Depositing method for Ag/ZnO/Mg photoelectric transparent conducting thin film

A technology of a transparent conductive film and a deposition method, which is applied in the plating of superimposed layers, ion implantation plating, gaseous chemical plating, etc. The deposition process is easy to control, the preparation process is simple, and the photoelectric properties are excellent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

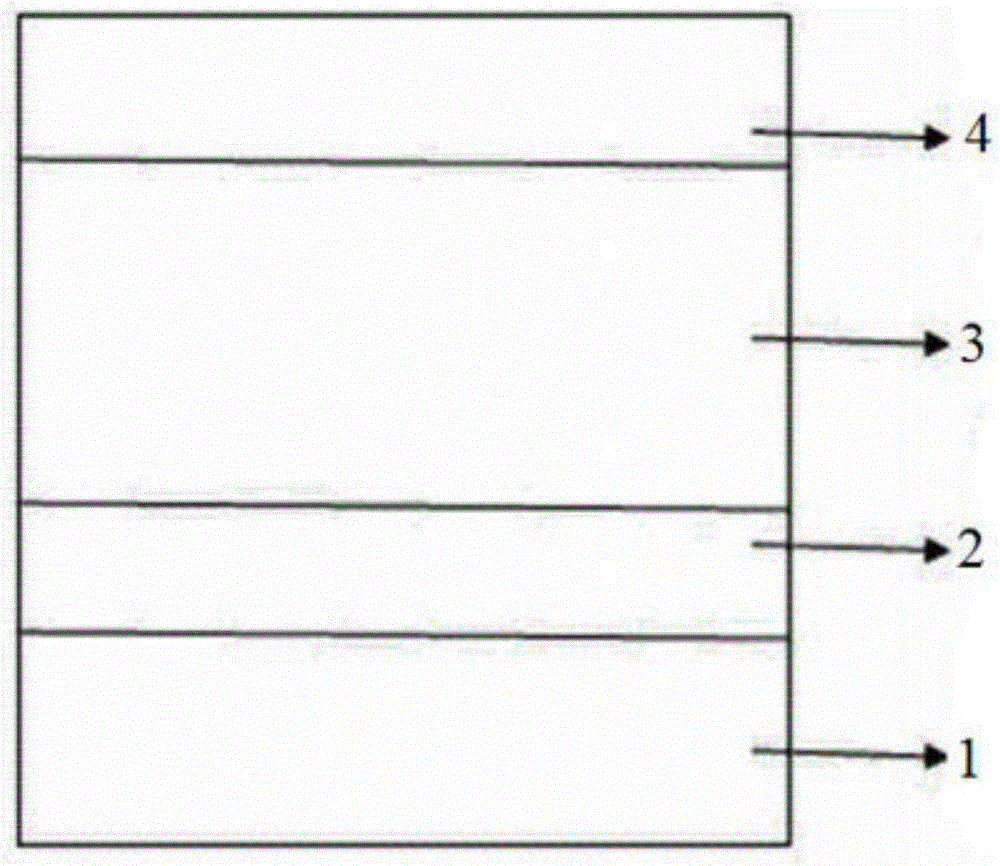

Image

Examples

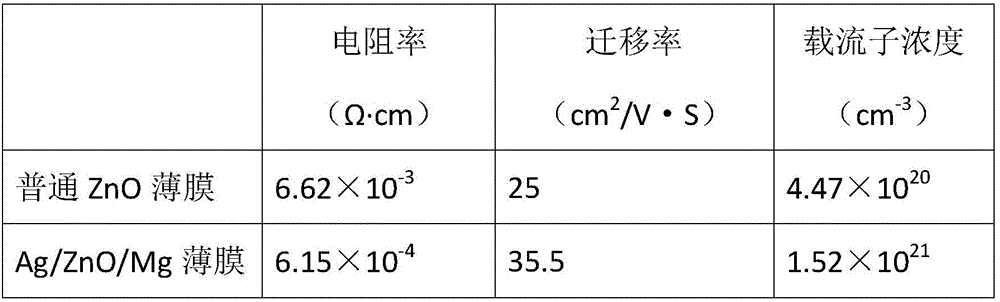

Embodiment 1

[0023] After the substrate was cleaned with acetone, ethanol and deionized water by ultrasonic waves in sequence, it was blown dry with nitrogen and sent to the reaction chamber.

[0024] Vacuum the background of magnetron sputtering to 9.5×10 -4 After Pa, the substrate was heated to 150° C. and the gas flow rate was adjusted so that the pressure reached 6 Pa, the sputtering power was 150 W, the sputtering time was 2 min, and the thickness of the Mg film was 20 nm.

[0025] Then, the ZnO thin film was deposited and prepared by plasma-enhanced electron cyclotron resonance chemical vapor deposition, and the vacuum was pumped to 7.5×10 -4 After Pa, the substrate was heated to 150°C, and Zn(CH 2 CH 3 ) 2 and O 2 After that, Zn(CH 2 CH 3 ) 2 and O 2 The flow ratio is controlled by a mass flowmeter to be 2sccm: 200sccm, and the total pressure of the gas is controlled to be 1.5Pa; at the electron cyclotron resonance frequency of 750W, the reaction takes 25min to obtain a 450n...

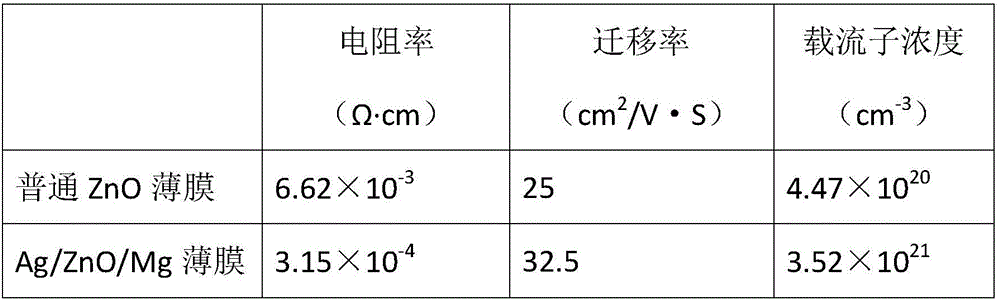

Embodiment 2

[0032] After the substrate was cleaned with acetone, ethanol and deionized water by ultrasonic waves in sequence, it was blown dry with nitrogen and sent to the reaction chamber.

[0033] Vacuum the background of magnetron sputtering to 9.5×10 -4After Pa, the substrate was heated to 150°C and the gas flow rate was adjusted to make the pressure reach 6Pa, the sputtering power was 150W, the sputtering time was 6min, and the thickness of the Mg film was 60nm.

[0034] Then, the ZnO thin film was deposited and prepared by plasma-enhanced electron cyclotron resonance chemical vapor deposition, and the vacuum was pumped to 7.5×10 -4 After Pa, the substrate was heated to 300°C, and Zn(CH 2 CH 3 ) 2 and O 2 After that, Zn(CH 2 CH 3 ) 2 and O 2 The flow ratio is controlled by a mass flowmeter to be 4sccm: 200sccm, and the total pressure of the gas is controlled to be 1.5Pa; at the electron cyclotron resonance frequency of 750W, the reaction takes 45min to obtain a 650nm ZnO thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com