Method for preparing transparent copper thin film conductive electrode through replacement reaction via atomic layer deposition technology

An atomic layer deposition and displacement reaction technology, applied in coatings, circuits, photovoltaic power generation, etc., can solve problems such as the limitation of transparent conductive electrode substrates, poor light transmittance of metal film electrodes, and poor physical adhesion of conductive films. Control, good uniformity, excellent photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

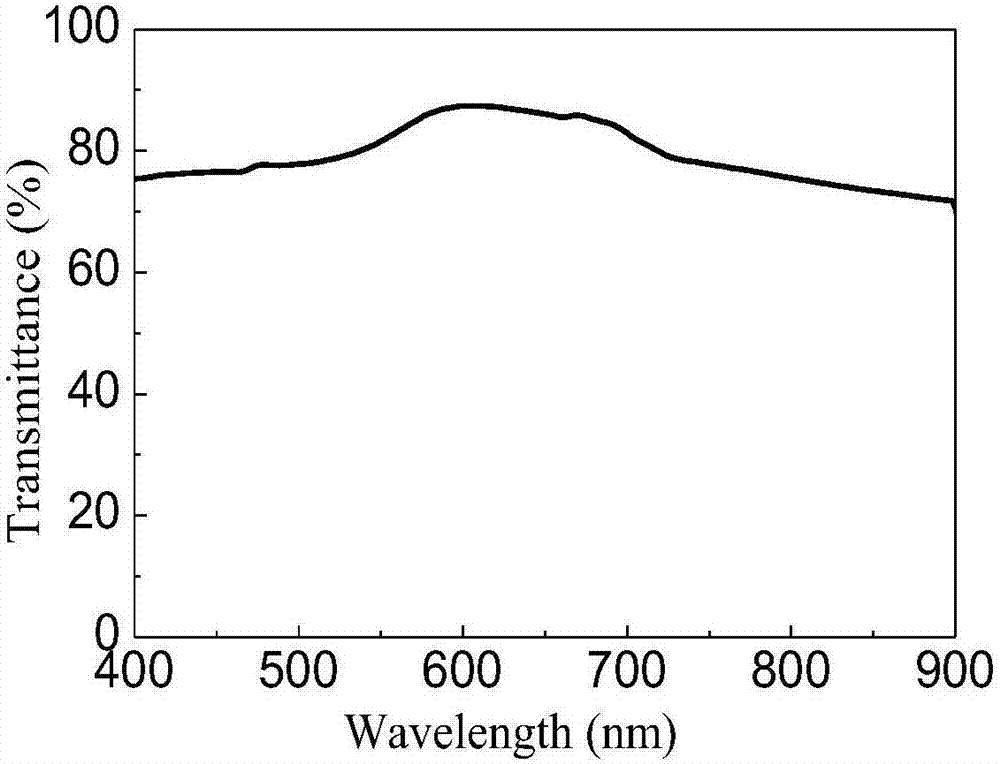

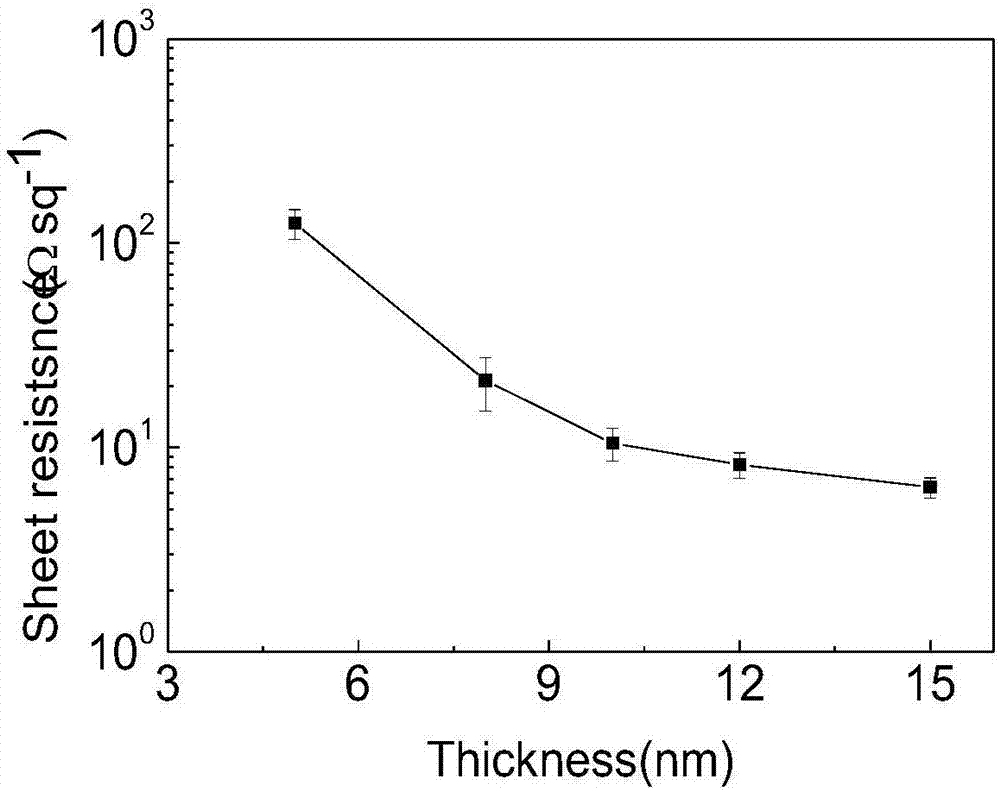

[0026] We prepared a sheet resistance as low as 6.2Ω / cm by atomic layer deposition through replacement reaction 2 , and the uniform transparent copper film conductive electrode with a light transmittance of about 80%.

[0027] The specific process is as follows:

[0028] 1) Wipe the 25×25mm glass substrate with acetone, ethanol and deionized water, then ultrasonically clean it with acetone, ethanol and deionized water, and then dry it with nitrogen;

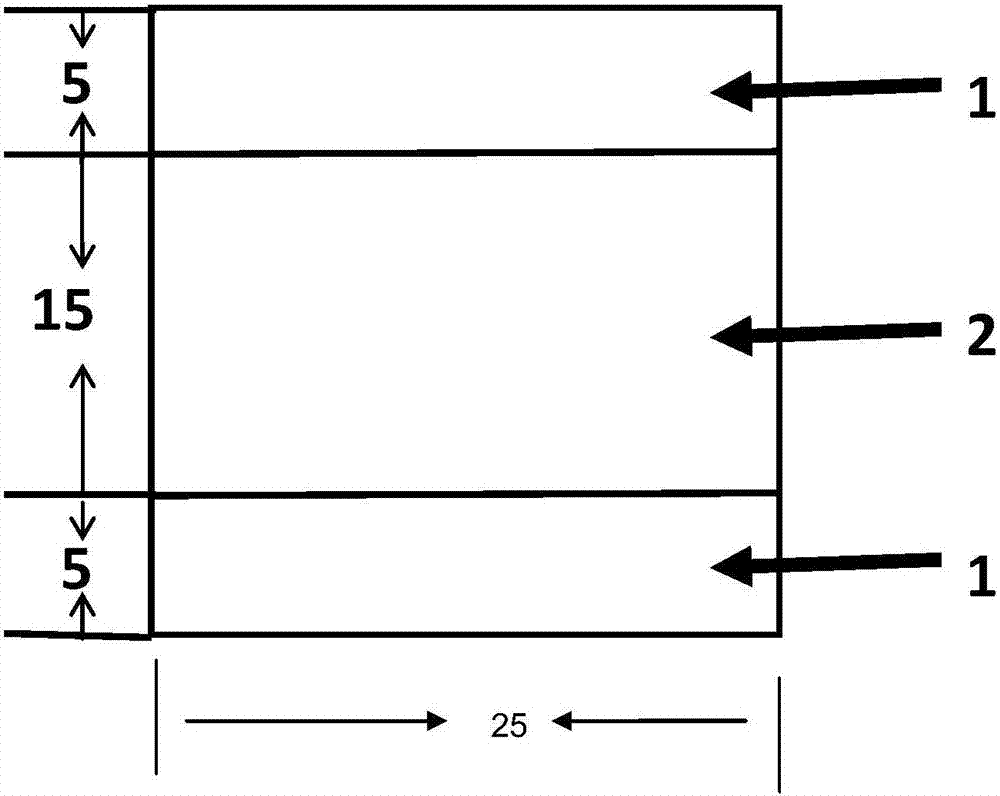

[0029] 2) Paste two separate silicon wafer protective films on the same side surface of the glass substrate cleaned in step 1), the structure and size of the protective film are as follows: figure 1 As shown, the upper and lower sides of the surface on the same side of the substrate are close to the edge of the protective film, its size is 25×5mm, and the middle part is the growth copper film area, its size is 25×15mm, and its function is to control the light-emitting area The area of the anode and cathode contact short circu...

Embodiment 2

[0034]We used atomic layer deposition technology to prepare a 12nm (600 cycles) thick patterned uniform transparent copper thin film conductive electrode through the replacement reaction principle, and on this basis prepared a structure A: glass / ITO / HAT-CN (5nm) / TAPC(50nm) / Ir(ppy) 3 : CBP 5% (percent unit is molar weight) (15nm) / TPBI (30nm) / Liq (1nm) / Al and structure is B: glass / Cu (transparent copper thin film conductive electrode prepared by the present invention, 12nm) / HAT -CN(5nm) / TAPC(50nm) / Ir(ppy) 3 : CBP 5% (15nm) / TPBI (30nm) / Liq (1nm) / Al OLED device, wherein, HAT-CN is the hole injection layer, TAPC is the hole transport layer, Ir (ppy) 3 : CBP is the light-emitting layer, TPBI is the electron transport layer, Liq is the buffer layer, and Al is the cathode.

[0035] Among them, the ITO of the A group device is used as the OLED anode, and the 12nm transparent copper film conductive electrode of the B group device is used as the OLED anode. The specific process is as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com