Patents

Literature

33 results about "Chromel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromel is an alloy made of approximately 90 percent nickel and 10 percent chromium that is used to make the positive conductors of ANSI Type E (chromel-constantan) and K (chromel-alumel) thermocouples. It can be used at temperatures up to 1,100 °C (2,010 °F) in oxidizing atmospheres. Chromel is a registered trademark of Concept Alloys, Inc.

Corrosion-resistance stainless steel electric welding rod used for nuclear power and production method thereof

ActiveCN103008913AStrong corrosion resistanceImprove impact performanceWelding/cutting media/materialsSoldering mediaNuclear powerNickel alloy

The invention discloses a corrosion-resistance stainless steel electric welding rod used for nuclear power and a production method thereof, and relates to a nuclear power product. The corrosion-resistance stainless steel electric welding rod used for the nuclear power consists of a chrome-nickel alloy welding core and a coating covered on the surface of the welding core, wherein the chrome-nickel alloy welding core comprises the following ingredients: less than or equal to 0.01wt% of C, 1.00-2.50wt% of Mn, less than or equal to 0.030wt% of Si, 19.6-21.0wt% of Cr, 9.6-10.6wt% of Ni, less than or equal to 0.20wt% of Mo, less than or equal to 0.10wt% of Co, less than or equal to 0.10wt% of Cu, less than or equal to 0.10wt% of V, less than or equal to 0.035wt% of N, less than or equal to 0.015wt% of S, less than or equal to 0.012wt% of P and the balance of Fe and impurities. Compared with the prior art, the corrosion-resistance stainless steel electric welding rod used for the nuclear power, which is disclosed by the invention, has the advantages of good molten slag liquidity during welding, stable electric arc, big electric arc blowing force, even molten slag coverage, small splashing, excellent slag removal, small welding smoke, light welding line, attractive appearance, moderate welding bead height and good full-position operation performance.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Spray coating material prepared by titanium-containing high-chromium-nickel alloy, preparation method and use thereof

InactiveCN101260487AExtended service lifeImprove anti-sulfur performanceMetal-working apparatusRheniumVulcanization

The invention relates to a titanium contained high chromel alloy and application thereof in spraying materials. The components of the alloy are (by weight percentage) as follows: the content of chromium is more than or equal to 15 percent and less than or equal to 25 percent, the content of titanium is more than or equal to 1 percent and less than or equal to 6 percent, the content of silicon is more than or equal to 1 percent and less than or equal to 6 percent, the content of carbon is more than or equal to 0 percent and less than or equal to 0.02 percent, the content of nickel is more than or equal to 20 percent and less than or equal to 55 percent, the content of rhenium is more than or equal to 0.5 percent and less than or equal to 6 percent, the content of aluminum is more than or equal to 0 percent and less than or equal to 6 percent, the content of sulfur is more than or equal to 0 percent and less than or equal to 0.035 percent, he content of phosphorus is more than or equal to 0 percent and less than or equal to 0.035 percent, the content of manganese is more than or equal to 0 percent and less than or equal to 0.2 percent, and the rest is iron. After the parts of working equipment are sprayed at high temperature oxidation and high temperature corrosion environments by the spraying material produced by the alloy, since the coating has good high temperature oxidation and vulcanization resistance and hot corrosion resistance performances, the service life of the parts can be greatly improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Cubic boron nitride superhard cutter

The invention discloses a superhard cutter with high hardness and good abrasive resistance and heat resistance. The cutter comprises the following components in percentage by weight: 75-85 percent of cubic boron nitride micro powder with the granularity of 1-10 mum, 0.5-3 percent of microlite powdered boron with the purity above 99.5 percent, 5-10 percent of microlite powdered aluminum with the purity above 99.5 percent, and 6-15 percent of carbon with a diamond structure. Because the invention is prepared by adopting the cubic boron nitride as a main raw material and adding the high-purity microlite powdered aluminum and the high-purity microlite powdered boron as well as the carbon with the diamond structure under super-high pressure and high temperature, the high hardness, the abrasive resistance and the heat resistance are obviously improved; and the superhard cutter is used for high-hardness alloy materials with turning HRC within 48-53, and has better effect particularly on chromel alloy materials.

Owner:刘书锋

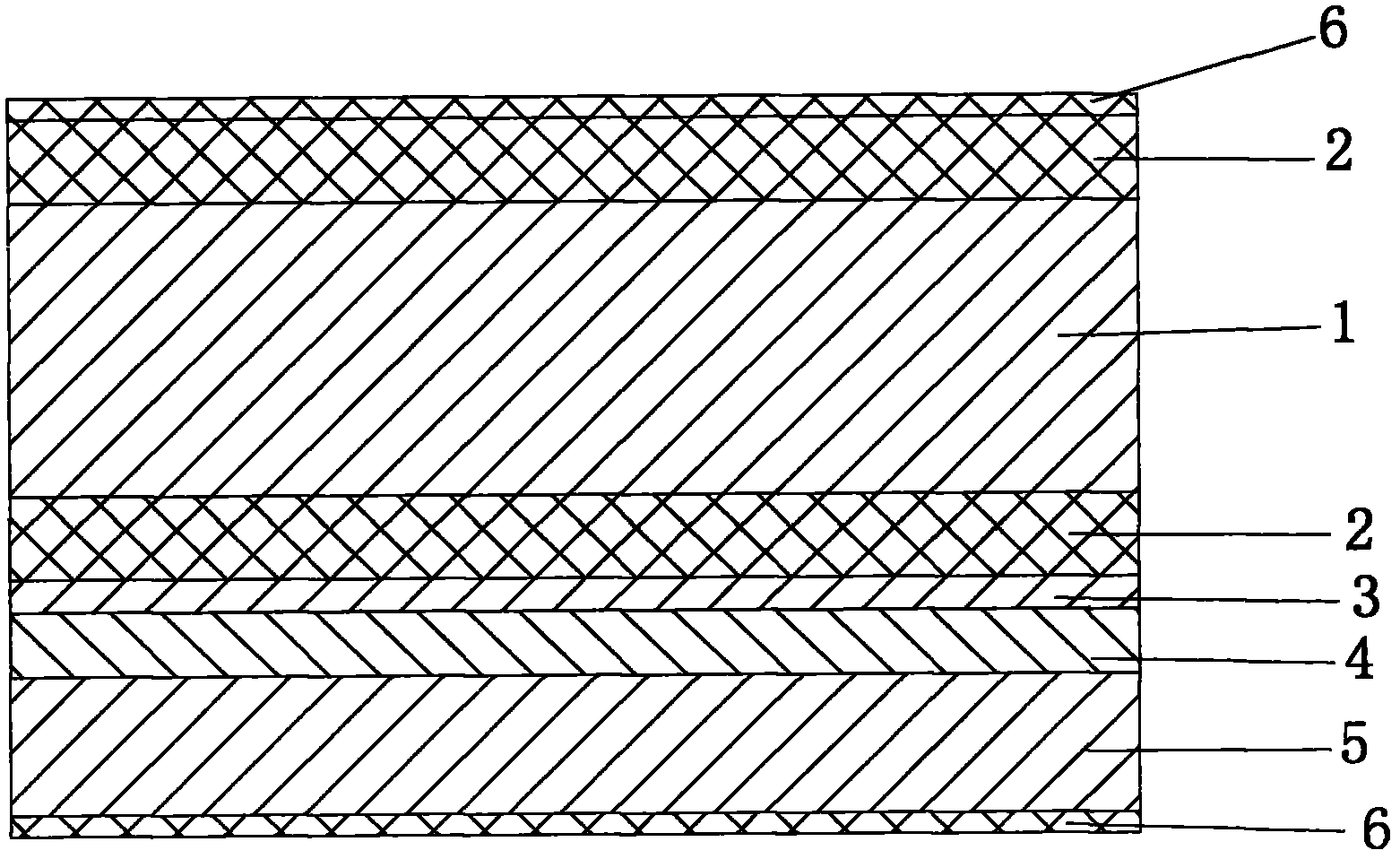

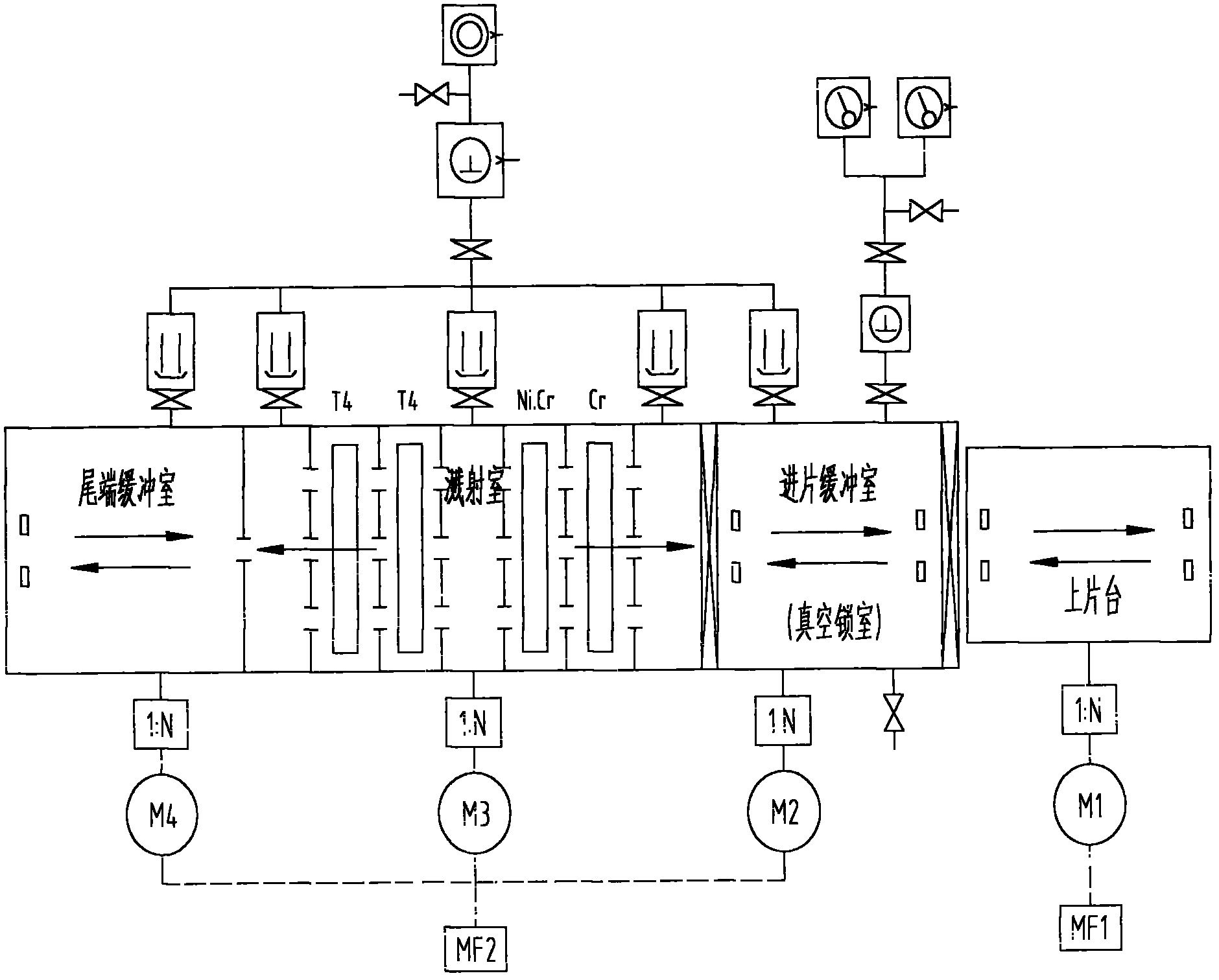

Aluminum base printed circuit board and preparation method thereof

InactiveCN102159024AOvercome the defect that it is easy to be broken down by high voltageImprove adhesionVacuum evaporation coatingSputtering coatingOptoelectronicsPrinted circuit board

The invention discloses an aluminum base printed circuit board and a preparation method thereof, which solves the technical problem that the insulating, temperature resistant and withstand voltage values and the scratch fineness of the printed circuit board are improved. An insulating layer is formed on the surface of an aluminum base plate; a copper conducting layer is covered on the insulating layer; and a transition layer and a copper conducting film are arranged between the insulating layer and the copper conducting layer. The preparation method comprises the steps of depositing a transition layer chromium, nickel or chrome-nickel alloy film on the insulating layer of the aluminum base plate, depositing the copper conducting film on the transition layer, and electroplating the copper conducting layer on the copper conducting film. Compared with the prior art, the aluminum base printed circuit board has the advantages that as the aluminum base plate is adopted, aluminum oxide of the aluminum base plate forms the insulating layer, as the nano transition layer is adopted, the adhesive force between the conducting layer and the base plate is greatly improved, and when traditional typographies, such as photograph and chemical corrosion, are adopted, scratch is finer, the manufacture is more precise, and the requirements on large power and high integration to the printed circuit board are satisfied, so that the large power and high integration of the printed circuit board are realized.

Owner:任正义

Method for preparing chromel alloy by stainless steel pickling sludge

ActiveCN103526029AHigh recovery rateIncrease contentProcess efficiency improvementChromium nickelSludge

The invention provides a method for preparing chromel alloy by stainless steel pickling sludge. The method comprises the steps as follows: an alkali liquor is added into the stainless steel pickling sludge, pH is adjusted to be in a range from 6.5 to 7.5, and neutral sludge is obtained; the neutral sludge is added into a rotary kiln for drying to obtain a dry basis; the dry basis is added into a ball forming machine, and coke and starch are simultaneously added for ball forming to obtain mixed particles; the mixed particles are added into the rotary kiln for reduction smelting, the smelting temperature is simultaneously controlled in a range from 1,250 DEG C to 1,400 DEG C, and an additive is simultaneously added for an early reduction reaction for 1-2 hours to obtain metallic balls; and a hot bag containing the metallic balls is placed into an electric plasma furnace for melting and smelting to obtain the chromel alloy. With the adoption of the method, waste is changed into valuable materials, the stainless steel pickling sludge which can pollute the environment is neutralized, nickel-chromium elements are reduced to obtain the chromel alloy for metal smelting; and the chromel alloy with high recovery rate and high content is obtained through addition of an NCP additive and sodium sulfate.

Owner:TAIZHOU YONGXING ALLOY MATERIAL TECH

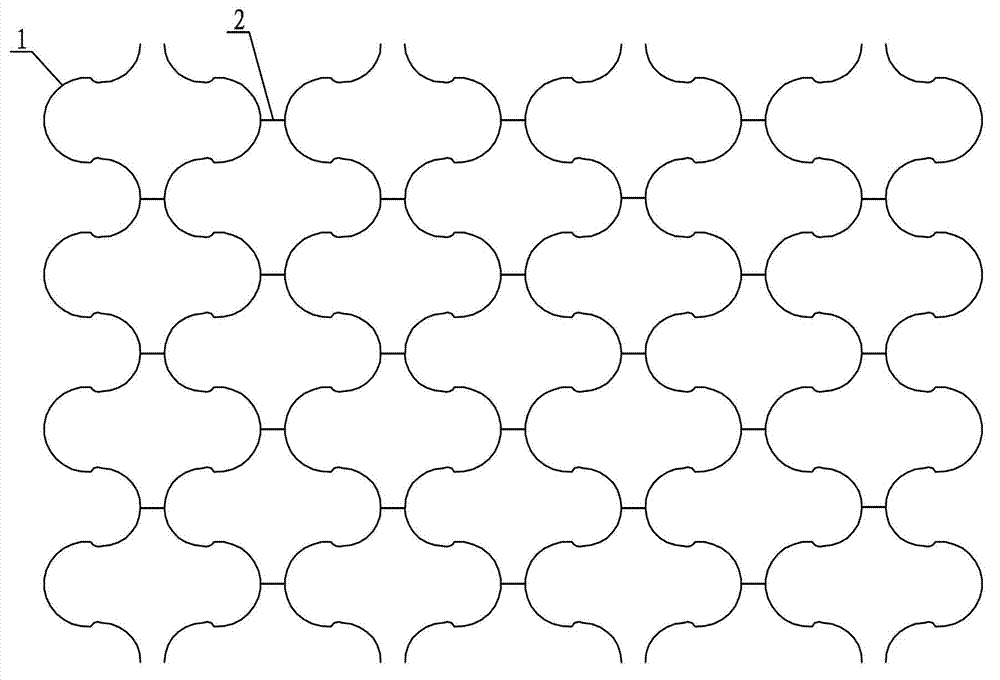

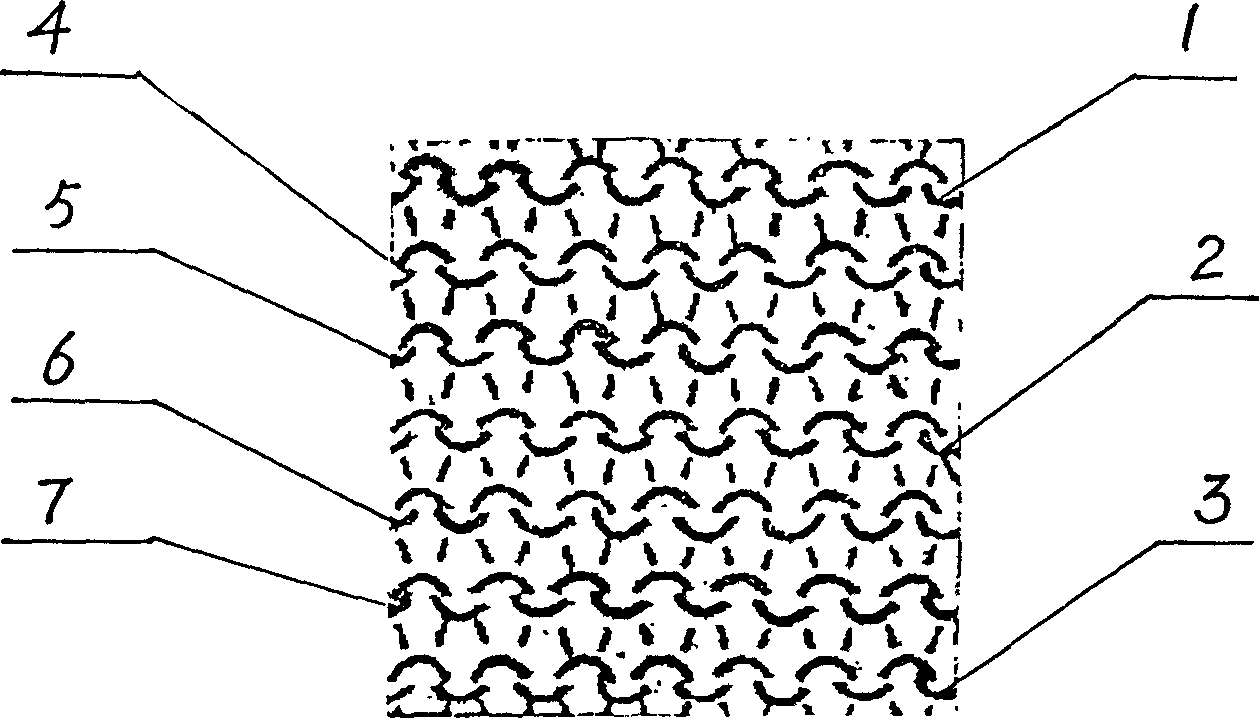

Magnesium alloy coronary support frame

ActiveCN103110465ADoes not cause toxic reactionsImprove the quality of lifeStentsSurgeryCoronary heart diseaseToxic reaction

The invention provides a magnesium alloy coronary support frame and relates to a metal coronary artery support frame. The problems that metal preparation which is not degradable of stainless steel, cobalt chrome alloy, platinum iridium alloy, chromel alloy, tantalum and the like are adopted by the prior support frame, toxic reaction is caused due to the fact that the support frame is implanted in a blood vessel as a foreign material are solved. The support frame is carved into a net shape round pipe structure by the magnesium alloy through a laser. The net shape round pipe structure is composed of a plurality of subject units and a plurality of straight line connecting bodies. Each subject unit is composed of a half circular ring, two quarters of round rings and two arcs. The two quarters of the round rings are arranged symmetrically at two ends of the half circular ring. The quarters of the round rings are connected with the half circular ring through the arcs. The plurality of the subject units are uniformly arranged along the axial direction and the circumference direction of a net pipe. Every adjacent two subject units are arranged symmetrically relative to a straight line connecting body in the plurality of the subject units arranged along the circumference direction. Arc top ends of every adjacent two half circular rings are connected with one straight line connecting body. The magnesium alloy coronary support frame is used for clinical curing coronary disease.

Owner:JIANGYIN BIODEGRADE MEDICAL TECH CO LTD

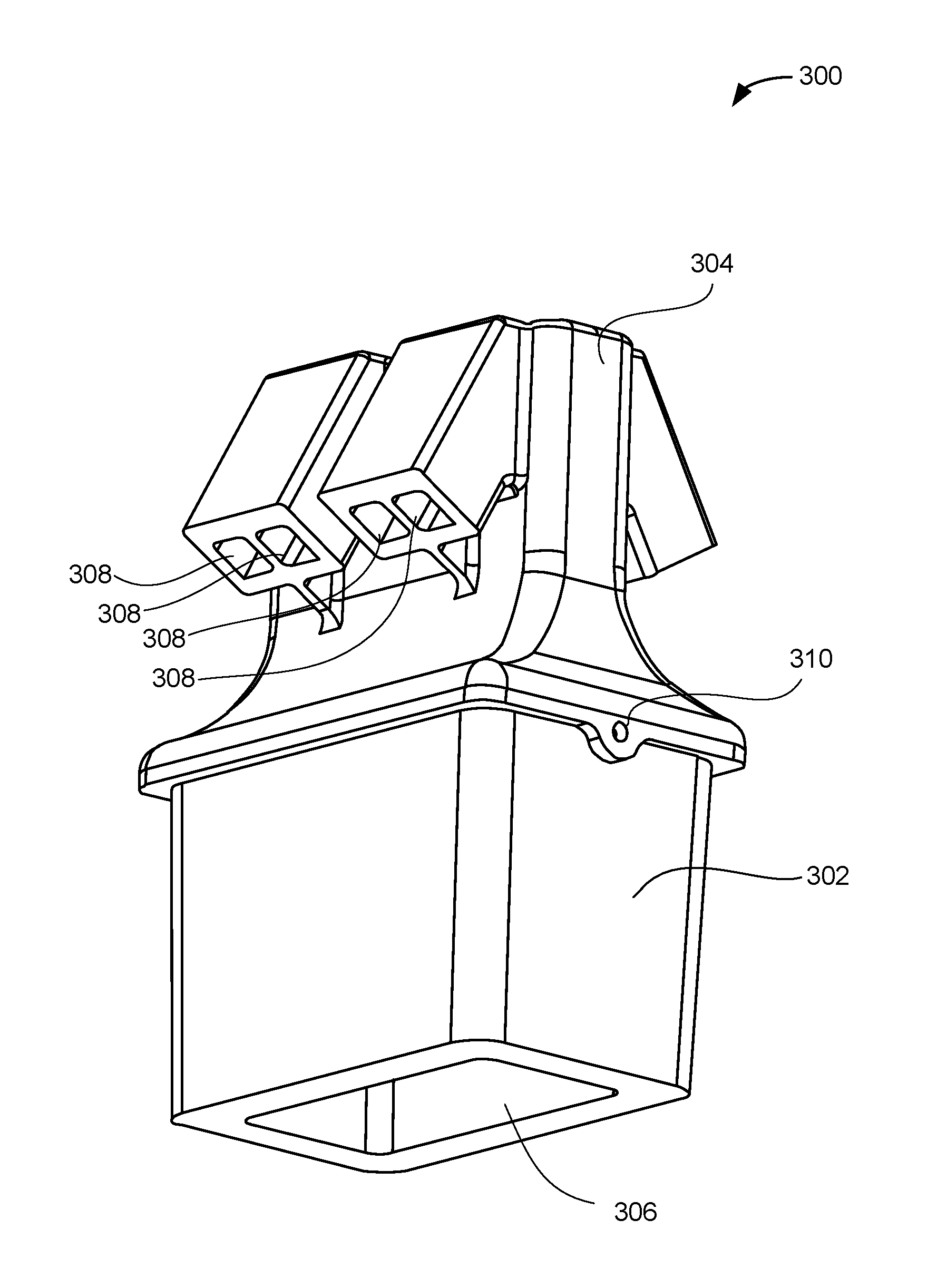

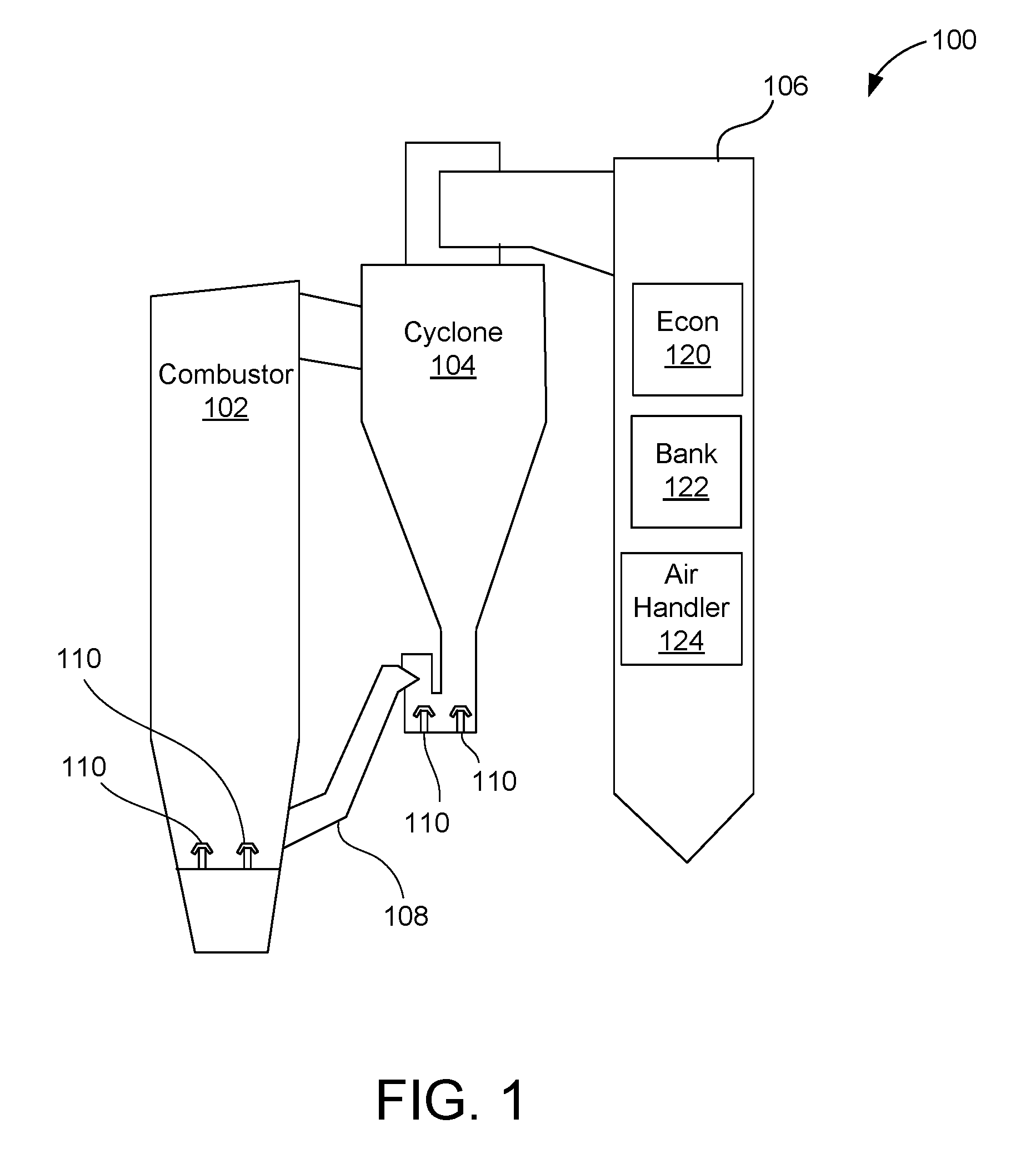

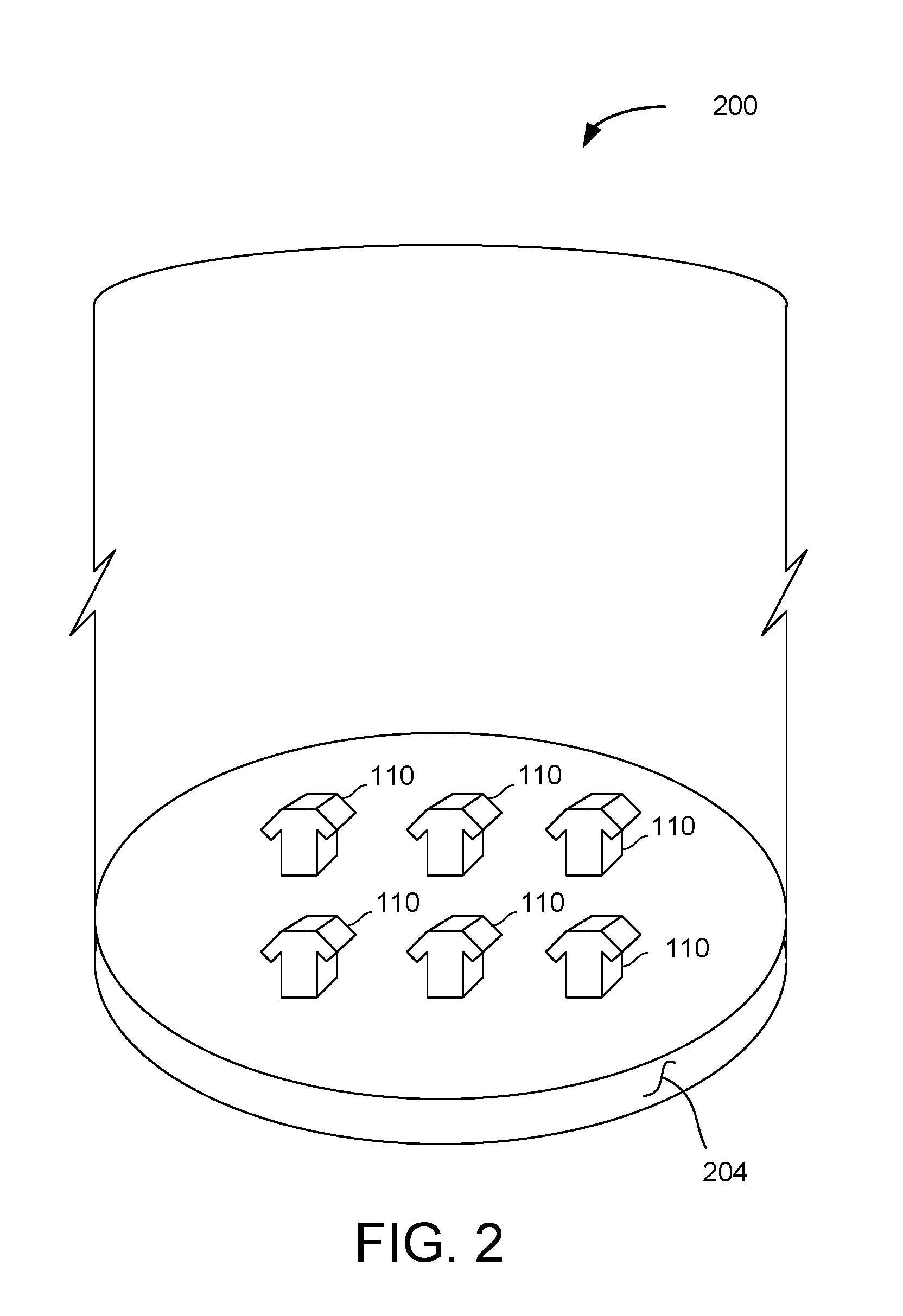

Two-part block nozzle

ActiveUS20170003019A1Limit scopeFluidized bed combustionChemical/physical processesNickel alloyDuctile iron

A two-piece block nozzle is disclosed. In some embodiments, the two-piece nozzle may include a nozzle section and a base section. The nozzle section may be detachably engaged to the base section. The nozzle section may be formed with a temperature resistant material such as, for example, a chrome-nickel alloy or a stainless steel alloy. The base section may be formed with a relatively lower cost material such as, for example, a ductile iron material.

Owner:BROWNLEE DAVID ALLEN

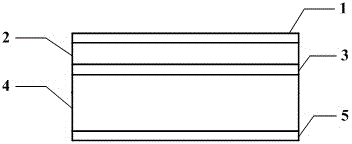

High-strength and high ductility-roughness sandy water erosion resisting clean martensitic stainless steel alkaline welding electrode and preparation method thereof

ActiveCN107971656AGood mechanical operationGuaranteed uptimeWelding/cutting media/materialsSoldering mediaSlagMartensitic stainless steel

The invention discloses a high-strength and high ductility-roughness sandy water erosion resisting clean martensitic stainless steel alkaline welding electrode and a preparation method thereof. The high-strength and high ductility-roughness sandy water erosion resisting clean martensitic stainless steel alkaline welding electrode comprises a chrome-nickel alloy core wire and a coating wrapping thesurface of the core wire. The coating comprises the following components, by weight, of 7-11 parts of marble, 8-11 parts of fluorite, 0.4-2 parts of rare earth fluoride, 2-5 parts of silicate, 0.4-2parts of electrolytic manganese, 1-3 parts of ferrotitanium, 1-3 parts of ferrosilicon, 4-6 parts of ferrous powder, 3-5.6 parts of ferrochromium, 0-2 parts of nickel powder, 1.6-3.0 parts of ferromolybdenum and 0.4-1.0 part of sodium carbonate. When the high-strength and high ductility-roughness sandy water erosion resisting clean martensitic stainless steel alkaline welding electrode is welded,an electric arc is stable, splashing is little, the fluidity of slag is good, the deslagging effect is good, a formed weld joint is attractive, and operability in the full position is good. The mechanical properties, such as tensile strength (Rm), yield strength (Rp0.2), the after-fracture elongation (A) and impact energy (KV) at the temperature of 0 DEG C, of welding deposited metal are excellentunder the heat treatment state and the normal-temperature condition, especially, impact absorbed energy at the temperature of 0 DEG C reaches 70 J or above under the situation that the strength is larger than 850 MPa.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

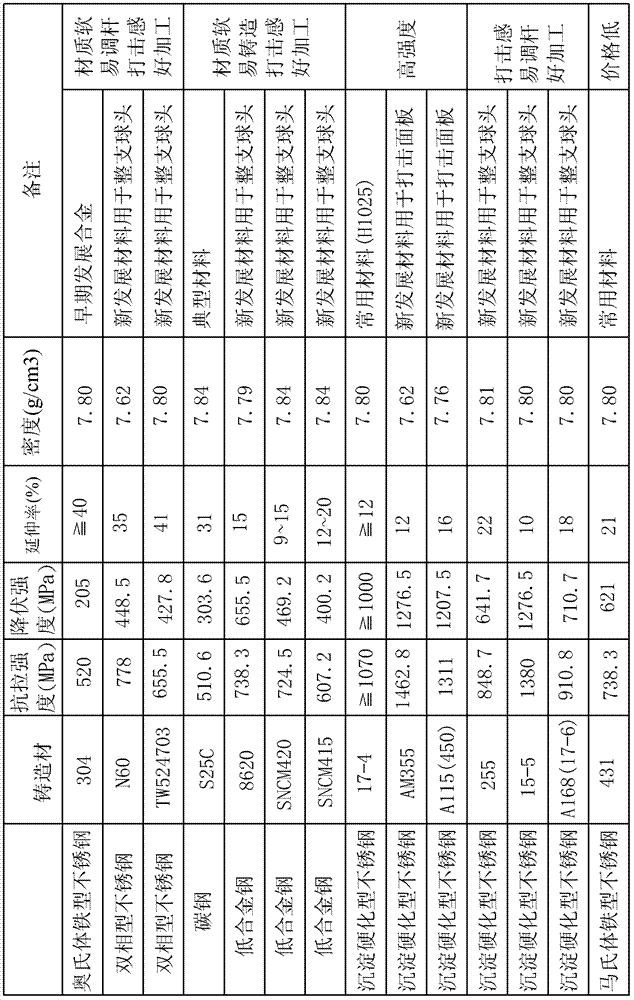

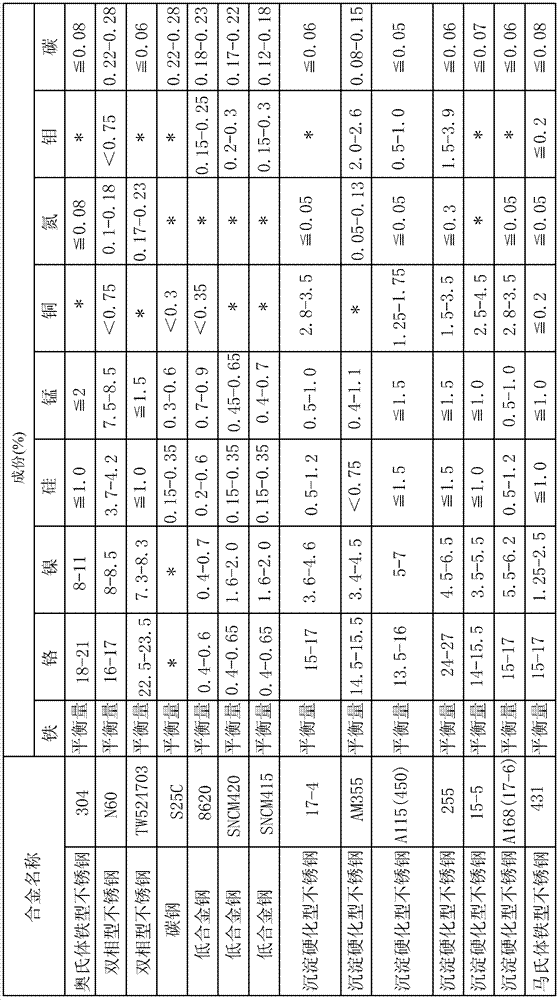

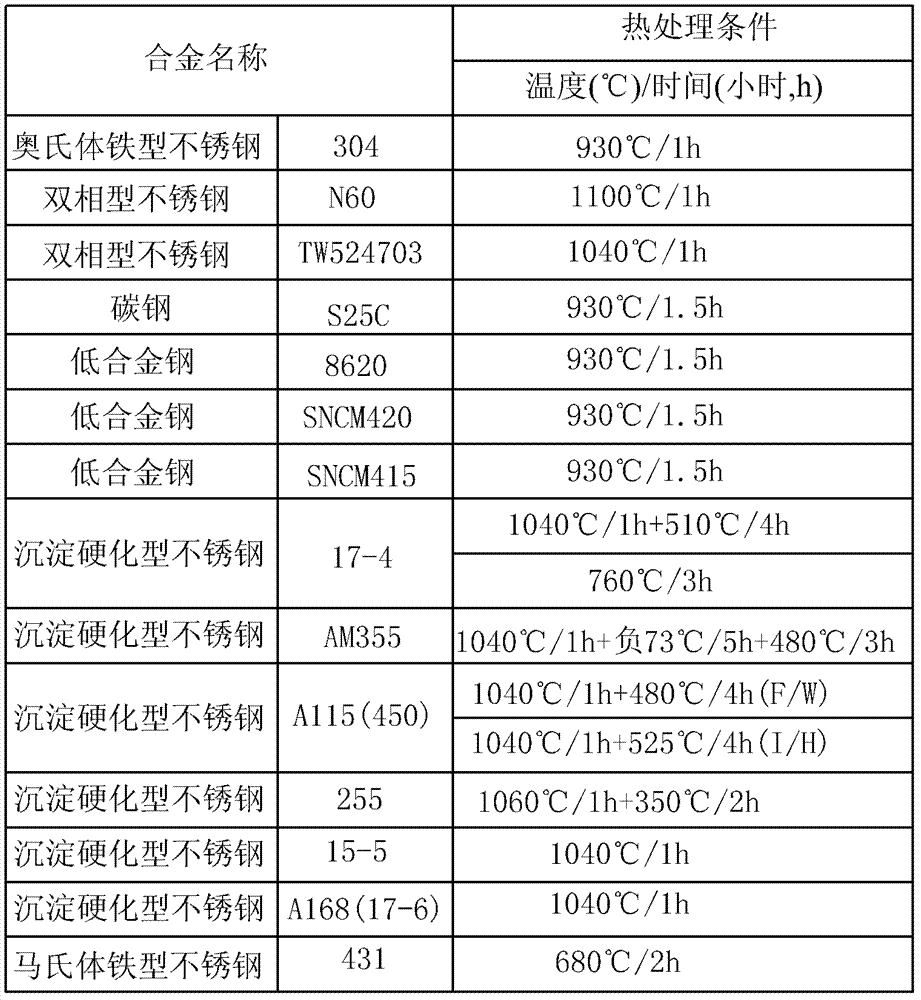

Fe-Cr-Ni alloy of golf club head

InactiveCN103243274ABoth process costImprove mechanical propertiesFurnace typesGolf clubsManganeseAlloy

An Fe-Cr-Ni alloy of a golf club head includes 13.5-14.5wt% of Cr, 3.5-4.8wt% of Ni, 0.02-0.15wt% of C, 0.02-0.15wt% of Ti, 0.02-0.15wt% of N, 0.02-0.25wt% of Al, 0.2-1.2wt% of Mn, 0.2-1.2wt% of Si, and / or 1.5-3.0wt% of Cu, and the balance Fe and other inevitable impurities generated in the alloy material casting process. The Fe-Cr-Ni alloy undergoes high-temperature normalization treatment after the casting operation to obtain a tempered martensite structure matrix and a microstructure containing a tiny amount of alumina and a titanium carbide stable phase. The golf club head made through using the Fe-Cr-Ni alloy has the advantages of simple making process, no need of any ageing treatment, good strength, good elongation rate, and no rust.

Owner:O TA PRECISION IND

Method for smelting chromel alloy by stainless steel dedusting ash and laterite-nickel ore

ActiveCN103526030AEliminate pollutionHigh recovery rateProcess efficiency improvementSteelmakingNickel chromium alloy

The invention discloses a method for smelting chromel alloy by stainless steel dedusting ash and laterite-nickel ore. The method comprises the steps as follows: a stainless steel dedusting ash briquette is manufactured; the stainless steel dedusting ash briquette is added into the laterite-nickel ore, the laterite-nickel ore is placed in an electric plasma furnace to be molten into a mother liquid, the temperature of the molten mother liquid ranges from1,650 DEG C-1,750 DEG C; coke is added for smelting after the mother liquid is molten completely, the smelting temperature is controlled in a range from 1,650 DEG C to 1,750 DEG C simultaneously, and an additive is simultaneously added for an early reduction reaction for 1-2 hours; after the early reduction reaction is finished, a fluxing agent and calcium carbonate are added for continuous reduction reaction for 1-2 hours, so that a metal liquid is obtained; the temperature of the metal liquid is adjusted in a range from 1,650 DEG C to 1,750 DEG C, dregs are removed, and the metal liquid is remained; and pouring is performed to form ingots. With the adoption of the method, waste is reused, so that pollution of the waste on the environment is reduced; and further, steel-making dedusting ash and the laterite-nickel ore are sufficiently combined for smelting, and the chromel alloy with high recovery rate and high content is obtained through addition of an NCP-2 additive.

Owner:TAIZHOU YONGXING ALLOY MATERIAL TECH

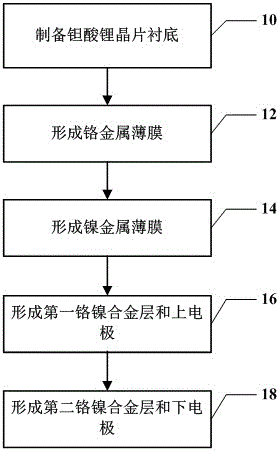

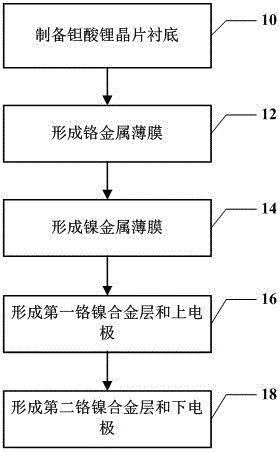

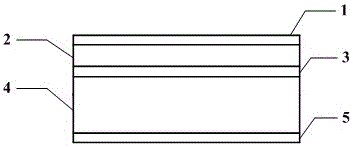

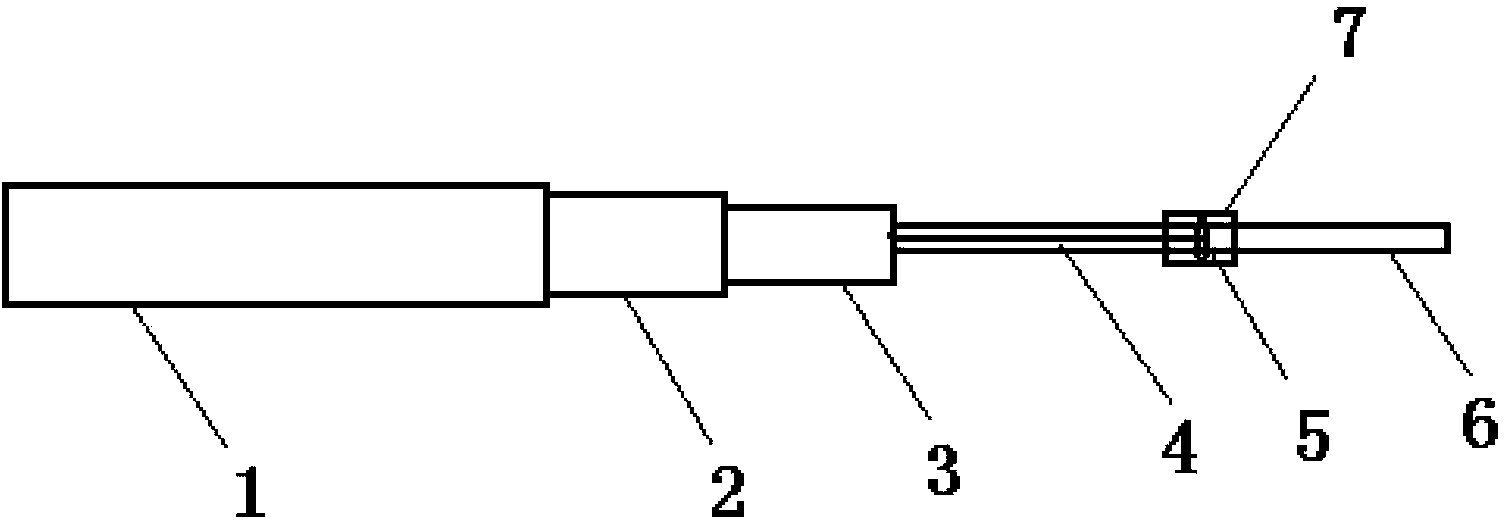

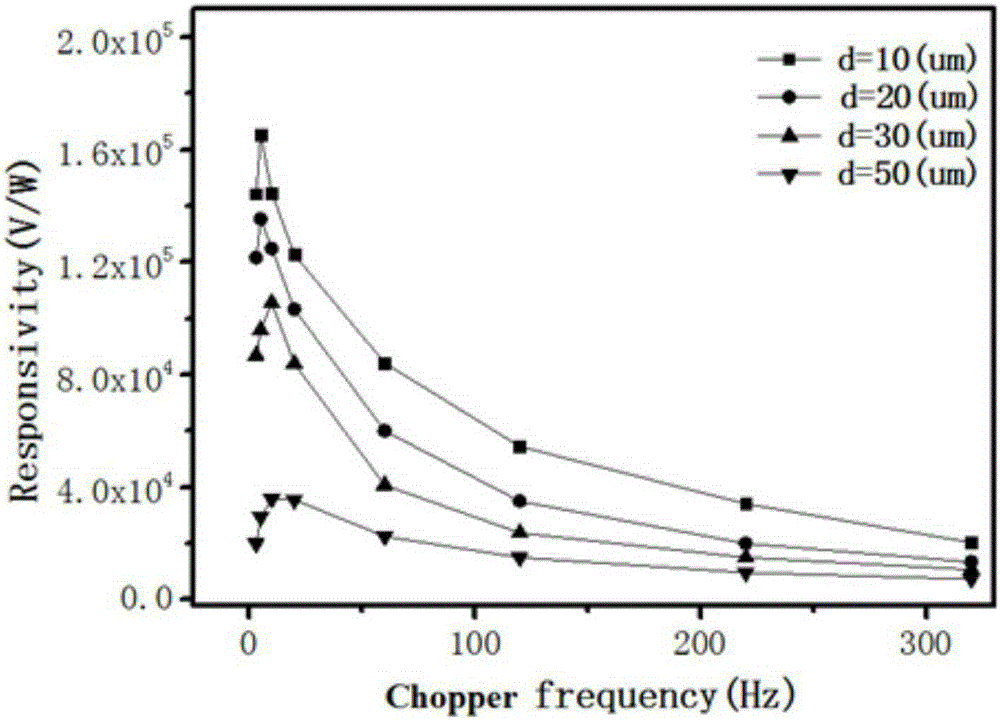

Pyroelectric infrared detector sensing unit and manufacturing method thereof

ActiveCN104465851AFirmly attachedGood repeatabilityFinal product manufactureSemiconductor devicesOptoelectronicsMetal thin film

The embodiment of the invention discloses a manufacturing method of a pyroelectric infrared detector sensing unit. The manufacturing method includes the steps that a lithium tantalite wafer substrate is manufactured; a chromium metallic film is formed on the first surface of the lithium tantalite wafer substrate; a nickel metallic film is formed on the chromium metallic film; a first chrome-nickel alloy layer is formed on the nickel metallic film, and an upper electrode is formed through etching; a second chrome-nickel alloy layer is formed on the second surface of the lithium tantalite wafer substrate, and a lower electrode is formed through etching. An absorbing layer of the pyroelectric infrared detector sensing unit manufactured through the method has the advantages of being good in repeatability, high in absorptivity, small in specific heat capacity and excellent in heat transfer performance, attachment is firm, the absorbing wave band is wide, the spectrum is flat, and the absorbing layer can simultaneously serve as an electrode and therefore is suitable for serving as the absorbing layer of the pyroelectric infrared detector sensing unit.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Chromium nickel alloy powder for flux-cored wire, flux-cored wire and preparation method of flux-cored wire

ActiveCN107214435AAddressing physical propertiesHigh physical ductilityWelding/cutting media/materialsSoldering mediaMaterials scienceHeat treated

The invention relates to chromium nickel alloy powder for a flux-cored wire, the flux-cored wire and a preparation method of the flux-cored wire. The chromium nickel alloy powder comprises the following components of, by mass, 37-45% of Cr, 18-23% of Ni, 0.03% or less of C, 1.0% or less of the Si, 2.5% or less of Mn, 0.02% or less of S, 0.025% or less of P, 0.5% or less of Cu, 0.5% or less of Mo and the balance Fe. By adding the chromium nickel alloy powder in the flux-cored wire, drawing of a small-diameter welding wire is facilitated, and a large-diameter welding wire does not need to be subjected to heat treatment firstly; and meanwhile, in welding, the flux-cored wire is more even and stable, and splashing is effectively reduced.

Owner:JIANGSU JIUZHOU NEW MATERIAL TECH CO LTD

A kind of method for preparing nickel-chromium alloy from stainless steel pickling sludge

ActiveCN103526029BHigh recovery rateIncrease contentProcess efficiency improvementNickel chromium alloyChromium nickel

The invention provides a method for preparing chromel alloy by stainless steel pickling sludge. The method comprises the steps as follows: an alkali liquor is added into the stainless steel pickling sludge, pH is adjusted to be in a range from 6.5 to 7.5, and neutral sludge is obtained; the neutral sludge is added into a rotary kiln for drying to obtain a dry basis; the dry basis is added into a ball forming machine, and coke and starch are simultaneously added for ball forming to obtain mixed particles; the mixed particles are added into the rotary kiln for reduction smelting, the smelting temperature is simultaneously controlled in a range from 1,250 DEG C to 1,400 DEG C, and an additive is simultaneously added for an early reduction reaction for 1-2 hours to obtain metallic balls; and a hot bag containing the metallic balls is placed into an electric plasma furnace for melting and smelting to obtain the chromel alloy. With the adoption of the method, waste is changed into valuable materials, the stainless steel pickling sludge which can pollute the environment is neutralized, nickel-chromium elements are reduced to obtain the chromel alloy for metal smelting; and the chromel alloy with high recovery rate and high content is obtained through addition of an NCP additive and sodium sulfate.

Owner:TAIZHOU YONGXING ALLOY MATERIAL TECH

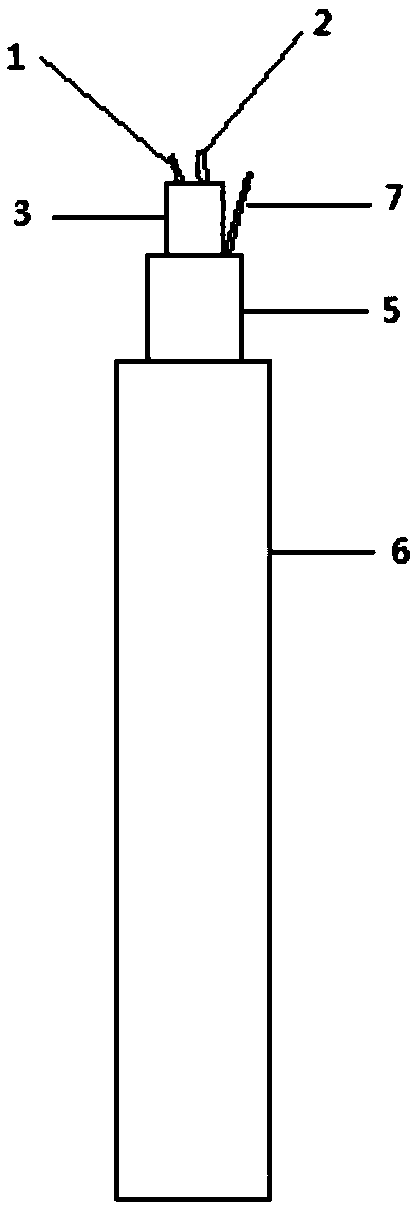

On-instant-heating quick heat generating wire

InactiveCN108260238ANo harmReduce electromagnetic radiationHeating element shapesElectricitySafety index

The invention relates to the field of floor heating devices, in particular to an on-instant-heating quick heat generating wire which comprises a heat generating wire body, an insulating layer, a grounding wire, a shielding layer and a protective jacket. The heat generating wire body is divided into a cold wire and a hot wire, the cold wire is a tinned copper wire, the hot wire is chrome-nickel alloy, and the weight percentage of chrome and nickel in the chrome-nickel alloy is 3:7; the cold wire and the hot wire are connected by stranding, and lay ratio of stranding is not smaller than 12; a power source wire is arranged on the outer layer of the heat generating wire body, the power source wire and the heat generating wire body are arranged in the shielding layer side by side, and an electricity leaking protection switch is arranged at a position where the power source wire is connected with a power source. When the heat generating wire body is damaged, the shielding layer is conductive, and the electricity leaking protection switch cuts off a power source, so that the technical defect that heat generating wires are slow in temperature rise and many in potential safety hazards in the prior art is overcome; the quick heat generating wire can realize instant heating immediately after being powered on and is high safety index.

Owner:王婷

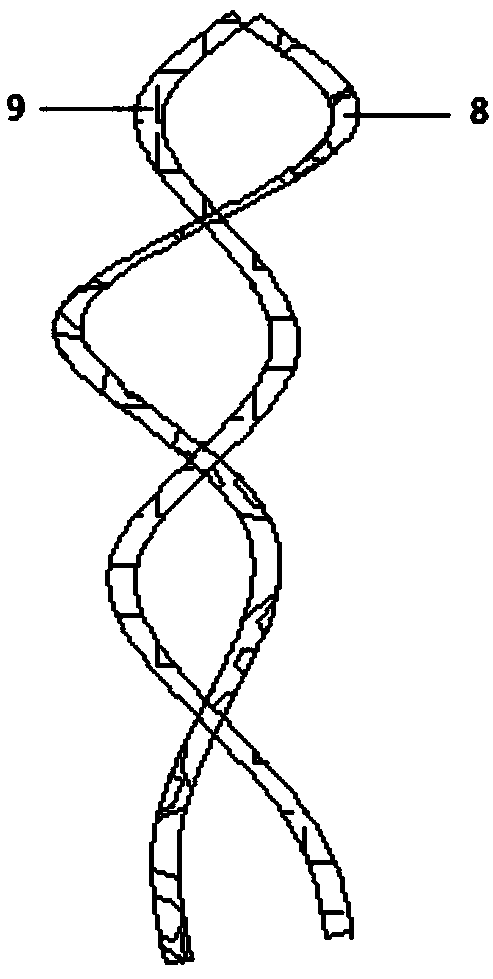

Knitted cloth with heat release function

InactiveCN1837433ASoft touchGood moisture absorption and air permeabilityWeft knittingOhmic-resistance heatingYarnFiber

This invention relates to the thermal cloth of latent heat knitting, which is knitted with general yarn and exothermic yarn. The inner core of exothermic yarn is exothermic wire twisted with exothermic metal wire, and the thermal layer outside exothermic yarn is soybean fiber yarn, cotton yarn, or blended yarn. The exothermic wire of inner core of exothermic yarn is nickel wire, Chromel wire or titanium alloy wire, and the inner core of exothermic yarn is connected with direct current source. The thermal cloth can be dealed by rinsing, dyeing, printing, drying, shaping and so on like general knitted cloth, and also can be knitted with many weave crafts such as linter, jacquard. The underclothes made from it are as the same as general underclothes in appearance, and can be washed with washer or hand, dewatered and folded optionally. It is soft, of good air permeability and hygroscopicity, of quick heat diffusion and heating-up and safe to use.

Owner:YANCHENG INST OF IND TECH

Metal part surface repair material and metal part surface processing technology and application

PendingCN111500895AExcellent self-flux performanceExcellent high temperature wear resistance and corrosion resistanceMolten spray coatingCrack resistanceMotor vehicle part

The invention relates to the technical field of automobile part surface repair, in particular to a metal part surface repair material and a metal part surface processing technology and application. The metal part surface repair material is prepared from the following components in percentage by mass: 10-20% of Cr, 1-10% of Si, 1-10% of B, 1-10% of Cu, 1-10% of Mo, 0-5% of Fe, 0-3% of C, 1-20% of WC, and the balance of Ni. The metal part surface repair material has the excellent self-fluxing performance, and a coating prepared through the repair material has the excellent high-temperature wearresistance and corrosion resistance. When the thickness of the coating reaches the 1.5mm ultra-thick thickness, the excellent coating anti-cracking performance is still achieved, and common chromel alloy powder cannot reach the excellent coating anti-cracking performance.

Owner:LONGKOU ZHONGYU THERMAL MANAGEMENT SYST SCIAND TECH

Abrasion-resistant aluminum alloy

A wear-resistant aluminum alloy belongs to the technical field of alloys. The wear-resistant aluminum alloy of the present invention is composed of the following materials in parts by weight: 1-6 parts of magnesium, 1-3 parts of silicon, 1-3 parts of iron, 1-3 parts of nodular cast iron, 0.1-0.6 parts of titanium, 1-3 parts of nickel-chromium alloy 5 parts, 0.1-1 parts of zinc, 0.1-1.5 parts of manganese, 1-4 parts of copper, 0.1-1 parts of boron, 0.1-0.5 parts of vanadium, 0.1-1 parts of cobalt, 0.1-1 parts of cerium, 0.1-0.5 parts of ytterbium , 1-3 parts of nickel, 1-2 parts of strontium, 0.1-1 part of chromium, and 100 parts of aluminum. The invention improves the strength of the aluminum alloy, has good manufacturing performance and mechanical performance, and enhances the wear resistance and corrosion resistance of the aluminum alloy.

Owner:史晓强

Production method for chromium-nickel alloy

The invention relates to a production method for a chromium-nickel alloy. The method comprises the steps of: firstly conducting burdening according to alloy components and proportion through alloy design, carrying out horizontal continuous casting, preparing a tube blank, performing homogenizing heat treatment, shelling, repeated stretching and intermediate annealing softening, then conducting finished product stretching, and finally carrying out cutting and packaging, thus obtaining the finished product. The alloy material mainly comprises the chemical components of: 36-45 of Cr, 66-75 of Ni, less than or equal to 0.035 of Fe, less than or equal to 0.035 of Cu, less than or equal to 0.08 of Mn and the like, and Ni is taken as the main element. The tube adopting the chromium-nickel alloy has higher seawater corrosion resistance and lower corrosion rate, thus reducing the material cost, enhancing the cost performance, and enlarging application of chromium-nickel alloy in the fields of condensation tubes and heat exchange tubes.

Owner:丹阳市锦雄机械制造有限公司

Inconel for golf club heads

InactiveCN103243274BBoth process costImprove mechanical propertiesFurnace typesGolf clubsManganeseAlloy

An Fe-Cr-Ni alloy of a golf club head includes 13.5-14.5wt% of Cr, 3.5-4.8wt% of Ni, 0.02-0.15wt% of C, 0.02-0.15wt% of Ti, 0.02-0.15wt% of N, 0.02-0.25wt% of Al, 0.2-1.2wt% of Mn, 0.2-1.2wt% of Si, and / or 1.5-3.0wt% of Cu, and the balance Fe and other inevitable impurities generated in the alloy material casting process. The Fe-Cr-Ni alloy undergoes high-temperature normalization treatment after the casting operation to obtain a tempered martensite structure matrix and a microstructure containing a tiny amount of alumina and a titanium carbide stable phase. The golf club head made through using the Fe-Cr-Ni alloy has the advantages of simple making process, no need of any ageing treatment, good strength, good elongation rate, and no rust.

Owner:O TA PRECISION IND

A kind of method for smelting nickel-chromium alloy with stainless steel dedusting ash and laterite nickel ore

ActiveCN103526030BEliminate pollutionHigh recovery rateProcess efficiency improvementSteelmakingIngot

The invention discloses a method for smelting chromel alloy by stainless steel dedusting ash and laterite-nickel ore. The method comprises the steps as follows: a stainless steel dedusting ash briquette is manufactured; the stainless steel dedusting ash briquette is added into the laterite-nickel ore, the laterite-nickel ore is placed in an electric plasma furnace to be molten into a mother liquid, the temperature of the molten mother liquid ranges from1,650 DEG C-1,750 DEG C; coke is added for smelting after the mother liquid is molten completely, the smelting temperature is controlled in a range from 1,650 DEG C to 1,750 DEG C simultaneously, and an additive is simultaneously added for an early reduction reaction for 1-2 hours; after the early reduction reaction is finished, a fluxing agent and calcium carbonate are added for continuous reduction reaction for 1-2 hours, so that a metal liquid is obtained; the temperature of the metal liquid is adjusted in a range from 1,650 DEG C to 1,750 DEG C, dregs are removed, and the metal liquid is remained; and pouring is performed to form ingots. With the adoption of the method, waste is reused, so that pollution of the waste on the environment is reduced; and further, steel-making dedusting ash and the laterite-nickel ore are sufficiently combined for smelting, and the chromel alloy with high recovery rate and high content is obtained through addition of an NCP-2 additive.

Owner:TAIZHOU YONGXING ALLOY MATERIAL TECH

Spray coating material prepared by titanium-containing high-chromium-nickel alloy, preparation method and use thereof

InactiveCN101260487BExtended service lifeImprove anti-sulfur performanceMetal-working apparatusRheniumVulcanization

The invention relates to a titanium contained high chromel alloy and application thereof in spraying materials. The components of the alloy are (by weight percentage) as follows: the content of chromium is more than or equal to 15 percent and less than or equal to 25 percent, the content of titanium is more than or equal to 1 percent and less than or equal to 6 percent, the content of silicon is more than or equal to 1 percent and less than or equal to 6 percent, the content of carbon is more than or equal to 0 percent and less than or equal to 0.02 percent, the content of nickel is more thanor equal to 20 percent and less than or equal to 55 percent, the content of rhenium is more than or equal to 0.5 percent and less than or equal to 6 percent, the content of aluminum is more than or equal to 0 percent and less than or equal to 6 percent, the content of sulfur is more than or equal to 0 percent and less than or equal to 0.035 percent, he content of phosphorus is more than or equal to 0 percent and less than or equal to 0.035 percent, the content of manganese is more than or equal to 0 percent and less than or equal to 0.2 percent, and the rest is iron. After the parts of workingequipment are sprayed at high temperature oxidation and high temperature corrosion environments by the spraying material produced by the alloy, since the coating has good high temperature oxidation and vulcanization resistance and hot corrosion resistance performances, the service life of the parts can be greatly improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

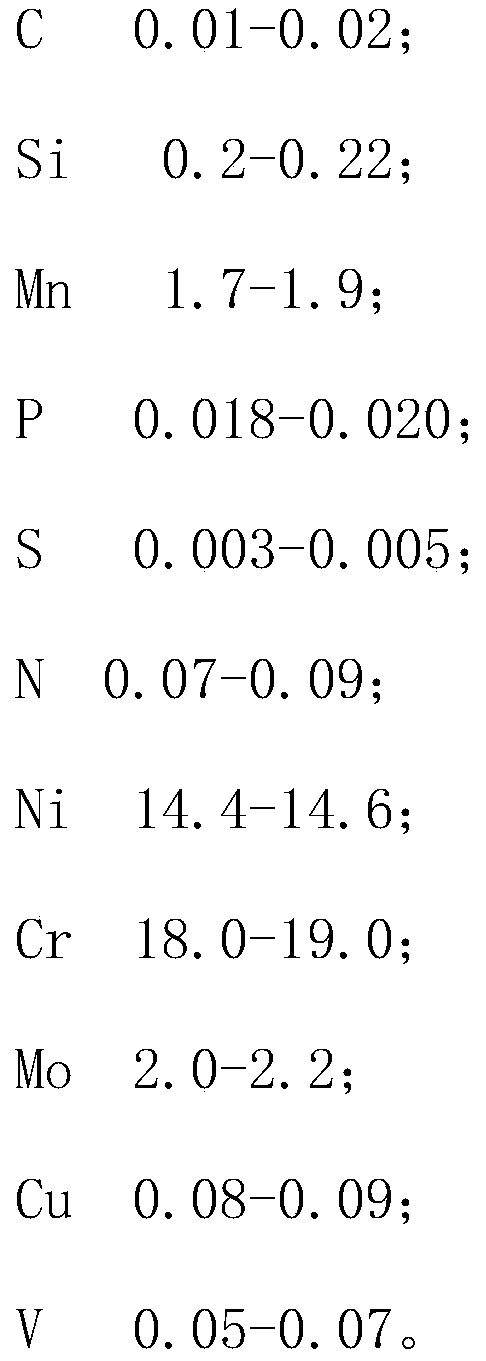

Ultra-pure dual smelting formula applied to semiconductor valve

The invention discloses an ultra-pure dual smelting formula applied to a semiconductor valve. The formula comprises, by mass ratio, 0.01 to 0.02 of C, 0.2 to 0.22 of Si, 1.7 to 1.9 of Mn, 0.018 to 0.020 of P, 0.003 to 0.005 of S, 0.07 to 0.09 of N, 14.4 to 14.6 of Ni, 18.0 to 19.0 of Cr, 2.0 to 2.2 of Mo, 0.08 to 0.09 of Cu and 0.05 to 0.07 of V. According to the ultra-pure dual smelting formula,a reasonable data range is adopted, due to the base material of the pure steel, electronic state electrochemical polishing treatment is facilitated, after EP treatment, better nicochrome deposition isachieved, a nicochrome layer is formed, acid and alkali corrosion resistance is improved, a better polishing degree shows on the runner surface, the dust accumulation amount can be reduced to the minimum, and the nanoscale dustproof environment use standard is achieved.

Owner:JIANGSU FANBANG SEMICON MATERIAL TECH CO LTD

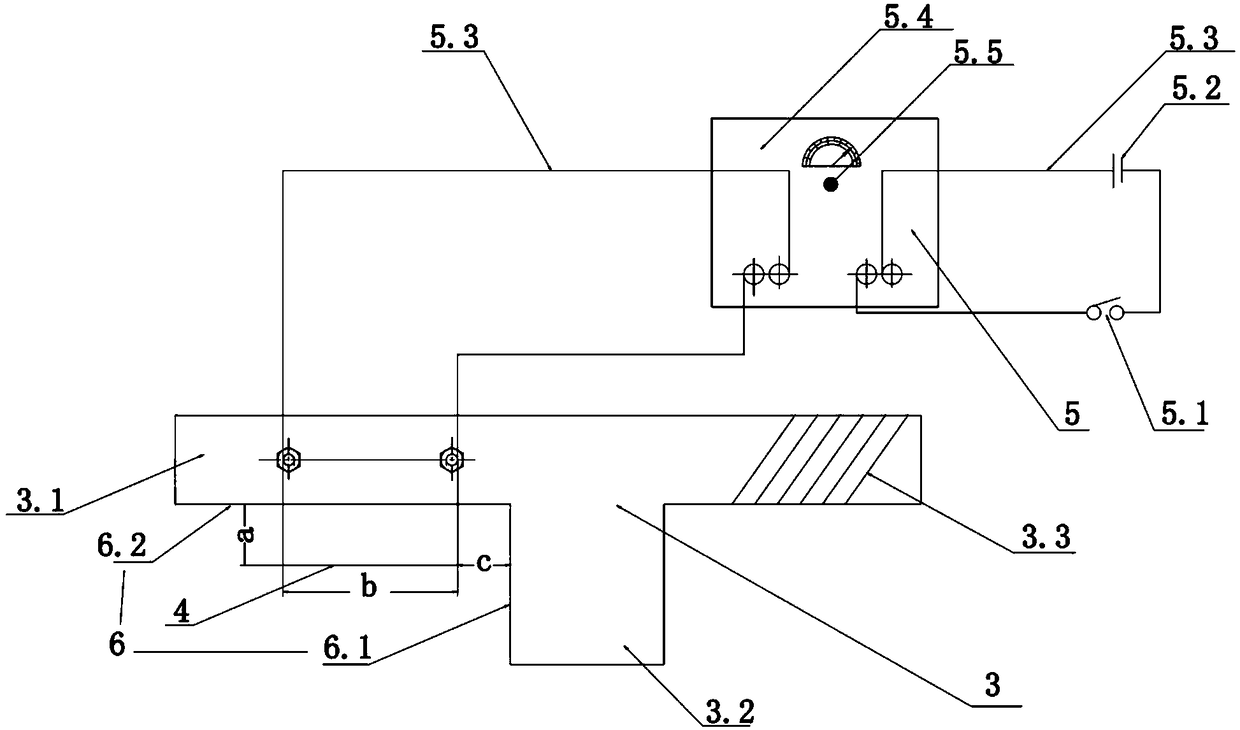

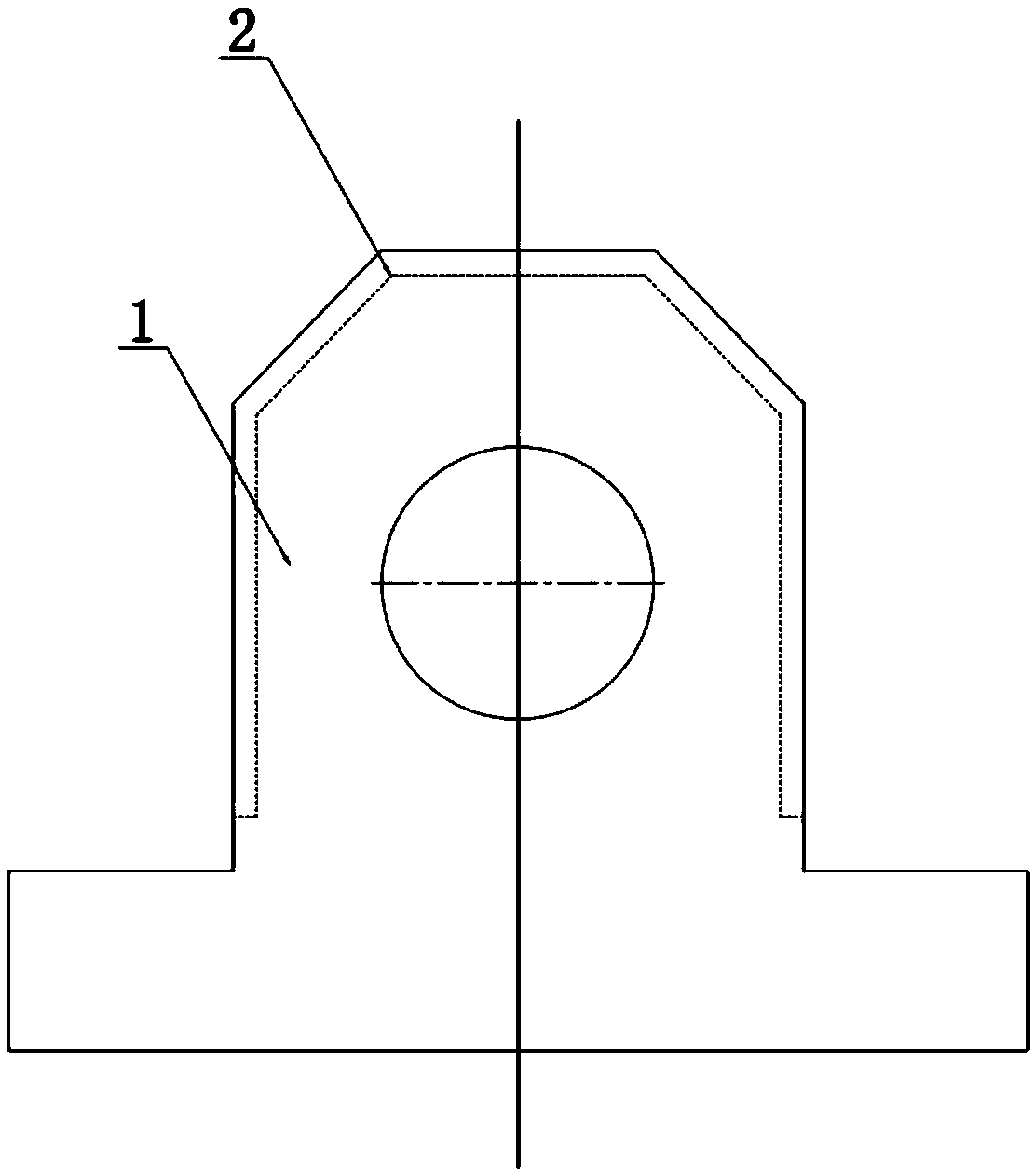

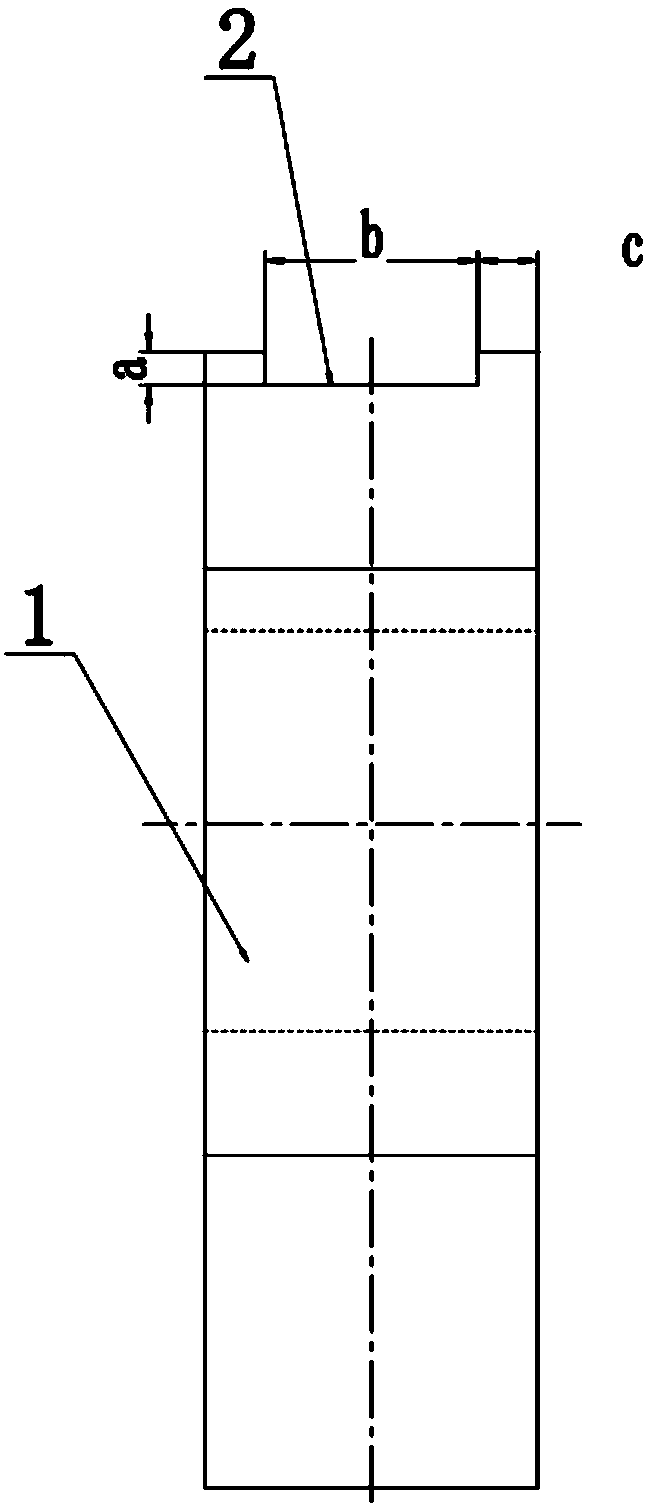

Tool for manufacturing water-cooling bearing pedestal blank model by one-time molding

InactiveCN109226673ATemperature controlShorten production timeFoundry moulding apparatusElectrical resistance and conductanceHeat resistance

The invention discloses a tool for manufacturing a water-cooling bearing pedestal blank model by one-time molding. The tool comprises a water-cooling bearing pedestal blank model, a tooling part and acontrol part, wherein the tooling part comprises a top plate and a positioning block; a heat resistance wire is fixed on the top plate; an open space is formed by the top plate and the positioning block; and the control part comprises a control switch, a power supply, a lead wire and a contact voltage regulator. According to the tool, a water-cooling tank is processed by matching of the tooling part and the control part, processing is convenient, applicability is flexible and reliable, size precision is high, work intensity is reduced, time for manufacturing a water-cooling bearing pedestal blank model is reduced, and work efficiency is improved; the tooling part is made of an insulating material, and the strength and safety can be ensured; the heating resistance wire made of a chromel filament having a diameter of 3mm can ensure the cutting strength; and the current strength in a lead wire loop is controlled by adjusting the knob of the contact voltage regulator, and the temperatureof the heating resistance wire is controlled. The tool is simple and convenient.

Owner:济南市白象科技发展有限公司

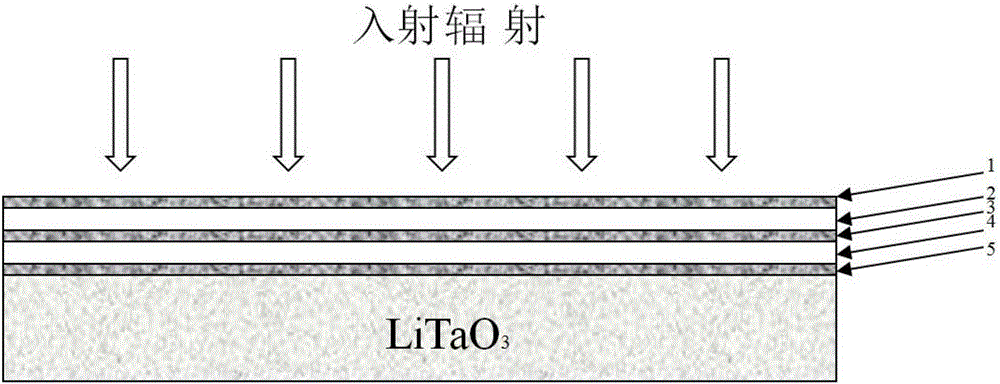

A pyroelectric infrared detector sensitive unit and its manufacturing method

ActiveCN104465851BFirmly attachedGood repeatabilityFinal product manufactureSemiconductor devicesHeat sensitiveOptoelectronics

The embodiment of the present invention discloses a method for manufacturing a sensitive unit of a pyroelectric infrared detector, comprising: preparing a lithium tantalate wafer substrate; forming a chromium metal film on the first surface of the lithium tantalate wafer substrate; Forming a nickel metal film on the chromium metal film; forming a first chromium-nickel alloy layer on the nickel metal film and etching to form an upper electrode; forming a second chromium-nickel alloy layer on the second surface of the lithium tantalate wafer substrate and etching A lower electrode is formed. The absorption layer of the sensitive unit of the pyroelectric infrared detector manufactured according to the method of the embodiment of the present invention has the advantages of firm adhesion, good repeatability, wide absorption band, flat spectrum, high absorption rate, small specific heat capacity, and excellent heat transfer performance. At the same time, the absorbing layer can also serve as an electrode, and is suitable as the absorbing layer of the pyroelectric infrared detector.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Cleaning spraying agent

The invention discloses a cleaning spraying agent. The cleaning spraying agent comprises, by weight percentage, 8.5-14.5% of acid, 0.1-2.0% of a corrosion inhibiting agent, 0.1-2.0% of a foaming agent, 2-10% of sodium succinate and water supplementing 100%. By weight percentage, the cleaning spraying agent further comprises 0.1-5% of a surface active agent; and the surface active agent is selectedfrom fatty alcohol polyoxyethylene ether. According to application of the cleaning spraying agent, the cleaning spraying agent is used for chrome alloy cleaning and is especially used for chrome alloy hub cleaning. According to the cleaning spraying agent, the sodium succinate is used as the surface active agent to be applied in the acidic cleaning spraying agent, the system is made to have the beneficial effects of being good in stability and good in cleaning effect, the surface of a cleaned alloy is bright, and a compact protecting film is provided and can slow down alloy rusting.

Owner:GUANGZHOU COMEBEST IND CO LTD

Heating cable for geothermal heating

The invention discloses a heating cable for geothermal heating. The heating cable comprises a heating element which comprises cold wires and a hot wire. The hot wire is arranged under the earth surface, and the cold wires are fixedly connected with the two ends and are led out of the earth surface to be connected with a power switch. The outside of the heating element is covered with an insulation layer, a shielding layer and a protection sleeve successively. The heating cable is made of chrome-nickel alloy wires and is soft in texture, fast in heating, stable in heat and safe to use; the insulation layer, the shielding layer and the protection sleeve further protect the usage safety of the heating cable from all sides.

Owner:ANBANG ELECTRICAL GRP

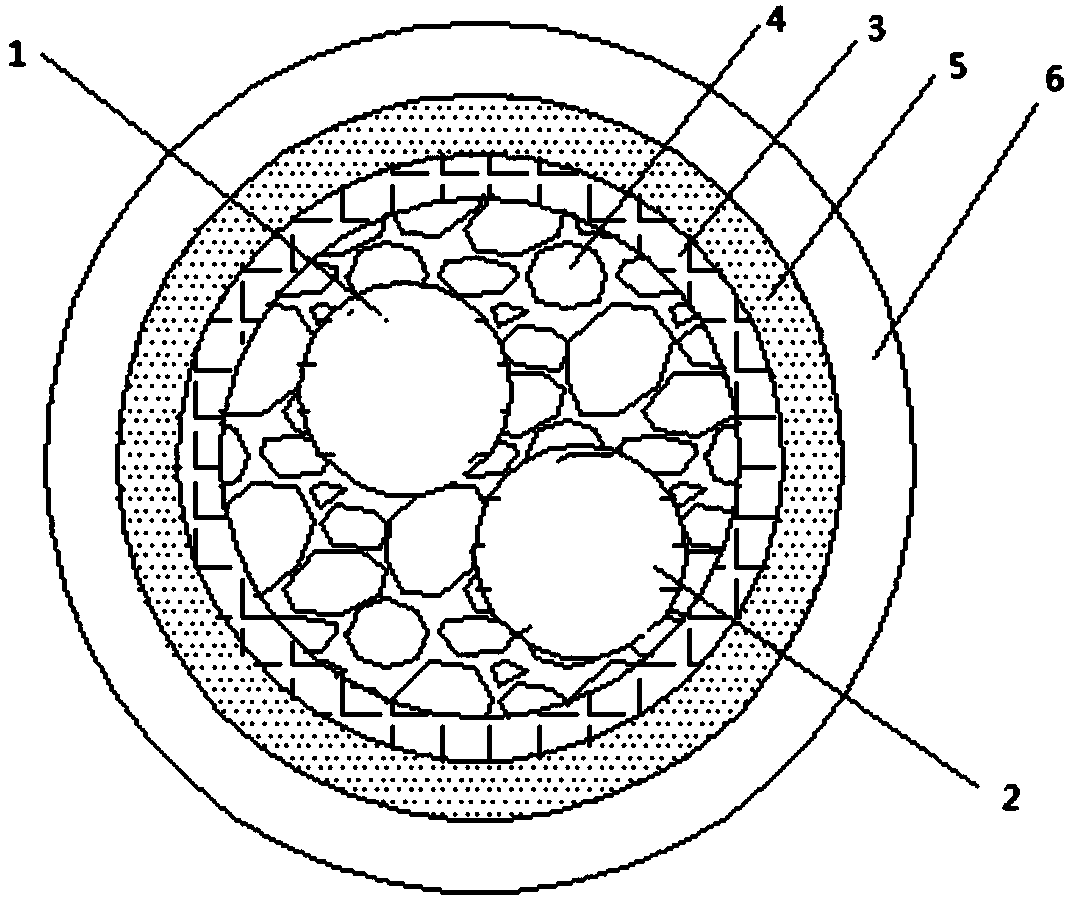

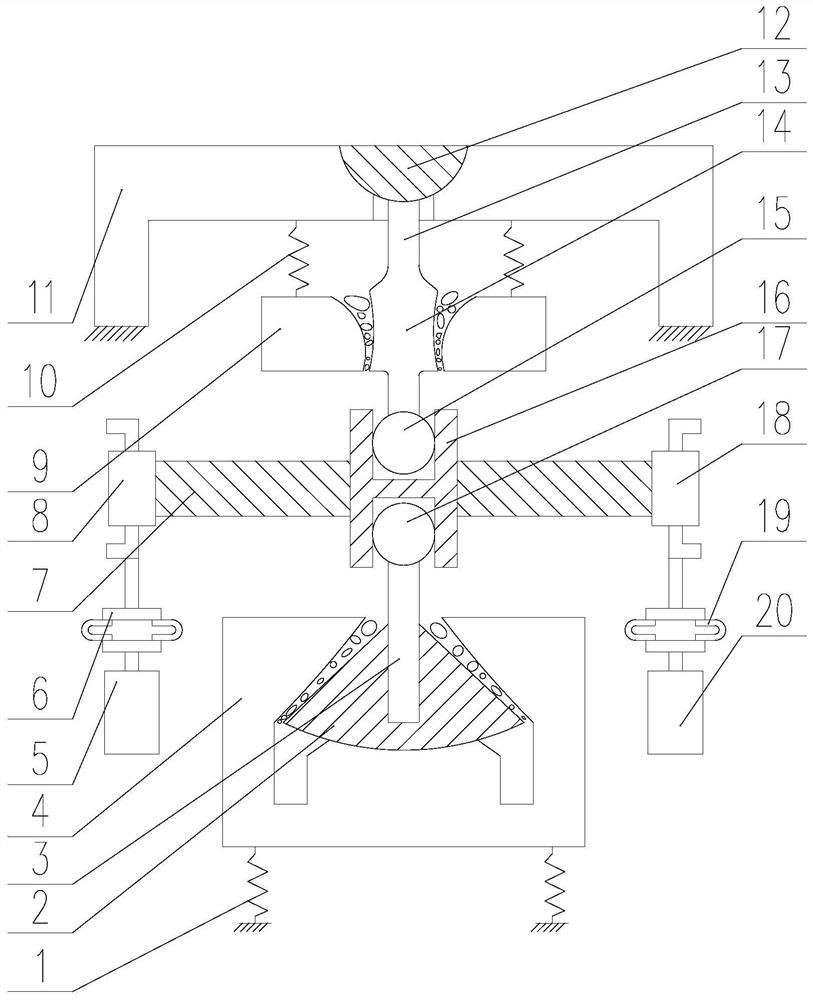

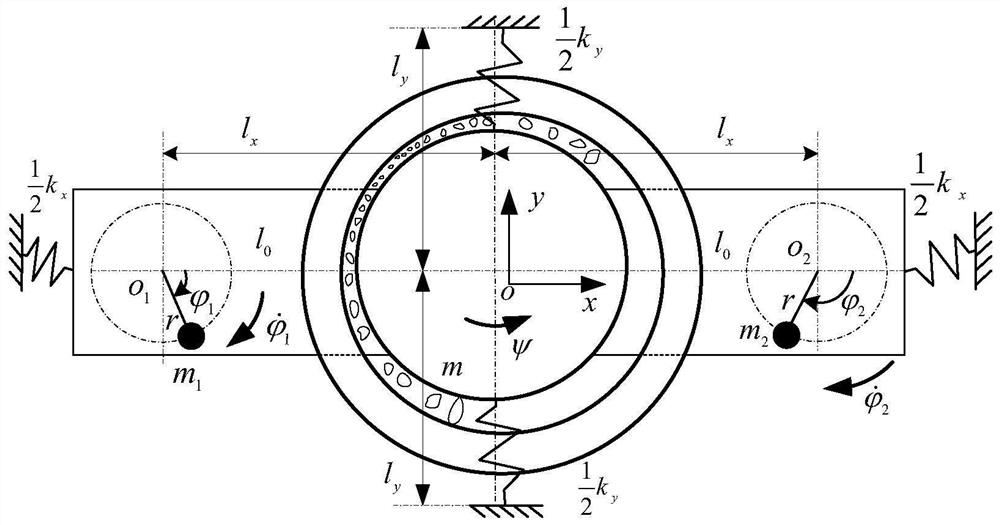

A vertical dual-channel dual-machine self-synchronizing vibration inertial crusher and its parameter determination method

ActiveCN107127035BIncrease powerIncrease productionMechanical vibrations separationGrain treatmentsCouplingControl engineering

The invention discloses a vertical dual-channel dual-machine self-synchronous vibrating inertial crusher. The device includes upper and lower vibration isolation springs, upper and lower working outer cones, upper and lower working inner cones, upper and lower working body main shafts, Upper and lower ball handles, connecting blocks, beams, hemispheres, motors A, B, couplings A, B, vibrators A, B. Feed materials to the upper and lower feed ports. At the same time, the two motors rotate in the same direction, and the vibrator is driven to excite the beam and the connecting block, as well as the upper and lower working inner cones connected to the main shaft to swing, and the upper and lower working outer cones are placed in it. The material is crushed and ground. The device uses upper and lower channels to crush materials, which greatly improves the efficiency. The dual-machine self-synchronous drive is adopted, and the two machines rotate in the same direction, which increases the power of the machine, realizes the enlargement of the equipment, increases the output, and achieves energy saving through self-synchronous drive; vibration crushing improves the crushing ratio and can crush super hard materials. Ore materials, such as chromium alloy ore, etc.

Owner:NORTHEASTERN UNIV LIAONING

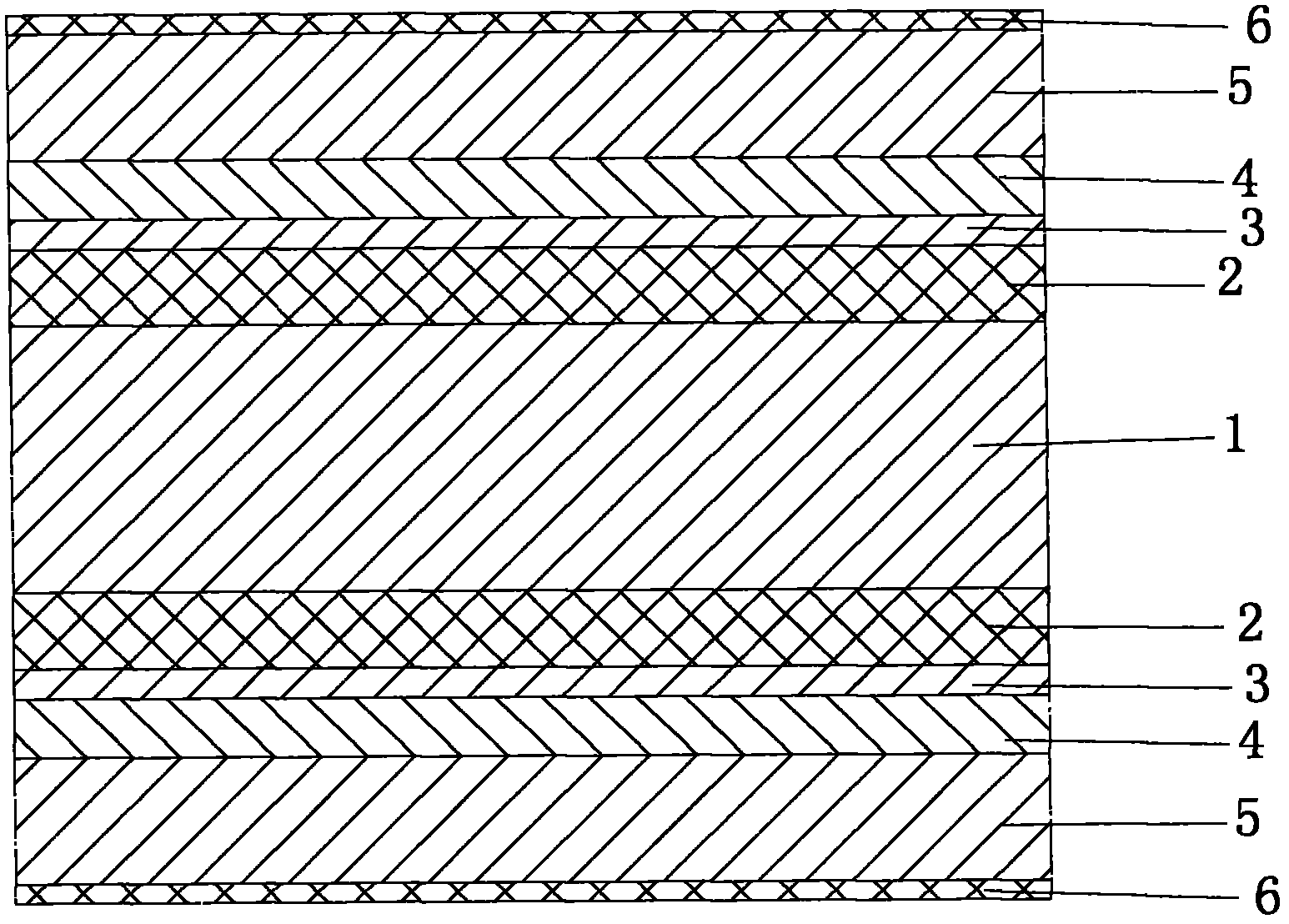

Absorption layer for broadband spectrum pyroelectric detector and preparation method thereof

ActiveCN105352608AFirmly attachedGood repeatabilityPyrometry using electric radation detectorsPyroelectric detectorsMaterials science

The invention provides an absorption layer for a broadband spectrum pyroelectric detector. The absorption layer comprises a first chrome-nickel alloy layer, a first silicon nitride thin film, a second chrome-nickel alloy layer, a second silicon nitride thin film and a third chrome-nickel alloy layer from the top down in an incidence sequence of the incident radiation. The invention also provides a preparation method of the absorption layer. The method comprises the following steps: preparing the absorption layer on a LiTaO3 wafer, cleaning the LiTaO3 wafer and depositing the third chrome-nickel alloy layer on the A surface of the LiTaO3 wafer; etching the A surface of the LiTaO3 wafer to form a shape structure and size of an electrode, carrying out photoetching patterning on the A surface of the LiTaO3 wafer, and depositing the second silicon nitride thin film on the A surface of the LiTaO3 wafer; depositing the second chrome-nickel alloy layer on the A surface of the LiTaO3 wafer, and carrying out photoetching patterning on the A surface of the LiTaO3 wafer; and 9) depositing the first silicon nitride thin film on the A surface of the LiTaO3 wafer, and depositing the first chrome-nickel alloy layer on the A surface of the LiTaO3 wafer. The absorption layer has the advantages of firm adhesion, good repeatability, wide and flat absorption band, high absorptivity, small specific heat capacity and excellent heat transfer performance and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

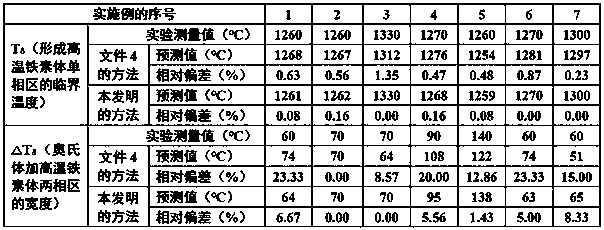

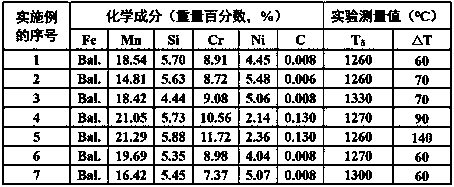

Method for predicting formation temperature of high temperature ferrite in Fe-Mn-Si-Cr-Ni alloy

InactiveCN109943695ASimple methodLow costSpecial data processing applicationsAusteniteHigh-temperature corrosion

The invention discloses a method for predicting a formation temperature range of a high temperature ferrite in a Fe-Mn-Si-Cr-Ni alloy. The method is that a critical temperature Tsigma of forming a high temperature ferrite single-phase zone and a width delta T of an austenite plus high temperature ferrite two-phase zone can be calculated directly by putting the weight percentage of each element inthe alloy into a formula. The method is simple and easy to execute, has an accurate the prediction result, can be used as a tool to design the composition of the Fe-Mn-Si-Cr-Ni alloy with high recovery strain and no training and to formulate the heat treatment process, and has important engineering value.

Owner:SICHUAN UNIV

Stainless steel smelting method

The invention relates to the technical field of stainless steel smelting, in particular to a stainless steel smelting method. In the stainless steel smelting method, a liquid chrome-nickel alloy pig iron melt is used directly, links of cooling, conveying and secondary heating after production of chrome-nickel alloy pig iron are omitted, energy consumption is reduced, meanwhile, after the temperature of high carbon ferro-chrome liquid is controlled to be equal to the melting point of the high carbon ferro-chrome liquid, the high carbon ferro-chrome liquid is added in a chrome-nickel alloy pig iron liquid steel ladle in which the temperature of chrome-nickel alloy pig iron liquid is higher than the melting point of the chrome-nickel alloy pig iron liquid by 50-100 DEG C, nickel is adjusted by pure nickel, steel is discharged and cooled after the liquid is stirred for 3-5 minutes, the high carbon ferro-chrome liquid becomes fused floccules due to slightly cold melting point, and after the steel is cooled, the ductility and the hardness of the product are improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com