Low-temperature fast-curing epoxide powder paint and preparation method thereof

A fast-curing, epoxy powder technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., to achieve strong adhesion, lower coating temperature, excellent solvent resistance and acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

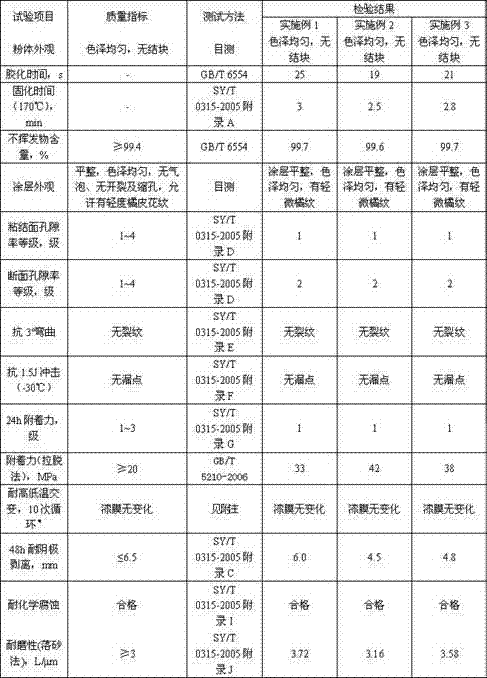

Examples

Embodiment 1

[0021] A low-temperature fast-curing epoxy powder coating has the following formula by weight percentage: 30 parts of bisphenol A epoxy resin, 15 parts of novolak epoxy resin, 1 part of triglycidyl isocyanurate, long-chain polyamine curing agent 8 parts, 0.1 part of diphenyl imidazoline, 30 parts of precipitated barium sulfate, 8 parts of mica powder, 5 parts of titanium dioxide, 1 part of titanate coupling agent, 1 part of general leveling agent, 0.5 part of benzophenone , 0.3 parts of fumed silica.

[0022] The preparation process is as follows:

[0023] (1) Weigh epoxy resin, curing agent, pigments and fillers and additives according to the formula dosage, and pre-mix on a high-speed mixer for 3 minutes.

[0024] (2) Use a twin-screw extruder with a screw length-to-diameter ratio of 16:1 and a rotational speed of 500r / min for melt extrusion. The temperature in zone I is set at 120°C, the temperature in zone II is set at 97°C, and the temperature in zone III is set at The ...

Embodiment 2

[0027] A low-temperature fast-curing epoxy powder coating has the following formula by weight percentage: 52 parts of bisphenol A epoxy resin, 13 parts of novolac epoxy resin, 5 parts of triglycidyl isocyanurate, long-chain polyamine curing agent 18 parts, 0.5 part of diphenylimidazoline, 4 parts of precipitated barium sulfate, 4 parts of mica powder, 2 parts of titanium dioxide, 0.5 part of titanate coupling agent, 0.5 part of general leveling agent, 0.4 part of benzophenone , 0.1 part of fumed silica.

[0028] The preparation process is as follows:

[0029] (1) Weigh epoxy resin, curing agent, pigments and fillers and additives according to the formula dosage, and pre-mix on a high-speed mixer for 5 minutes.

[0030] (2) A twin-screw extruder with a screw length-to-diameter ratio of 16:1 and a rotational speed of 500r / min is used for melt extrusion. The temperature in zone I is set at 110°C, the temperature in zone II is set at 90°C, and the temperature in zone III is set a...

Embodiment 3

[0033] A low-temperature fast-curing epoxy powder coating has the following formula by weight percentage: 45 parts of bisphenol A epoxy resin, 15 parts of novolac epoxy resin, 3 parts of triglycidyl isocyanurate, long-chain polyamine curing agent 15 parts, 0.4 parts of dimethylimidazole, 9 parts of precipitated barium sulfate, 6 parts of mica powder, 3.8 parts of titanium dioxide, 0.8 parts of silane coupling agent, 0.8 parts of general leveling agent, 1 part of benzophenone, gas phase dioxide Silicon 0.2 parts.

[0034] The preparation process is as follows:

[0035] (1) Weigh epoxy resin, curing agent, pigments and fillers and additives according to the formula dosage, and pre-mix on a high-speed mixer for 5 minutes.

[0036] (2) A twin-screw extruder with a screw length-to-diameter ratio of 16:1 and a rotational speed of 500r / min is used for melt extrusion. The temperature in zone I is set at 115°C, the temperature in zone II is set at 95°C, and the temperature in zone III...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com