Patents

Literature

62results about How to "Increase crushing ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

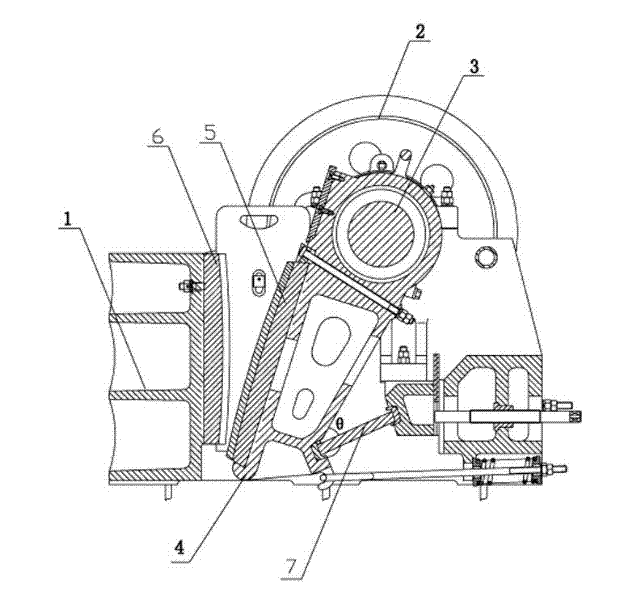

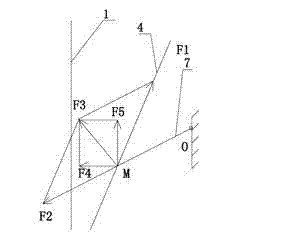

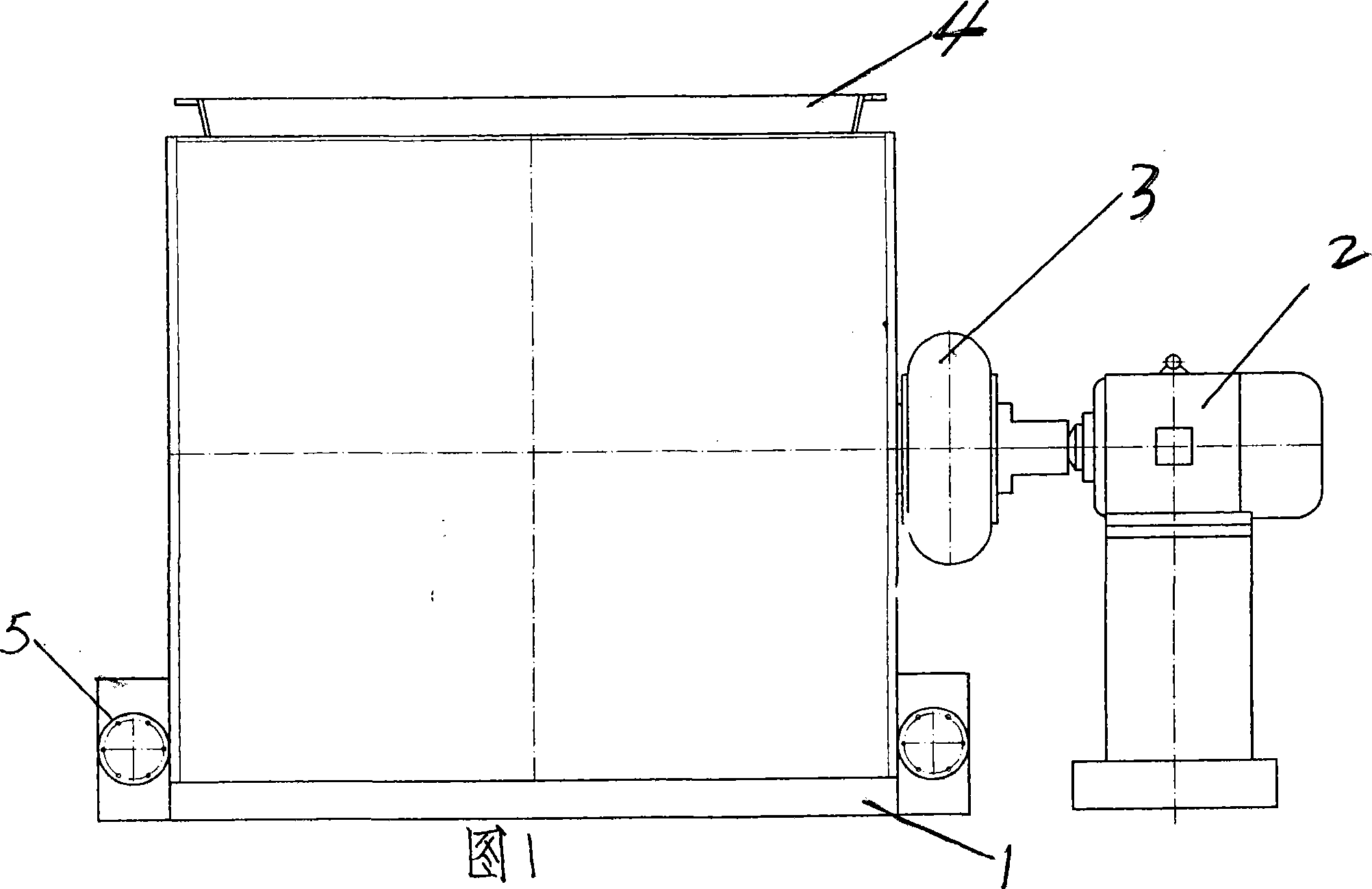

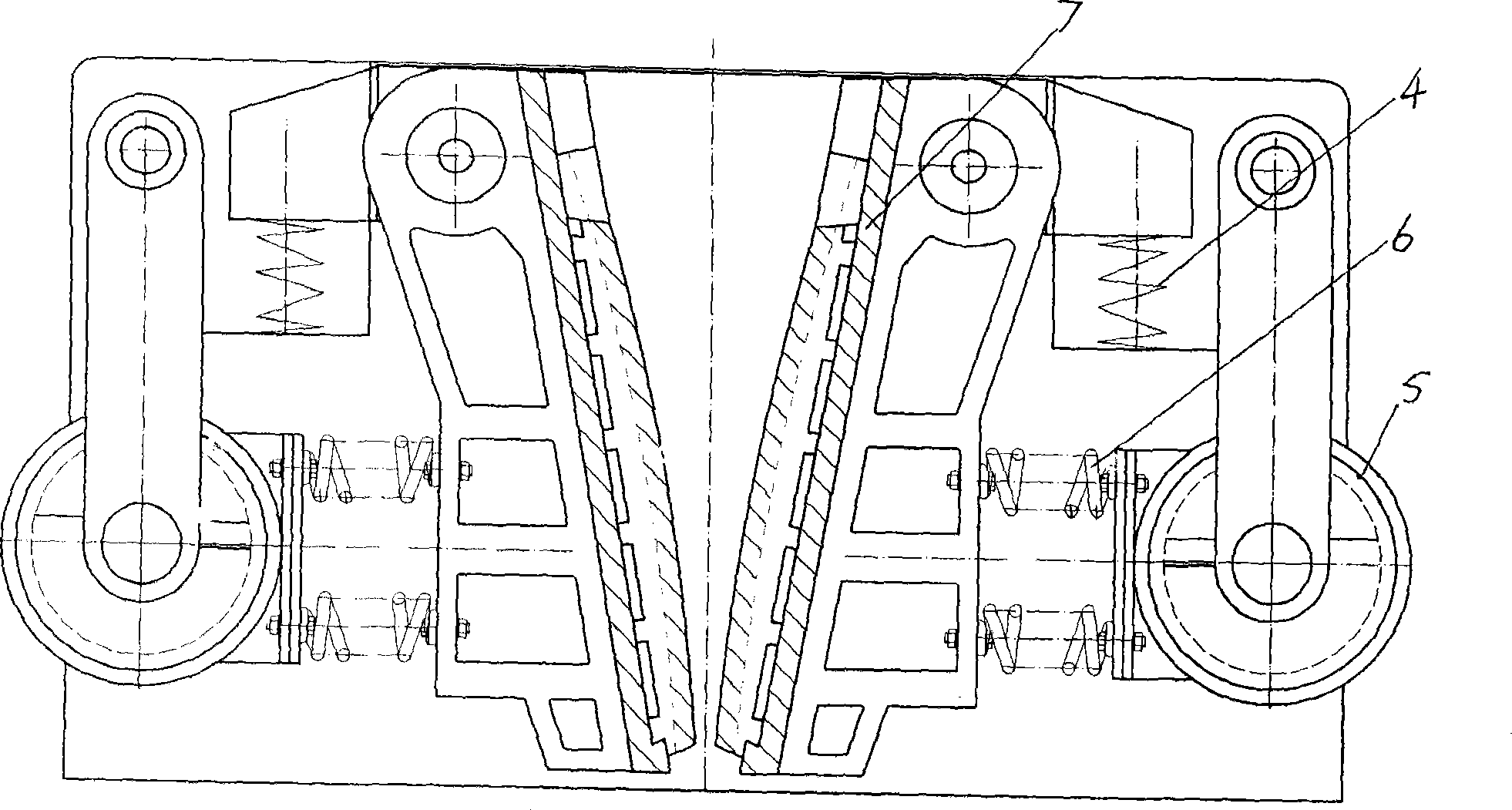

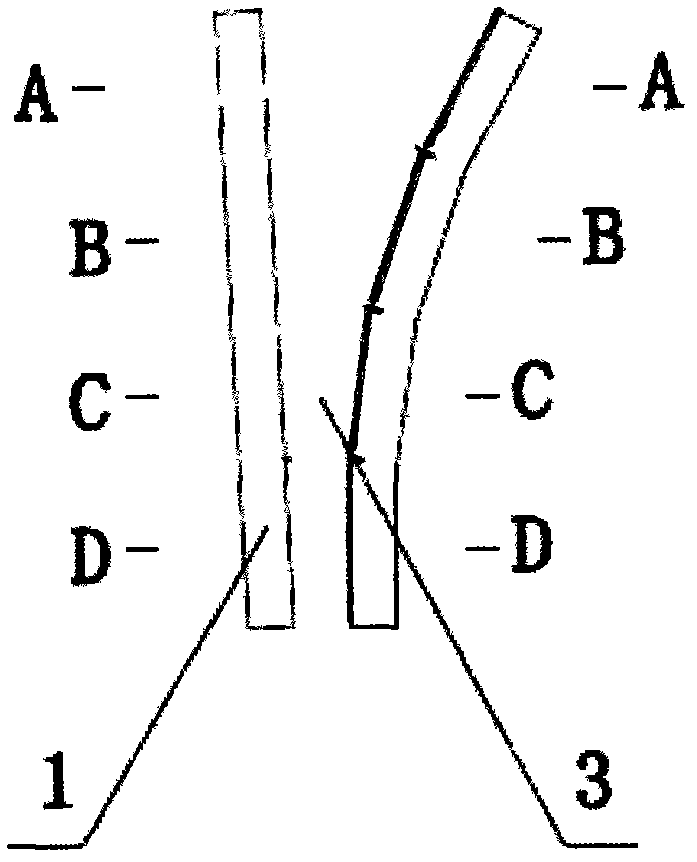

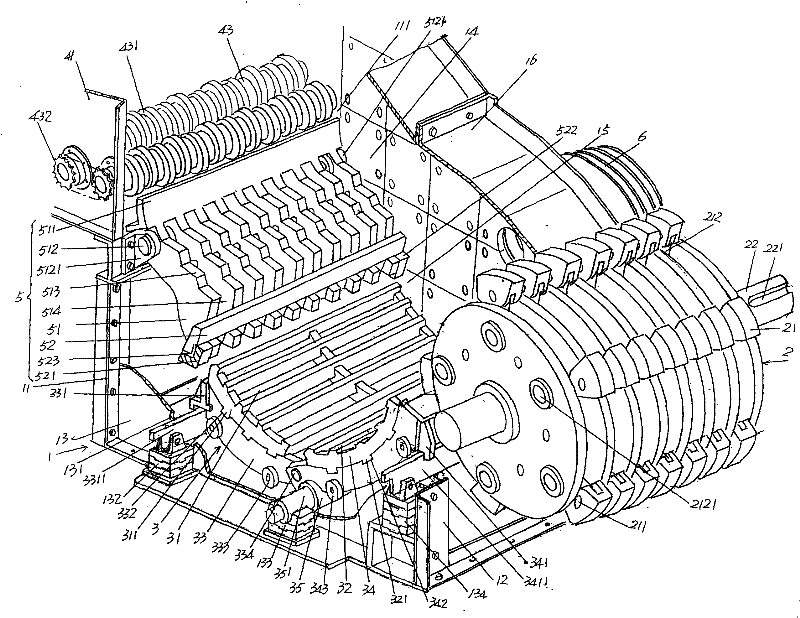

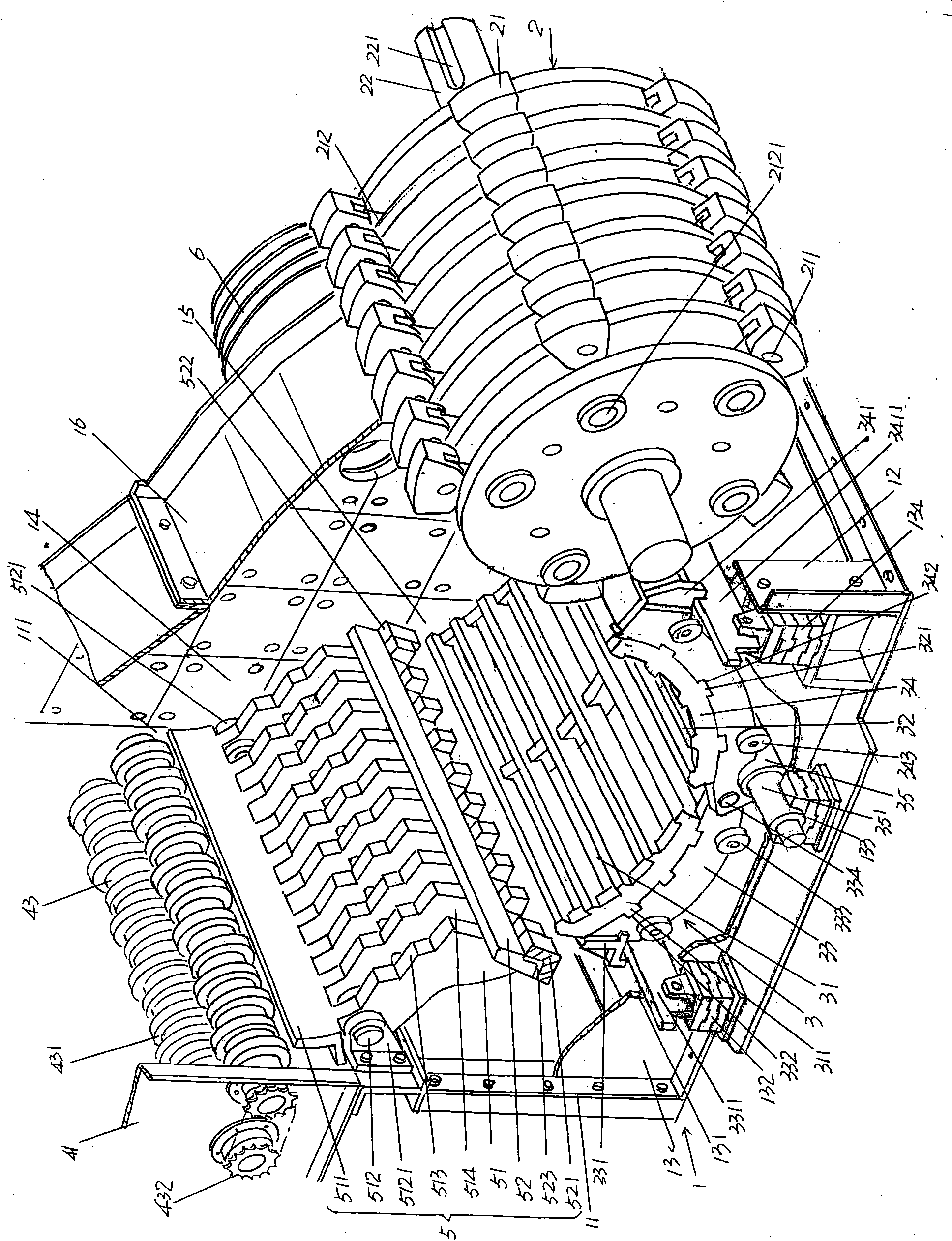

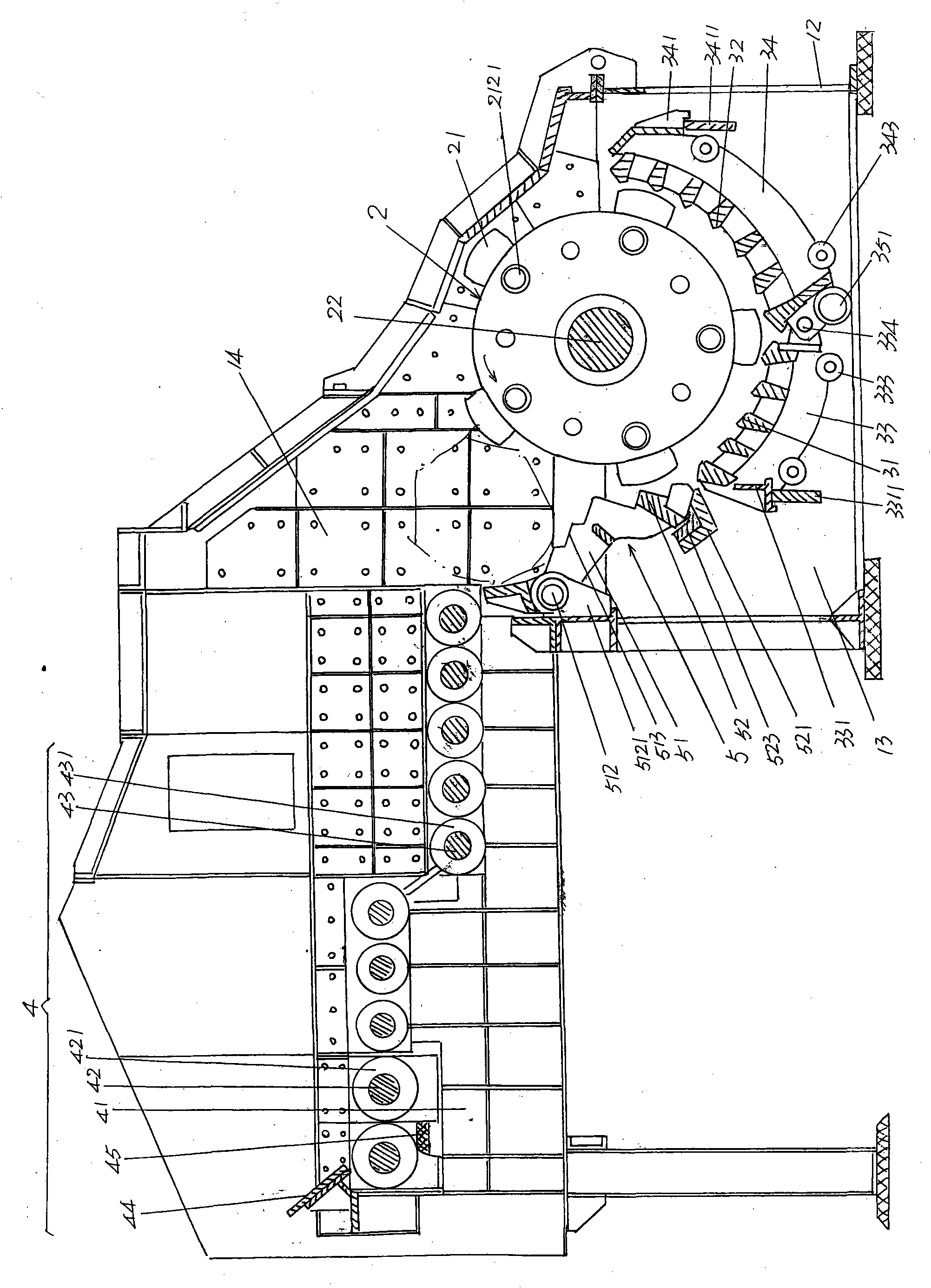

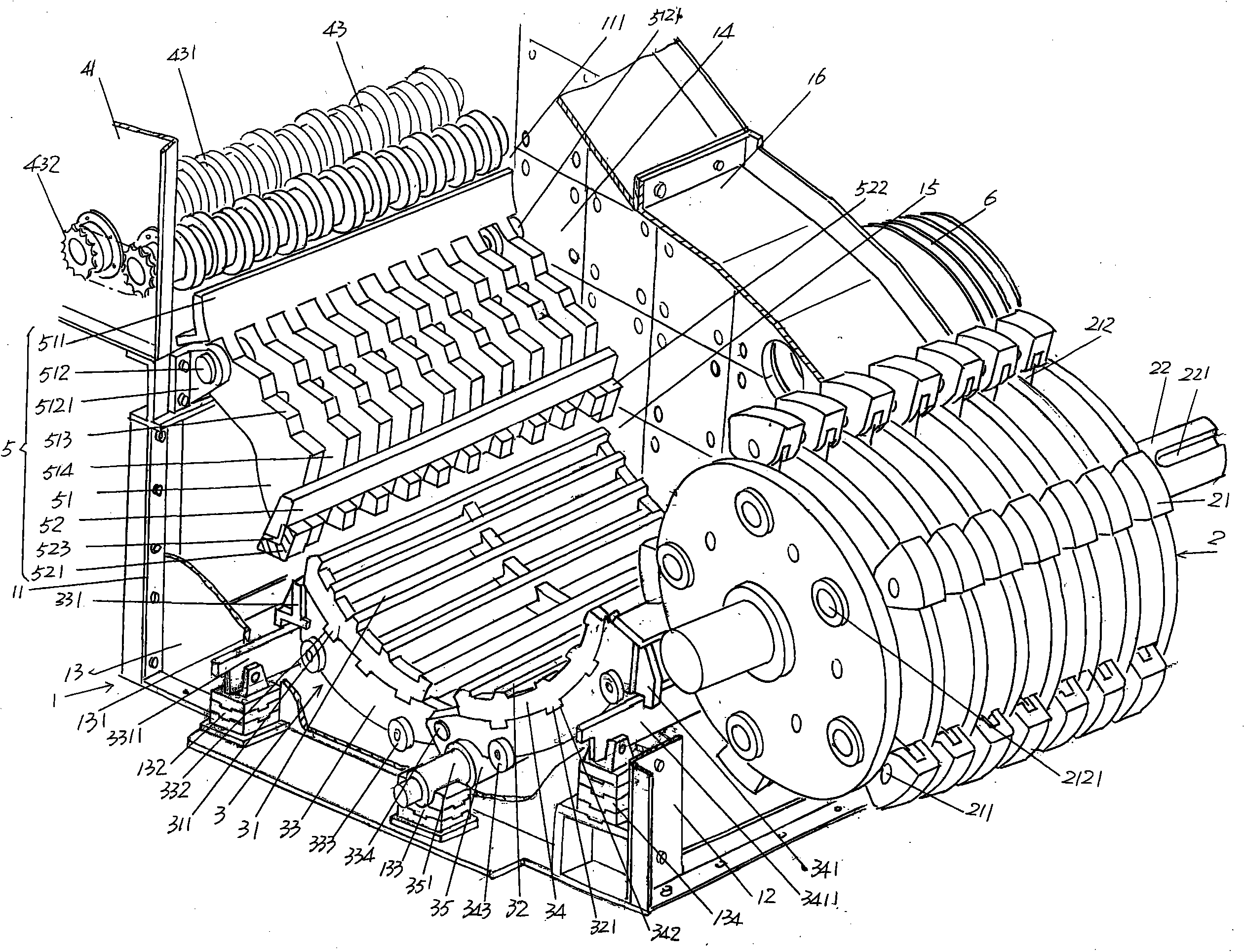

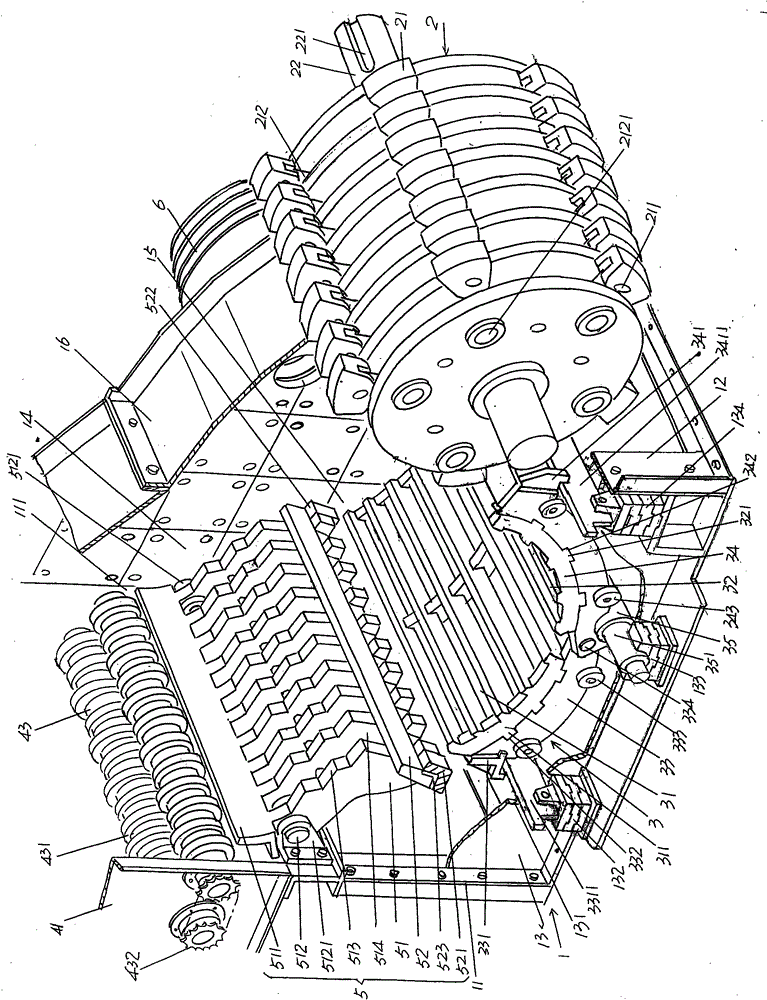

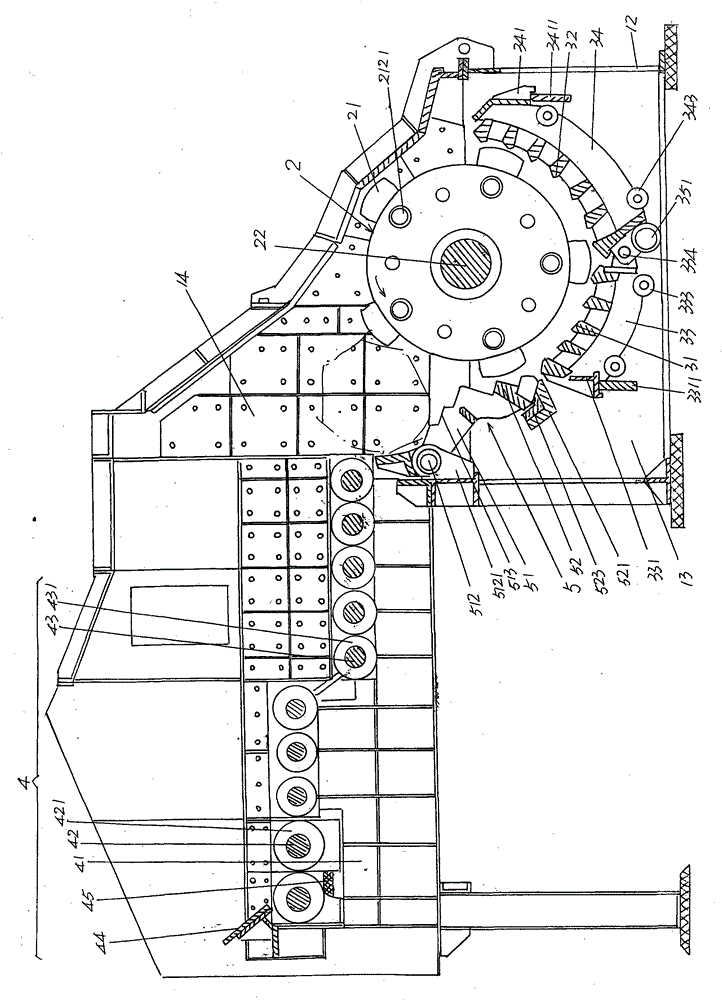

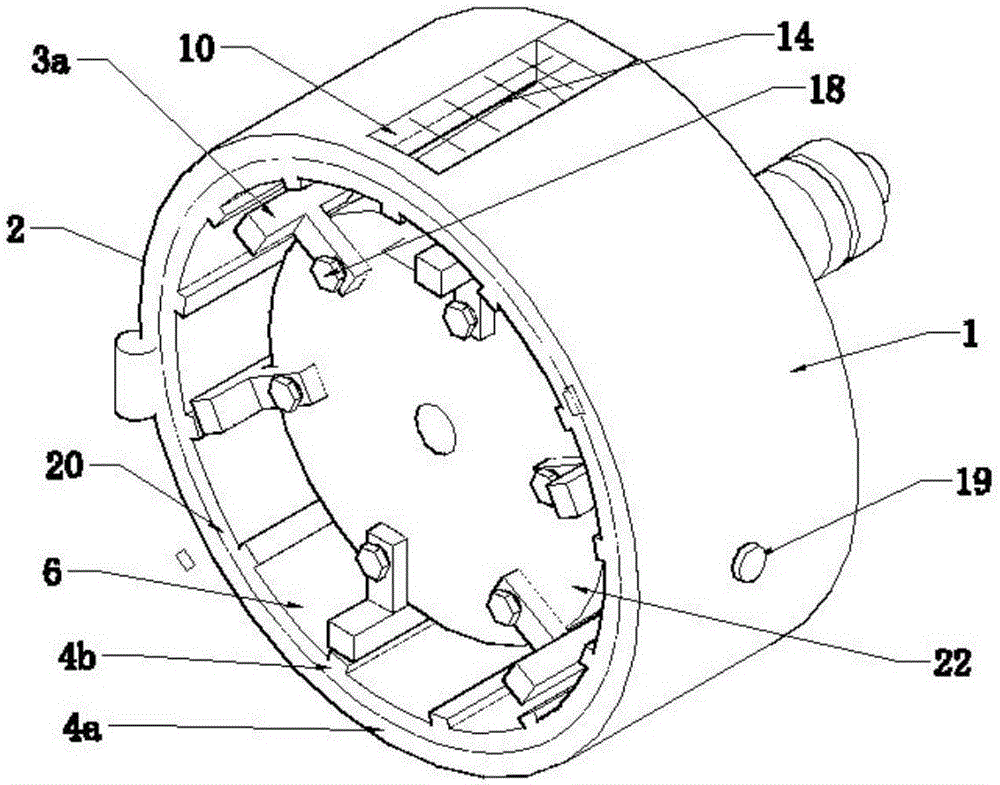

Jaw crusher with single-shaft double-crank-rocker mechanism

ActiveCN102198409AChange the mechanical structureEasily brokenGrain treatmentsDrive wheelDrive shaft

The invention discloses a jaw crusher with a single-shaft double-crank-rocker mechanism. The jaw crusher comprises a frame, a fixed jaw plate, a movable jaw plate, a front crank-rocker mechanism, a rear crank-rocker mechanism and a driving wheel, wherein, the front crank-rocker mechanism comprises a front movable jaw, a front toggle plate and an eccentric drive shaft; the rear crank-rocker mechanism comprises a rear movable jaw, a rear toggle plate and an eccentric drive shaft; the front movable jaw and the rear movable jaw are jointly pivoted with the eccentric drive shaft; one end of the front toggle plate is pivoted below the rear side of the front movable jaw, the other end of the front toggle plate is pivoted below the front side of the rear movable jaw, one end of the rear toggle plate is pivoted below the rear side of the rear movable jaw, and the other end of the rear toggle plate is pivoted with the frame; and the movable jaw plate is fixedly connected with the front movable jaw and is opposite to the fixed jaw plate to form a crushing cavity together with the fixed jaw plate. The jaw crusher has the obvious effect that horizontal movement stroke of the lower parts of the movable jaws with the main function of discharging materials is improved to a stroke with a main function of crushing so that one crusher has two-stage crushing efficacy.

Owner:ZHEJIANG SHENGDA MACHINERY

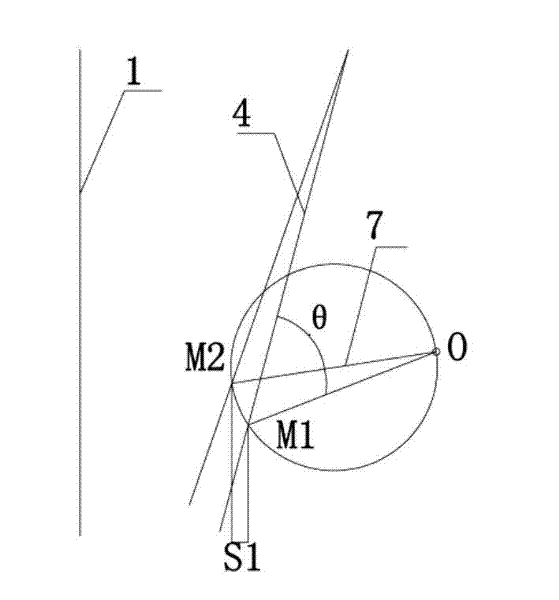

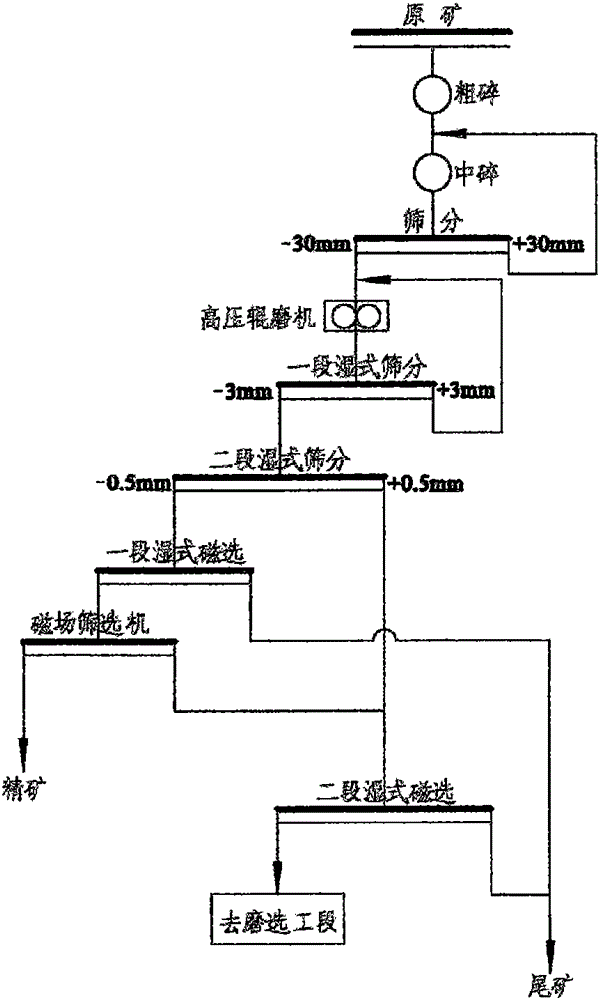

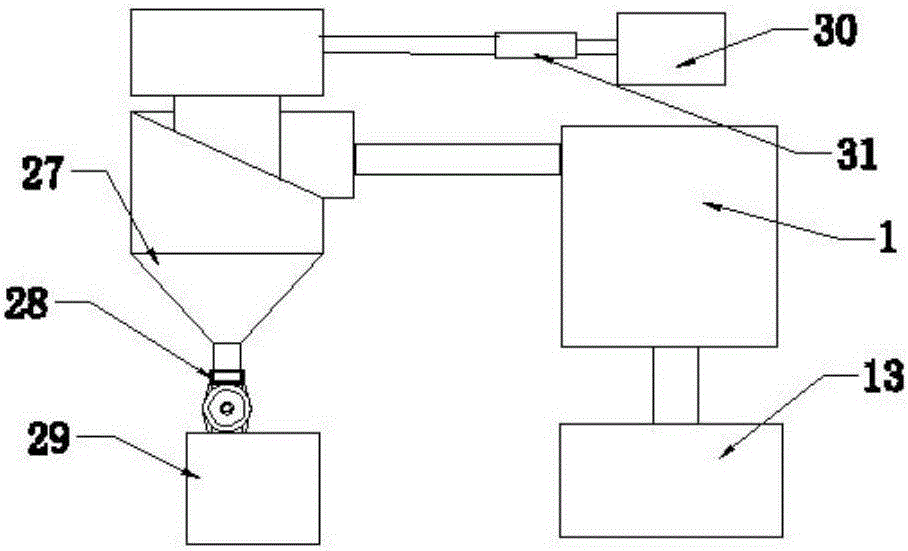

Combined mineral separation technology for ferric oxide mineral

InactiveCN107185686AThrow out earlyReduce transportationMagnetic separationGrain treatmentsIronstoneOxide minerals

The invention discloses an iron oxide ore joint beneficiation process, which comprises the following steps: (1) dry selection and discarding of iron oxide ore to obtain pre-selected coarse-grained ore, pre-selected fine-grained ore and waste rock; (2) high-pressure Roller mill crushing: the pre-selected coarse-grained ore obtained in step (1) is fed into a high-pressure roller mill for crushing; (3) dry grinding: the crushed product in step (2) and the pre-selected fine-grained ore in step (1) Combined for dry closed-circuit grinding; (4) Fluidized reduction roasting: a. Put the ground product obtained in step (3) into the fluidized reduction roaster; b. Preheating; c. Heating; d. Magnetization roasting; e . Cool to below 200°C to obtain roasted ore with a magnetite content greater than 90%; (5) beneficiation of roasted ore to obtain iron concentrate products with a grade of 57%-65%. The present invention can effectively solve the current iron oxide ore beneficiation There are technical problems such as low resource utilization rate, poor concentrate quality and high energy consumption in the process.

Owner:JIUQUAN IRON & STEEL GRP

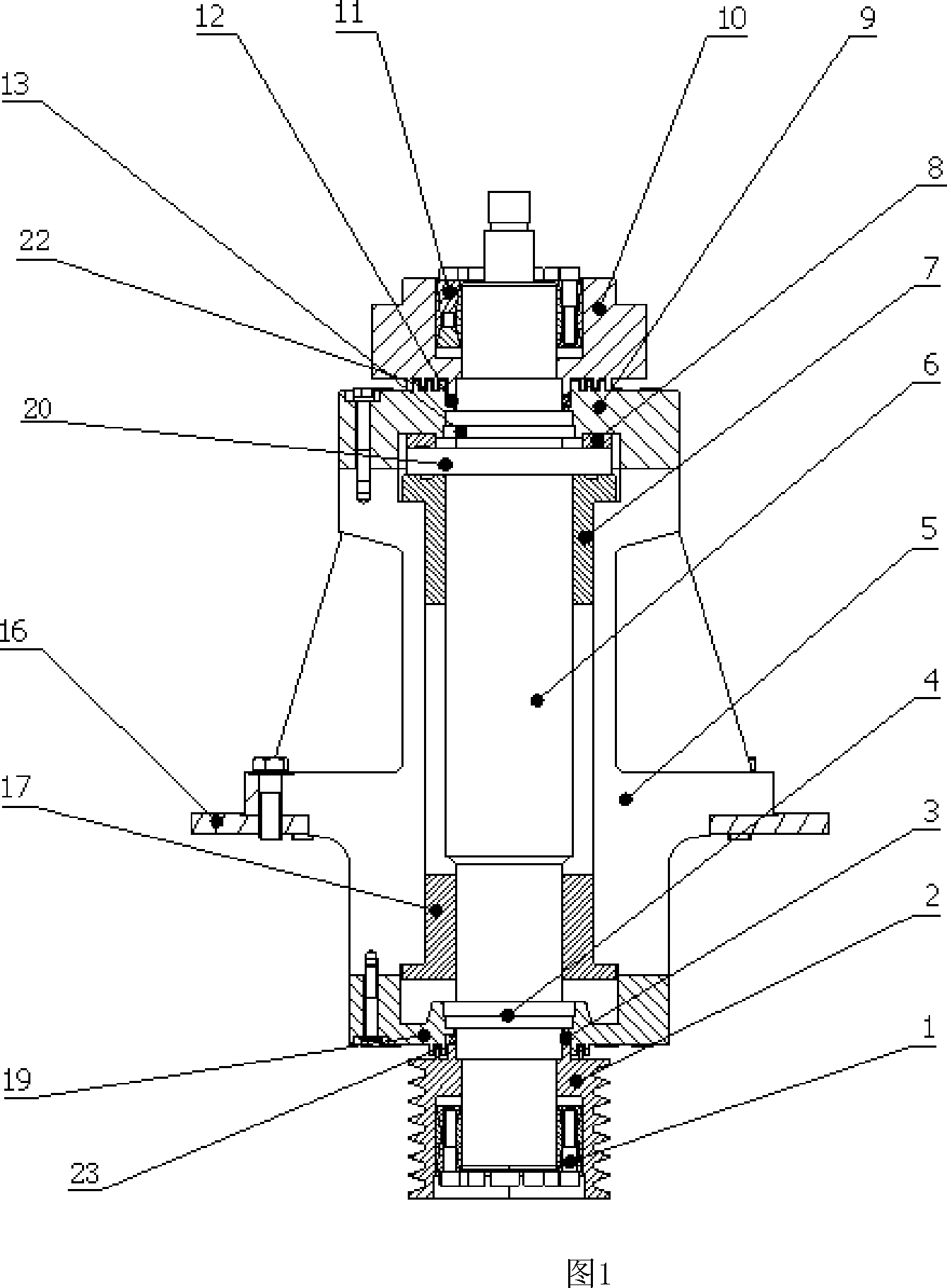

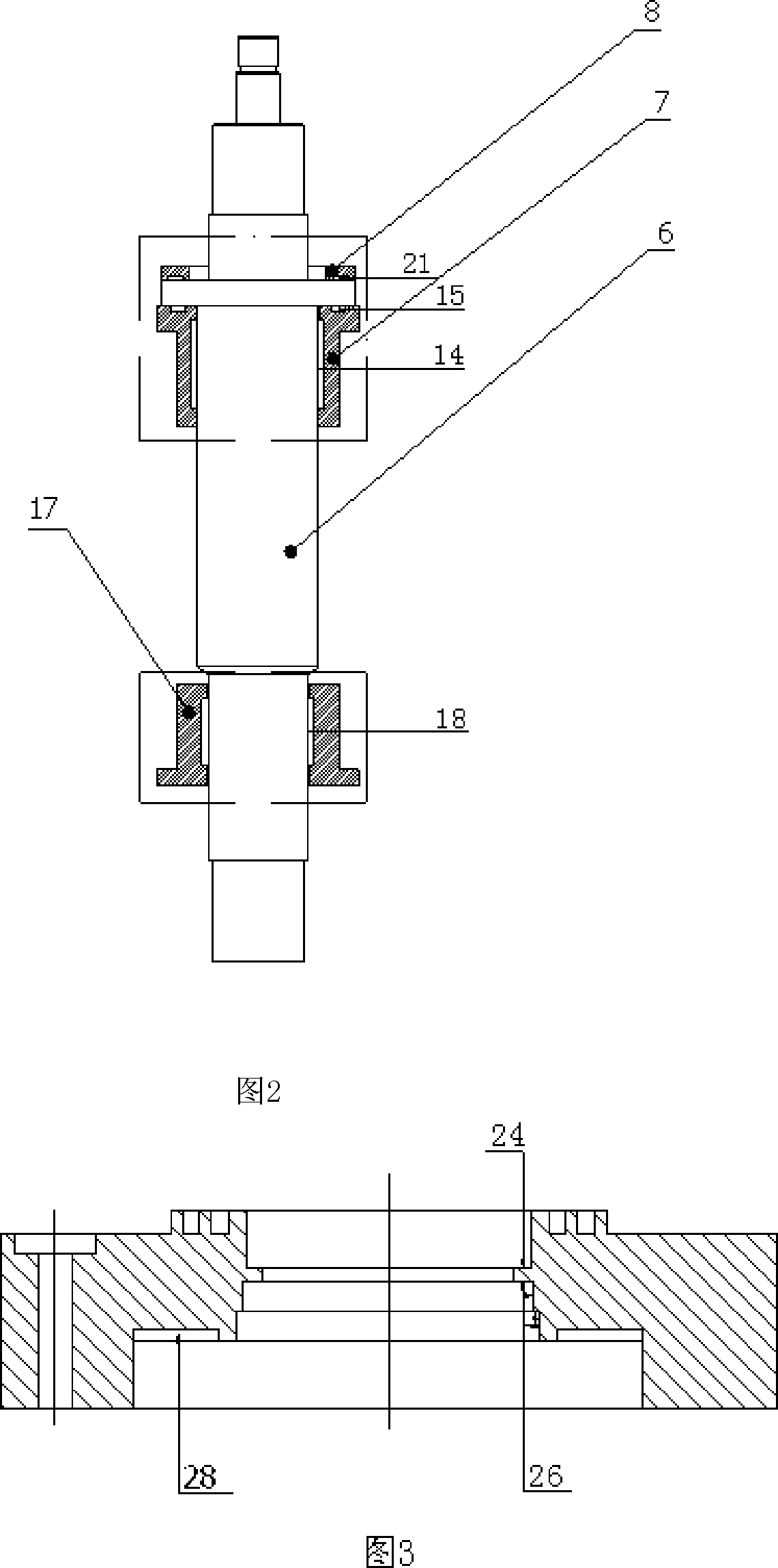

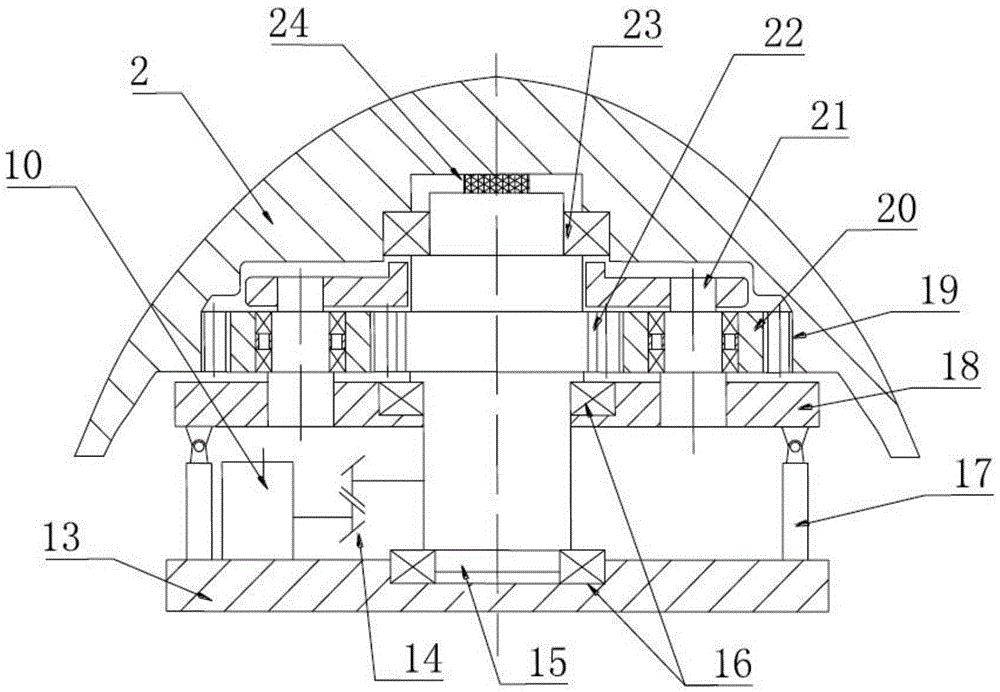

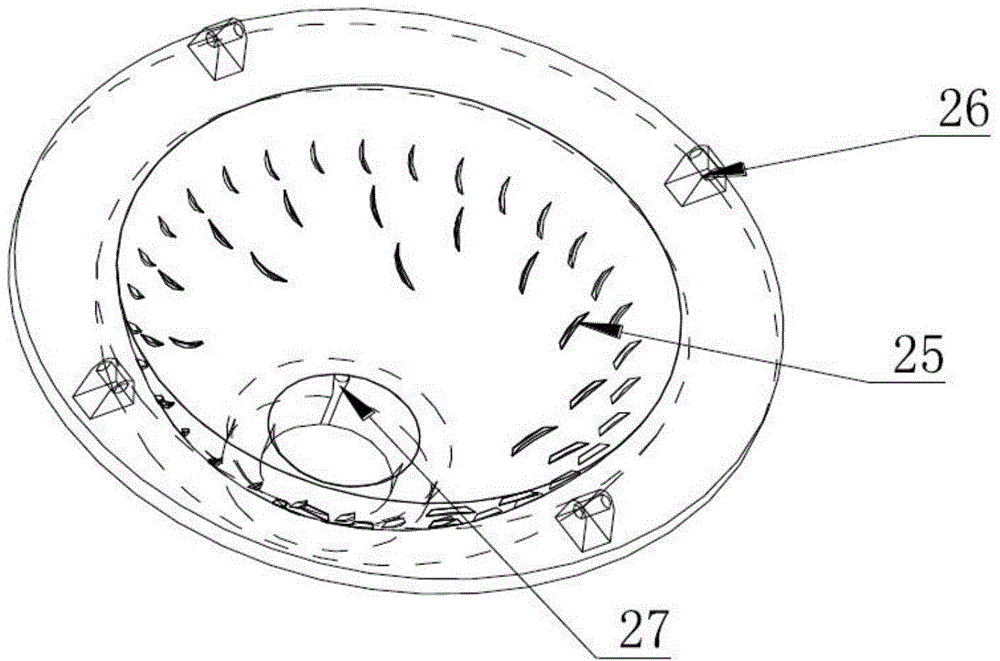

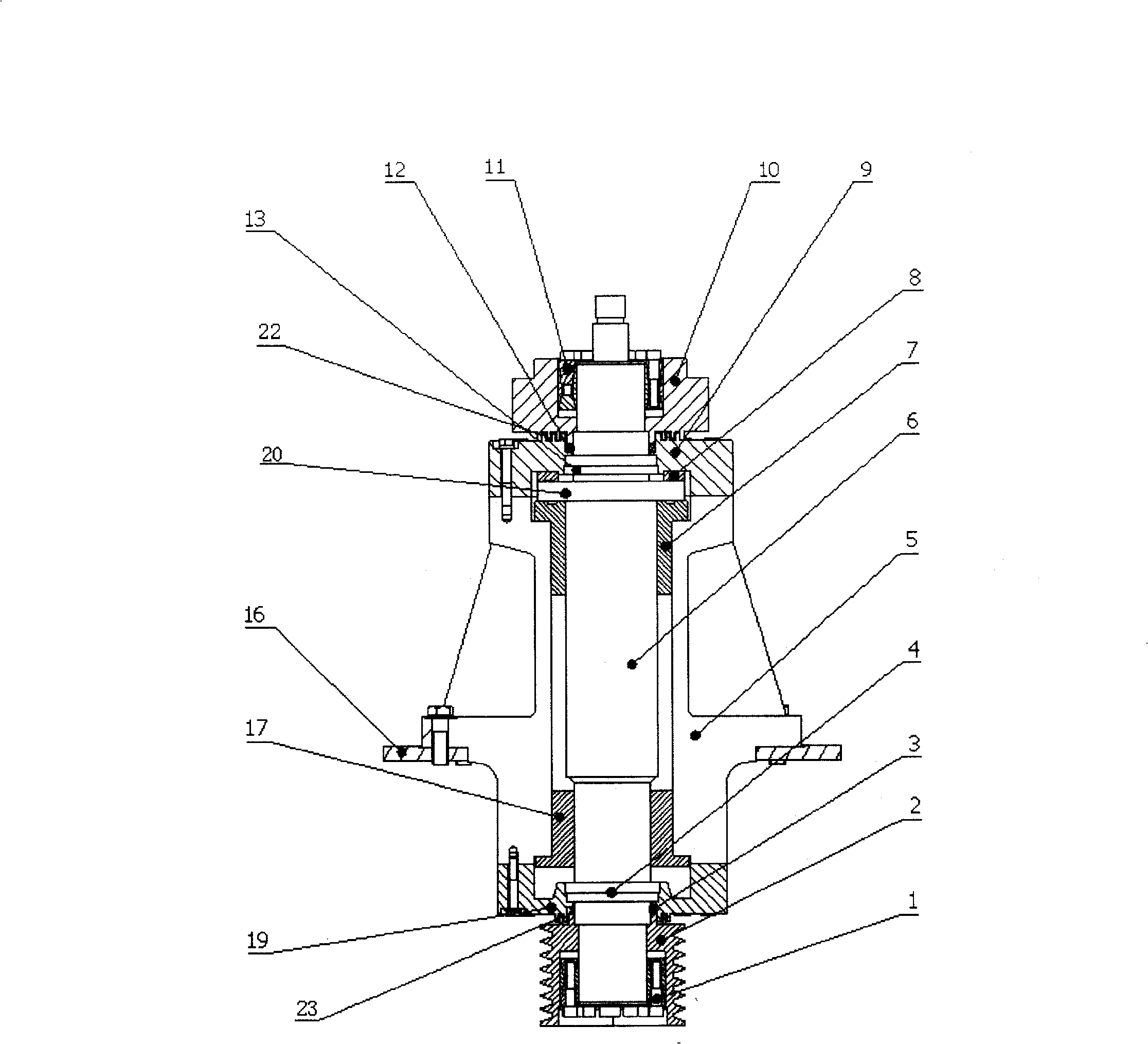

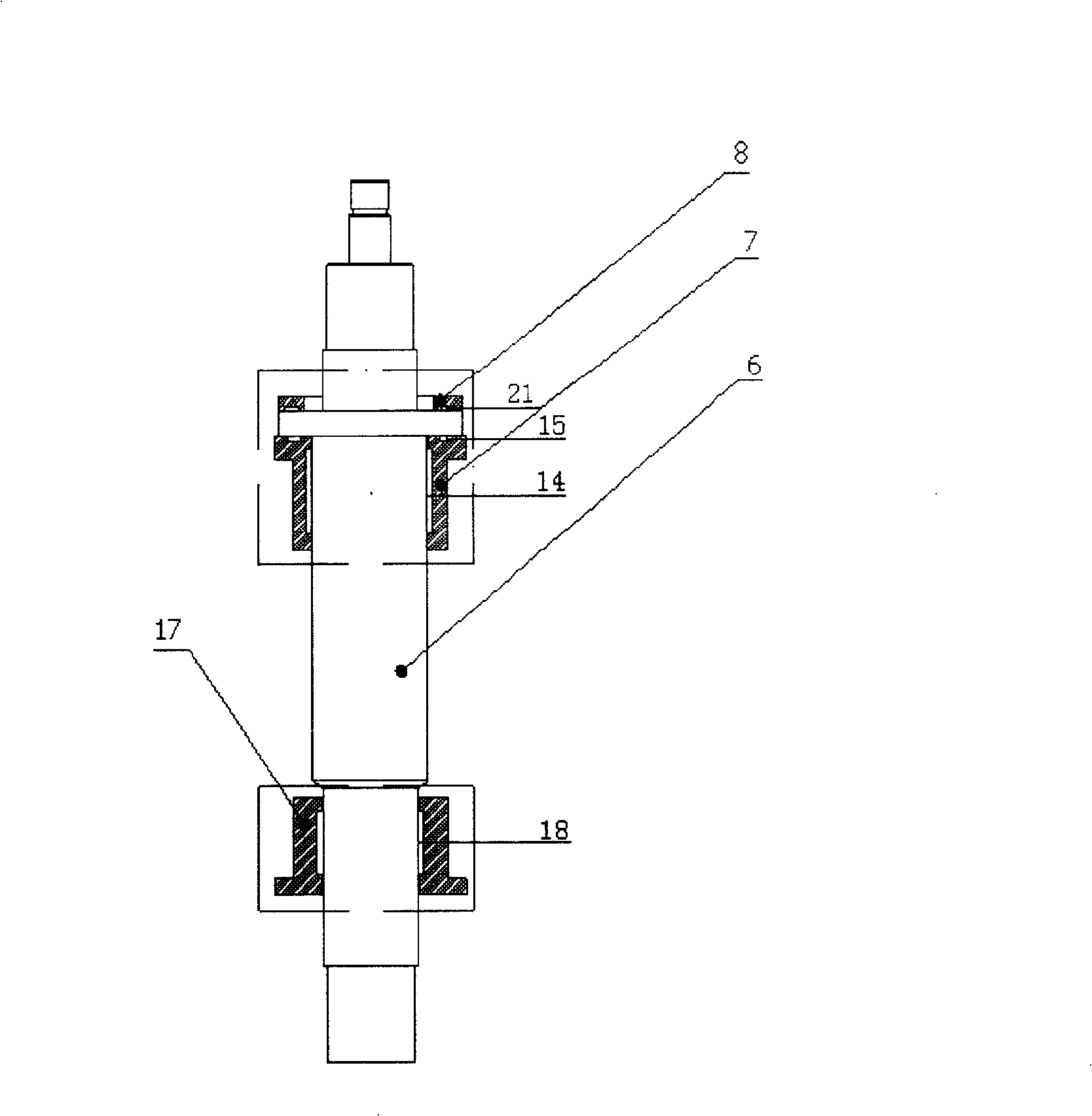

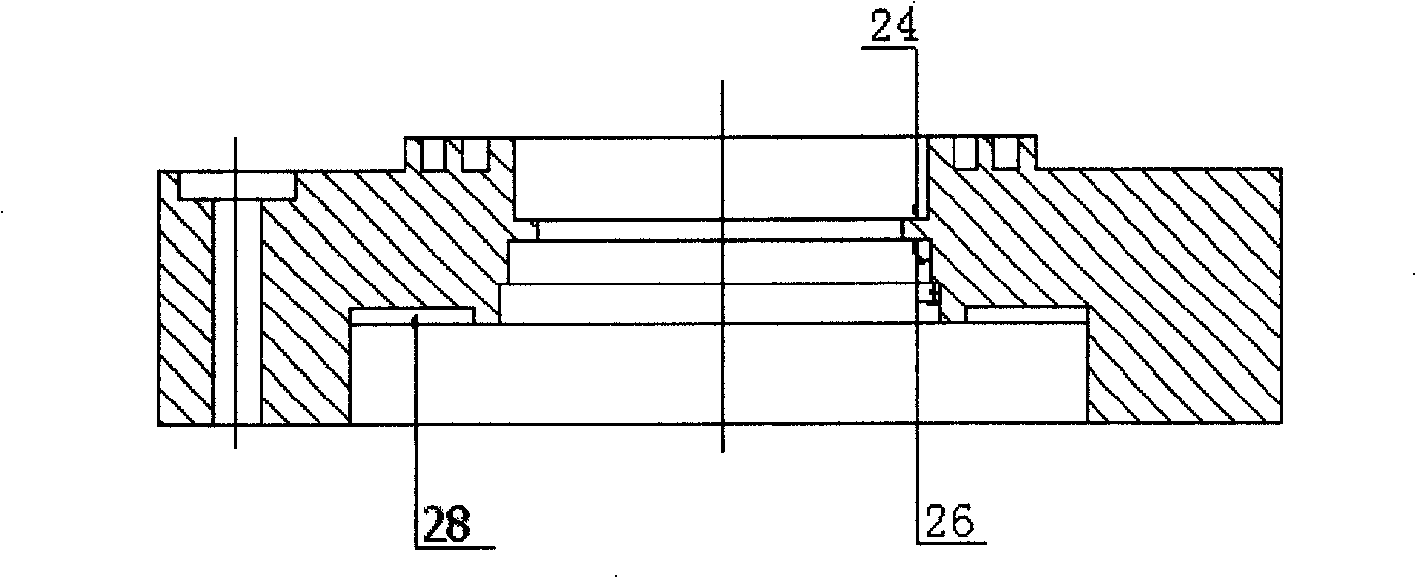

Vertical shaft support system of vertical shaft type impact crusher, and vertical shaft support device

InactiveCN101091932AImprove support conditionsImprove impact resistanceEngine sealsGrain treatmentsSupporting systemRolling-element bearing

The invention publishes a vertical shaft supporting system of the vertical spindle type crusher and its vertical shaft fulcrum arrangement, including the vertical shaft support abutment box body, the vertical shaft installs on the vertical shaft support abutment box body, in the upper extreme and the lower extremity of the vertical shaft support abutment box body separately connects the superior cover and the interior cover; liquid hydrostatic bearing which supports the vertical shaft all install on the support abutment box body and the bearing seat of the superior cover. The invention replaces the rolling bearing of the supporting vertical shaft in the existing vertical spindle type crusher by using the liquid hydrostatic bearing, and uses the characteristic of the liquid hydrostatic bearing to improve the supporting condition of the vertical shaft, thus enhances the rotor speed, the bearing life and to compatibility of the continuance random vibration of the vertical spindle type breaker.

Owner:贵州优利斯凯机械有限公司

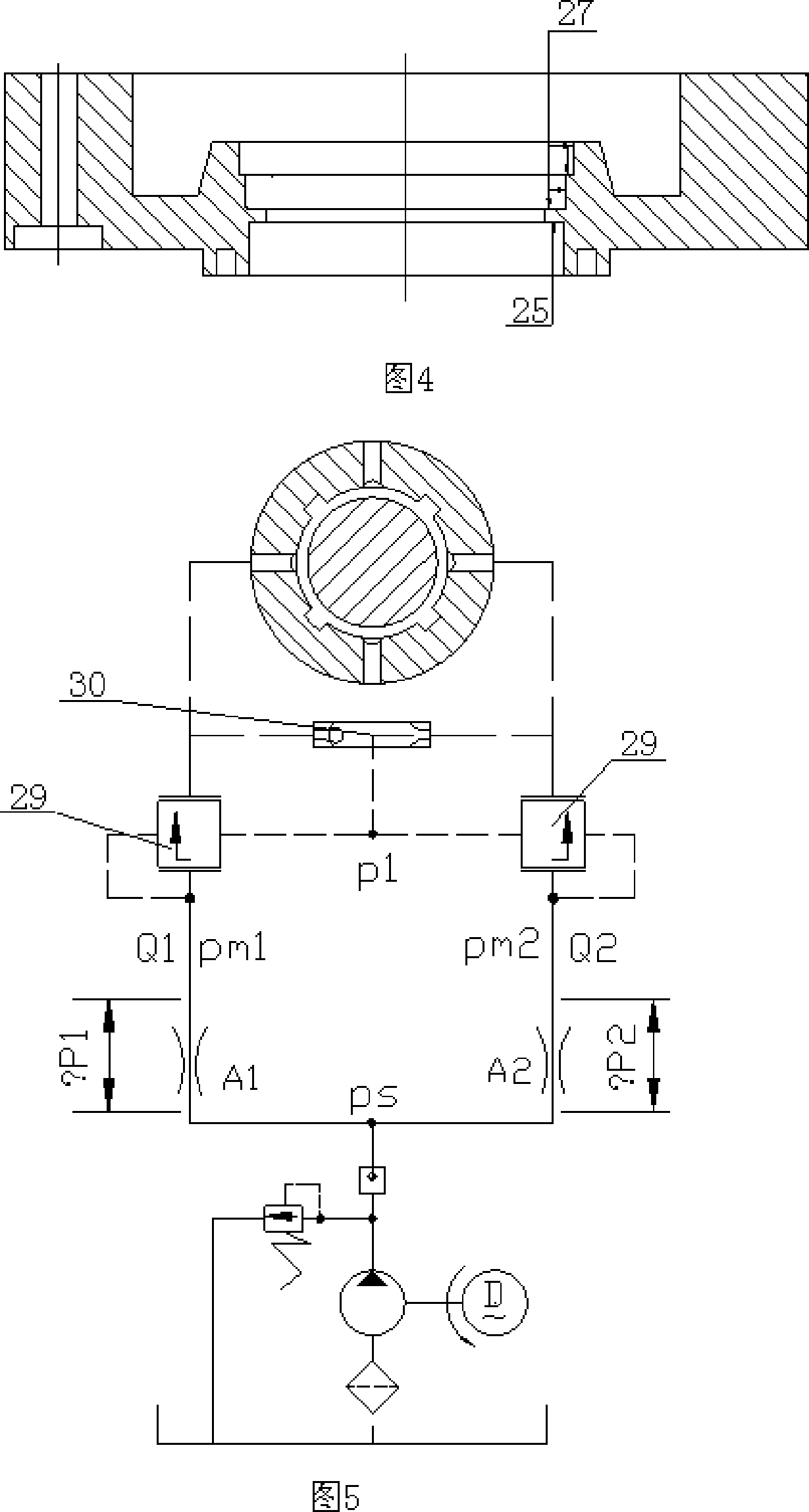

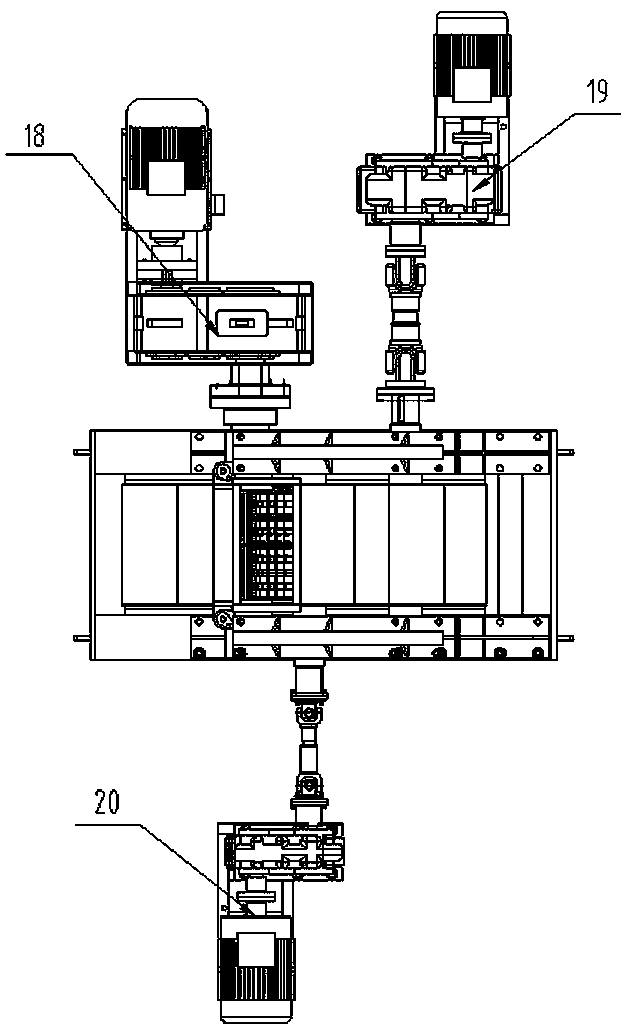

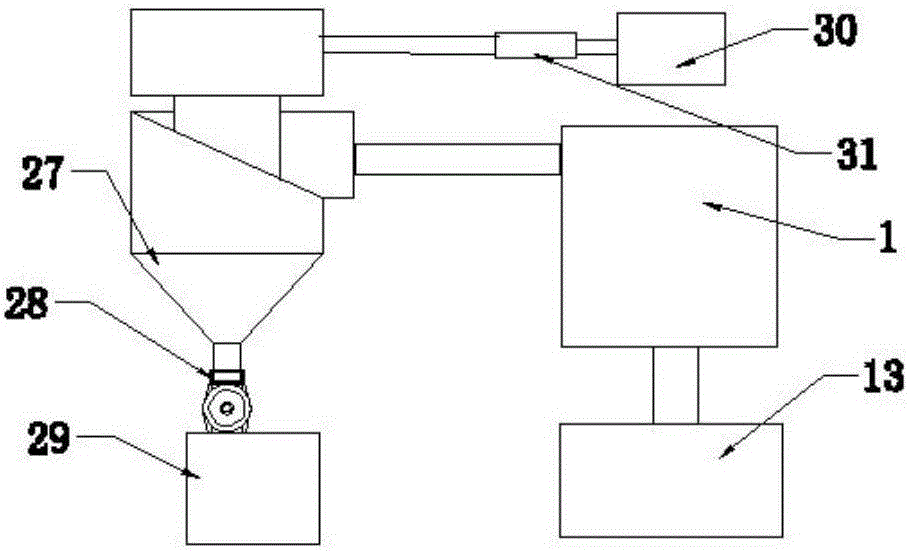

Efficient mineral processing technology achieved through cooperation of high-pressure grinding roller and magnetic field screening machine

InactiveCN105032582AEasy to handleFully dissociatedSolid separationGrain treatmentsOperational costsEconomic benefits

The invention discloses an efficient mineral processing technology achieved through cooperation of a high-pressure grinding roller and a magnetic field screening machine. The efficient mineral processing technology is scientific and simple in technological process and low in operating cost. The high-pressure grinding roller is high in reduction ration and small in product particle size, and therefore the iron mineral monomer separation degree is effectively improved during crushing operation, and the processing capacity of the grinding roller is greatly improved. For high-pressure roller fine fraction products, part of qualified iron core concentration where monomer separation is conducted is selected through the magnetic field screening machine, and therefore the excessive grinding amount and the grinding and separating operation ore quantity are effectively decreased, energy conservation and consumption reduction are achieved, and economic benefits are obvious.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

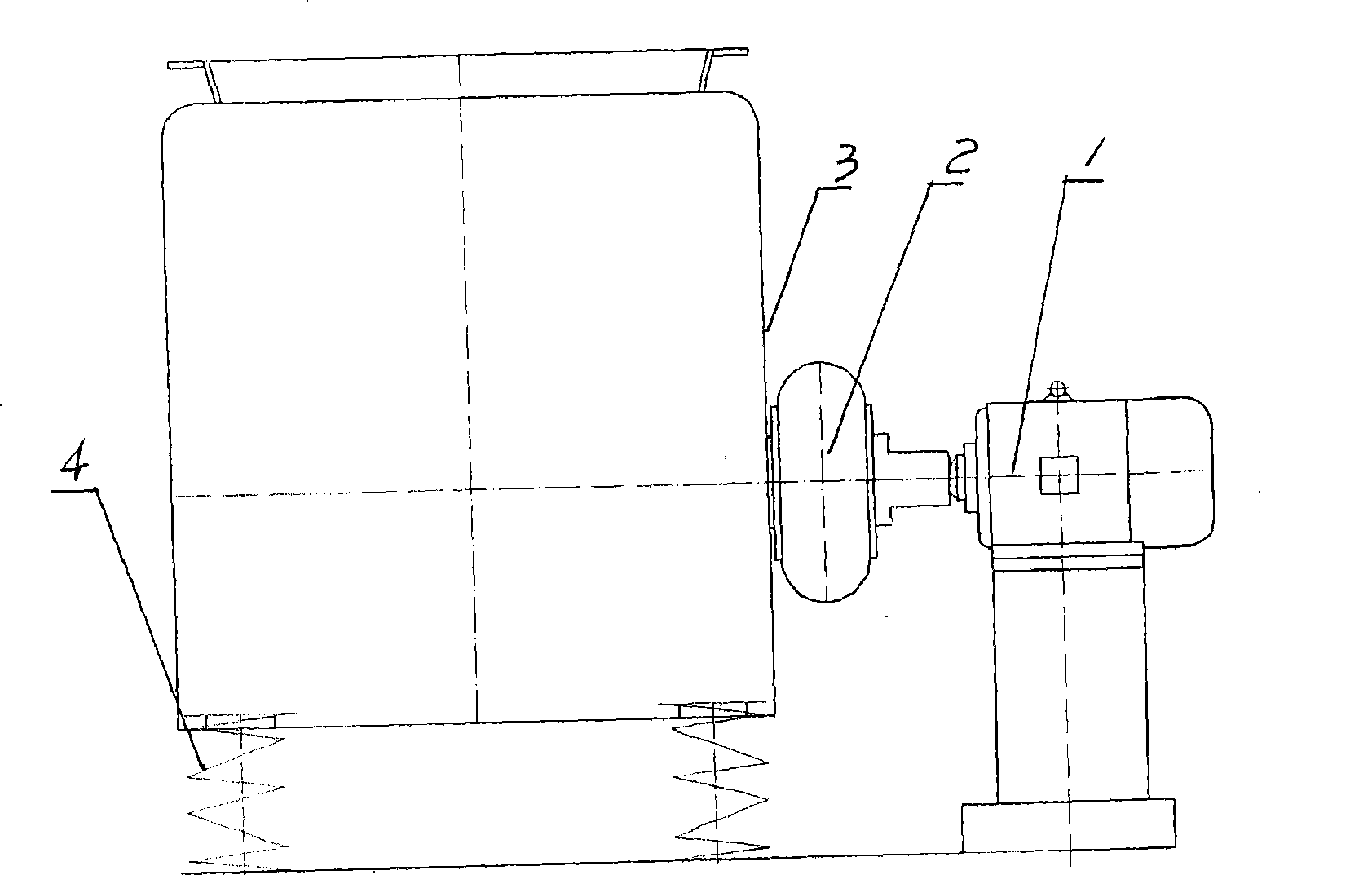

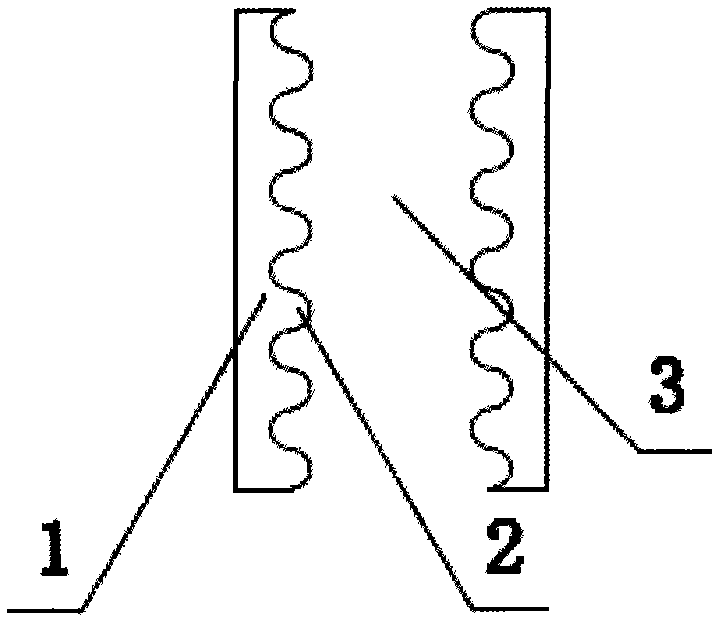

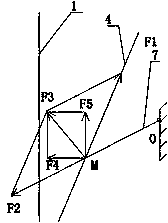

Double-plastid rectilinear vibration crusher

The invention discloses a dual-mass body linear vibration crusher, relating to a crusher. The invention aims at providing a dual-mass body linear vibration crusher which has high material crushing ratio and the parts of which are not easy to be damaged. The technical proposal is that the dual-mass body linear vibration crusher comprises a jaw plate and an exciter; the exciters which are arranged at the external sides of the left jaw plate and the right jaw plate are respectively driven by two normal motors; an upper rubber plate spring and a lower rubber plate spring are respectively arranged between the upper part and lower part of the shell of the exciter and the movable jaw; and a damping rubber spring is arranged between the machine body and a base. The dual-mass body linear vibration crusher is used for crushers.

Owner:王建喜

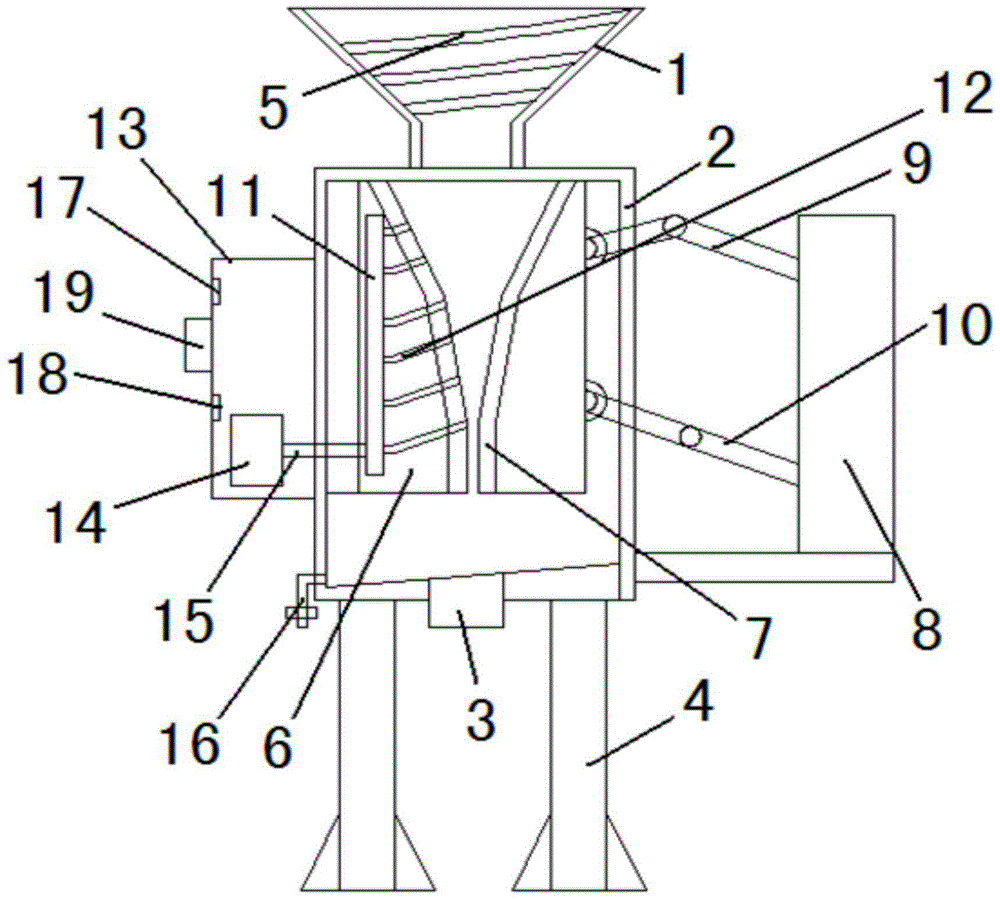

Self-dedusting type breaker

InactiveCN105170224AIncrease frictional resistanceExtension of timeGrain treatmentsBroken jawsCrusher

The invention relates to a self-dedusting type breaker. The self-dedusting type breaker comprises a feed hopper, a smashing chamber, an outlet hopper and a machine frame, wherein the feed hopper and the outlet hopper are arranged above and below the smashing chamber respectively, and a spiral feeding slideway is arranged inside the feed hopper; a fixed breaking jaw and a movable breaking jaw are arranged in the smashing chamber, the fixed breaking jaw is fixedly connected with the inner side wall of the smashing chamber, and a power device is arranged on the outer side of the smashing chamber; the movable breaking jaw is connected with the power device through an upper transmission mechanism and a lower transmission mechanism, a main water spraying pipeline and a plurality of branch water spraying pipelines are arranged in the fixed breaking jaw, and the branch water spraying pipelines are all communicated with the main water spraying pipeline; a water tank is arranged on the outer side of the portion, where the fixed breaking jaw is located, of the smashing chamber, and a water supplying pump in the water tank is communicated with the main water spraying pipeline through a water supply pipe.

Owner:灌阳县鸿运矿山设备有限公司

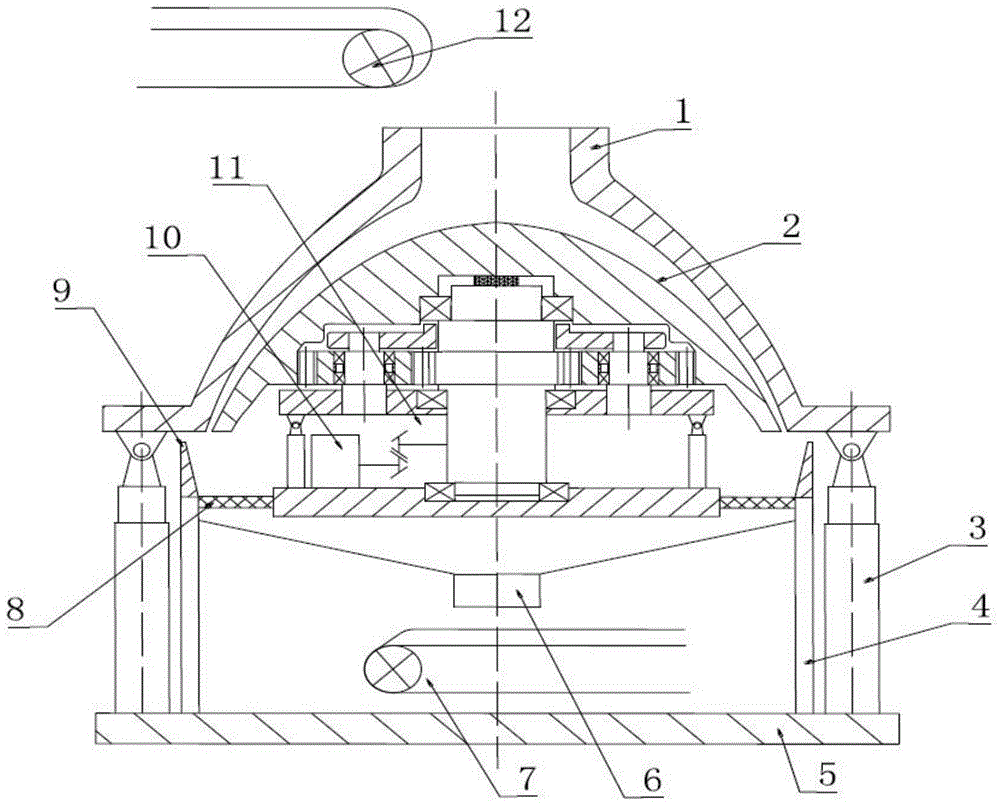

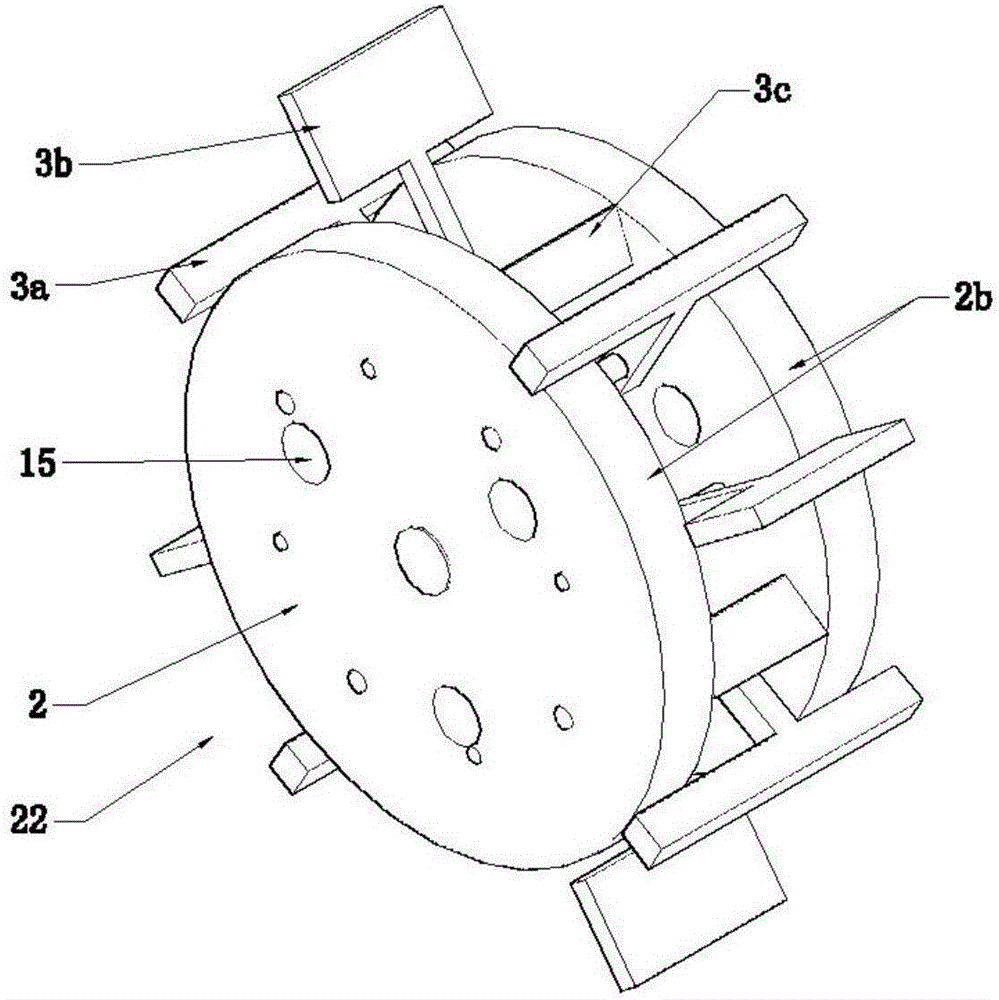

Method and equipment for simultaneously crushing and grinding ores

The invention discloses a method and equipment for simultaneously crushing and grinding ores. The method includes overlaying an upper arc-shaped grinding face on a lower arc-shaped grinding face, forming spatial regions which are gradually diminished from top to bottom between the inner surface of the upper arc-shaped grinding face and the outer surface of the lower arc-shaped grinding face, dividing the spatial regions into crushing regions and grinding regions from top to bottom, respectively arranging cutting teeth and fixing teeth on the inner surface of the upper arc-shaped grinding face and the outer surface of the lower arc-shaped grinding face in the crushing regions and arranging smooth arc faces on the outer surfaces of the upper arc-shaped grinding face and the lower arc-shaped grinding face in the grinding regions; enabling the upper arc-shaped grinding face and the lower arc-shaped grinding face to rotate relatively, feeding the ores into the crushing regions from a feed inlet in the top of the upper arc-shaped grinding face, fixing the ores by the aid of the fixing teeth, crushing the ores by the cutting teeth, enabling the crushed ores to fall into the grinding regions, grinding the ores by the smooth arc faces and enabling grains of the ores to fall via gaps at the lower ends of the upper arc-shaped grinding face and the lower arc-shaped grinding face. The method and the equipment have the advantages that the traditional crushers and ore grinding machines can be replaced, the ores can be crushed at first and then can be ground and integrally manufactured, and the equipment is high in crushing ratio.

Owner:CHINA UNIV OF MINING & TECH

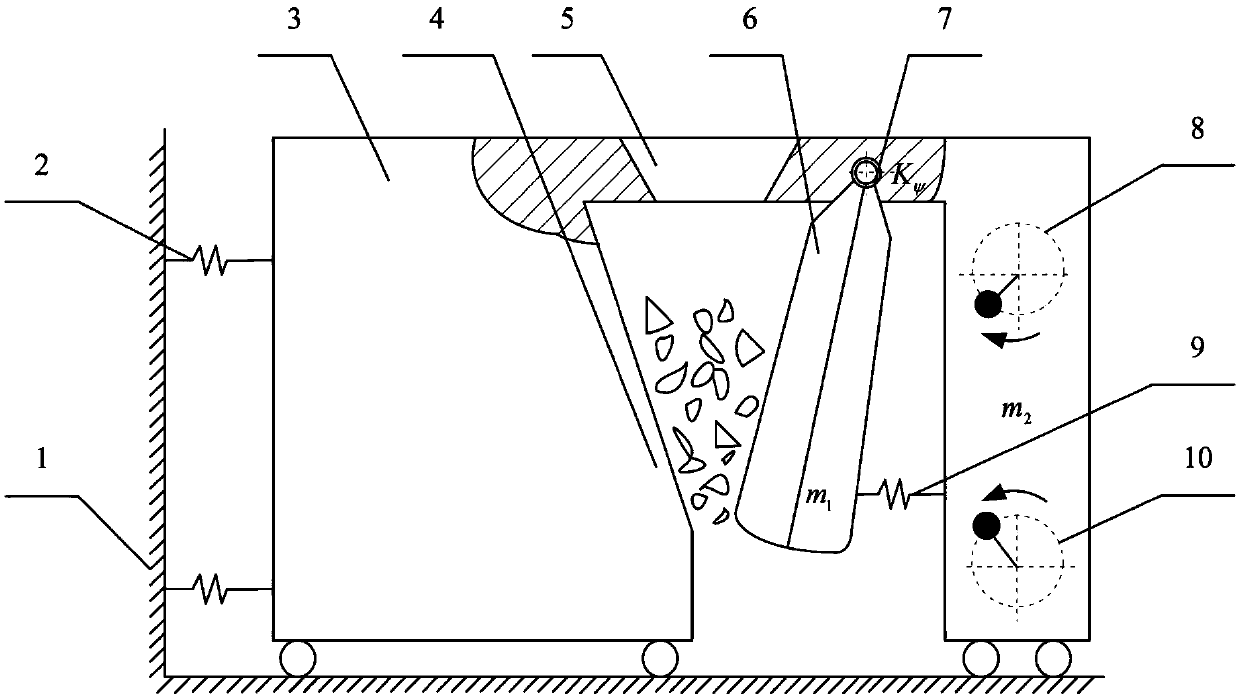

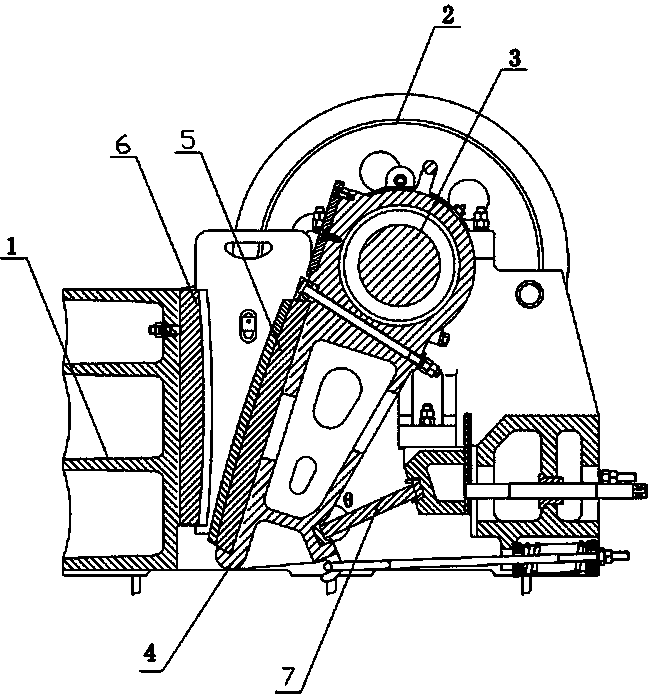

Dual-drive single pendulum type sub-resonance vibration crushing machine

InactiveCN109622176ASynchronized and stable operationStable jobGrain treatmentsPhase differenceCrushed stone

The invention belongs to the field of self-synchronous vibration machinery, and discloses a dual-drive single pendulum type sub-resonance vibration crushing machine. The dual-drive single pendulum type sub-resonance vibration crushing machine includes a machine frame, vibrate-isolation springs, a box body mechanism, a torsion spring, a movable jaw, a fixed jaw, vibration exciters and a master vibration spring. Two eccentric blocks synchronously operate and the phase difference can be stabilized around at 0 degrees when the two vibration exciters symmetrically installed up and down in the box body mechanism works, two alternating current motors drive the eccentric blocks to run in reverse so that force components, in the vertical direction, of generated inertia forces cancel out each other,and the force components, in the horizontal direction, of the generated inertia forces are superimposed each other so as to drive the movable jaw to realize the self-synchronous relative swing, mutual extrusion forces are formed by the movable jaw and a static jaw to achieve the purpose of crushing stones. According to the dual-drive single pendulum type sub-resonance vibration crushing machine,the self-synchronization principle of the sub-resonance double-vibration-exciter, the resonance principle and the double-mass-body vibration principle are combined to realize energy saving of the crushing machine; and by using the double-mass-body vibration principle, the crushing machine has the advantages of large amplitude, large processing capacity, sensitive response to changes in feeding, stable operation and the like.

Owner:NORTHEASTERN UNIV

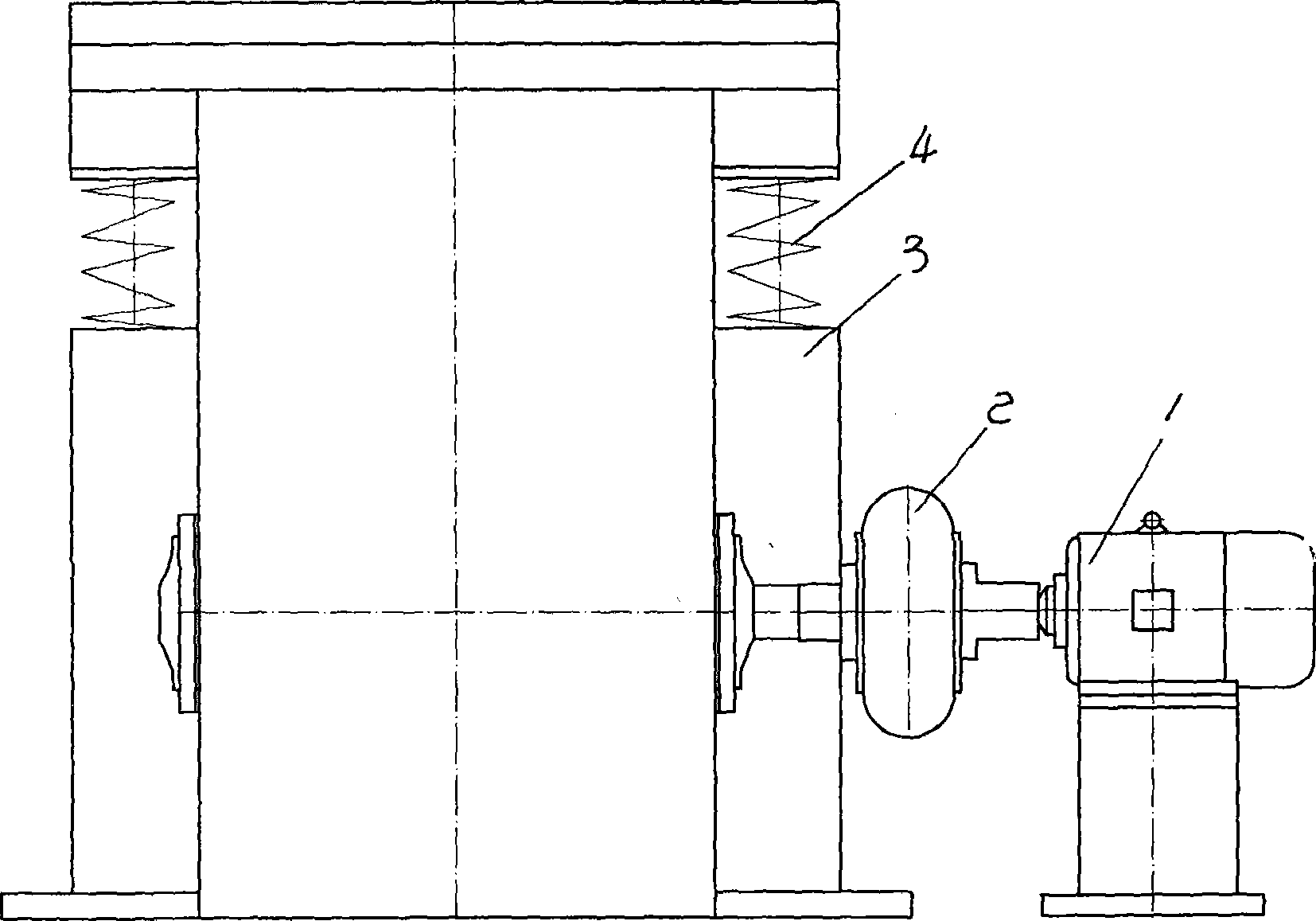

Single-plastid vibration crusher

InactiveCN101417252AIncrease crushing ratioSolution to short lifeNon-rotating vibration suppressionGrain treatmentsLow noiseEngineering

The invention discloses an elemental body vibration crusher, relating to a crusher. The invention aims at providing the elemental body vibration crusher which has high material crushing ratio, long service life and low noise. The technical proposal is that the elemental body vibration crusher comprises a motor and a jaw plate; a spring is respectively arranged between the left jaw plate and the right jaw plate and the exciter; the upper end of the jaw plate is pivotally connected with the machine body; the motor is connected with the exciter by a flexible coupler; a damping spring is arranged between the exciter and the upper part of the machine body; and the elemental body vibration crusher is used for crushers.

Owner:王建喜

Single-plastid rectilinear vibration crusher

InactiveCN101417250AIncrease crushing ratioExtended service lifeNon-rotating vibration suppressionGrain treatmentsLow noiseEngineering

The invention discloses an elemental body vibration crusher, relating to a crusher. The invention aims at providing the elemental body vibration crusher which has high material crushing ratio, long service life and low noise. The technical proposal is that the elemental body vibration crusher comprises a motor, a jaw plate and an exciter; the external sides of the left jaw plate and the right jaw plate are respectively provided with a pair of exciters; the upper ends of the left movable jaw plate and the right movable jaw plate are respectively provided with an eccentric shaft which is pivotally connected with a machine body; and a rubber plate spring is obliquely arranged between the lower end of the jaw plate and the machine body. The elemental body vibration crusher is used for crushers.

Owner:王建喜

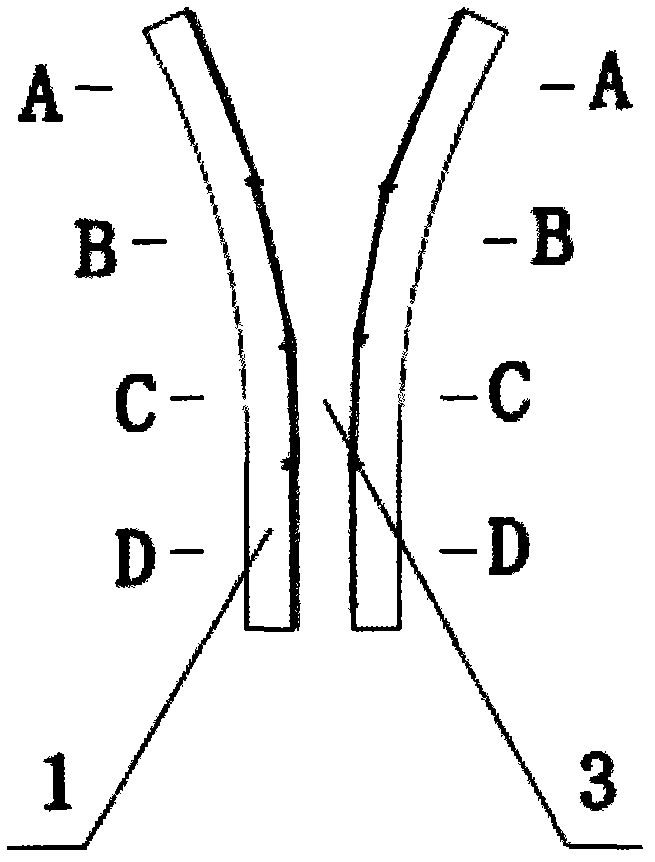

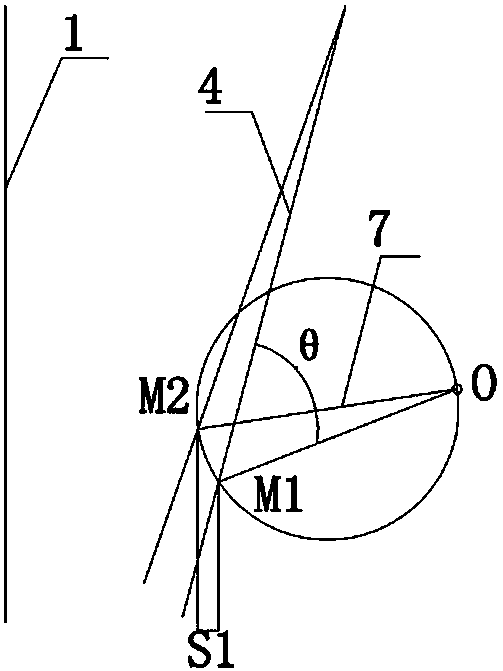

Crushing pair with superfine crushing function and implementation method of superfine crushing function thereof

The invention discloses a crushing pair with a superfine crushing function and an implementation method of a superfine crushing function thereof. The crushing pair comprises two jaw plates which are oppositely arranged to form an at least two-level step structure type crushing cavity, wherein the step structure type crushing cavity formed by the opposite working surfaces of the two jaw plates is gradually reduced step by step from top to bottom and forms an angle-step type structure, and the working surfaces of the two jaw plates of the final-level crushing cavity at the lower end in the step structure type crushing cavity are of a long and narrow structure. The remarkable functional characteristic of the crushing pair disclosed by the invention is to realize a supernormal and superfine crushing function. By improving the matched crusher structure, single-machine direct crushing for sand production and even crushing for powder production can be realized.

Owner:义乌市凌丰知识产权服务有限公司

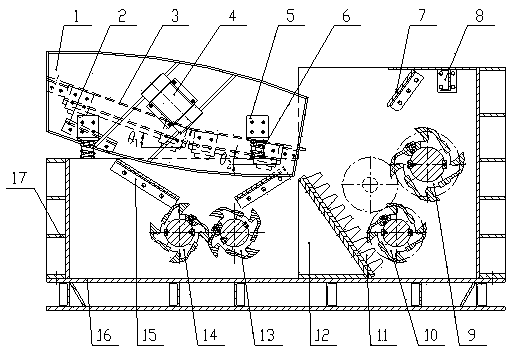

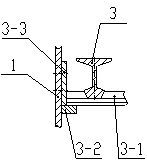

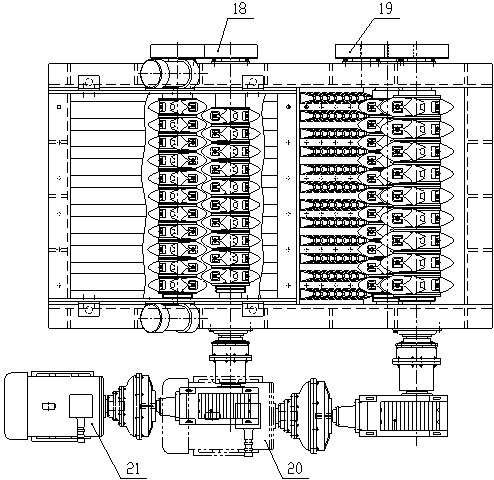

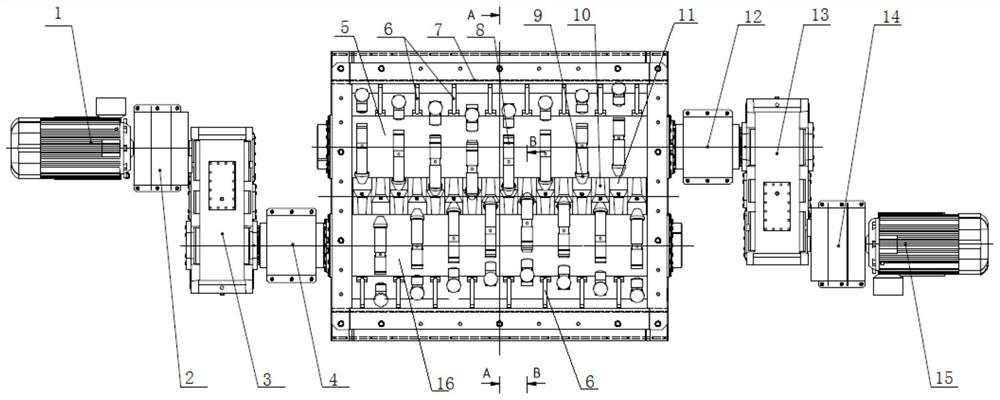

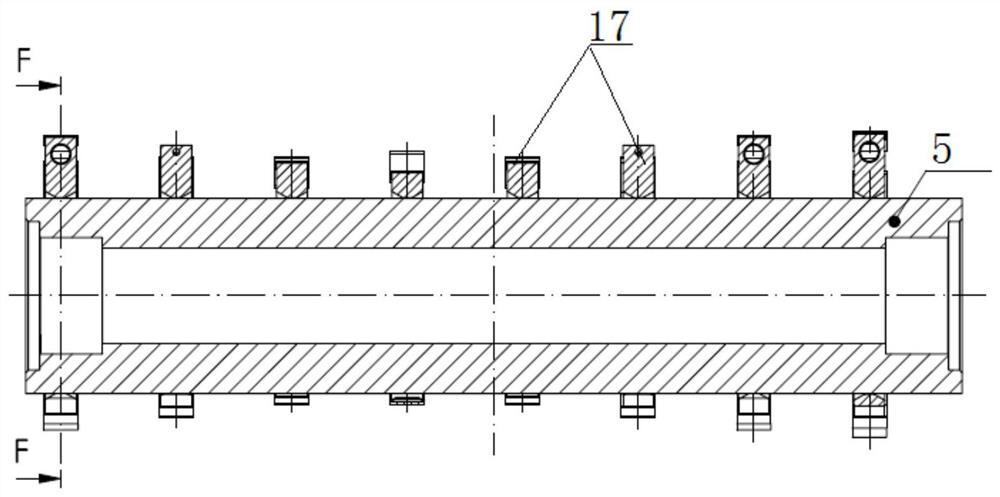

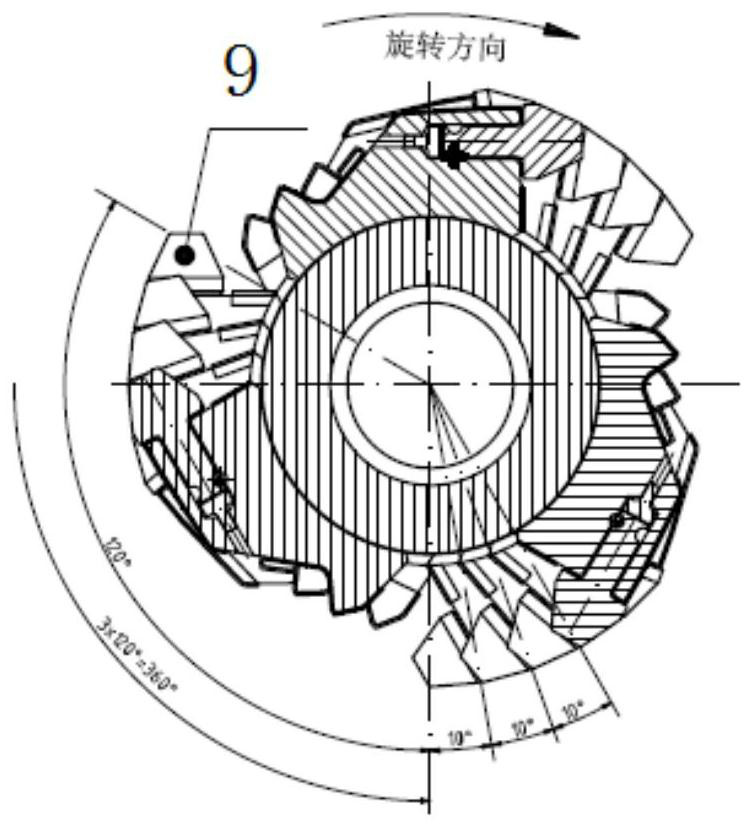

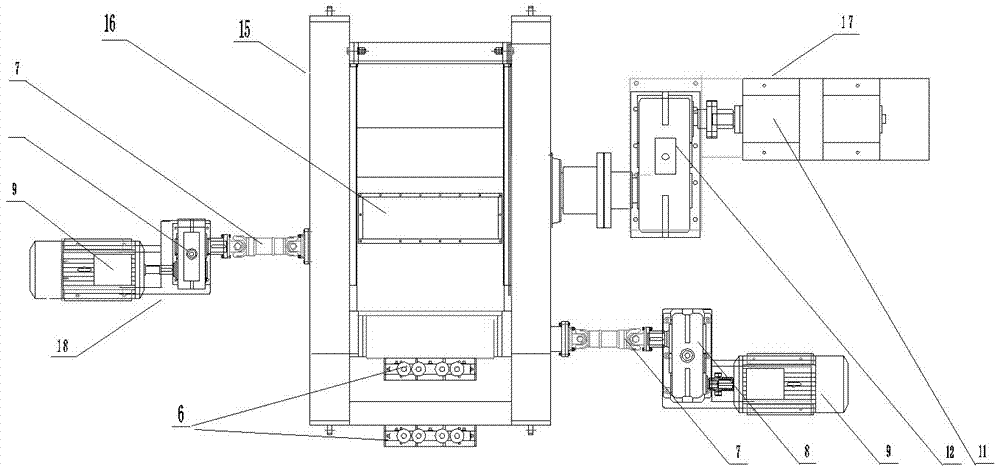

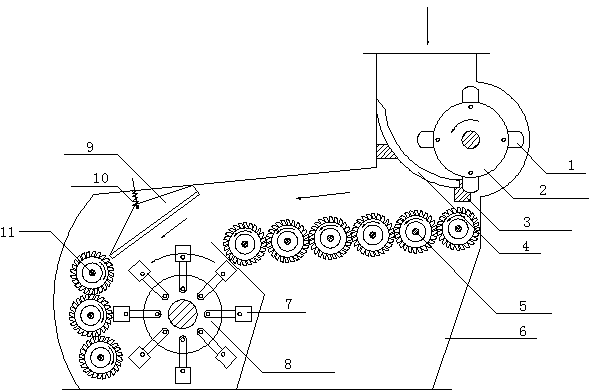

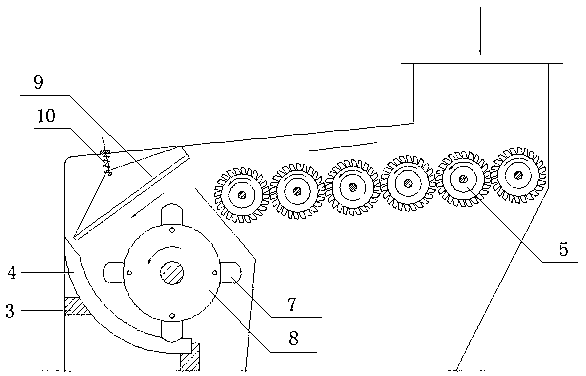

Mining differential high-crushing-ratio four-roller tooth-type crusher

The invention discloses a mining differential high-crushing-ratio four-roller tooth-type crusher. The mining differential high-crushing-ratio four-roller tooth-type crusher comprises a one-stage crushing cavity, a two-stage crushing cavity and a linear vibration equal-thickness lattice bar screening device; materials enter the linear vibration equal-thickness lattice bar screening device from a material charge end to be subjected to equal-thickness screening; small materials falling off to the first-stage crushing cavity are shorn and crushed by a pair of small drive pin roll (13) and small driven pin roll (14) which perform opposite differential motion; large materials are rapidly conveyed to the second-stage crushing cavity under the effect of vibration force and are subjected to multi-stage crushing under the comprehensive effect of a large drive pin roll (9) and a small driven pin roll (10) which are arranged up and down and perform same-direction differential motion as well as a tooth plate (11). The mining differential high-crushing-ratio four-roller tooth-type crusher has the characteristics of high crushing ratio, high working efficiency, large processing capability, high reliability, low energy consumption, no blocking, capability of preventing excessive crushing of materials and the like.

Owner:中国矿业大学盱眙矿山装备与材料研发中心

Cone crusher

The invention relates to the technical field of ore crushing, in particular to a cone crusher. The cone crusher comprises a movable cone. A stationary cone is arranged outside the movable cone. An eccentric shaft sleeve is sleeved with the movable cone and connected with a motor through a transmission device. The movable cone comprises a movable cone body; at least one groove is formed in the outer surface of the movable cone body; an extensible grinding bar is arranged at the bottom of each groove; a grinding pressure plate is arranged at one end of each extensible grinding bar; the other end of each extensible grinding bar is connected with a drive motor located in the movable cone body; and a plurality of grinding grains used for grinding ore are arranged on the outer side face and the inner side face of each grinding pressure plate correspondingly. According to the cone crusher, the movable cone body is provided with the at least one groove and the grinding pressure plates which are matched with the grooves and have an extensible function; while the crusher is used for crushing the ore, the grinding pressure plates can be used for conducting secondary grinding on the preliminarily crushed ore, the crushed ore is made smaller, and the crushing ratio of the whole crusher is higher.

Owner:CHENGDU DAHONGLI MACHINERY

Structurally improved single-section hammer type screening crusher

Owner:SINOMA CHANGSHU HEAVY MACHINERY

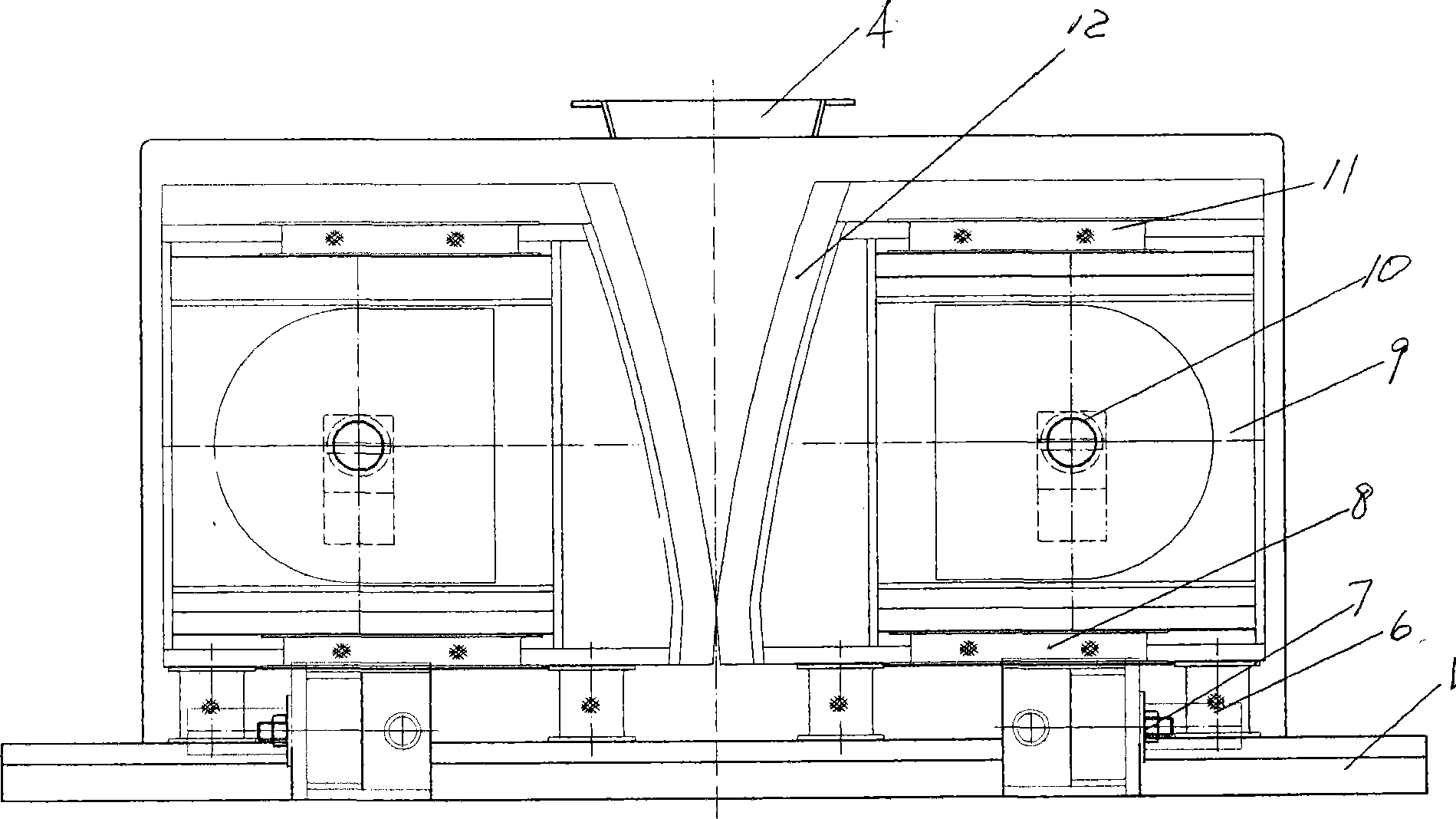

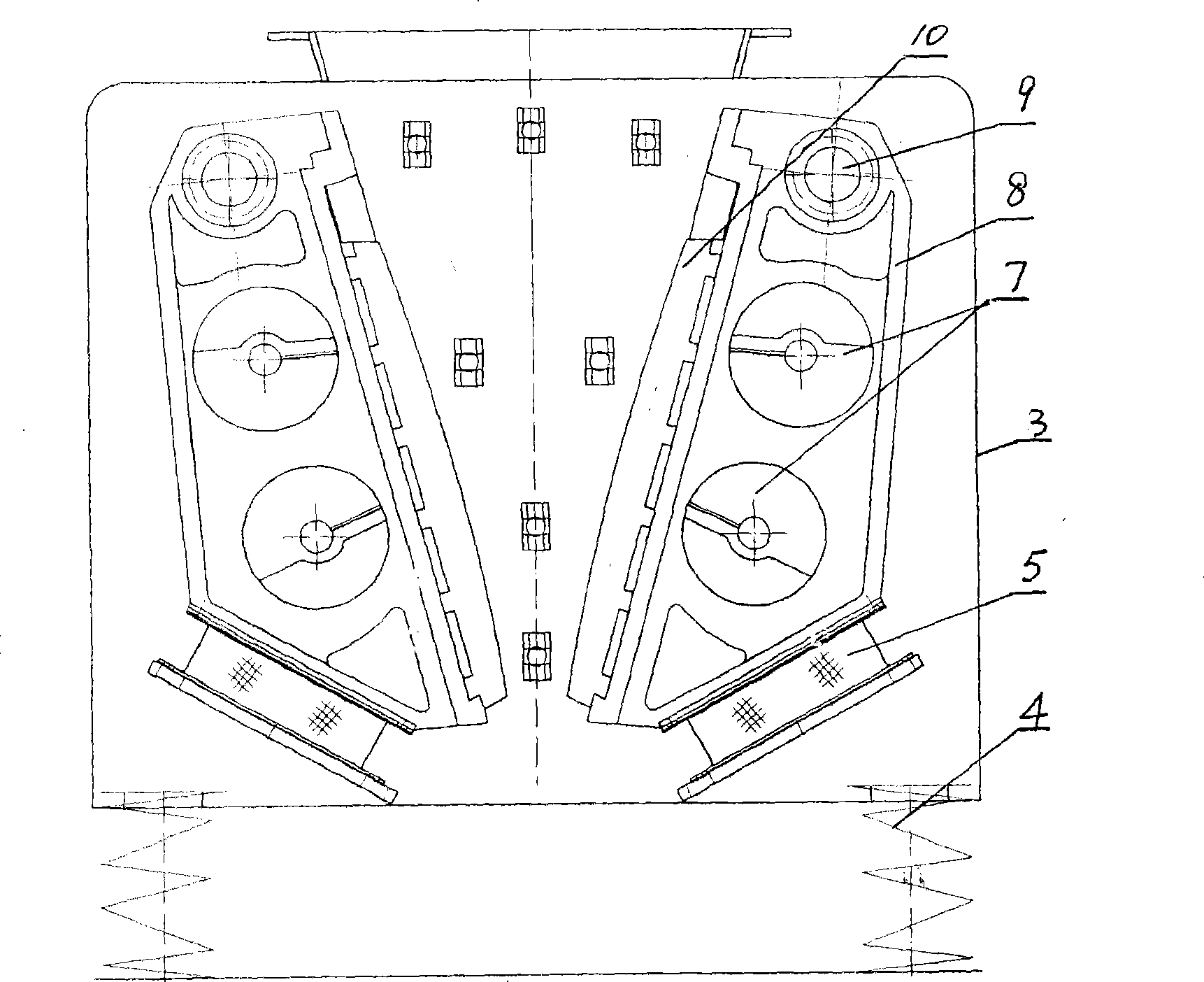

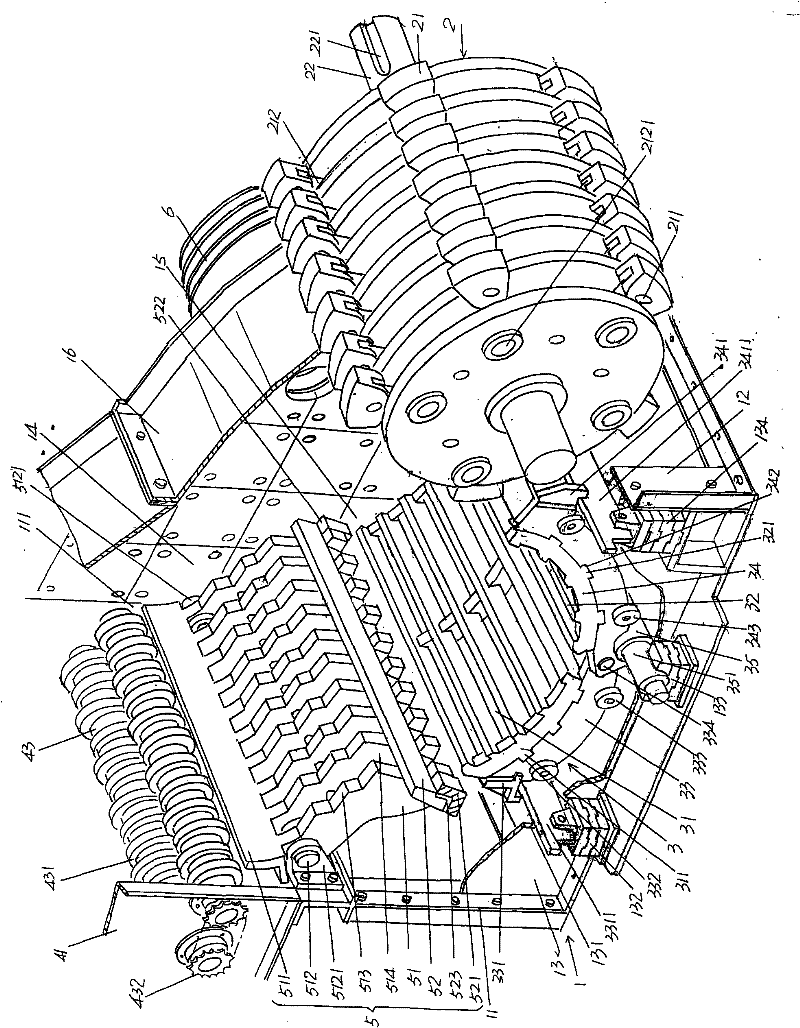

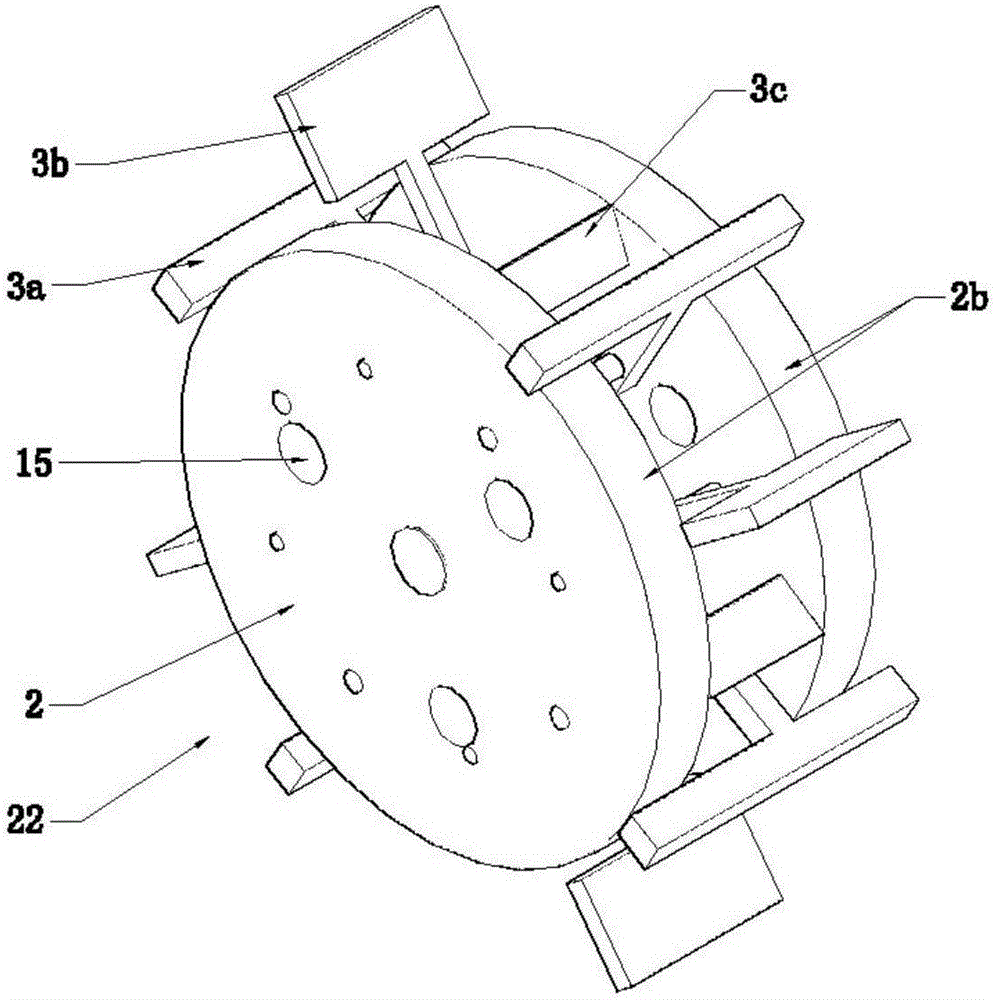

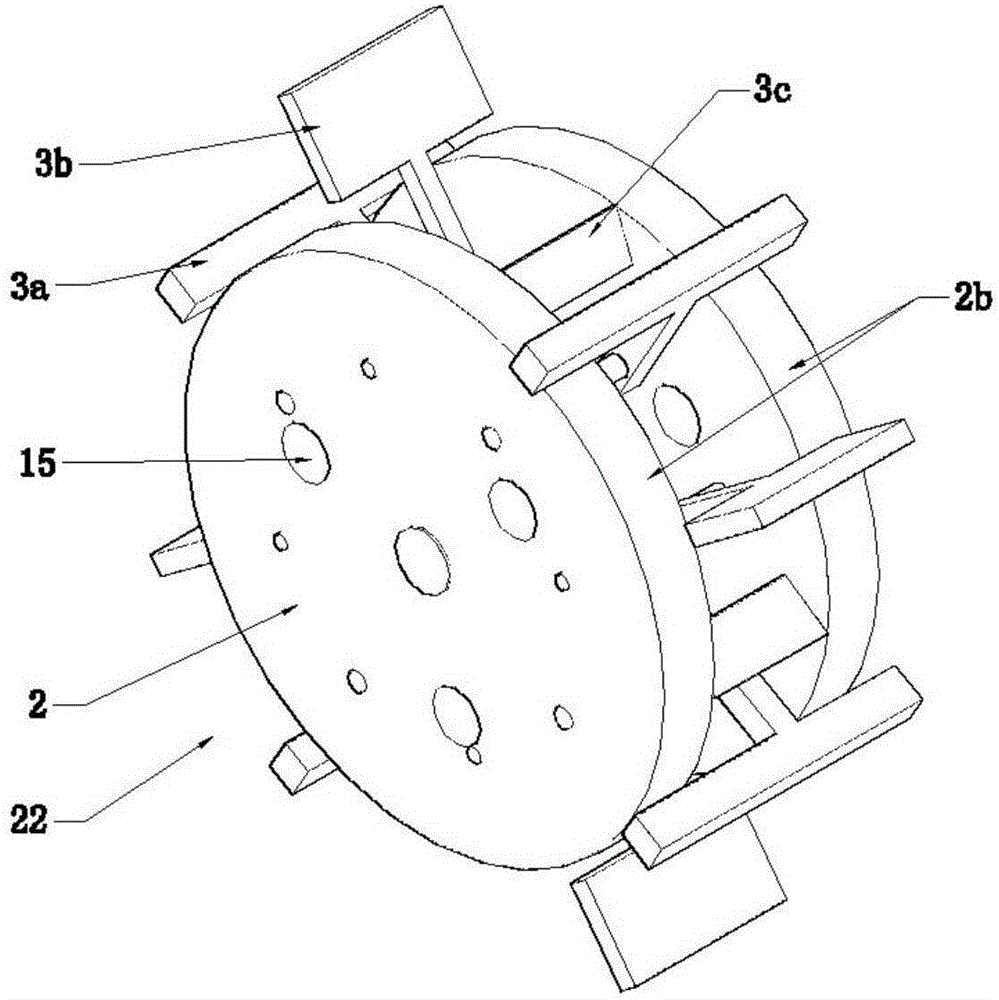

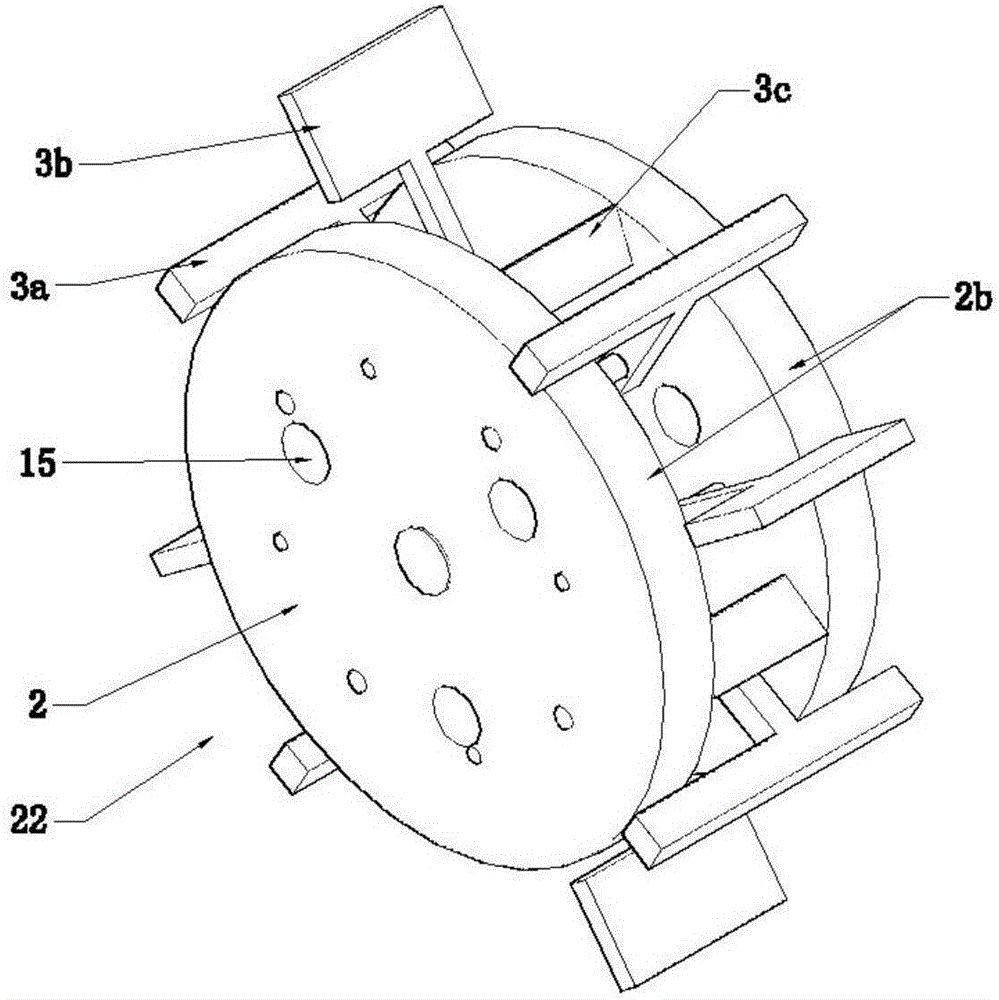

Jaw crusher with double shafts and double crank and rocker mechanisms

The invention discloses a jaw crusher with double shafts and double crank and rocker mechanisms. The jaw crusher comprises a rack, a fixed jaw plate, a movable jaw plate, a front crank and rocker mechanism, a rear crank and rocker mechanism and transmission wheels, wherein the front crank and rocker mechanism comprises a front movable jaw, a front knee plate and a front eccentric driving shaft; the rear crank and rocker mechanism comprises a rear movable jaw, a rear knee plate and a rear eccentric driving shaft; the front and rear jaw plates are respectively pivoted on the front and rear eccentric driving shafts; the front and rear eccentric driving shafts are respectively connected with the transmission wheels; one end of the front knee plate is pivoted below the rear side of the front movable jaw, and the other end of the front knee plate is pivoted below the front side of the rear movable jaw; one end of the rear knee plate is pivoted below the rear side of the rear movable jaw, and the other end of the front knee plate is pivoted on the rack; and the movable jaw plate is fixedly connected to the front movable jaw and faces the fixed jaw plate to form a crushing cavity. The jaw crusher has the advantages that: the function of the lower horizontal motion travel of the movable jaw is improved from material discharge to crushing, so crusher equipment has a secondary-crushing effect.

Owner:义乌市凌丰知识产权服务有限公司

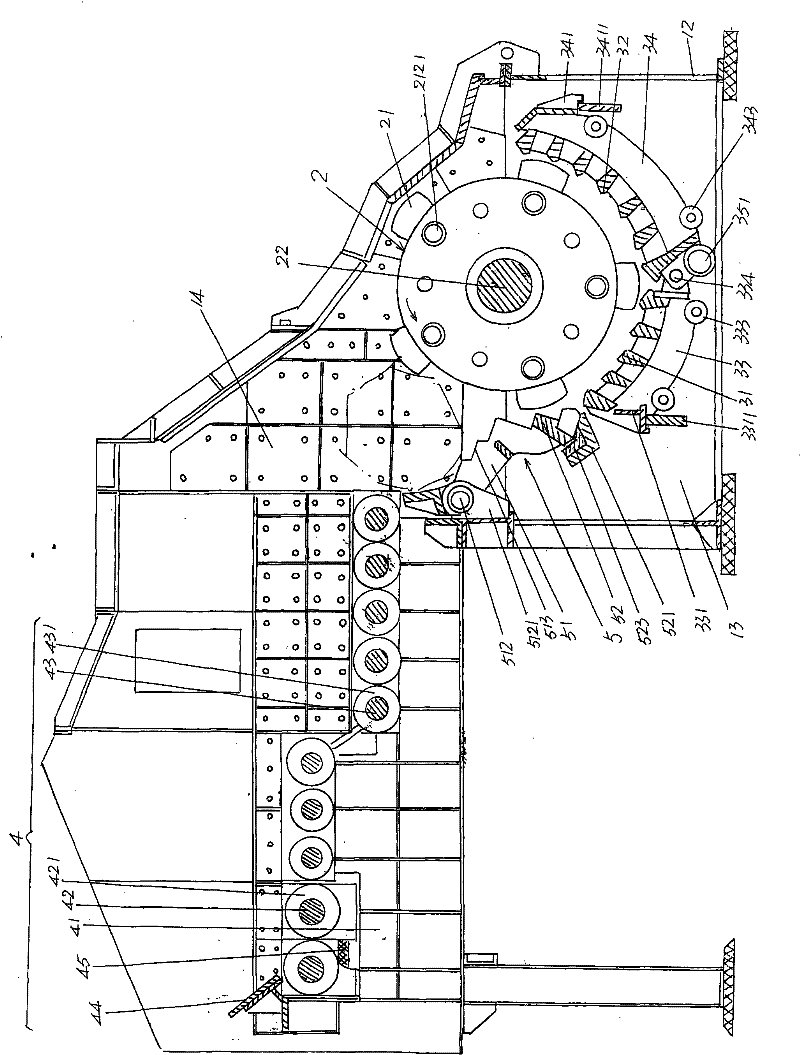

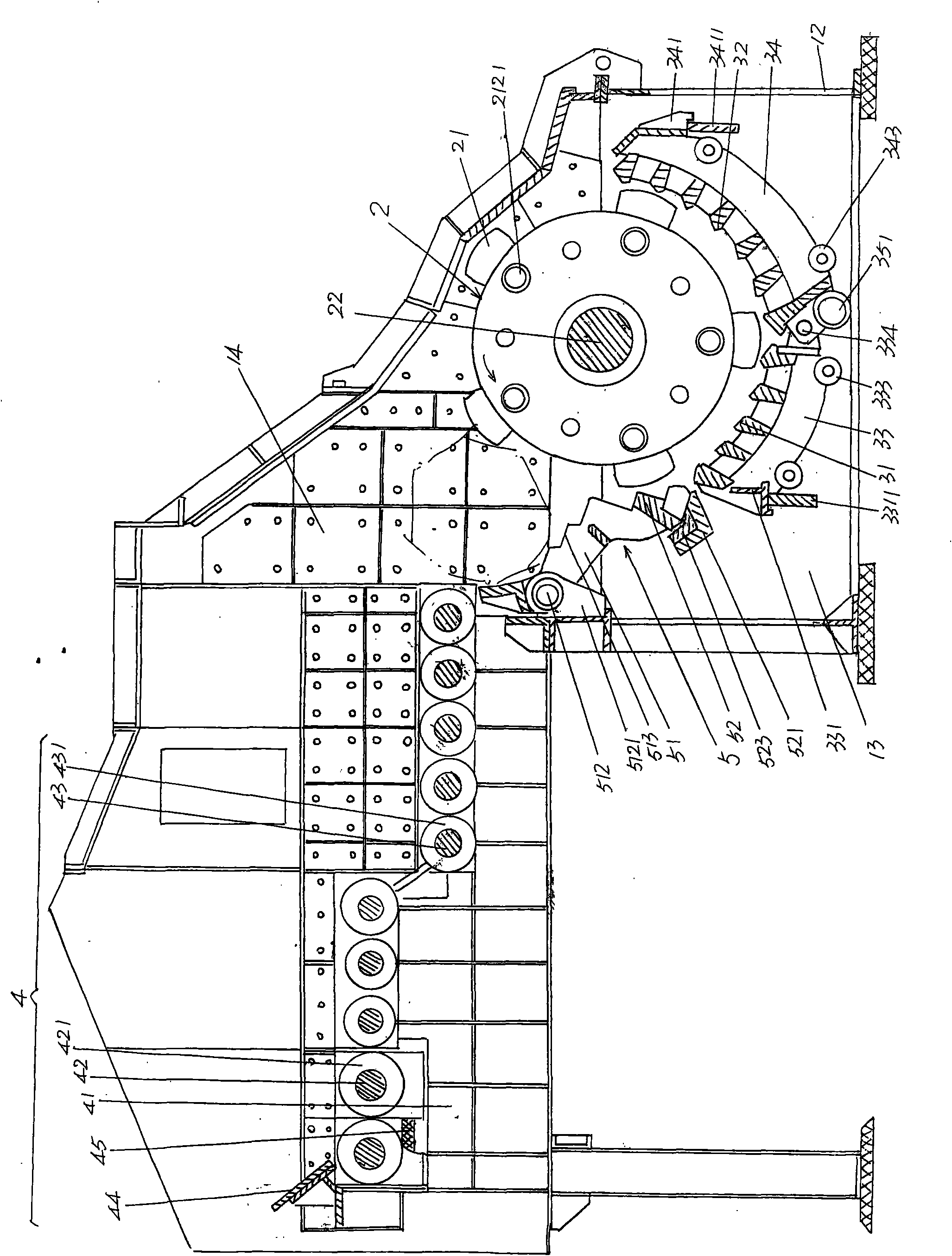

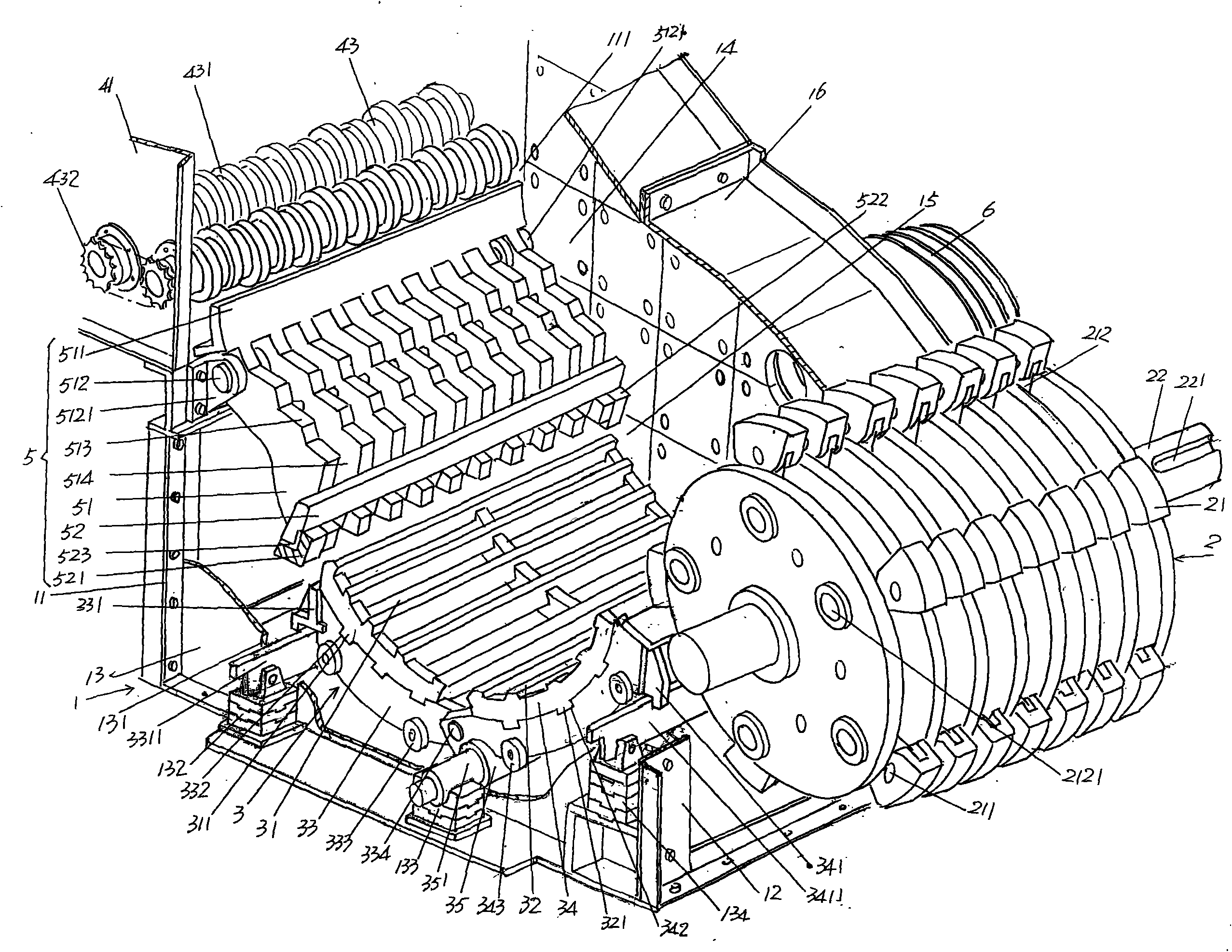

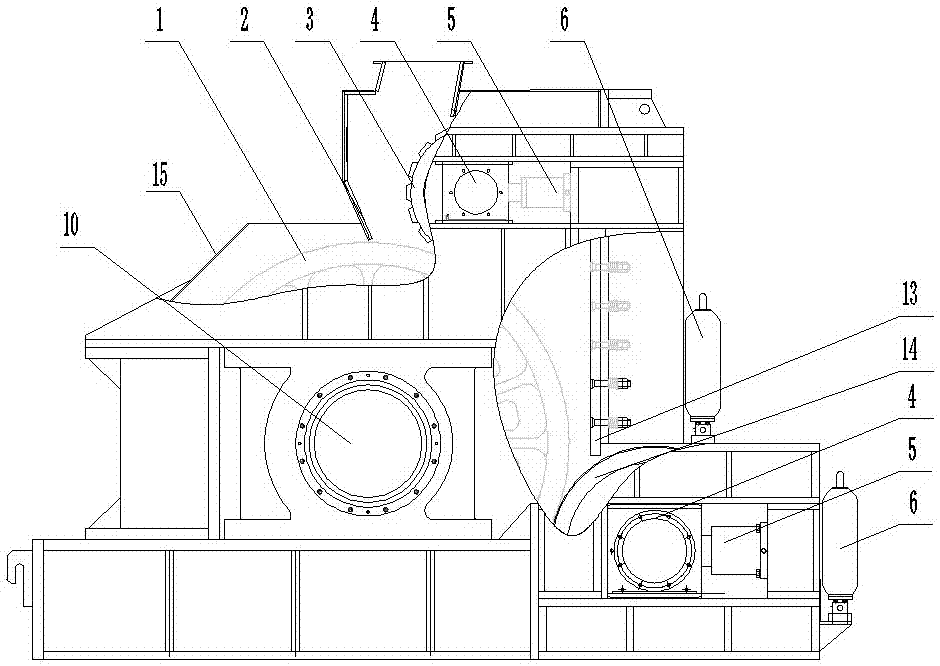

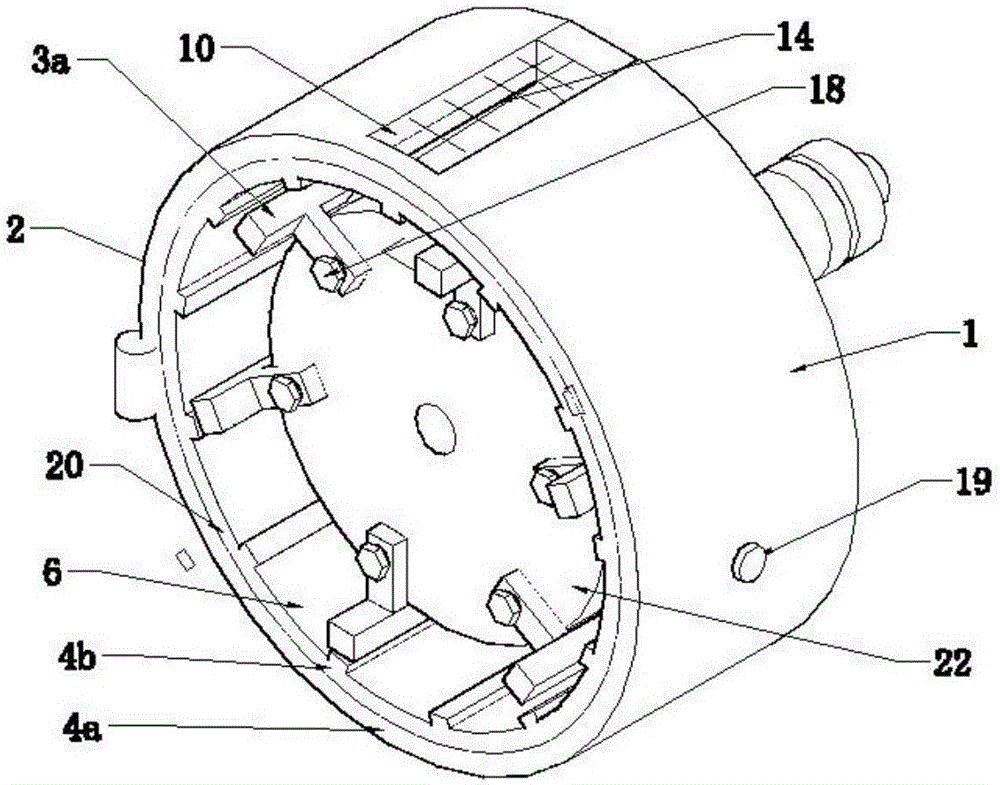

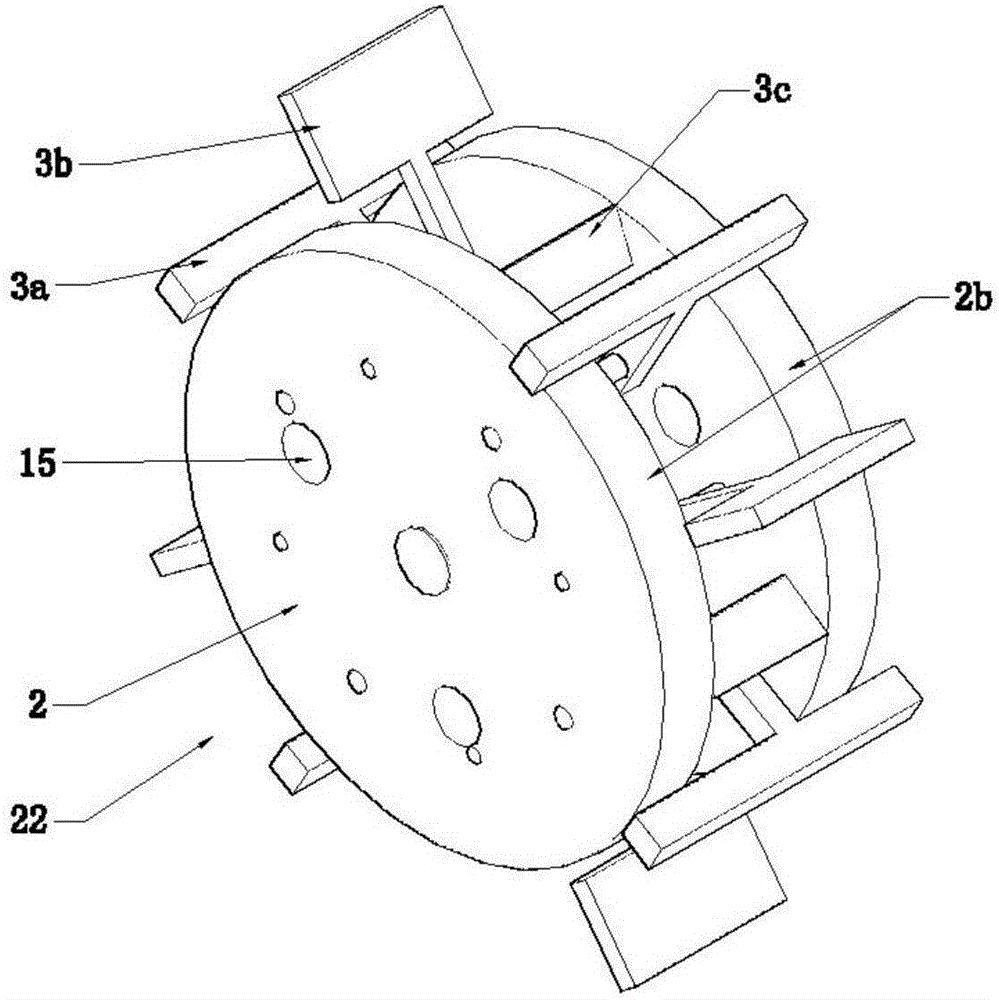

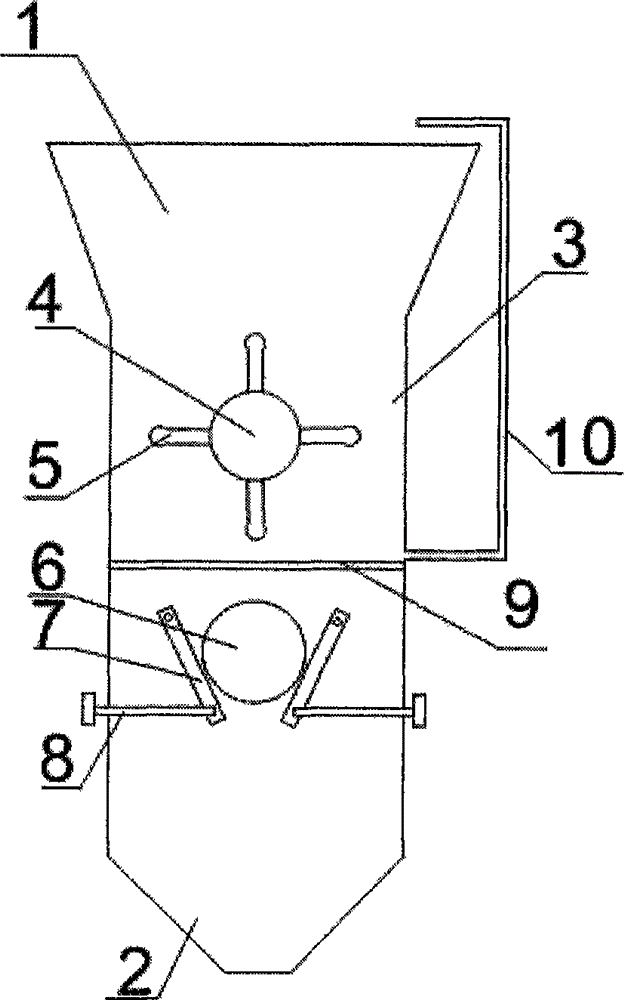

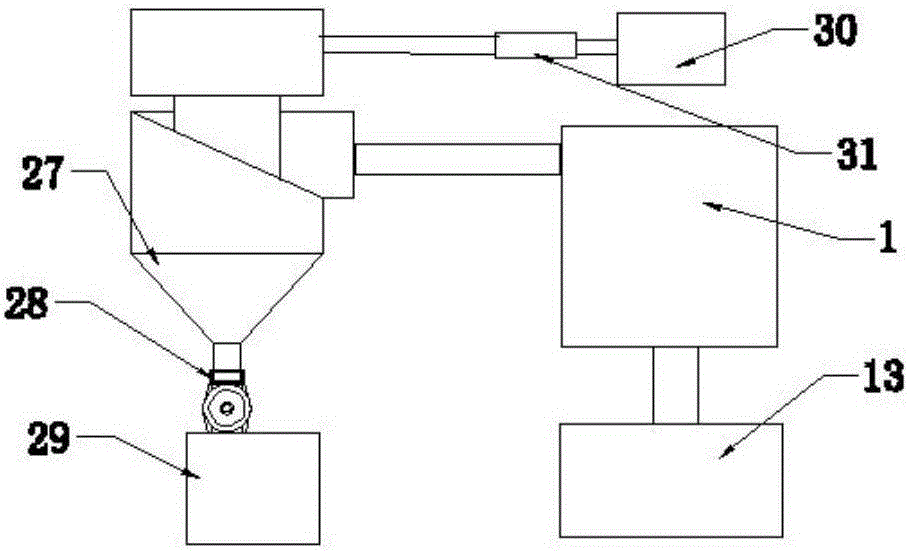

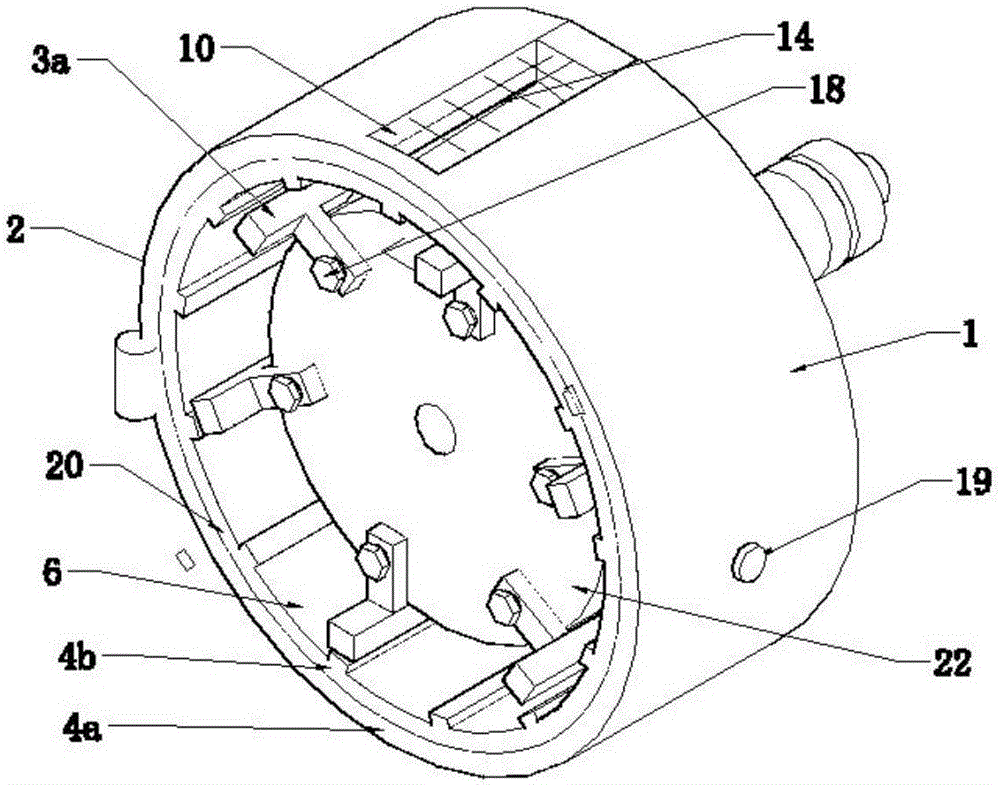

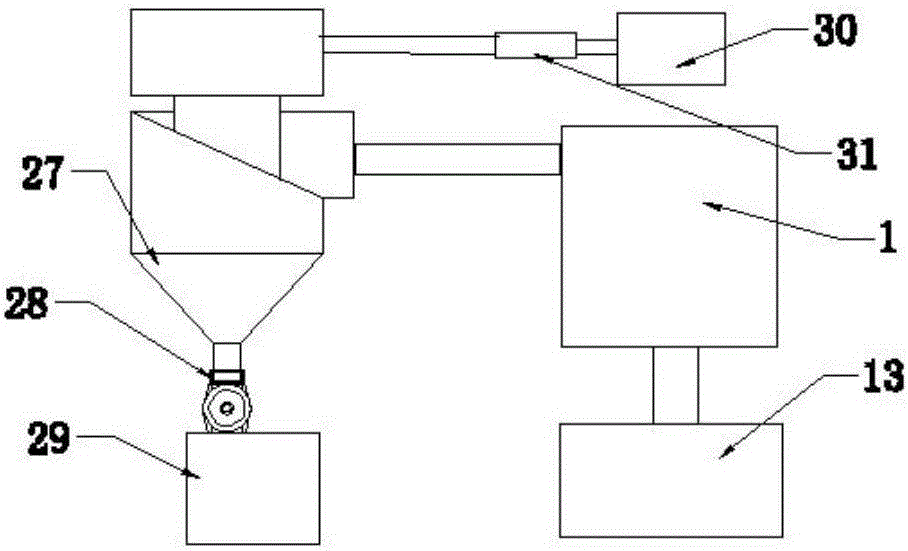

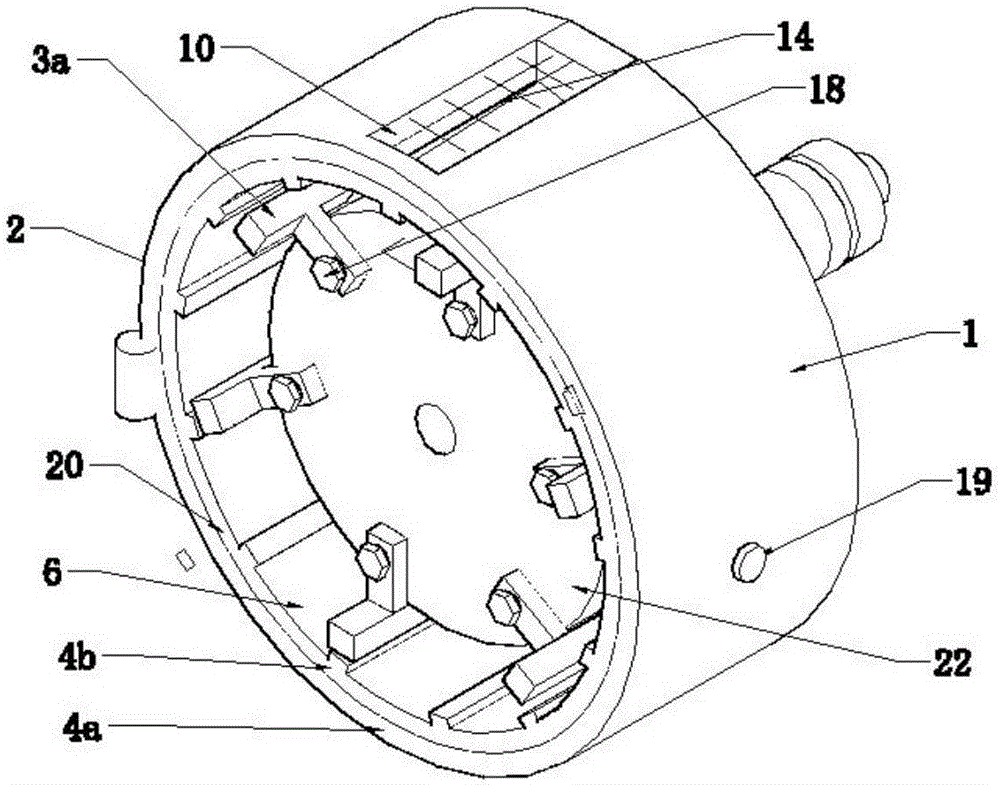

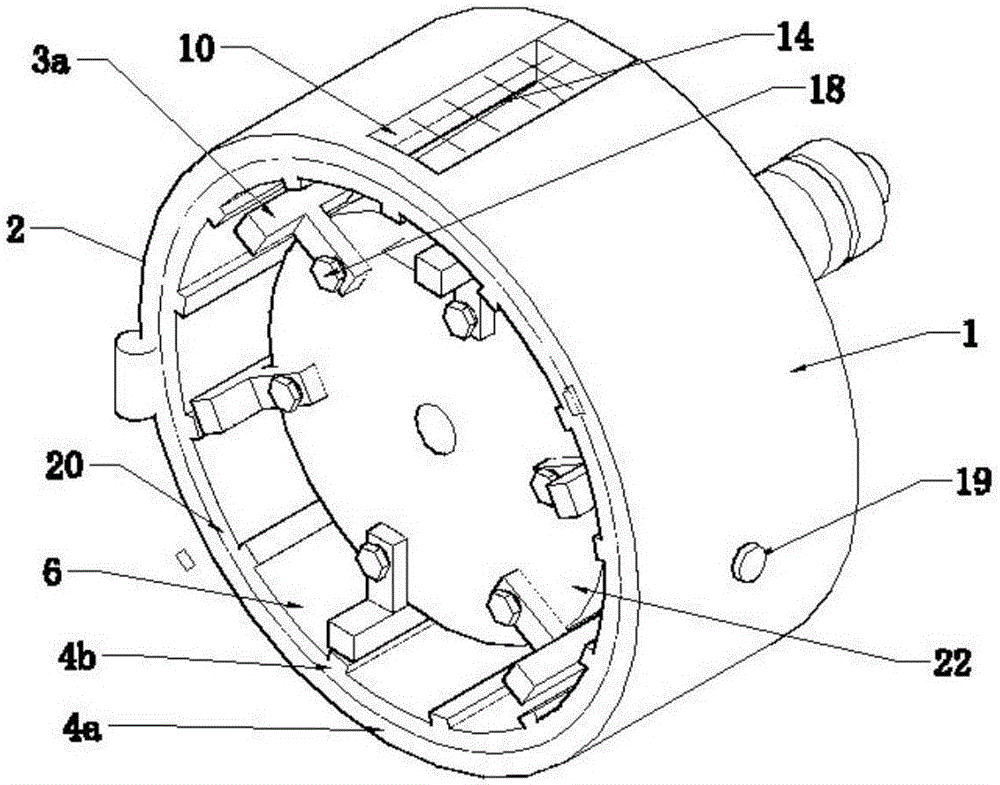

Single-section hammer type screening crusher

ActiveCN101972682ASuppression of crushingAvoid over-shreddingGrain treatmentsPre screeningEngineering

The invention discloses a single-section hammer type screening crusher, belonging to mining machinery and comprising a crusher box body, a crushing rotor and a final screening mechanism, wherein the crusher box body comprises a left box body, a right box body, a front box body, a rear box body and an upper box body and is provided with a crushing work cavity; a feed opening is arranged at the upper part of the left box body; the crushing rotor is positioned in the crusher box body, is arranged on the front box body and the rear box body and is provided with a hammer head; and the final screening mechanism is arranged in the crushing work cavity. The single-section hammer type screening crusher is characterized in that a pre-screening mechanism is arranged at the position of the outer sideof the left box body, which corresponds to the feeding opening; a grill body is arranged on the left box body, orients towards one side of the crushing work cavity and corresponds to the upside of the feeding opening; and the pre-screening mechanism, the grilling body and the final screening mechanism sequentially form the gradient relationship of gradually reducing from top to bottom in the height. The single-section hammer type screening crusher has the advantages of inhibiting the over crushing, ensuring that coarse materials in the crushing work cavity are first crushed and first output, saving the energy source consumption of the crusher and improving the crushing efficiency.

Owner:常熟中材装备重型机械有限公司

Single-section hammer type screening crusher

The invention discloses a single-section hammer type screening crusher, belonging to mining machinery and comprising a crusher box body, a crushing rotor and a final screening mechanism, wherein the crusher box body comprises a left box body, a right box body, a front box body, a rear box body and an upper box body and is provided with a crushing work cavity; a feed opening is arranged at the upper part of the left box body; the crushing rotor is positioned in the crusher box body, is arranged on the front box body and the rear box body and is provided with a hammer head; and the final screening mechanism is arranged in the crushing work cavity. The single-section hammer type screening crusher is characterized in that a pre-screening mechanism is arranged at the position of the outer side of the left box body, which corresponds to the feeding opening; a grill body is arranged on the left box body, orients towards one side of the crushing work cavity and corresponds to the upside of the feeding opening; and the pre-screening mechanism, the grilling body and the final screening mechanism sequentially form the gradient relationship of gradually reducing from top to bottom in the height. The single-section hammer type screening crusher has the advantages of inhibiting the over crushing, ensuring that coarse materials in the crushing work cavity are first crushed and first output, saving the energy source consumption of the crusher and improving the crushing efficiency.

Owner:SINOMA CHANGSHU HEAVY MACHINERY

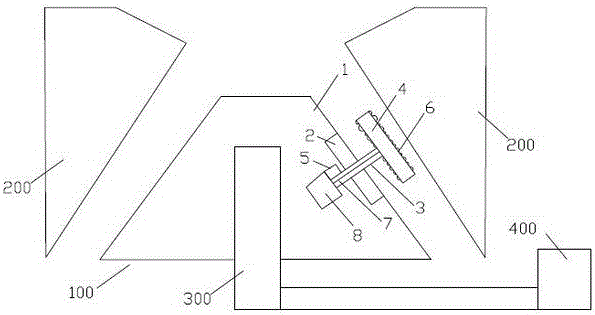

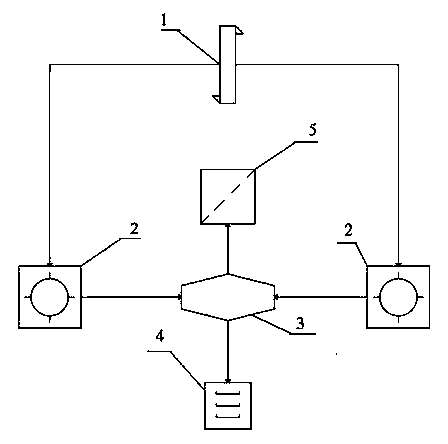

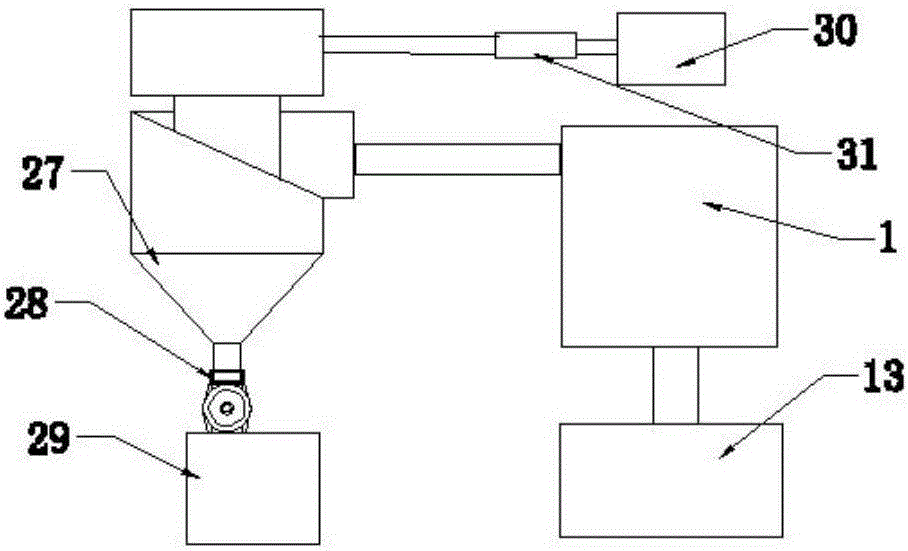

Symmetric integrated crushing system

The invention discloses a symmetric integrated crushing system, mainly comprising a vertical hoister, a horizontal crusher, a center body, a negative pressure powder removing device and a grading and vibrating screen, wherein the vertical hoister, the horizontal crusher, the center body, the negative pressure powder removing device and the grading and vibrating screen are arranged on a same frame and form a stereoscopic structure. Two lateral discharge holes are respectively connected with a left feed inlet and a right feed inlet of the center body, so material crashing and crushing zones are further formed in the center body, and the area of a bottom outlet of the center body matches with the area of a screen surface of the grading and vibrating screen. The crushing system is of a totally-enclosed structure. The symmetric integrated crushing system provided by the invention has the advantages of a compact designed structure, easy and convenient installation, good adaptability, good sealing performance, uniform granularity of a discharged material, great production capacity, a high crushing ratio, environment friendliness, conservation of energy and capacity of saving more than 30% of energy.

Owner:TAI ZHOU TENG DA CONSTR ENG MACHINERY

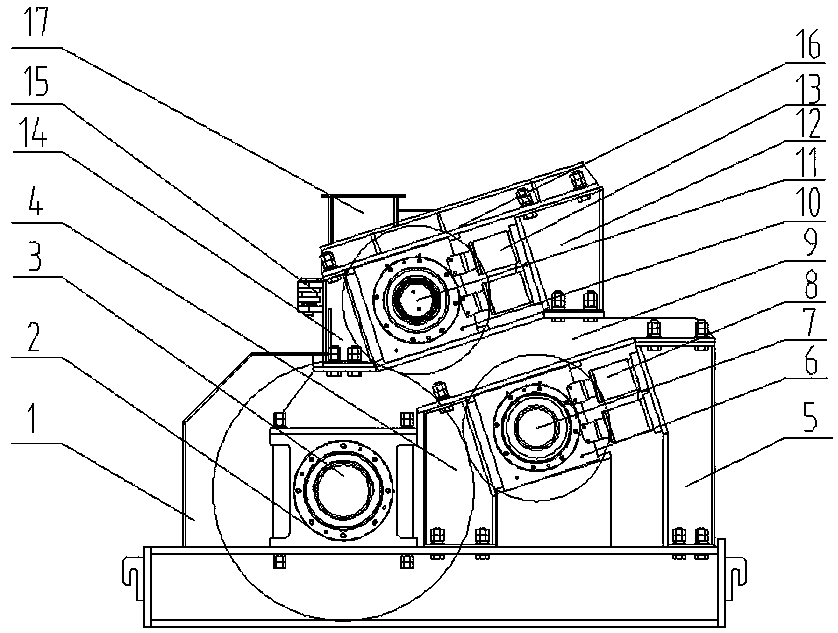

Hydraulic multistage composite roller crusher

PendingCN111450927AImprove efficiencyLarge crushing ratioGrain treatmentsFixed bearingStructural engineering

The invention belongs to the technical field of crushing devices and particularly relates to a hydraulic multistage composite roller crusher which comprises a rack; a fixed roller is fixed and supported on the rack through a fixing bearing; an upper pressing plate and a lower pressing plate are arranged on the outer side of the rack and are slantly fixedly connected with slideways; all slideways are obliquely downwards from one end far away from the fixed roller to the end close to the fixed roller; an upper movable bearing pedestal is arranged in the slideway connected with the upper pressingplate and supports an upper movable roller; a lower movable bearing pedestal is arranged in the slideway connected with the lower pressing plate and supports a lower movable roller; the upper movablebearing pedestal is connected with an upper bidirectional oil cylinder; and the lower movable bearing pedestal is connected with a lower bidirectional oil cylinder. The hydraulic multistage compositeroller crusher can realize composite type crushing operation to greatly improve the crushing efficiency and effectively save energy, and can avoid by self when meeting extremely large or extremely hard material to greatly prolong the service life.

Owner:徐州市诚信破碎机械厂

High-crushing-ratio double-tooth-roller crusher

ActiveCN112871293ALarge crushing ratioIncrease crushing ratioGrain treatmentsElectric machineryEngineering

The invention discloses a high-crushing-ratio double-tooth-roller crusher. The high-crushing-ratio double-tooth-roller crusher comprises a crusher shell, a first tooth roller shaft, a second tooth roller shaft, a first coupler, a second coupler, a first speed reducer, a second speed reducer, a first hydraulic coupler, a second hydraulic coupler, a first motor, a second motor, a hydraulic jack, a bolt support, a crushing beam fixing bolt, a crushing beam and lower crushing teeth, wherein a plurality of rows of roller teeth are distributed on the first tooth roller shaft at equal intervals in the axial direction; a plurality of rows of roller teeth are distributed on the second tooth roller shaft at equal intervals in the axial direction; the first tooth roller shaft and the second tooth roller shaft are arranged in the crusher shell in parallel; and the bolt support is located on the hydraulic jack and connected with an end plate of the crushing beam through the crushing beam fixing bolt. The lower crushing teeth are connected to the crushing beam. The high-crushing-ratio double-tooth-roller crusher can crush materials three times, and the crushing ratio is high; the granularity of finished products can be strictly controlled; large materials can be crushed, and the crushing efficiency is high; and falling on the whole tooth roller shafts is uniform, and the crushing capacity is high.

Owner:江苏羚羊机械有限公司

Structurally improved single-section hammer type screening crusher

The invention relates to a structuraly improved single-section hammer type screening crusher which belongs to mine machinery. The single-section hammer type screening crusher comprises a crusher box body, a crushing rotor, a final screening mechanism and a prescreening mechanism, wherein the crusher box body consists of a left box body, a right box body, a front box body, a back box body and an upper box body and is provided with a crushing work cavity; a feeding opening is arranged at the upper part of the left box body; the crushing rotor is positioned in the crusher box body and arranged on the front box body and the back box body; a hammer head is pivoted on the crushing rotor; the final screening mechanism is arranged in the crushing work cavity; and the prescreening mechanism is arranged at the top outside the left box body. The single-section hammer type screening crusher is characterized in that a grate body which consists of a group of grates and a grate lower connecting beam is configured on one side of the left box body, facing the crushing work cavity. The invention has the advantages of inhibiting overcrushing, ensuring that ore in the crushing work cavity is crushed and discharged at first, saving the energy consumption of the crusher and improving the crushing efficiency.

Owner:SINOMA CHANGSHU HEAVY MACHINERY

Vertical shaft support system of vertical shaft type impact crusher, and vertical shaft support device

InactiveCN100455356CImprove support conditionsImprove impact resistanceEngine sealsGrain treatmentsSupporting systemRolling-element bearing

Owner:贵州优利斯凯机械有限公司

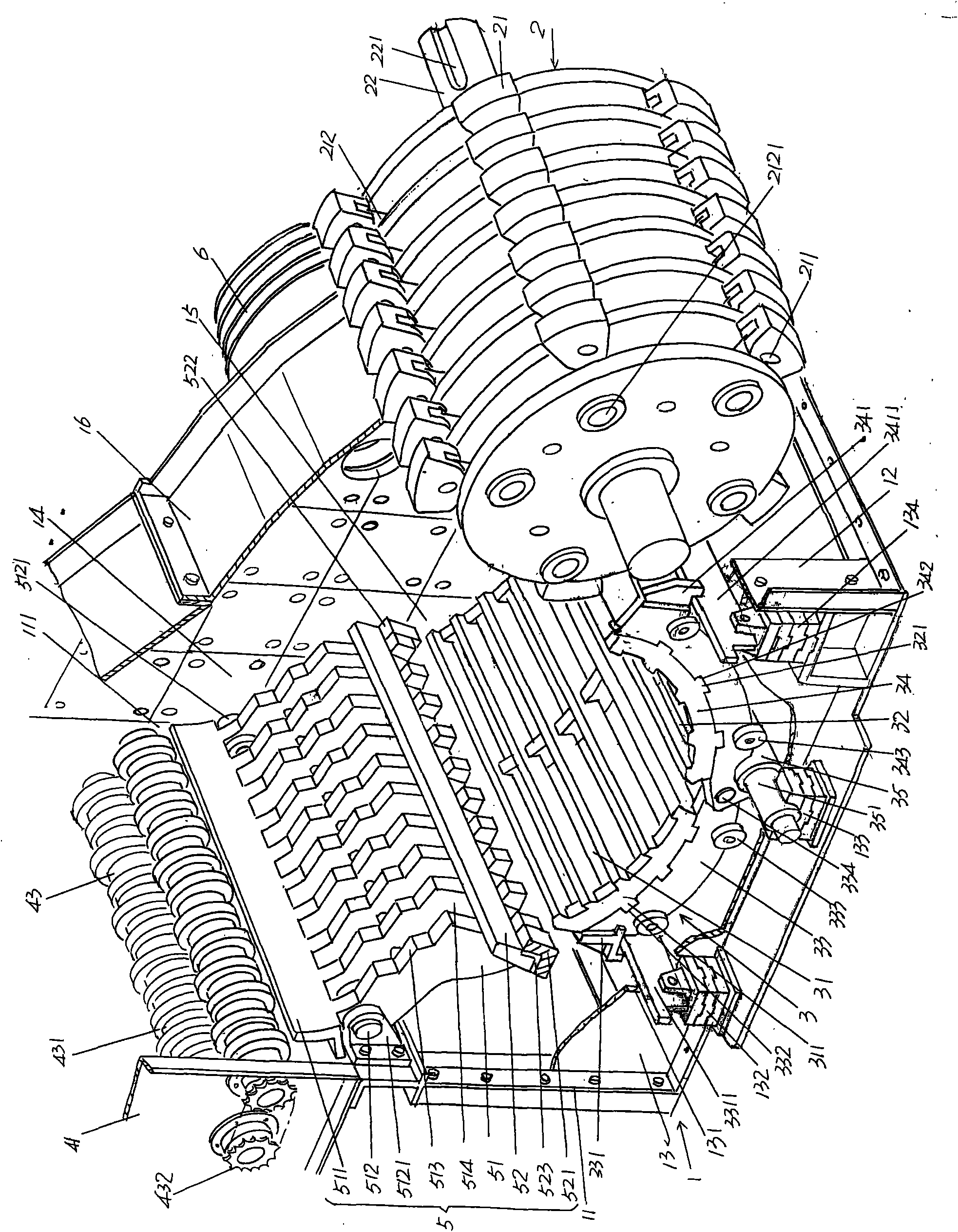

Hydraulic compound roll crusher

PendingCN107115918AImprove transmission efficiencyGuaranteed crushing operationGrain treatmentsFixed bearingStructural engineering

The invention discloses a hydraulic compound roll crusher. The hydraulic compound roll crusher comprises a fixed master roller and at least two movable rollers which are arranged in a crusher body, a feeding inlet is formed in the position, above the fixed master roller, of the crusher body, and the movable rollers are mounted on the lower rotary side from top to bottom in the rotary direction of the fixed master roller; guide plates are arranged in front of the movable rollers; and the fixed master roller is fixed in the crusher body through a fixing bearing seat, a master roller driving device is connected with the fixed master roller, and a movable roller driving device is connected with the movable rollers. The hydraulic compound roll crusher has obvious effects and is convenient and practical, and by reasonable arrangement of the fixed master roller and the multiple movable rollers, multi-stage and compound crushing operation is achieved, so that the efficiency of the crushing operation can be remarkably improved; meanwhile, the hydraulic compound roll crusher is simple in structure, convenient to maintain in the later period, and high in cost performance; and the hydraulic compound roll crusher is easy to operate, high in crushing ratio and long in service life.

Owner:徐州市诚信破碎机械厂

Efficient pharmaceutical pulverizer

InactiveCN106563528AIncrease crushing ratioIncrease the amount of crushingGrain treatmentsCouplingEngineering

The invention discloses an efficient pharmaceutical pulverizer. The efficient pharmaceutical pulverizer comprises a pulverization chamber, wherein the pulverization chamber comprises a cylinder body and a cylinder cover which is movably connected with the cylinder body; the cylinder body comprises an outer cylinder and a lining cylinder which is connected with the inner wall of the outer cylinder; the lining cylinder is connected through a corresponding connection device; racks are distributed on the inner circumferential surface of the lining cylinder; a driving device comprises a DC driving motor; and a coupling is connected between a turntable frame and the DC driving motor. The efficient pharmaceutical pulverizer is extremely simple and reasonable in structure, high in working efficiency, high in relative pulverization ratio, long in service life and low in energy consumption, is capable of satisfying the diversified production requirements of a plurality of materials which comprise biomass particle raw materials, and integrates pulverizing and screening to ensure that the working efficiency is high and the production cost is low.

Owner:YICHUN WANSHEN PHARMA MACHINERY

Compound ceramic crusher

The invention discloses a compound ceramic crusher which comprises a feed opening, a crushing chamber and a discharge opening, wherein a coarse crushing device and a fine crushing device are arranged in the crushing chamber; the coarse crushing device comprises a roller and crushing hammers fixed on the roller; the fine crushing device is arranged below the coarse crushing device and mainly comprises a driving crushing roller and two crushing plates; the two crushing plates are arranged on two sides of the driving crushing roller; the upper parts of the crushing plates are fixed through rotating shafts; angle adjusting mechanisms are arranged at the lower parts of the crushing plates; a vibrating screen is arranged between the coarse crushing device and the fine crushing device; and the vibrating screen is connected with a coarse material circulating system. According to the compound ceramic crusher, two stages of crushing devices are arranged, materials are crushed to specified meshes by the coarse crushing device at first and then enter the fine crushing device to continue to be crushed, and relatively coarse materials circularly enter the feed opening to be crushed repeatedly, so that the crushing efficiency is increased. The crushing fineness of the fine crushing device can be adjusted through the angle adjusting mechanisms, so that the overall crushing ratio of the materials is improved.

Owner:SICHUAN XGR ENERGY MATERIALS

Drug raw material separation pulverizer

InactiveCN106423504AImprove crushing effectLarge crushing ratioGrain treatmentsEngineeringEnergy consumption

The invention discloses a drug raw material separation pulverizer, which comprises a rack, a pulverizing room arranged on the rack, a hammer mechanism arranged in the pulverizing room and connected to a corresponding drive device, and a corresponding screen plate connected to a discharge hole of the pulverizing room. The hammer mechanism comprises a hammer frame and a plurality of corresponding hammers; the discharge hole of the pulverizing room is connected with a cyclone separator; the cyclone separator is connected with an air lock and a fan; the air lock and the fan are connected with corresponding collectors; and the hammer frame comprises a swing hold fixedly connected to a corresponding rotary shaft. The drug raw material separation pulverizer is extremely simple and reasonable in structure, high in work efficiency, big in relative pulverizing ratio, long in service life, and low in energy consumption, and can meet diversified production requirements of various materials including biomass particle raw materials.

Owner:YICHUN WANSHEN PHARMA MACHINERY

Efficient smashing device for raw materials of medicine

InactiveCN106492928AImprove crushing effectIncrease the amount of crushingGrain treatmentsEnergy consumptionRaw material

The invention discloses a processing device for raw materials of medicine, in particular to an efficient smashing device for the raw materials of the medicine. The device comprises a smashing mechanism, the smashing mechanism comprises a smashing rotation body located in a smashing cavity of a smashing bin and a plurality of movable hammer heads, the smashing rotation body is a rotary plate bracket, and the rotary plate bracket is fixedly connected to a corresponding rotary shaft of the smashing mechanism. The device integrates the smashing function and the screening function and is high in work efficiency and low in manufacturing cost. The processing device for the raw materials of the medicine is simple and reasonable in structure, high in work efficiency, high in relative smashing ratio, long in service life and low in energy consumption and can meet the diversified production requirements of various materials comprising biomass particles.

Owner:YICHUN WANSHEN PHARMA MACHINERY

High-effective pharmaceutical crusher

InactiveCN106563529AIncrease crushing ratioIncrease the amount of crushingGrain treatmentsCouplingEngineering

The invention discloses a high-effective pharmaceutical crusher, which includes a crushing chamber. The crushing chamber includes a cylinder body and a cylinder cover movably connected thereto. The cylinder body includes an outer cylinder and an inner lining cylinder connected to the inner wall of the outer cylinder. The outer cylinder is connected to the inner lining cylinder through corresponding connection apparatus. Racks are distributed on the inner periphery surface of the inner lining cylinder. A driving apparatus includes a DC driving motor. A coupling is connected between a rotary disk bracket and the DC driving motor. The pharmaceutical crusher has very simple and reasonable structure, is high in work efficiency, is high in relative crushing ratio, has long service life and is low in energy consumption. The pharmaceutical crusher can satisfy diversified production demands on various materials such as biomass granular raw materials. In addition, the pharmaceutical crusher integrates both crushing and sieving, so that the crusher is high in work efficiency and is low in production cost.

Owner:YICHUN WANSHEN PHARMA MACHINERY

Movable-type pharmaceutical raw material comprehensive processing machine

InactiveCN106563558AGood crushing effectLarge crushing ratioGrain treatmentsEngineeringIntegrated processing

The invention discloses a movable-type pharmaceutical raw material comprehensive processing machine, which includes a machine body. The machine body is provided with a crushing chamber, a crushing mechanism and a material separator. A chamber cover and a corresponding material inlet port are arranged on the crushing chamber, wherein the material inlet port is formed in the center of the chamber cover. An inclined material inlet pipe, which is formed in a manner that a free end or one end, being closed to the outer side of the chamber cover, of the material inlet pipe is inclined upwardly at a degree, is connected to the material inlet port. The inclined material inlet pipe is also connected to a vertical material guide pipe. The crushing chamber is connected to a horizontal material delivery hopper through the inclined material inlet pipe and the vertical material guide pipe. A walking mechanism is arranged on the bottom of the machine body and includes a support and universal wheels arranged thereon. The comprehensive processing machine integrates crushing and sieving functions and has high work efficiency.

Owner:YICHUN WANSHEN PHARMA MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com