Method of industrial producing fine powder or powder sizeg and its multifunction fine powder grinding series equipment

A micro-powder, multi-functional technology, applied in the multi-functional micro-pulverizing series equipment, industrial production of micro-powder or powder slurry field, can solve the problems of complex equipment structure, large vibration and low technology integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

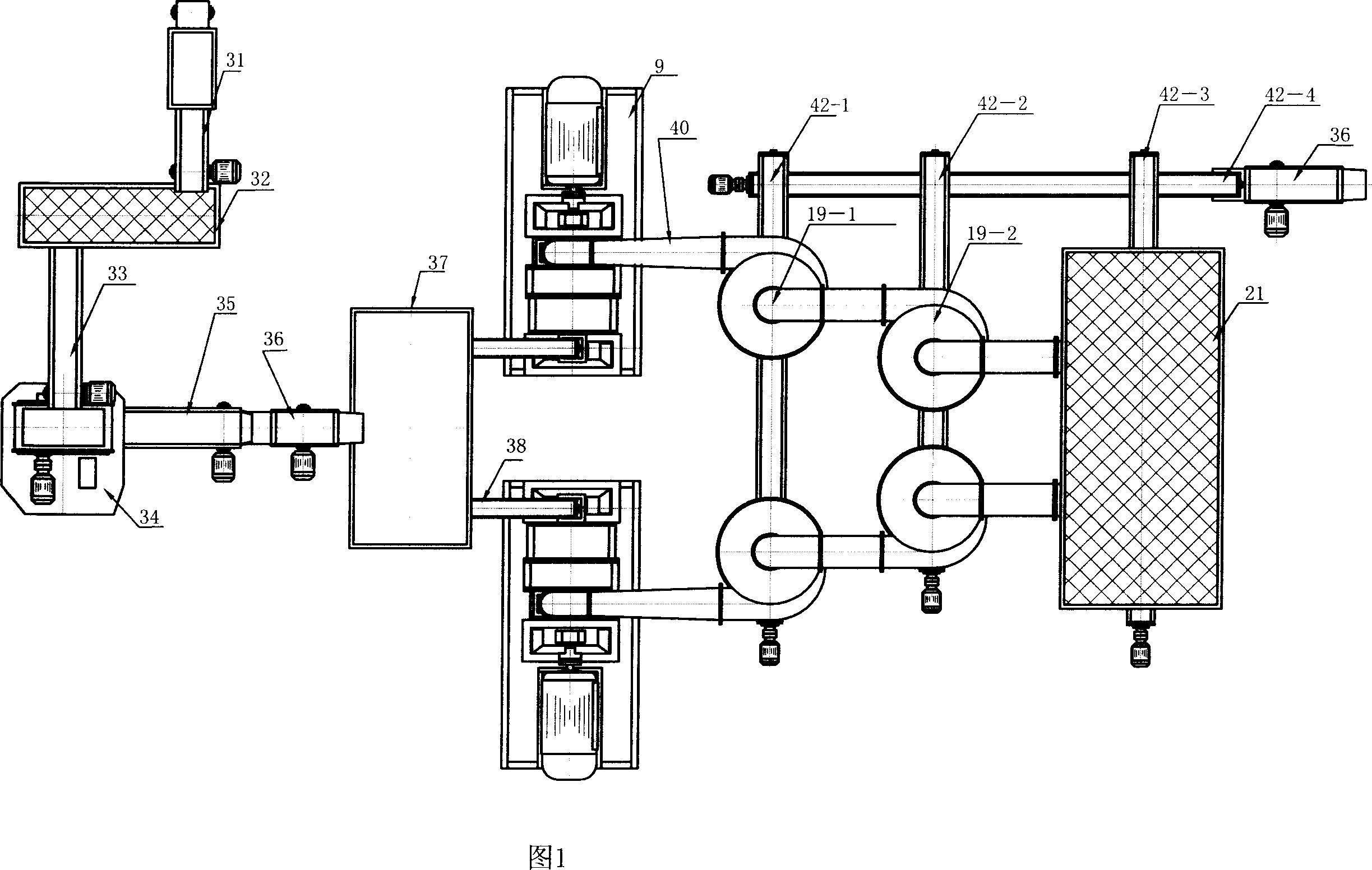

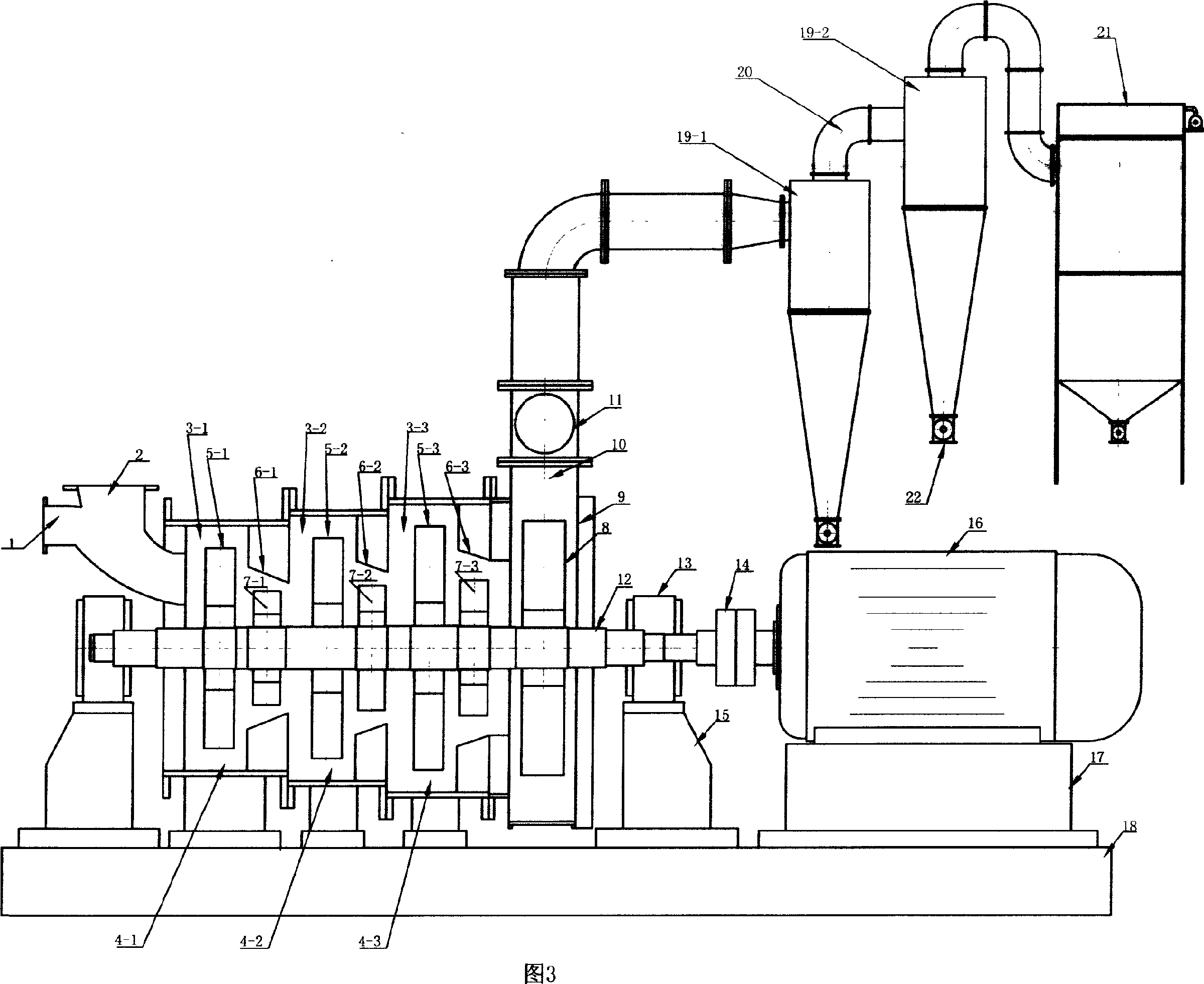

[0054] The slag with medium Mohs hardness is industrially produced fine powder according to the process flow of the above-mentioned Figure 1 and the three-stage progressive pulverizer.

[0055]The raw material enters the screening machine 32 from the raw material conveyor 31, removes large pieces of material, and then passes through the iron removal conveyor 33, removes iron, enters the coarse crusher 34, and coarsely crushes the raw material to slag material of ≤3mm, and then passes through the conveyor 35. The elevator 36 enters the feed bin 37, and then is sent to the feed port 2 of the 3-stage flow-by-flow pulverizer through the quantitative feeder 38, so that the machine can automatically inhale and perform 3-stage pulverization, and the pulverized fine powder is combined with the air Through the discharge pipe 10, it first enters the material collector 19-1, and then enters the material collector 19-2. The wind and residual micropowder from the material collector 19-2 ent...

Embodiment 2

[0059] The steps of embodiment 2 are the same as those of embodiment 1, except that the present embodiment uses a 6-stage progressive pulverizer for pulverization, and the results are listed in Table 2.

Embodiment 3

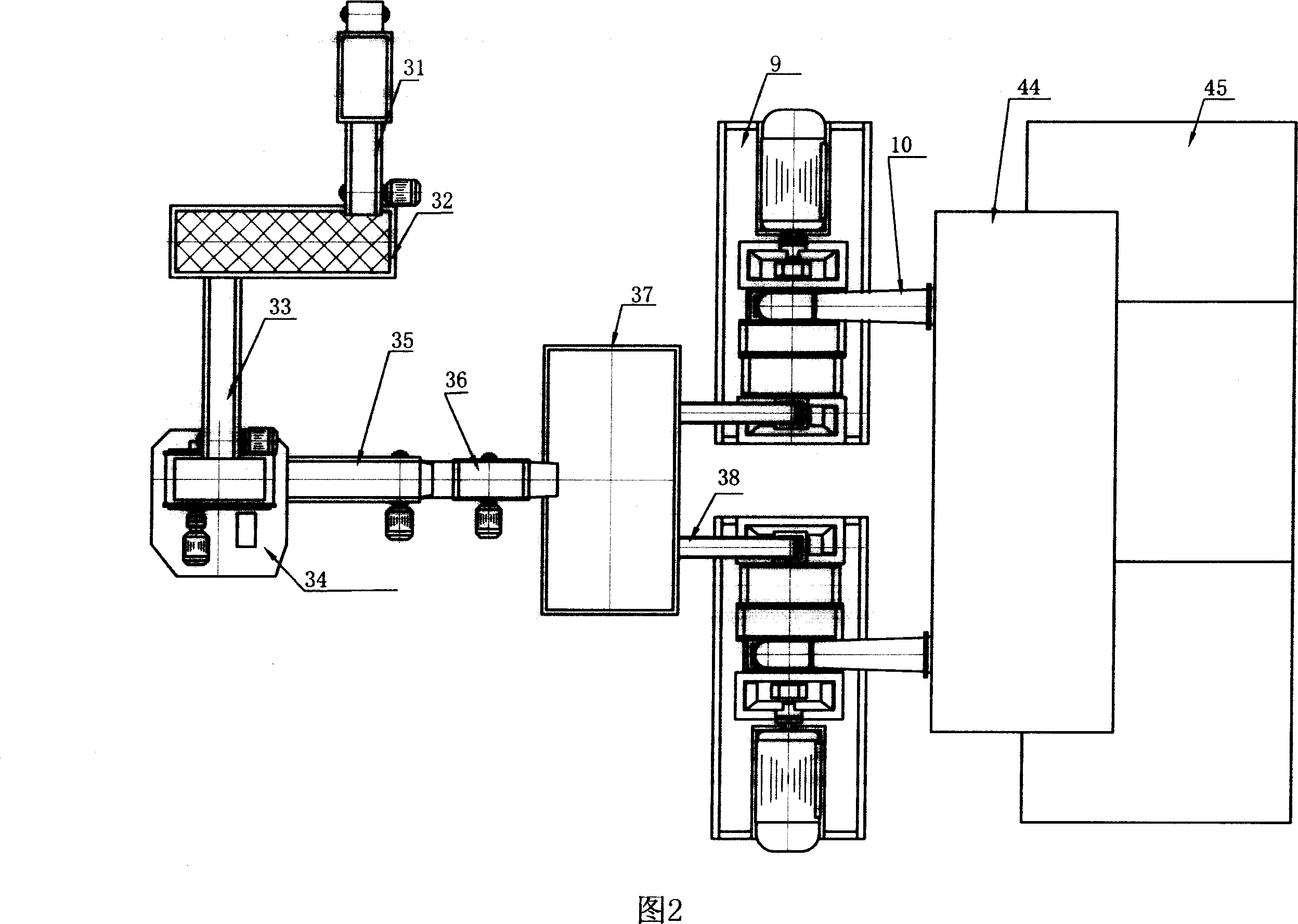

[0061] Carry out industrial production of fine powder slurry according to the flow process of above-mentioned Fig. 2 and 3 grades of flow-by-flow pulverizers.

[0062] The slag raw material enters the screening 32 from the raw material conveyor 31, removes large pieces of material, and then passes through the iron removal conveyor 33, removes iron, enters the coarse crusher 34, and coarsely crushes the raw material to a slag material of ≤3mm, and then passes through the conveyor 35. The elevator 36 enters the feed bin 37, and then is sent to the feed port 2 of the multifunctional flow-by-flow pulverizer through the quantitative feeder 38, so that the machine can automatically inhale and pulverize, and the pulverized fine powder is discharged together with the air. The pipe 10 automatically enters the spray chamber 44 and sprays with water. The micropowder and water sink to the bottom of the chamber together, slide into the slurry pool through a landslide, and become slurry afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com