A vertical dual-channel dual-machine self-synchronizing vibration inertial crusher and its parameter determination method

A self-synchronized vibration, dual-channel technology, applied in the direction of fluid and grain processing using vibration, can solve the problems of low efficiency, small output, and equipment cannot be enlarged, and achieve the effect of increasing output, increasing crushing ratio, and increasing power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

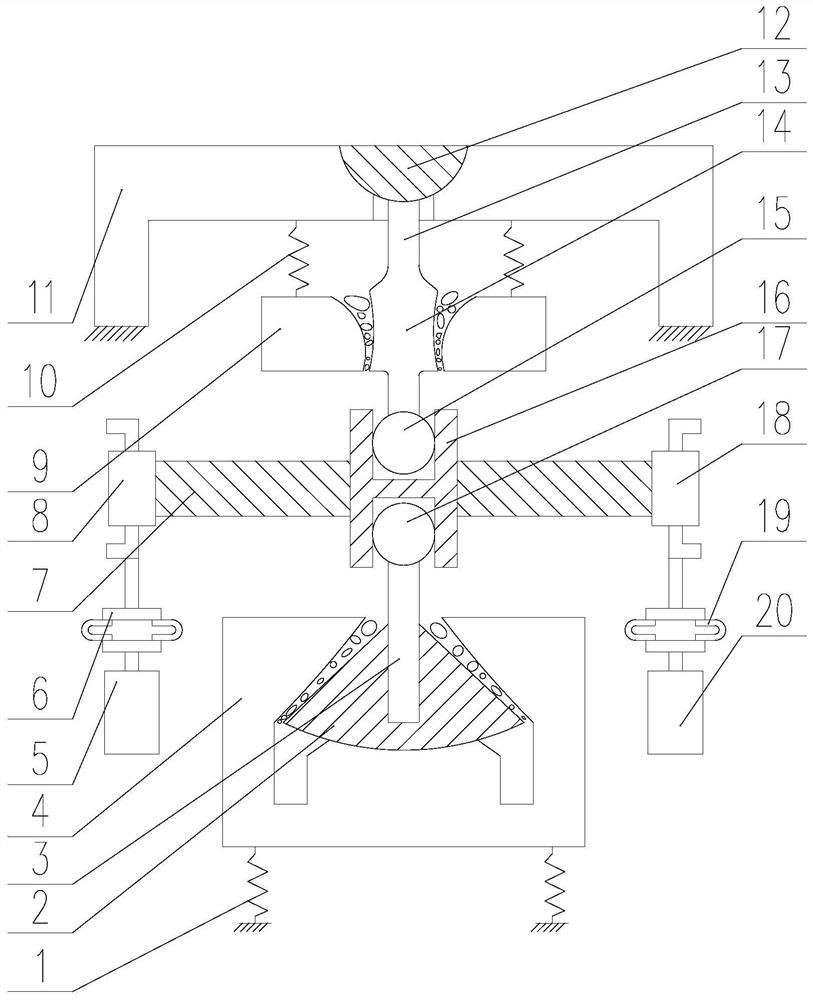

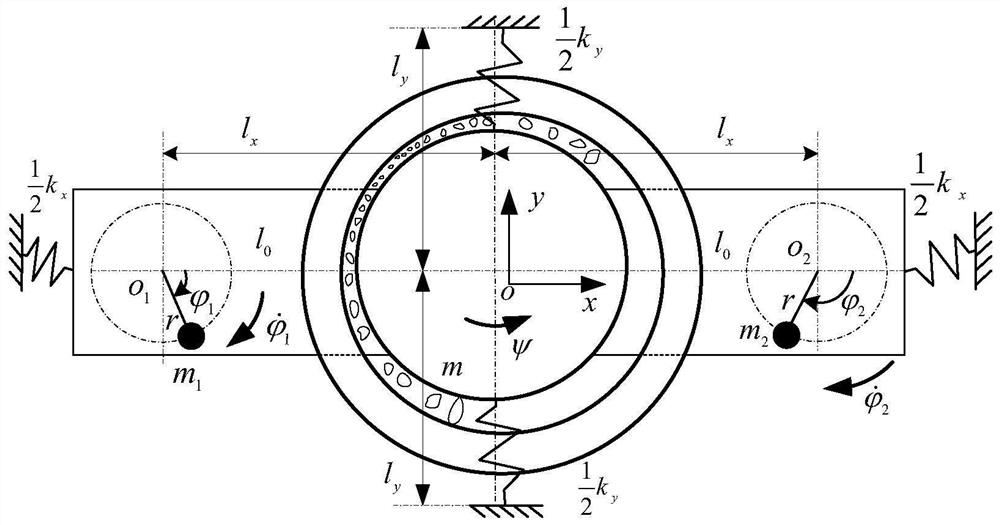

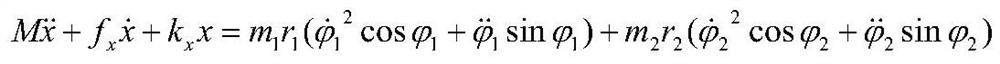

[0017] A vertical dual-channel dual-machine self-synchronized vibration inertia crusher, comprising a lower vibration isolation spring 1, a lower outer cone 4, a lower inner cone 2, a main shaft 3 of the lower working body, a lower ball handle 17, a connecting block 16, and a beam 7. Upper ball handle 15, upper working body main shaft 13, upper working inner cone 14, upper working outer cone 9, upper vibration isolation spring 10, hemisphere 12, motor A5, motor B20, coupling A6, coupling B19 , vibration exciter A8, vibration exciter B18 and support 11; one end of the main shaft of the upper working body is fixed on the support through the hemispherical spherical support, and the support is fixed on the ground; the main shaft of the upper working body passes through the connected upper work The inner cone; the outer cone of the upper working body is surrounded by the inner cone of the upper working body, and is connected to the support through the upper vibration isolation sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com