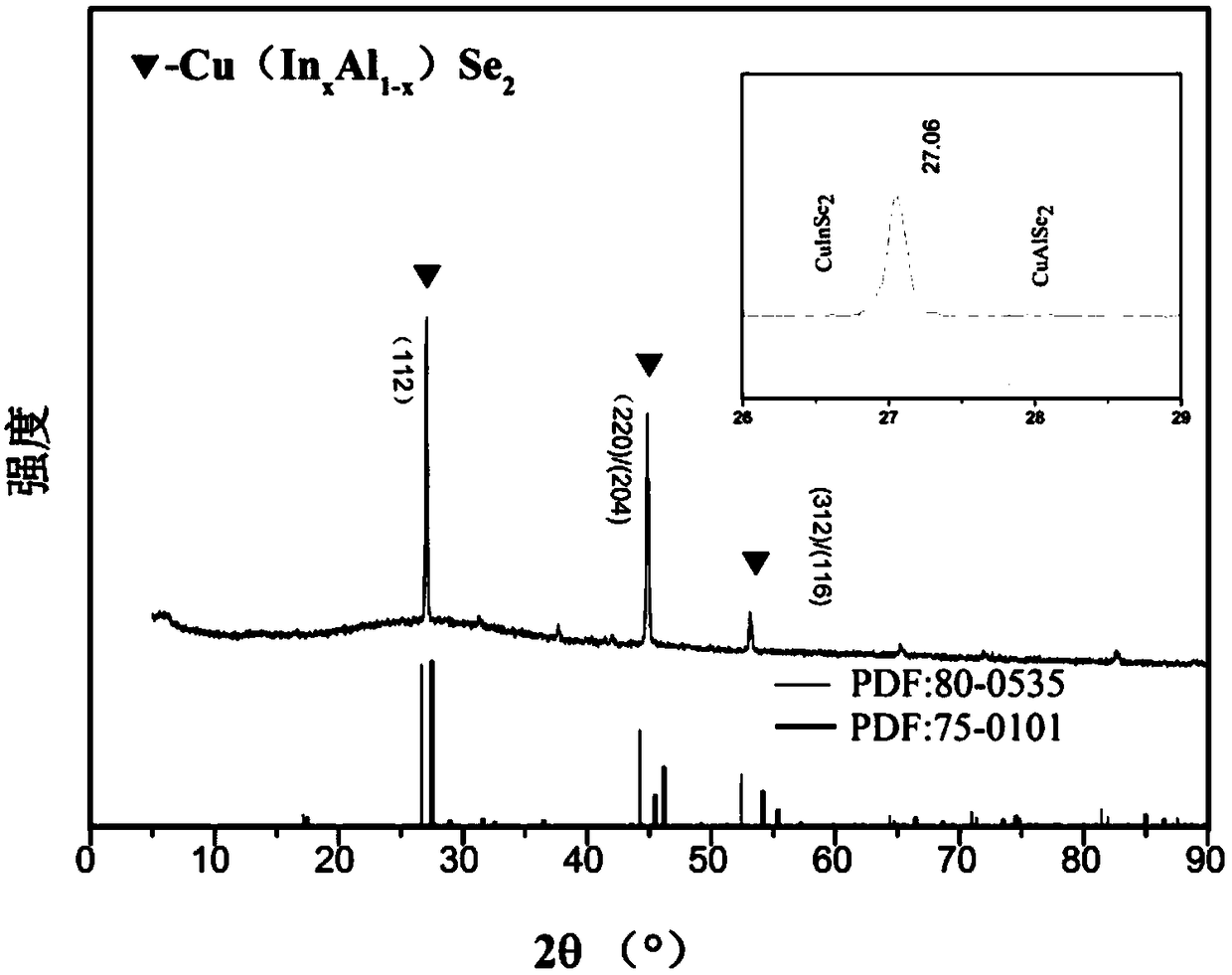

Method of preparing copper indium aluminum selenium solar cell film materials through selenized annealing after layered electrodeposition

A solar cell, copper indium aluminum selenium technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of large difference in deposition potential, poor film quality, and difficult control of the deposition process, and achieve low cost and easy control , the effect of adjustable stoichiometric ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

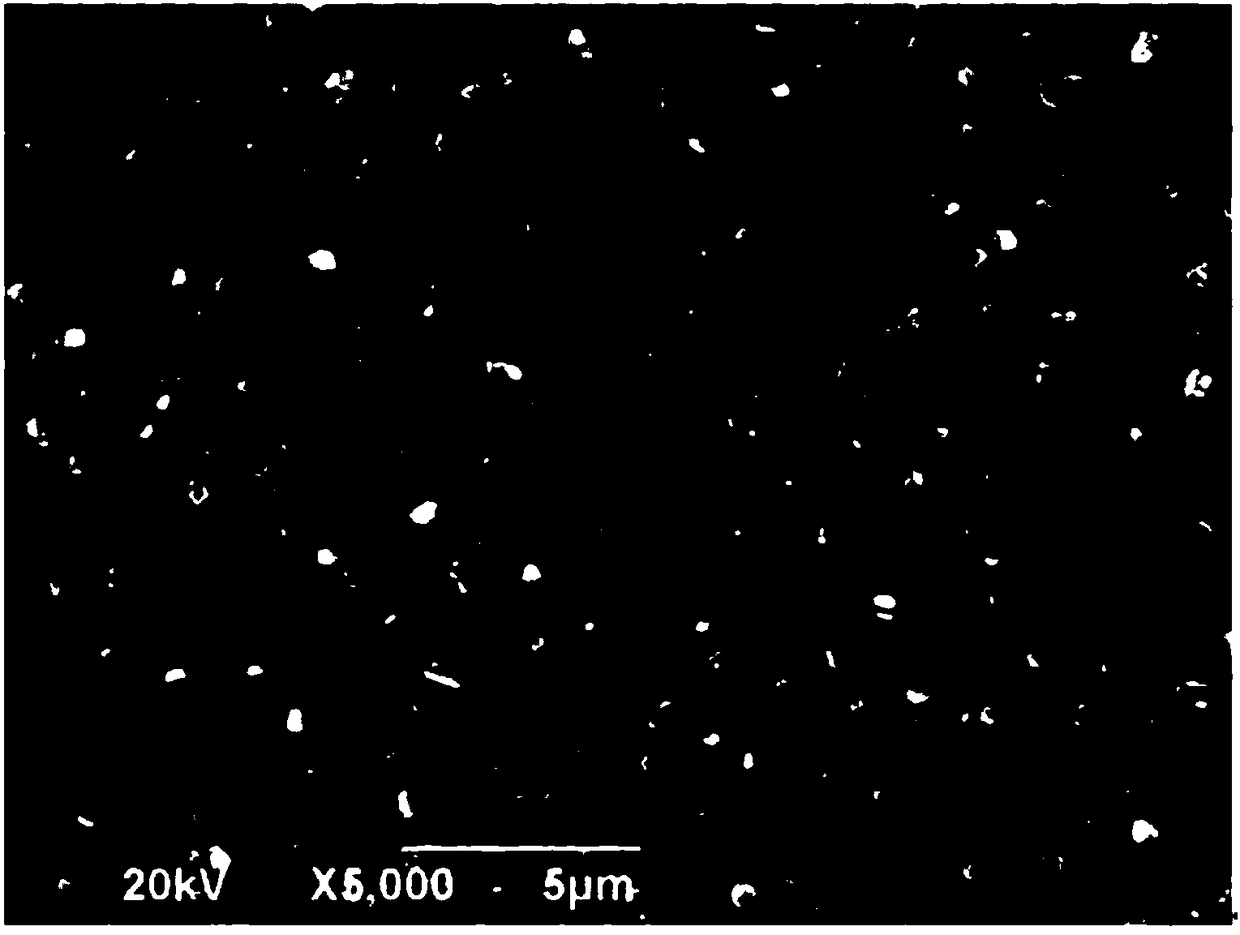

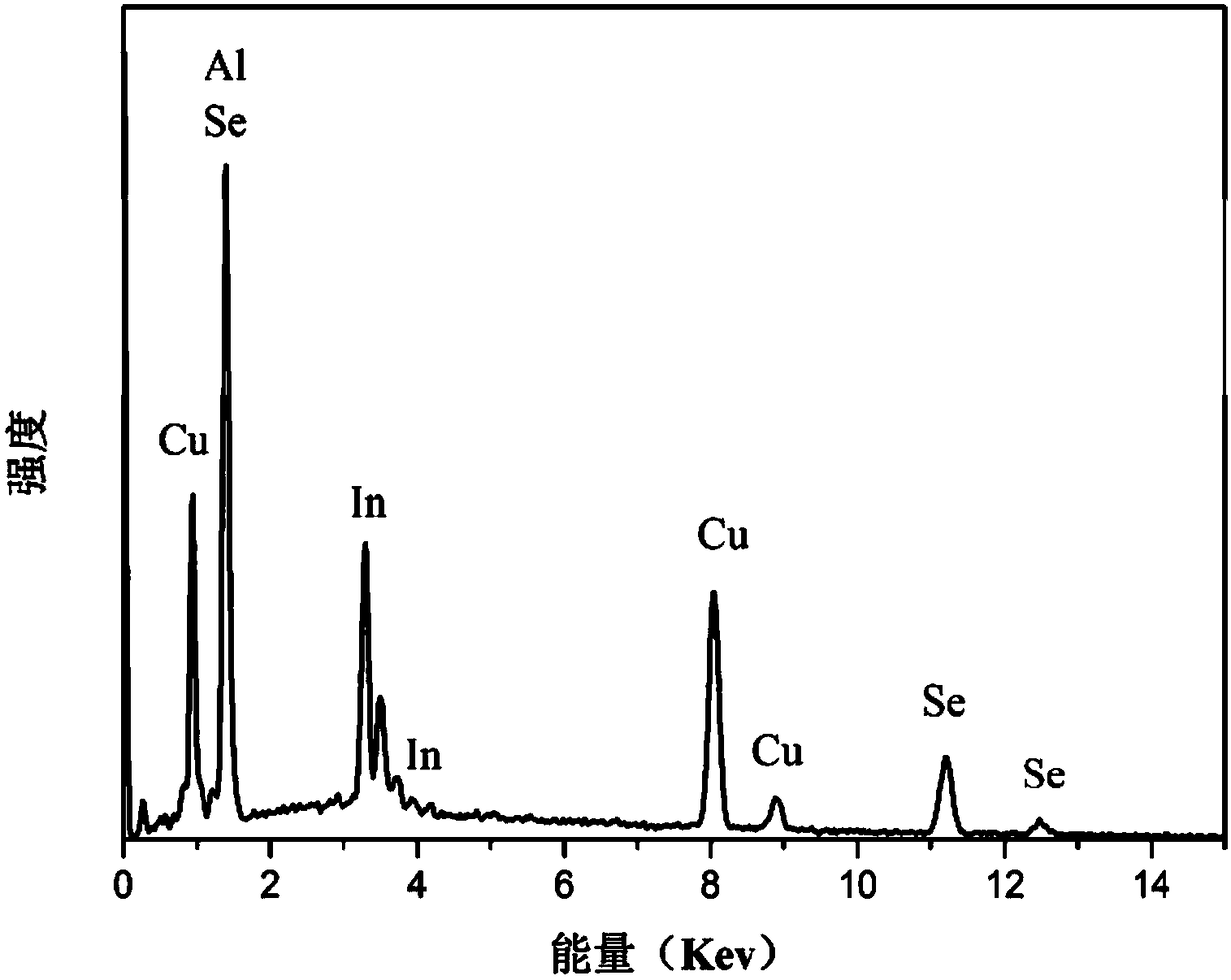

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing copper indium aluminum selenium solar cell thin film material after layered electrodeposition by selenization annealing, the preparation steps are as follows:

[0037] (1) Place analytically pure NaCl and KCl in a muffle furnace at 400°C for 5 hours, then mix with analytically pure AlCl 3 by AlCl 3 , NaCl, KCl 8:1:1 mass ratio is fully mixed to prepare AlCl 3 -NaCl-KCl ternary inorganic molten salt system;

[0038] (2) heating with a heat-collecting stirrer, controlling the temperature to 130°C for the inorganic molten salt system obtained in step (1) to melt the mixed salt;

[0039] (3) Raise the temperature of the molten salt obtained in step (2) to 150°C, and then insert two aluminum electrodes to pre-electrolyte decontaminate the molten salt. 2 , the electrolysis time is 0.5h;

[0040] (4) The molybdenum glass is ultrasonically cleaned with acetone and ethanol for 30 minutes, then ultrasonically cleaned with deionized water for 20 minutes,...

Embodiment 2

[0050] A method for preparing copper indium aluminum selenium solar cell thin film material after layered electrodeposition by selenization annealing, the preparation steps are as follows:

[0051] (1) Place analytically pure NaCl and KCl in a muffle furnace at 400°C for 5 hours, then mix with analytically pure AlCl 3 by AlCl 3 , NaCl, KCl 8:1:1 mass ratio fully mixed, prepared into AlCl 3 -NaCl-KCl ternary inorganic molten salt system;

[0052] (2) Heating with a heat collecting stirrer, controlling the temperature of the inorganic molten salt system obtained in step (1) to 130° C. to melt the mixed salt.

[0053] (3) Raise the temperature of the molten salt obtained in step (2) to 150°C, and then insert two aluminum electrodes to pre-electrolyte decontaminate the molten salt. 2 , the electrolysis time is 0.5h;

[0054](4) The molybdenum glass is ultrasonically cleaned with acetone and ethanol for 20 minutes, then ultrasonically cleaned with deionized water for 20 minutes...

Embodiment 3

[0059] A method for preparing copper indium aluminum selenium solar cell thin film material after layered electrodeposition by selenization annealing, the preparation steps are as follows:

[0060] (1) Dissolve 10g of copper sulfate pentahydrate in 50ml of deionized water, then add 3g of sulfuric acid and stir to fully dissolve it, and prepare an acidic copper sulfate copper plating electrolyte solution, ultrasonically clean the molybdenum glass with acetone and ethanol for 20 minutes, and then use Ultrasonic cleaning with deionized water for 20 minutes and drying. The cleaned molybdenum glass is used as the cathode, and the high-purity copper sheet is used as the anode for electrodeposition, and the current density of the electrodeposition is 10A / dm 2 , the deposition time is 60 seconds, after the deposition is completed, wash with deionized water and absolute ethanol and dry;

[0061] (2) Place analytically pure NaCl and KCl in a muffle furnace at 400°C for 5 hours, then co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com