Magnesium alloy coronary support frame

A magnesium alloy, coronary artery technology, used in stents, medical science, surgery, etc., can solve problems such as toxic reactions and human incompatibility, and achieve the effects of high safety, improved quality of life, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

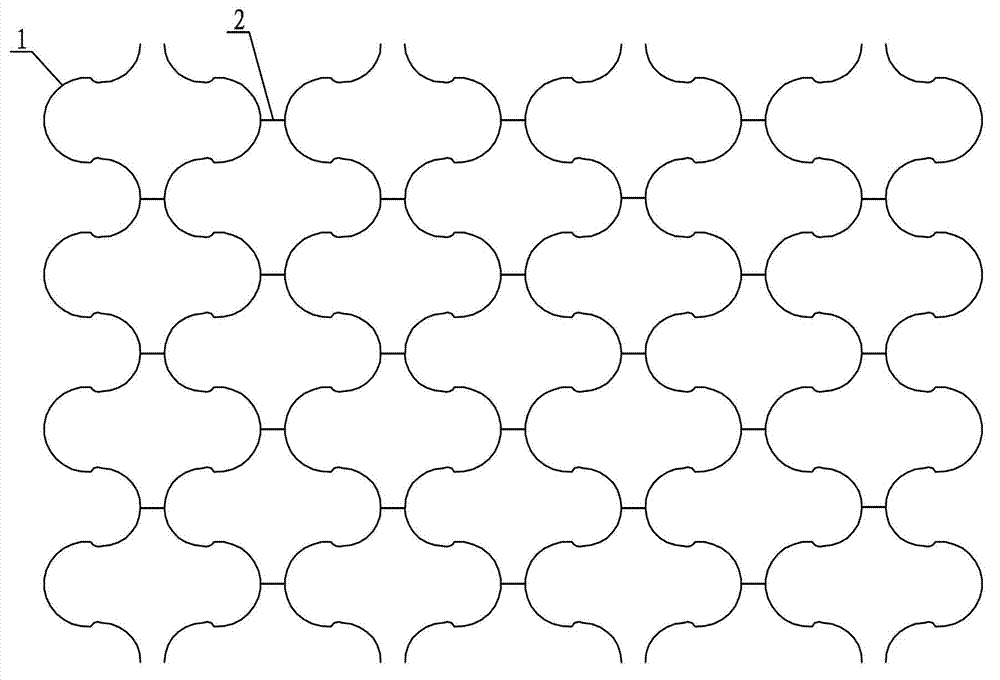

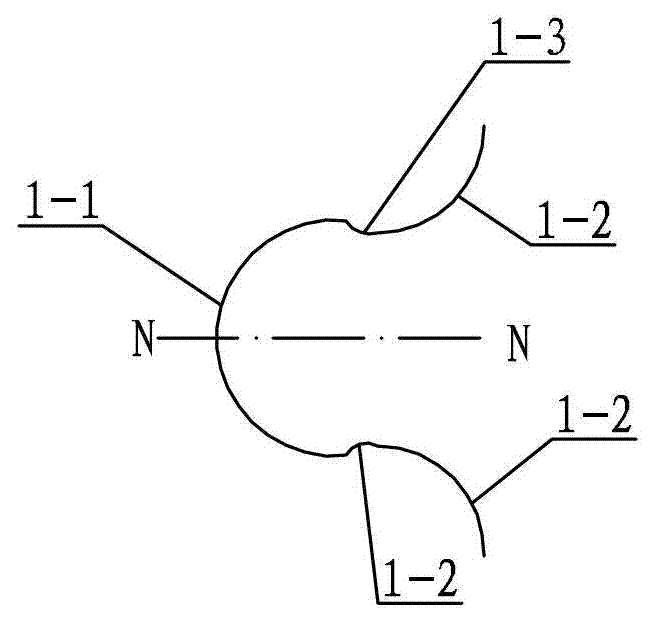

[0016] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, the stent of this embodiment is made of magnesium alloy and laser-engraved into a net-like circular tube structure. The net-like circular tube structure is composed of several main body units 1 and several linear connectors 2, and each main body unit 1 It is composed of a semicircle 1-1, two quarter circles 1-2 and two arcs 1-3, and the two quarter circles 1-2 are arranged symmetrically on the semicircle 1-1 , and the quarter ring 1-2 and the half ring 1-1 are connected by an arc 1-3, and the concave direction of the arc 1-3 faces the center of the half ring 1-1, and the number Two to four main body units 1 are arranged along the axial direction of the network management system, and eight to eighteen main body units 1 are arranged along the circumferential direction of the network management system. Among the several main body units 1 arranged in the circumferential directio...

specific Embodiment approach 2

[0017] Embodiment 2: The outer diameter of the meshed circular tube structure in this embodiment is Φ1 mm to Φ5 mm, the wall thickness is 0.1 mm to 0.2 mm, and the length of the meshed circular tube structure is 5 mm to 50 mm. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 The present embodiment will be described. The length of the linear connector 2 of the present embodiment is 0.1 mm to 0.3 mm. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com