A kind of lead silicate glass microchannel plate and the method for preparing Ni-doped Al2O3 high-resistance film on the inner wall of microchannel plate

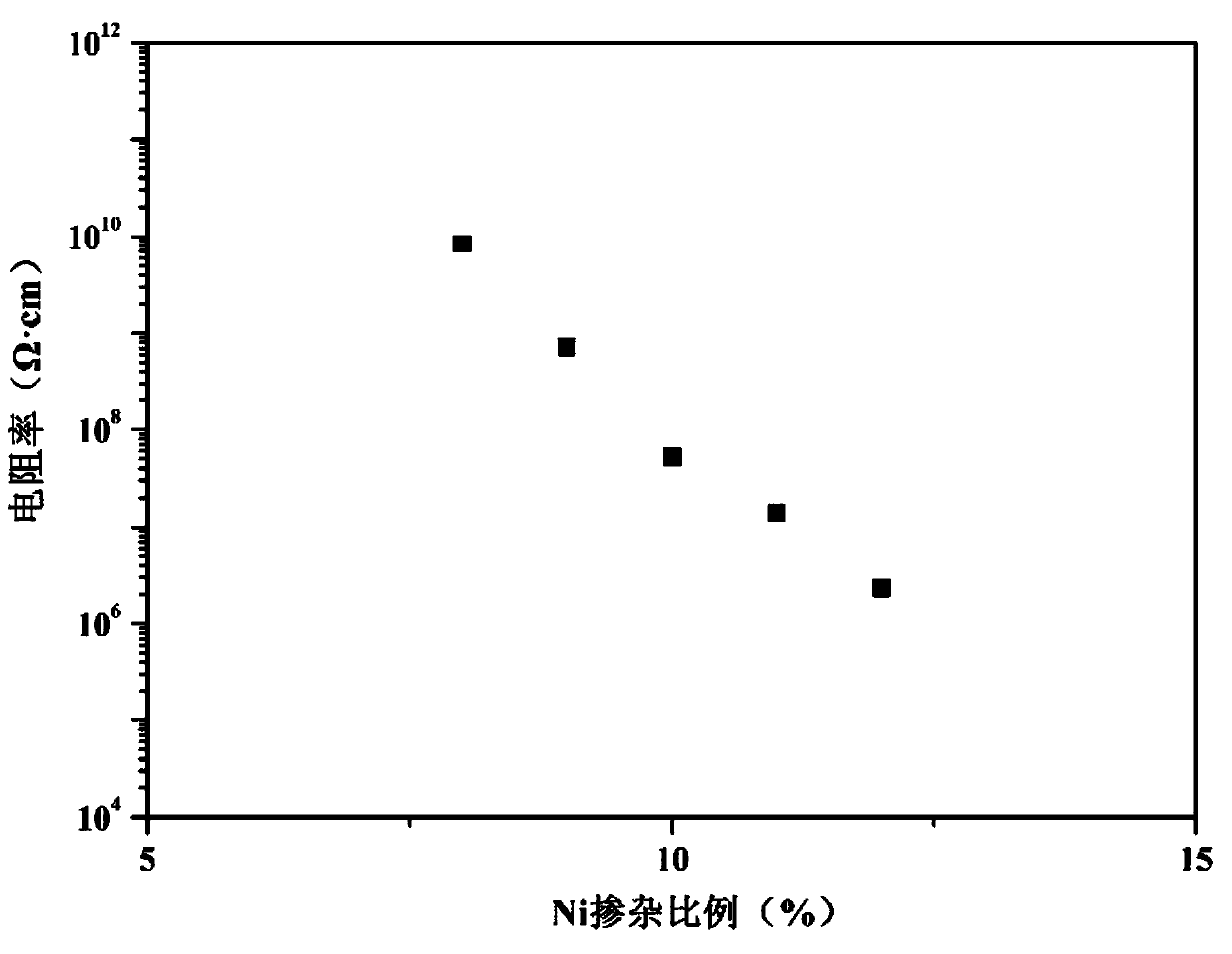

A lead silicate glass and micro-channel plate technology is applied in the field of film doping, which can solve the problems of unstable performance of micro-channel plates and changes in resistivity, and achieve the effect of excellent thermal stability of the film, constant resistivity, and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

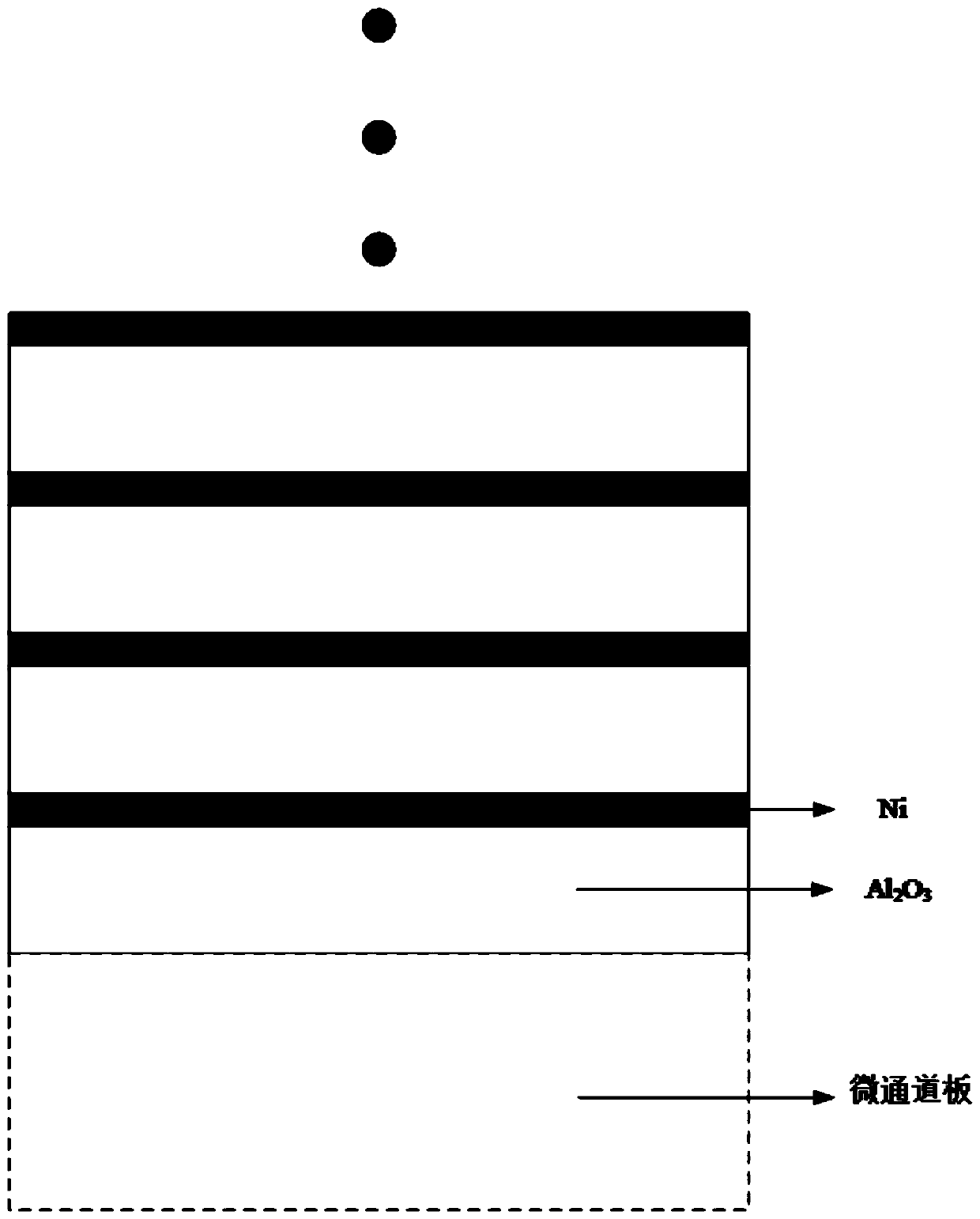

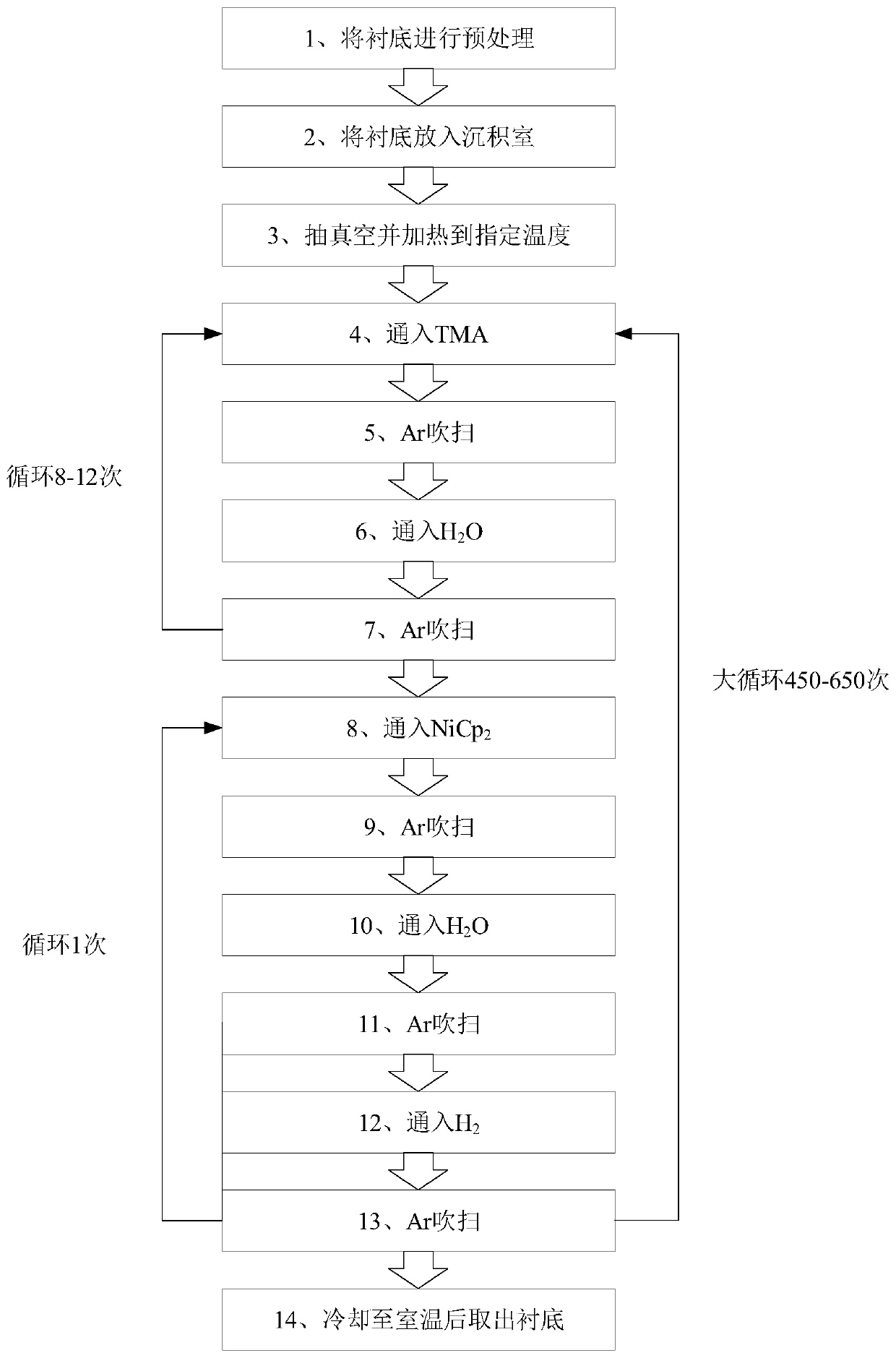

[0054] Place the microchannel plate in RCA standard cleaning solution SC-2 (HCl: H 2 o 2 :H 2 O=1:1:5), after ultrasonic cleaning at 85°C for 10 minutes, placed in HF solution (HF:H 2 (0=1:50) after ultrasonic cleaning, put the microchannel plate into the atomic layer deposition chamber, and vacuumize to 10 -1 Pa, and the temperature of the deposition chamber and the microchannel plate was heated to 150 °C, and the Al 2 o 3 deposition, i.e. TMA / Ar / H 2 O / Ar=(0.1s / 5s / 0.1s / 5s), after 12 cycles, 1 cycle of Ni deposition, namely NiCp 2 / Ar / H 2 O / Ar / H 2 / Ar=(4s / 10s / 8s / 10s / 15s / 10s), 12 times Al 2 o 3 After the deposition cycle and 1 Ni deposition cycle are 1 large cycle, the deposition is stopped after 450 large cycles, and after the deposition chamber drops to room temperature, the deposition chamber is opened, and the deposited Ni-doped Al 2 o 3 Thin film microchannel plate.

Embodiment 2

[0056] Place the microchannel plate in RCA standard cleaning solution SC-2 (HCl: H 2 o 2 :H 2 O=1:1:5), after ultrasonic cleaning at 85°C for 10 minutes, placed in HF solution (HF:H 2 (0=1:50) after ultrasonic cleaning, put the microchannel plate into the atomic layer deposition chamber, and vacuumize to 10 -2 Pa, and the temperature of the deposition chamber and the microchannel plate was heated to 180°C, and the Al 2 o 3 deposition, i.e. TMA / Ar / H 2 O / Ar=(0.1s / 5s / 0.1s / 5s), after 11 cycles, 1 cycle of Ni deposition, namely NiCp 2 / Ar / H 2 O / Ar / H 2 / Ar=(4s / 10s / 8s / 10s / 15s / 10s), 11 times Al 2 o 3 After the deposition cycle and 1 Ni deposition cycle is a large cycle, the deposition is stopped after 500 large cycles, and after the deposition chamber is lowered to room temperature, the deposition chamber is opened, and the deposited Ni-doped Al 2 o 3 Thin film microchannel plate.

Embodiment 3

[0058] Place the microchannel plate in RCA standard cleaning solution SC-2 (HCl: H 2 o 2 :H 2 O=1:1:5), after ultrasonic cleaning at 85°C for 10 minutes, placed in HF solution (HF:H 2 (0=1:50) after ultrasonic cleaning, put the microchannel plate into the atomic layer deposition chamber, and vacuumize to 10 -3 Pa, and the temperature of the deposition chamber and the microchannel plate was heated to 200°C, and the Al 2 o 3 deposition, i.e. TMA / Ar / H 2 O / Ar=(0.1s / 5s / 0.1s / 5s), after 10 cycles, 1 cycle of Ni deposition, namely NiCp 2 / Ar / H 2 O / Ar / H 2 / Ar=(4s / 10s / 8s / 10s / 15s / 10s), 10 times Al 2 o 3 After the deposition cycle and 1 Ni deposition cycle are 1 large cycle, the deposition is stopped after 550 large cycles, and after the deposition chamber is lowered to room temperature, the deposition chamber is opened, and the deposited Ni-doped Al 2 o 3 Thin film microchannel plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com