Micro-fine particle grade horizontal grinding device

A micro-grain and ore grinding technology, which is applied in grain processing and other fields, can solve the problems of low power coefficient, low energy utilization rate, large ball mill volume, etc., and achieve the effect of increasing useful power coefficient, reducing over-grinding phenomenon, and reasonable particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

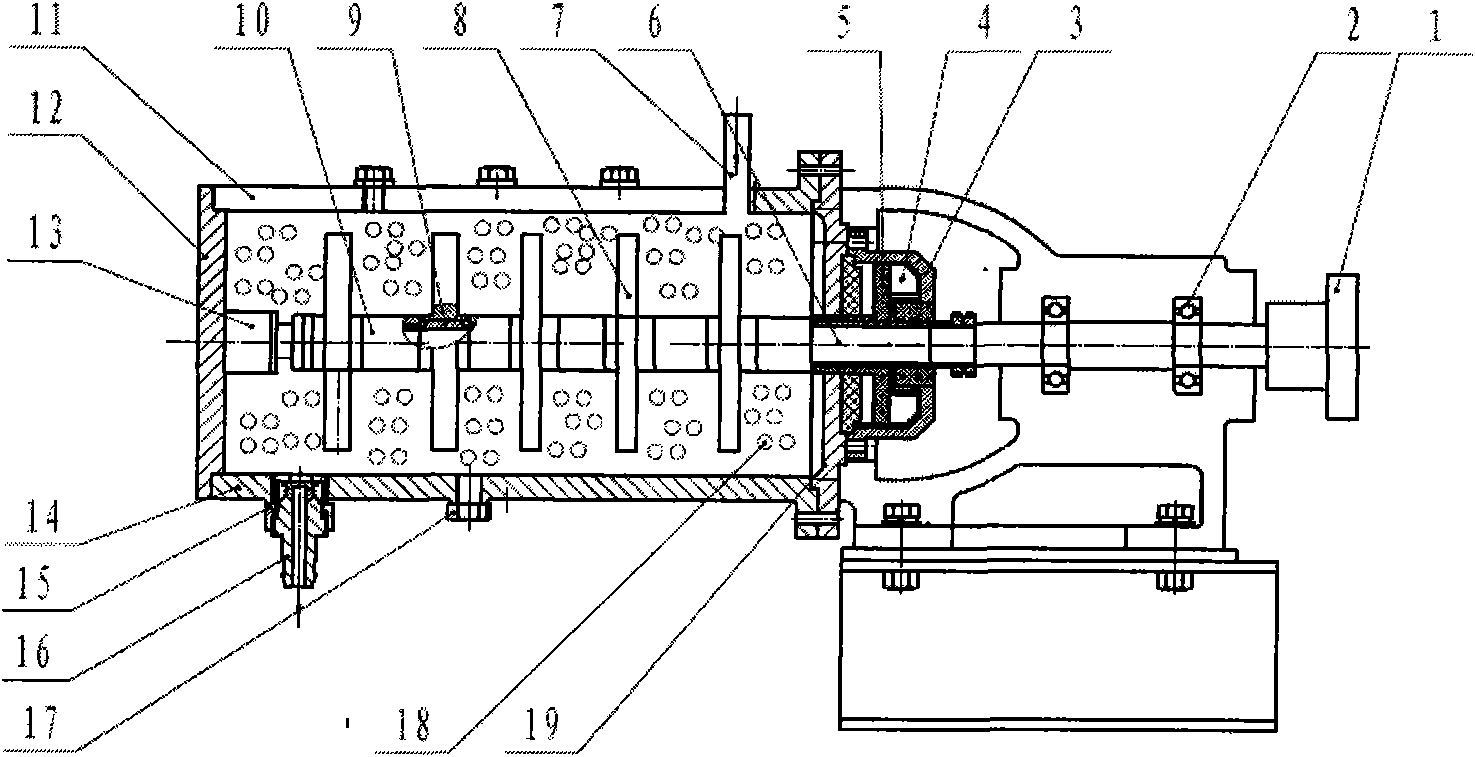

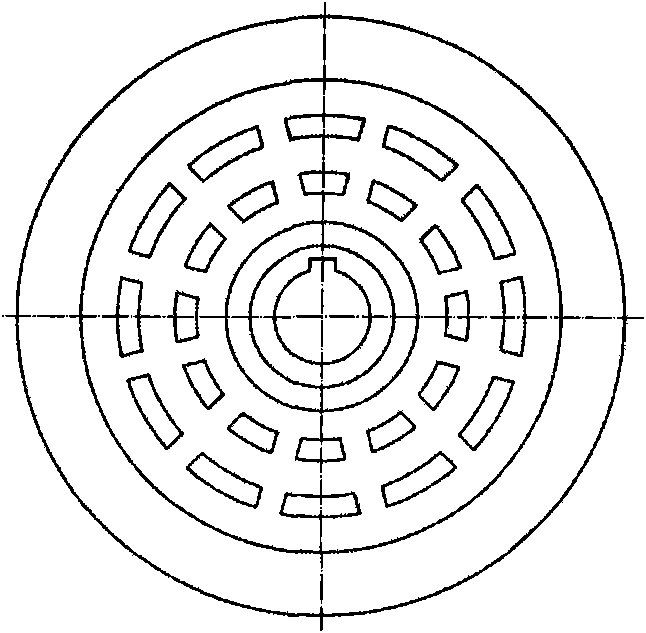

[0026] A fine-grained horizontal grinding equipment is composed of a grinding chamber and a transmission mechanism. Its structure is as follows: figure 1 Shown: the shell of the grinding chamber is a cylindrical shell, the installation centerline of the shell is horizontal, the horizontal length of the shell is 1.5 to 2.0 times the diameter of the inner circle of the shell, and the inner surface of the shell is evenly lined There are wear-resistant materials, and the cylinder is filled with grinding media 18; the centerline of the main shaft 6 coincides with the centerline of the cylinder, and 5 to 6 stirring impellers 8 are vertically installed on the main shaft 6, and a row is arranged directly below the left end of the cylinder. The mining device is provided with an ore feeding port 7 just above the right end of the cylinder.

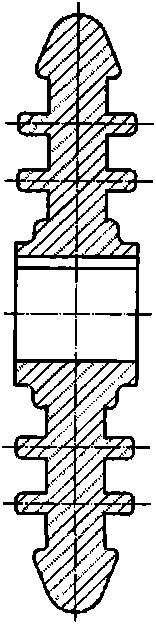

[0027] The transmission mechanism is: the left end of the main shaft 6 is installed in the bearing bush 13, the bearing bush 13 is fixed at the cent...

Embodiment 2

[0036] The utility model relates to a fine-grained horizontal grinding equipment. The horizontal length in the cylinder is 2.0 to 2.5 times the diameter of the inner circle of the cylinder, 7 to 8 stirring impellers 8 are vertically installed on the main shaft 6, and the outer diameter of the stirring impeller 8 is 0.9 times the diameter of the inner circle of the cylinder. The installation distance between the stirring impellers 8 is 0.8 to 1 times the diameter of the outer circle of the impellers; the auxiliary impeller 5 is equipped with 7 to 8 blades 4, and the gap between the blades 4 and the sealing cover 3 is 0.8 to 1 mm; the upper part of the plug 15 is provided with 4 ~5 strip holes 24, the upper end of the discharge channel 23 is provided with 7 to 8 discharge holes 22 communicating with the discharge channel 23, the angle between the center line of the discharge hole 22 and the center line of the discharge channel 23 is 30 ~45°. The grinding medium 18 is natural or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com