Method for preparing Al-doped ZnO transparent conductive film by atomic layer deposition

A transparent conductive film, atomic layer deposition technology, applied in coating, metal material coating process, gaseous chemical plating and other directions, can solve the problems of uneven doping of Al composition, high resistivity of AZO film, etc., and achieve photoelectric performance. Excellent, easily controllable deposition process, improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

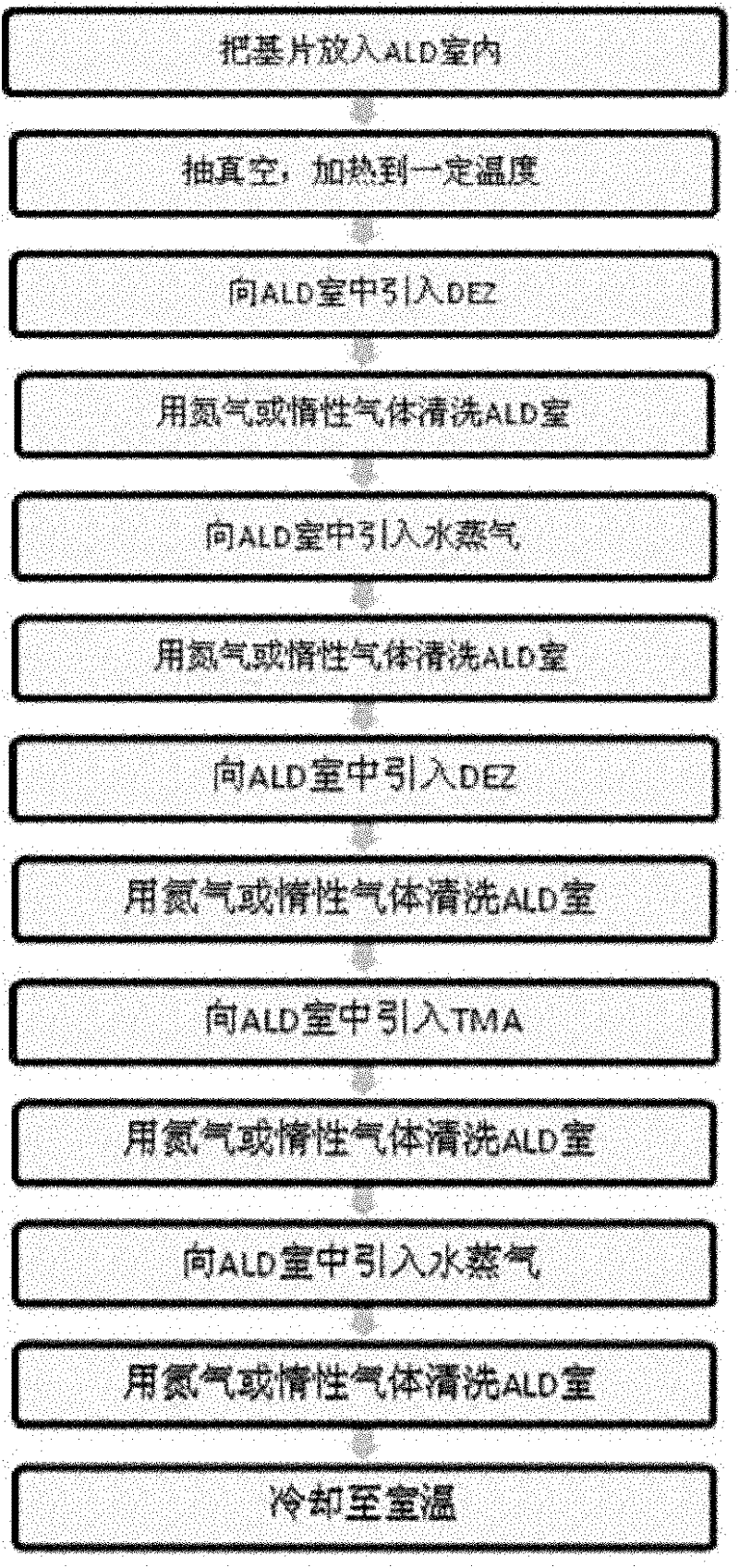

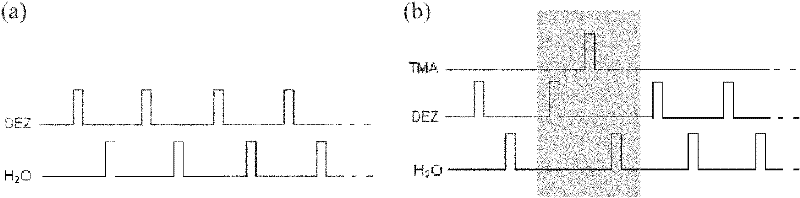

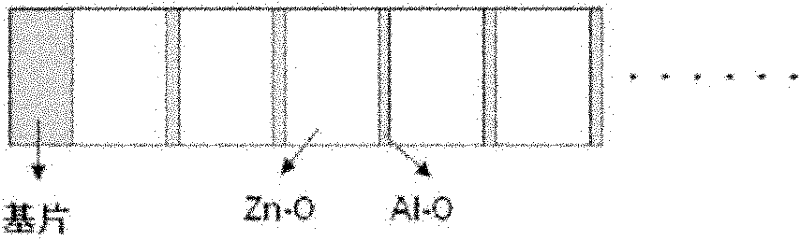

[0022] The glass substrate was cleaned with isopropanol and deionized water in an ultrasonic cleaner, dried and placed in an atomic layer deposition chamber. Vacuum to 10hPa ~ 16hPa, heat the substrate to 200°C, and carry out ZnO deposition cycle, that is, diethylzinc / N 2 / H 2 O / N 2 =(0.1s / 3s / 0.1s / 3s), after 9 cycles, an Al-doped deposition cycle is performed, that is, diethylzinc / N 2 / trimethylaluminum / N 2 / H 2 O / N 2 =(0.1s / 3s / 0.1s / 3s / 0.1s / 3s), the ZnO deposition cycle and the Al-doped deposition cycle are a large cycle, and the large cycle is performed 50 times. After the temperature of the deposition chamber drops to room temperature, the deposition Chamber, made a thin film with a thickness of about 80nm, and analyzed by ICP composition, the doping amount of Al was 4.6at.%.

Embodiment 2

[0024] The glass substrate was cleaned with isopropanol and deionized water in an ultrasonic cleaner, dried and placed in an atomic layer deposition chamber. Vacuum to 10hPa ~ 16hPa, heat the substrate to 200°C, and carry out ZnO deposition cycle, that is, diethylzinc / N 2 / H 2 O / N 2 =(0.1s / 3s / 0.1s / 3s), after 14 cycles, an Al-doped deposition cycle is performed, that is, diethylzinc / N 2 / trimethylaluminum / N 2 / H 2 O / N 2 =(0.1s / 3s / 0.1s / 3s / 0.1s / 3s), the ZnO deposition cycle and the Al doping deposition cycle are a large cycle, and the large cycle is performed 34 times. After the temperature of the deposition chamber drops to room temperature, the deposition Chamber, made a thin film with a thickness of about 80nm, and analyzed by ICP composition, the doping amount of Al was found to be 3.7 at.%.

Embodiment 3

[0026] The glass substrate was cleaned with isopropanol and deionized water in an ultrasonic cleaner, dried and placed in an atomic layer deposition chamber. Vacuum to 10hPa ~ 16hPa, heat the substrate to 200°C, and carry out ZnO deposition cycle, that is, diethylzinc / N 2 / H 2 O / N 2 =(0.1s / 3s / 0.1s / 3s), after 19 cycles, an Al-doped deposition cycle is performed, that is, diethylzinc / N 2 / trimethylaluminum / N 2 / H 2 O / N 2 =(0.1s / 3s / 0.1s / 3s / 0.1s / 3s), the ZnO deposition cycle and the Al-doped deposition cycle are a large cycle, and the large cycle is performed 25 times. After the temperature of the deposition chamber drops to room temperature, the deposition Chamber, made a thin film with a thickness of about 100nm, and analyzed by ICP composition, the doping amount of Al was found to be 2.9 at.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com