Deposition method of Cu/ZnO/Al photoelectric transparent conducting film

A transparent conductive film and deposition method technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of high hardness, difficult etching, and doping process of FTO films, and achieve easy control of the deposition process and improved conductivity , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] After the substrate was cleaned with acetone, ethanol and deionized water by ultrasonic waves in sequence, it was blown dry with nitrogen and sent to the reaction chamber.

[0029] Vacuum the background of magnetron sputtering to 9.0×10 -4 After Pa, the substrate is heated to 100°C and the gas flow rate is adjusted to make the pressure reach 5Pa, the sputtering power is 100W, the sputtering time is 1min, and the thickness of the Al film is 30nm.

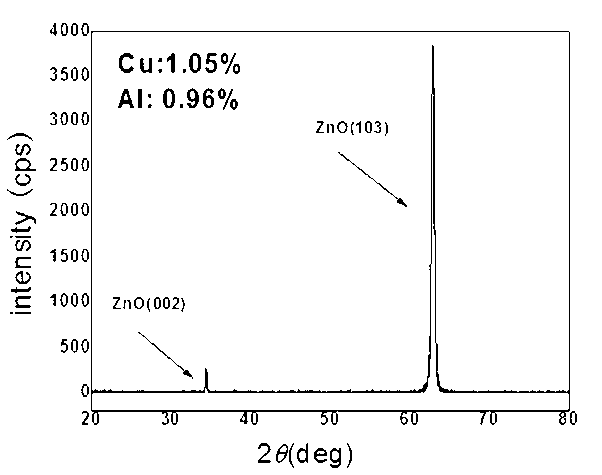

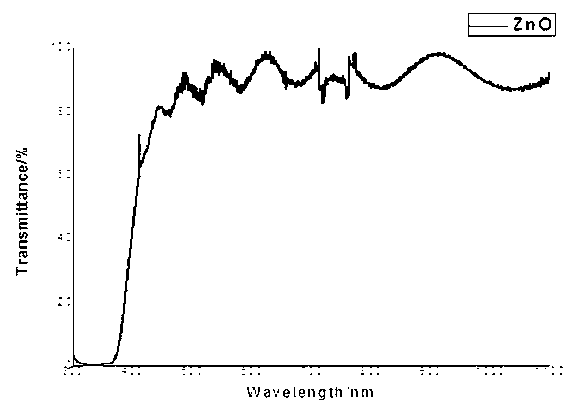

[0030] Then, the ZnO film was deposited and prepared by plasma-enhanced electron cyclotron resonance chemical vapor deposition, and the vacuum was pumped to 7.0×10 -4 After Pa, the substrate was heated to 100°C, and diethylzinc Zn(CH 2 CH 3 ) 2 and oxygen O 2 After that, Zn(CH 2 CH 3 ) 2 and O 2 The flow ratio is controlled by a mass flowmeter to be 1sccm: 100sccm, and the total pressure of the gas is controlled to be 1.6Pa; at the electron cyclotron resonance frequency of 650W, the reaction takes 25min to obtain a 40...

Embodiment 2

[0039] After cleaning the substrate with acetone, ethanol and deionized water with ultrasonic waves in sequence, blow it dry with nitrogen and send it into the reaction chamber, and vacuum the background of magnetron sputtering to 9.0×10 -4 After Pa, the substrate is heated to 100°C and the gas flow rate is adjusted so that the pressure reaches 5Pa, the sputtering power is 100W, and the sputtering time is 1min, the thickness of the Al film is 30nm.

[0040] Then, the ZnO film was deposited and prepared by plasma-enhanced electron cyclotron resonance chemical vapor deposition, and the vacuum was pumped to 7.0×10 -4 After Pa, the substrate was heated to 100°C, and diethylzinc Zn(CH 2 CH 3 ) 2 and oxygen O 2 After that, Zn(CH 2 CH 3 ) 2 and O 2 The amount is controlled by a mass flow meter to 2sccm: 200sccm, and the total pressure of the controlled gas is 1.8Pa; at the electron cyclotron resonance frequency of 650W, react for 30 minutes to obtain a 500nm ZnO thin film.

...

Embodiment 3

[0047] After cleaning the substrate with acetone, ethanol and deionized water with ultrasonic waves in sequence, blow it dry with nitrogen and send it into the reaction chamber, and vacuum the background of magnetron sputtering to 9.0×10 -4 After Pa, the substrate is heated to 100°C and the gas flow rate is adjusted so that the pressure reaches 5Pa, the sputtering power is 100W, and the sputtering time is 5min. The thickness of the Al film is 50nm.

[0048] Then, the ZnO film was deposited and prepared by plasma-enhanced electron cyclotron resonance chemical vapor deposition, and the vacuum was pumped to 7.0×10 -4 After Pa, the substrate was heated to 100°C, and diethylzinc Zn(CH 2 CH 3 ) 2 and oxygen O 2 After that, Zn(CH 2 CH 3 ) 2 and O 2 The amount is controlled by a mass flow meter to 2sccm: 150sccm, and the total pressure of the controlled gas is 2.0Pa; at the electron cyclotron resonance frequency of 650W, react for 40min to obtain a 600nm ZnO thin film.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com