Patents

Literature

127 results about "Heavy mineral" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geology, a heavy mineral is a mineral with a density that is greater than 2.9 g/cm³, most commonly referring to dense components of siliciclastic sediments. A heavy mineral suite is the relative percentages of heavy minerals in a stone. Heavy mineral suites are used to help determine the provenance and history of sedimentary rocks.

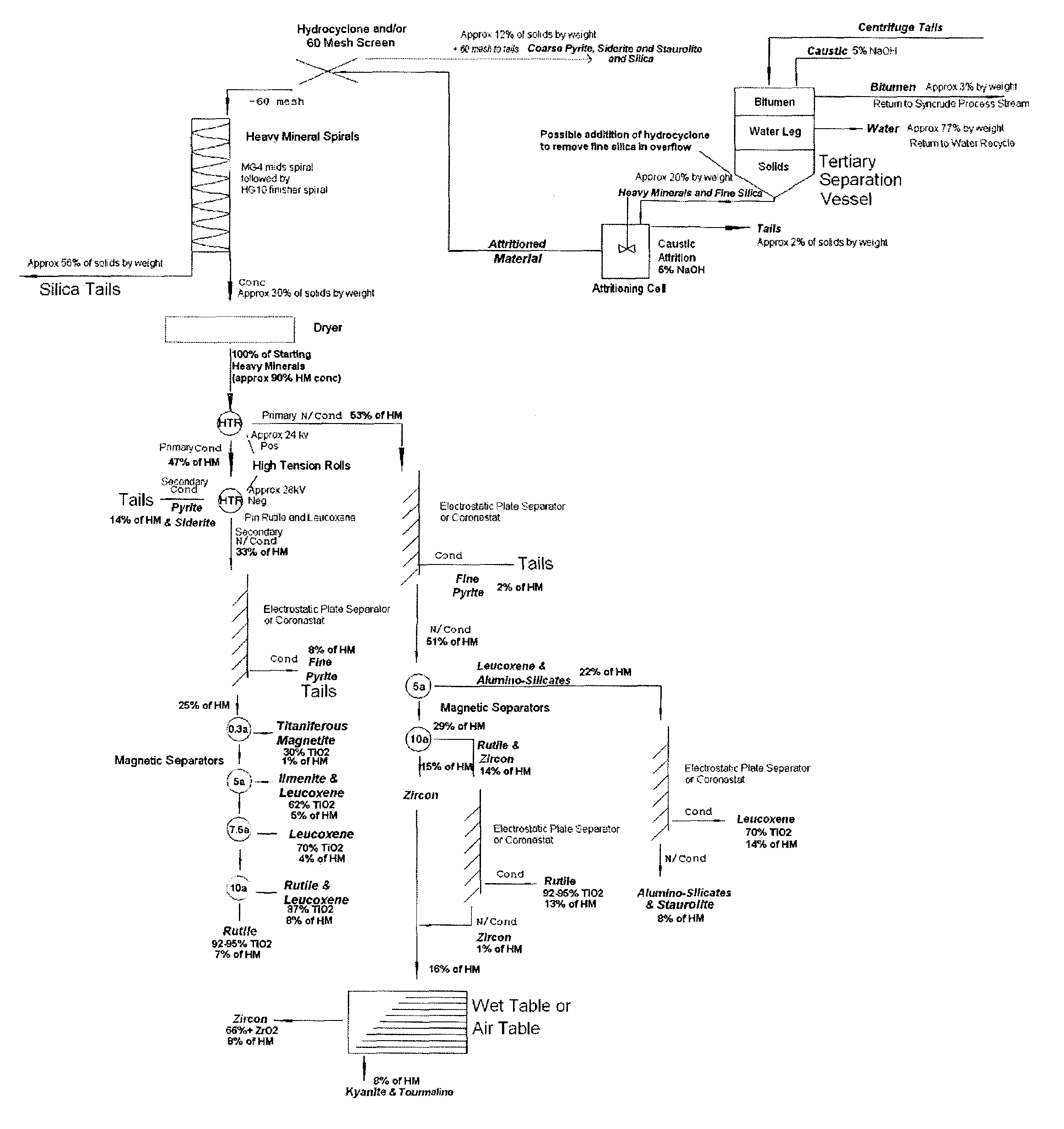

Recovery of heavy minerals from a tar sand

A process for recovering heavy minerals (e.g., titanium minerals such as TiO2) from a feedstock comprising tar sands or a tar sands-derived solids fraction. The feedstock comprises bitumen and heavy minerals. The process comprises the steps of: (i) contacting the solids fraction with water at a temperature of at least about 100° F. to cause production a bituminous phase and a heavy minerals phase; and (ii) separating the heavy minerals phase from the bituminous phase. Optionally, these steps may be preceded by one or more steps used to produce a tar-sands derived solids fraction from a tar sands feedstock.

Owner:TITANIUM CORP

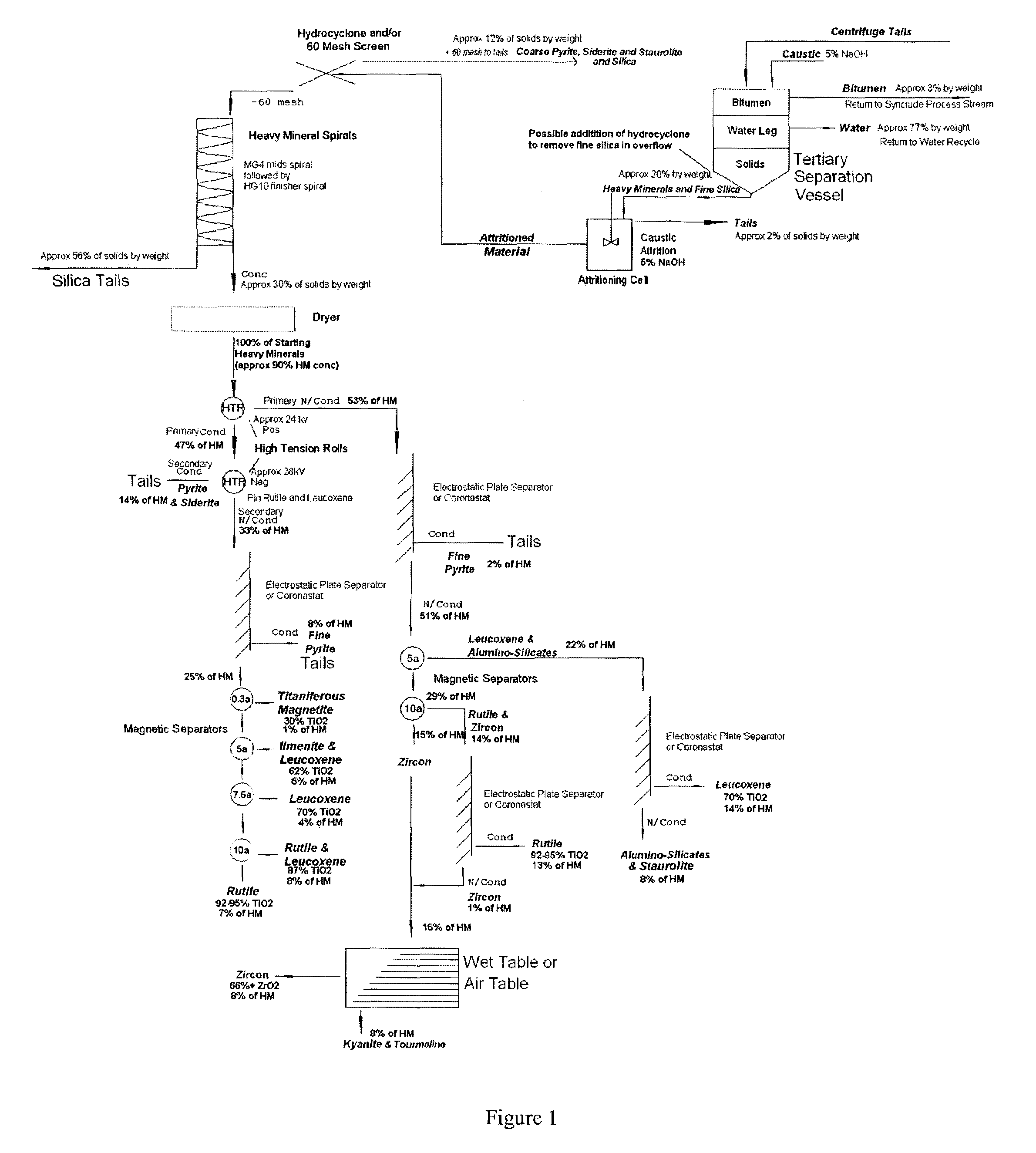

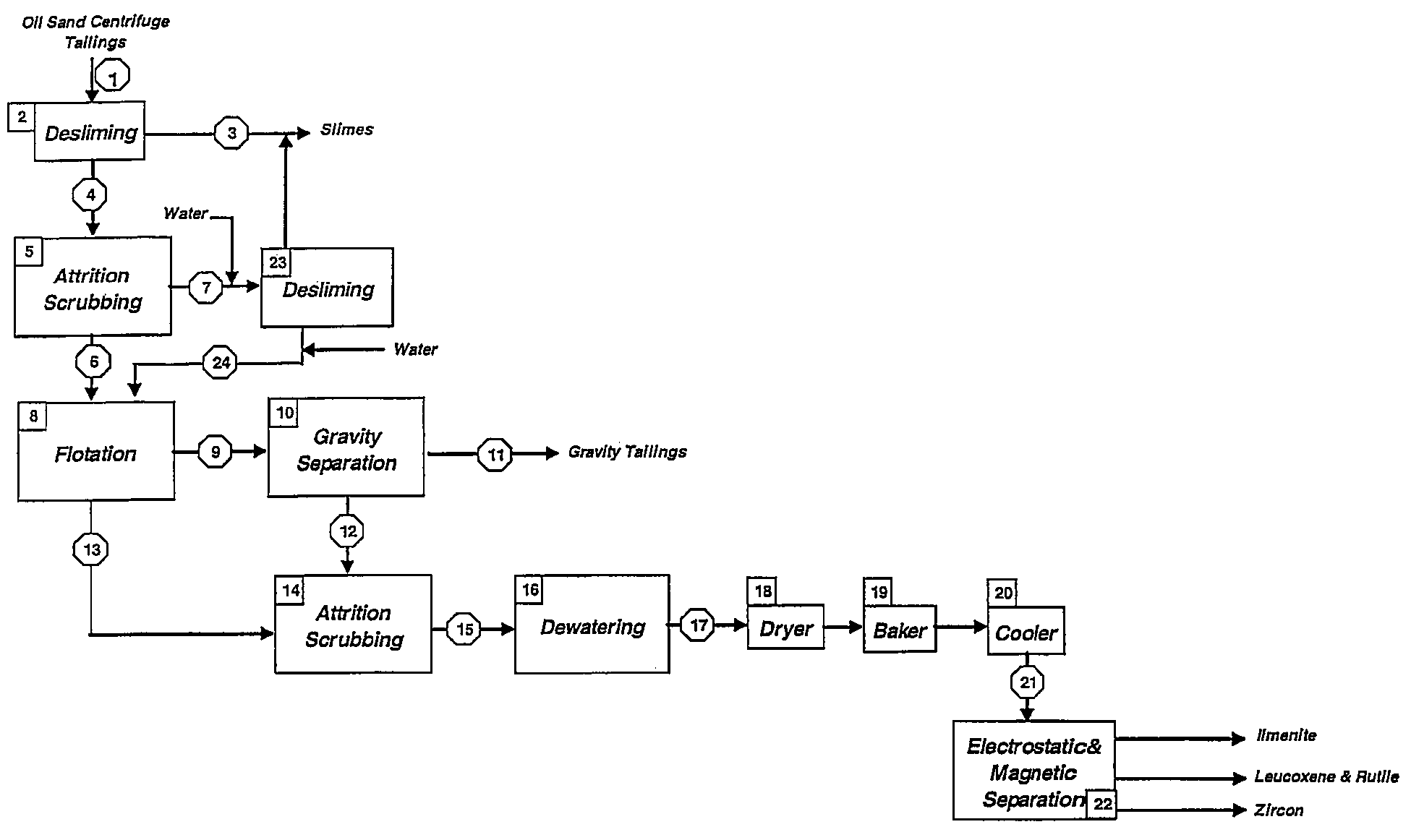

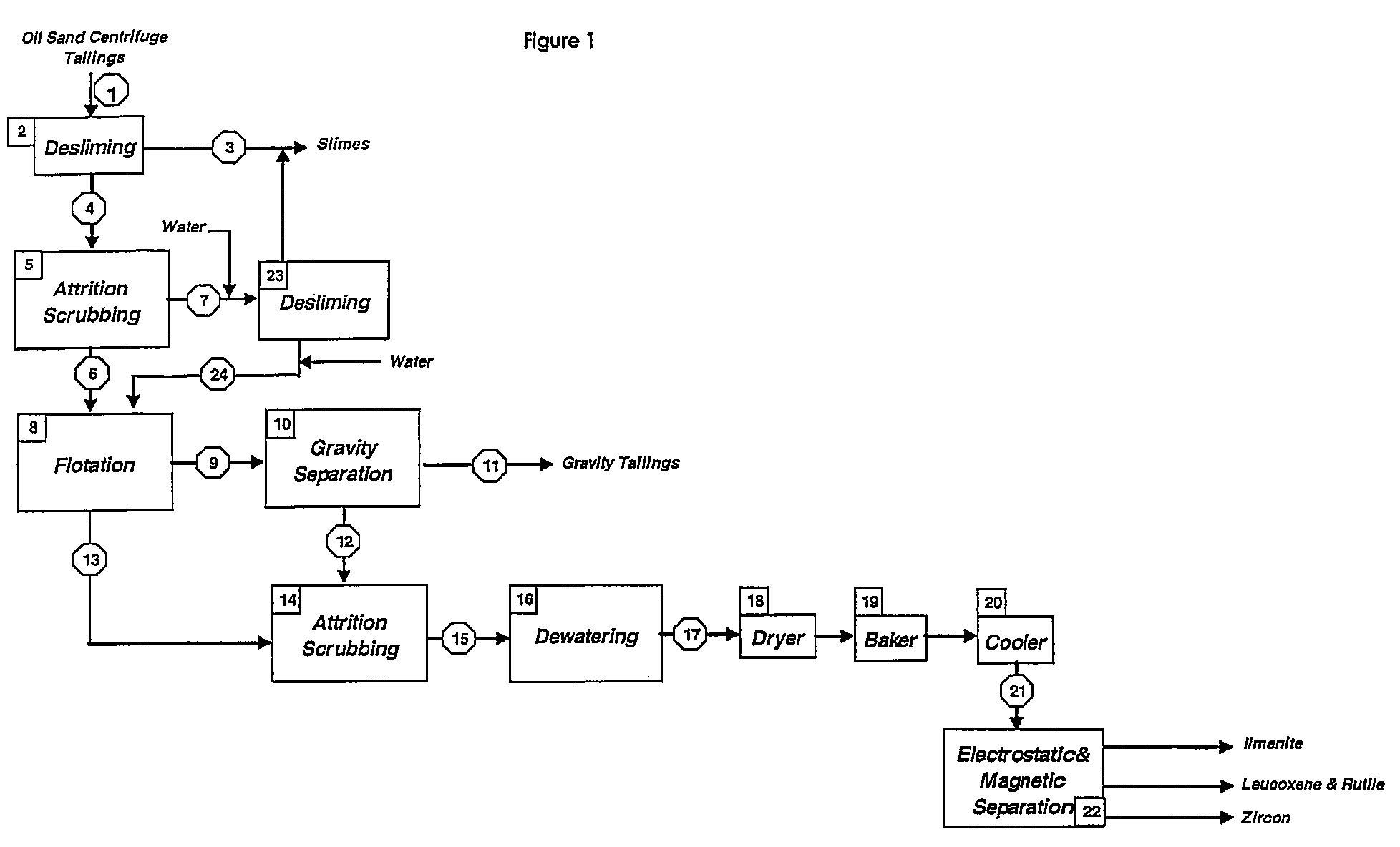

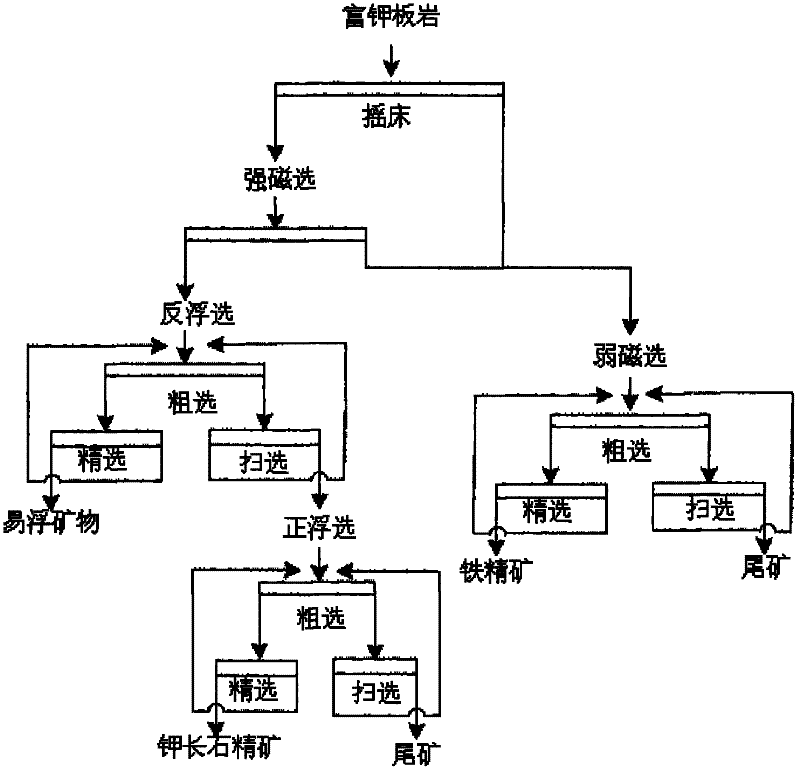

Process for recovering heavy minerals from oil sand tailings

ActiveUS20070272596A1Quality improvementExpansion quantityWater/sewage treatment by centrifugal separationCentrifugal force sediment separationSilicon dioxideMaceral

A process is provided for recovering heavy minerals from aqueous oil sand tailings, the oil sand tailings having heavy minerals, other coarse solids such as silica, fines, residual bitumen and water, including desliming the oil sand tailings in a desliming means by removing a portion of free fines and residual bitumen from the oil sand tailings; attritioning the oil sand tailings in an attritioner to remove adhered fines and residual bitumen from the heavy minerals and other coarse solids; and subjecting the deslimed and attritioned tailings to separation in a separation means to separate the heavy minerals from the other coarse solids present in the deslimed and attritioned tailings and produce a concentrated heavy minerals fraction.

Owner:TITANIUM CORP

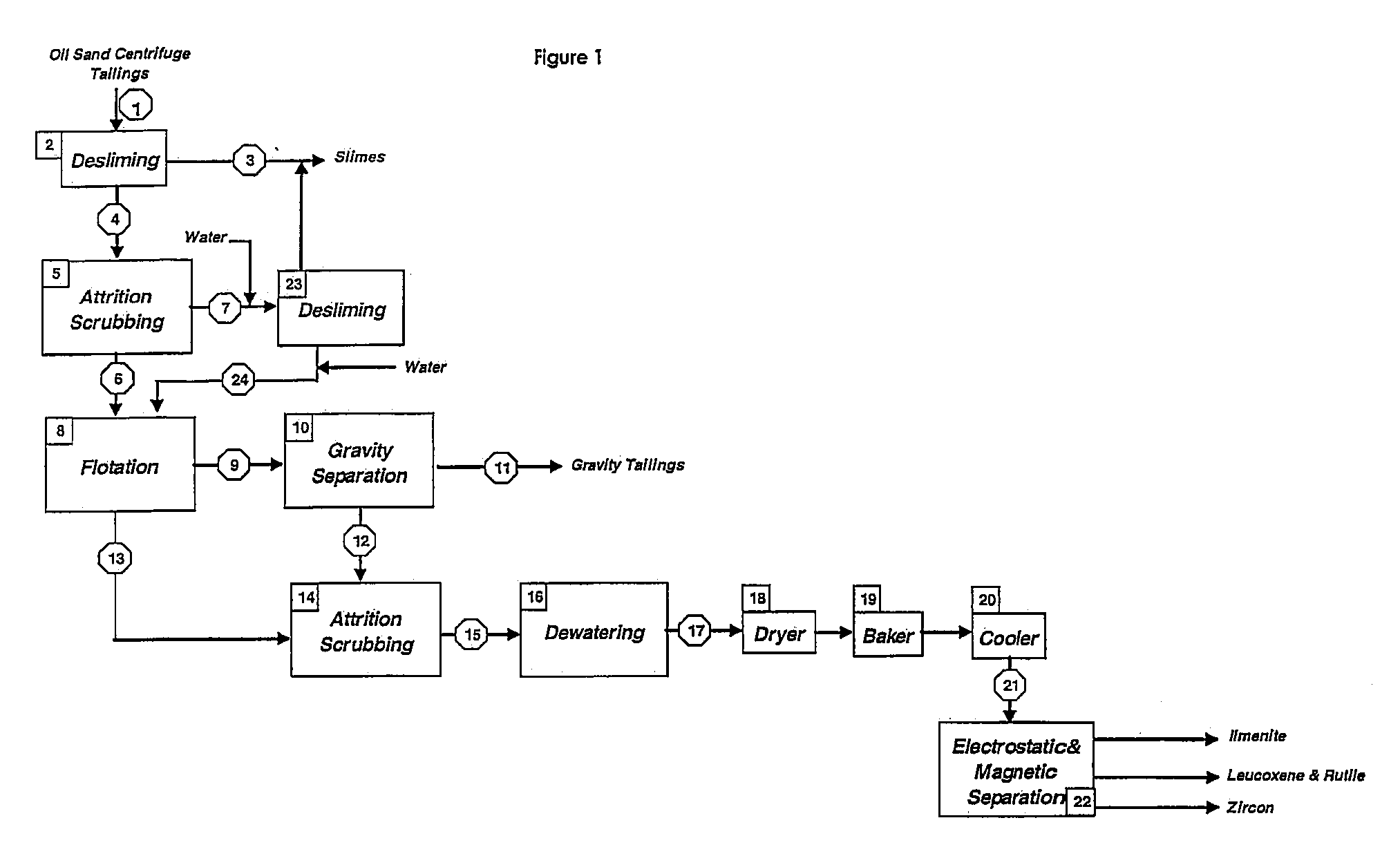

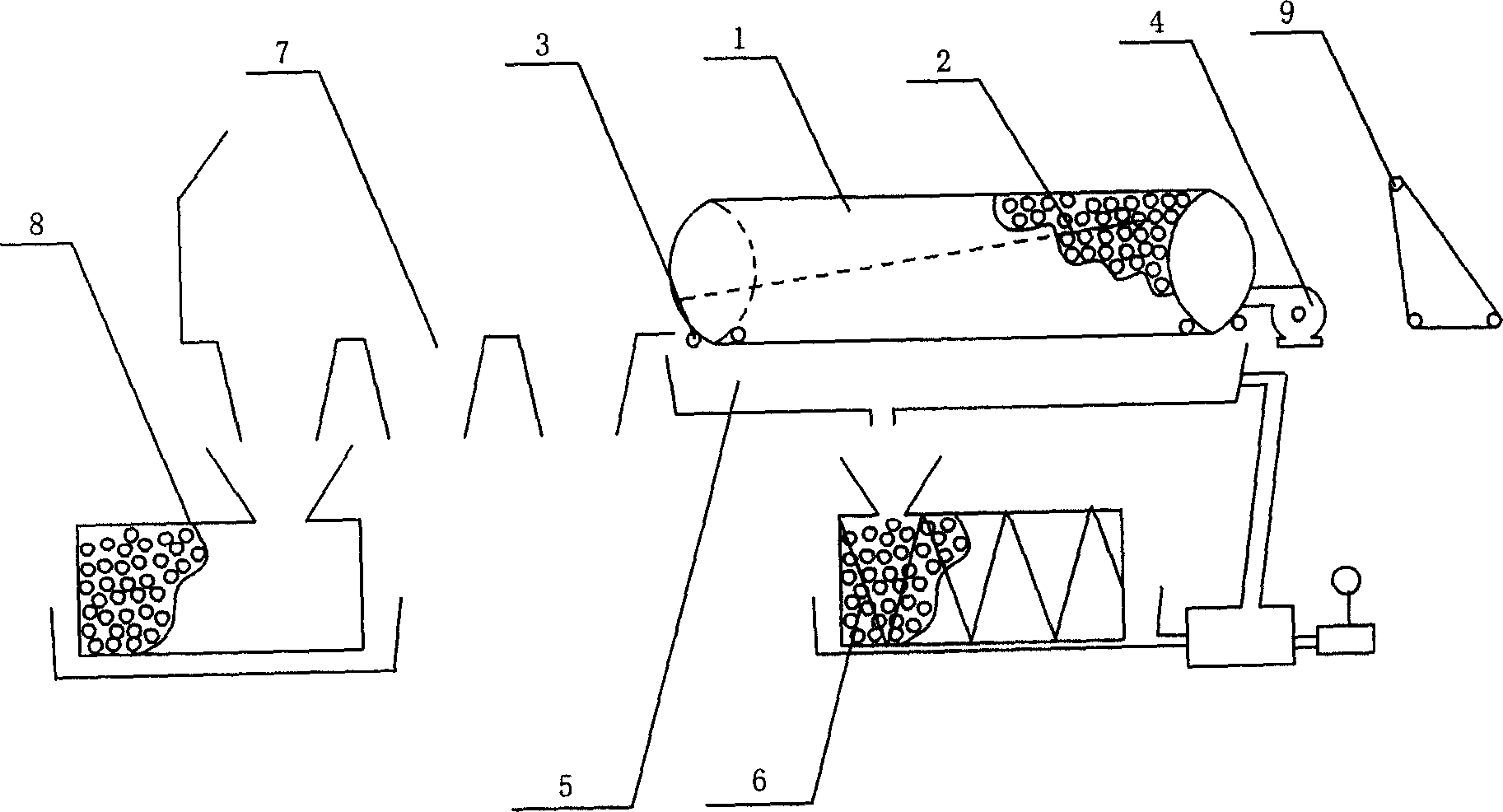

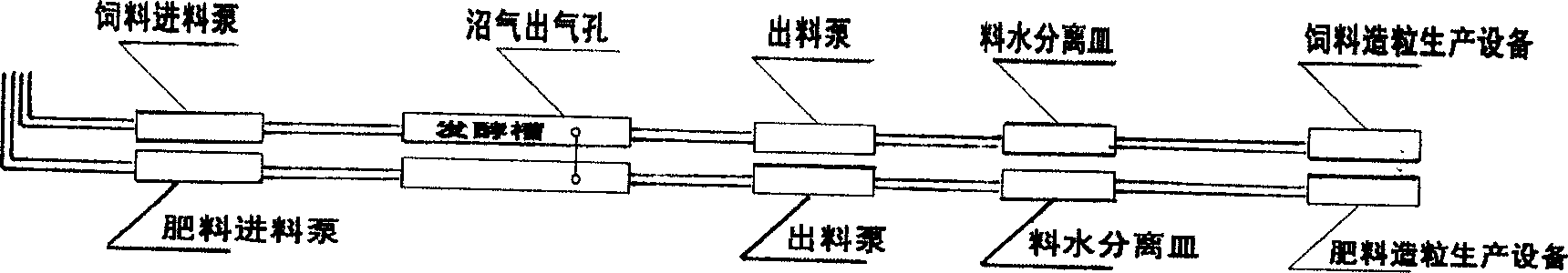

Domestic garbage processing process

InactiveCN1843643AAdvanced technologyReasonable designBio-organic fraction processingSolid waste disposalEconomic benefitsEngineering

The invention discloses a method for treating life waste, which comprises following steps: 1, original selection: selecting humus organics and some mineral waste whose diameter is smaller than 20mm; and via wind device, wind selecting the life waste of rotating screen; 2, refining: water selecting the life waste whose diameter is smaller than 20mm to separate the light humus organics from heavy mineral; the wind device feeds plastic bag, plastic cloth, paper and foam life waste into storehouse; and using plastic-paper separator to separate the plastic from the paper; the plastic, rubber and metallic life wastes left in the rotational screen falls from the end of rotational screen to the storehouse via the front force of crusher; and using electromagnetic iron to separate metallic waste; 3, treating the refined waste to prepare product. The invention has high treating speed, high safety and high economic benefit without secondary pollution.

Owner:张国利

Process for recovering heavy minerals from oil sand tailings

ActiveUS7695612B2Quality improvementExpansion quantityWater/sewage treatment by centrifugal separationCentrifugal force sediment separationSilicon dioxideMaceral

A process is provided for recovering heavy minerals from aqueous oil sand tailings, the oil sand tailings having heavy minerals, other coarse solids such as silica, fines, residual bitumen and water, including desliming the oil sand tailings in a desliming means by removing a portion of free fines and residual bitumen from the oil sand tailings; attritioning the oil sand tailings in an attritioner to remove adhered fines and residual bitumen from the heavy minerals and other coarse solids; and subjecting the deslimed and attritioned tailings to separation in a separation means to separate the heavy minerals from the other coarse solids present in the deslimed and attritioned tailings and produce a concentrated heavy minerals fraction.

Owner:TITANIUM CORP

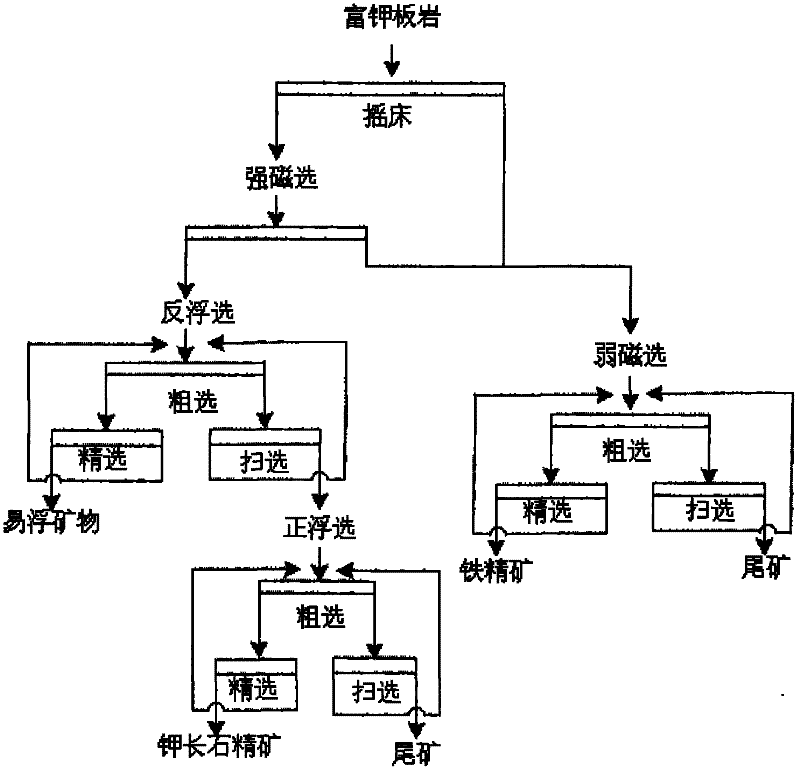

Method for separating potassium feldspar ore concentrate and iron ore concentrate from Baiyunebo potassium rich slate

The invention relates to a method for separating potassium feldspar ore concentrate and iron ore concentrate from Baiyunebo potassium rich slate, and belongs to the field of ore dressing. The method comprises the following steps of: reselection: performing table reselection on the potassium rich slate, over 90 percent of which has the granularity of 200 meshes, and separating out heavy minerals and light minerals; strong magnetic separation: performing strong magnetic separation on the light minerals obtained by reselection to obtain magnetic minerals and nonmagnetic minerals; weak magnetic separation: merging the heavy minerals obtained by reselection and the magnetic minerals obtained by strong magnetic separation, performing weak magnetic separation to obtain the iron ore concentrate; and flotation: performing reverse flotation and positive flotation to obtain the potassium feldspar ore concentrate. The method is scientific and reasonable, and the potassium feldspar ore concentratewith the purity of 95 percent and the yield of 85 percent and the iron ore concentrate with the full iron grade of over 65 percent and the yield of more than 95 percent can be obtained.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Method for recycling mica, feldspar and quartz sand from kaolin tailings

The invention provides a method for recycling mica, feldspar and quartz sand from kaolin tailings. The method includes the following steps that the kaolin tailings are subjected to selective milling; then screening is conducted, oversize coarse products are almost flaky pure mica, and undersize products are subjected to hydraulic classification so that fine sand containing mud can be removed; classification settled sand is reselected repeatedly so that heavy minerals can be removed; reselected fine sand is subjected to medium magnet and strong magnet operations and then magnetic separation fine sand can be obtained; the magnetic separation fine sand is subjected to the first segment of flotation, the mica can be separated at first, and a fragmental mica product is obtained; the feldspar is separated from quartz in the second segment of flotation; and finally the mica, feldspar and quartz product can be obtained, and the fine sand and milltailings produced in the beneficiation process can be used for unfiring of new building materials like aerated bricks. By adoption of the method, kaolin tailing resources can be utilized comprehensively and effectively; and moreover, the technological process is simple, energy consumption is low, 'zero' release of solid waste is realized, the policy requirements of environmental protection act can be met, and the economic, social and environmental protection benefits are good.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

Recovery of heavy minerals from a tar sand

A process for recovering heavy minerals (e.g., titanium minerals such as TiO2) from a feedstock comprising tar sands or a tar sands-derived solids fraction. The feedstock comprises bitumen and heavy minerals. The process comprises the steps of: (i) contacting the solids fraction with water at a temperature of at least about 100° F. to cause production a bituminous phase and a heavy minerals phase; and (ii) separating the heavy minerals phase from the bituminous phase. Optionally, these steps may be preceded by one or more steps used to produce a tar-sands derived solids fraction from a tar sands feedstock.

Owner:TITANIUM CORP

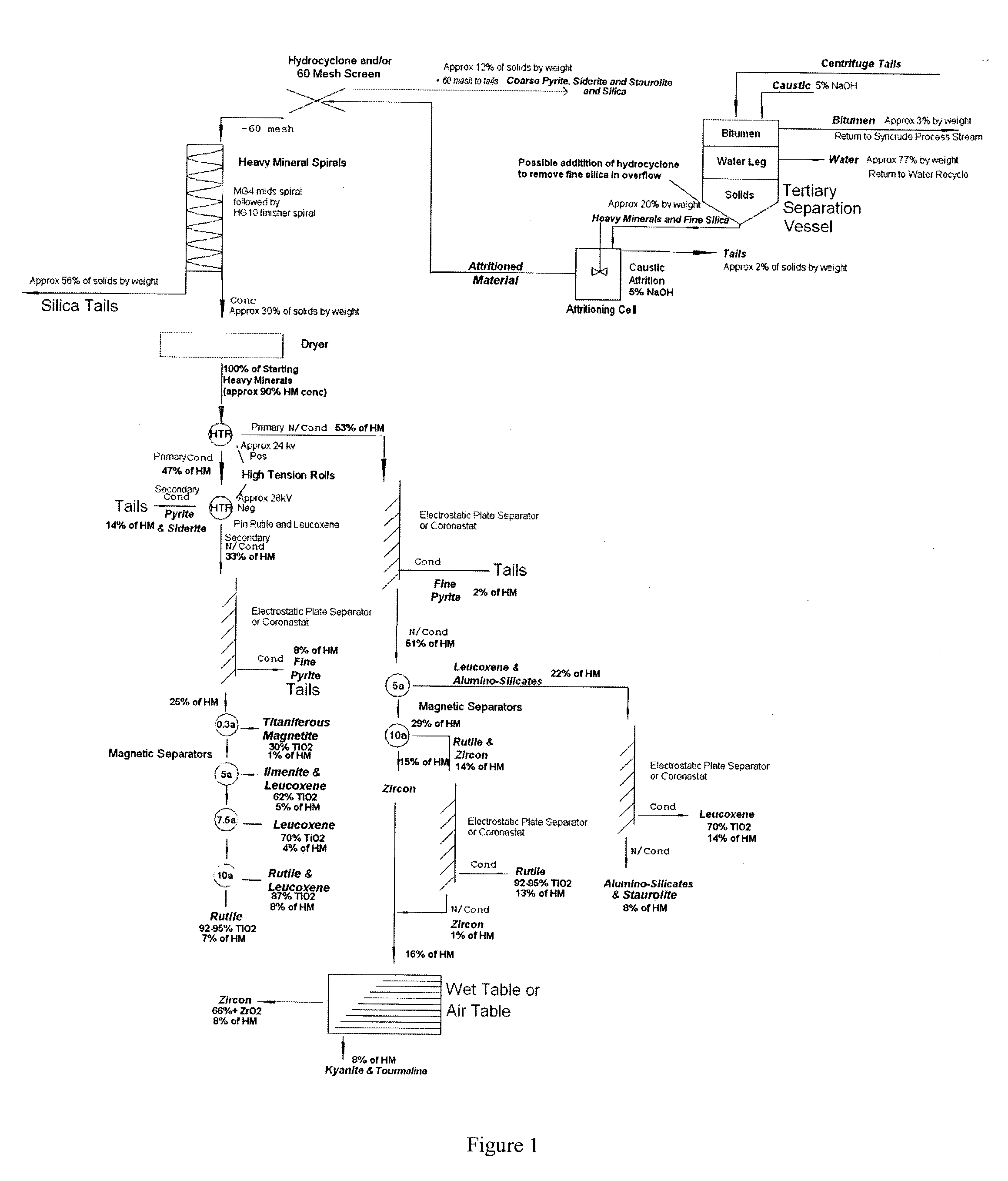

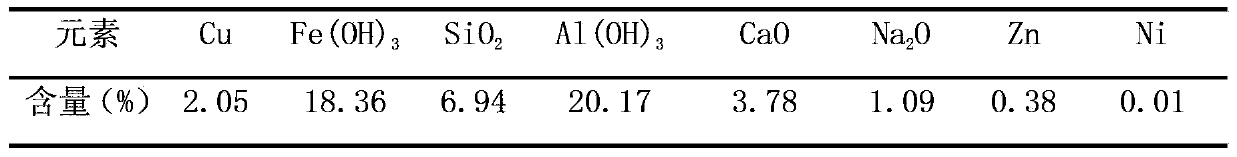

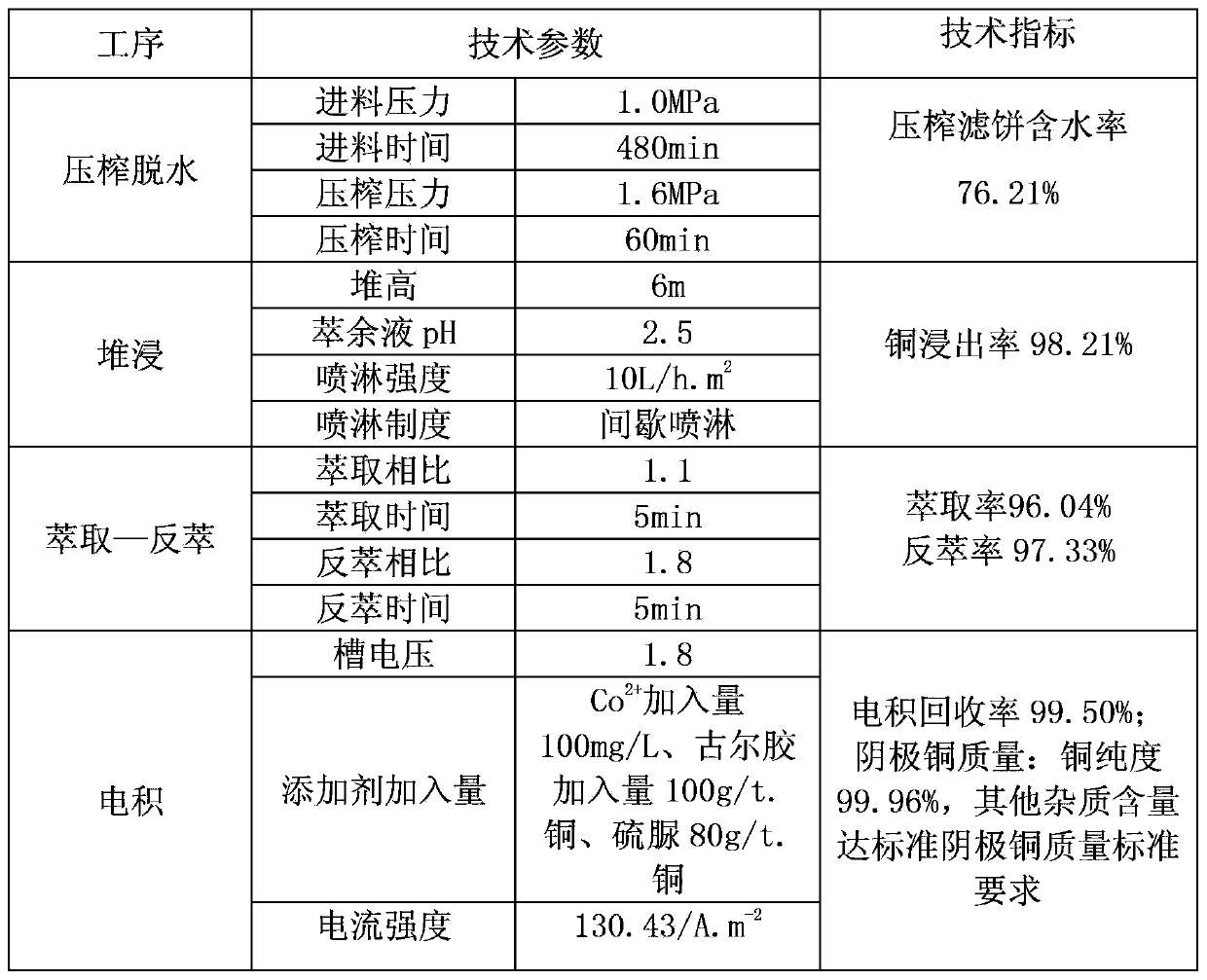

Method for producing tough cathode with cupric sludge

ActiveCN103422119AImprove leaching rateGood washing rateSludge treatment by de-watering/drying/thickeningPhotography auxillary processesSludgeMature technology

The invention relates to a method for producing tough cathode with cupric sludge. The method comprises the following processing steps: step 1, squeezing and dewatering: squeezing and dewatering cupric sewage; step 2, heap leaching or pickling: sprinkling acid solution on a columnar heap and feeding obtained heap leaching pregnant solution to an extraction system, or feeding squeezed and dewatered lump sludge to a pickling pool to pickle the squeezed and dewatered lump sludge with acid solution and feeding obtained pickling pregnant solution to the extraction system; step 3, extraction-reverse extraction: performing extraction on the heap leaching pregnant solution or the pickling pregnant solution obtained in the step 2, and performing reverse extraction on obtained loaded organic phase to obtain copper pregnant solution; step 4, electro-deposition: performing electro-deposition on the copper pregnant solution obtained in the step 3 under a copper condition to obtain tough cathode. The method has the advantages of low energy consumption, environmental friendliness, applicability to sludge with a low copper content, easiness in solid-liquid separation, high washing rate, high total recovery rate of copper, mature technology and the like and is applicable to industrial fields such as heavy mineral mining, non-ferrous metal smelting, machining and electroplating.

Owner:ZIJIN MINING GROUP

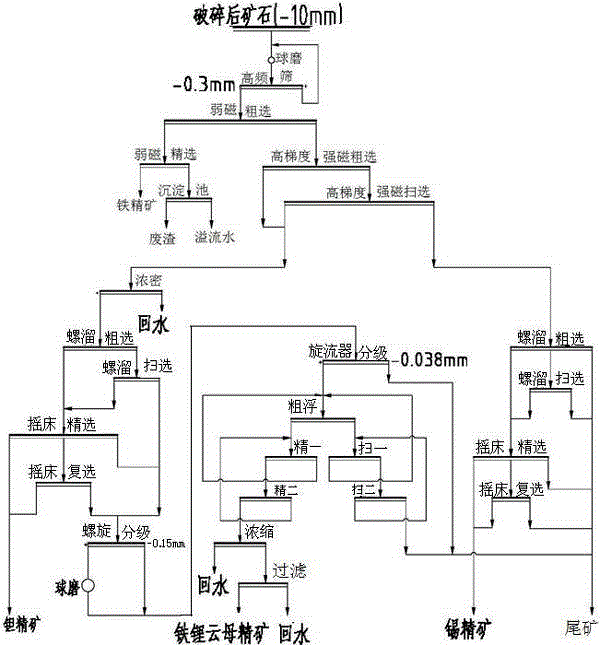

Mineral processing technology capable of effectively separating tantalum, tin and lepidomelane

The invention discloses a mineral processing technology capable of effectively separating tantalum, tin and lepidomelane. A ball mill and a high-frequency screen closed circuit are adopted, so that the grading effect is greatly improved, and the condition that heavy minerals return to the mill again to cause over crushing is avoided; a high-gradient high-intensity magnetic separator is adopted, so that the washability of extremely difficultly separated tantalum minerals is improved, the tantalum and the tin which are equivalent in specific gravity are effectively separated, and the floatation amount of a floatation system is greatly reduced, so that the investment is saved, the production cost is reduced and environment protection is also facilitated. Flux weakening iron removal is adopted before high-gradient high-intensity magnetic separation, so that the interference to mineral processing of valuable minerals such as tantalum and tin due to iron with relatively greater specific gravity can be avoided, and the problem that the high-gradient magnetic separator is blocked can be effectively solved. According to the high-gradient high-intensity magnetic separator, ore concentrate is concentrated by a thickener before entering reselection, the reselection requirement can be met; overflow water of the thickener can be directly used as operation wash water of the high-gradient high-intensity magnetic separator; the workflow can be simplified; and the return water utilization ratio is greatly improved.

Owner:CHINA NERIN ENG

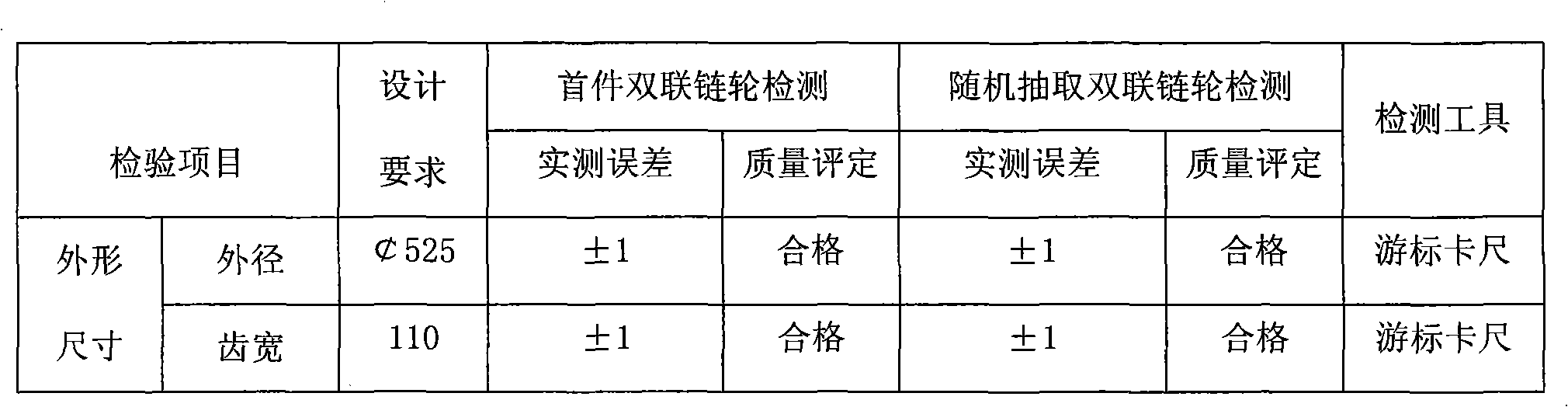

Method for manufacturing heavy type mining gipsy sheave

InactiveCN101279417AGuaranteed manufacturing accuracyExtended service lifeCopying process control systemsGas flame welding apparatusEngineeringSprocket

The invention relates to a method for manufacturing a heavy mineral sprocket that is suitable for a scraper conveyor and a transfer machine, which is characterized in that: the method comprises the following steps that: a rough machining is applied to a forging blank, the forging blank is heated to the temperature ranging from 300 DEG C to 450 DEG C and then a material blank is lifted into a profiling cutting bracket; a core shaft is positioned and aligned, and a pressure plate is compressed tightly and subject to the profiling air cutting formation. The invention has the following technical advantages that: 1. by adopting the profiling allowance-free cutting tooth-shaped process, the manufacturing precision of the sprocket is ensured, so as to be beneficial to prolonging the service life of the sprocket and the achieving the internationally advanced level; 2. the effect of energy saving is distinctive, and the energy consumption of the profiling cutting sprocket only accounts for 1 / 3 of that of the electrolytic sprocket; 3. the working hours of the electrolytic sprocket account for 3 times of the that of the profiling cutting sprocket and the working hours of the profiling milling processing sprocket only account for 3.5 times of that of the profiling cutting sprocket. Obviously, the profiling cutting sprocket not only reduces the manufacturing cost, but also greatly enhances the production efficiency.

Owner:NINGXIA TIANDI BENNIU IND GRP

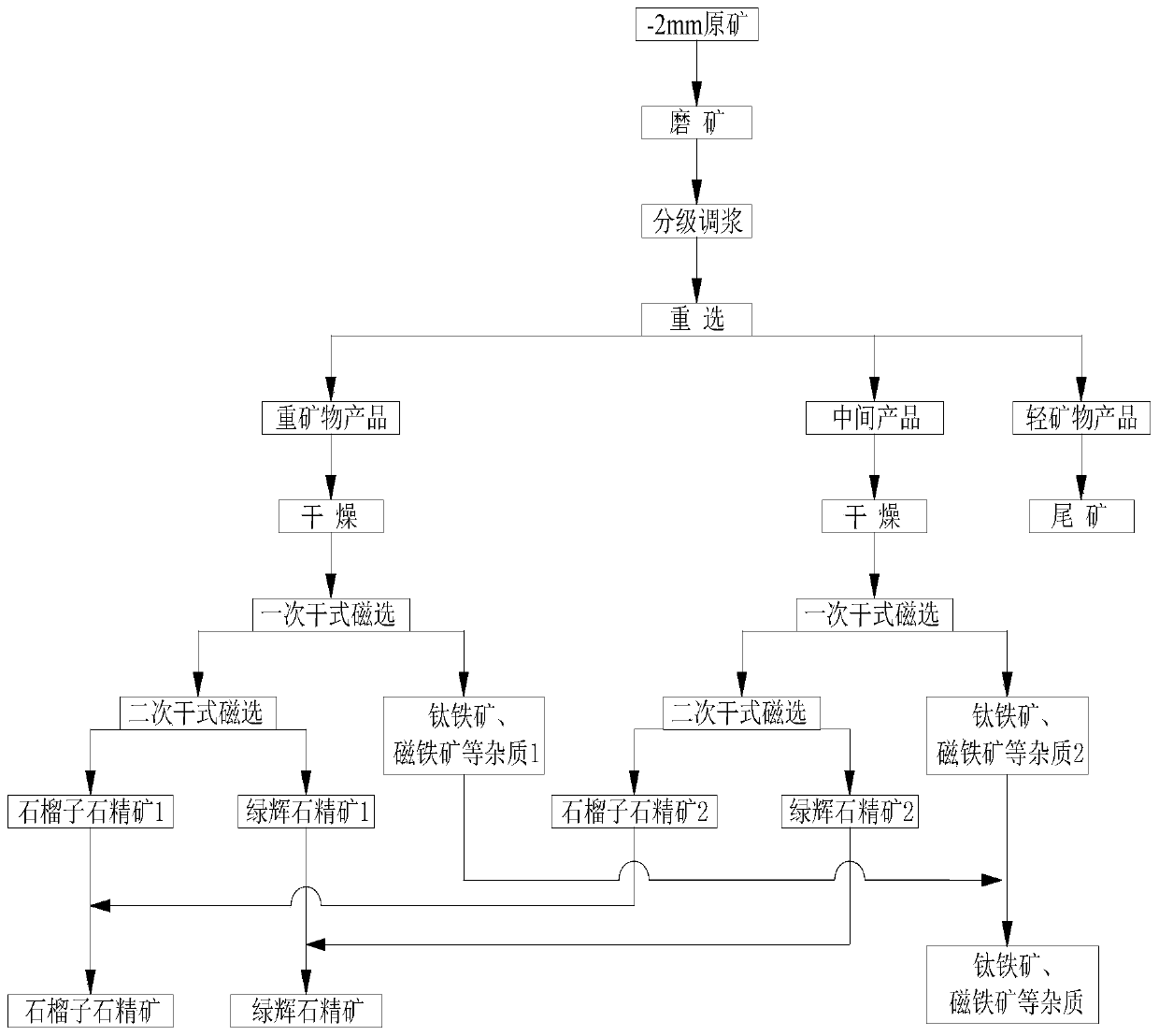

Method for recovering garnet and omphacite from eclogite ore

The invention provides a method for recovering garnet and omphacite from eclogite ore. The method comprises the following steps that raw ore samples are subjected to grinding through a rod mill; ground mineral products are screened and classified so as to be divided into a plurality of grain grades; grain products of each grain grade are subjected to pulp mixing to obtain ore pulp, and reselectingis carried out correspondingly; three products are obtained through reselecting of the grain products of each grain grade, namely heavy mineral products, intermediate products and light mineral products, and the light mineral products are taken as tailings; the heavy mineral products of each grain grade and the intermediate products of each grade are dried correspondingly; and the dried heavy mineral products and the intermediate products are subjected to primary dry magnetic separation and secondary dry magnetic separation respectively, wherein the primary dry type magnetic separation is weak magnetic separation, and the secondary dry type magnetic separation is strong magnetic separation. According to the method for recovering the garnet and the omphacite from the eclogite ore, the quality of the garnet and the eclogite ore concentrate can be effectively improved, specifically, the garnet mineral content is more than 91%, the garnet mineral recovery rate is more than 85%, the eclogite ore mineral content is more than 90%, the eclogite ore mineral recovery rate is more than 84.50%, the production cost is reduced, and the environmental pollution is reduced.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

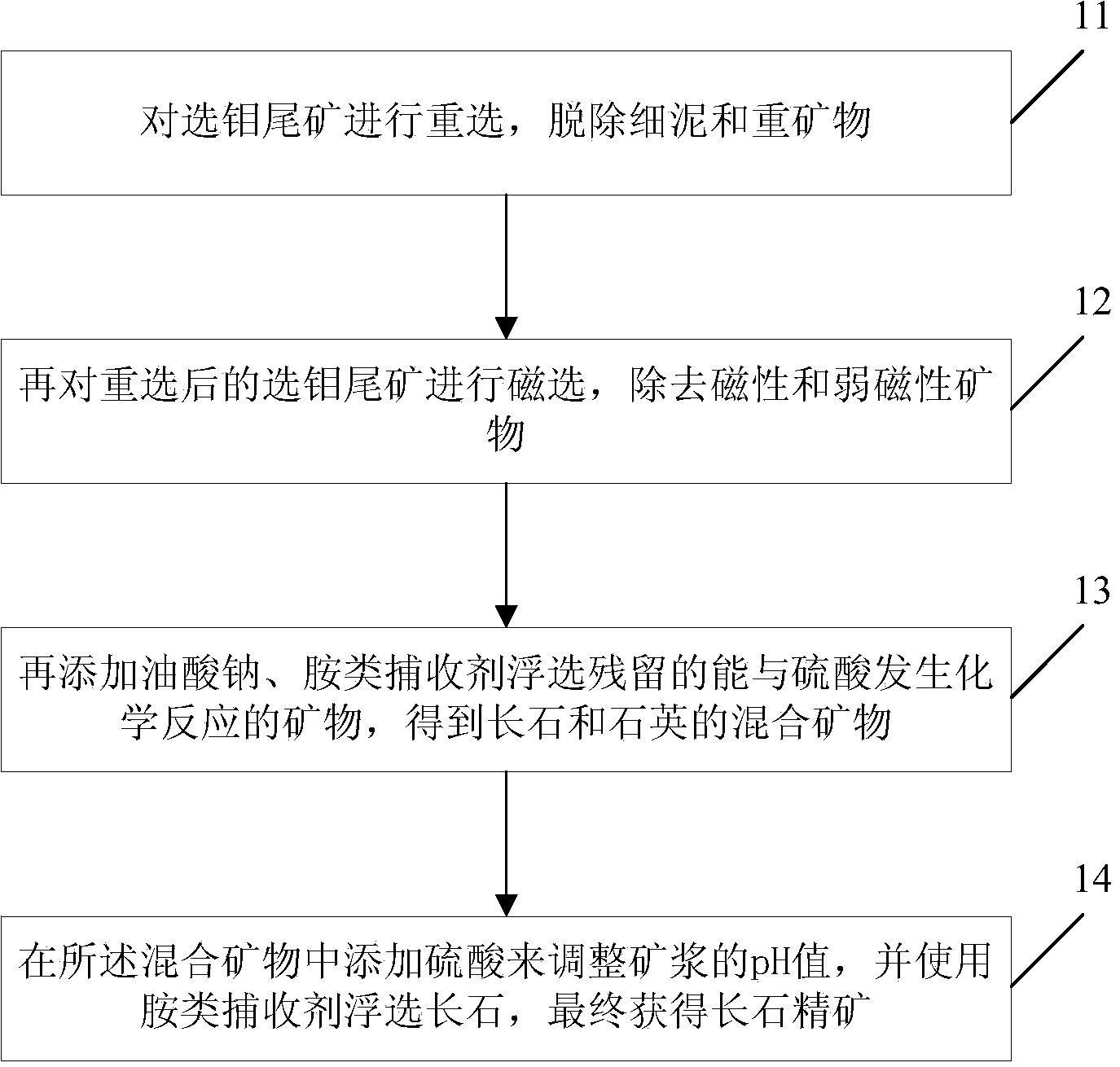

Method for recovering feldspar from molybdenum separation tailings

ActiveCN103447146ADecrease stockSolve the problem of comprehensive recyclingFlotationWet separationChemical reactionPotassium

The invention discloses a method for recovering feldspar from molybdenum separation tailings. The method includes separating the molybdenum separation tailings again to remove mud and heavy minerals, performing magnetic separation to the molybdenum separation tailings after re-separation, adding sodium oleate and amine collectors to perform floatation to minerals capable of being in chemical reaction with sulphuric acid to obtain mixed minerals of feldspar and quartz, adding sulphuric acid into the mixed minerals to regulate the pH value of pulp, performing floatation of feldspar by the aid of amine collectors so as to obtain the feldspar concentrates finally. By the method, the difficult problem in comprehensive recovery of low-grade K-Na feldspar is solved, production of high-grade feldspar concentrates is facilitated, storage of the tailings is reduced, and environmental benefit is remarkable.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Fine grinding and comprehensive recycling beneficiation process of copper-containing sulfur concentrate

ActiveCN105327771AReduce pollutionFacilitate drug removalFlotationMagnetic separationTreatment effectGravity separation

The invention discloses a fine grinding and comprehensive recycling beneficiation process of copper-containing sulfur concentrate. The process comprises the steps of performing concentration, graded fine grinding and reagent removal on copper-containing sulfur concentrate; performing bulk flotation during which one-time rough copper flotation, two-time scavenging and three-time precise copper flotation are carried out, so as to produce a copper rough concentrate product with the copper content of 10% or above; performing wet permanent magnet magnetic separation on the flotation tailings, so as to obtain a high-iron sulfur concentrate product of pyrrhotite with the sulphur content of 33% or above and the iron content of 50% or above; and feeding the tailings of magnetic separation into a two-stage shaking table for gravity separation, separating heavy metal minerals to produce a mixed product of tin, tungsten, bismuth and arsenic valuable metal heavy minerals, and dehydrating the gravity separation tailings to obtain a sulfur concentrate product. The fine grinding and comprehensive recycling beneficiation process is economic and practical, and is relatively low in treatment cost, good in treatment effect, and relatively small in influence to the environment, and the sulfur concentrate produced during sulphide ore beneficiation can be effectively recycled.

Owner:YUNNAN TIN

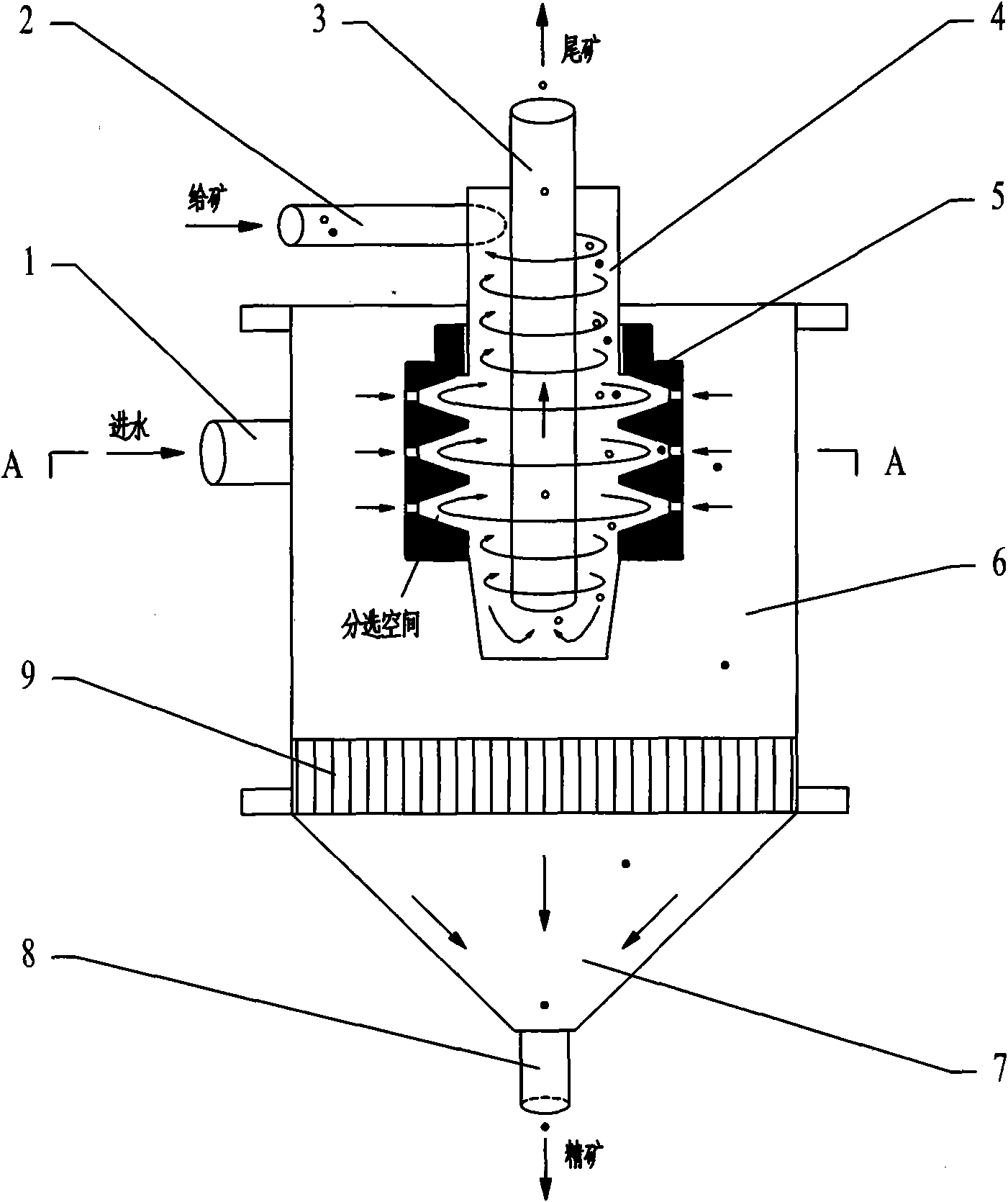

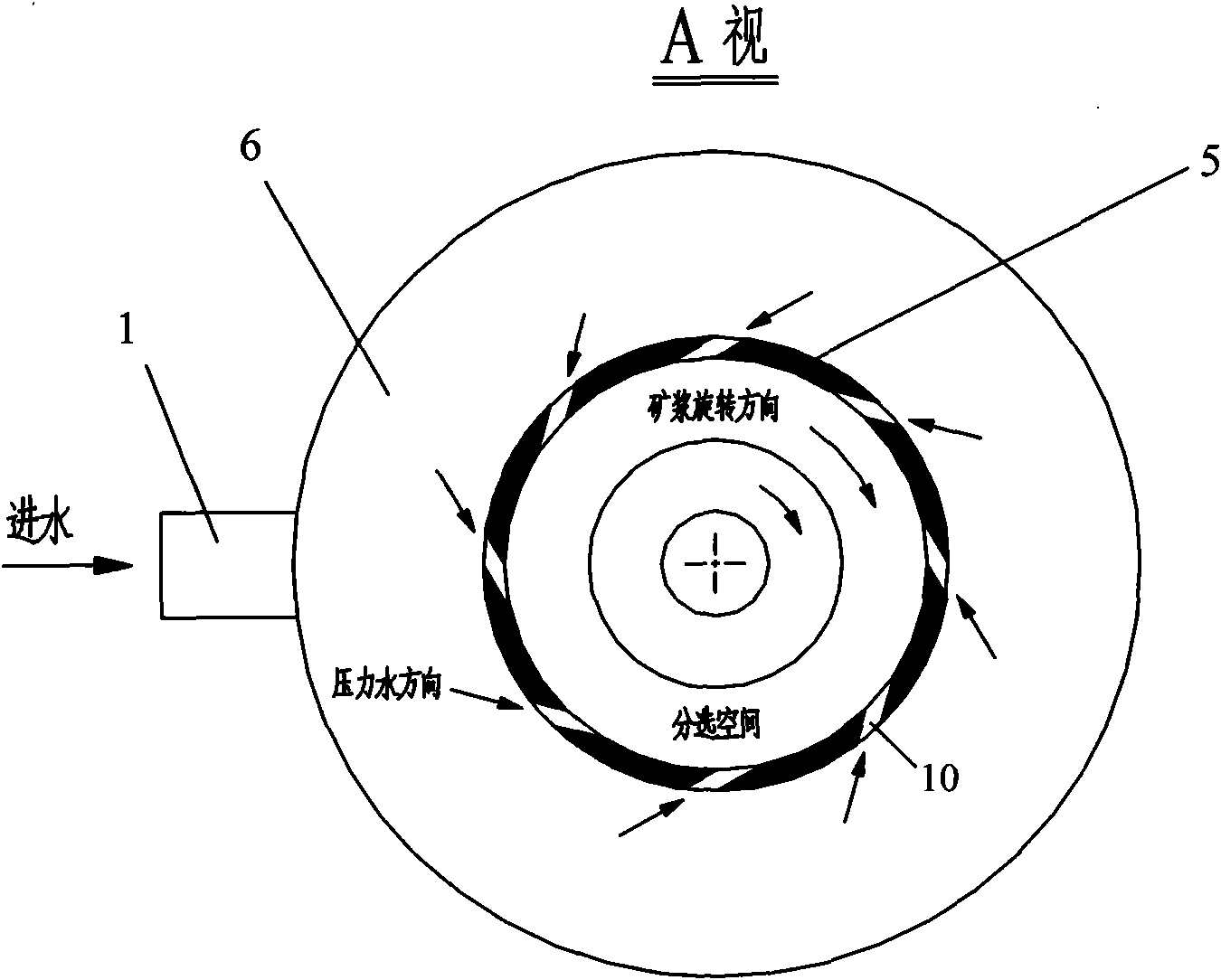

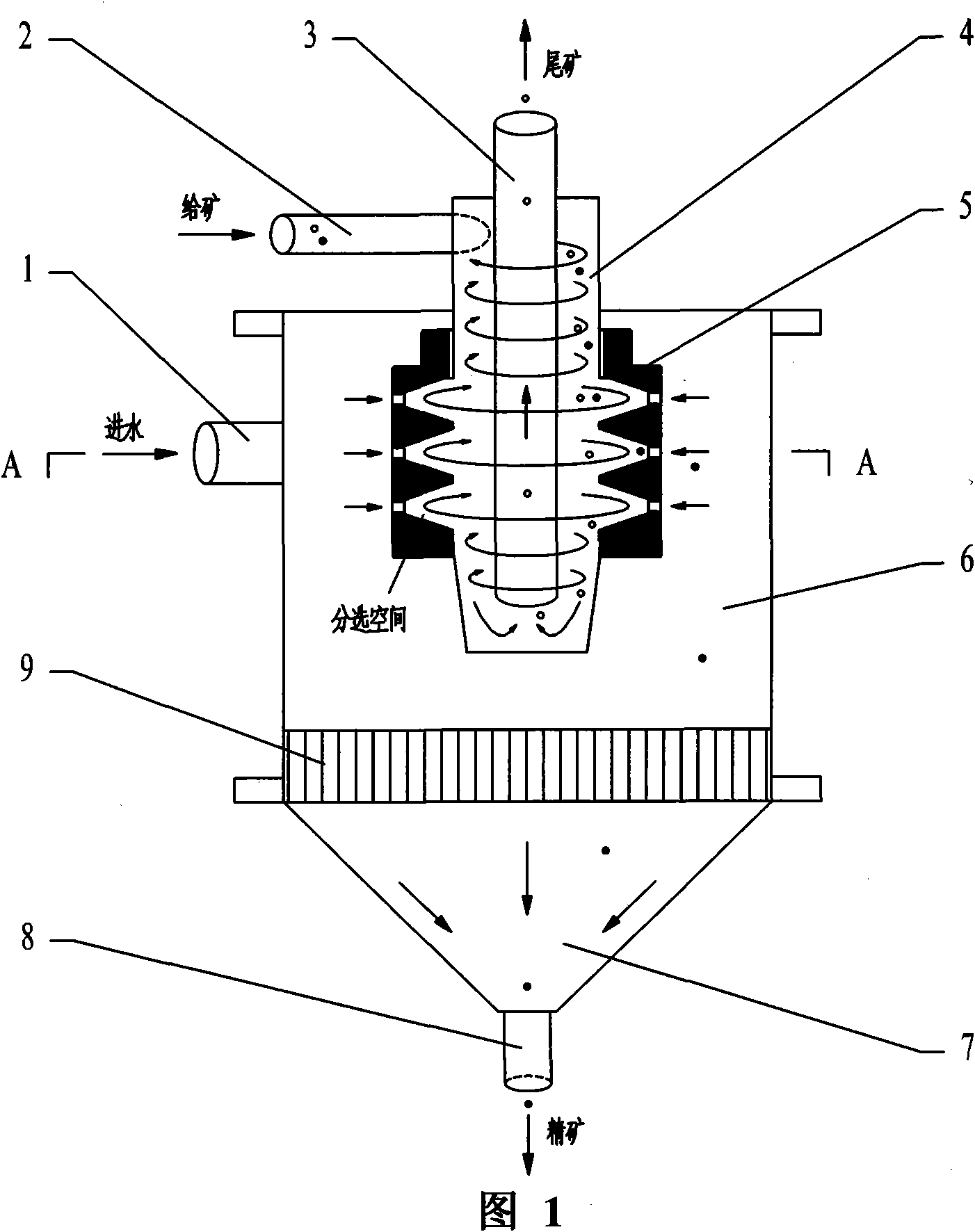

Spiral flow continuous centrifugal classifier

InactiveCN101890393AIncreasing the thicknessImproved Selective SeparationWet separationEngineeringCast films

The invention relates to a classifier for the centrifugal classification of minerals and the classifier can effectively separate minerals with different heavy mineral contents and be especially suitable for the deep concentration of fine minerals with high heavy mineral contents. In the classifier, a water inlet pipe is connected on the wall of a sealed barrel-shaped settling chamber, the upper part of the settling chamber is provided with a barrel-shaped spiral flow column, the lower part is connected with a concentration cone; the lower end of the concentration cone is connected with a concentrate pipe; the upper part of the spiral flow column is connected with a mineral-feeding pipe tangentially, the lower part is connected with a coaxial sorting cone with a sealed bottom, tangential fluidization holes are uniformly distributed at the bottom of a conical ring slot on the inner wall of the sorting cone, and the top of the spiral flow column is provided with a tailing pipe which is communicated with the lower part of the sorting cone. The classifier of the invention utilizes the rotation of pulp to establish a centrifugal field; the formed cast film has large thickness and strong mineral storage and buffer capacities; and minerals with high heavy mineral content and concentrate yield or minerals with low heavy mineral content and concentrate yield can be effectively sorted, thus the classifier has strong adaptability.

Owner:KUNMING UNIV OF SCI & TECH

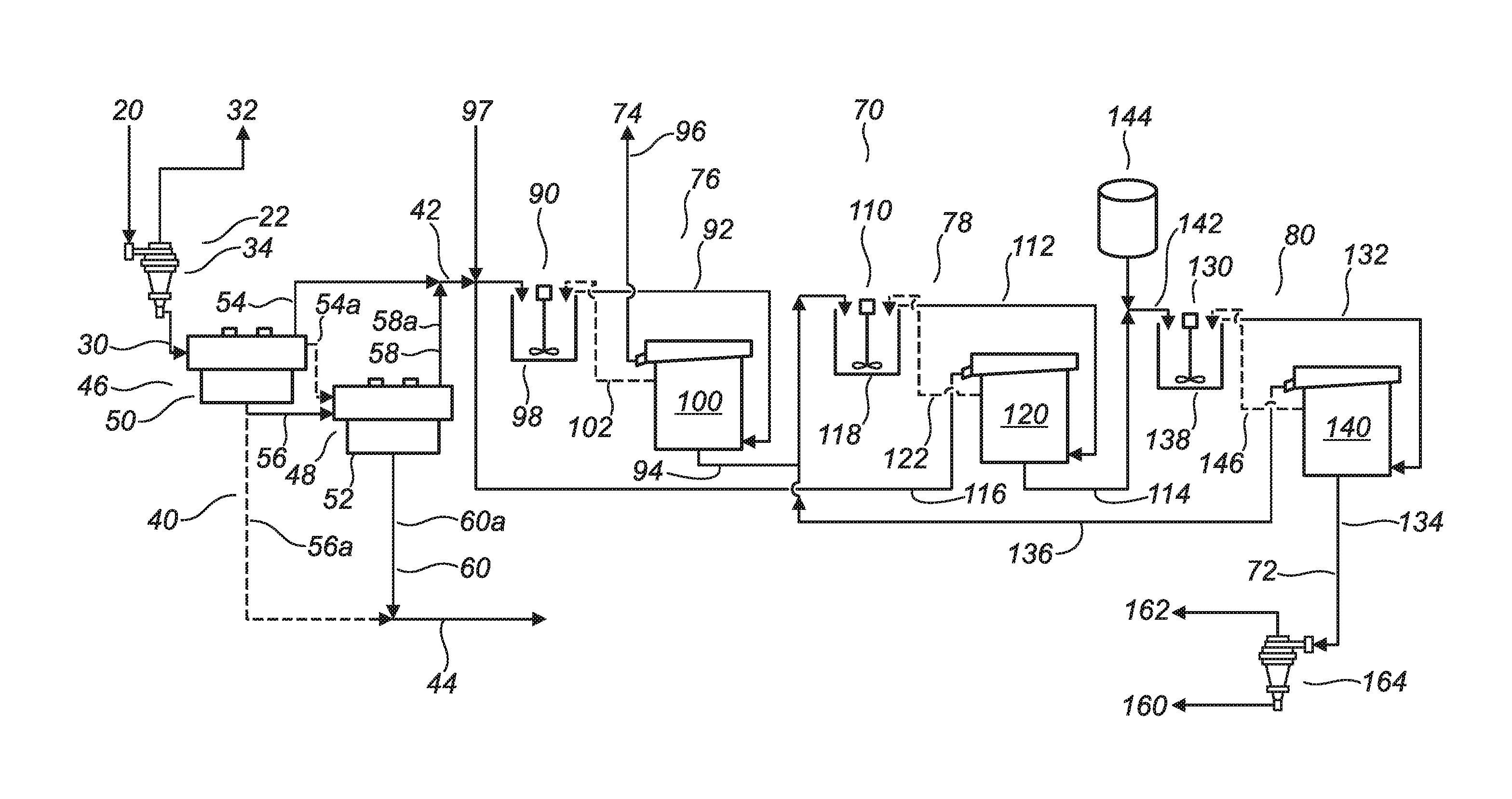

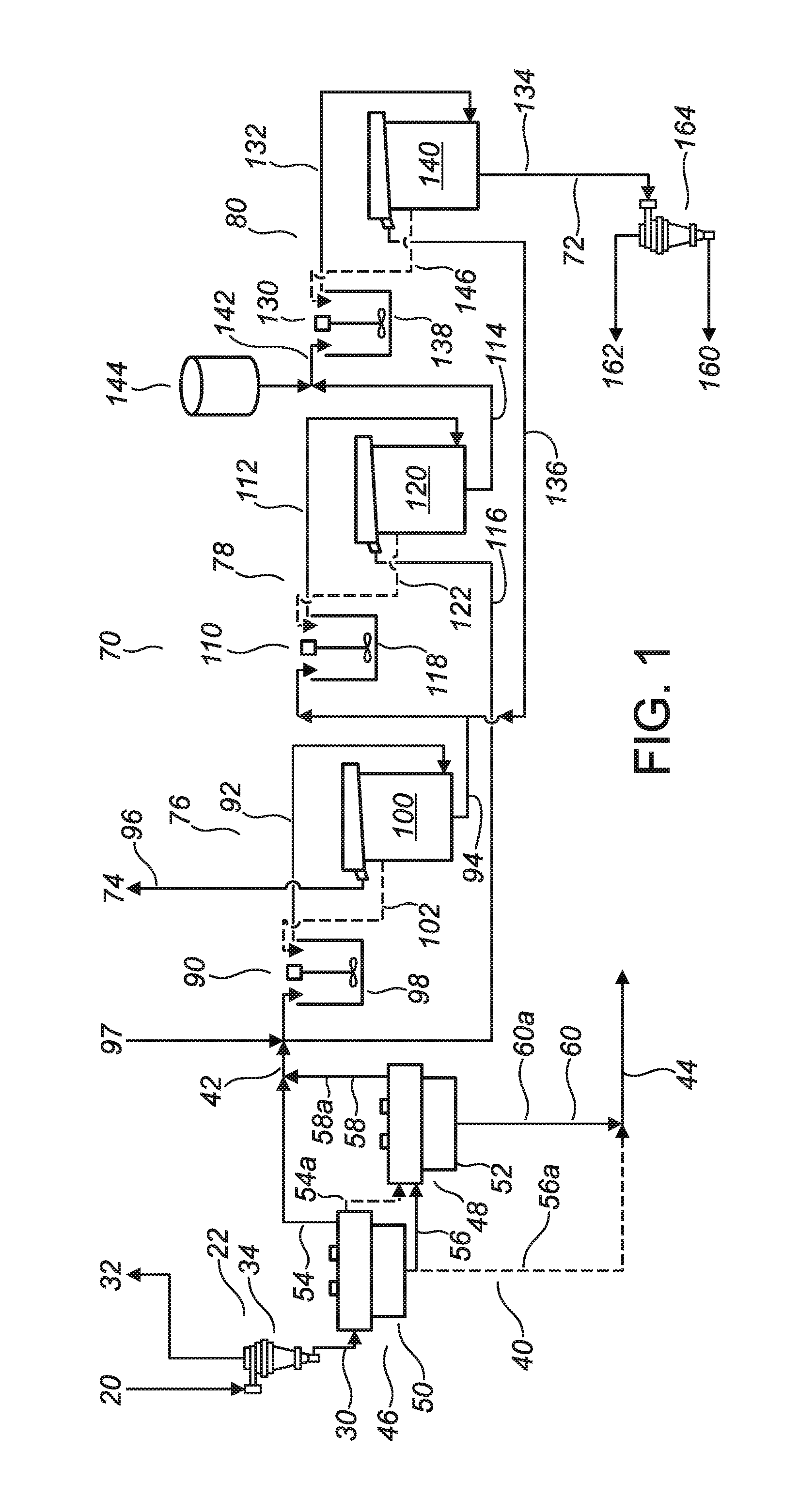

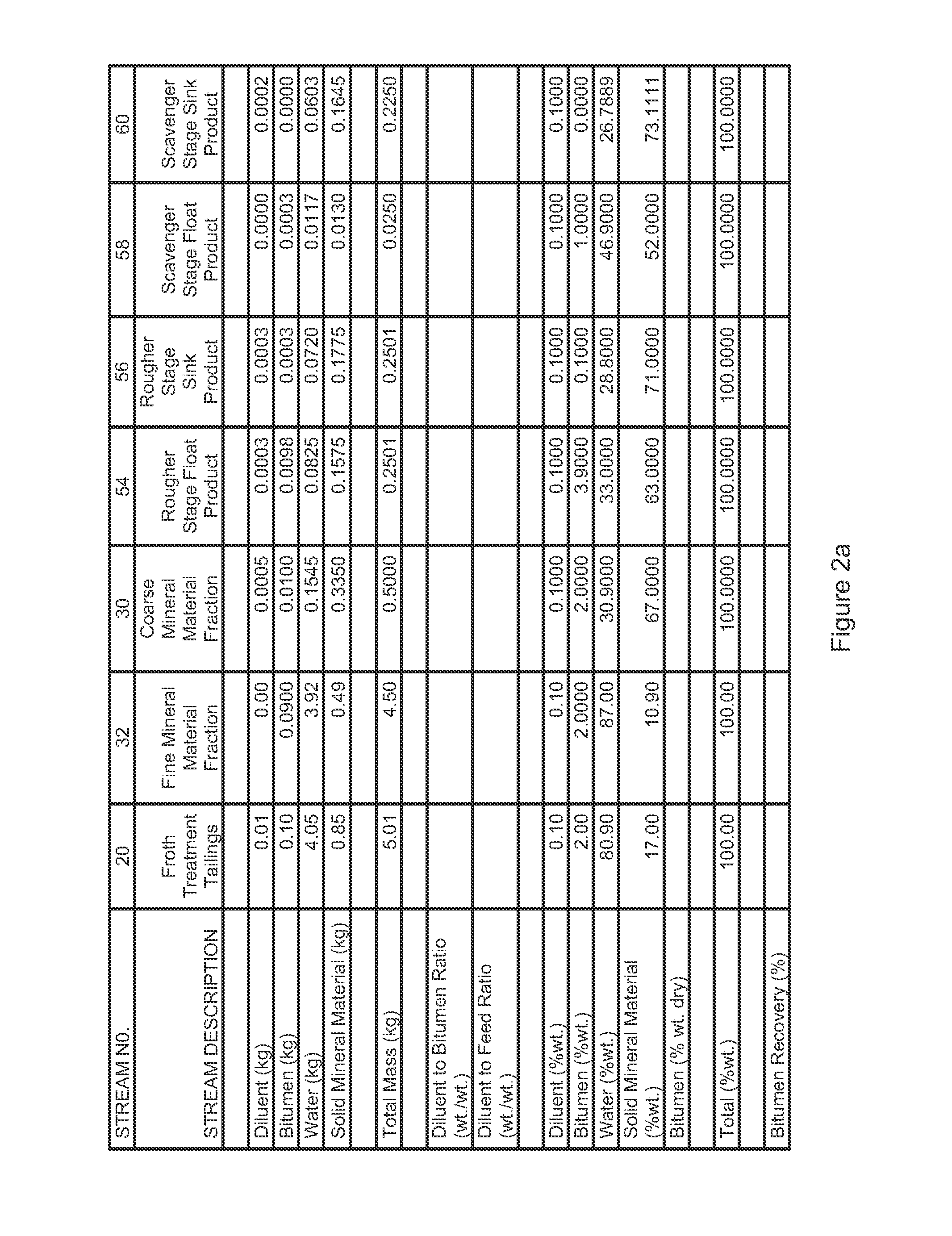

Method for processing froth treatment tailings

ActiveUS20110233115A1Promote recoveryIncrease volumeDewatering/demulsification with mechanical meansLiquid hydrocarbon mixture productionFroth treatmentMaterials science

Owner:TITANIUM CORP

A method for reprocessing and comprehensive utilization of red mud

ActiveCN102295396ASimple methodTechnical parameters are easy to controlSludge treatmentRed mudMagnetic separator

The invention discloses a reprocessing and comprehensive utilization method of red mud, comprising the following steps: (1) carrying out mashing on red mud, and carrying out artificial mineral dressing on heavy mineral to respectively obtain coarse sand and mortar; (2) drying the coarse sand, then carrying out magnetic separating to respectively obtain quartz sand and level 1 magnetic material; (3) carrying out magnetic separating on the level 1 magnetic material to respectively obtain magnetite powder and tailing 1; and (4) putting the mortar in a magnet separator for magnetic separating to respectively obtain fine iron ore and tailing 2. The method is simple and practicable and has the advantages of easily controllable technical parameters, little energy consumption and low cost, can process more than 100 Mtpa per year, reduce the discharging capacity of red mud by 35-70 % and reduced the production cost of alumina. The main products of the method are magnetite powder and quartz, and the obtained two tailings can be used in preparing dry cement or in damming, so that the purpose of comprehensive utilization of red mud is achieved.

Owner:中铝山东有限公司

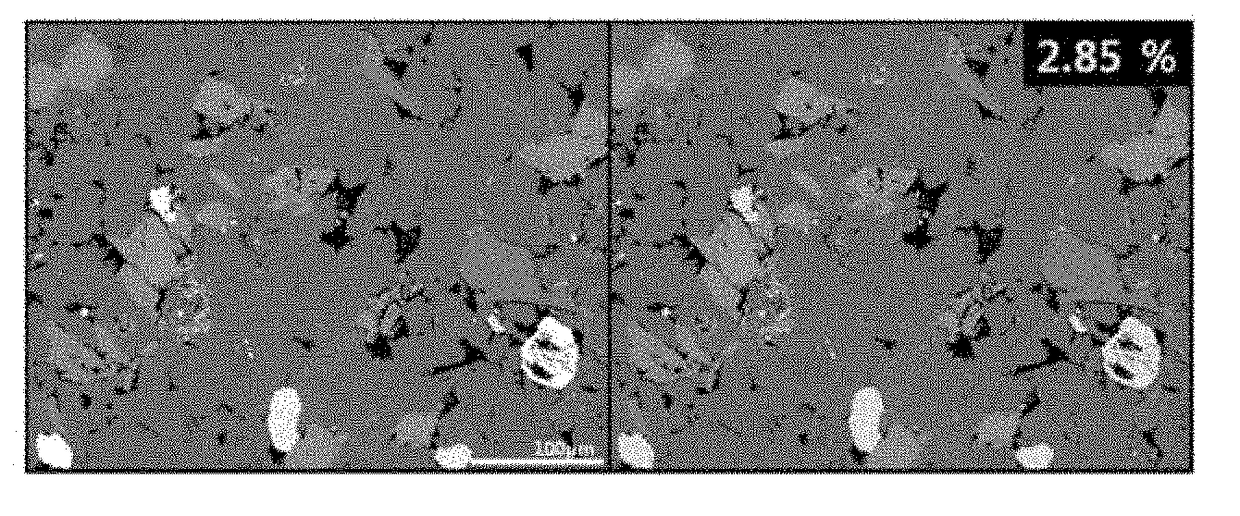

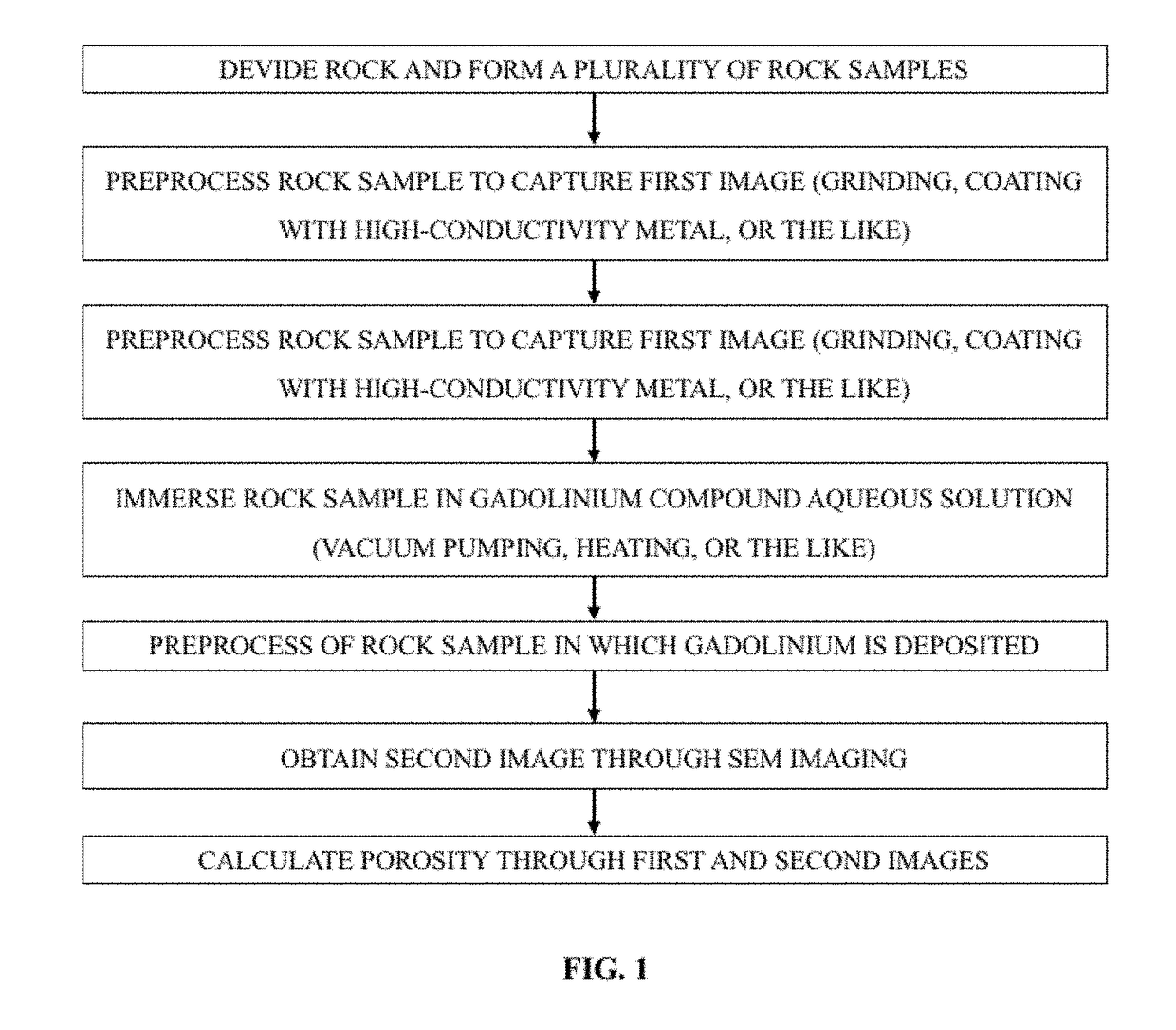

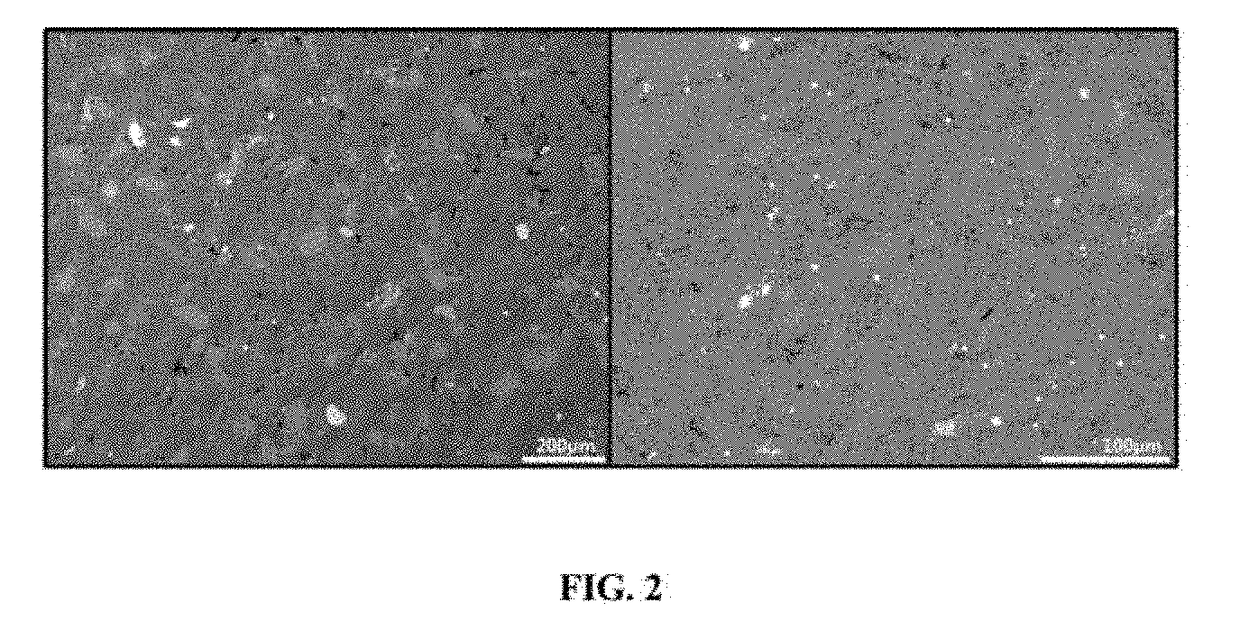

Method for porosity measurement using sem images of rock samples reacted with a gadolinium compound

ActiveUS20180120215A1Improve accuracyDistinguish clearlyElectric discharge tubesMicroscopesPorosityGadolinium

The present invention relates to a method for measuring porosity of a rock according to the present invention including: (a) capturing a first image by using SEM with respect to a rock sample; (b) determining a first area of a portion determined to be a heavy mineral in the first image; (c) immersing the rock sample in an aqueous solution in which a gadolinium compound is dissolved in that the aqueous solution flows into pores and the gadolinium compound is deposited in pores inside the rock sample; (d) capturing a second image by using SEM with respect to the rock sample; and (e) determining a second area of a portion determined as a heavy mineral and a pore in the second image, and then subtracting the first area from the second area to determine an area of pores in the rock sample.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

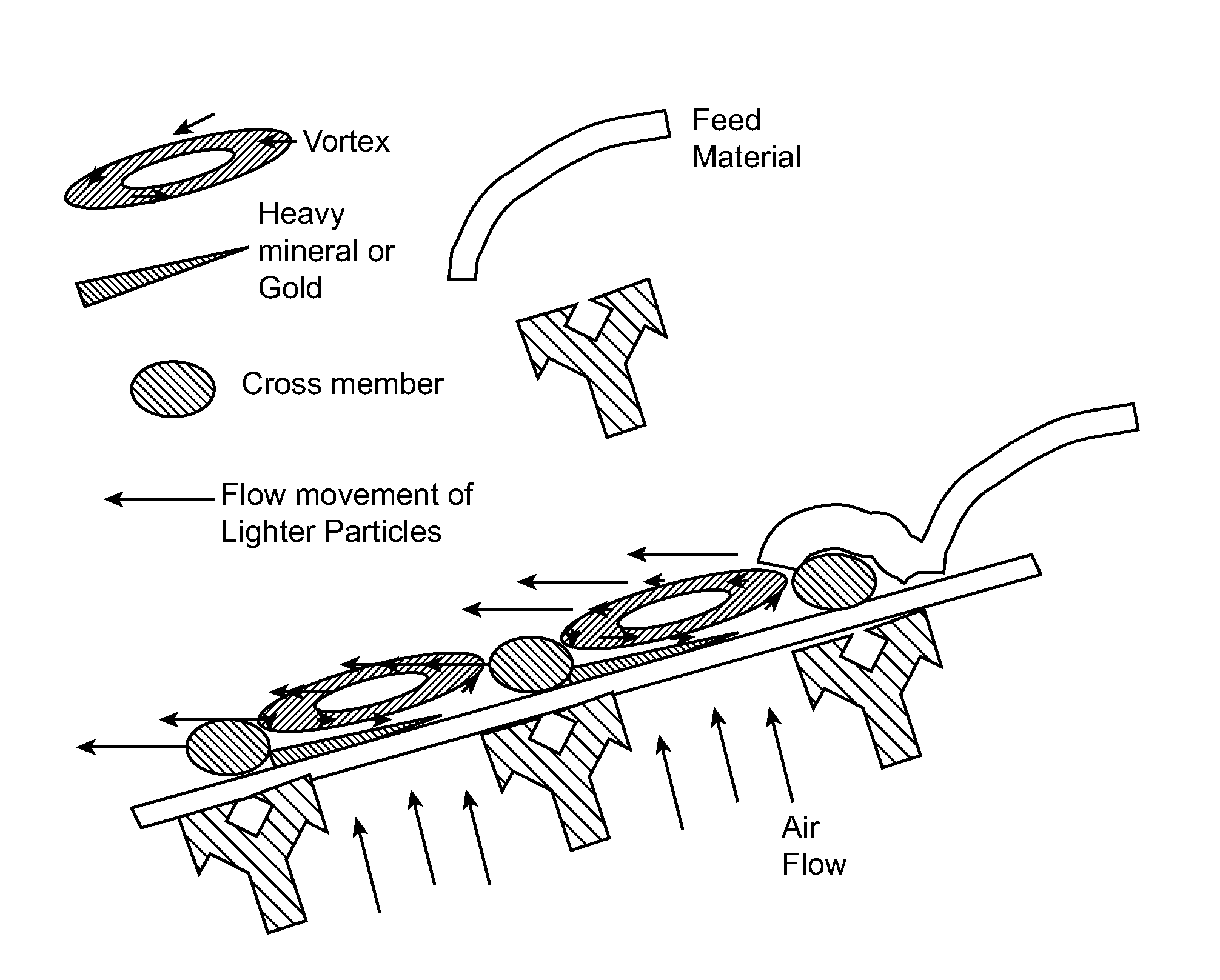

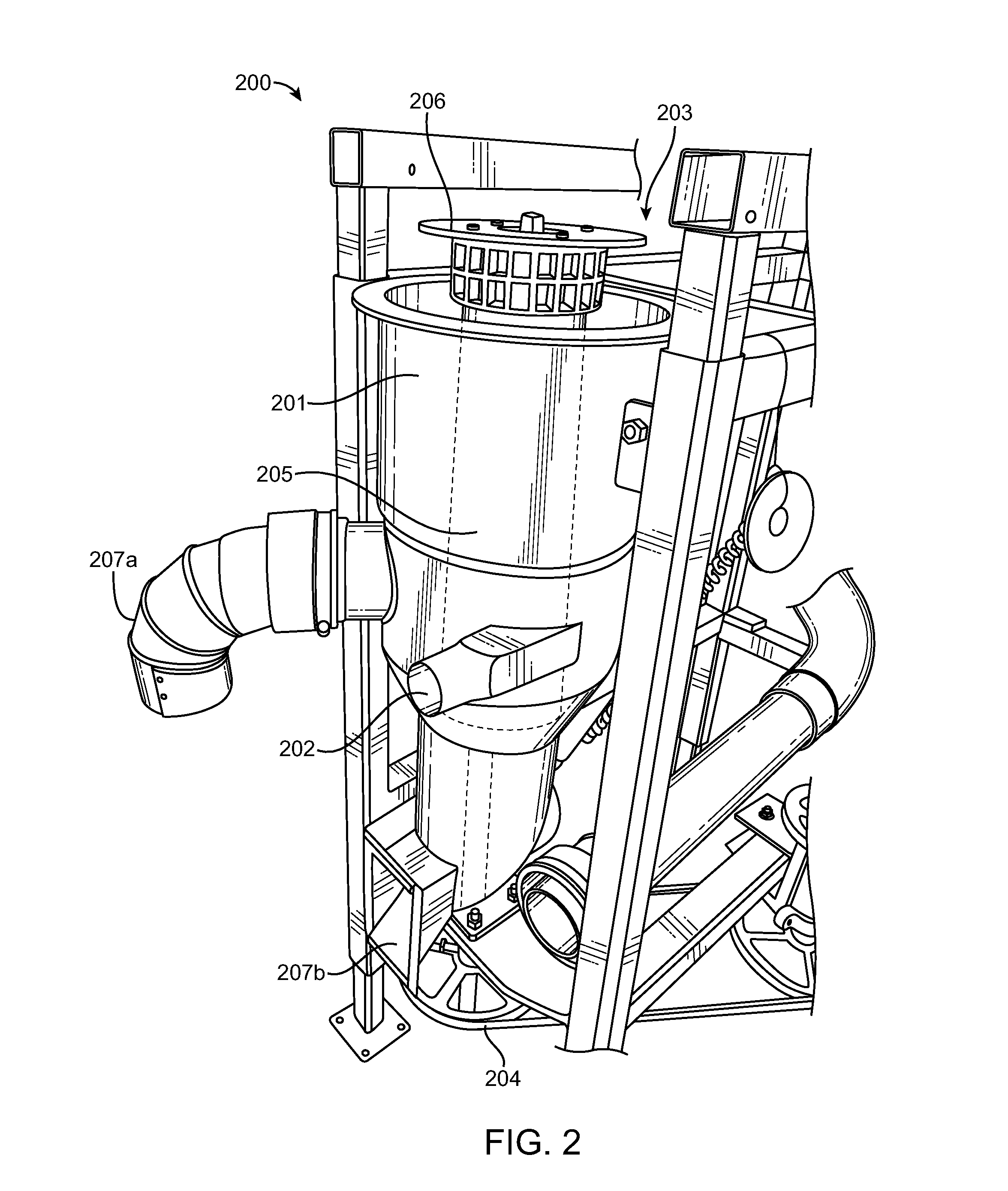

Systems and methods for the environmental remediation of materials contaminated with heavy minerals

ActiveUS20160067744A1Prevent escapeSievingGas current separationEnvironmental engineeringEnvironmental remediation

The invention relates to a method and system for the environmental remediation of materials that are contaminated with heavy minerals, such as heavy metals. The invention finds utility in removing heavy minerals from materials such as soils, sediments, mine tailings and ores. The invention provides a means for removing heavy minerals from contaminated materials without the use of water while reducing the generation of dust. Thus, the invention provides an environmentally friendly method for the remediation of sites that are contaminated with heavy minerals.

Owner:VORTEX TECH LLC

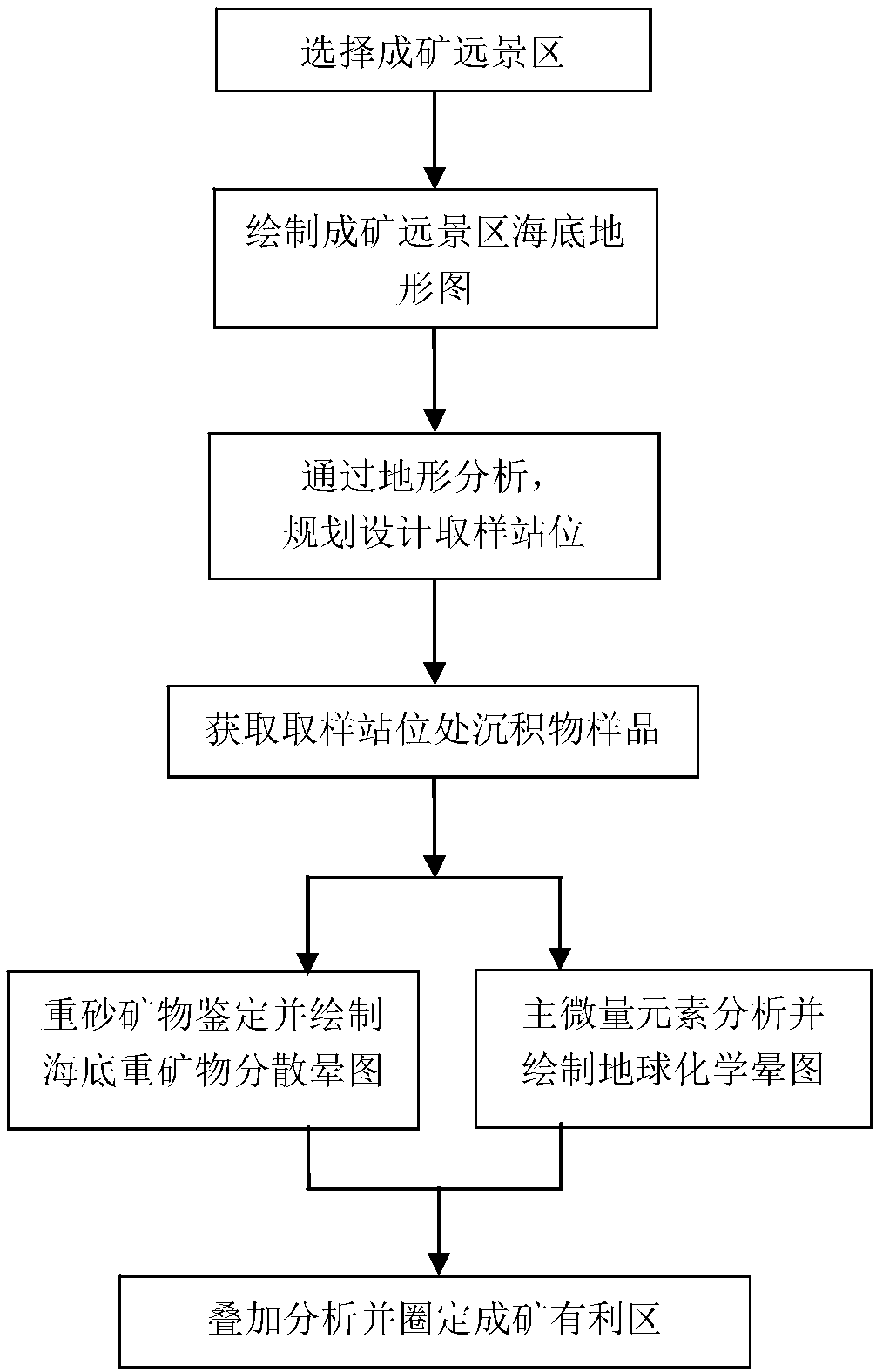

Seabed sulfide ore prospecting method based on topographic analysis

ActiveCN109188556AReasonable and efficient layoutImprove rationalityGeological measurementsOcean bottomSeabed sediment

The invention discloses a seabed sulfide ore prospecting method based on topographic analysis, which comprises the following steps: step 1: selecting a mineralizing prospect area; step 2: searching for topographic data of the mineralizing prospect area and drawing a topographic map of the seabed; step 3: analyzing the topographic map of the seabed, and planning and designing a sampling station; step 4: obtaining a sediment sample at the sampling station position in the step 3; step 5: performing heavy sand mineral identification and main trace element analysis on the sediment sample, and drawing a seabed heavy mineral dispersion halo map and a geochemical halo map; step 6: performing overlay analysis on the seabed heavy mineral dispersion halo map and the geochemical halo map, and defininga favorable mineralization area in combination with the topographic analysis. The method in the invention optimizes and innovates the sampling station setting of the seabed sediment, and the samplingstation setting is more reasonable and effective; combined with the heavy mineral and geochemical methods, a better detection effect is achieved for the inactive hydrothermal zone concealed sulfide and secondary enrichment mineralization; and the cost is low compared with other methods.

Owner:SECOND INST OF OCEANOGRAPHY MNR

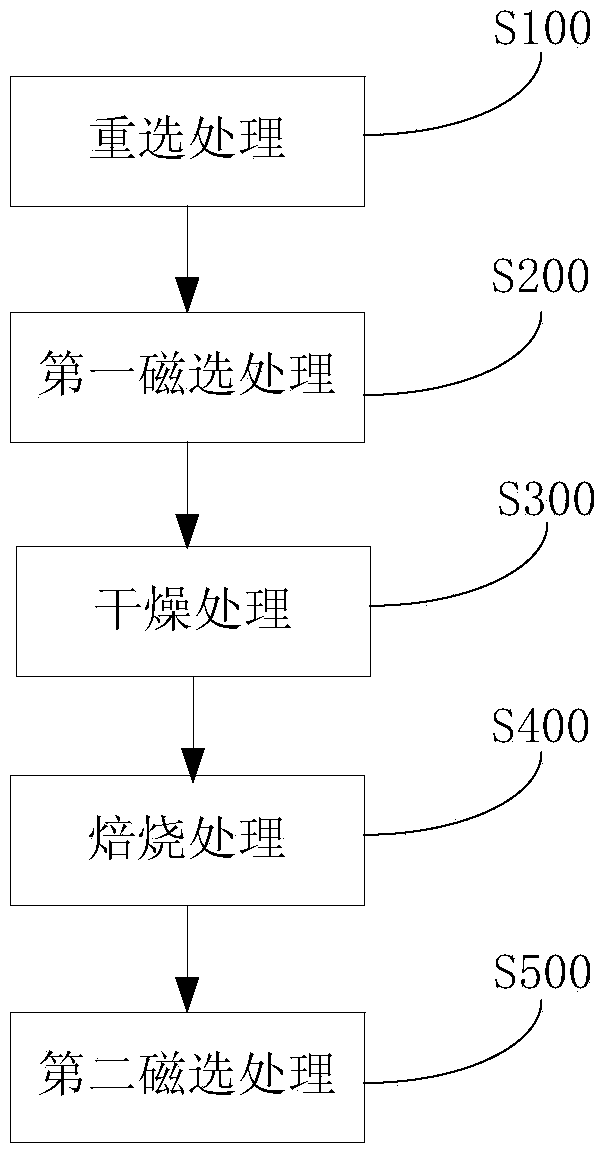

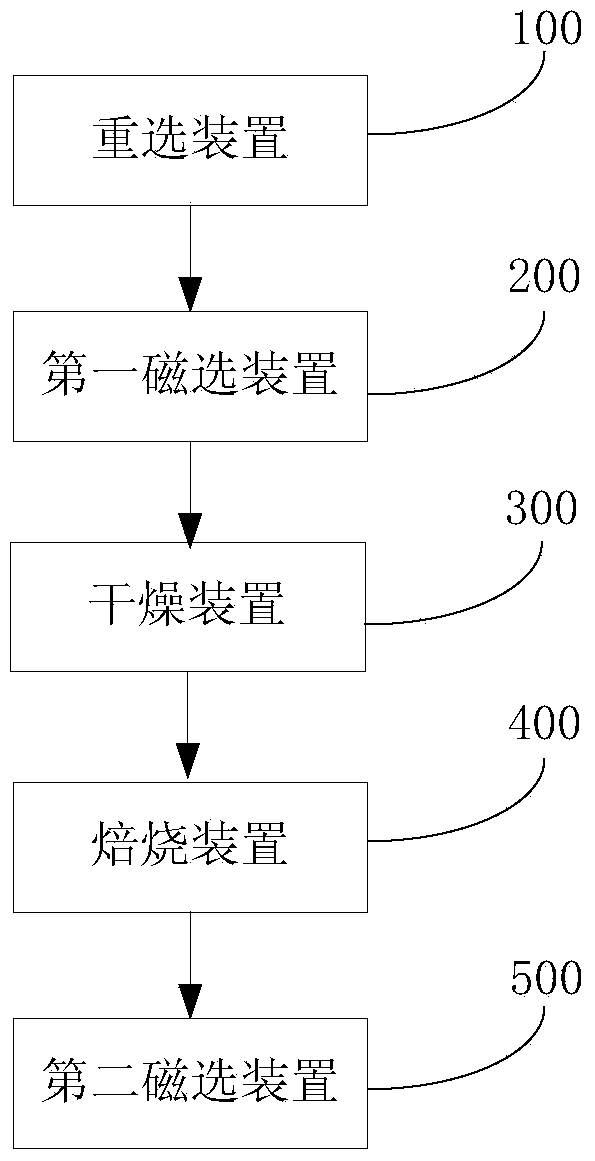

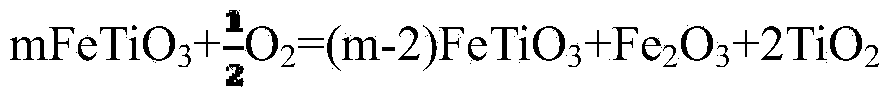

Method and system for separating high-chrome ilmenite

InactiveCN103736585AMeet quality requirementsEfficient separationMagnetic separationWet separationGravity separationMaterials science

The invention discloses a method and a system for separating high-chrome ilmenite. The method includes: performing gravity separation on raw ores so as to obtain heavy minerals and tailings; performing first magnetic separation on the heavy minerals to obtain ferrotitanium rough concentrate and magnetic minerals; drying the ferrotitanium rough concentrate; roasting the dried ferrotitanium rough concentrate in a fluidized roasting furnace to obtained roasted products; performing second magnetic separation on the roasted products to obtain ilmenite concentrate and tailings. By the method combining fluidized roasting with magnetic separation, the ilmenite concentrate with Cr2O3 content not higher than 0.35wt% and TiO2 content being 46-48wt% can be effectively separated from the high-chrome ilmenite, and the quality requirements of subsequent chloride titanium white industries can be satisfied.

Owner:YUNNAN METALLURGICAL XINLI TITANIUM IND CO LTD

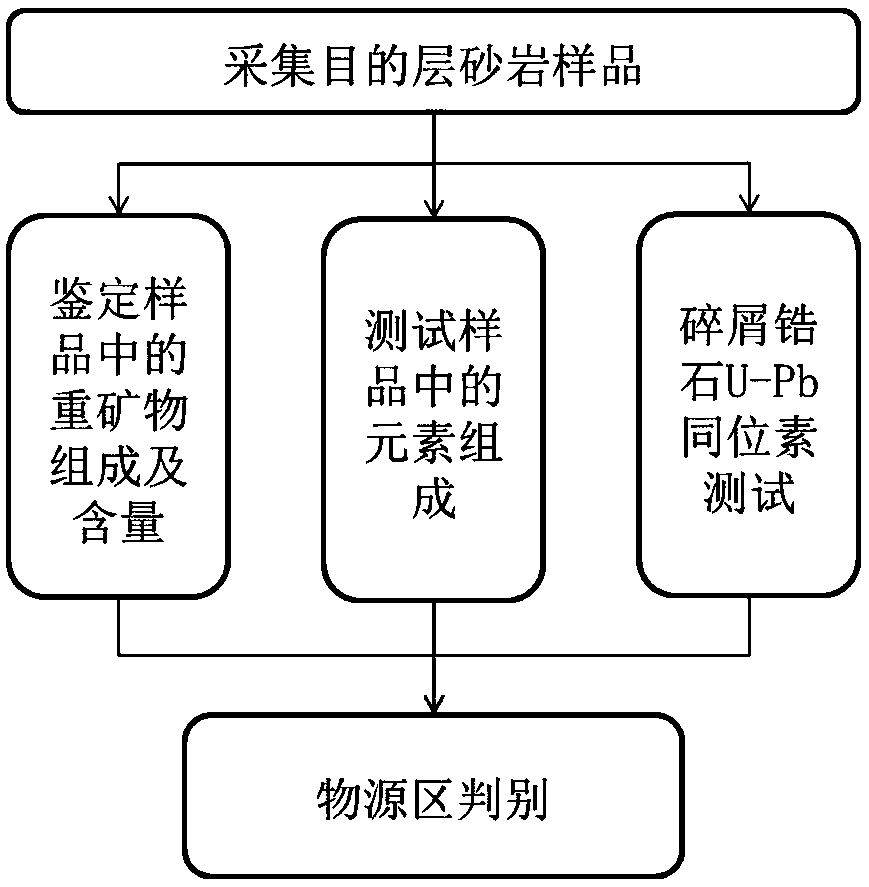

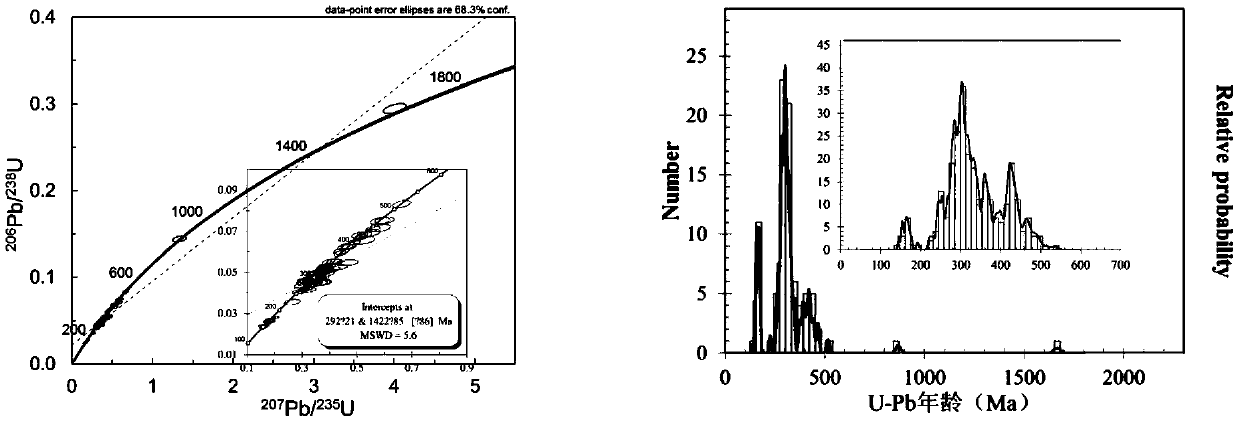

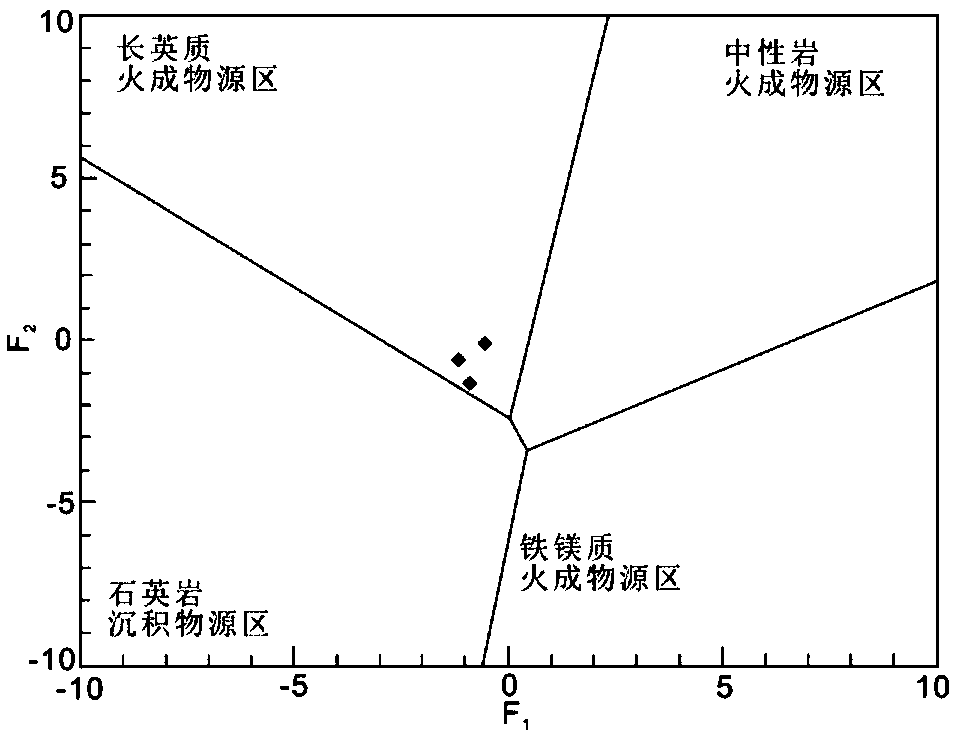

Comprehensive method for identifying source of sandstone-type uranium mineralization target stratum

InactiveCN109580687AImprove objectivityHigh precisionMaterial analysis using wave/particle radiationElemental compositionElemental analysis

The invention belongs to the field of uranium mineralization theories and prospecting technology methods, and particularly relates to a comprehensive method for identifying a source of a sandstone-type uranium mineralization target stratum. The comprehensive method comprises the following steps that 1, a sandstone sample of the target stratum is collected; 2, the composition and content of heavy minerals in the sample are identified; the collected sandstone sample is crushed to 80 mesh, and the heavy minerals in the sample are selected by levigating, and the composition of the heavy minerals and the relative content of various heavy minerals are identified under binoculars; 3, elemental composition in the sample is detected; part of the sample is pulverized to 200 mesh, and an ICP-MS traceelement analyzer and an X fluorescence spectrometer are used for correspondingly testing the content of trace elements and major elements in the sample; 4, detrital zircon U-Pb isotope test is carried out; the detrital zircon is separated from the heavy minerals, and laser ablation plasma mass spectrometry LA-ICP-MS is used for testing the U-Pb isotope composition of zircon in the detrital zircon; and after U-Pb isotope data are obtained, a Isoplot 4.15 software is used for processing, and an age harmonic map is fitted; and 5,source area discrimination is carried out.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

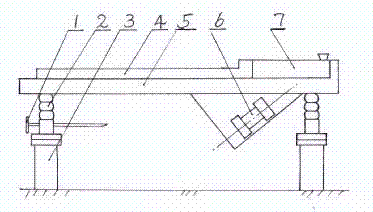

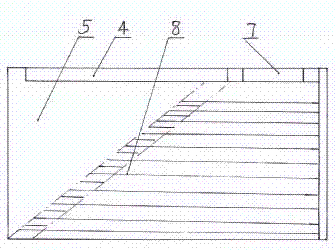

Frequency modulating linear motion transverse water current gravity ore dressing bed

InactiveCN102343302ALoose Layering AccelerationBand fastWet separationVertical vibrationLinear motion

The invention discloses a frequency modulating linear motion transverse water current gravity ore dressing bed, which comprises a sorting bed, a feeding groove, a flushing water groove and a rifle bar, wherein the sorting bed is supported by springs; the springs are arranged on machine bases; a vibration exciter is arranged on the abdomen of the sorting bed; the included angle between the vibrating direction of the vibration exciter and the be surface of the sorting bed is 0-80 degrees; the amplitude and frequency of the vibration exciter are adjusted by using a stepless speed change motor; four springs are arranged on four machine bases; the vibration exciter can be arranged on a frame of the multilayer sorting bed; the frame is supported on the springs or hung by the springs; and one vibration exciter is used for driving a plurality of sorting beds to vibrate simultaneously. Compared with the conventional swinging bed, the frequency modulating linear motion transverse water current gravity ore dressing bed has the advantage: the motion characteristics are improved. Apart from horizontal swinging force, buoyancy of transverse flushing water and flushing force, vertical vibration force is applied to mineral particles, mineral particle groups move on the bed surface like the jump of a frog, and the loosening and layering of the mineral particles are accelerated remarkably, so that zoning of light and heavy minerals is accelerated, and the treating capability and enrichment ratio of equipment are increased.

Owner:金国栋

Method for recycling accompanying rare elements in ion adsorption type rare earth tailings

The invention discloses a method for recycling accompanying rare elements in ion adsorption type rare earth tailings. The method comprises the following steps of: (1) loading 1 part by weight of ion adsorption type rare earth tailings into a stirring machine, adding water and a dispersing agent, and uniformly stirring to get ore slurry; (2) introducing the ore slurry into a spiral chute, enabling a part which is rich in heavy minerals to be enriched on the inner side of the lower part of the spiral chute in virtue of centrifugal force, friction force and flow dynamics of the chute, and discharging slurry and light-weight sand on the outer side to a tailing pond; (3) introducing the part which is rich in the heavy minerals into a shaking table for further separation so as to get concentrate of the heavy minerals; and (4) separating magnetite from the concentrate of the heavy minerals by low intensity magnetic separation and recycling the magnetite as a by-product, wherein the remaining concentrate of the heavy minerals is rich in rare and rare dispersive elements. According to the method disclosed by the invention, the economic benefits of a mine can be greatly increased and the utilization rate of resources is improved. The recycling method provided by the invention has the advantages of low consumption of chemicals, simple process flow, low initial investment, higher economic benefits and higher comprehensive utilization efficiency.

Owner:ZHEJIANG UNIV

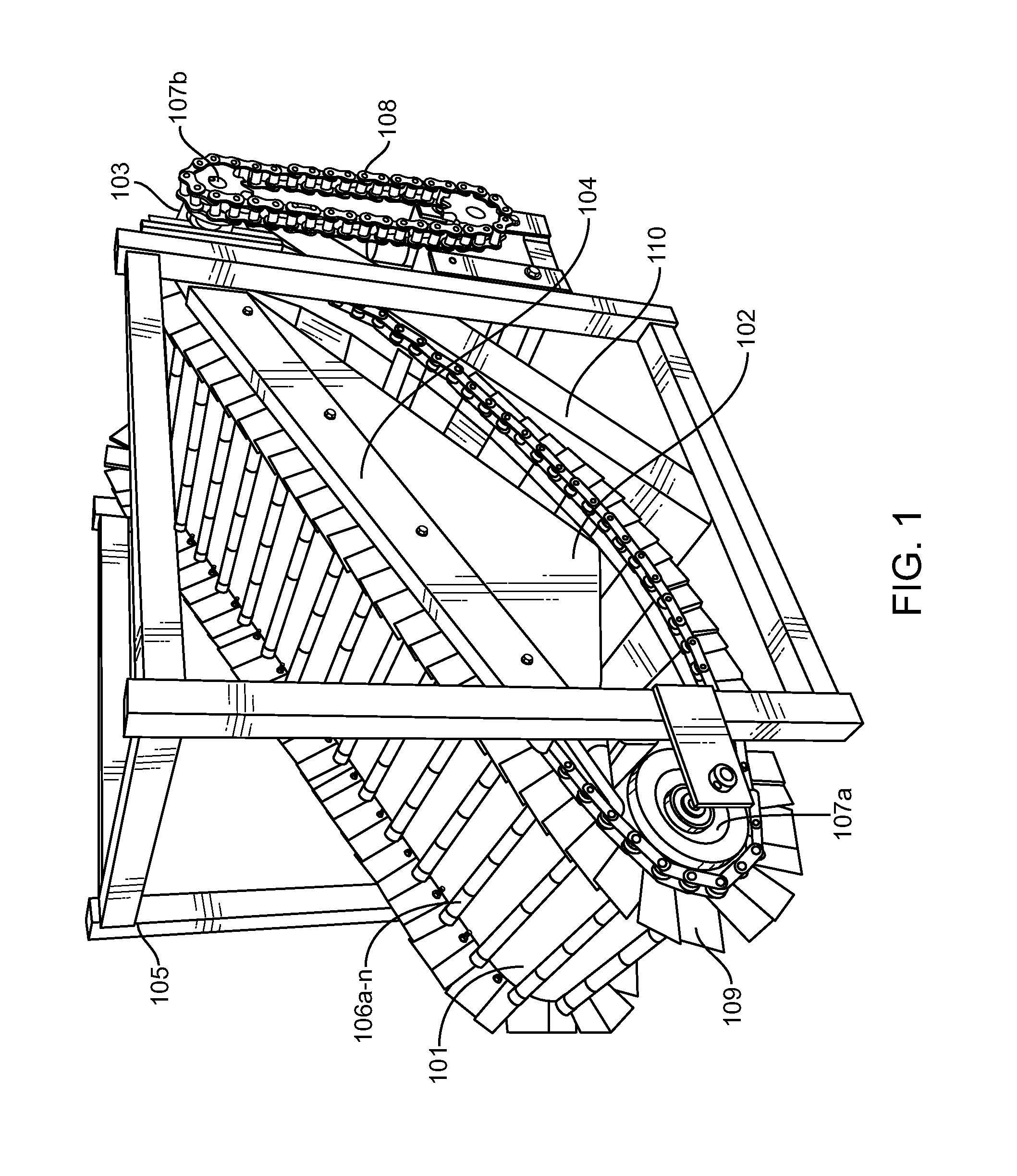

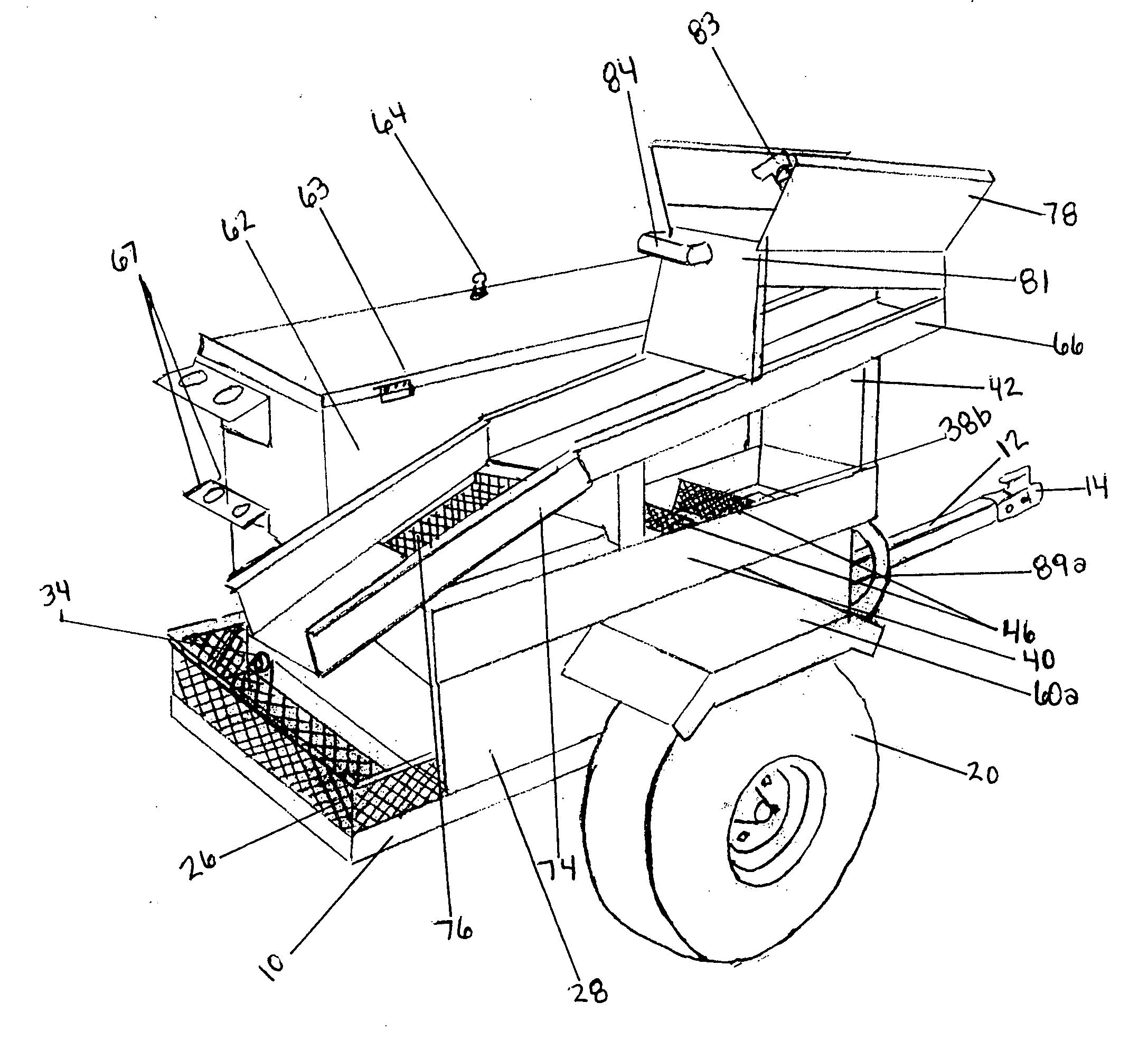

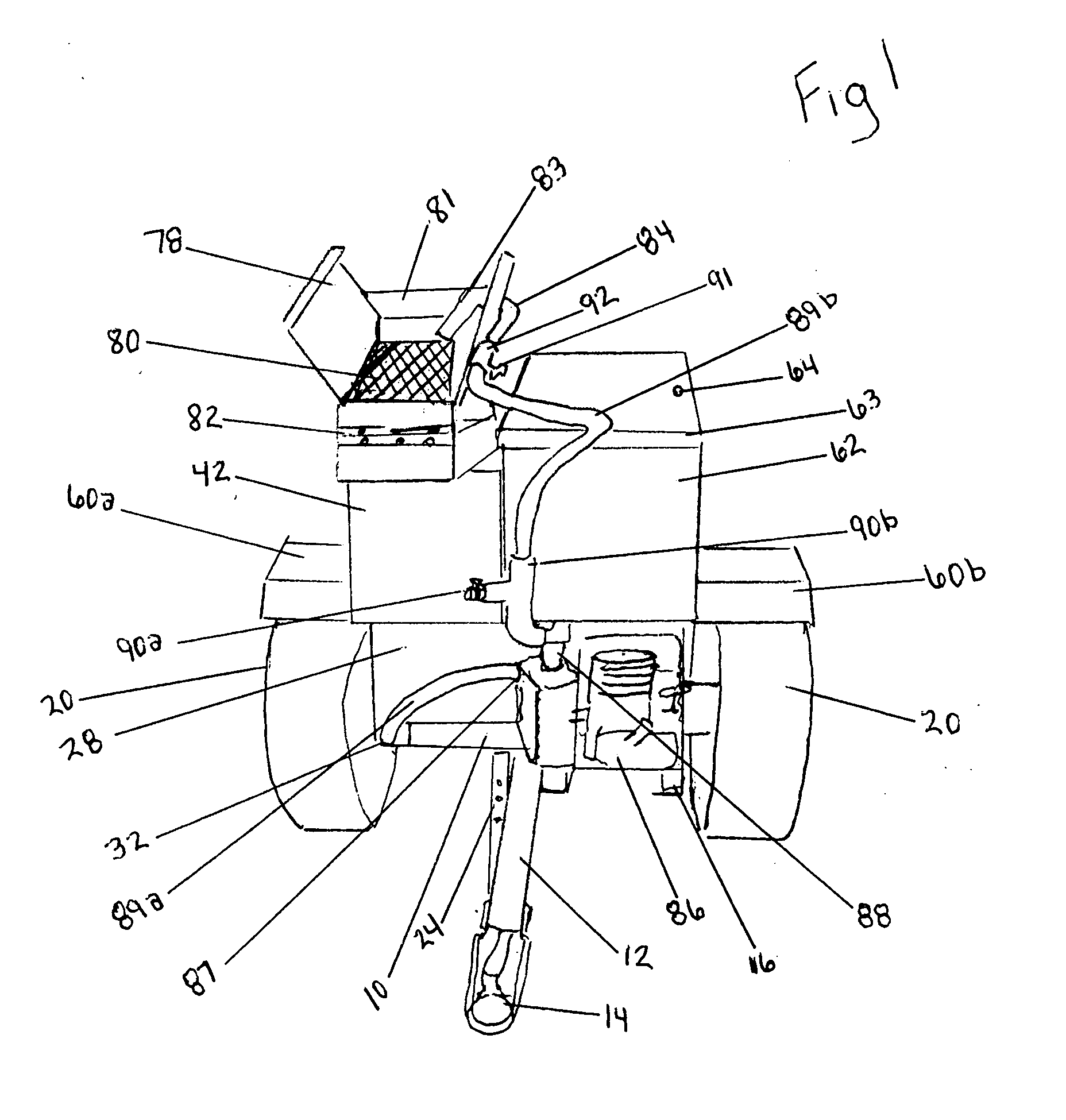

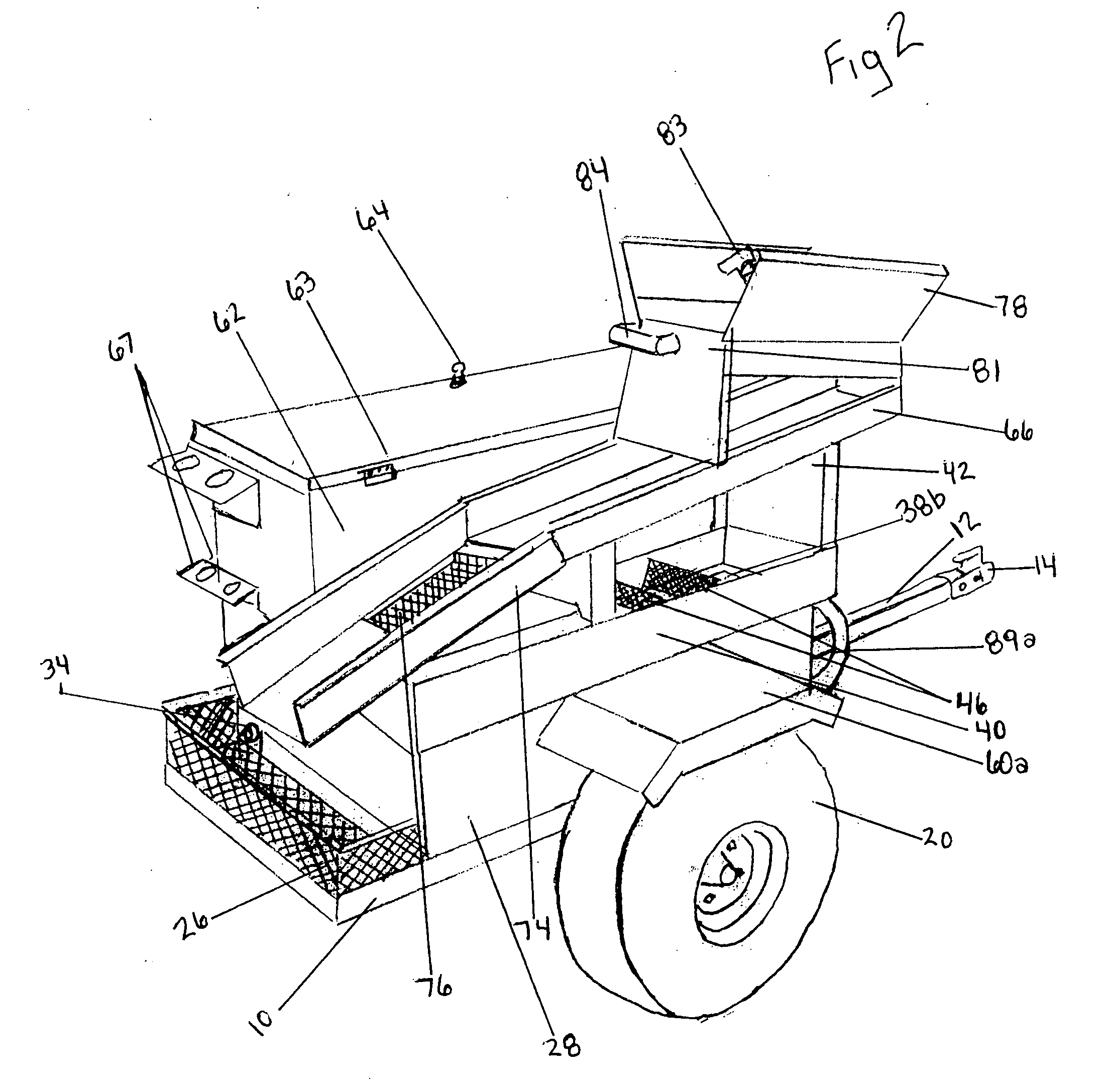

Transportable, self-contained, recirculation, wash plant

A combination of prospecting equipment and apparatus, for the purpose of collecting precious minerals from mineral bearing sand and gravel, located in regions that are arid in nature, have little water or limited water usage, due to environmental concerns. The Wash Plant Unit comprising; A feed hopper for receiving and washing materials. A sluice box and apparatus for collecting precious minerals. A sluice box extension with a filter screen for separating gravel from sand and water. A filtration box with a sediment pan and screening devices for separating sand from water. A receptacle and implement holder for holding miscellaneous prospecting supplies. A water pump with a suction and discharge for drawing and dispensing water. All built upon and attached to its own water reservoir, which is attached to a frame with a hitch, built upon a set of axles with tires, suitable for being transported by an All Terrain Vehicle.

Owner:ROPER VIRGIL LELAND

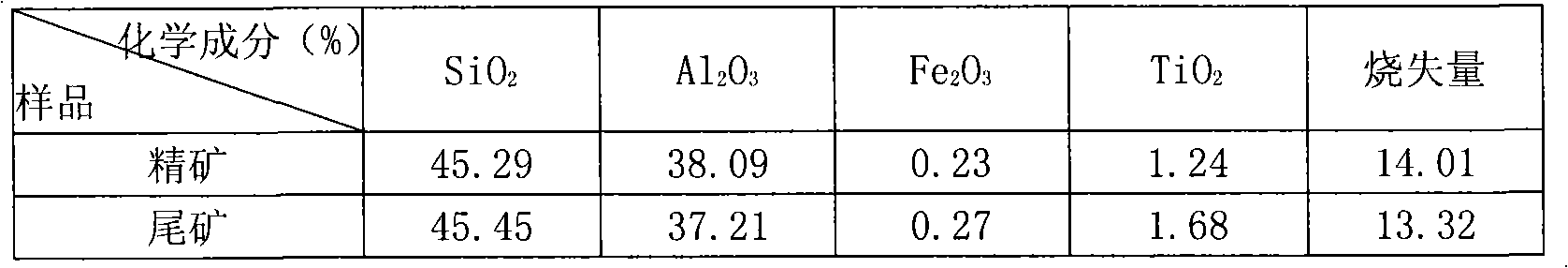

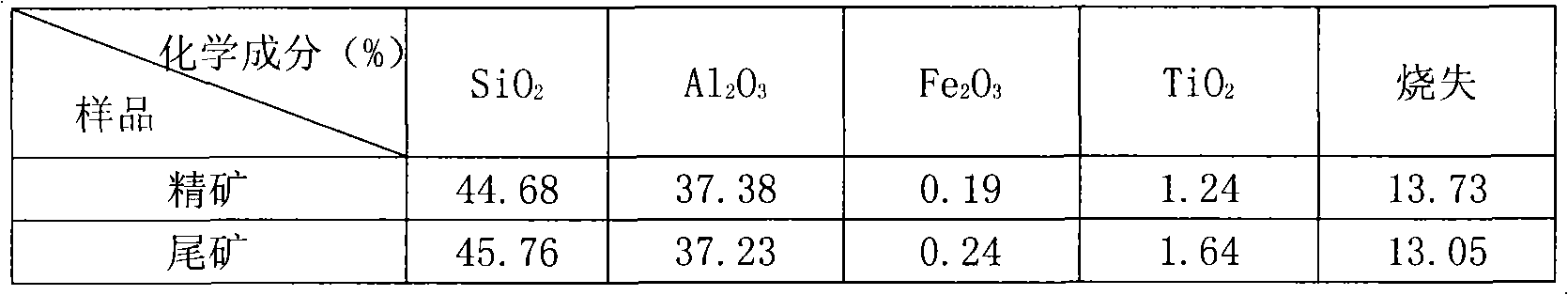

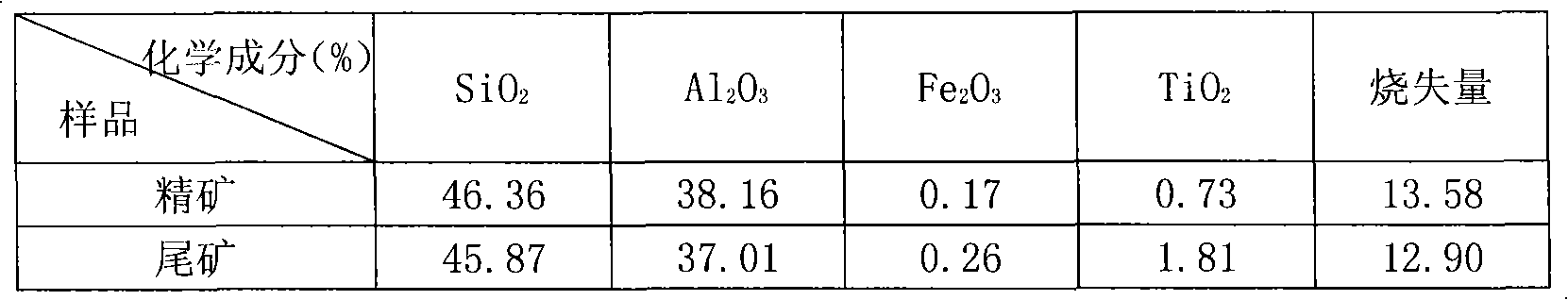

Beneficiation method for coal series kleit

The invention relates to a beneficiation method of coal-series kaolin, which is characterized in that the coal-series kaolin is crushed into 700 mu or more, then is added with water to make ore slurry with concentration ranging from 20 percent to 40 percent; then a dispersing agent, namely sodium hexametahposphate is added and stirred for uniform mixing; then the mixed solution is graded in a hydrocyclone; in this way, the concentrate ore slurry is separated from the mixed solution. At last, concentrate ore slurry is centrifugated, dehydrated and dried, thereby obtaining the coal-series kaolin with high purity. By adopting the hydrocyclone for the grading and beneficiation of the coal-series kaolin, the method can effectively remove heavy minerals in the coal-series kaolin, and can significantly reduce the content of Fe2O3 and TiO2, and the treatment volume is large; therefore, the method is particularly suitable for beneficiation purification of coal-series kaolin and iron, titanium impurities in the mineral content of the large kaolin which is rich in impurities, such as iron and titanium. The concentrate ore calcined products can be used in fields of high-grade ceramics, paint, paper making, etc.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

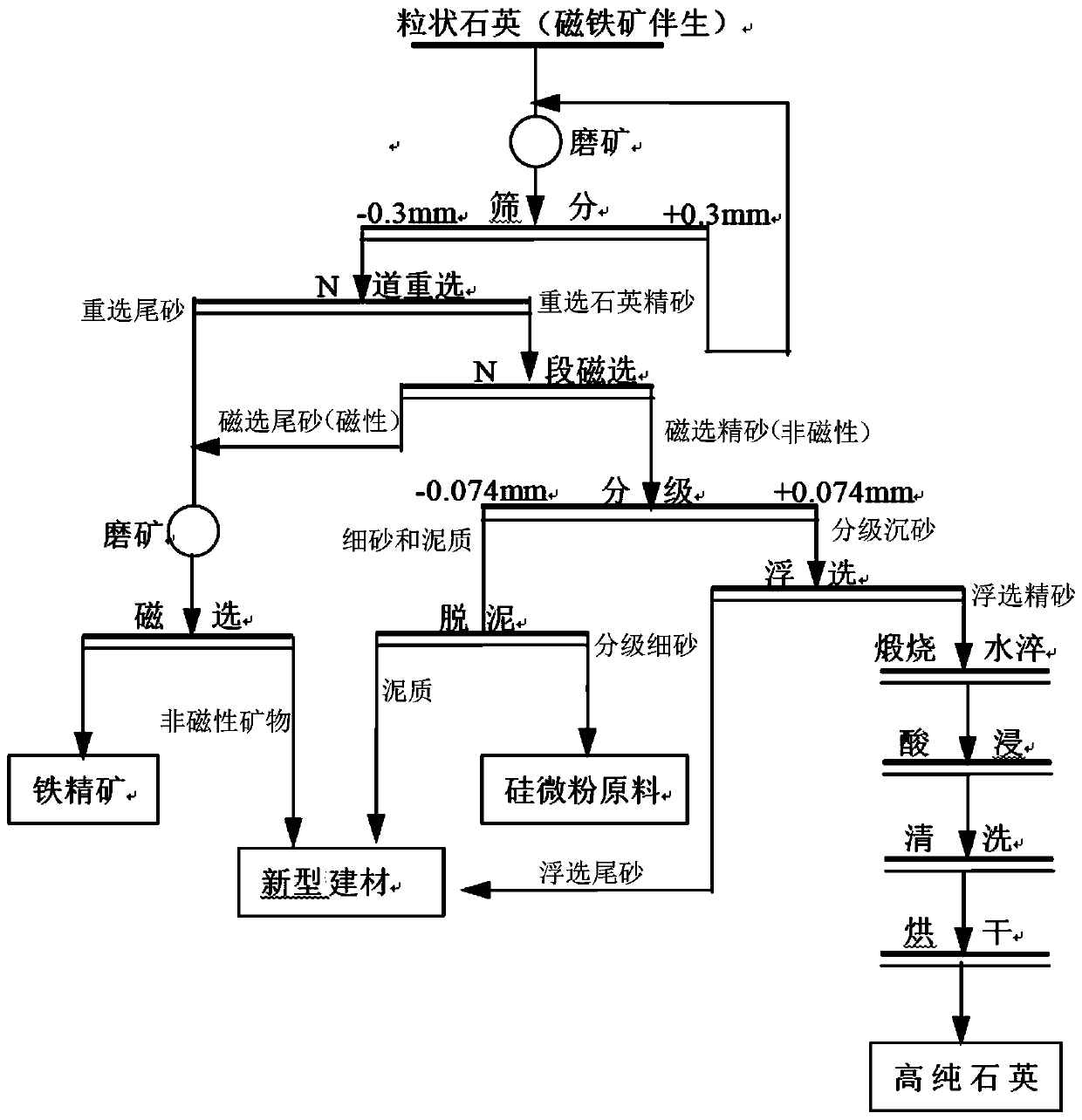

Method for preparing high-purity quartz sand iron ore concentrate from magnetite associated granular quartz

InactiveCN110976077AAchieve separationAvoid secondary pollutionSolid separationGravity separationMagnetic separation

The invention relates to a method for preparing high-purity quartz sand iron ore concentrate from magnetite associated granular quartz. The method comprises the following steps of, grinding and screening granular quartz, returning oversize products for regrinding, and carrying out gravity separation on undersize products to remove heavy minerals; carrying out medium magnetism and strong magnetismon the gravity separation fine sand to obtain magnetic minerals and non-magnetic quartz minerals; removing fine particles and mud of quartz through grading and desliming, taking graded fine sand as anelectrical and electronic grade silica micropowder raw material, and removing non-quartz particles of graded settled sand through flotation; carrying out "calcination, water quenching, acid leaching,cleaning and drying" on the flotation fine sand to obtain the high-purity quartz sand; carrying out ball milling and magnetic separation on gravity separation tailings and magnetic separation magnetic minerals to obtain high-grade iron ore concentrate; and using tailing mud and tailing sand generated in the ore dressing process as a novel building material raw material. According to the method, comprehensive utilization of resources can be achieved, and good economic, social and environment-friendly benefits are achieved.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

Process for discarding tailings in mechanical beneficiation of absorption-state vanadium ores

The invention provides a process for discarding tailings in the mechanical beneficiation of absorption-state vanadium ores. The process comprises the following steps: crushing and grinding the absorption-state vanadium ores to negative 200 meshes; beneficiating on a spiral concentrator or a spiral chute; collecting fine-fraction minerals and light minerals as spiral concentrate; and carrying out floatation operation on heavy minerals and coarse-fraction minerals by using H2SO4 as the pH regulator to regulate the pH value to 4 to 6, using dodecyl amine-hydrochloride as the collector with the amount of 100 to 500g / t, and using isooctanol as the frother with the amount of 5 to 50g / t to carry out the flotation from section one to section ten, wherein, the floating foam part and the spiral concentrate are merged to constitute the main concentrate; and the part in the chute constitutes the main tailings to be discarded. The invention has the advantages that the process is direct and efficient, and the cost is low, the range of beneficiation is wide, the adaptability to ores with various properties is high, the tailings can be pre-discarded before chemical vanadium extraction so as to increase the content of V2O5 of the materials of the chemical vanadium extraction, and the production cost can be obviously reduced.

Owner:西安西北有色地质研究院有限公司

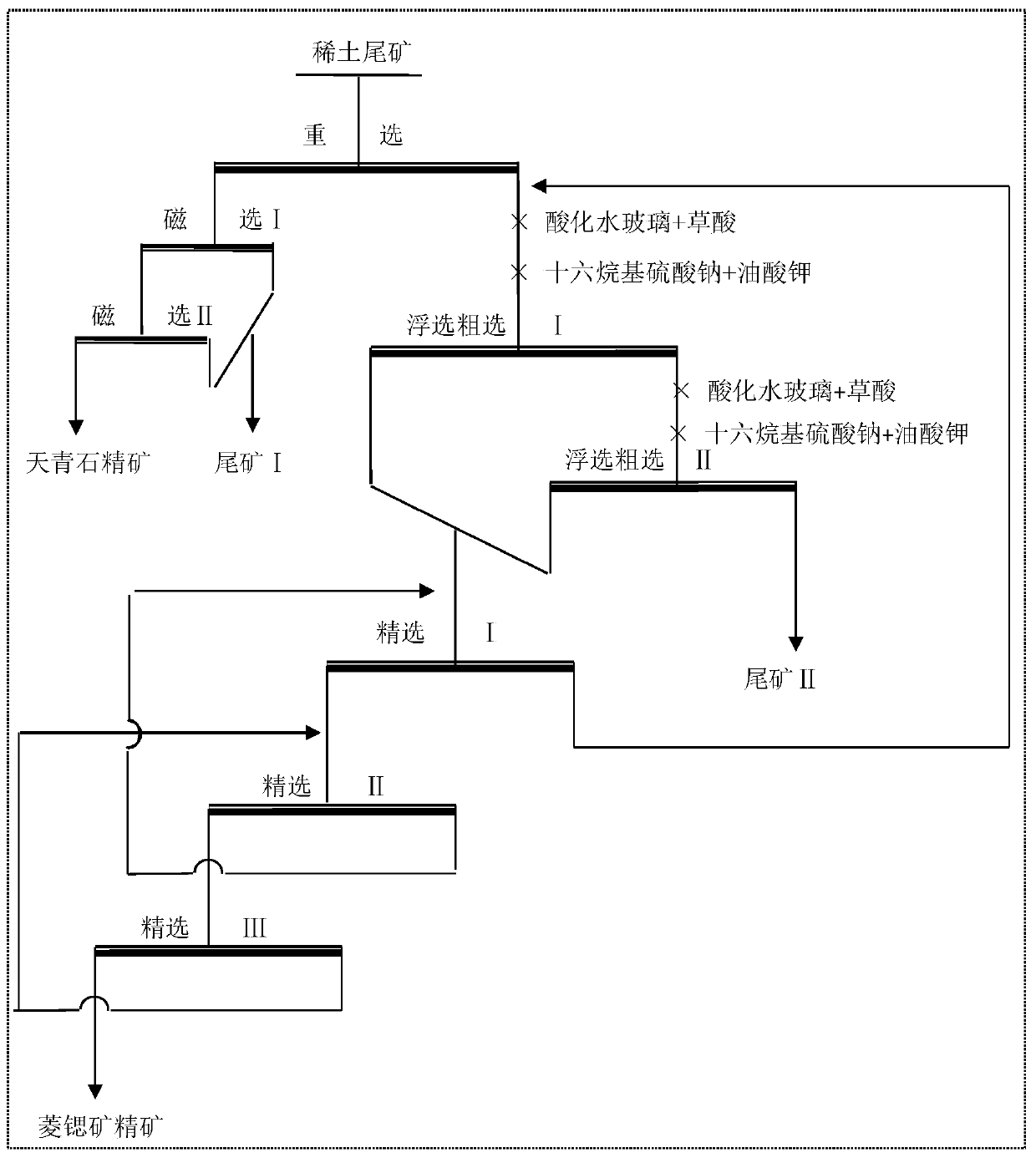

Beneficiation method for comprehensively recycling strontium mineral from rare earth tailings

The invention discloses a beneficiation method for comprehensively recycling a strontium mineral from rare earth tailings and relates to a beneficiation method for the rare earth tailings containing celestite and strontianite. The beneficiation method comprises the following steps that (1) heavy minerals in the rare earth tailings are screened out through gravity concentration, so that gravity concentrate is obtained; (2) rare earth, iron and other magnetic minerals in the gravity concentrate in the step (1) are attracted out through strong magnetic separation, so that celestite concentrate isobtained; (3) the strontianite mineral in the gravity tailings in the step (1) is floated out through flotation, so that strontianite concentrate is obtained. The beneficiation method for comprehensively recycling the strontium mineral from the rare earth tailings has the beneficial effects of remarkably recycling the strontium mineral from the rare earth beneficiation tailings, improving the comprehensive utilization value of resources and greatly lowering the discharge amount of tailings.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

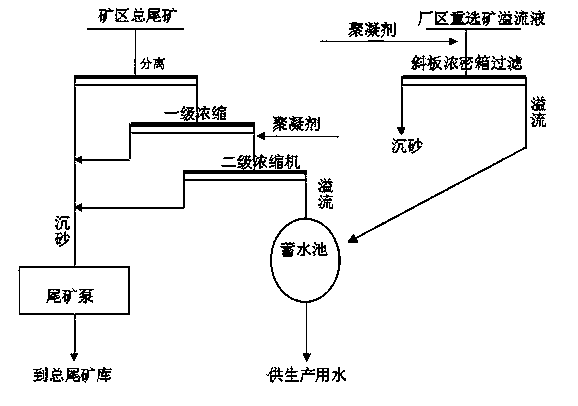

Mineral processing water-saving and emission reduction device and method

InactiveCN103382060AImprove processing efficiencyReduce contentMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationLiquid wasteWater saving

The invention discloses a mineral processing water-saving and emission reduction device and method. The method comprises processes of two aspects of recycling overflow liquid produced by tailings of a mining area and recycling overflow liquid produced by heavy mineral processing of a plant area; the mineral processing water-saving and emission reduction device comprises a separator, concentrators and the like, the concentrators comprise a combination of a primary concentrator and a secondary concentrator, and after concentration is performed on mineral processing waste liquor twice, the impurity content is reduced greatly; flocculants are added in a secondary concentration process, so that the impurities in the overflow liquid is further deposited, and the obtained overflow liquid is completely in conformity with the requirements of production water; in the whole process, waste liquor can be directly used for production after separation and concentration, the waste liquor treatment efficiency is improved significantly, the problems of low recovery and poor purification quality of traditional mineral processing waste liquor treatment devices are solved, apart from water quality needed by normal tailing transportation, the mineral processing waste liquor can be almost completely recycled and is not drained to nature, and environmental pollution caused by a mineral processing process can be greatly reduced.

Owner:广西华锡集团股份有限公司

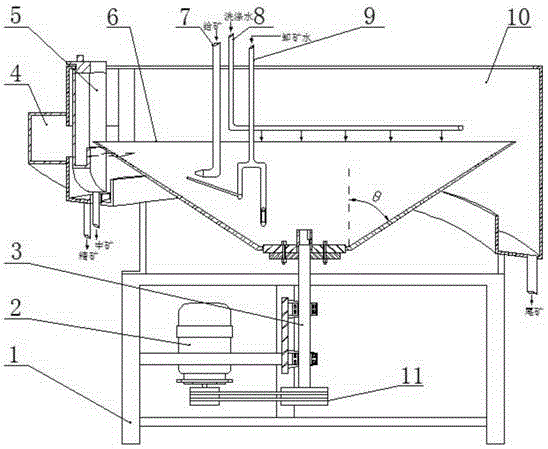

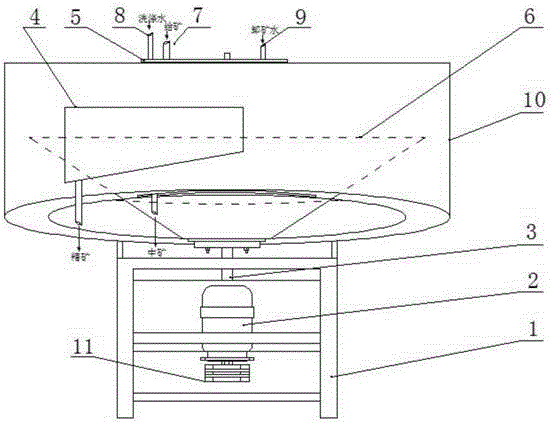

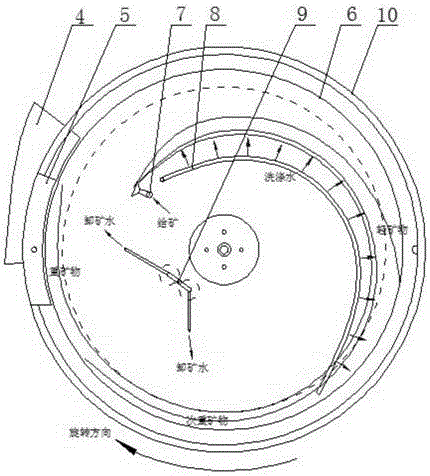

KGS concentrating machine

The invention belongs to the technical field of fine-grain mineral separation equipment, and discloses a KGS concentrating machine. The KGS concentrating machine comprises a frame, a motor, a turntable main shaft, a concentrate tank, a middling cutter, a separation turntable, a feeding device, a washing water pipe, an unloading water pipe, a tailing cover and a belt wheel; the motor is arranged on one side of the frame; the turntable main shaft and the belt wheel arranged at the bottom of the turntable main shaft are arranged on the other side of the frame; the belt wheel is connected with the motor through a belt; the separation turntable is arranged at the top of the turntable main shaft, and is connected with the turntable main shaft; the tailing cover is arranged at the top of the frame; the separation turntable is arranged in the tailing cover; and the bottom of the tailing cover is set as a certain inclination, and the lowest point is connected with a tailing discharge port. The KGS concentrating machine designs a sorting machine with reasonable structure and capable of controlling the concentrate quality through adjusting the middling yield according to the motion trail pitch difference of light and heavy minerals in a composite force field and a centrifugal flowing film beneficiation principle.

Owner:杨波

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com