Light-emitting diode (LED) with indium tin oxide (ITO)/zinc oxide based composite transparent electrode and preparation method of LED

A technology of light-emitting diodes and transparent electrodes, which is applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of indium toxicity and complicated process, and achieve the effect of low cost, simple preparation process, and good ohmic contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

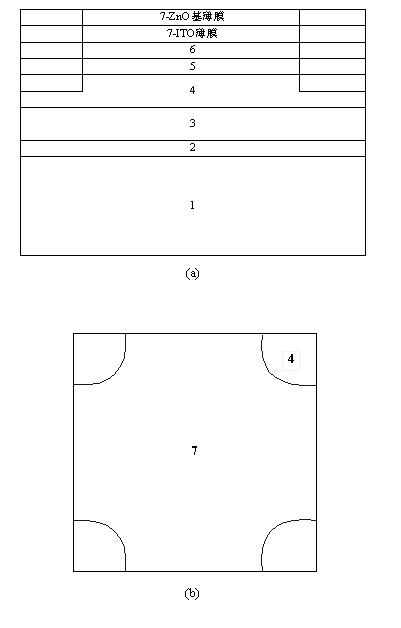

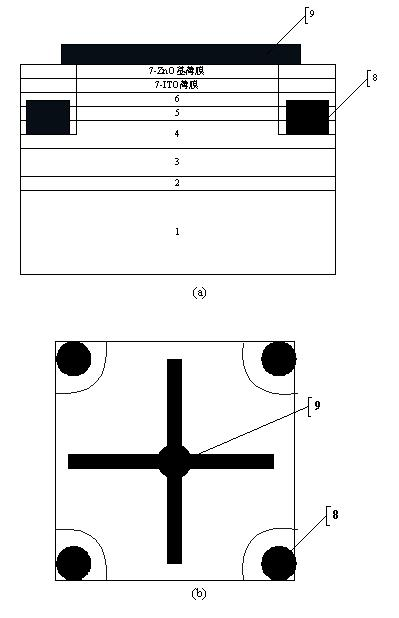

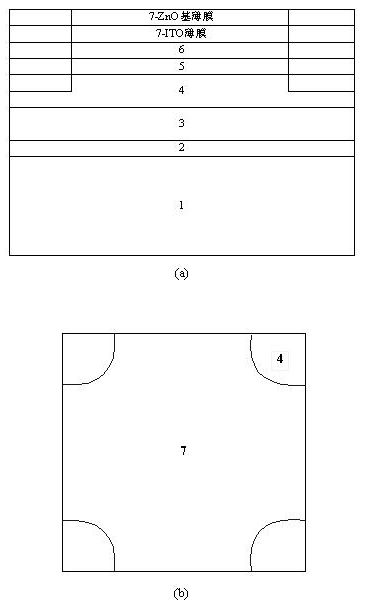

[0027] Embodiment one: see figure 1 and figure 2 , the ITO / ZnO-based transparent electrode light-emitting diode includes: a buffer layer 2, an intrinsic layer 3, an n-type gallium nitride 4, a quantum well 5, a p-type gallium nitride 6 and a transparent electrode on a sapphire substrate 1 in sequence. 7. An n-type metal electrode (PAD) 8 is connected to the n-type gallium nitride 4, and a p-type metal electrode (PAD) 9 is connected to the transparent electrode 7. The buffer layer 2, the intrinsic layer 3, the n-type gallium nitride 4, the quantum well 5, and the p-type gallium nitride 6 are sequentially grown in MOCVD; the transparent electrode 7 is an ITO / zinc oxide composite transparent electrode , where the material of the ITO film is Sn 2 o 3 :In 2 o 3 =1:9 indium tin oxide, the material of the zinc oxide-based transparent conductive film is ZnO:Ga or ZnO:Al or ZnO:In; the n-type metal electrode (8) is a metal composite electrode, and the material is Ti / Al or Cr / Pt...

Embodiment 2

[0028] Embodiment 2: This embodiment is basically the same as Embodiment 1. The special feature is: the special shape of the p-type electrode: a positive cross shape. The p-type metal electrode 9 of this shape makes the current spread more uniform and improves the LED chip. reliability.

Embodiment 3

[0029] Embodiment three: the manufacturing method of the transparent electrode light-emitting diode chip is as follows: first, buffer layer 2, intrinsic layer 3, n-type gallium nitride 4, quantum well 5, p-type gallium nitride are successively formed on the substrate by MOCVD method 6; followed by magnesium activation annealing treatment on the epitaxial wafer; then use chemical reagents such as KOH or HCl or aqua regia to carry out surface treatment on the epitaxial wafer, deposit ITO transparent conductive film by electron beam evaporation, and then pass radio frequency magnetron sputtering The ITO / ZnO-based composite transparent electrode 7 is formed by irradiating the zinc oxide transparent conductive film. The composite transparent electrode is etched into the required pattern by wet etching, and then the n-type gallium nitride is etched by ion etching or ICP etching. Exposed and annealed; deposit n-type metal electrodes (PAD) 8 and p-type metal electrodes (PAD) 9 by therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com