Construction method for converting dangerous rock treatment blasting material into dam filling-level burdening

A construction method and a technology of graded ingredients, which are applied in the field of converting blasting materials for dangerous rock treatment into dam filling-grade ingredients, can solve problems such as the inability to fully meet the construction requirements of reservoir dams and the small blasting slag, and increase the blockage of blast holes. The effect of length, increasing rock content, increasing rock particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A construction method for converting hazardous rock treatment blasting materials into dam filling-level ingredients. The hazardous rock mass adopts a layered and partitioned blasting construction scheme, and pre-split blasting is carried out along the design contour surface of the excavation slope. After excavation layer by layer, blasting is carried out. The slag is transported back to the reclaiming platform 12 whose height is lower than the construction surface;

[0040] Include the following steps:

[0041] 1) The "deep hole step blasting method" is used for slope cutting construction, and the trailing edge parent rock is grading;

[0042] 2) Use the drilling rig 9 to drill the blast hole 8, and the drilling angle of the blast hole 8 is the same as the design slope angle;

[0043] 3) The blasting hole 8 is filled with explosives by means of spaced charge, and the single-hole single-ring blasting network is used for detonation to increase the clamping effect of rock...

Embodiment 2

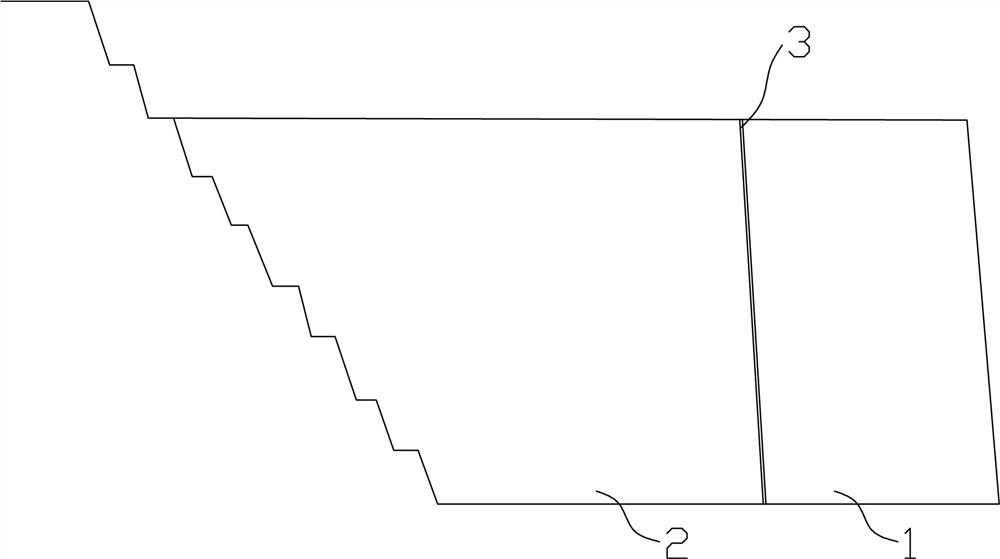

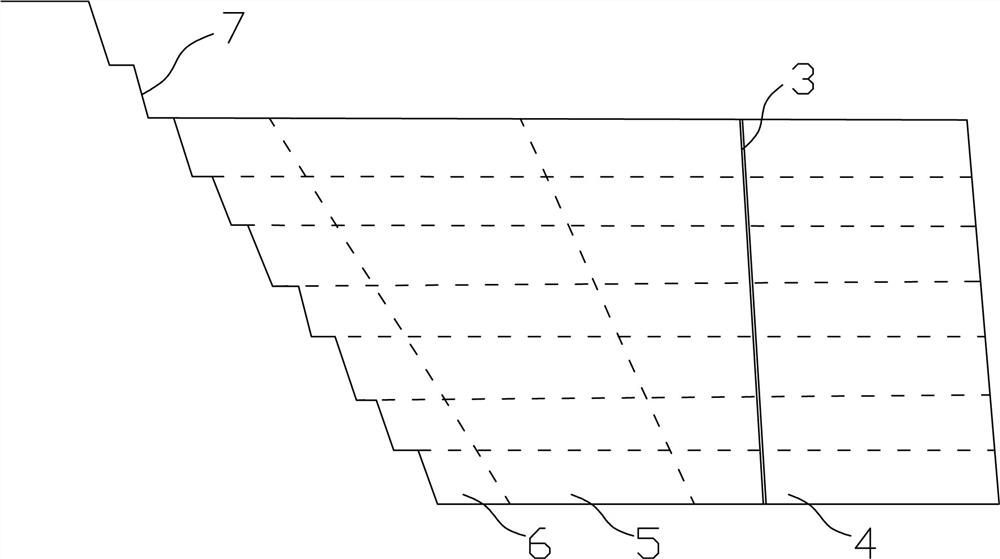

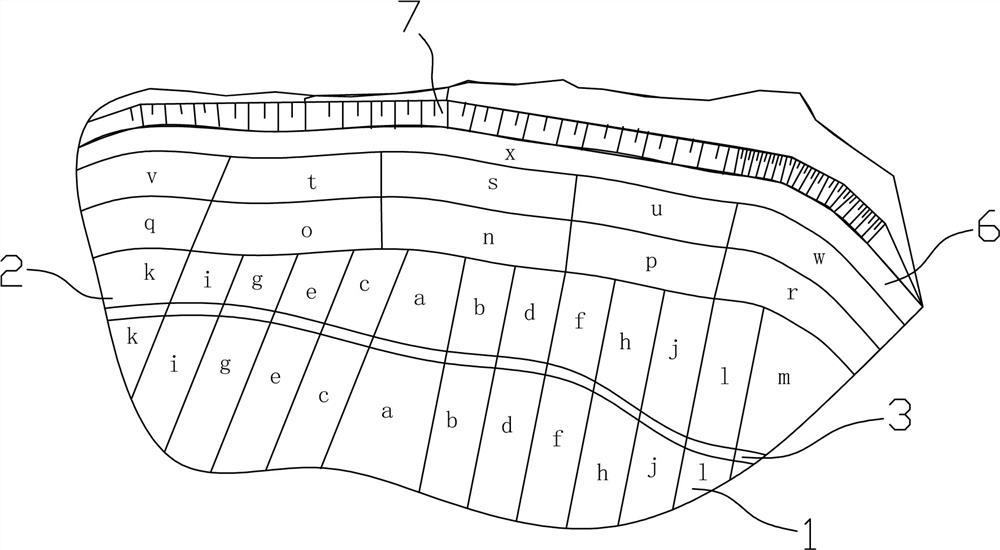

[0050] like Figure 2-3 , on the basis of Example 1, the first section of construction area 4 is excavated from the dangerous rock mass 1 to the parent rock 2 to exceed the crack 3, and the excavation area includes the dangerous rock mass 1 and the parent rock 2;

[0051] The second-stage construction area 5 is excavated from the parent rock 2 in the direction of the side slope 7 to approach the side slope 7 and a protective layer 6 is reserved;

[0052] The protection layer 6 is excavated after the excavation of the first-stage construction area 4 and the second-stage construction area 5 is completed and the subsequent slope support construction is completed.

[0053] The horizontal excavation on the plane to the parent rock 2, that is, the construction part includes the dangerous rock mass 1 and part of the parent rock 2, can ensure that the dangerous rock mass 1 suddenly collapses to the parent rock 2 quickly.

[0054] The preferred solution is image 3 Among them, the fi...

Embodiment 3

[0057] like Figure 5-7 , On the basis of Example 1, in the step 3), the density coefficient of the blasthole 8 is greater than 1, the delay time difference between the blastholes in the front and rear rows is 110ms, and the delay time difference between blastholes in the same row is 50ms. Section detonator detonator.

[0058] When the density coefficient of the blast hole 8 is greater than 1, the particle size of the rock after blasting is larger, and the content of particles with a particle size greater than 5 mm in the blasting slag can be increased.

[0059] The preferred solution is Image 6 In the step 4), the charging section 801 and the packing section 802 are staggered in the blasting hole 8, and the detonating detonator 803 is penetrated in the charging section 801 and the packing section 802, and extends to the blasting hole 8 outside the orifice. The above-mentioned interval charging method is adopted to disperse the explosive energy and reduce the excessive cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com