Patents

Literature

49results about How to "Reduce over crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

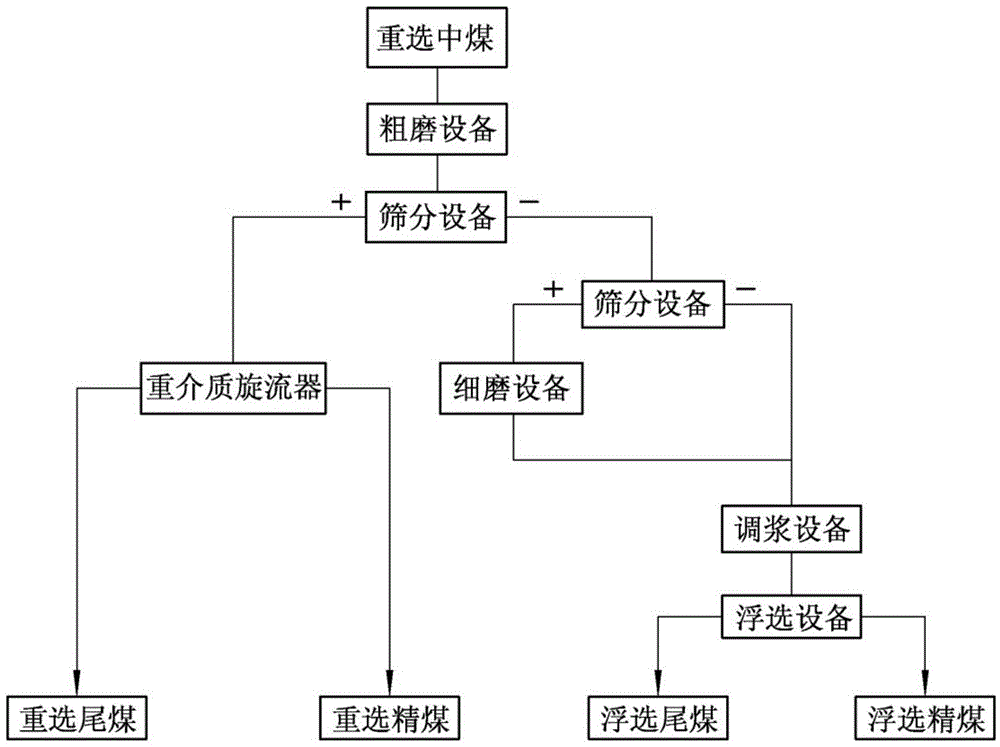

Gravity separation middling coal separation technology

InactiveCN104437831AReduce over-crushingImprove equipment sorting efficiencyGrain treatmentsWet separationGravity separationEngineering

The invention belongs to a coal washing method and discloses a gravity separation middling coal separation technology. Gravity separation middling coal is fed into rough grinding equipment. Products obtained after rough grinding is fed into screening equipment for primary classifying, and primary plus-sieve products and primary minus-sieve products are obtained. The primary plus-sieve products are fed into a dense medium cyclone for separation. The primary minus-sieve products are fed into separation equipment for secondary classification, and secondary plus-sieve products and secondary minus-sieve products are obtained. The secondary plus-sieve products are fed into fine grinding equipment for fine grinding. Products obtained after fine grinding and the secondary minus-sieve products are fed into size mixing equipment together for completing flotation. Two-time ore grinding, gravity separation and floatation combination and classifying separation are combined to separate gravity separation middling coal, under the premise that the middling coal dissociation degree is improved, the phenomena of over crushing are reduced, equipment separation efficiency is obviously improved, clean coal in the middling coal is recycled to the maximum degree, the coal preparation plant clean coal productivity is increased, and enterprise economical benefit is improved.

Owner:CHINA UNIV OF MINING & TECH

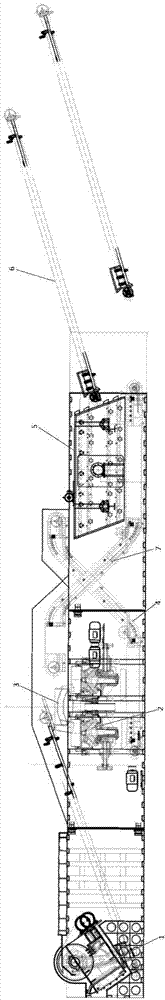

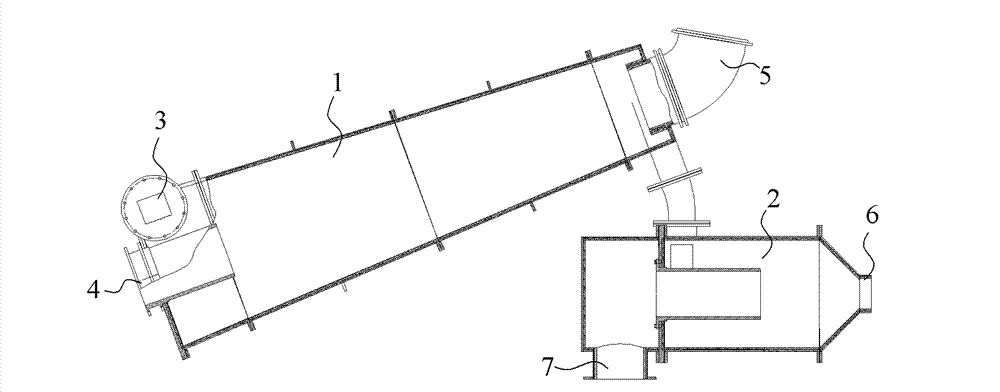

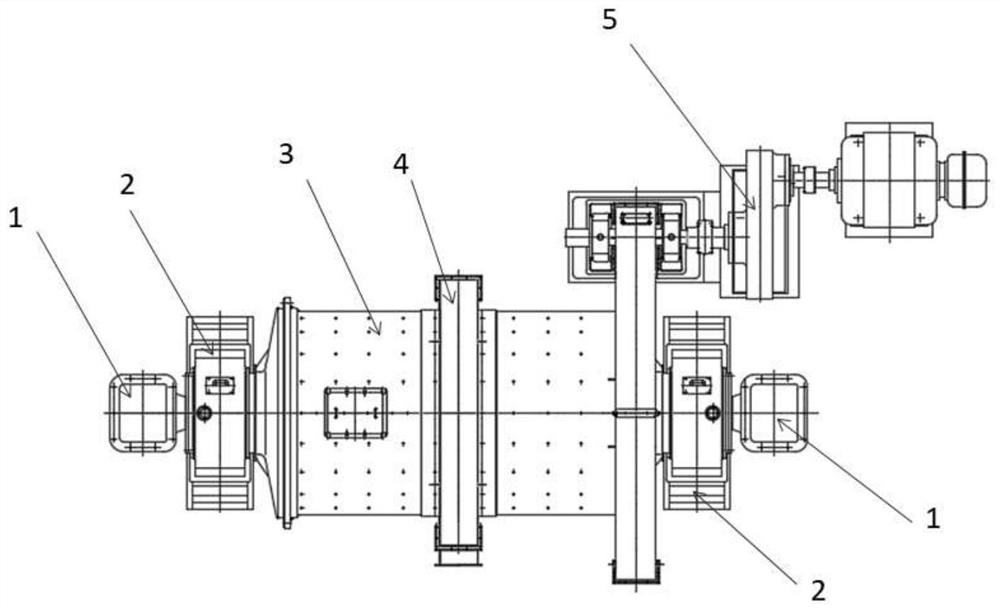

Selective crusher for underground use

The invention relates to a selective crusher for underground use, which comprises a supporting stand, a supporting roller mechanism and a revolving drum body, wherein the supporting roller mechanism is arranged on the supporting stand, and the revolving drum body is horizontally installed on the supporting roller mechanism through a rolling ring which is arranged around the drum body and is matched with a supporting roller in the supporting roller mechanism; the inner cavity of the roller is provided with a pre-screening section, a pushing and screening section, a crushing and screening section and a discharge section sequentially backwards from the feed end, wherein a pre-screening section discharge opening is arranged below the pre-screening section, and a discharge chute is arranged below the crushing and screening section; a center shaft which is coaxial with the roller and is driven by a power source to rotate is installed in the roller, a beater plate is arranged on the shaft body of the center shaft at the section matched with the pre-screening section, a rotor in the shape of an oblique tooth is arranged on the shaft body of the center shaft at the section matched with the crushing and screening section, and a spiral discharge auger is arranged on the shaft body of the center shaft at the section matched with the discharge section; and a plurality of axially arranged lifting plates and nail plates are installed on the inner wall of the screening drum of the crushing and screening section at intervals.

Owner:HENAN POLYTECHNIC UNIV

Method for selectively milling cassiterite multi-metal sulfides ores

The invention discloses a method for selectively milling cassiterite multi-metal sulfides ores. In the method, by utilizing the hydrophily / hydrophobicity difference between the surface of cassiterite and the surfaces of sulfides ores such as pyrite, pyrrhotite, blende and jamesonite, and by adding a floating agent in a milling process, floatation separation of cassiterite and the sulfides ores in ores can be realized under a condition of larger milling granularity by using a floatation method. The method disclosed by the invention can be adopted for treating the cassiterite multi-metal sulfides ore which contains 0.5 to 1 percent of Sn and 12 to 17 percent of S; and by adopting the method, the ore milling granularity required in floatation can be decreased, the content of fine-grained cassiterite (with the granularity of minus 0.039 millimeter) is reduced by 20 percent, and over-crushing phenomena of cassiterite are greatly reduced.

Owner:CENT SOUTH UNIV +1

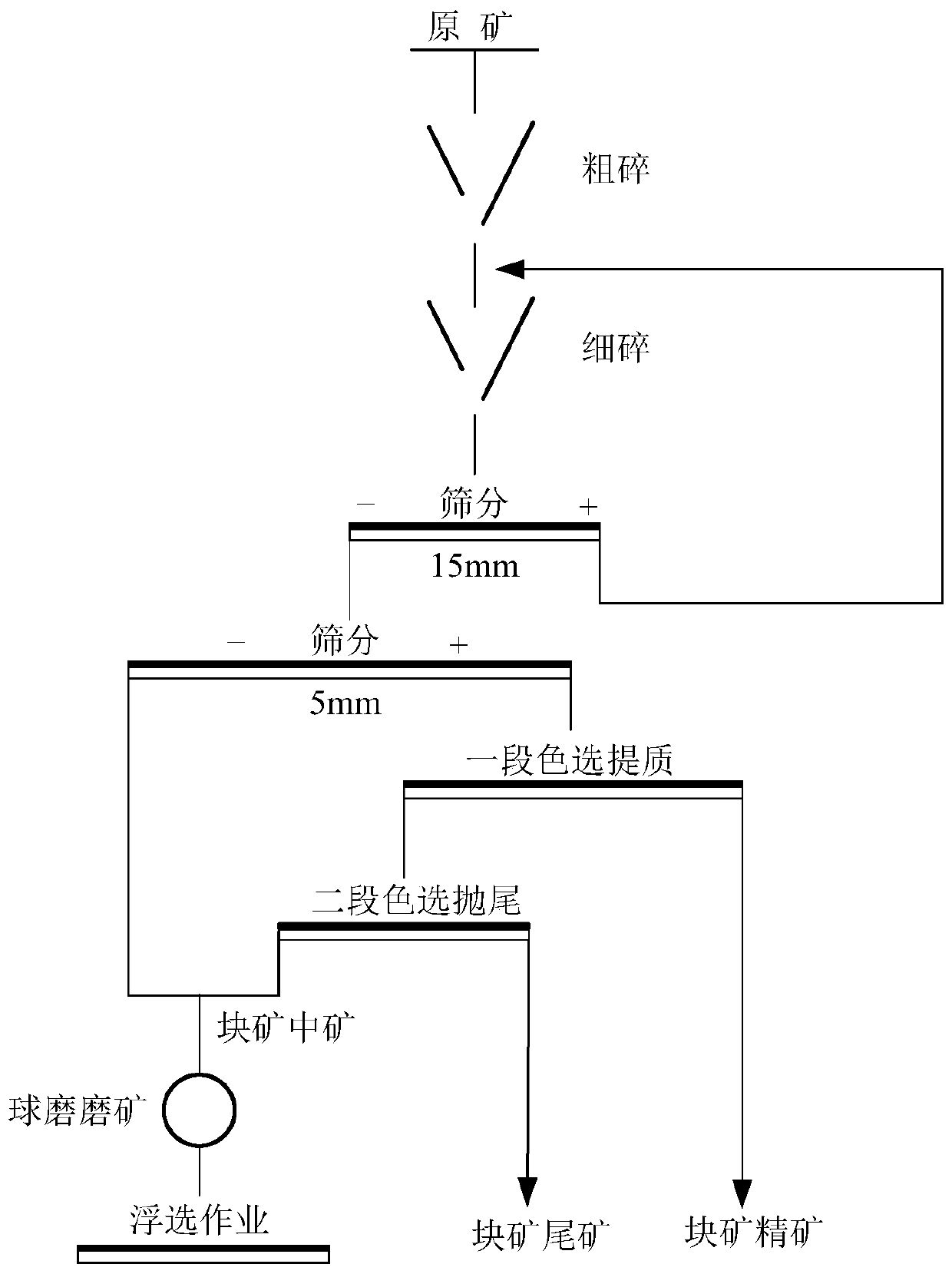

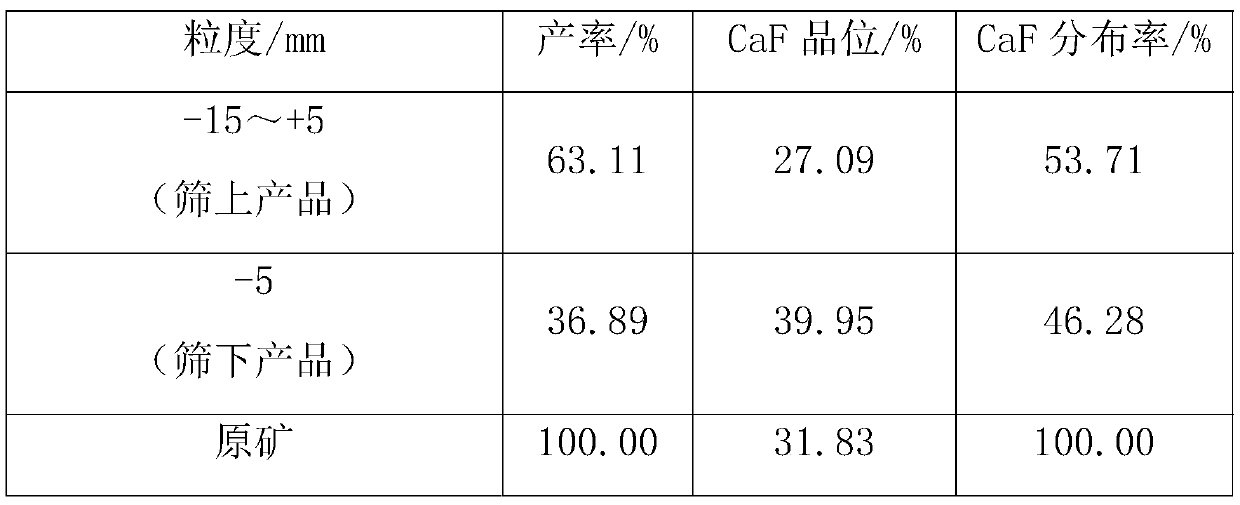

Fluorite lean ore color sorting upgrading-tailing pre-sorting method

The invention provides a fluorite lean ore color sorting upgrading-tailing pre-sorting method. The method comprises the following steps that (1) fluorite lean ore is crushed through two sections of closed circuits, and crushed products are -15 mm; (2) the crushed products are screened to obtain oversize products and undersize products, wherein the size of sieve pores is 5 mm, and the oversize products enter a first section color sorter for fluorite upgrading and sorting to obtain lump ore concentrates; (3) tailings sorted through the first section of color sorter enter into a second-section color sorter for tailing discarding sorting to obtain lump ore tailings and lump ore middlings; and (4) the undersize products in the step (2) and the lump ore middlings in the step (3) are mixed and ground, and then flotation is conducted. According to the method, the raw ore amount entering a ball mill is greatly reduced by pre-upgrading and sorting and pre-tailings-discarding of a large quantityof hard minerals, so that the beneficiation feed grade is improved, over-crushing of the hard minerals to the fluorite in the ore grinding process is reduced, so that the production cost is reduced, and the sorting quality is improved.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

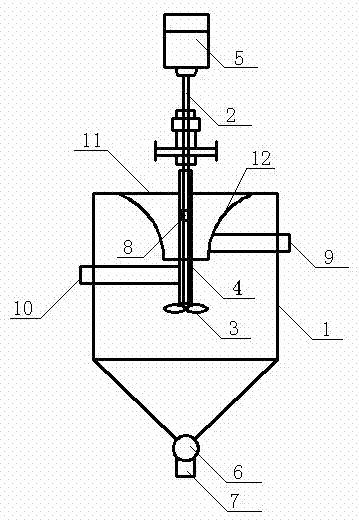

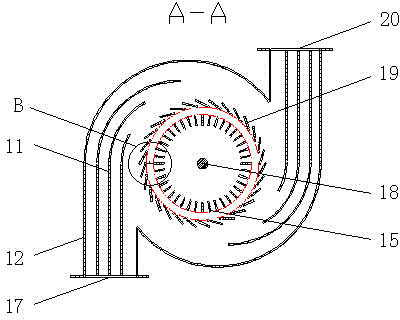

Centrifugal classifier

InactiveCN103028497AReduce headImprove classification efficiencyDispersed particle separationCentrifugal force sediment separationImpellerEngineering

The invention relates to classifying equipment, in particular to a centrifugal classifier, which comprises a body, a feed pipe opening, a discharge pipe, a sand discharge port, a discharger, an impeller, an air inlet, a cover, a motor, an end cover and a rotation shaft. The centrifugal classifier is characterized in that the upper part of the body is sealed by the end cover, a separating cover is fixedly arranged on the upper end of a hollow cavity body in the body and connected with one end of the discharge pipe, the other end of the discharge pipe extends outside the body, and a feed pipe is fixedly arranged on the side of the body; the motor is fixedly arranged on the upper part of the body and is in driving connection with the impeller through the rotation shaft which extends into the body and is coaxial with the body; the impeller is arranged on the lower end of the separating cover, a sleeve is sheathed outside the rotation shaft, and the air inlet is formed in the side wall of the sleeve, which is positioned in the separating cover; and the discharger is connected to the bottom of the body, and the lower end of the discharger is connected with the sand discharge port. The centrifugal classifier has the advantages of high classifying efficiency, certain classifying particle size, stable classifying effect, energy saving and wear resistance, and the classifying particle size can be regulated.

Owner:刘晔

Method of industrial producing fine powder or powder sizeg and its multifunction fine powder grinding series equipment

InactiveCN100998958AReduce microcracksLow mechanical strengthGrain treatmentsMohs scale of mineral hardnessAutomatic control

A process for industrially preparing superfine powder or powder slurry includes such steps as breaking raw material to become particles equal to or less than 3 mm, multi-stage pulverizing to become superfine powder, and directly mixing it with water to become powder slurry. Its multifunctional superfine pulverizing system is also disclosed.

Owner:何永峰

Multistage screening mechanism

PendingCN107282257AReduce the burden onReduce workloadDirt cleaningGrain treatmentsEngineeringMachining

The invention relates to the technical field of material crushing, in particular to a multistage screening mechanism. The multistage screening mechanism comprises a first-stage primary crushing unit and a fine crushing unit arranged on the downstream part of the primary crushing unit, wherein the primary crushing unit and the fine crushing unit each comprise a screening structure which is used for screening out materials with a preset grain diameter so as to avoid over crushing of the materials in the units. According to the multistage screening mechanism, the materials with the preset grain diameter can be screened out of the current crushing units timely in the crushing process and can be prevented from being crushed continuously, and therefore over crushing is avoided, and the machining workload is reduced.

Owner:NENGCHENG GRP

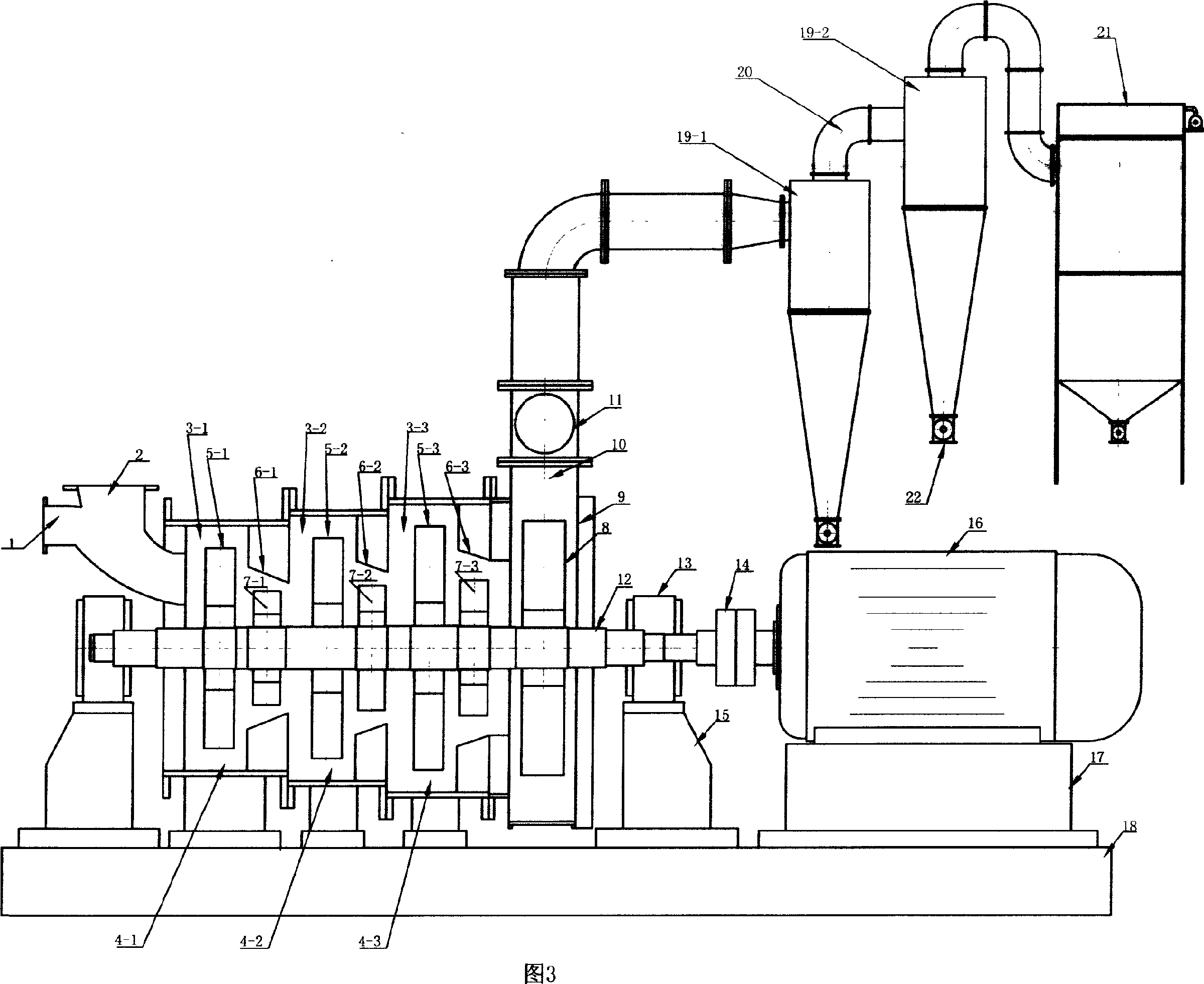

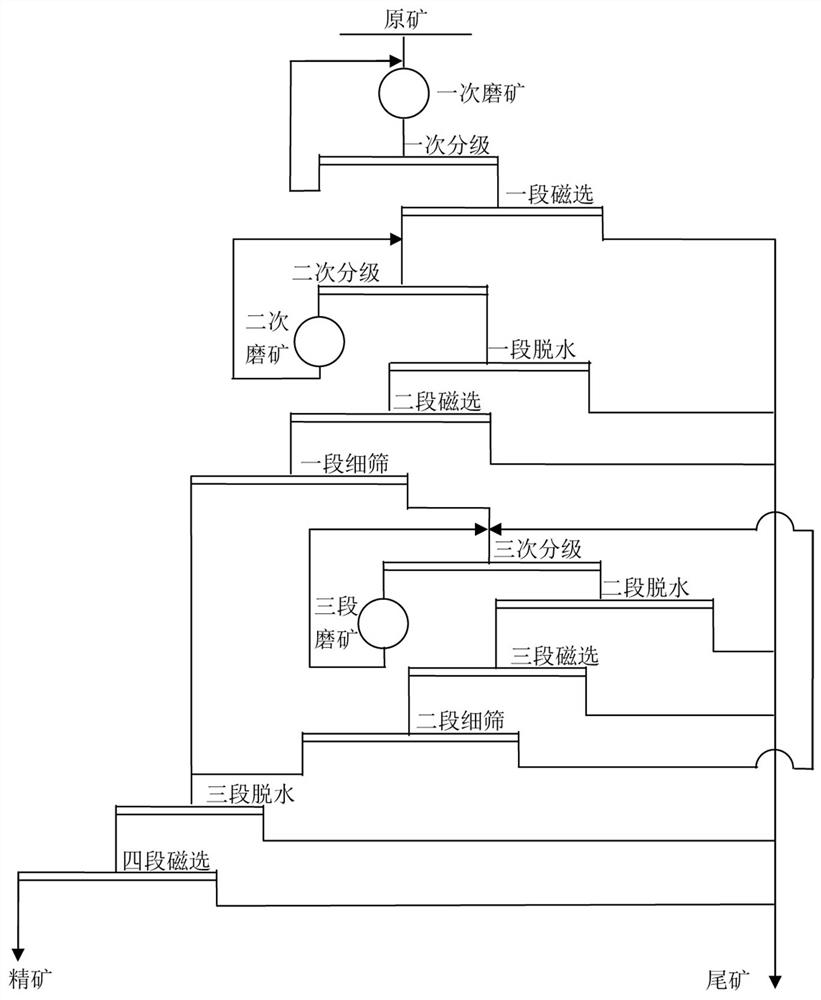

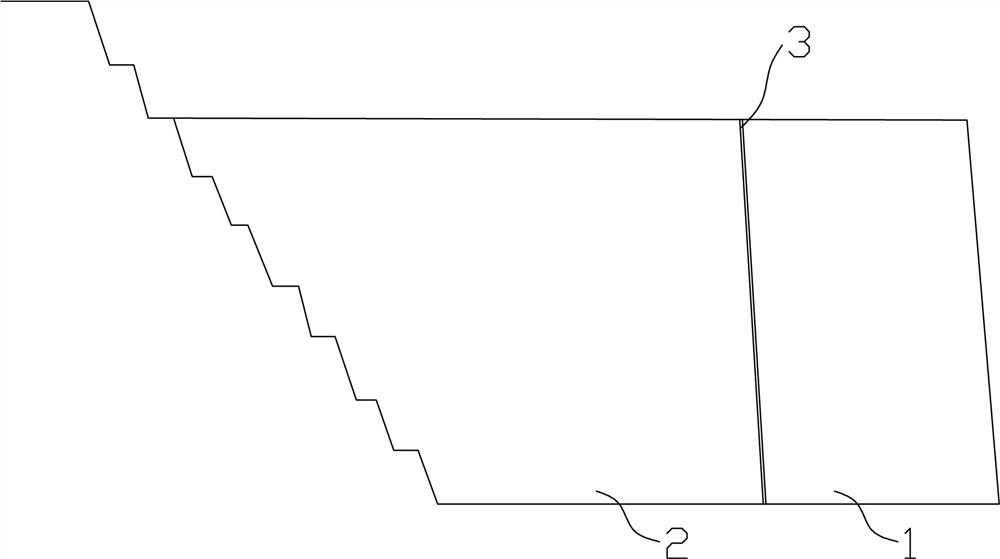

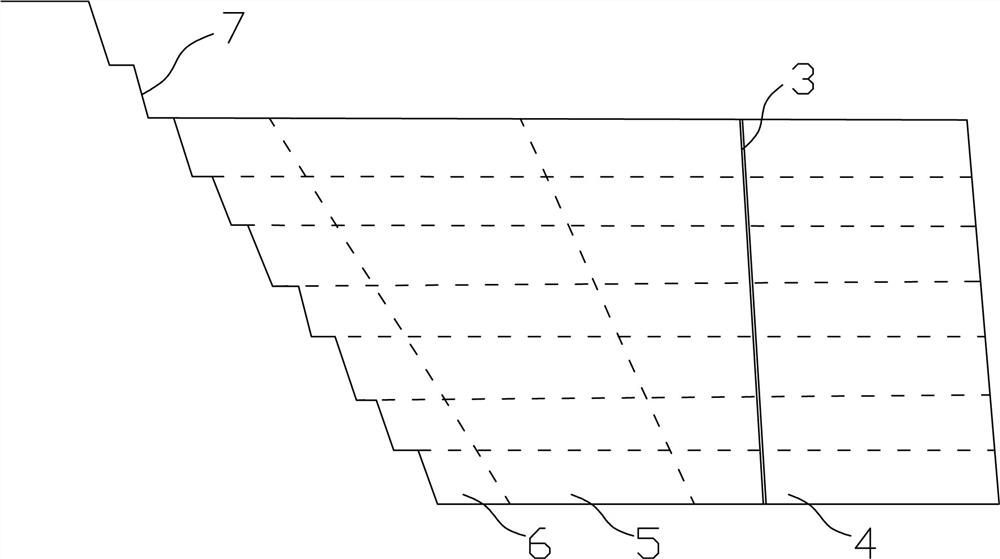

Ore grinding process for lowering energy consumption of ore grinding and reducing over-crushing

ActiveCN109550566AReduce rationalityGuaranteed reasonablenessGrain treatmentsClosed loopHigh pressure

The invention discloses an ore grinding process for lowering energy consumption of ore grinding and reducing over-crushing. The ore grinding process comprises the steps that firstly, crushed materialsare classified in advance through a first-stage linear vibrating screen, oversize materials enter a high-pressure roller mill to be milled, high-pressure roller milled products are inspected and graded through a second-stage linear vibrating screen, undersize materials of the first-stage linear vibrating screen and oversize materials of the second-stage linear vibrating screen are merged and thenfed into a first-stage ball mill, first-stage ball mill discharged ore and undersize materials of the second-stage linear vibrating screen jointly enter a hydrocyclone set to be subjected to in-advance inspection and classification, classified overflow is fed into a high-frequency vibrating fine screen to be inspected, controlled and classified, oversize materials of the high-frequency vibratingfine screen and hydrocyclone settled sand are fed into a second-stage ball mill to form a closed loop. According to the ore grinding process, the high-pressure roller mill and the sieving link is additionally arranged, the qualified particle grade is separated in time, the ore grinding amount entering the ball mill is decreased, and the purposes of lowering the energy consumption of ore grinding and reducing over-crushing are achieved; and the mode of combination of the hydrocyclone set and the high-frequency vibrating fine screen is adopted in second-stage ore grinding classification, and therationality of the feed particle size is ensured.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

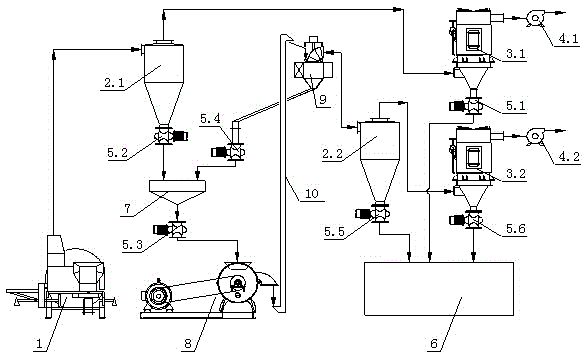

System for preparing straw micro powder

ActiveCN104826721AControl granularityQuality assuranceGas current separationGrain treatmentsEngineeringAir classifier

The invention discloses a system for preparing straw micro powder, and relates to a micro powder grinding facility. A turbo air classifying technology is used to optimize the system, and the system is composed of a pre-grinding subsystem and a grinding and classifying subsystem. The system comprises a straw pre-grinding machine, a cyclone separator, a pulse-jet bag dust collector, a blower fan, an air-lock feeder, a finished product chamber, a semi-finished product collecting chamber, a straw grinding machine, an elevating machine, and a turbo air classifier. The system can grind, classify and collect crop straws, is capable of effectively controlling the particle size of the straw micro powder, and thus guarantees the quality of finished products. The finished product fineness (D98) is adjustable in a range of 80 to 200 um. The system is a closed circulation system, can work continuously, saves the time, and shortens the production period. At the same time, the whole production process is carried out under a negative pressure, so no ash is generated, and the system is clean and environment-friendly.

Owner:SOUTHWEAT UNIV OF SCI & TECH

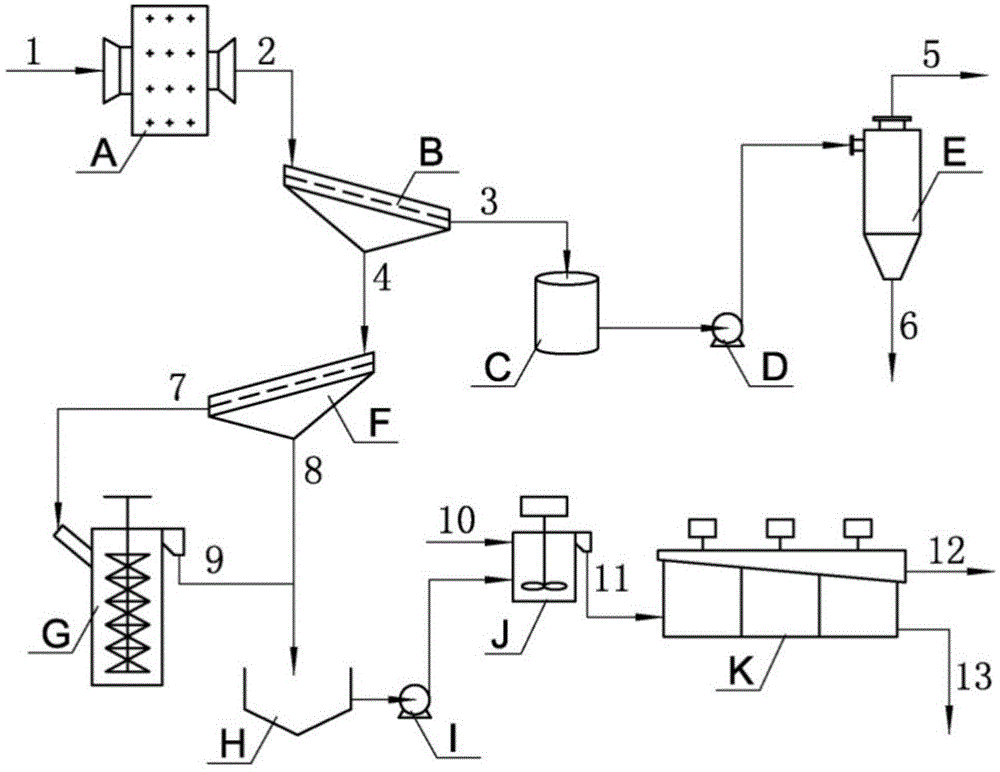

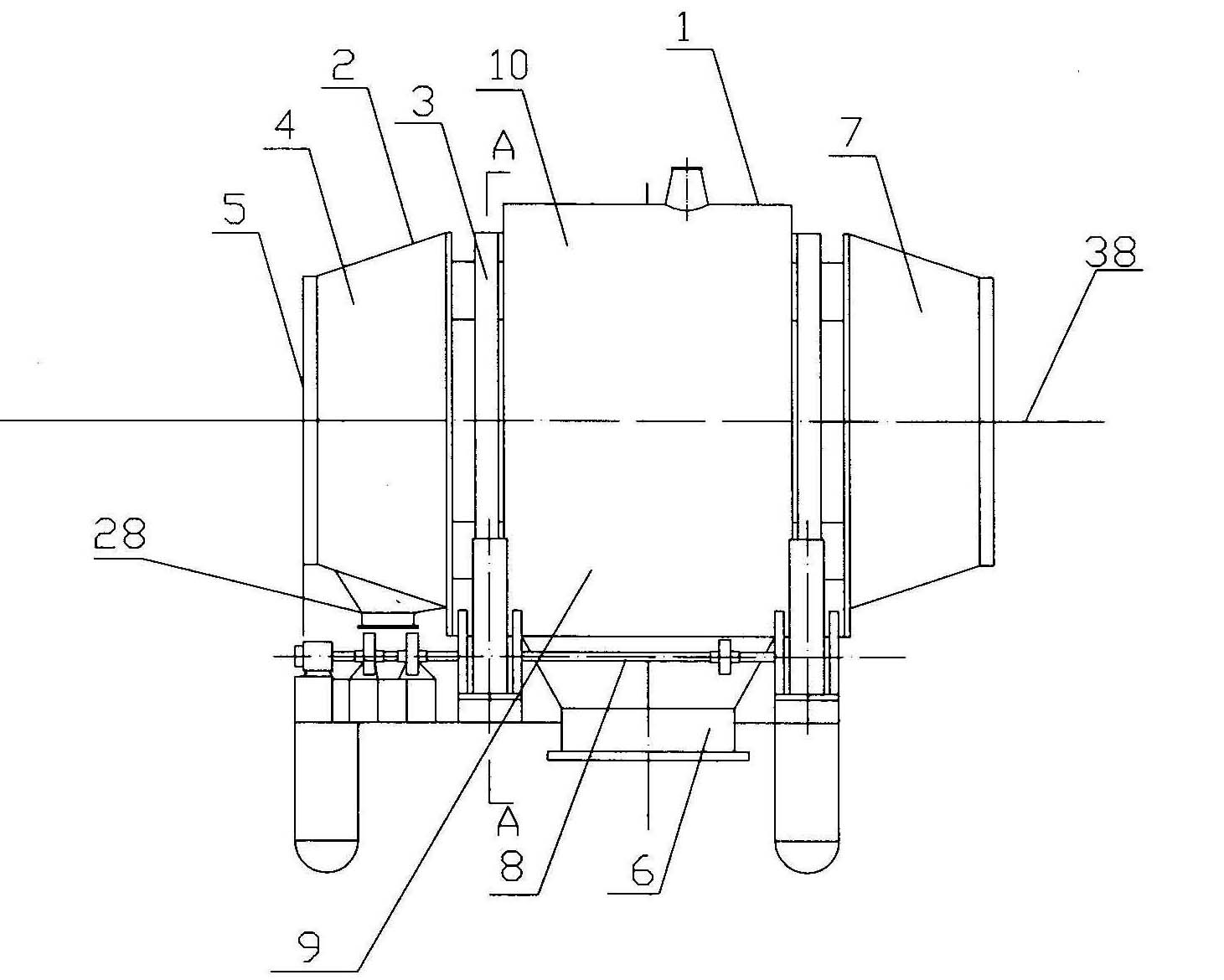

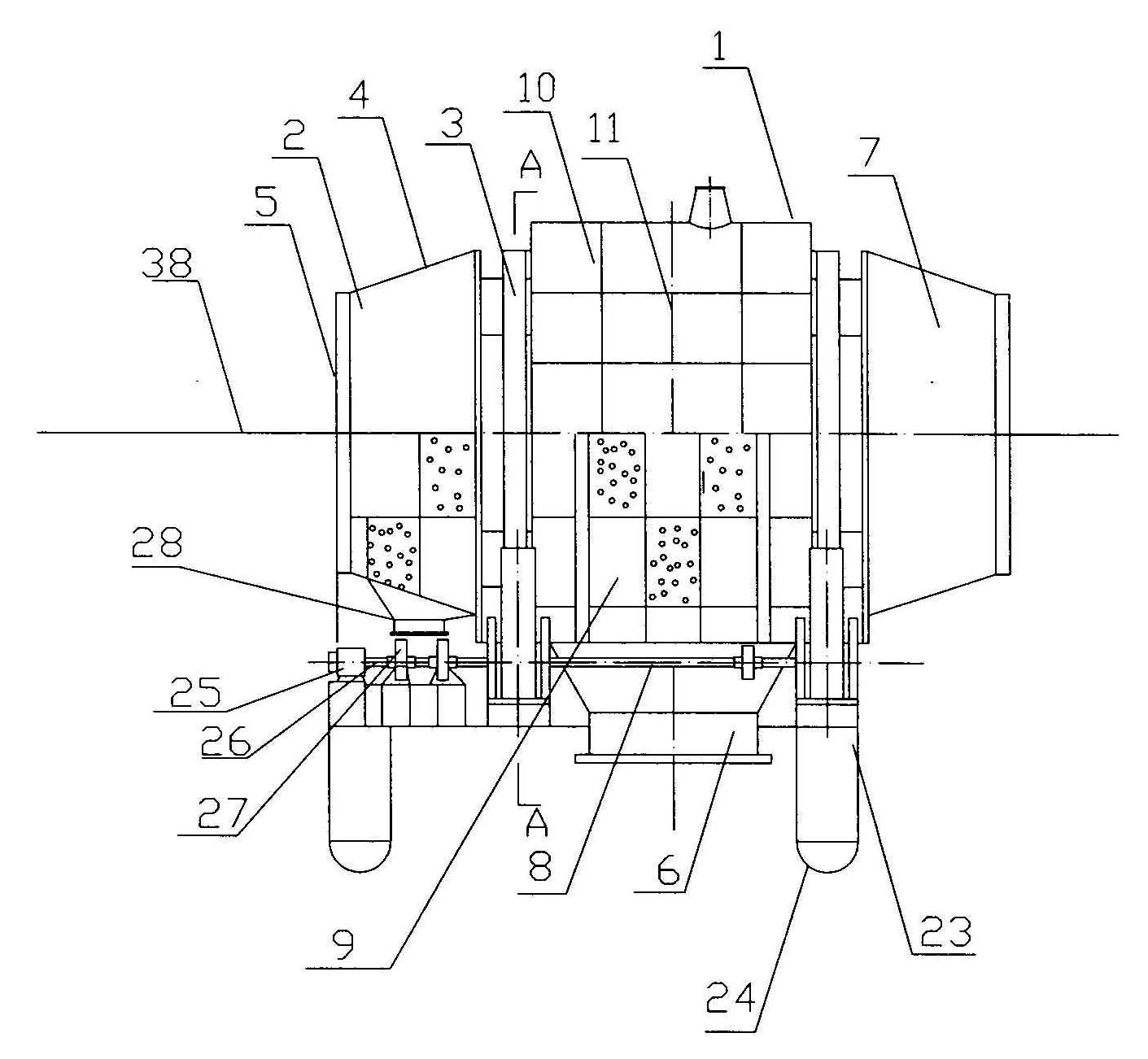

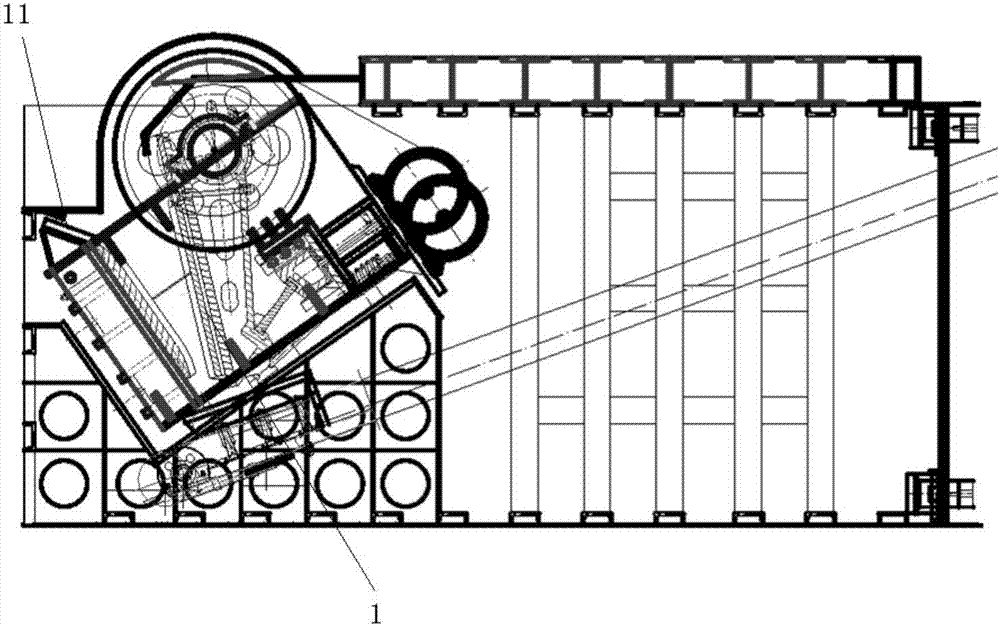

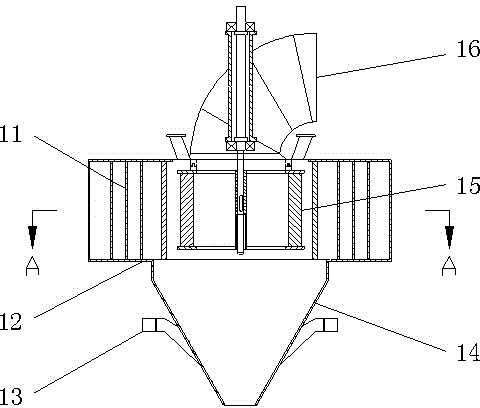

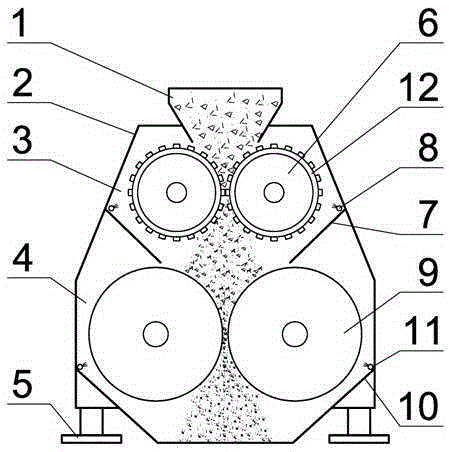

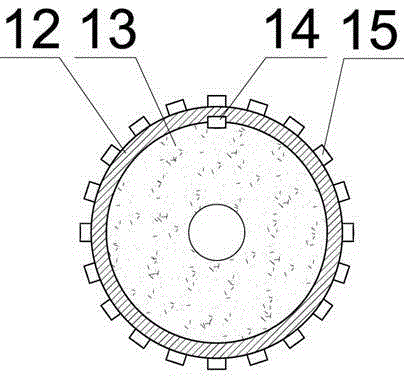

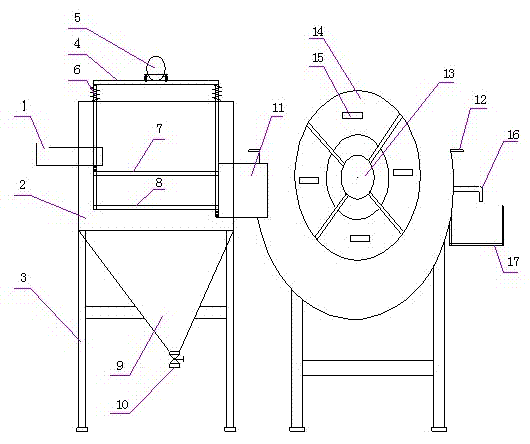

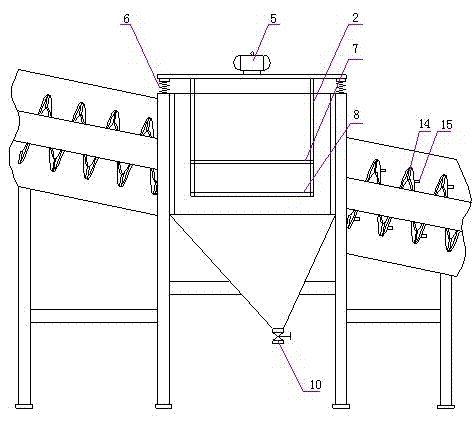

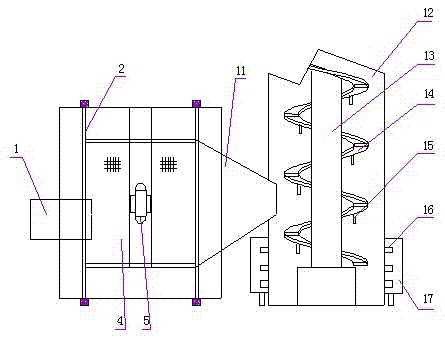

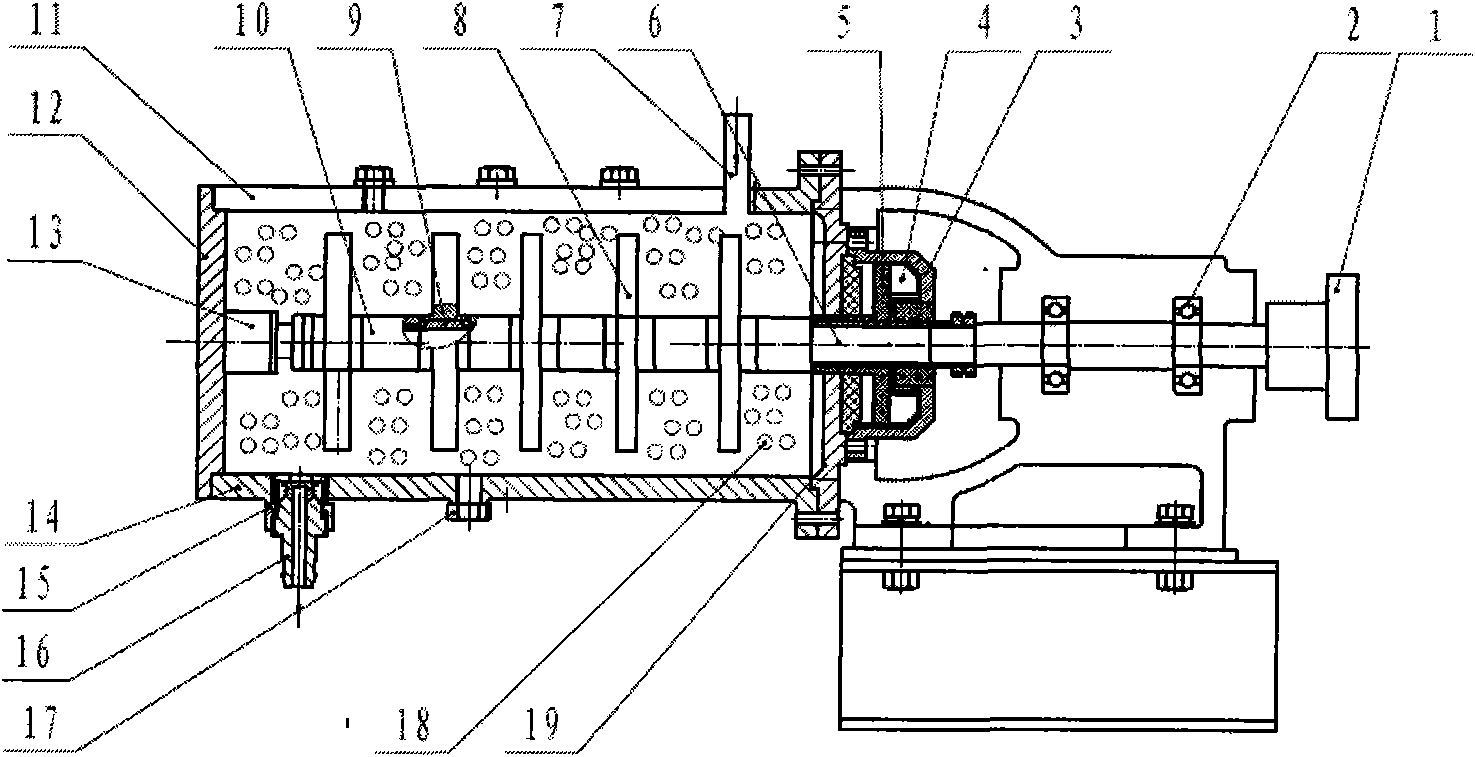

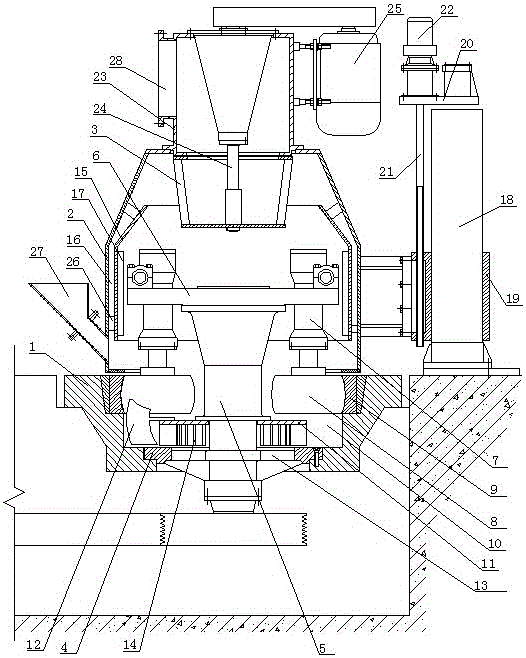

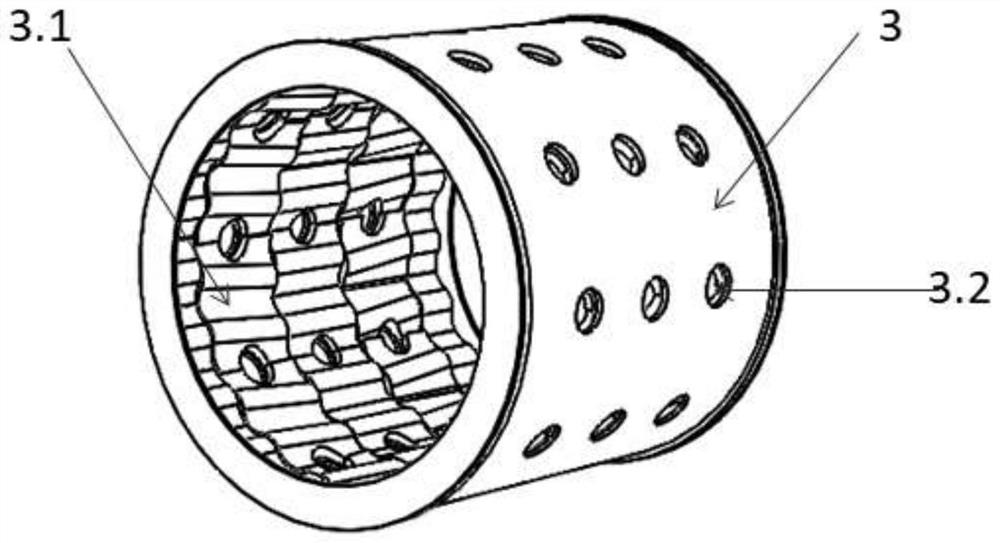

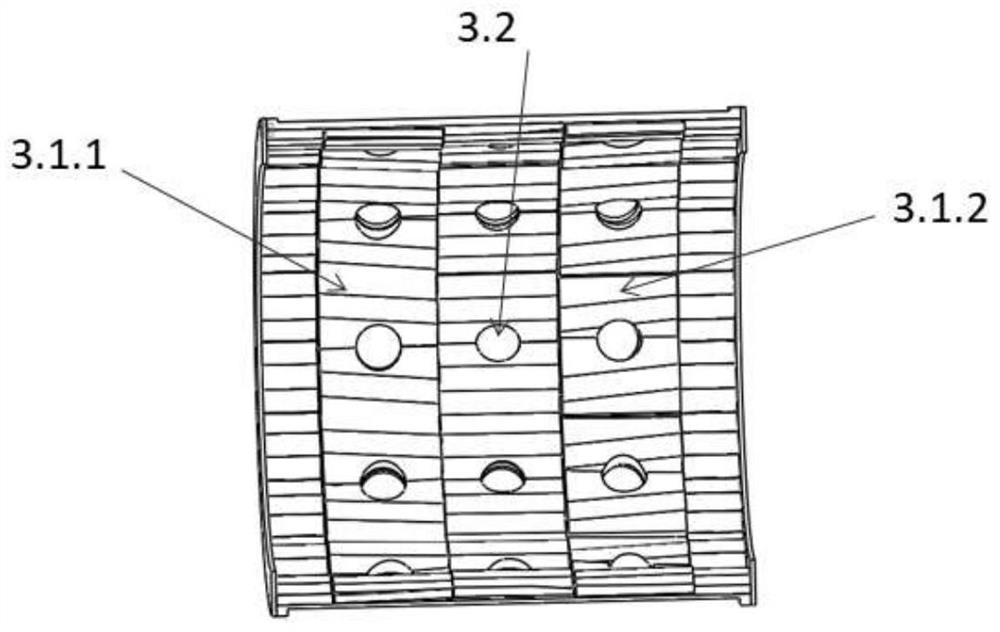

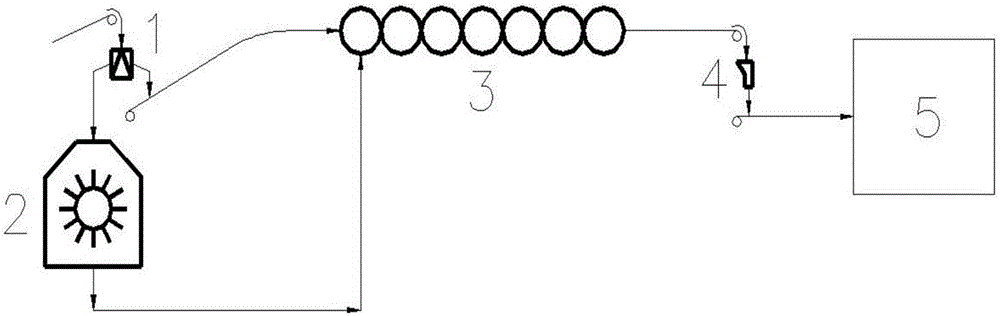

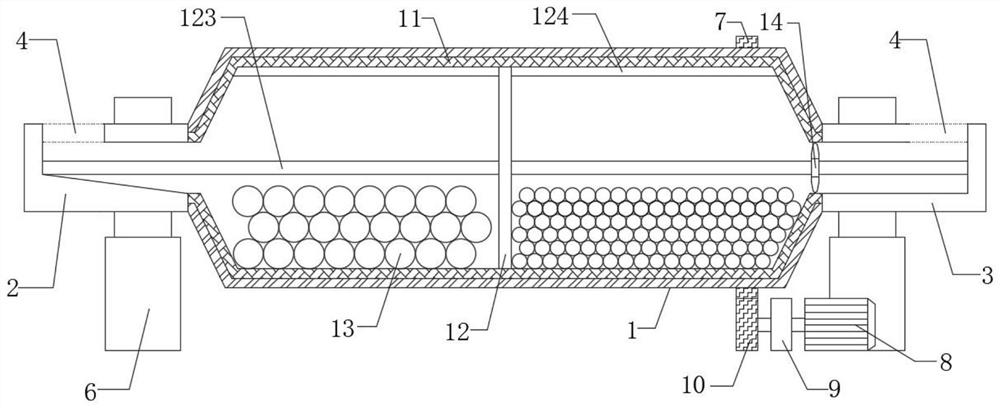

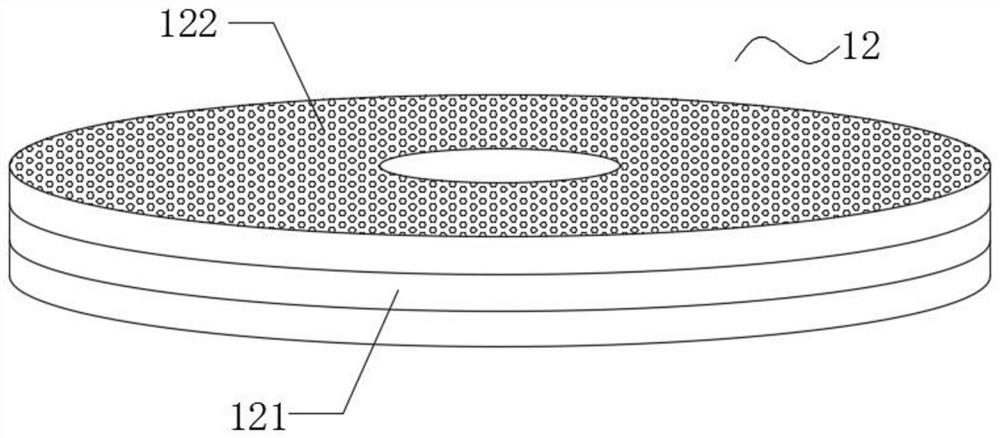

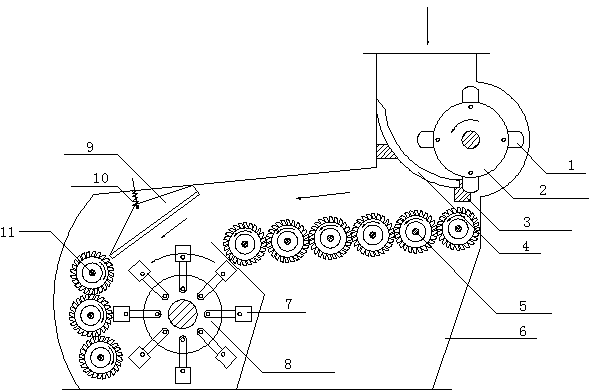

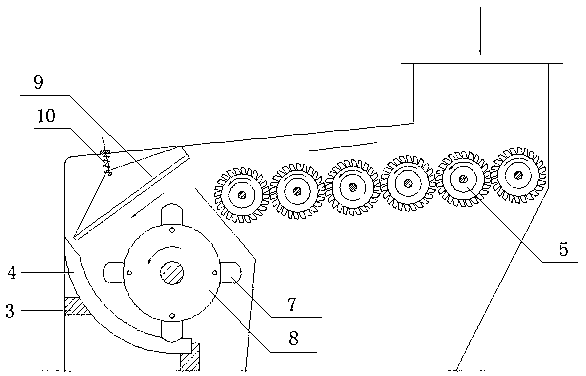

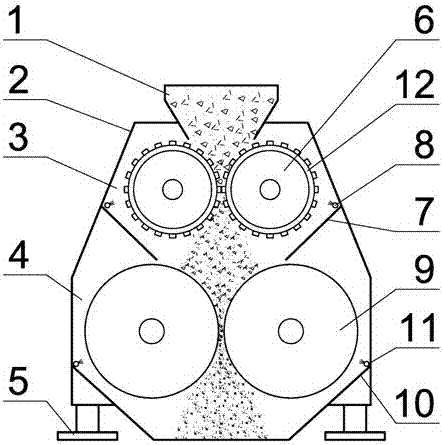

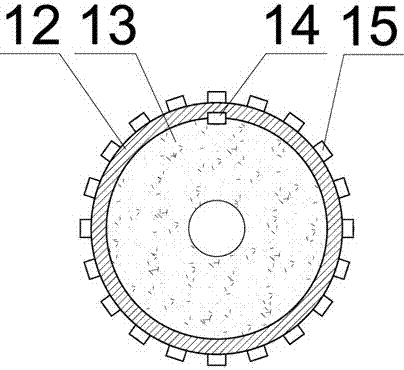

Coarse and fine crushing integrated type middling coal wet crushing machine

ActiveCN105413794ALow particle size limitSimple structureGrain treatmentsEngineeringHigh water content

A coarse and fine crushing integrated type middling coal wet crushing machine is especially suitable for crushing and dissociating high-water-content middling coal obtained after gravity separation and medium draining in a coal preparation plant. The coarse and fine crushing integrated type middling coal wet crushing machine comprises a feed hopper, a first crushing chamber, a second crushing chamber and a discharge hopper. The first crushing chamber is located above the second crushing chamber and communicated with the second crushing chamber. Blade type crushing rollers are arranged in the first crushing chamber and used for coarsely crushing the middling coal, and groove type crushing rollers are arranged in the second crushing chamber and used for finely crushing the coarsely crushed middling coal. Anti-blocking flushing water pipes are arranged on the lower side inner wall of the first crushing chamber and the lower side inner wall of the second crushing chamber respectively. The coarse and fine crushing integrated type middling coal wet crushing machine is simple in structure, coarse crushing and fine crushing of the high-water-content middling coal are achieved in the same machine, and blocking is unlikely to occur; the upper limit of particle sizes of crushed products is low, the particle sizes of the products are uniform, and the frequency of excessive crushing phenomena is low; no dust is generated during crushing, and secondary separation in gravity separation of the middling coal after crushing and dissociation is facilitated.

Owner:CHINA UNIV OF MINING & TECH

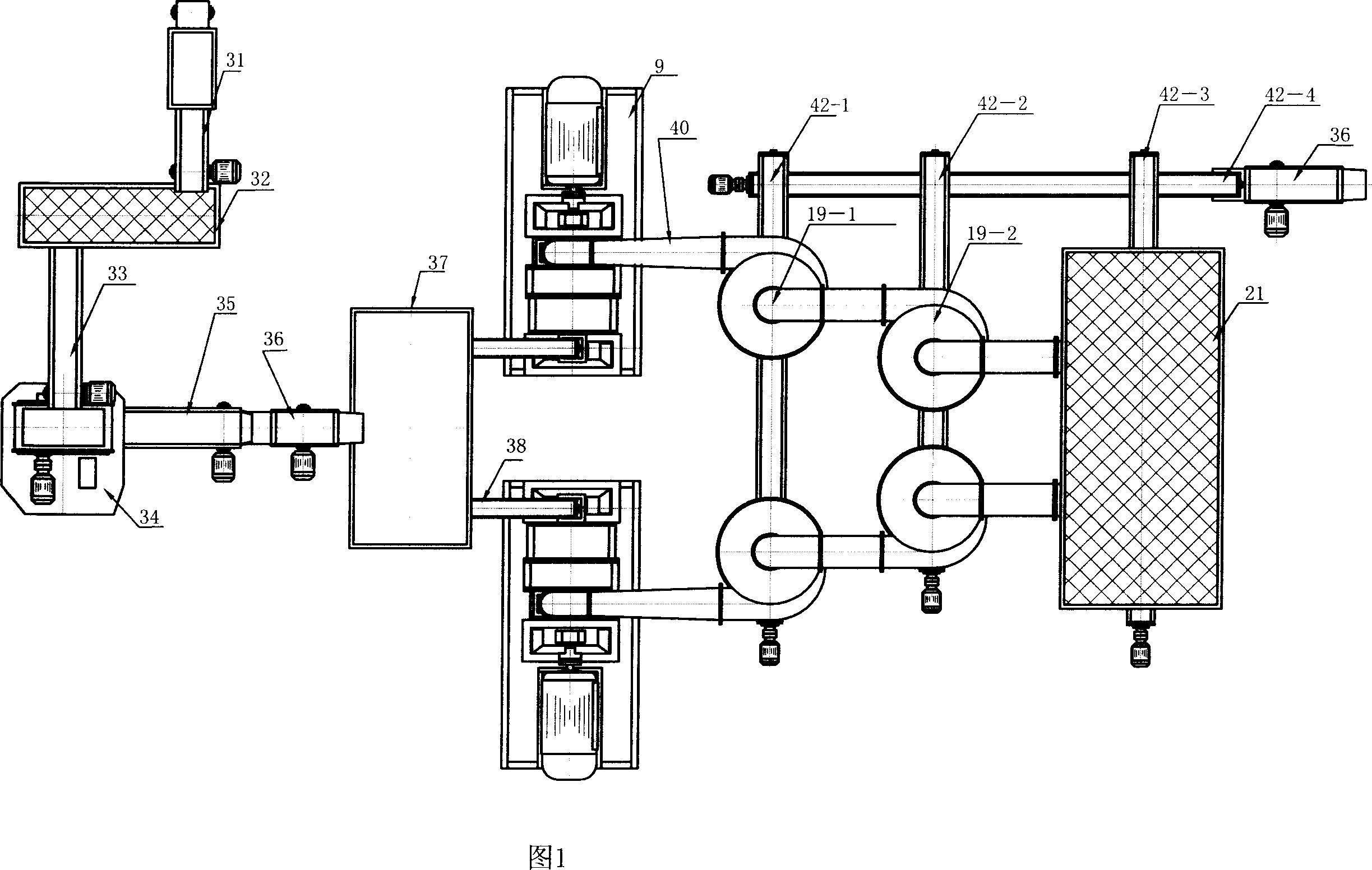

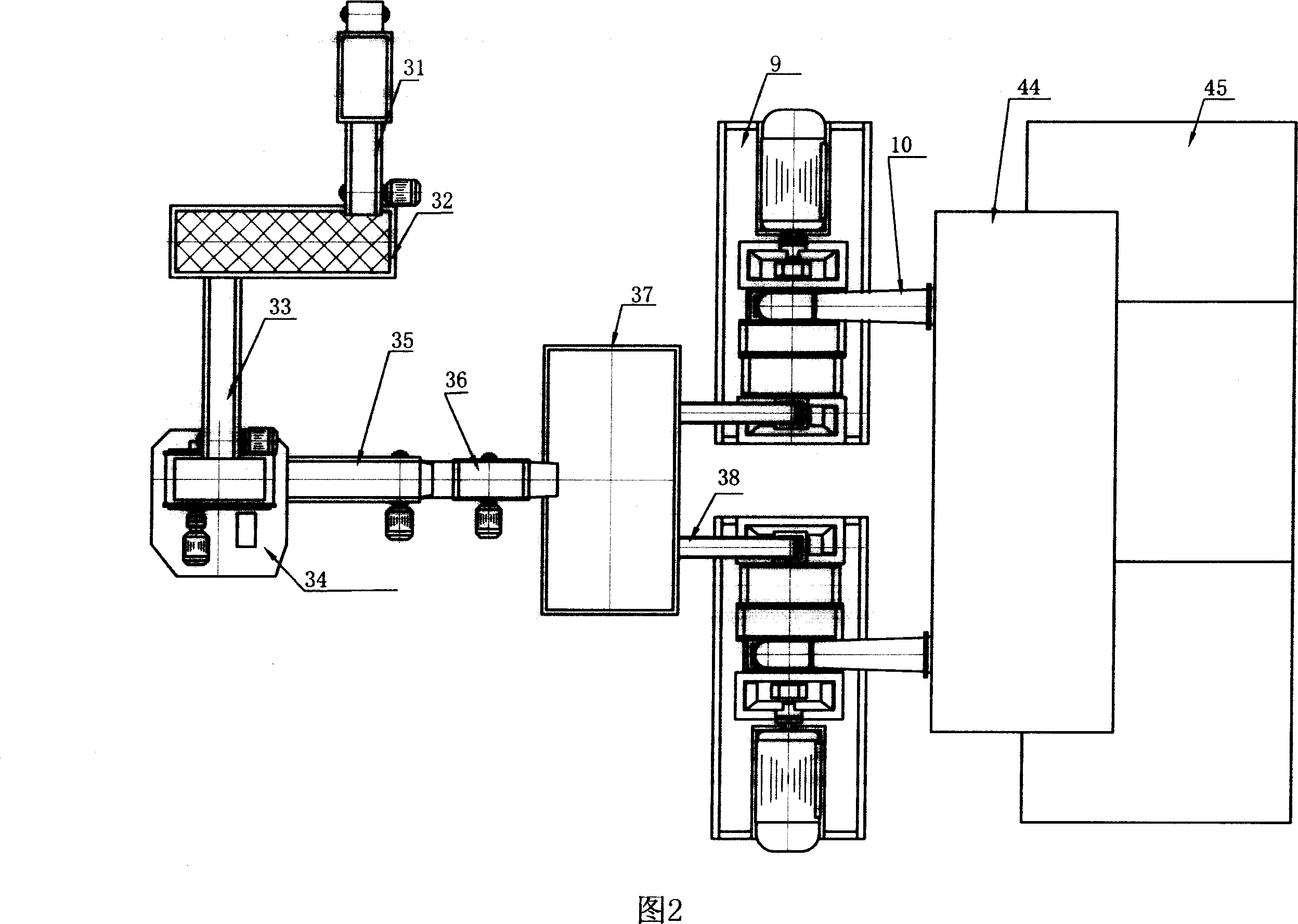

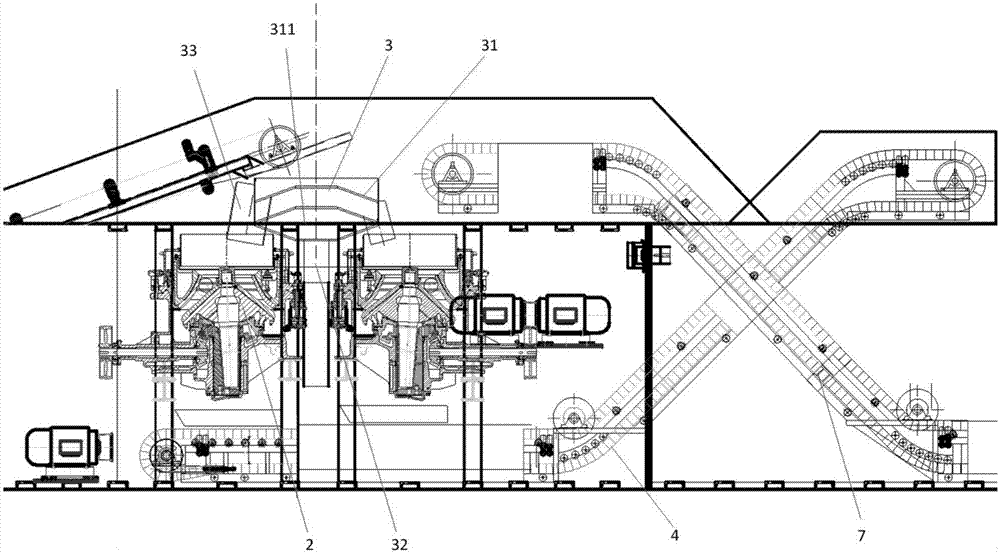

Compound classification method and equipment for ground ore product

ActiveCN102228866AReduce anti-enrichment phenomenonReduce over crushingSievingScreeningMining engineeringMineralogy

The invention relates to a compound classification method and equipment for a ground ore product, belonging to the technical field of ore processing. The compound classification method is characterized by combining vibration screening with spiral classification methods and comprising the following steps of: firstly carrying out vibration screening on the ground ore product with a double-layer chute vibrating screen to obtain a plus sieve material and a minus sieve material, then directly conveying the plus sieve material to a spiral classifier for classification, returning the coarse material to an ore grinding machine for grinding again, overflowing and discharging the fine material from both sides of the classifier, mixing with the minus sieve material and conveying to subsequent sorting operation, wherein the chute vibrating screen is arranged beside the spiral classifier, the end of the ore discharge chute of the chute vibrating screen is directly connected with the ore feeding port on the tank body of the spiral classifier, and the classification region tank body of the spiral classifier is higher than conventional tank body. The compound classification method and equipment have the advantages of significantly reducing the derichment of fine-grained heavy ore in settled sand and returned sand, low closed-circuit ore grinding over-grinding and inclusion in settled sand, high classification efficiency, achieving direct closed-circuit with the ore grinding machine and the like, and can be used for transforming existing ground ore classification equipment and manufacturing novel screening-spiral compound classifiers supporting the use of the ore grinding machine.

Owner:KUNMING UNIV OF SCI & TECH

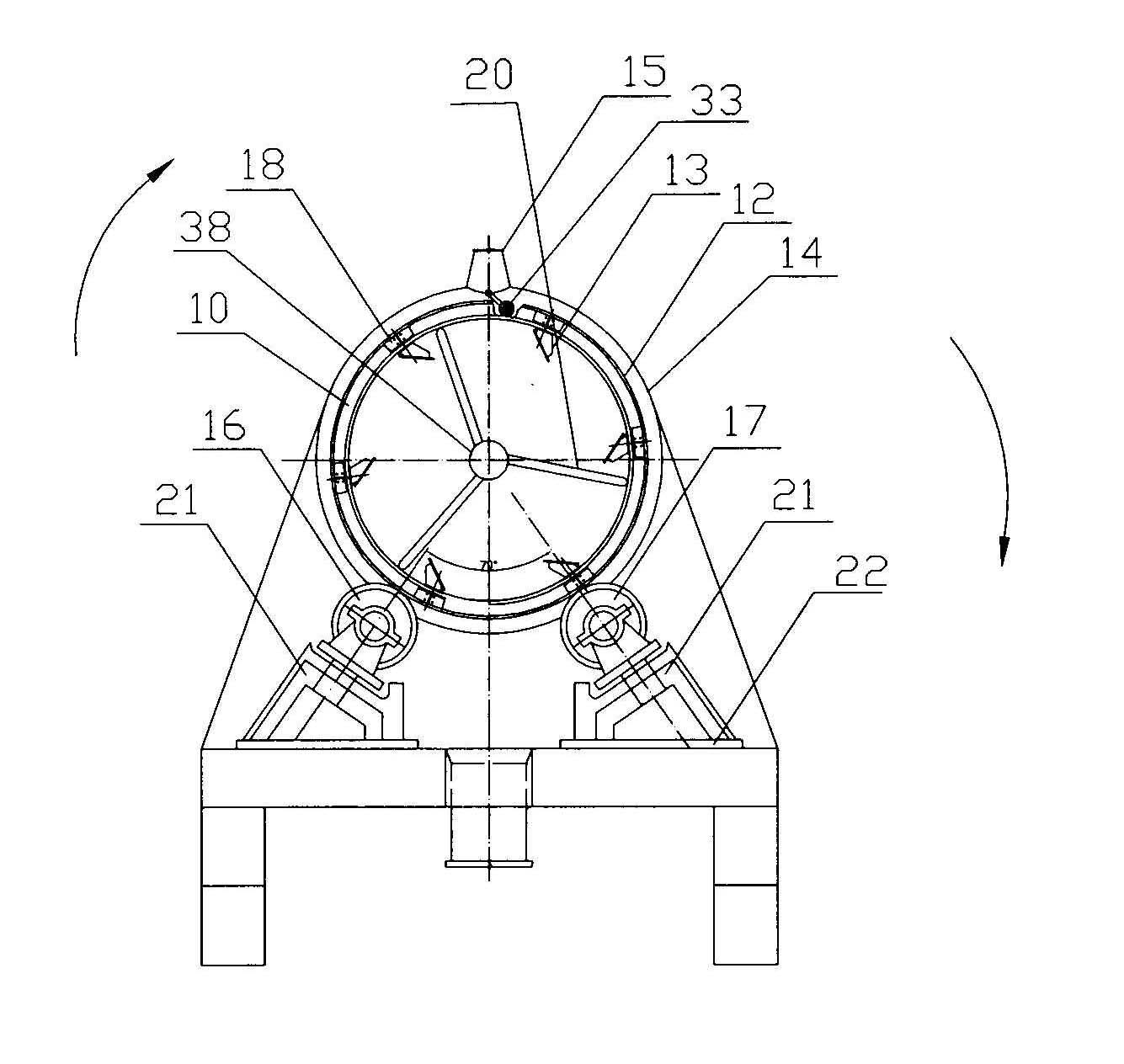

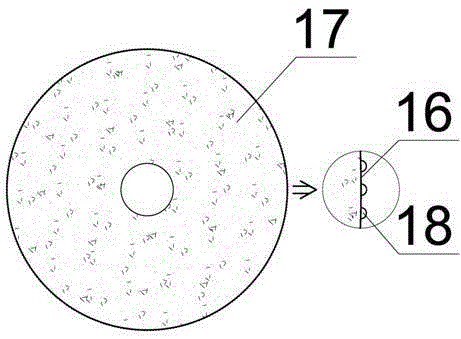

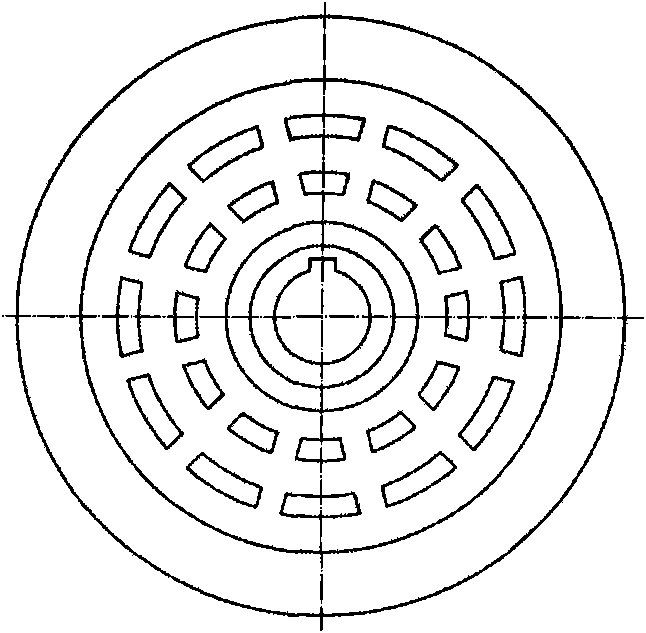

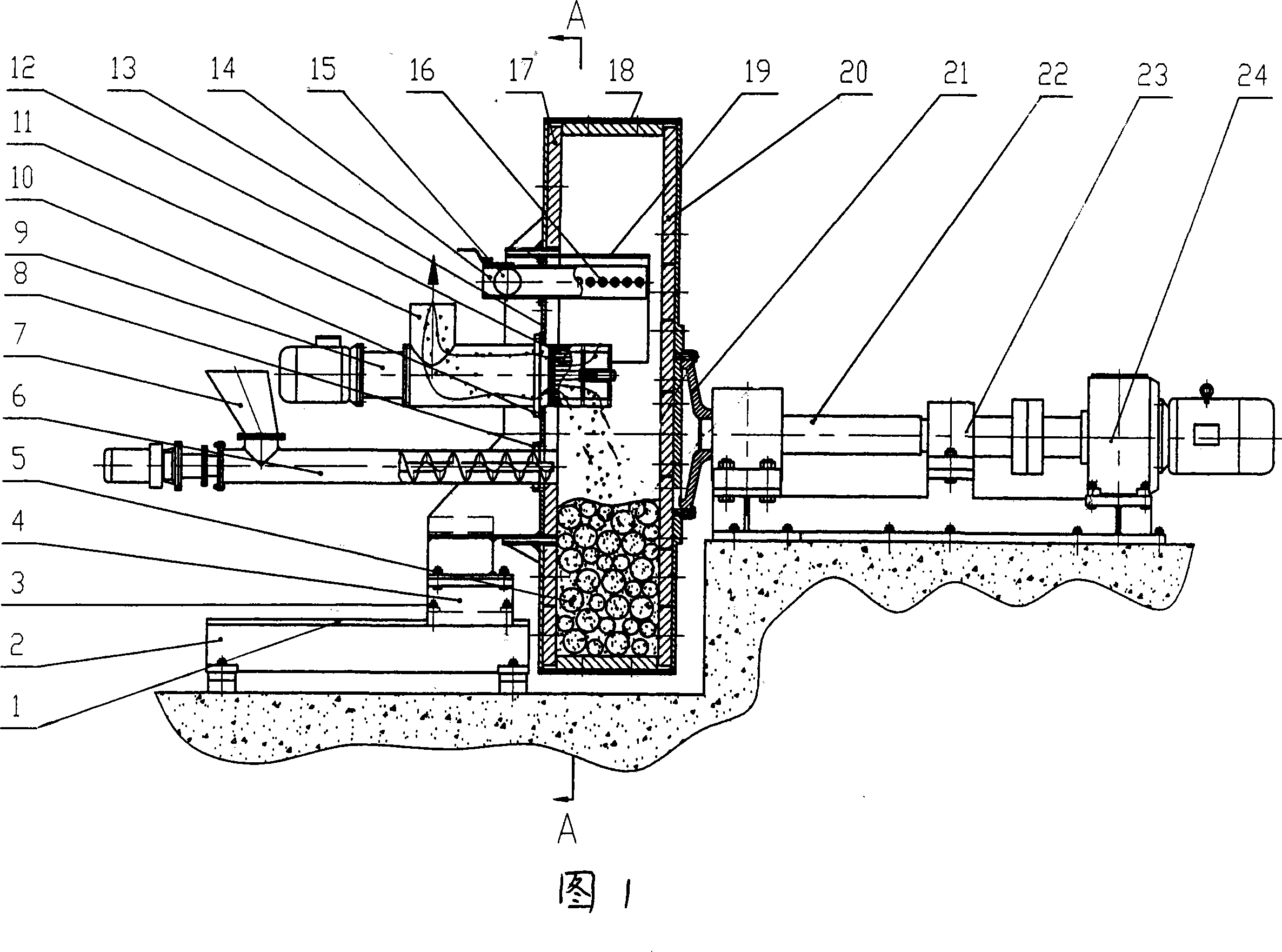

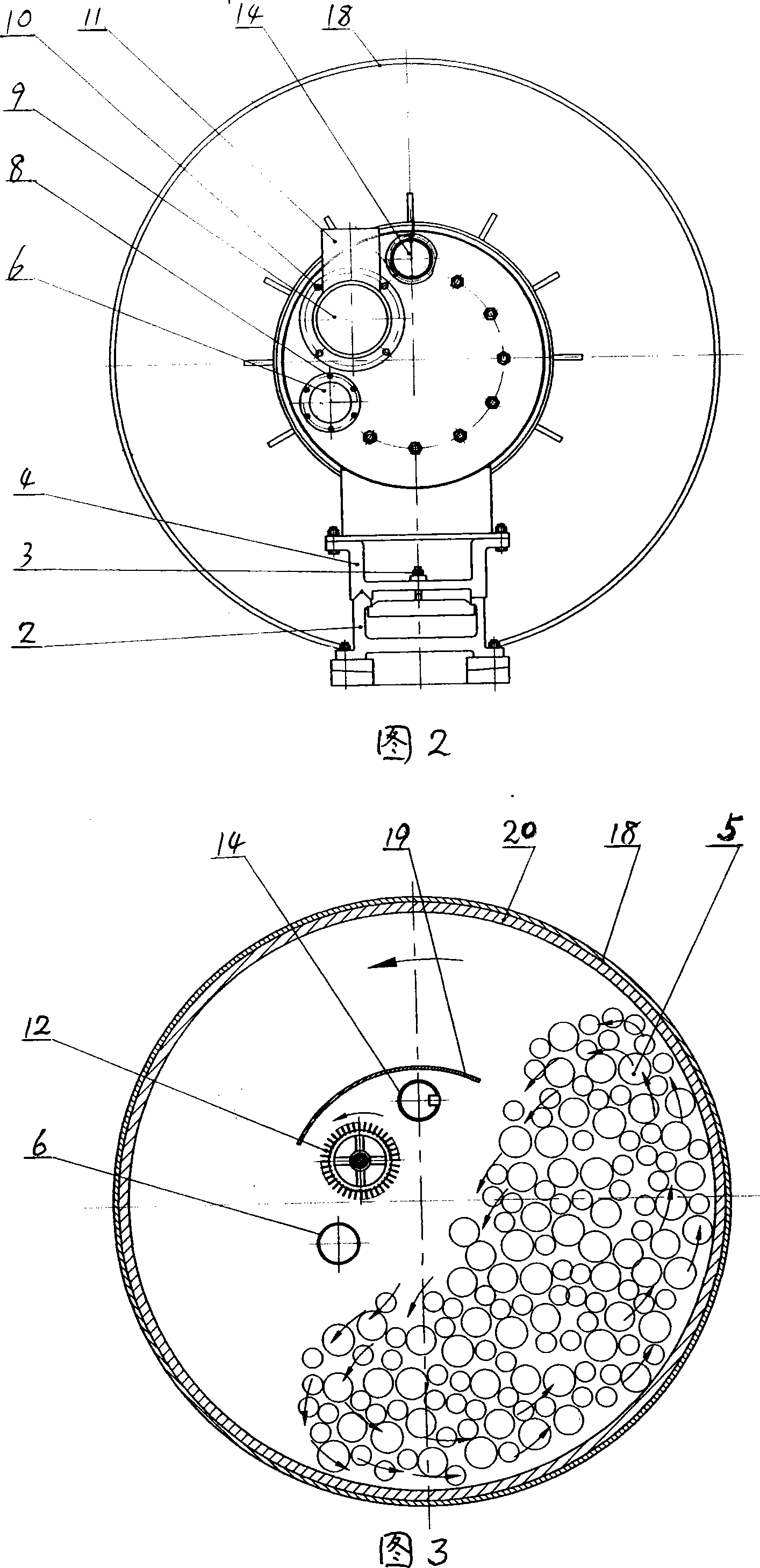

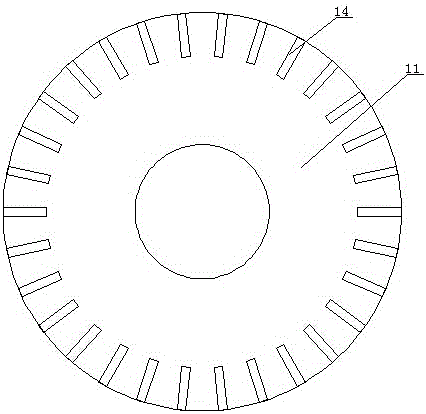

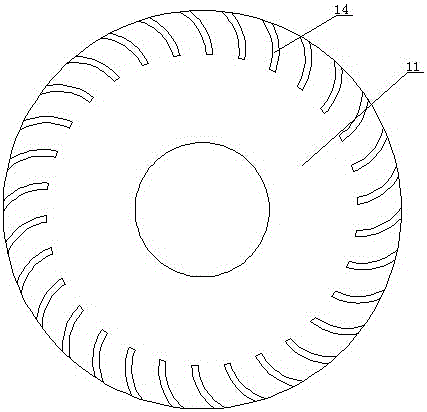

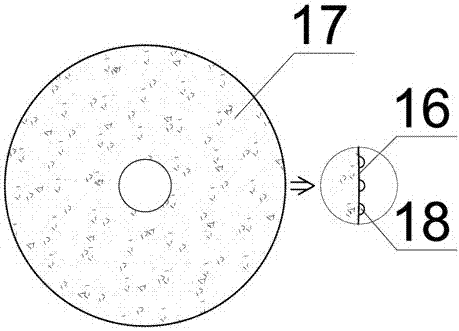

Micro-fine particle grade horizontal grinding device

InactiveCN101549312AIncreased useful power coefficientReduce over-crushingGrain treatmentsImpellerEnergy density

The invention concretely relates to a micro-fine particle grade horizontal grinding device. The grinding device is composed of a grinding chamber and a drive mechanism; the barrel installation center line of the grinding chamber is horizontal and the horizontal length in the barrel is 1.5-2.5 times of the inner circle diameter of the barrel and the inner surface of the barrel is abrasion resistance material and the grinding medium (18) is filled into the barrel; the 5-8 agitating vanes (8) are vertically mounted on the main axle (6) coincident with the barrel center line and a material discharging device is set at the right downside of the left end of the barrel and a material feeding port (7) is set on the right upside of the right end of the barrel; the left end of the main axle (6) is mounted in a bearing liner (13) and the bearing linear (13) is fixed on the center of the left end cover (12) of the barrel and the right end of the main axle (6) passes through a bearing (2) and is connected with the motor by a shaft coupling (1); an accessory impeller (5) is mounted on the main axle (6) of the right side of the barrel. The material pulp of the device is brushed under the high-speed mobile grinding medium colliding, grinding action with features of simple start, large medium energy density and high grinding efficiency.

Owner:WUHAN UNIV OF SCI & TECH +1

Unpressurized feeding three-product dense medium cyclone for high-density separation

InactiveCN102764706AIncrease sorting densityEfficient sortingVortex flow apparatusCycloneHigh density

The invention discloses an unpressurized feeding three-product dense medium cyclone for high-density separation and belongs to the technical field of sorting equipment. The dense medium cyclone comprises a primary truncated cone-shaped cyclone and a secondary cylindric-conoid cyclone which communicate with each other through pipelines. The cone angle of the primary cyclone is 5-20 degrees and the cone angle of the cone part of the secondary cyclone is 30-180 degrees. One end of the primary cyclone is provided with a low-density heavy medium fluid suspension inlet and a concentrate outlet, and the other end is provided with a raw ore inlet. One end of the secondary cyclone is provided with a mine tailing outlet and the lower portion of the secondary cyclone is provided with a middling outlet. The unpressurized feeding three-product dense medium cyclone provided by the invention can be used to effectively sort high-density minerals and is especially suitable for sorting of minerals with the density being greater than 2.4 kg / L. The dense medium cyclone has advantages of simple production technology, low cost, little environmental pollution and high grade of obtained concentrate products.

Owner:韦善兵

Internal grading ball mill

ActiveCN101143344ADischarge in timeReduce regrindingGas current separationGrain treatmentsImpellerEngineering

An inner classified ball mill includes a ball grinding cylinder, which is driven by a transmission device to rotate. One side of the ball grinding cylinder is open. The opening position is equipped with a stator disc, which is fixed on a sliding seat. The stator disc and the ball grinding cylinder form a ball grinding cavity. The sliding seat is installed on a rail seat. A classifier, an adjustable air inlet pipe and a feed screw conveyer are fixed on the stator disc. An impeller of the classifier is arranged in the ball grinding cavity. The present invention can realize the classification of fines in the ball grinding cavity. The over grinding of the materials is reduced. The condition that superfine powder hinders the grinding of crude materials can be avoided. The grinding efficiency is greatly improved. The equipment energy loss is lowered. And the mill has the advantages of simple structure and less occupied area and can be used for the grinding of heat-sensitive materials.

Owner:WEIFANG JINGHUA POWDER ENG EQUIP

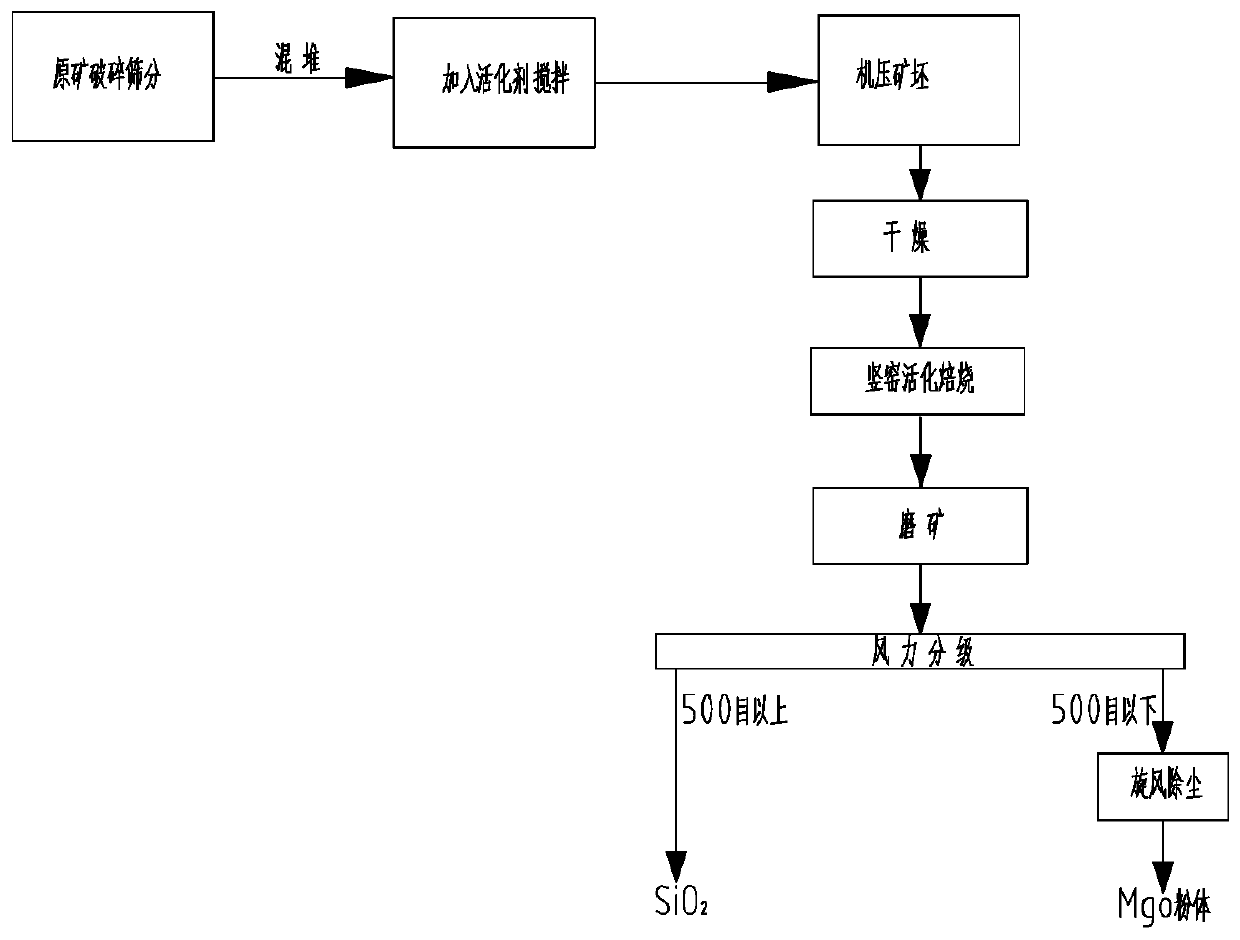

Magnesite activated-roasting, reselecting and silica-removing process

The invention relates to a magnesite activated-roasting, reselecting and silica-removing process. The magnesite activated-roasting, reselecting and silica-removing process is characterized by comprising the following steps that lean magnesite is crushed and screened to obtain raw magnesite having the granularity of 0-30 mm; 5%-10% of fine magnesium oxide powder is added into the raw magnesite, 0.5%-1% of magnesium chloride and 7%-12% of water are added, even stirring is performed, mechanical pressing is performed to form magnesite blanks, the blanks are put in a drying furnace for drying and dehydration; then, the blanks are put in a shaft kiln of 900-1100 DEG C, and activated roasting is performed for 1.5-2.5 hours; the roasted magnesite blanks are fed into a mill to be stirred and ground; air classification is conducted on the ground products, the products greater than 500 mesh are impurities, the products smaller than 500 mesh are directly fed into a cyclone dust collector for gas-solid separation, and a magnesium oxide product having the obtained magnesium oxide content of 96.6% or above and the SiO2 content lower than 0.32% is obtained. Compared with the prior art, the magnesite activated-roasting, reselecting and silica-removing process has the advantages of being simple in technological process, good in raw ore adaptability, suitable for industrial production, low in cost and low in investment.

Owner:宋重本

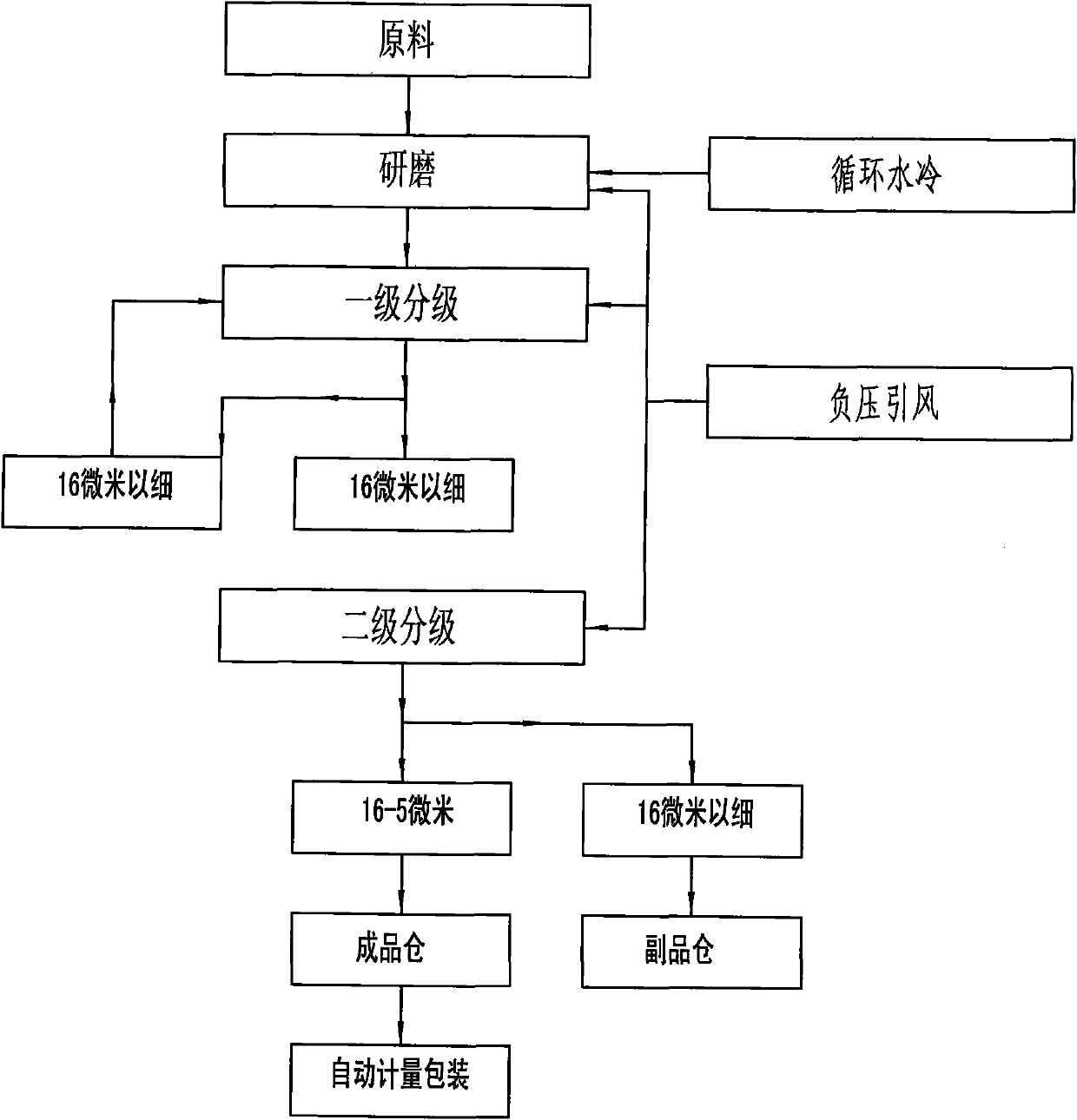

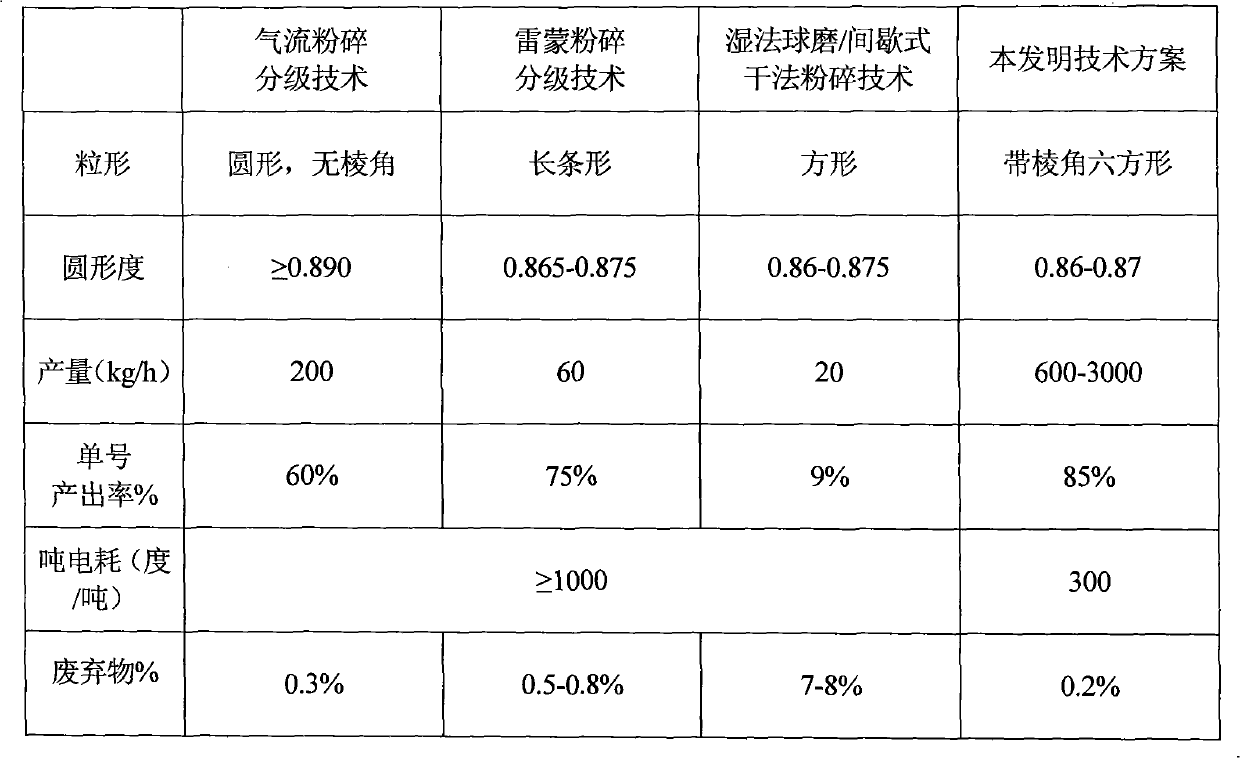

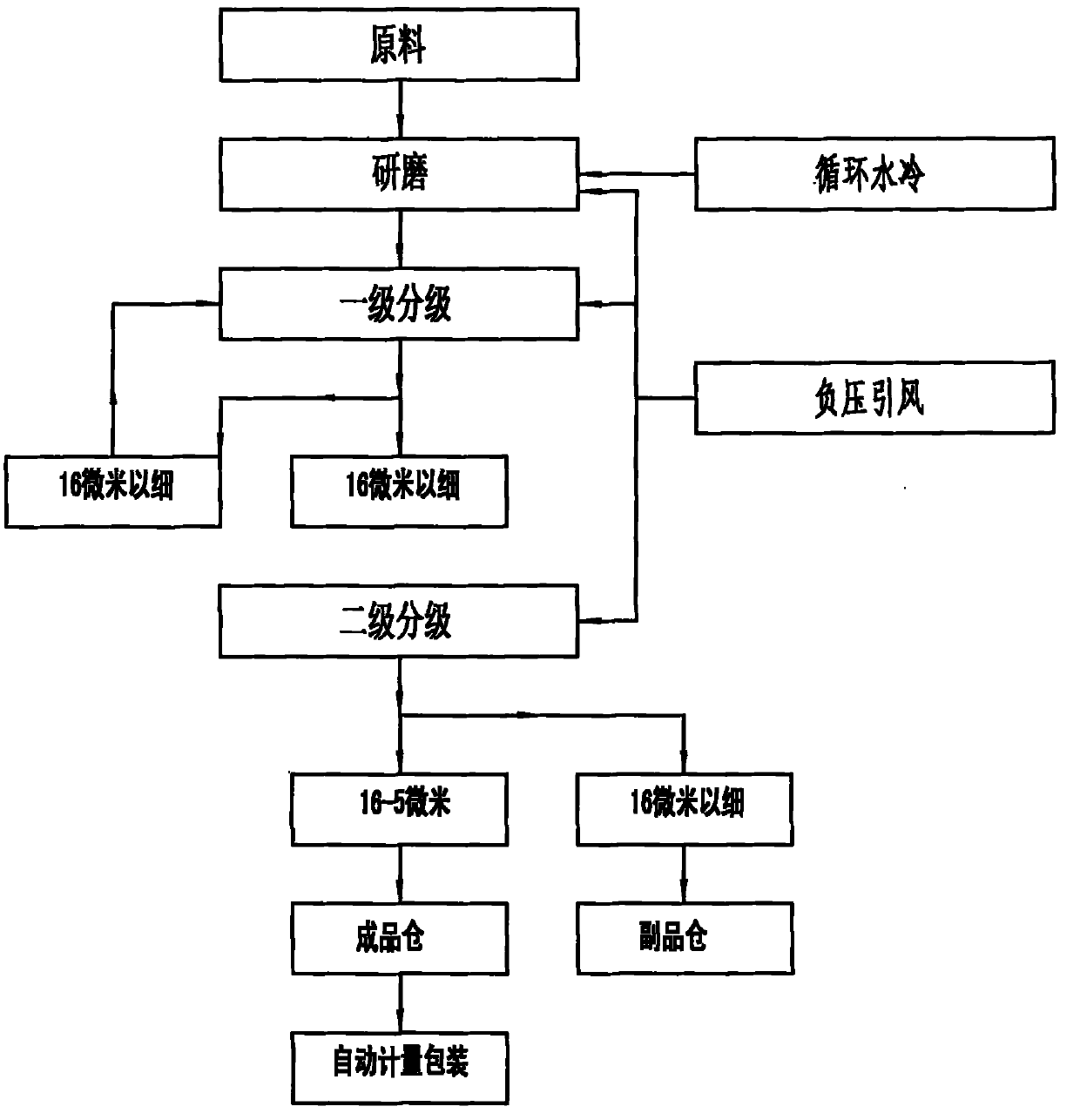

Method for forming blade material particles special for wire-electrode cutting of semiconductor material and ultra-hard material

InactiveCN101947483ASatisfy pellet molding requirementsMeet the preparation and molding requirementsGrain treatmentsSuperhard materialSemiconductor materials

The invention discloses a method for forming blade material particles special for wire-electrode cutting of a semiconductor material and an ultra-hard material, which comprises the steps of: 1, selecting a 6H-SiC silicon carbide or silicon carbide compound diamond ultra-hard material as a raw material; 2, feeding the raw material into a grinding machine to be ground; 3, carrying out primary grading on ground powder by an air inducing device, selecting fine particles with 16 micrometers for carrying out secondary grading, returning rough particles with 16 micrometers to the grinding machine to be continuously ground; 4, feeding finished particles of 16-5 micrometers through secondary grading to a packaging bin for packaging; and 5, feeding the fine particles with micrometer grade as a secondary product to a cyclone device for collecting. The particle forming method can meet the requirement for particle forming of free multiple wire-electrode cutting of the semiconductor material at present on a particle blade product, also satisfies the requirement for the preparation formation of blade particles special for a solidification jigsaw, lays the technical foundation for the free multiple wire-electrode cutting of the semiconductor material, and becomes the low-consumption and pollution-free processing manner.

Owner:河南晟道科技有限公司

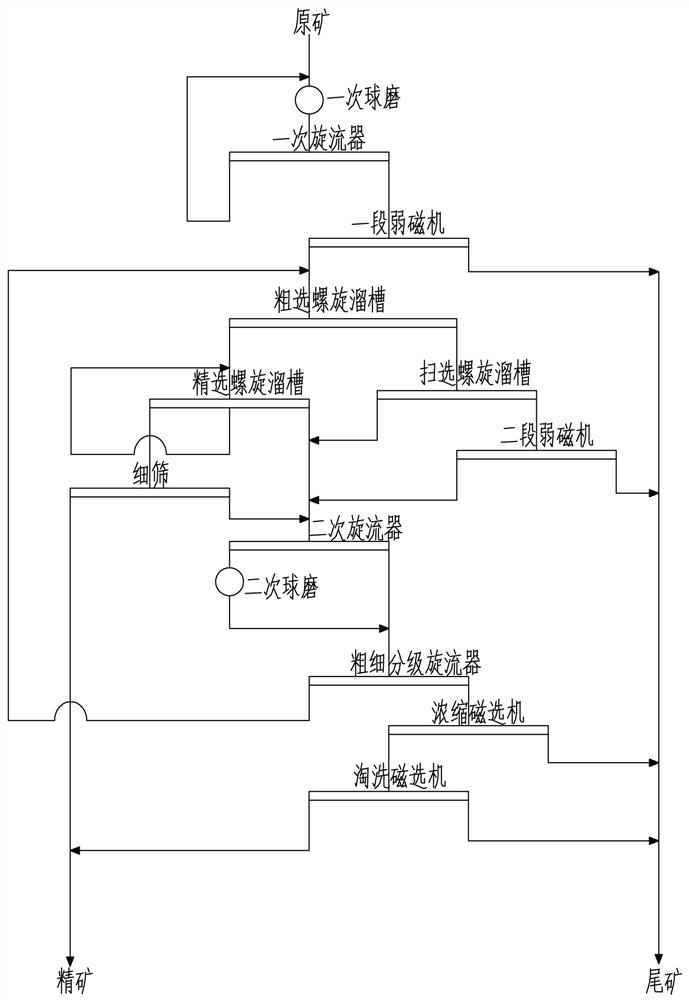

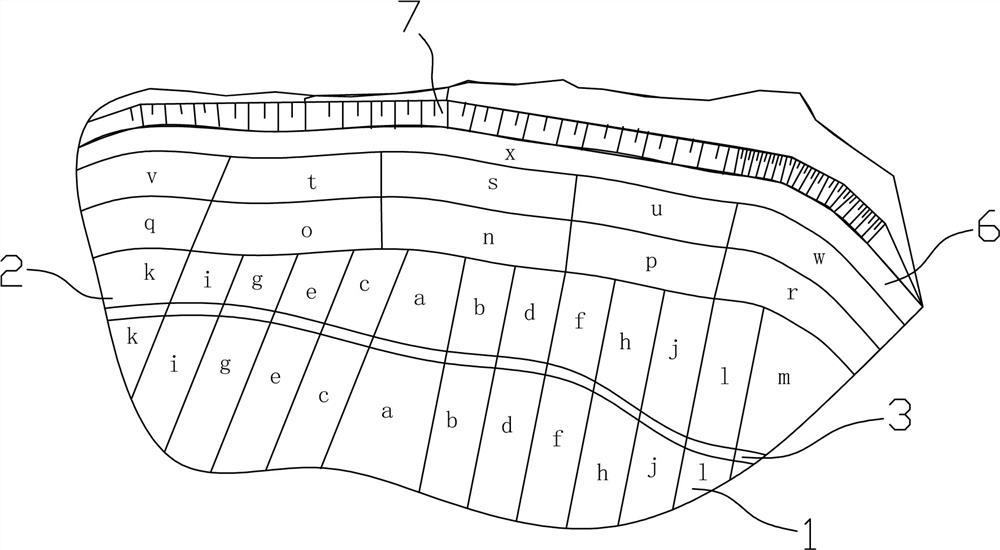

Magnetic-gravity-magnetic combined separation process for treating lean magnetite

ActiveCN113385299ARealize coarse-grained precisionReduce loadWet separationGravity separationBeneficiation

The invention relates to a magnetic-gravity-magnetic combined separation process for treating lean magnetite. The process comprises the following step of feeding the magnetite with a grade of 24%-30% to be sequentially subjected to first-section closed circuit grinding and first-section weak magnetic separation to obtain first-section weak magnetic separation concentrate; and the process is characterized in that the first-section weak magnetic separation concentrate is sequentially subjected to subsequent gravity and weak magnetic separation combined operation, secondary grinding grading operation and third-section weak magnetic separation operation to obtain final concentrate and final tailings; the gravity and weak magnetic separation combined operation is performed through a spiral chute, a fine screen and a two-section weak magnetic separation machine, wherein a gravity separation process performed through the spiral chute is a gravity separation process of once coarse separation, once fine separation and once sweeping, the two-section weak magnetic separation machine is used for treating sweeping snail tailings, the fine screen is used for treating fine snail concentrate, and gravity separation concentrate is obtained; and secondary grinding grading operation and three-section weak magnetic separation operation are performed on the ores during the gravity and weak magnetic separation combined operation to obtain weak magnetic separation concentrate. The process has the advantages that the process is simplified, coarse grains are fined, over-grinding is reduced, energy is conserved, consumption is reduced and capability of a ball mill is released.

Owner:ANSTEEL GRP MINING CO LTD

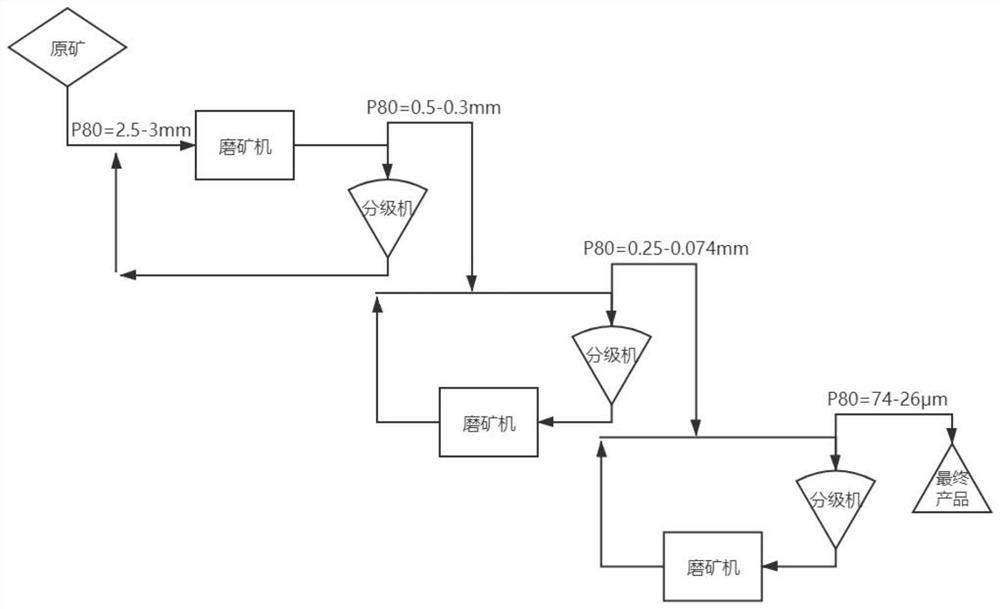

Steel-ball-free ore grinding method

ActiveCN112958258AReduce incidenceEfficient grindingCement productionGrain treatmentsSteel ballBall mill

The invention discloses a steel-ball-free ore grinding method. The steel-ball-free ore grinding method comprises the following steps: ore with the grinding particle size P80 of 2.5-3.0 mm is fed into an ore grinding machine, and first-stage ore grinding is carried out; an ore grinding medium of a mixed ceramic section is loaded into the ore grinding machine, and the mixed ceramic section comprises cylindrical ceramic sections with different lengths and different diameters; the P80 of an overflow product of a classifier is controlled to be 0.5-0.3 mm, and if the ore dressing granularity requirement is met, only first-stage ore grinding is carried out; and if the ore dressing granularity requirement is not met, second-stage ore grinding is carried out, and during second-stage ore grinding, an ore grinding medium mixed with ceramic balls is loaded into the ore grinding machine. According to the steel-ball-free ore grinding method, the mixed ceramic section is used as the ore grinding medium, crushing is carried out mainly by line contact and supplemented by surface contact, efficient grinding can be carried out in the ore grinding process, and the over-crushing generation rate of ore grinding products can be reduced; and besides, an ore grinding section can be a one-section ore grinding process or a multi-section ore grinding process, and the ore grinding machine mainly adopts a horizontal ball mill, so that the ore grinding requirements of different ores and different metal disseminated particle sizes can be met.

Owner:JIANGXI UNIV OF SCI & TECH +1

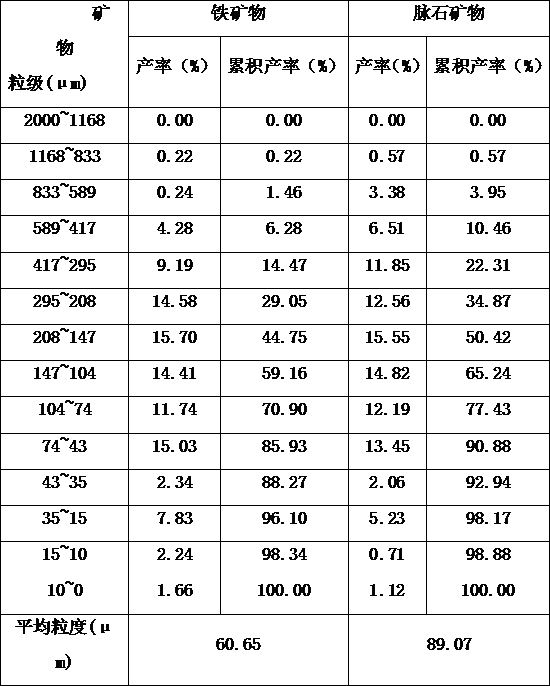

Beneficiation method capable of recycling valuable metal from tin magnetic pyrite

InactiveCN107051712AReduce over crushingIncrease monomer dissociationWet separationSpecific gravityPrecondition

The invention discloses a beneficiation method capable of recycling valuable metal from tin magnetic pyrite. The method comprises graded ore grinding work, magnetic separation work, thick flotation work and reselection work. The method has the beneficial effects that a bar grinding machine is adopted to grade ground ore in advance, over pulverizing of tin stone can be reduced, the single separation degree of the tin stone can be increased, and the precondition is provided for effective recycling of the tin stone; secondly, magnetic separation is adopted to remove the magnetic pyrite with the large proportion and the higher iron containing rate, floatation is adopted to remove the magnetic pyrite with the large proportion and the higher sulphur containing rate, disturbance of heavy mineral is reduced, and the advantage is created for subsequent reselection and separation of tin stone; thirdly, the middling re-grinding and reselection flow is adopted, energy consumption of ore grinding can be reduced, over pulverizing of the tin stone is reduced, the single separation degree of tin stone can be improved, the cost is low, and industrial production is easily achieved; fourthly, secondary pollutions in the production process are not needed, and the method is friendly to the environment.

Owner:KUNMING METALLURGY INST

Method for recovering indium-enriched marmatite from copper, zinc and indium coexisting polymetallic ore under low-alkaline condition

ActiveCN106622641AReduce over-crushingIncrease dissociationFlotationMechanical material recoveryIndiumSulfur

The invention discloses a method for recovering indium-enriched marmatite from copper, zinc and indium coexisting polymetallic ore under a low-alkaline condition. By adoption of the method, the technical problems that under the high-alkaline condition, indium-enriched marmatite is poor in floatability, difficult in excitation and low in indium recovery rate, and concentrate metals are high in content are solved. The method comprises the steps that a chemical agent is added into crushed and ground raw ore, slurry is formed through blending, and then copper, zinc and sulfur iso-flotation is conducted; and coarse grains are reground after iso-flotation rough concentrate is graded, an inhibitor is added for adjusting the mineral slurry and the pH value of the slurry, then copper selection is conducted, and copper concentrate and copper cleaner tailings are obtained; the copper cleaner tailings and copper, zinc and sulfur iso-flotation tailings are blended, then an activator is added and blended with the slurry, zinc and sulfur bulk flotation is conducted, and coarse grains are reground after zinc and sulfur bulk flotation rough concentrate is graded; and lime is added for adjusting the pH value of the mineral slurry, then zinc selection is conducted, and zinc concentrate and zinc cleaner tailings are obtained. By adoption of the method, the use amount of the inhibitor in the copper and zinc grading operation, the flotation mineral flurry pH value and the concentrate metal contents are lowered, and the indium and zinc recovery rates are increased; and meanwhile, the flotation process is simplified, and the flotation efficiency is improved.

Owner:KUNMING UNIV OF SCI & TECH

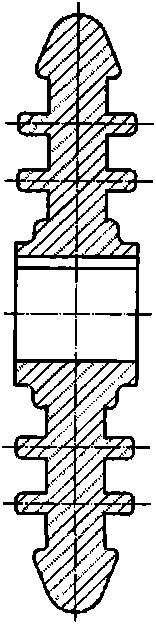

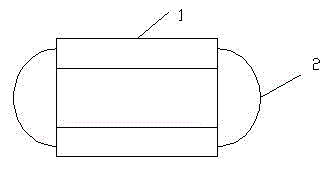

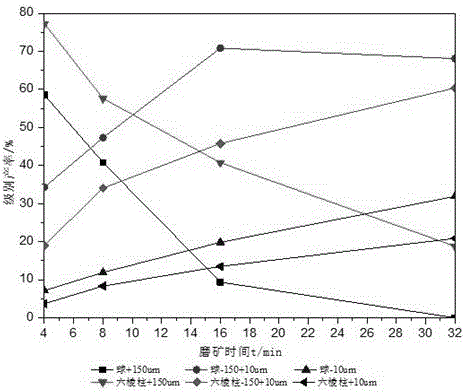

Grinding medium adopting shape of dual-spherical hexagonal prism

InactiveCN104888904AQuality improvementReduce over crushingGrain treatmentsHardnessMaterials science

The invention discloses a grinding medium adopting a shape of a dual-spherical hexagonal prism, belongs to the grinding medium, and mainly relates to the shape, material components, a processing technology and a metallographic structure of the medium. According to the grinding medium, the problem that over-crushing is serious, that is, the particle size is smaller than or equal to 10 mu m, in the grinding process of the spherical grinding medium is solved; the grinding medium adopts the shape of the dual-spherical hexagonal prism and mainly adopts surface contact, line contact, point contact and mixing contact in the grinding process. The material components are used for guaranteeing the wear resistance of the grinding medium, and the processing technology mainly aims to improve the hardness of the grinding medium. The grinding medium adopting the shape of the dual-spherical hexagonal prism is mainly applied to a metallic mineral grinding process and preparation of other materials with narrow and fine fraction.

Owner:JIANGXI UNIV OF SCI & TECH

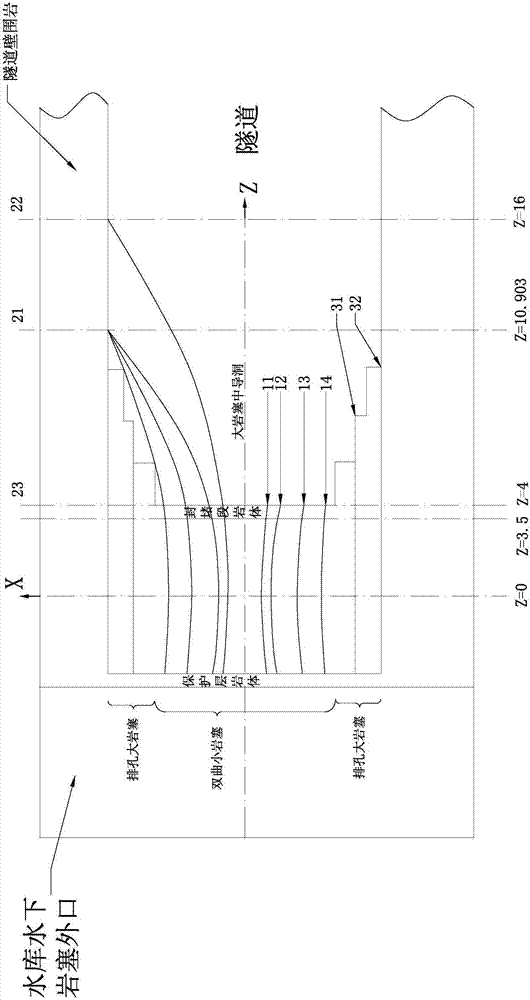

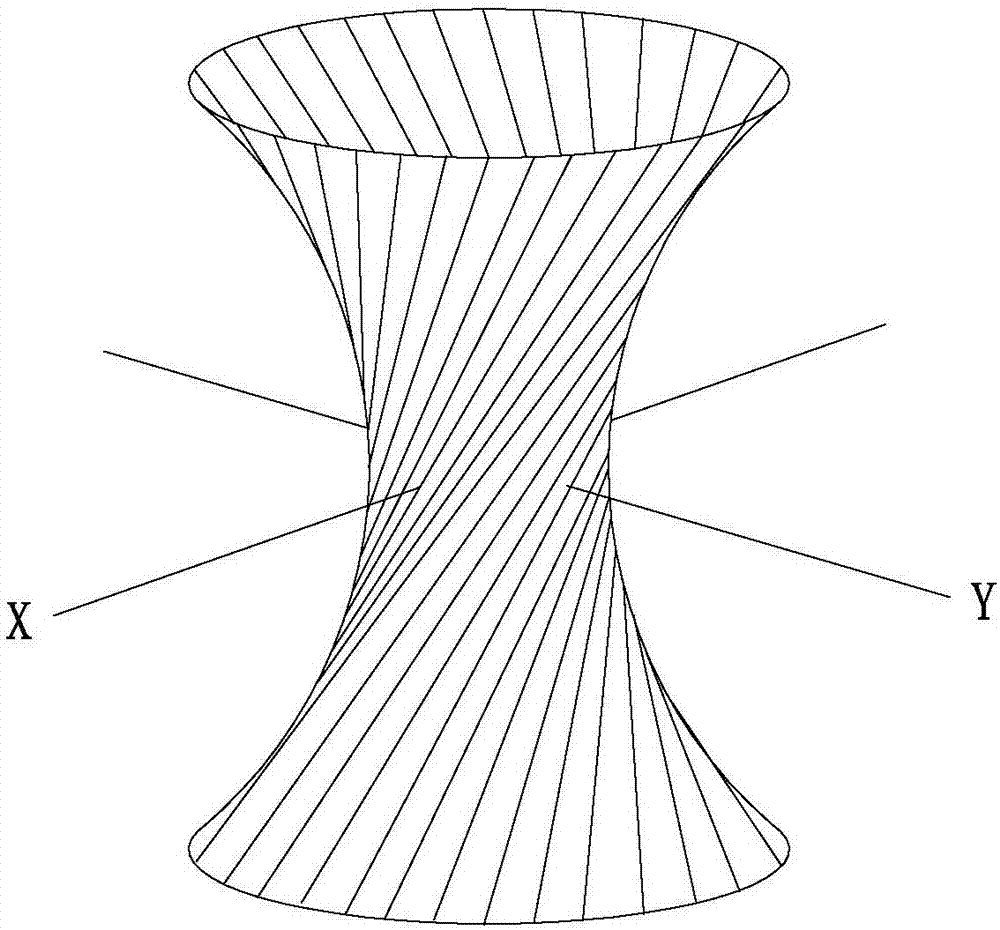

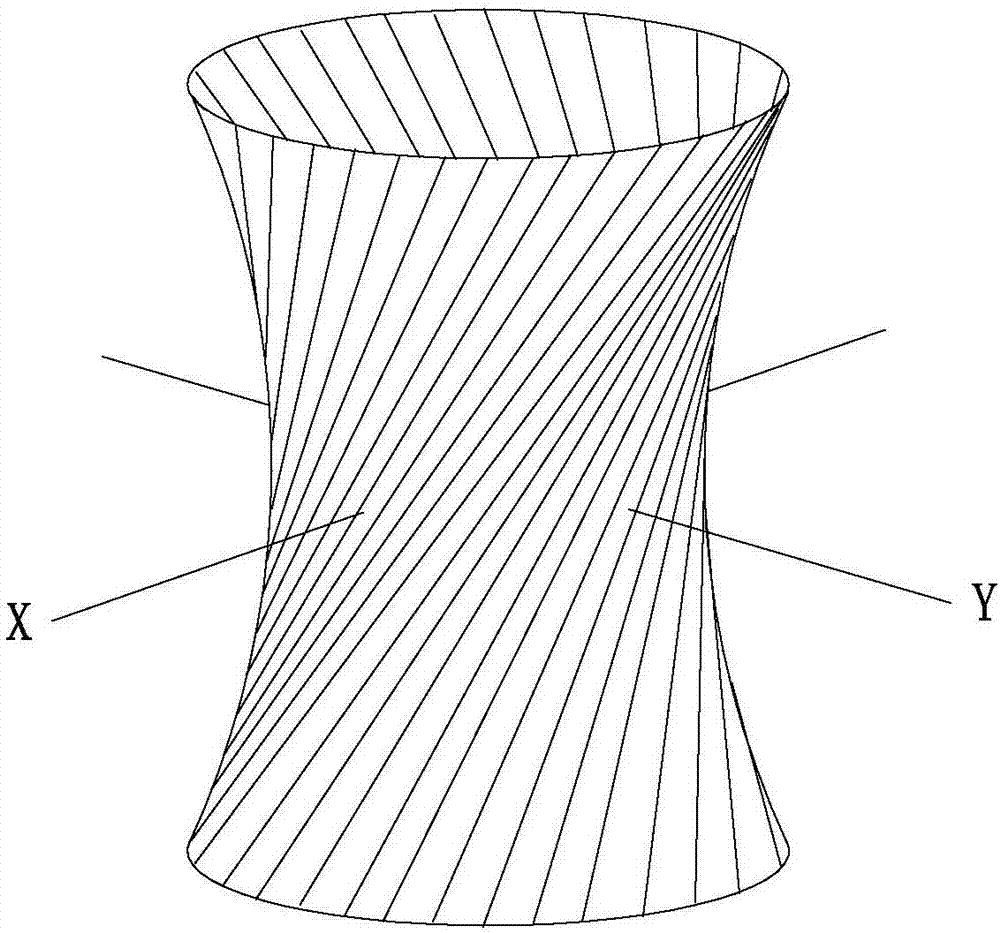

Uniparted hyperboloid coring and chambering rock-plug blasting method

ActiveCN107036495ARealize two-way diggingThrow blasting goodDirectional drillingBlastingHyperboloidBlast effects

The invention provides a rotary uniparted hyperboloid coring and chambering rock-plug blasting method. The method comprises the steps that laser orientation drilling is conducted along at least one coring hyperboloid which is coaxial with a rock plug, and a levo / dextro linear generatrix of at least one chambering hyperboloid on the underwater or non-underwater rock plug, hyperbolic coring holes and chambered holes with high-precision linear generatrices are obtained, explosives are installed in the hyperbolic coring holes and the chambered holes, and blasting is conducted sequentially from inside to outside; due to the fact that the drilled holes in the waist portion of the coring hyperboloid are distributed densely and serve as a high-temperature and high-pressure center at the moment of blasting, blast crushed stones are cast towards the two ends of the hyperboloid, a bidirectional coring mechanism is achieved, through decoupling charge, over crushing is relieved advantageously, the proportion of casting work is increased, a good pinpoint blasting effect and a good outlining blasting effect are achieved for a cored body, and towering conditions are created for subsequent blasting; and hyperbolic chamber can be qualified to transitional linkage chambering blasting of an annular and tubular rock mass with a thick waist portion and two thin ends after the rock plug is cored and is through. The hyperbolic holes can also be used for rock plug pre-splitting or smooth surface forming blasting.

Owner:NORTH CHINA BEIJING GUOYAN TECHN TESTING

High Efficiency Raymond Mill

The invention discloses an efficient Raymond mill. The efficient Raymond mill comprises a base and an outer cylinder, wherein a classifier is mounted at the top of the outer cylinder, and classifying impellers are located at the top of an inner chamber of the outer cylinder; a shaft seat is fixedly connected to the lower part of an inner chamber of the base; a spindle is rotationally connected in the shaft seat, the upper end of the spindle extends into the inner chamber of the outer cylinder, and the lower end penetrates out of the base; a grinding roll bracket is connected to the upper end of the spindle, grinding roll shafts are hinged to the grinding roll bracket, and grinding rolls are mounted at the lower ends of the grinding roll shafts; a grinding ring capable of cooperating with the grinding rolls is fixedly connected to the upper part of the inner chamber of the base; a shoveling chamber is formed in a chamber section between the grinding ring and the shaft seat in the inner chamber of the base, a shovel blade rotating disc fixedly connected onto the spindle and connected with a shovel blade is arranged in the shoveling chamber, and a feeding port is formed in the outer cylinder; air inlets are formed in the shaft seat and communicate the shoveling chamber and external space of the bottom of the base, so that air feeding from the bottom of the Raymond mill is realized. The efficient Raymond mill has low air inlet resistance and can reduce energy consumption; over grinding of materials can be reduced, the grinding efficiency is high, and the noise is small.

Owner:WEIFANG JINGHUA POWDER ENG EQUIP

High Capacity Rod Mill

The invention belongs to the technical field of rod mills, and discloses a high-yield rod mill, which has a cylinder body, the inner wall of the cylinder is equipped with a liner, and a liner with an inclined convex line as a guiding convex line or a liner with an inclined The groove is used as the lining plate of the guide groove, and the cylinder body is provided with multiple circles of discharge holes, and the discharge holes of the cylinder body are attached with a discharge screen. In the present invention, by arranging the oblique convex strips or grooves of the liner of the cylinder, the material is guided to move to the discharge end during rotation, and the speed of material movement is accelerated; a discharge port is added between the traditional feed port and the discharge port, and the discharge A screen is added to the feed port, so that the ground qualified stone leaves the cylinder as soon as possible, reducing the phenomenon of over-grinding; dry production can avoid water treatment, thereby increasing the processing capacity of the rod mill.

Owner:南昌矿机集团股份有限公司

Process for preparing coking charging coal from coking mixed coal

InactiveCN104962303AHigh specific gravityUniform particle size distributionCoke ovensSpecific gravityElectro hydraulic

The invention discloses a process for preparing coking charging coal, and various kinds of coking coal conveyed from coal storing apparatuses are separated; if the fineness of the coal satisfies the requirement, the coal is directly conveyed to a coal blending apparatus for storage through an electro hydraulic reverse turning bed without crushing; if the fineness of the coal does not satisfy the requirement, the kind of coal is turned by the electro hydraulic reverse turning bed and is crushed by an newly established crushing apparatus, and after crushing, the coal is conveyed to the coal blending apparatus for storage; various kinds of coking coals of different finenesses are automatically blended into a mixed coal in the coal blending apparatus according to the coal blending ratio determined by a coal blending test, and after mixing by a coal mixing apparatus, the charging coal which meets the fineness requirement is conveyed to the top of a coal tower for coking production of a coke oven; compared with the prior process for preparing the charging coal in domestic coking enterprises with a first coal blending step and a second crushing step, the process provided by the invention with a first crushing step and a second coal blending step without influencing the production condition contains the following steps: crushing various kinds of coal into different finenesses, blending coals, mixing coals and conveying the coals to the top of the coal tower for coking production in the coke oven. The invention has the advantages of uniform distribution of charging coal particle fractions, improved charging coal pile proportion, obviously reduced over crushing of coking coal and fat coal, thereby improving production capacity of the coke oven as well as stabilizing or improving the quality of the coke.

Owner:北京金日新事业技术有限公司

Processing technology of cement clinker

InactiveCN112473889AEasy to GrindAvoid another hitHollow article cleaningCleaning using toolsGear wheelElectric machinery

The invention provides a processing technology of cement clinker. The processing technology comprises a barrel, a feeding bin, a discharging bin, a feeding port, a discharging port, a supporting seat,a large gear, a motor, a speed reducer, a small gear, a lining, a partition plate mechanism and an iron ball. The feeding bin is movably mounted on one side of the barrel, and the discharging bin ismovably mounted on the other side of the barrel. The feeding port and the discharging port are formed in the sides, away from the barrel, of the outer surfaces of the upper ends of the feeding bin andthe discharging bin correspondingly, the supporting seat is fixedly installed at the lower ends of the feeding bin and the discharging bin, and the large gear is connected to the side, close to the discharging bin, of the outer surface of the barrel in a sleeving mode. The motor is movabley installed to the side, close to the discharging bin, of the lower end of the front of the barrel. The speedreducer is movably installed on one side of the motor. According to a processing device of cement clinker, multi-section type ball milling is adopted, a partition plate can be prevented from being blocked by cement, feeding is not likely to be blocked, the ball milling efficiency is high, and the inner wall of the barrel is convenient to clean.

Owner:王克瑶

A Coarse and Fine Crushing Integrated Medium Coal Wet Crusher

A coarse and fine crushing integrated type middling coal wet crushing machine is especially suitable for crushing and dissociating high-water-content middling coal obtained after gravity separation and medium draining in a coal preparation plant. The coarse and fine crushing integrated type middling coal wet crushing machine comprises a feed hopper, a first crushing chamber, a second crushing chamber and a discharge hopper. The first crushing chamber is located above the second crushing chamber and communicated with the second crushing chamber. Blade type crushing rollers are arranged in the first crushing chamber and used for coarsely crushing the middling coal, and groove type crushing rollers are arranged in the second crushing chamber and used for finely crushing the coarsely crushed middling coal. Anti-blocking flushing water pipes are arranged on the lower side inner wall of the first crushing chamber and the lower side inner wall of the second crushing chamber respectively. The coarse and fine crushing integrated type middling coal wet crushing machine is simple in structure, coarse crushing and fine crushing of the high-water-content middling coal are achieved in the same machine, and blocking is unlikely to occur; the upper limit of particle sizes of crushed products is low, the particle sizes of the products are uniform, and the frequency of excessive crushing phenomena is low; no dust is generated during crushing, and secondary separation in gravity separation of the middling coal after crushing and dissociation is facilitated.

Owner:CHINA UNIV OF MINING & TECH

Construction method for converting dangerous rock treatment blasting material into dam filling-level burdening

The invention discloses a construction method for converting dangerous rock treatment blasting material into dam filling-level burdening. The construction method comprises the following steps that 1),slope cutting construction is carried out through a deep hole bench blasting method, and sloping is carried out on trailing edge mother rock; 2), blast hole drilling operation is performed by using adrilling machine, and the blast hole drilling angle is the same as the designed slope angle; 3), the blast holes are filled with explosives in an interval charging mode, and detonating is carried outby adopting a single-hole single-sound detonation network; and 4), after layered and sectioned excavation, the blasting slag materials are transferred through a dump truck, and the blasting slag materials are pushed to a material taking platform through a bulldozer. By the adoption of the method, the purpose of changing blasting gradation is achieved by optimizing blasting parameters, the proportion of large-diameter stones after blasting is increased, and when the large-diameter stones are blasted and pushed to the material taking platform, stone sources meeting other construction projects are formed by means of collision of the large-diameter stones, and the purpose of directly applying the blasting slag materials to dam construction can be achieved.

Owner:CHINA GEZHOUBA (GRP) FIRST ENG CO LTD

A grinding process that reduces grinding energy consumption and reduces over-grinding

ActiveCN109550566BReduce rationalityGuaranteed reasonablenessGrain treatmentsProcess engineeringBall mill

The invention discloses a grinding process for reducing grinding energy consumption and reducing over-grinding. The crushed materials are pre-graded through a section of linear vibrating screen, and the materials on the screen are put into a high-pressure roller mill for rolling, and the high-pressure roller mill product is passed through two The first-stage linear vibrating screen is inspected and classified. The material under the first-stage linear vibrating screen is combined with the material on the second-stage linear vibrating screen and then fed into the first-stage ball mill. The first-stage ball mill discharges ore and the second-stage linear vibrating screen. After pre-checking and grading is completed, the grading overflow is sent to the high-frequency vibrating fine sieve for inspection and control grading, and the material on the high-frequency vibrating fine sieve and the sand settling of the cyclone are sent to the second-stage ball mill to form a closed loop. The present invention adds a high-pressure roller mill and a screening link to separate the qualified particle size in time, reduces the amount of ore grinding that enters the ball mill, and achieves the goals of reducing energy consumption of ore grinding and reducing over-grinding. And in the second-stage grinding and classification, the combination of cyclone group and high-frequency vibrating fine screen is used to ensure the rationality of the selected particle size.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com