A kind of ABS type adhesive tape solder and preparation method thereof

A solder and adhesive tape technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve long-term problems, and achieve the effect of short time consumption, simple method and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 thickness is the preparation of the AgMnAl adhesive tape solder of 0.4mm

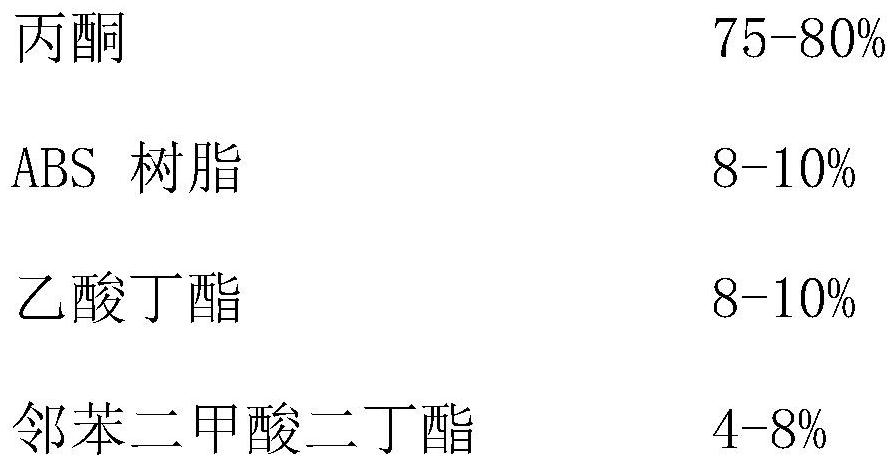

[0027] (1) Weigh 2.6g of ABS resin and dissolve it in 30g of acetone. After fully dissolving, add 1.4g of dibutyl phthalate and 2.6g of butyl acetate solution to mix. Put the mixed solution into a 65°C beaker and heat it in a water bath. Until the solution has no bubbles, weigh the mass of the remaining solvent, and add butyl acetate to make up the total mass of the solution to 6.6g.

[0028] (2) Weigh 46g of 300-mesh silver-aluminum-manganese solder powder, mix it with the prepared binder solution, stir it evenly, pour it into a tray and place it in an oven, adjust the temperature to about 50°C, Keep it warm for 30 minutes, take it out when the solder is muddy, and add butyl acetate dropwise if it is too dry.

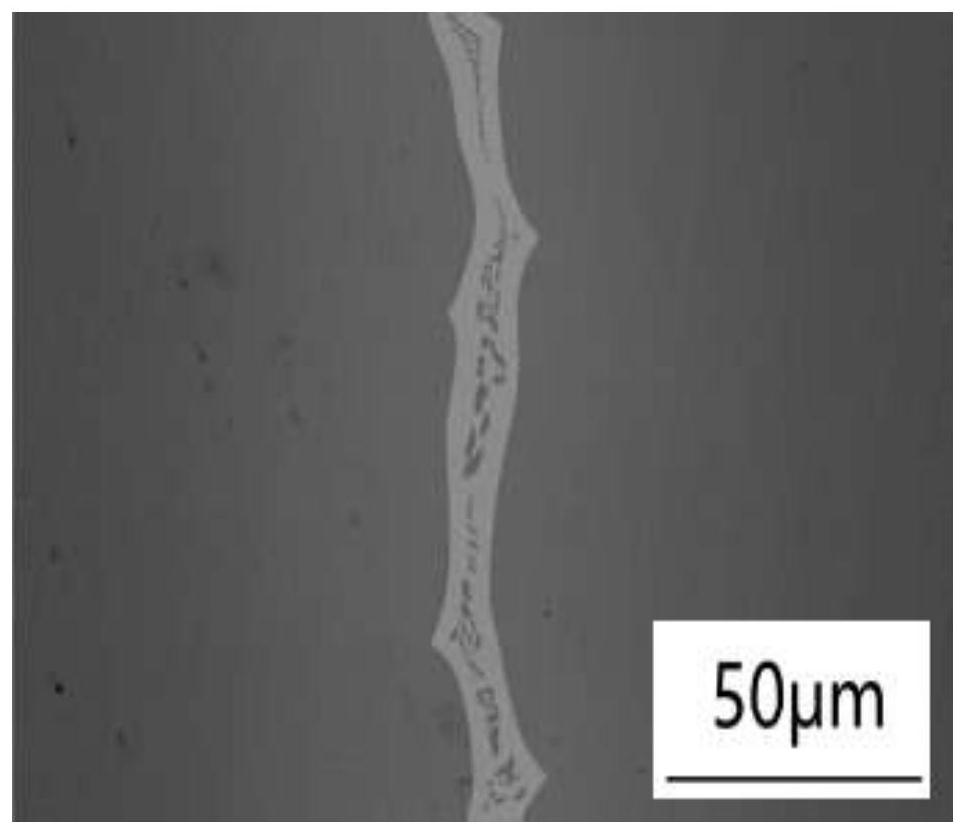

[0029] (3) Put the muddy solder into the rolling mill, adjust the roller spacing to 1.5mm, and perform more than 20 repeated rolls until the solder is uniform in color and h...

Embodiment 2

[0036] Embodiment 2 thickness is the preparation of the AgMnAl adhesive tape solder of 0.2mm

[0037] The difference is that the 600 mesh 44g AgAlMn solder powder, 3.6g ABS resin, 2.4g dibutyl phthalate, and 2.4g butyl acetate are used to make a binder solution, and the mixed and dried solder is placed In a roll mill, roll both sides according to the roller spacing of 2mm, 1.5mm, 1mm, 0.5mm, and 0.4mm, and then place it in a cool place to dry naturally.

[0038] Performance indicators of adhesive tape solder:

[0039] Thickness 0.206mm

[0040] Breaking strength 3.2N

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com