a ws x /me/a-c/me nanometer multilayer structure solid lubricating film and preparation method thereof

A nano-multilayer, solid lubrication technology, applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve the problem of low friction coefficient and wear rate, insufficient anti-oxidation and wear resistance, hardness and bonding force Low friction factor, improved anti-oxidation performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

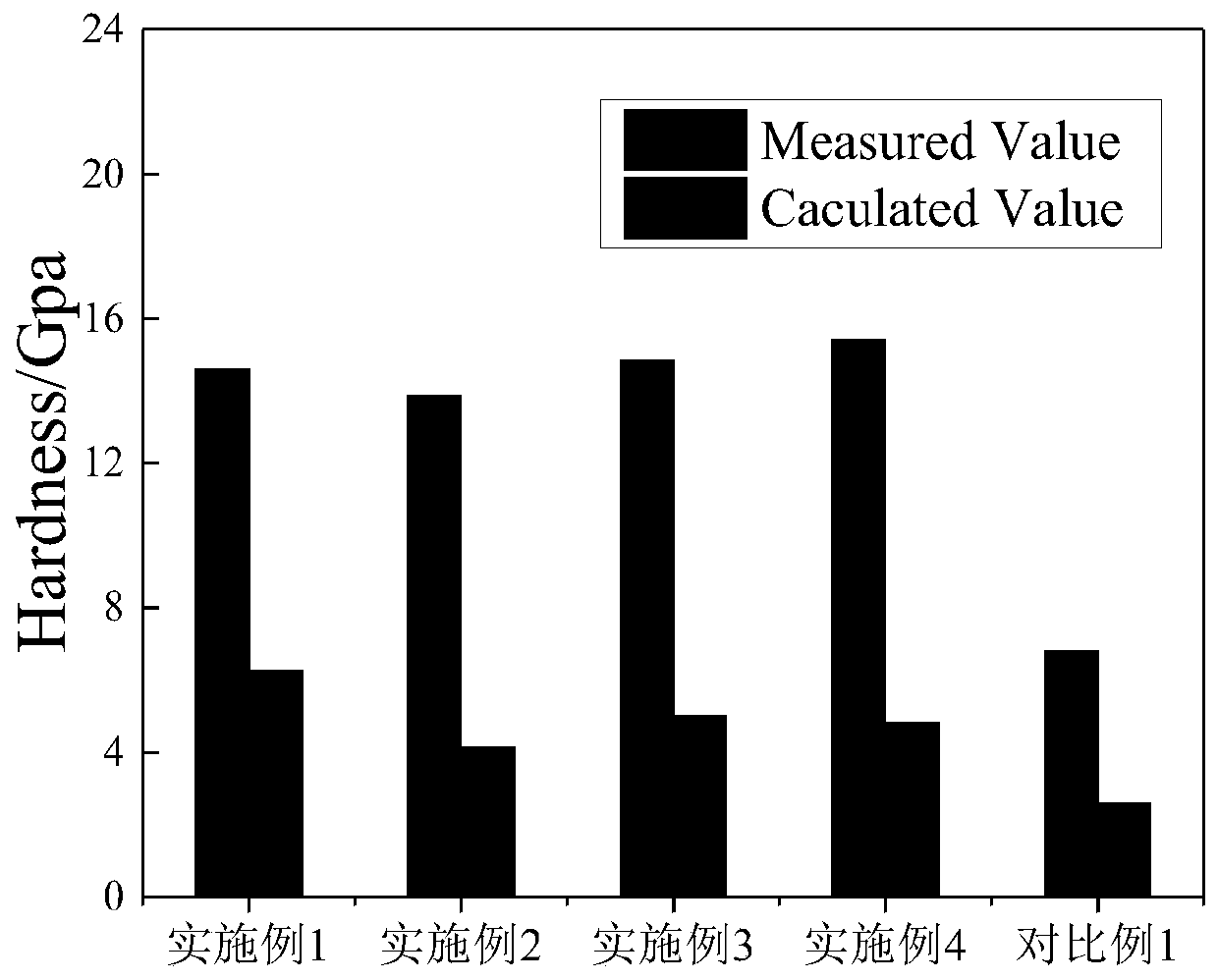

Embodiment 1W

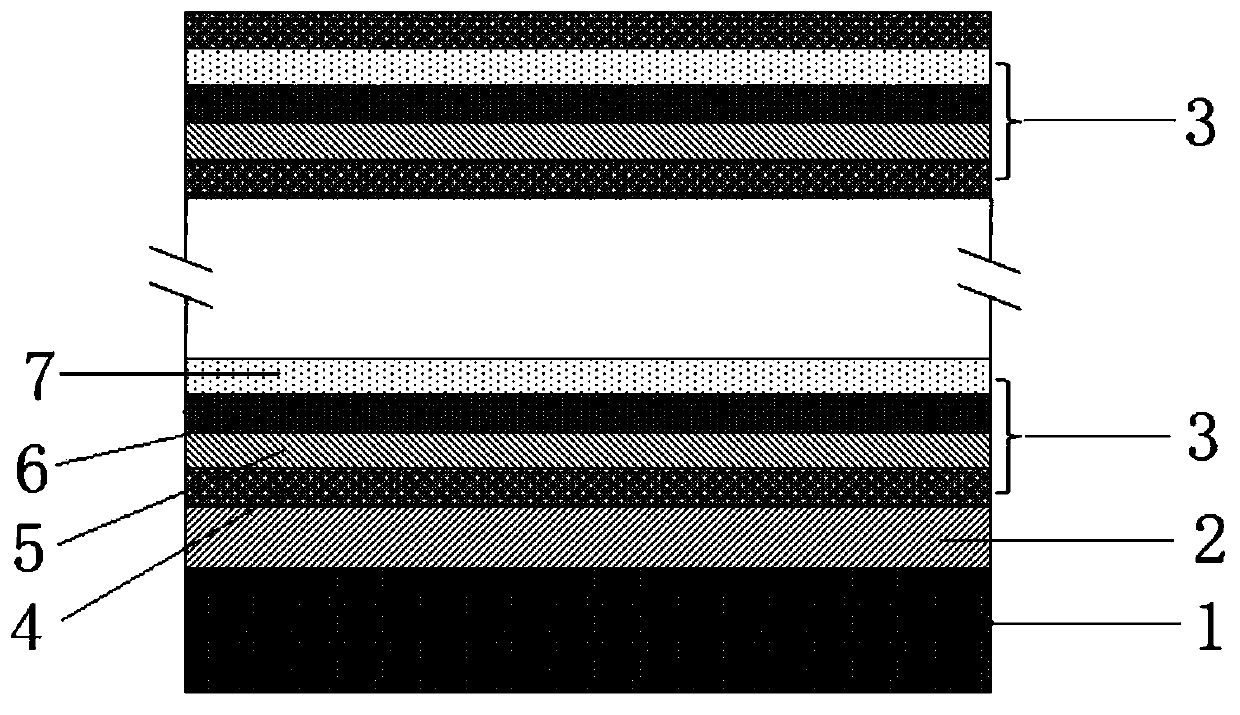

[0045] Embodiment 1WS x Preparation of / Ti / a-C / Ti nano-layer solid lubricating film

[0046] (1) Pretreatment of the substrate: Soak the polished single-crystal silicon wafer (with an orientation of ) in a hydrofluoric acid solution with a volume fraction of 10% for 10 minutes, then ultrasonically clean it with acetone and absolute ethanol for 15 minutes each , then dry it and quickly put it into the sputtering chamber;

[0047] (2) Experiment preparation: the WS 2 The target, Ti target and graphite target are fixed on the corresponding target stage, and the base distance of the target is adjusted to 70mm. After the inspection is correct, close the sputtering chamber and pump the background vacuum to 1.0×10 -3 Below Pa, heat the substrate to 200°C and keep it warm, then pass in argon gas, adjust the deposition pressure to 1.0Pa, add a DC bias voltage to -100V, and start the autorotation motor;

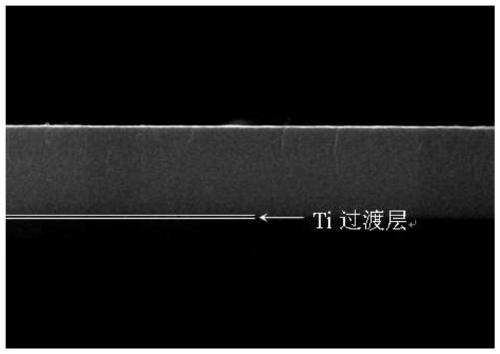

[0048] (3) Preparation of Ti transition layer: first keep the substrate away fr...

Embodiment 2W

[0050] Embodiment 2WS x Preparation of / Cr / a-C / Cr Nano Multilayer Structure Solid Lubricating Film

[0051] (1) Substrate pretreatment: After the polished low-carbon steel sheet is degreased and the oxide layer is removed, it is placed in distilled water for ultrasonic cleaning for 10 minutes, then air-dried and placed in the sputtering chamber;

[0052] (2) Experiment preparation: the WS 2 The target, Cr target and graphite target are fixed on the corresponding target stage, and the base distance of the target is adjusted to 70mm. After the inspection is correct, close the sputtering chamber and evacuate the background vacuum to 1.0×10 -3 Below Pa, heat the substrate to 200°C and keep it warm, then pass in argon gas, adjust the deposition pressure to 1.0Pa, add a DC bias voltage to -100V, and start the autorotation motor;

[0053] (3) Preparation of the Cr transition layer: first keep the substrate away from the Cr target, turn on the sputtering power of the Cr target, then...

Embodiment 3W

[0055] Embodiment 3WS x Preparation of / Ti / a-C / W nano-layered solid lubricating film

[0056] (1) substrate pretreatment: with the step (1) in the embodiment 1;

[0057] (2) Experiment preparation: the WS 2 The target, Ti target, W target and graphite target are fixed on the corresponding target stage, and the target base distance is adjusted to 70mm. After checking, close the sputtering chamber and pump the background vacuum to 1.0×10 -3 Below Pa, heat the substrate to 200°C and keep it warm, then pass in argon gas, adjust the deposition pressure to 1.0Pa, add a DC bias voltage to -100V, and start the autorotation motor;

[0058] (3) Preparation of Ti transition layer: with step (3) in embodiment 1;

[0059] (4)WS x / Ti / a-C / W multilayer films: During transition layer deposition, ignition of WS 2 target and graphite target. After the deposition of the transition layer is completed, start the program and control the substrate to stay in the WS 2 Directly above the target...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com