Gravity separation middling coal separation technology

A sorting and process technology, which is applied in solid separation, wet separation, grain processing, etc., can solve problems such as equipment sorting efficiency that does not take into account the problem of over-grinding, so as to improve equipment sorting efficiency and increase clean coal production. The effect of reducing the over-crushing phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

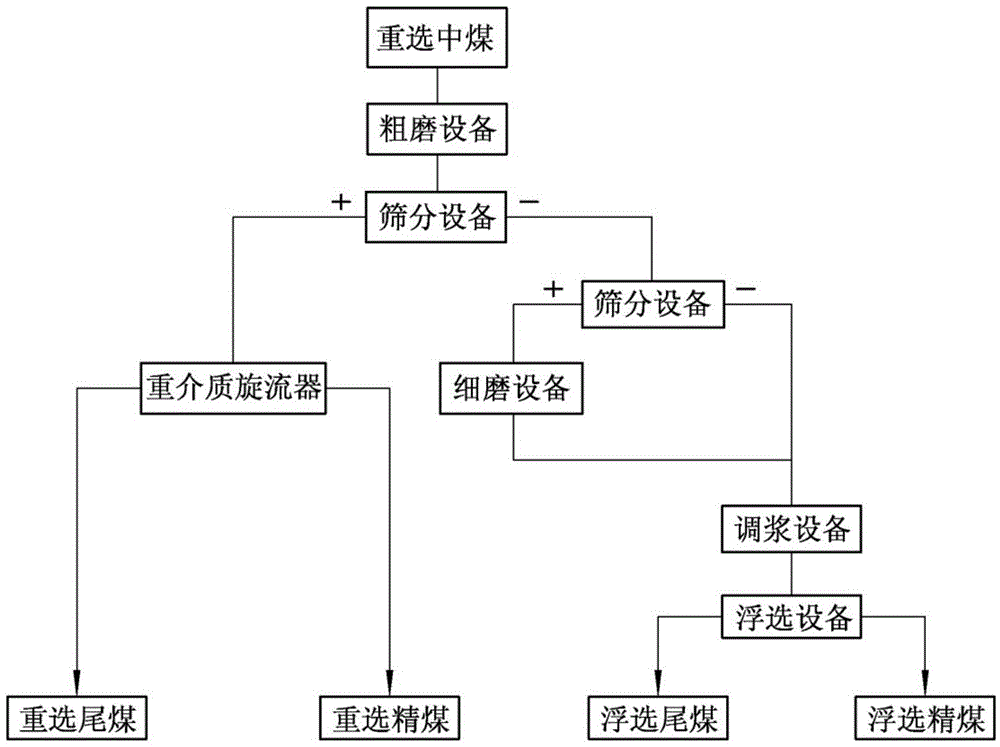

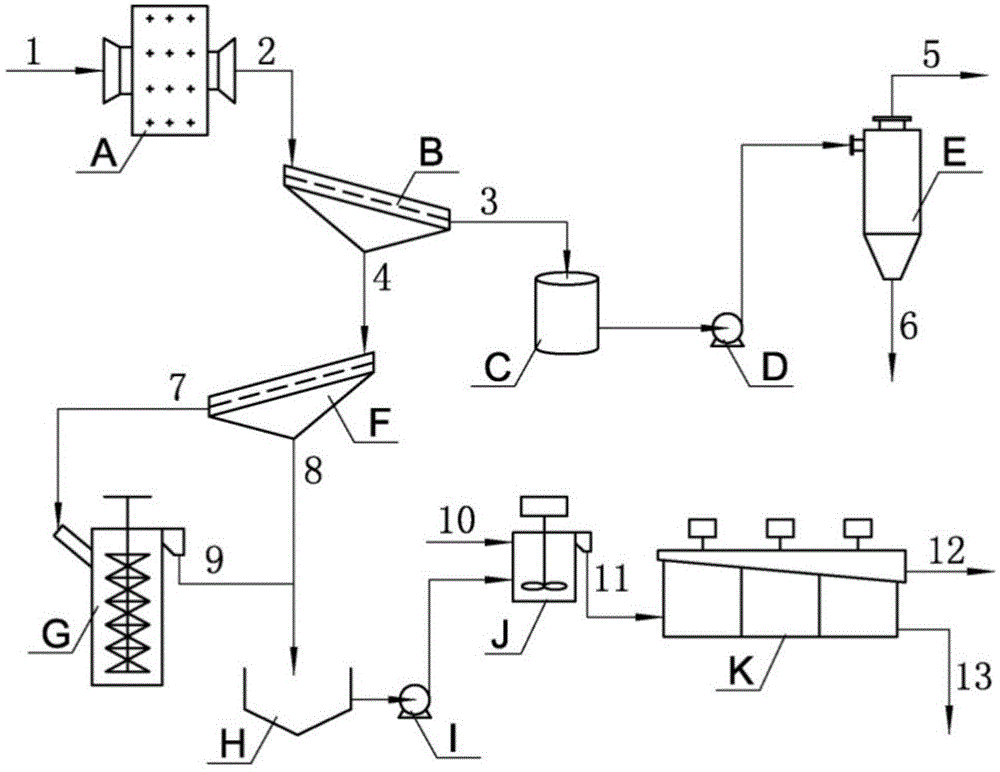

[0013] Such as figure 1 As shown, the heavily selected coal is fed into the coarse grinding equipment; the coarse grinding equipment is an autogenous mill or a rod mill. The coarsely ground product is sent to the sieving equipment for primary classification, and the product above the sieve and the product under the sieve are obtained; the product above the sieve is sent to the dense medium cyclone for sorting; the product under the sieve is fed into the sieve The equipment carries out secondary classification to obtain the product on the secondary sieve and the product under the secondary sieve; the product on the secondary sieve is fed into the fine grinding equipment for fine grinding; the fine grinding equipment is a stirring mill or a ball mill. The finely ground product and the product under the secondary sieve are sent to the pulping equipment to com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com