester resin capable of being used for outdoor dry mixed extinction powder coating

InactiveCN102719180ANo post-processingEasy material selectionPowdery paintsPolyester coatingsPolymer sciencePolyol

The invention relates to a preparation method of polyester resin capable of being used for an outdoor dry mixed extinction powder coating. The preparation method is characterized by comprising the following steps of: adding polybasic acid or anhydride, polyatomic alcohol, a catalyst and an antioxidant according to a mass ratio into a reaction kettle for mixing; introducing nitrogen; heating to a temperature of 100-300 DEG C until a reaction solution is completely clarified to obtain A-component polyester resin; adding polybasic acid or anhydride, polyatomic alcohol, a catalyst and an antioxidant into the reaction kettle to be mixed; introducing nitrogen; heating to a temperature of 100-300 DEG C until a reaction solution is completely clarified; and carrying out vacuum condensation polymerization on the clarified reaction solution until an acid value is 10-50 mg KOH / g and a viscosity is 30-100 P to obtain B-component polyester resin; mixing the A-component polyester resin with triglycidyl isocyanurate, barium sulfate, titanium dioxide, a flatting agent, a brightener and benzoin according to a mass ratio to obtain a powder coating I; mixing the B-component polyester resin with triglycidyl isocyanurate, barium sulfate, titanium dioxide, a flatting agent, a brightener and benzoin to obtain a powder coating II; and mixing the powder coating I with the powder coating II to obtain the powder coating with low brightness. The preparation method has the advantages of stable extinction effect of outdoor dry mixed extinction polyester, better coating property and the like.

Owner:佛山市顺德区伊诗德新材料科技有限公司

Low-temperature fast-curing epoxide powder paint and preparation method thereof

ActiveCN103666203AImprove water resistanceGood solvent resistanceAnti-corrosive paintsEpoxy resin coatingsPolymer scienceFirming agent

The invention relates to low-temperature fast-curing epoxide powder paint which comprises the following components in percentage by weight: 45-65% of epoxy resin, 1-5% of polyepoxy active crosslinking agent, 8-18% of curing agent, 0.1-0.5% of curing accelerating agent, 4-30% of precipitated barium sulfate, 4-8% of mica powder, 2-5% of titanium white, 0.5-1.0% of adhesion accelerating agent and assistants. According to the invention, the epoxide powder paint uses a blended resin system of high molecular weight bisphenol A type epoxy resin and novolac epoxy resin; and after being cured by the curing agent, an obtained paint film has the advantages of the epoxy resin such as high adhesion and good alkali resistance and the characteristics of the novolac resin such as favorable water resistance, solvent resistance and acid resistance, and the paint film has favorable heat resistance. Thus, the epoxide powder paint provided by the invention can be adapted to a high-temperature severe-corrosion environment and has favorable market application prospects.

Owner:洛阳双瑞防腐工程技术有限公司

High density polyoxymethylene compositions

A high-density polyoxymethylene resin composition that comprises polyoxymethylene; at least one coated mineral selected from zinc oxide, barium sulfate, and titanium dioxide; and at least one thermal stabilizer.

Owner:EI DU PONT DE NEMOURS & CO

Waterborne antirust paint and preparation method thereof

ActiveCN105238232AImprove densification performanceImprove shielding effectAntifouling/underwater paintsPaints with biocidesEpoxyPolymer science

The invention discloses waterborne antirust paint and a preparation method thereof. The waterborne antirust paint is prepared from, by mass, 10-25 parts of waterborne acrylic acid modified epoxy ester, 0.6-1.2 parts of neutralizer, 20-30 parts of deionized water, 0.5-1.5 parts of dispersing agents, 0.2-0.5 part of defoaming agent, 14-18 parts of iron oxide red, 2-4 parts of mica powder, 6-10 parts of modified zinc phosphate, 10-14 parts of precipitated barium sulphate, 1-2 parts of propylene glycol, 10-15 parts of styrene-acrylic emulsion, 0.5-1.0 part of coalescing agent, 0.5-1.0 part of waterborne flush rust prevention agent, 0.5-1.5 parts of thickening agents and 0.2-0.5 part of mildew prevention agent. The waterborne antirust paint is high in film hardness, good in adhesive force and excellent in corrosion-resistant performance and mechanical performance, dryness and initial water resistance of paint films are remarkably improved due to the addition of styrene-acrylic emulsion, and the flush rust restraining performance of paint films is improved due to the addition of the waterborne flush rust prevention agent. Water serves as the diluent for the waterborne antirust paint, VOC emission in production and construction projects is greatly reduced, and the waterborne antirust paint is safe, environmentally friendly and capable of being widely used for paint coating on the aspects of steel structures, pipelines, automobile parts and the like.

Owner:西北永新涂料有限公司

Wholly aromatic thermotropic liquid-crystal polyester resin composition, molded object, and LED reflector

ActiveUS8545718B2Good moldabilityIncrease resistanceLiquid crystal compositionsSolid-state devicesPolyester resinPolyresin

Owner:JX NIPPON OIL & ENERGY CORP

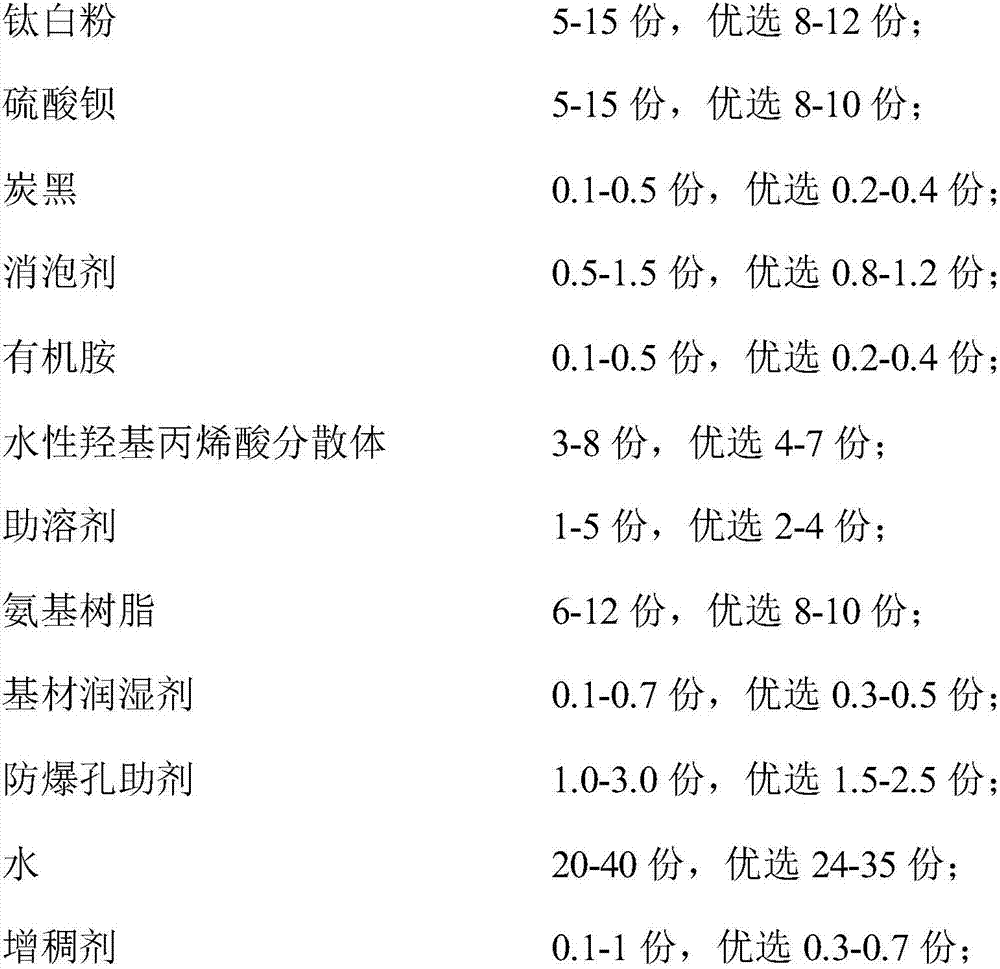

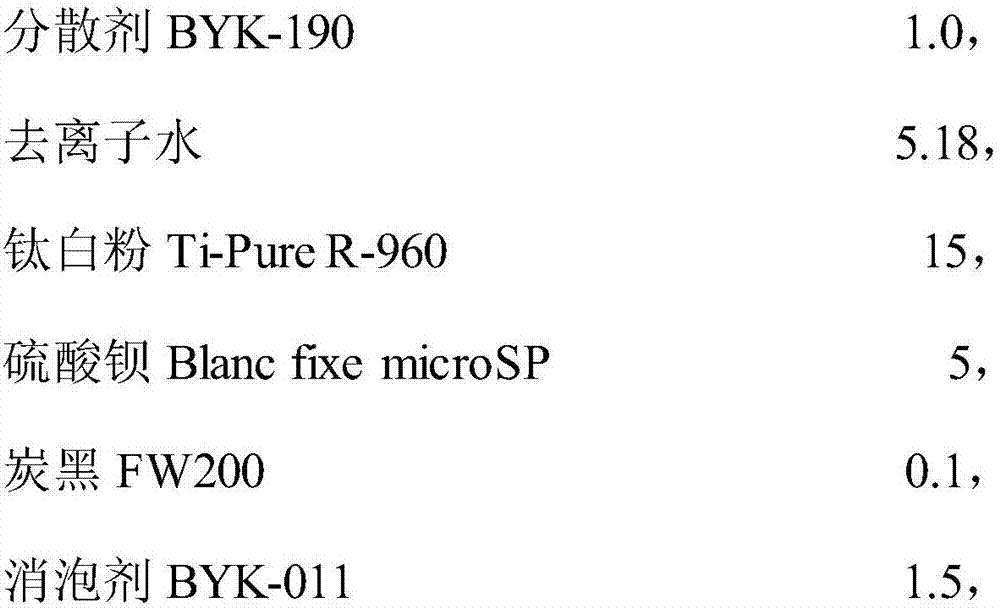

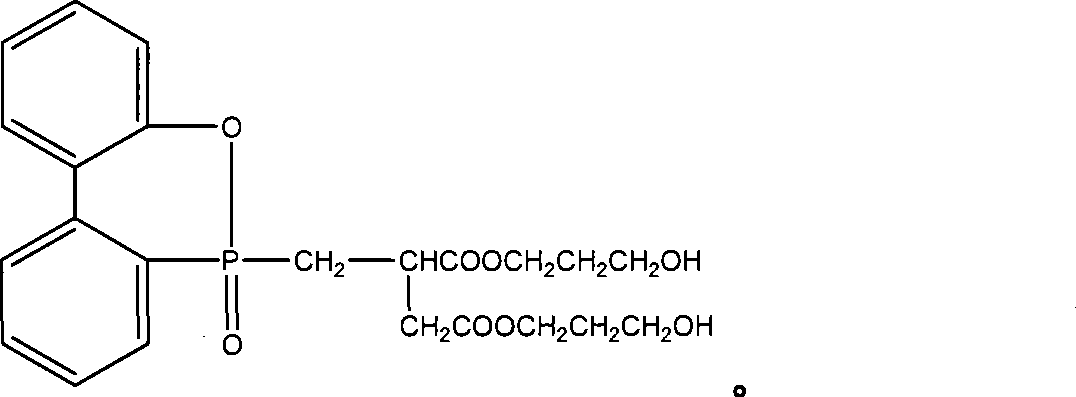

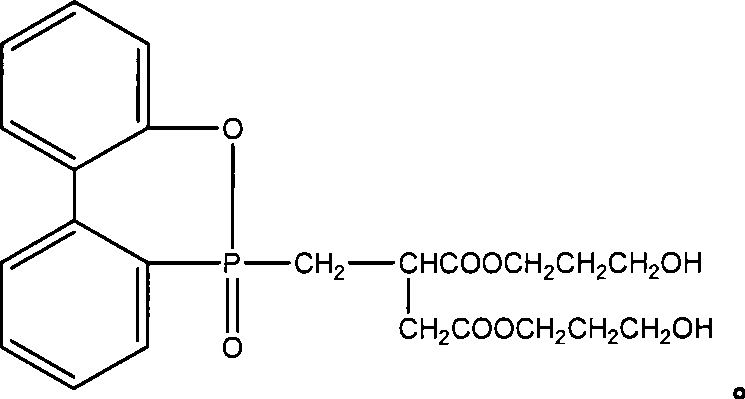

A waterborne automobile coating composition and a preparing method and applications thereof

InactiveCN107099238AImprove stone impact resistanceIncreased chemical resistancePolyurea/polyurethane coatingsPolyesterCooking & baking

A waterborne automobile coating composition is provided. The composition is prepared from, by weight, 20-60 parts of a waterborne polyurethane dispersoid, 1.0-3.5 parts of a dispersing agent, 5-15 parts of titanium dioxide, 5-15 parts of precipitated barium sulfate, 0.1-0.5 part of carbon black, 0.5-1.5 parts of a defoamer, 3-8 parts of a waterborne hydroxy acrylic acid dispersoid, 0.1-0.5 part of an organic amine, 6-12 parts of amino resin, 0.1-1 part of a substrate wetting agent, 1-3 parts of an explosion-proof auxiliary agent, 1-5 parts of a cosolvent, 20-40 parts of deionized water and 0.1-1 part of a thickening agent. The waterborne polyurethane dispersoid is a compound of a polycarbonate-type waterborne polyurethane dispersoid having hydroxy groups and a polyester-type waterborne polyurethane dispersoid preferably. The coating composition has excellent resistance to rock crash, and can meet requirements on an automobile coating process including three times of coating and one time of baking, namely a 3C1B process, in the field of environment protection.

Owner:WANHUA CHEM GRP CO LTD

Flame retardant PTT polyester fiber and production method thereof

ActiveCN101532189AImprove flame retardant performanceHigh breaking strengthFlame-proof filament manufactureMonocomponent polyesters artificial filamentBreakdown strengthFiber

The invention relates to a flame retardant PTT polyester fiber and production method thereof, wherein the polyester comprises a phosphor based copolymerization flame retardant accounting for 1.2-8.5% of the total weight of the polyester and the phosphor based copolymerization flame retardant comprises a double-reaction functional group and the phosphor element quality content in polyester is 1400-12000ppm and the PTT polyester also comprises an inorganic nano-material accounting for 0.1%-5.0% of the total weight of the polyester and the inorganic nano-material is selected from one kind or several kinds of silicon dioxide, calcium carbonate, magnesium carbonate and barium sulphate. The production method is the improvement of the conventional method, specifically before drying polyester chip, the polyester chip is precrystallized at 110-125 DEG C for 1.5-3 hour and the drying temperature is 130-145 DEG C and the drying time is 3.5-5 hours. The polyester fiber has features of good and permanent flare retardant resistance, high breakdown strength, good fiber forming property, good thermal stability and good thermal oxidation stability performance.

Owner:JIANGSU ZHONGLU TECH DEV

Polypropylene composite material with high strength and toughness and preparation method thereof

The invention discloses a polypropylene composite material with high strength and toughness and a preparation method thereof. The composite material comprises the following components in parts by weight: 28-58.5 parts of polypropylene, 10-40 parts of polycaprolactam, 14 parts of barium sulphate, 7 parts of glass fiber, 9 parts of compatilizer, 1 part of lubricant and 0.5-1 part of antioxidant; and the preparation method is as follow: drying the barium sulphate, the lubricant and the compatilizer, stirring at the temperature of 40-100 DEG C, evenly mixing the processed barium sulphate, polypropylene and polycaprolactam, performing melt blending by a double-screw extruder, introducing the glass fiber in the middle section of a screw, extruding, drawing and pelleting. The polypropylene has higher flexural modulus, tensile strength and impact strength which are endowed from the synergic toughness-strength enhancement effect of the inorganic rigid particle barium sulphate and the organic rigid resin polycaprolactam and the strength enhancement effect of the glass fiber, thus the composite material can be used as a plastic structure part.

Owner:SOUTH CHINA UNIV OF TECH

Low temperature curing powder coating and preparation method thereof

ActiveCN103333588AImprove mechanical propertiesPowdery paintsEpoxy resin coatingsEpoxyPolymer science

The invention relates to a low temperature curing powder coating and a preparation method thereof. The powder coating comprises the following components by weight percent: 28-30% of epoxy resin, 28-30% of low temperature curing polyester resin, 0.1-1% of low temperature curing catalyst, 0.1-0.4% of benzoin, 0.7-1.4% of imported flatting agent, 0.4-1% of hydrogenated castor oil, 5-10% of pigment, and 25-40% of precipitated barium sulphate. In the formula of the powder coating, the low temperature curing polyester resin and the low temperature curing catalyst are adopted, the film of the power coating product can be cured at lower curing temperature, and each mechanical property of the film can be guaranteed to be excellent, therefore, the powder coating is suitable for large-scale popularization and application.

Owner:JIANGSU HUAGUANG POWDER

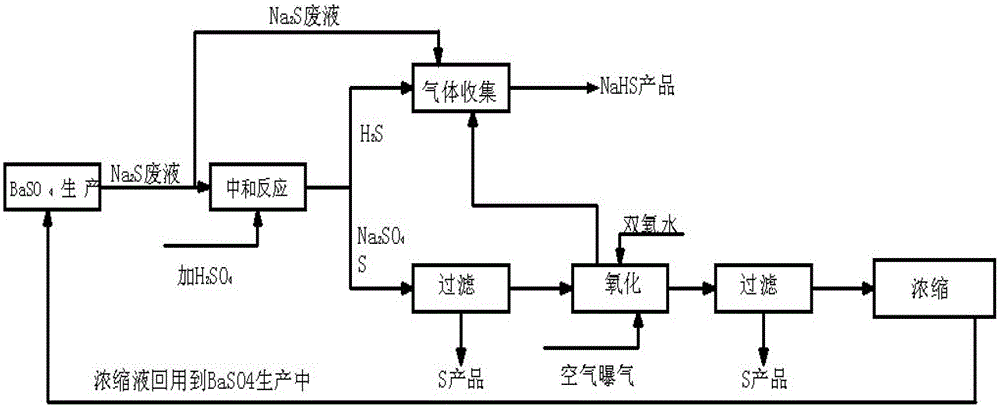

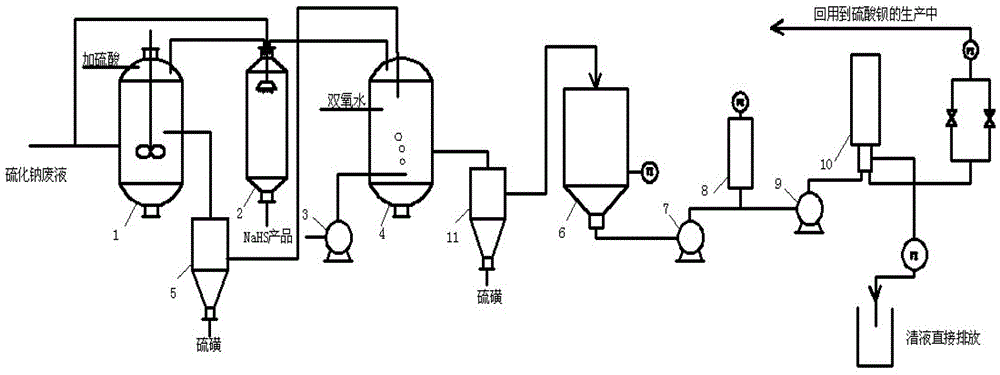

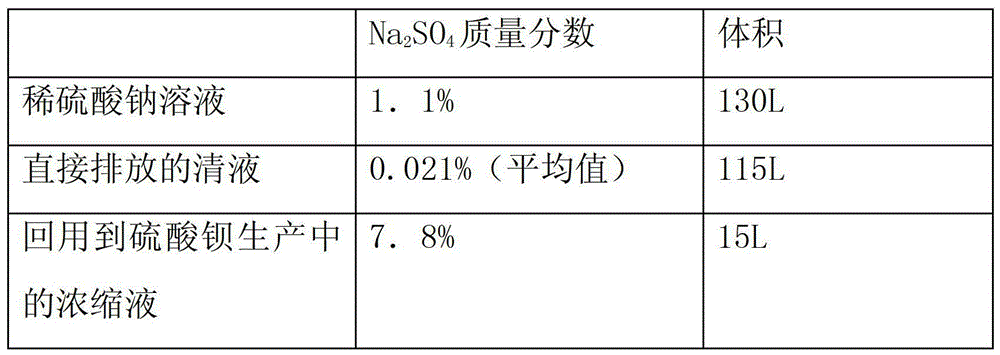

Process and device for recovering sodium sulphide wastewater in barium sulphate production

InactiveCN103058227AIncrease concentrationSulfate/bisulfate preparationSulfur preparation/purificationReverse osmosisHigh pressure

The invention discloses a process and a device for recovering sodium sulphide wastewater in barium sulphate production, belonging to the technical field of wastewater recovery. The process comprises the following steps performed by the corresponding devices: adding sulphuric acid to neutralize dilute sodium sulphide waste solution; absorbing hydrogen sulphide by a sodium sulphide spray tower; adding hydrogen peroxide in the sodium sulphate solution, so as to oxidize hydrogen sulphide which is dissolved in sodium sulphate solution into sulphur; filtering the sodium sulphate solution; and finally charging the sodium sulphate dilute solution in a disc-tube type reverse osmosis membrane system or a high-pressure flat-sheet membrane system, then concentrating, reusing the concentrate in barium sulphate production, and directly draining clear solution, so as to achieve the effect of turning waste into wealth.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com