Compound classification method and equipment for ground ore product

A classification method and technology of mineral products, applied in the direction of chemical instruments and methods, solid separation, wet separation, etc., can solve the problems that the equipment has not been widely popularized and applied, so as to reduce blockage and wear, reduce roughness, and The effect of stabilizing screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

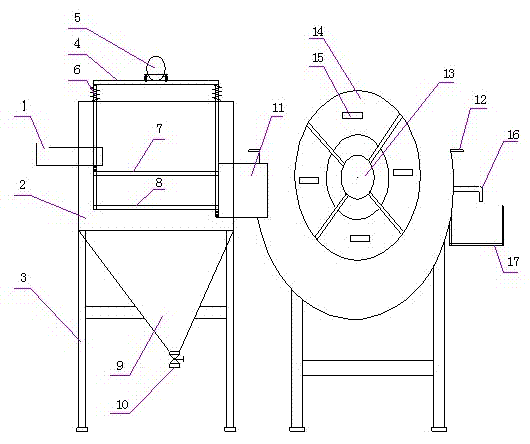

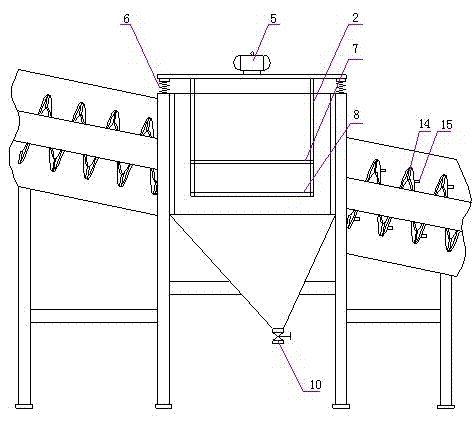

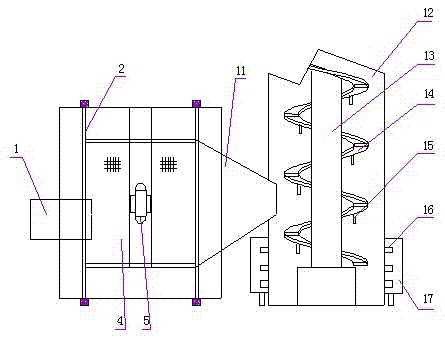

[0021] Example 1: A tin ore concentrator that processes 120 tons of ore a day uses a ¢1200 single-screw classifier and a ¢1500×3000 grinding machine for closed-circuit grinding and grading. The grinding fineness is -200 mesh, accounting for 75%. The actual measurement of the spiral classifier The classification quality efficiency calculated by 0.074mm is 38%, and the over-crushing rate (-10μm) of the classification overflow is 32%, and the subsequent sorting operation indicators are not ideal. The grading system is retrofitted with the method and apparatus of the present invention.

[0022] The compound classification method for grinding products is: combine the vibratory screening method with the spiral classification method to carry out compound classification for the grinding products. The sieve surface is soaked in the spiral grading overflow liquid, and the grinding products are vibratingly screened through the double-layer vibrating screen to obtain the on-screen mater...

Embodiment 2

[0026] Example 2: A copper ore concentrator that processes 1,500 tons of ore a day uses a ¢2000 double-screw classifier and a ¢2700×3600 grinding machine for closed-circuit grinding and grading in the first stage of grinding operation. The degree of -200 mesh accounts for 60%, the measured mass efficiency of the spiral classifier according to 0.3mm is 50%, the mass efficiency of the classification according to 0.074mm is 32%, and the over-grinding rate (-10μm) of the classification overflow is 26%. .

[0027] The grading system is modified with the method and equipment of the present invention, and the method and device used are the same as those in Example 1. That is, increasing the angle of the original grader to 15 0 , move outwards 1000mm, add the chute vibrating screen of the present invention between the grinding machine and the classifier, the length, width and height of the vibrating screen are 1200 × 800 × 1000mm, and the upper sieve of the vibrating screen adopts ...

Embodiment 3

[0029] Example 3: An iron ore dressing plant that processes 1,000 tons of ore a day uses the SLFS1500 screening spiral compound classifier of the present invention and the ¢2100×3000 ore grinding machine to perform closed-circuit grinding and grading in the first stage of grinding operation, and the ore discharge granularity is 0.4mm. The grinding fineness is -200 mesh, accounting for 55%. The specific method and device are the same as in Example 1.

[0030] The length, width and height of the chute vibrating screen of the screening spiral compound classifier are 1000×750×900mm. The upper sieve of the vibrating screen adopts a polyurethane sieve plate with an aperture of 6mm, and the lower layer adopts a wear-resistant stainless steel screen with an aperture of 0.45mm. The vibration frequency of the vibrator is 1480 times / min. The ore discharge chute of the vibrating screen and the feeding port of the spiral classifier are flexibly connected by rubber material. The spiral c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com