Waterborne antirust paint and preparation method thereof

A water-based anti-rust paint, water-based technology, applied in anti-corrosion coatings, biocide-containing paints, anti-fouling/underwater coatings, etc., can solve the problems of poor initial water resistance, poor anti-corrosion performance, and high cost, and achieve increased compactness, Effect of increasing hardness and wear resistance, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

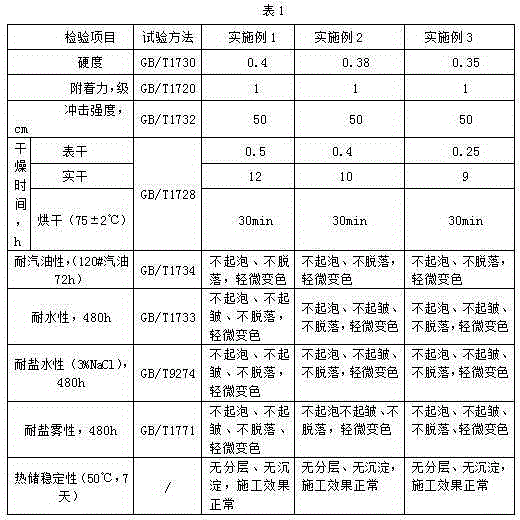

Examples

Embodiment 1

[0027] Step A, preparation of paint paste: Add 25kg of water-based acrylic modified epoxy ester resin into the batching basin, start stirring at 400 rpm, add 1.2kg of neutralizing agent and fully stir for 10min, adjust the pH value to 8, pay attention to scraping the basin wall Resin, after the resin is evenly neutralized, add 30kg of deionized water in 5 times, increase the stirring speed to 600 rpm to stir and disperse evenly, then add 1.5kg of dispersant and 0.2kg of defoamer, after fully mixing evenly, add iron oxide in turn Red 18kg, mica powder 4kg, zinc phosphomolybdate 8kg, precipitated barium sulfate 12kg, stir and mix for 20min at a stirring speed of 800 / min, then grind and disperse on a sand mill, the grinding temperature does not exceed 50°C, and grind until the fineness is not coarse At 40um, add 1kg of propylene glycol and stir evenly to obtain a paint slurry.

[0028] Step B, prepare water-based anti-rust paint: add 10 kg of styrene-acrylic emulsion to the paint...

Embodiment 2

[0031] Step A, prepare the paint slurry: Add 20kg of water-based acrylic modified epoxy ester resin into the batching basin, start stirring at 300 rpm, add 1kg of neutralizing agent and stir fully for 15min, adjust the pH value to 8.5, pay attention to scraping the resin on the basin wall After the resin is evenly neutralized, add 25kg of deionized water in 4 times, increase the stirring speed to 400 rpm, stir and disperse evenly, then add 1kg of dispersant and 0.1kg of defoamer, mix well and then add 16kg of iron oxide red in sequence, 2kg of mica powder, 10kg of iron zinc phosphate, 10kg of precipitated barium sulfate, stirring and mixing for 30min at a stirring speed of 600 / min, and then grinding and dispersing on a sand mill. Propylene glycol 2kg stirs and obtains paint slurry.

[0032]Step B, prepare water-based anti-rust paint: add 15 kg of styrene-acrylic emulsion to the paint slurry, adjust the stirring speed to 700 rpm, add 1.0 kg of film-forming aid, 0.1 kg of defoam...

Embodiment 3

[0035] Step A, preparation of paint paste: Add 10kg of water-based acrylic modified epoxy ester resin into the batching basin, start stirring at 200 rpm, add 0.6kg of neutralizing agent and fully stir for 20min, adjust the pH value to 9, pay attention to scraping the basin wall Resin, after the resin is evenly neutralized, add 20kg of deionized water in 3 times, increase the stirring speed to 300 rpm to stir and disperse evenly, then add 0.5kg of dispersant and 0.25kg of defoamer, and then add iron oxide red in turn after mixing well 14kg, 3kg of mica powder, 6kg of zinc iron phosphate and zinc phosphomolybdate (ratio 1:1), 10kg of precipitated barium sulfate, stirring and mixing for 25min at a stirring speed of 700 / min, and then grinding and dispersing on a sand mill. When the temperature exceeds 50°C, grind until the fineness is not thicker than 40um, add 1.5kg of propylene glycol and stir evenly to obtain a paint slurry.

[0036] Step B, prepare water-based anti-rust paint:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com