Compound ceramic crusher

A pulverizer and composite technology, which is applied in the field of composite ceramic pulverizers, can solve problems such as limited crushing, and achieve the effect of increasing the crushing ratio and crushing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

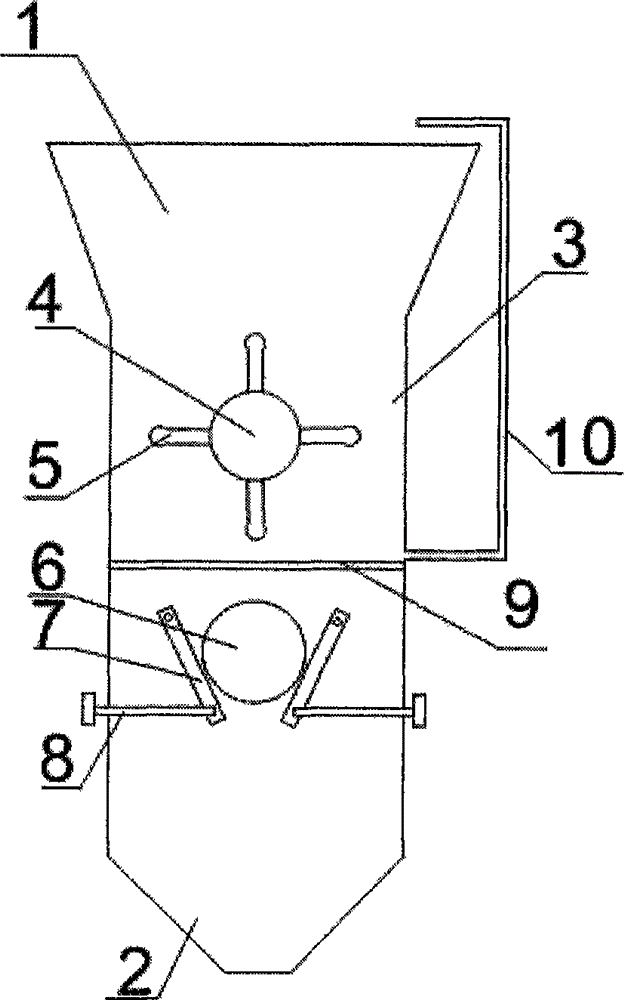

[0011] Such as figure 1 As shown, a composite ceramic pulverizer includes a feed port 1, a crushing chamber 3 and a discharge port 2. The crushing chamber 3 is provided with a coarse crushing device and a fine crushing device.

[0012] The coarse crushing device is composed of a rotating roller 4 and a crushing hammer 5 fixed on the rotating roller 4. The rotating roller 4 is driven to rotate by a motor. When large materials enter from the feed port 1, they are crushed by the rotating crushing hammer 5.

[0013] A vibrating screen 9 is installed below the coarse crushing device, and the materials that reach the predetermined mesh enter the fine crushing device through the vibrating screen 9, and the materials that do not reach the predetermined mesh are returned to the feeding port by the coarse material circulation system 10 for repeated crushing. The coarse material circulation system 10 adopts the most common conveyor belt form.

[0014] The fine crushing device is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com