Integrated equipment for crushing and sieving

A crushing, screening, and overall technology, applied in grain processing, etc., can solve problems such as material over-crushing, crusher load increase, maintenance difficulties, etc., and achieve the effects of reducing over-crushing, increasing the overall crushing ratio, and reducing congestion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

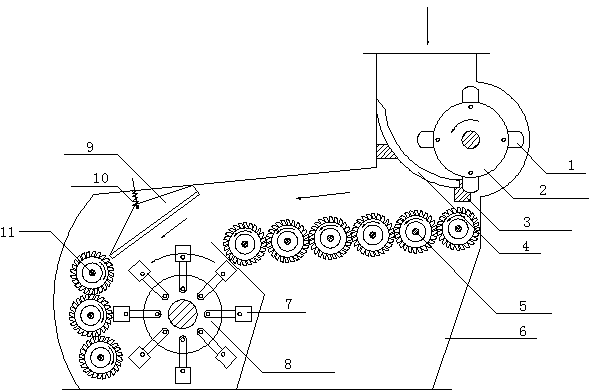

[0034] Embodiment 1, the present invention discloses a crushing and screening overall equipment, including a frame, and a first-stage crushing device, a screening device and a second-stage crushing device are respectively arranged in the frame, and the first-stage crushing device It includes a first-stage crushing rotor and a sieve for screening crushed materials, the first-stage crushing rotor and the sieve form a first-stage crushing cavity, and the screening device includes a plurality of screen rollers arranged side by side for conveying materials, The surfaces of multiple sieve rollers form a sieve surface for sieving materials, and the gap between any two rollers forms a sieve hole. The conveying inlet end of the sieving device is connected to the sieve, and the conveying outlet end of the sieving device is connected to the second sieve. Secondary crushing device.

Embodiment 2

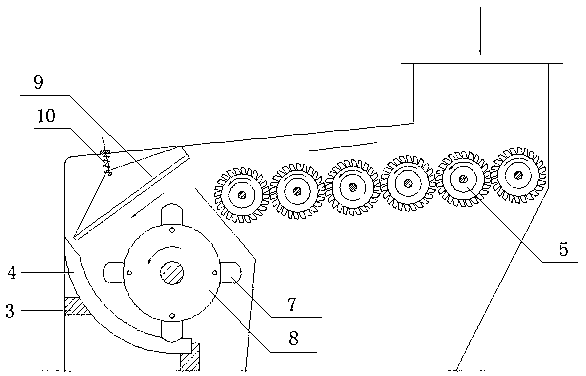

[0036] As a preferred embodiment of the present invention, the present invention discloses a crushing and screening overall equipment, including a frame, a coarse crushing rotor arranged in the frame, a screening device is arranged under the coarse crushing rotor, and the screening device One end communicates with the outlet of the coarse crushing rotor, and the other end of the screening device toothed roller screen communicates with the fine crushing chamber. The screening device includes multiple screen rolls arranged side by side, and multiple screen rolls form a screen for screening materials. On the surface, sieve teeth are set on the sieve rollers, and the sieve teeth gap between any two sieve rollers forms a sieve hole, and the sieve surface is an inclined plane that is higher at the end near the exit of the coarse crushing rotor and lower at the end near the fine crushing rotor. shape.

Embodiment 3

[0038] As the best embodiment of the present invention, with reference to the attached figure 1 and 2 , the present invention is provided with a fine crushing rotor below the outlet of the toothed roller screen, and the fine crushing device includes a fine crushing rotor, an impact plate, and a plurality of crushing toothed rollers (the crushing toothed rollers can be replaced by sieve bars). The crushing toothed rollers mesh with each other. The two ends of the screen roller screen are provided with a power device through transmission. Multiple sieve rollers are driven to rotate in the same direction. The sieve teeth are evenly distributed on the sieve roll. The coarse crushing device includes a coarse crushing rotor, and the surface opposite to the coarse crushing rotor is provided with a screen bar and a screen bar support in the installation frame, and the coarse crushing rotor and the screen bar form a material crushing cavity. All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com