Hydraulic compound roll crusher

A crusher and compound roll technology, which is applied in the field of crushing devices and hydraulic compound roll crushers, can solve the problems of affecting the service life of the crushing device, different sizes of materials, and damage to the crushing device, achieving high cost performance, stable crushing power, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

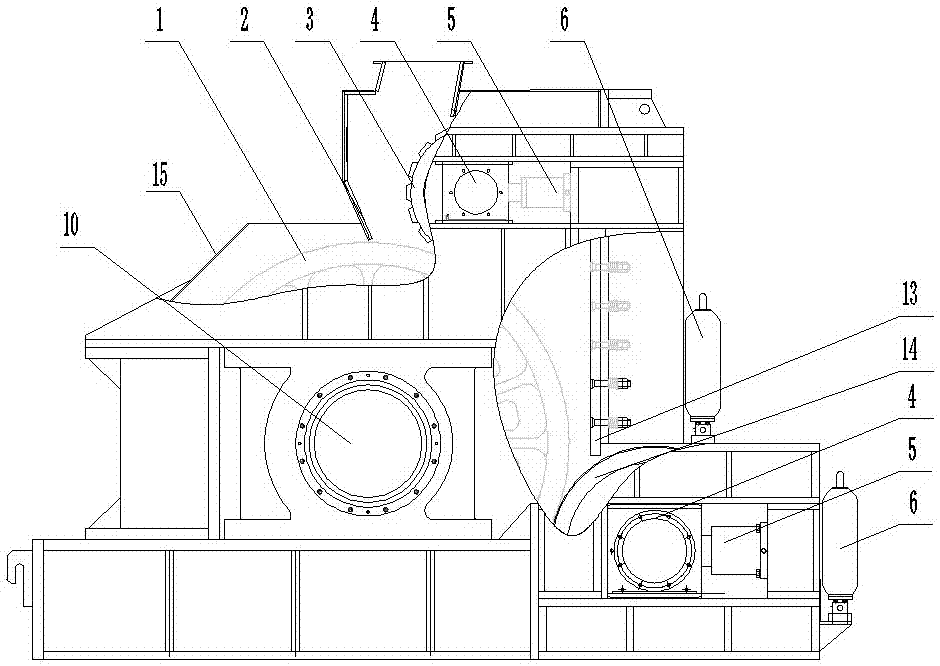

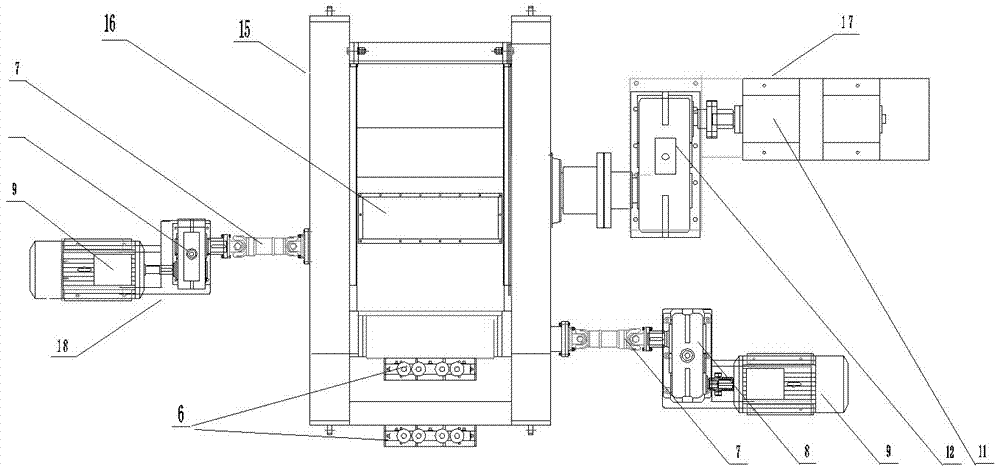

[0015] In the following, the present invention will be further explained through the double movable roller structure in conjunction with the drawings.

[0016] Such as figure 1 with figure 2 As shown, a hydraulic composite roller crusher includes a fixed main roller 1, a movable roller I3, and a movable roller II14 arranged in the main body 15 of the crusher. The main body 15 of the crusher has an inlet above the main fixed roller 1. The material port 16, the movable roller I3 and the movable roller II14 are installed from top to bottom along the downward rotation side of the fixed main roller 1, as figure 1 As shown, when the fixed main roller 1 works in a clockwise direction, the movable roller I3 is arranged above and on the right side of the fixed main roller 1, and the movable roller II14 is arranged below the right side of the fixed main roller 1; A material guide plate I2 and a material guide plate II13 are arranged in front of the movable roller I3 and the movable roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com