Patents

Literature

157results about How to "Sorting speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

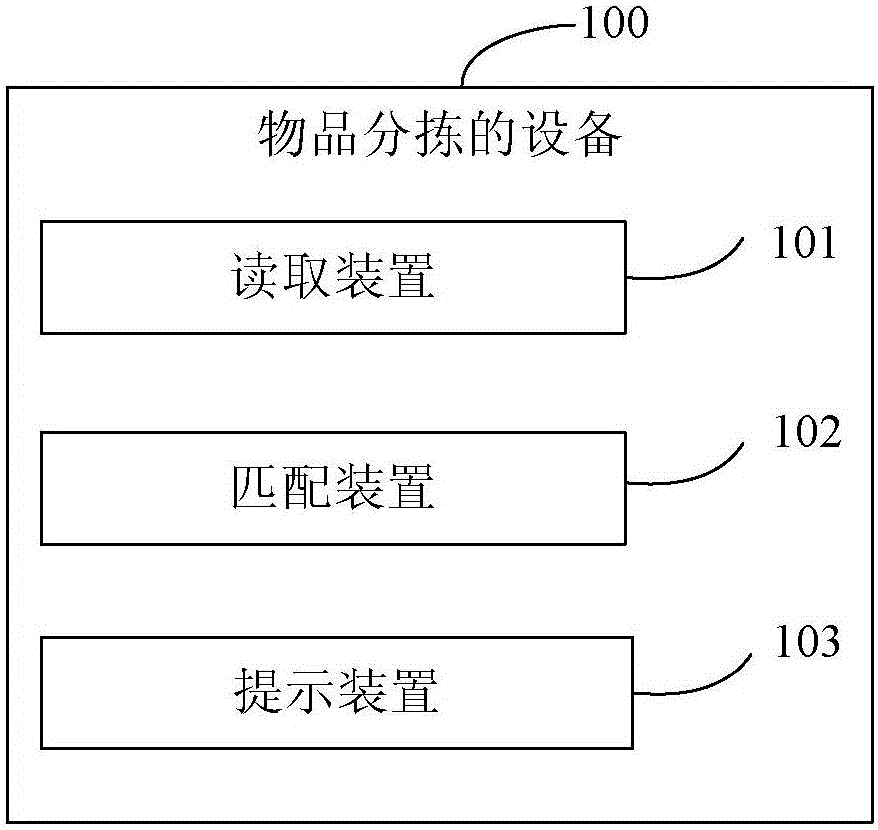

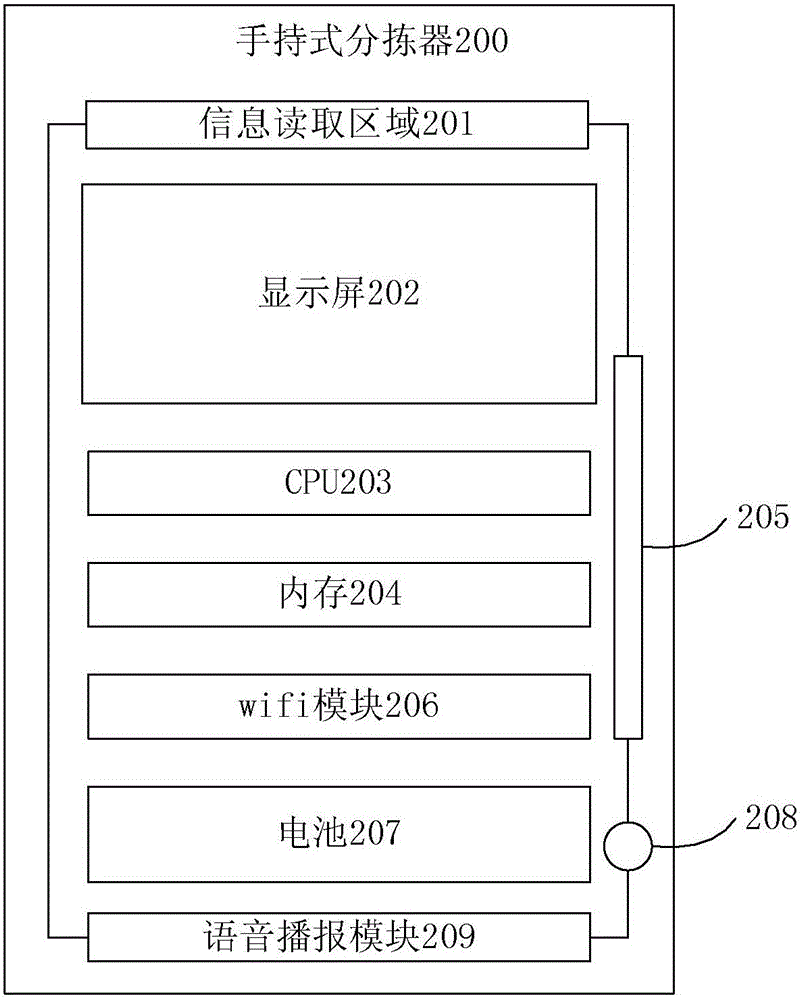

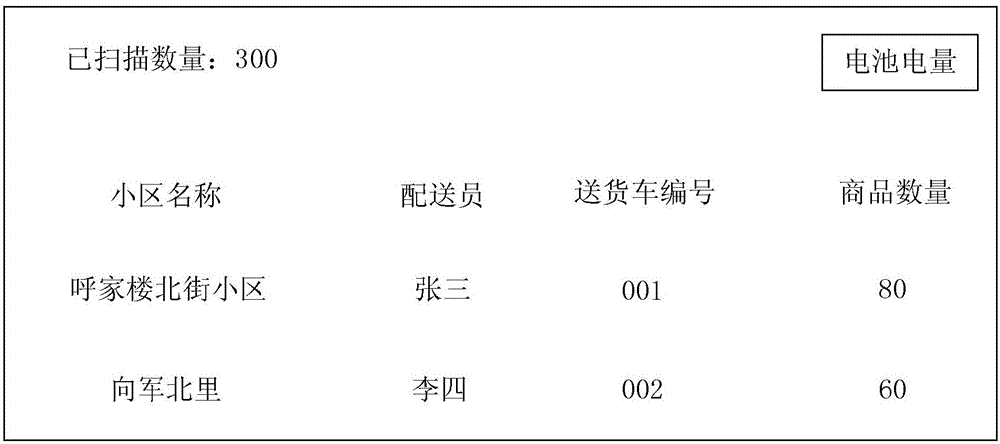

Article sorting device and method

InactiveCN105797980ARelieve work stressSorting speed is fastSortingService qualityLogistics management

The invention provides an article sorting device and method. The working pressure of front-line logistics distribution persons can be greatly remitted, the sorting speed and accuracy are improved, the distribution speed of the last link of logistics distribution is increased, and the overall service quality of logistics distribution is guaranteed. The article sorting device comprises a reading device, a matching device and a prompting device, wherein the reading device is used for obtaining article information from article labels and transmitting the article information to the matching device; the matching device is used for receiving the article information transmitted by the reading device and determining article distribution information according to a preset matching rule, and the preset matching rule is used for defining the congruent relationship between article distribution addresses in the article information and the distribution information; and the prompting device is used for receiving the distribution information transmitted by the matching device and outputting the distribution information, and therefore a distributor completes article sorting according to the distribution information.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

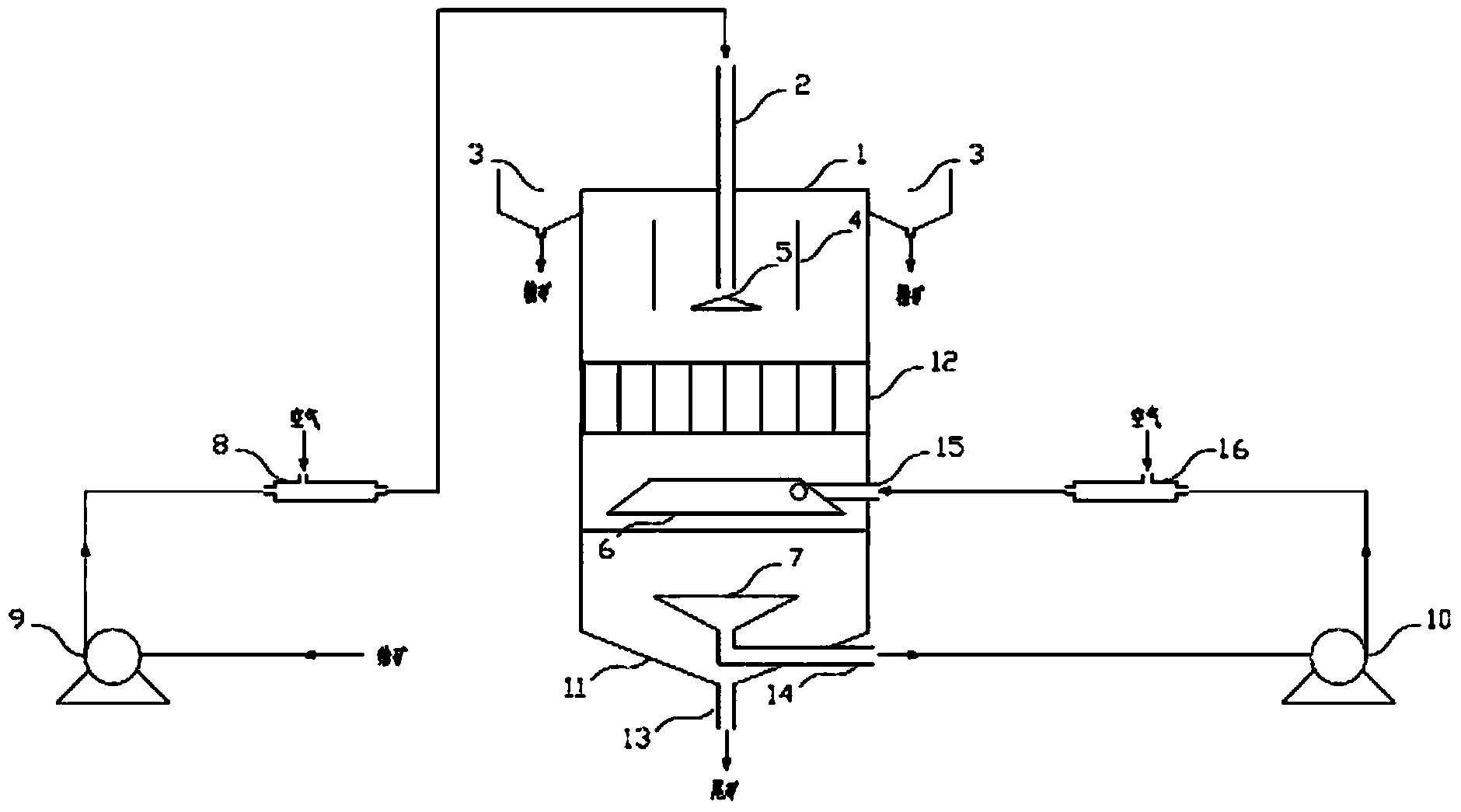

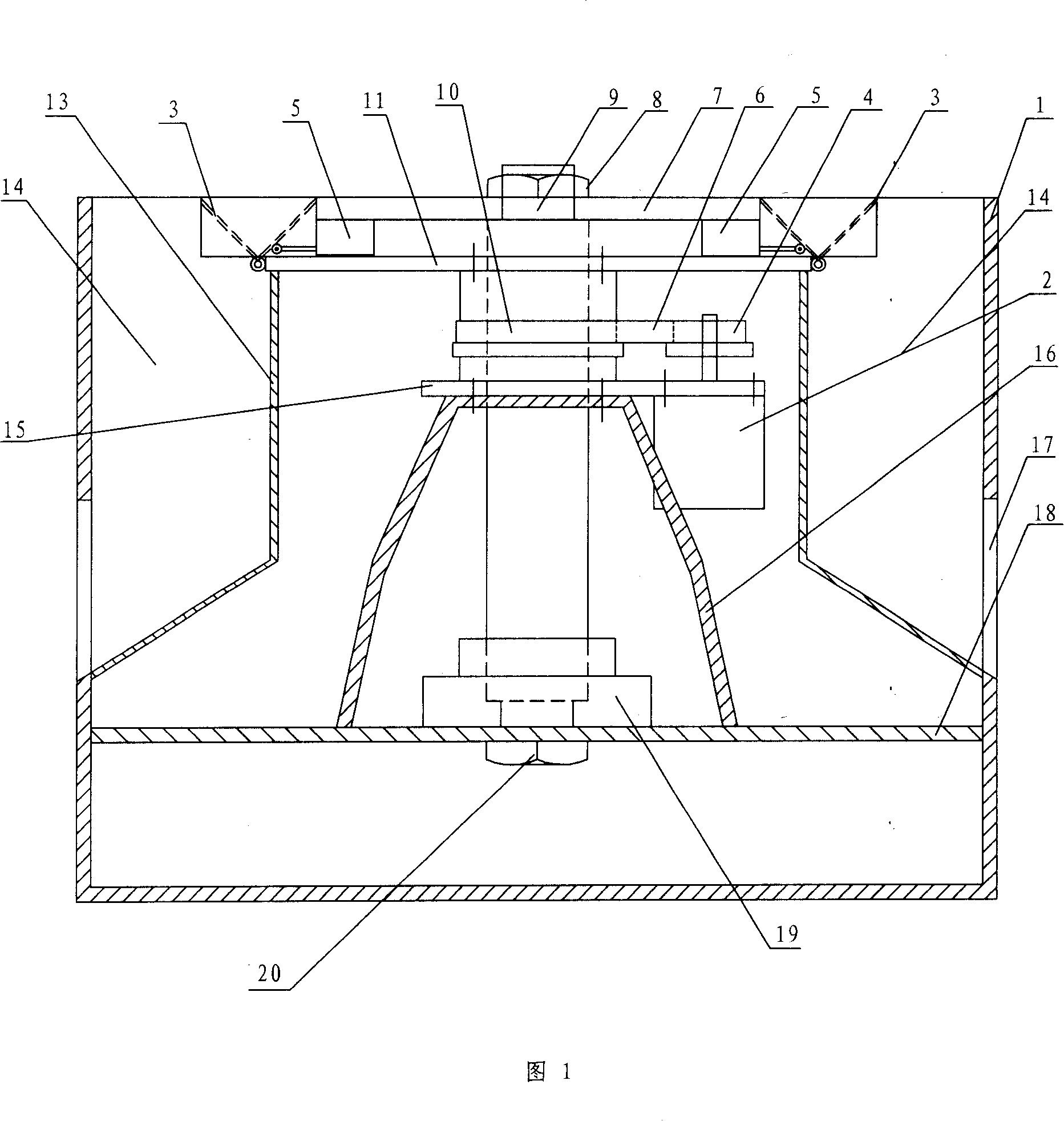

Fluorite ore sorting device and method

InactiveCN104289323AFast mineralization efficiencyFast flotation device mineralization efficiency High mineralization efficiencyFlotationMaceralEngineering

The invention relates to a fluorite ore sorting device and method and belongs to ore sorting devices and methods. The device comprises a coarse grain easy flotation ore rapid flotation device, a filling flotation device and a fine grain hard flotation ore strengthening collection device. The rapid flotation device comprises a flotation column, a lower guide pipe, a reflection false bottom, an annular sleeve, a foam collection tank and a bubble generator. The strengthening collection device comprises a cone, an inverted cone, a bubble generator, an ore pulp circulation pump and a lower inverted cone. The filling flotation device is a column segment between the rapid flotation device and the strengthening collection device and is provided with filler. The method includes the steps that feed ore is pressurized through a feed pump, subjected to the reaction in the bubble generator and the coarse grain easy flotation ore rapid flotation in the flotation column through the lower guide pipe, medium floatable ore is placed in the filling flotation device for further flotation sorting, and fine grain hard flotation ore is placed in the strengthening collection device for further sorting. The fluorite ore sorting device and method is high in mineralization efficiency, flotation speed and sorting efficiency and solves the problem that how to integrate the sorting of coarse grain easy flotation ore and fine grain hard flotation ore in one.

Owner:CHINA UNIV OF MINING & TECH

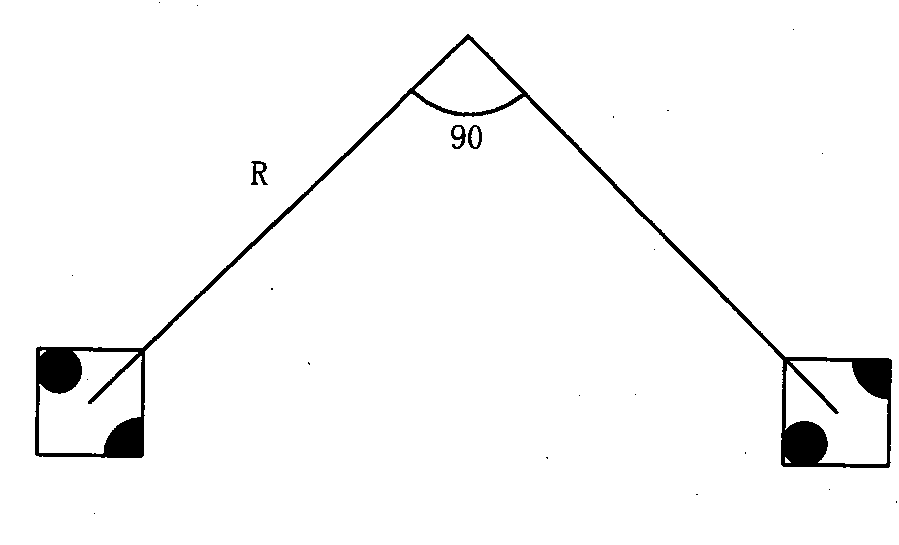

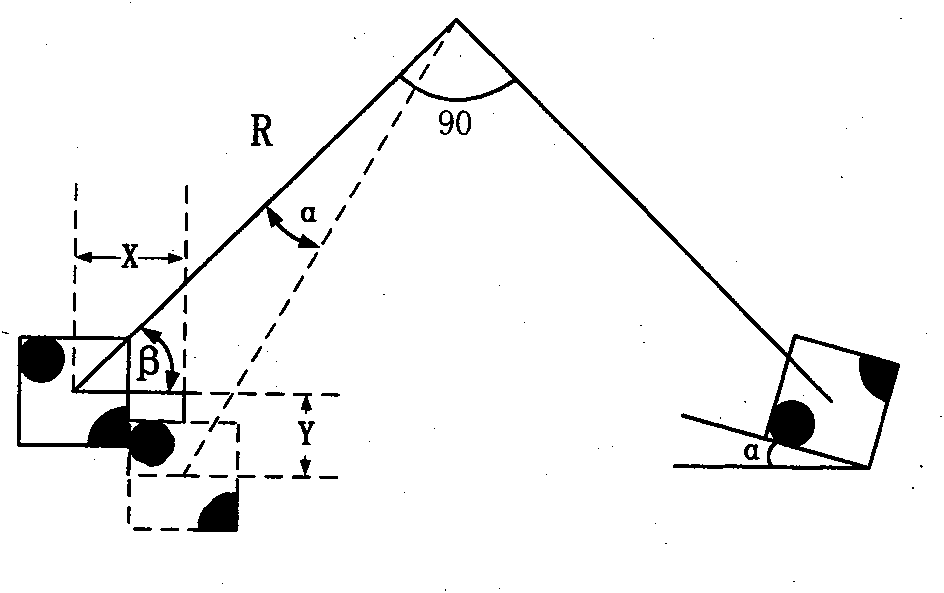

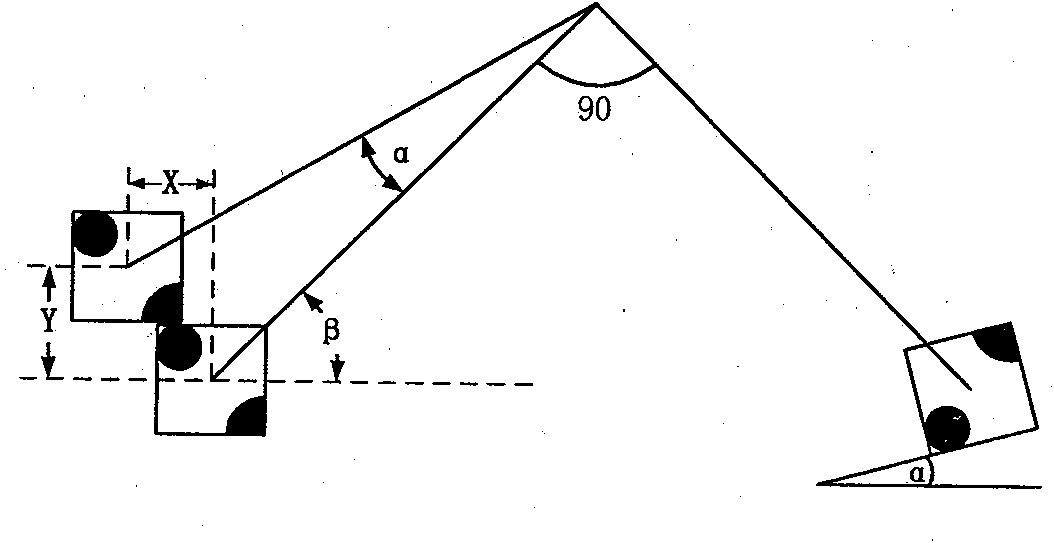

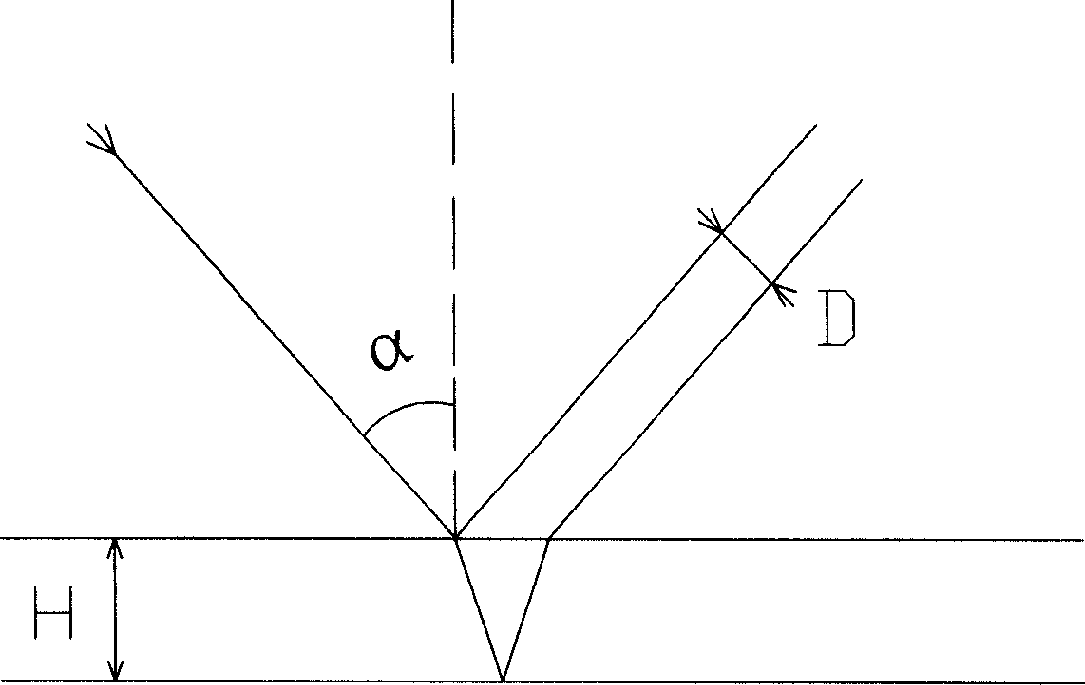

Crystal grain angle correction method applied to chip separating system

The invention relates to a crystal grain angle correction method applied to a chip separating system, which mainly comprises the following steps: judging a deflection angle of target crystal grains; driving a swinging arm of a crystal grain conveying mechanism to rotate 90 degrees minus alpha when the deflection angle alpha of the target crystal grains is a positive number, simultaneously executing the difference-alpha deflection angle position compensation on an arrangement region, and placing the target crystal grains into the arrangement region; driving the swinging arm of the crystal grain conveying mechanism to rotate 90 degrees plus alpha when the deflection angle alpha of the target crystal grains is a negative number, simultaneously executing the multi-alpha deflection angle position compensation on the arrangement region, and placing the target crystal grains into the arrangement region; and driving the swinging arm of the crystal grain conveying mechanism to rotate 90 degrees when the deflection angle alpha of the target crystal grains is zero, and directly placing the target crystal grains into the arrangement region. The invention combines the rotation movement of the crystal grain conveying mechanism and the translational movement of the arrangement region for compensating the angle deflection of the crystal grains, carries out parallel dispatch between the position compensation of a material supply region and the arrangement region, and realizes the automatic correction of the crystal grain angle under the condition of not reducing the conveying speed.

Owner:DG HUST MFG ENG RES INST +1

Method and apparatus for testing and sorting join arrangement electronic devices

The invention relates to method for testing and sorting the gang electronic device, which comprises the following steps: a) step-by-step driving the electronic device according to the space between two devices in sequence, b) transporting to the pre-cutting station, keeping one pin on the connecting plate and cutting off the other, c) transporting to the testing station to test, driving the testing box through the adjustable apparatus, connecting the tested electric pole with the pin to get the apparatus parameter, d) cutting the scoring pin in the final-cutting station, then transporting to the baiting sorting device. The invention has high precision of gearing and high automation, uses several photoelectric sensors and overtravel-limit switches to test, which can pinpoint exactly and judge the fault precisely, and increase the sorting speed violently.

Owner:南京熊猫仪器仪表有限公司

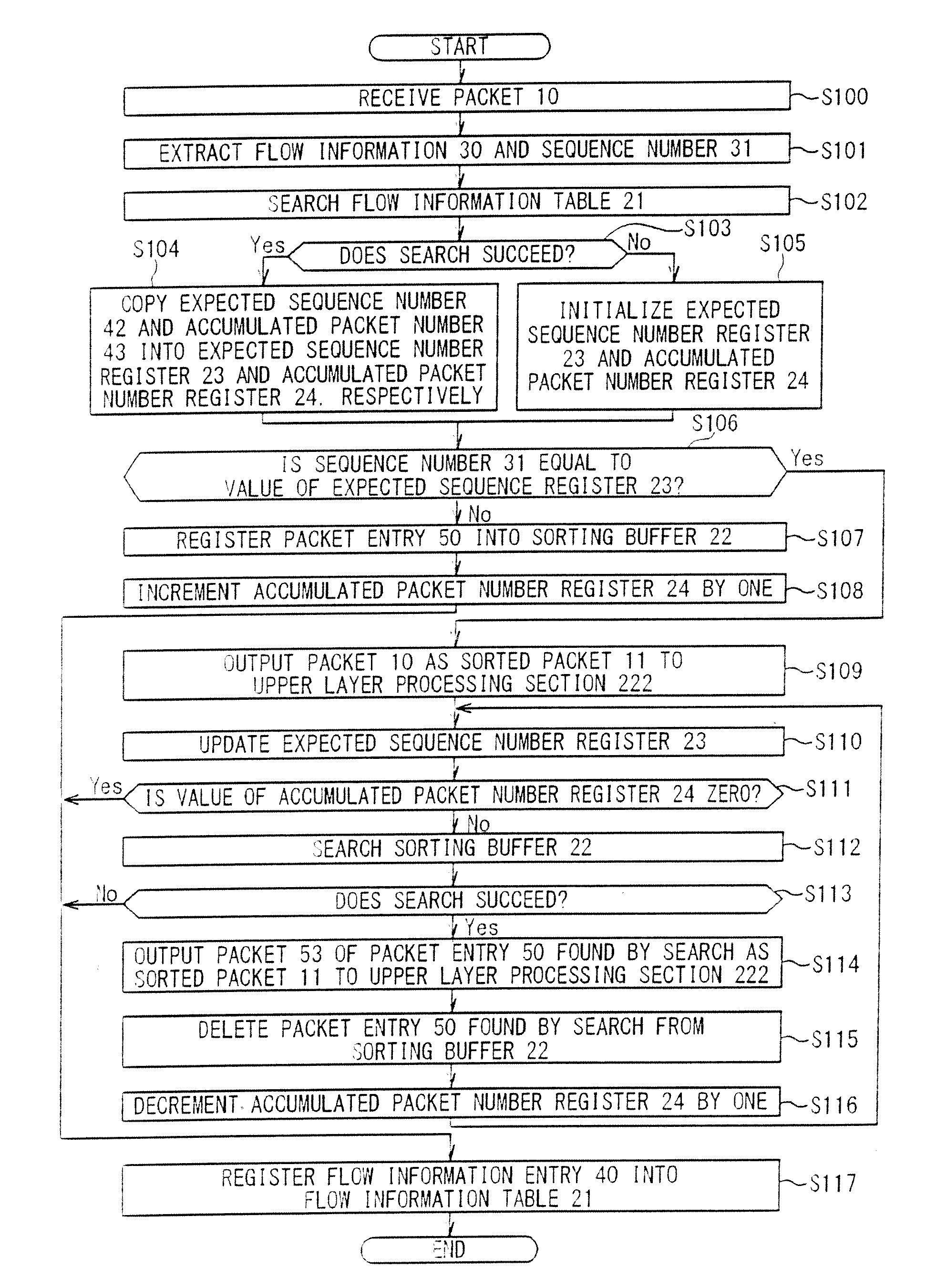

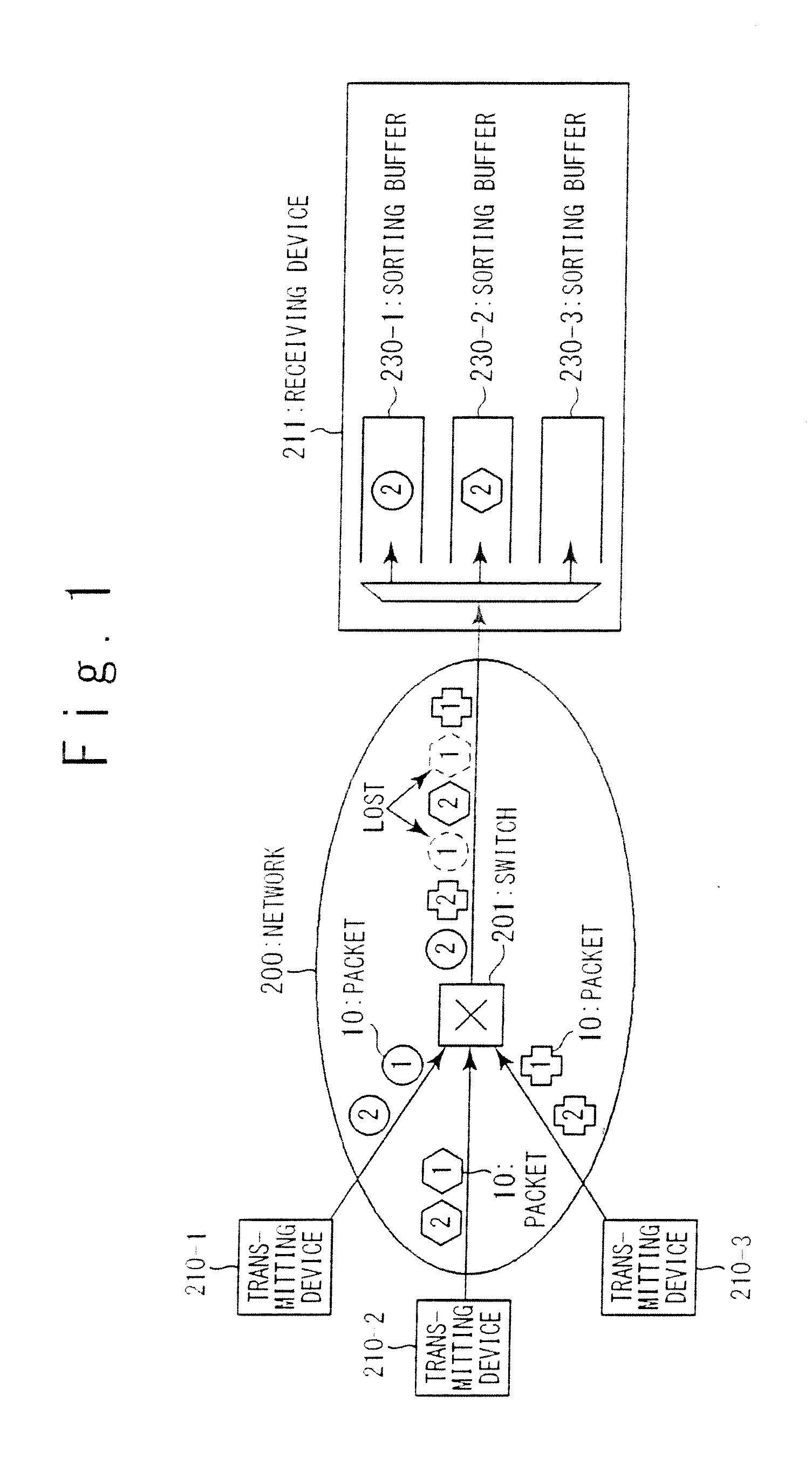

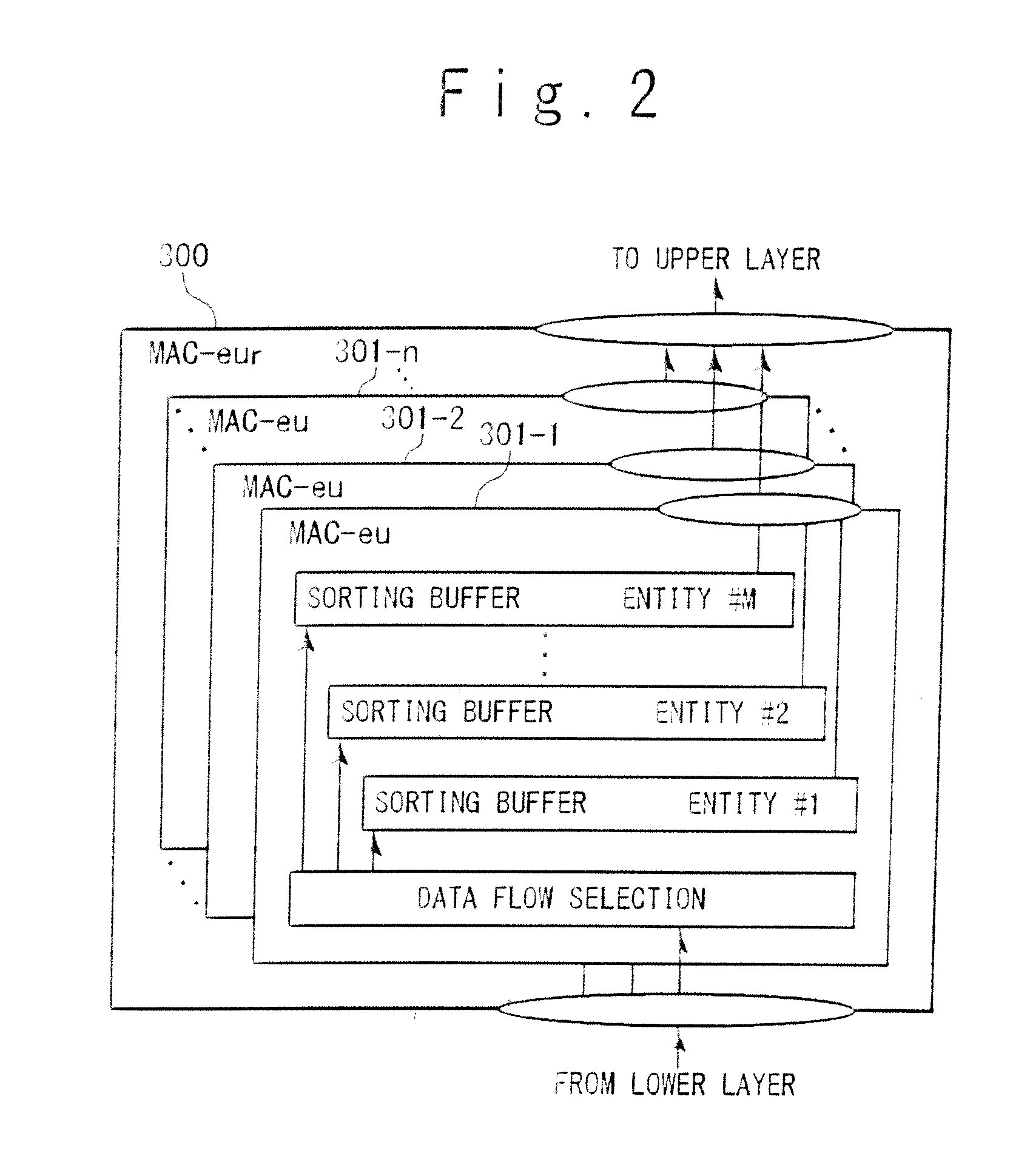

Packet sorting device, receiving device and packet sorting method

InactiveUS20110286461A1Memory resource is reducedSorting speed is fastData switching by path configurationClassification methodsTransmission order

A packet sorting device includes: a buffer for storing packets belonging to a plurality of communication flows; and a control section which determines, when receiving one of a series of packets, whether the one of the received packets is a disorder packet by a determination process, and sorts the received packets in a correct order by storing the disorder packet and communication flow information thereof in the buffer so that the disorder packet and communication flow identification information are correlated. The disorder packet is one of the received packets which is received in an order different from a transmission order of the packets. The communication flow information identifies the plurality of communication flows.

Owner:NEC CORP

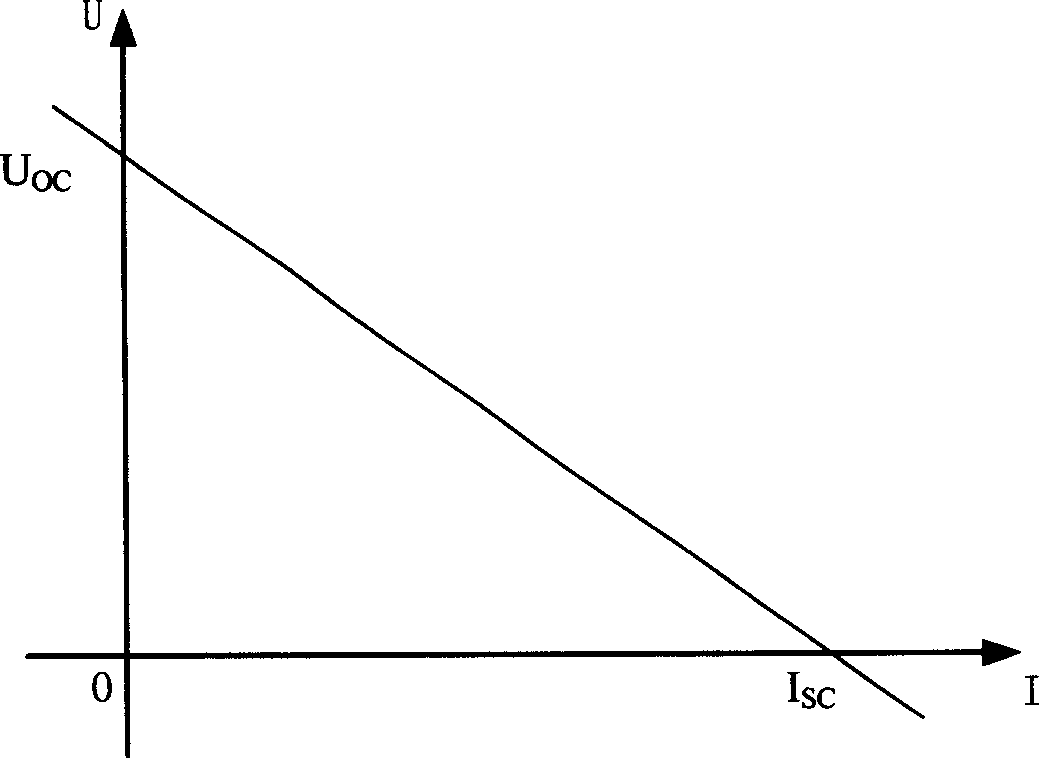

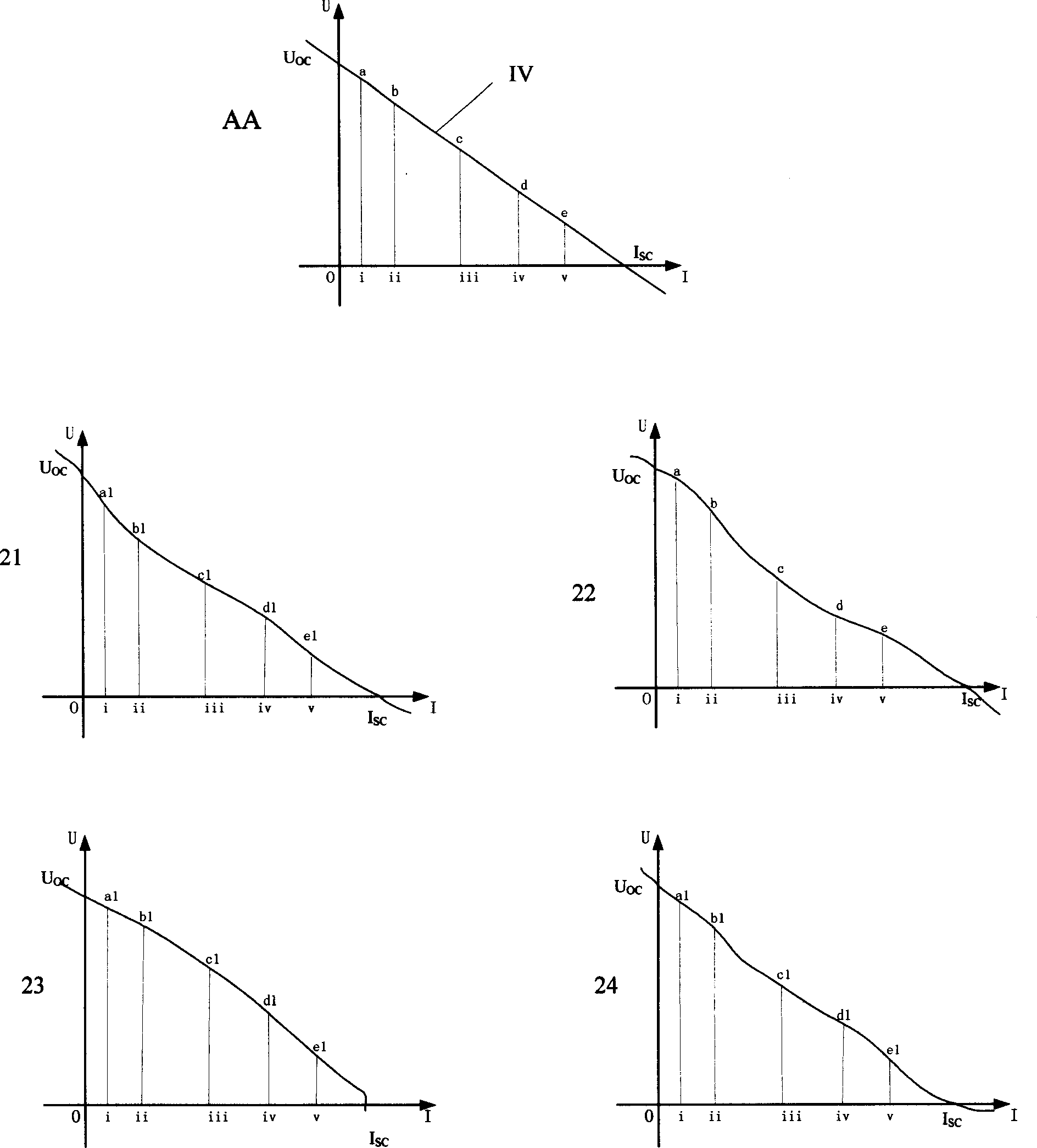

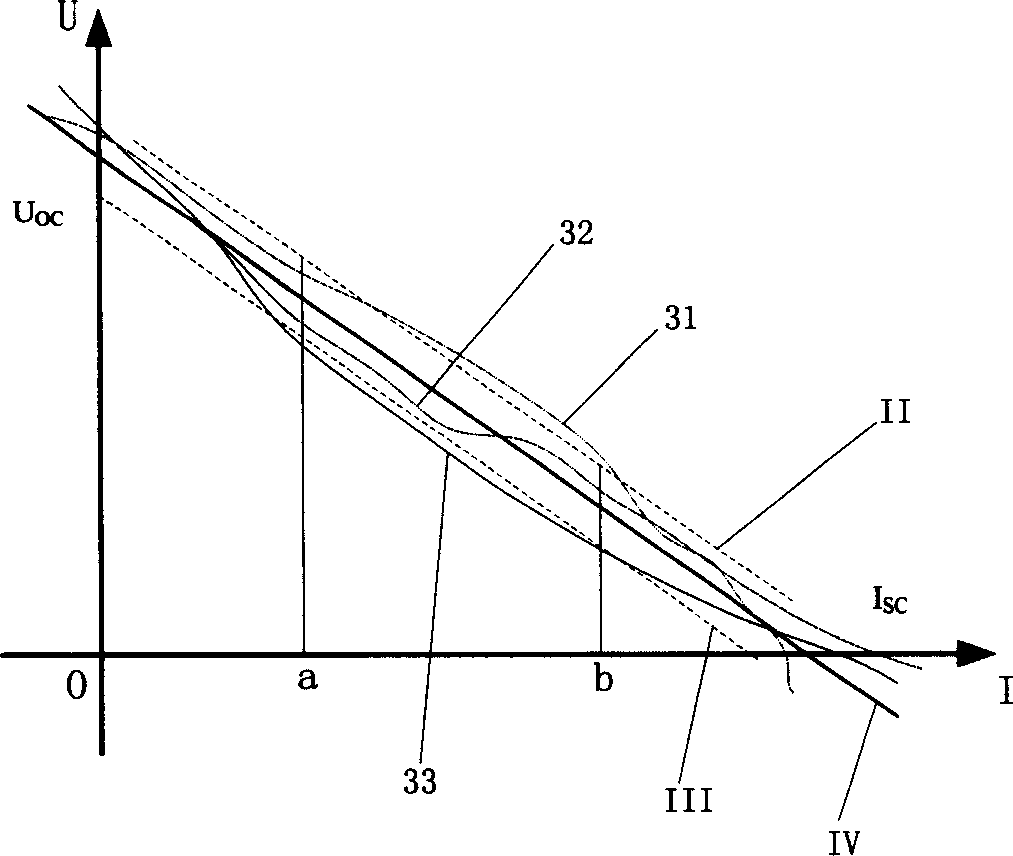

Method for sorting batteries according to battery volt-ampere curve

InactiveCN1664604ASorting speed is fastThe testing process is simpleElectrical testingData combinationCapacitance

This invention discloses one battery volt-ampere characteristic battery filtering method, which uses computer to control the charging process and collect the relative data on the characteristic curve and to filter the battery according to the data combination. The method is of high speed and is suitable for each type of batteries filtering.

Owner:韩伟

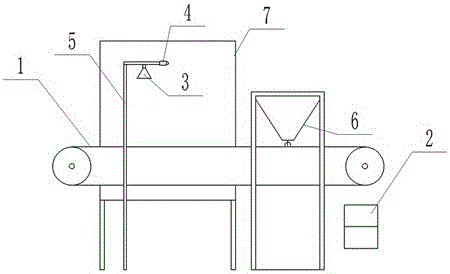

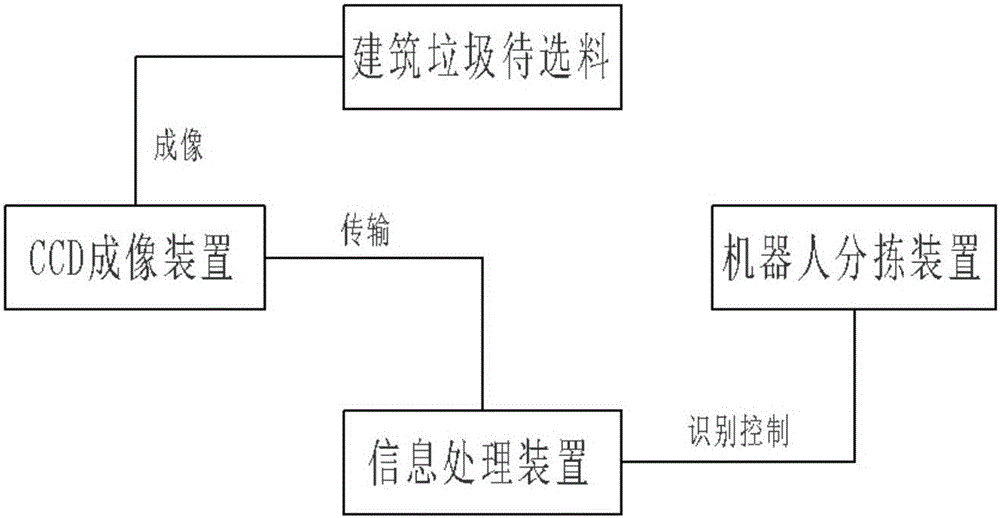

Intelligent robot sorting system and method for construction wastes

InactiveCN106540887ASorting speed is fastHigh sorting accuracySortingInformation processingConstruction waste

The invention provides an intelligent robot sorting system and method for construction wastes. The system mainly comprises a robot worktable, an image acquiring device, an information processing device and a robot sorting device, wherein the image acquiring device is arranged above the robot worktable and is connected with the information processing device; the information processing device is connected with the robot sorting device. The system has the advantages that the construction wastes can be automatically classified, and the manual sorting manner is replaced by the robot automatic sorting manner, so that the sorting efficiency can be greatly improved, and the cost can be saved; meanwhile, the system is high in reliability, accuracy and robustness.

Owner:徐州绿之源环境科技有限公司

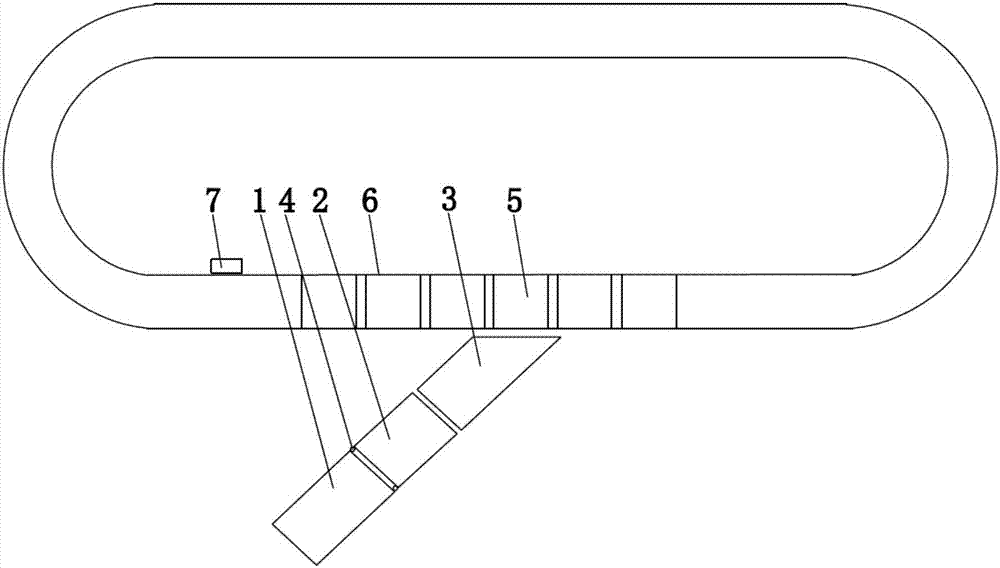

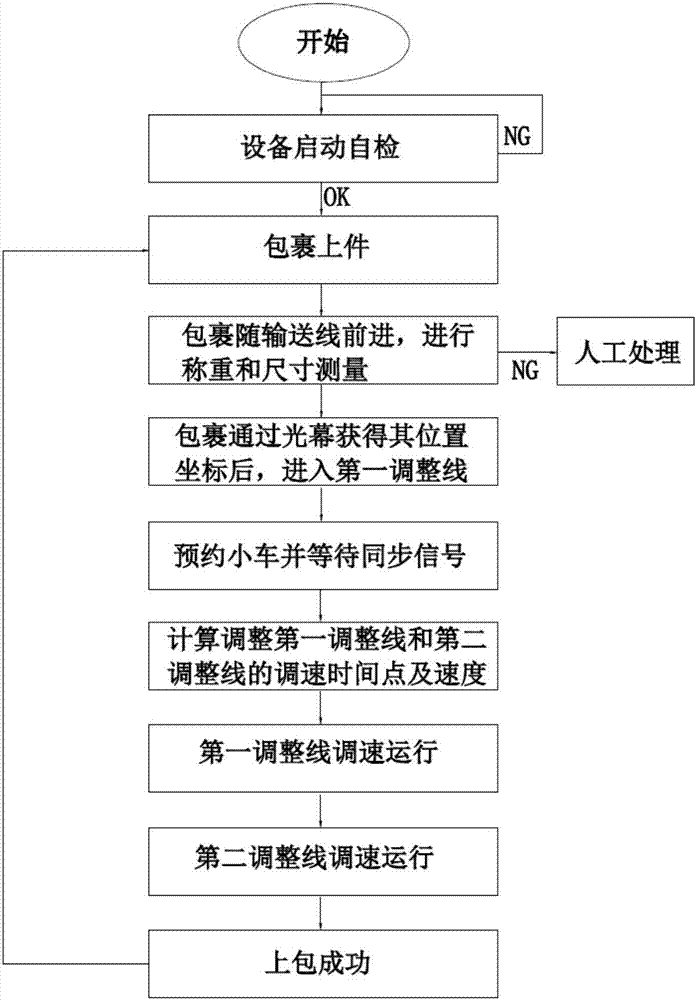

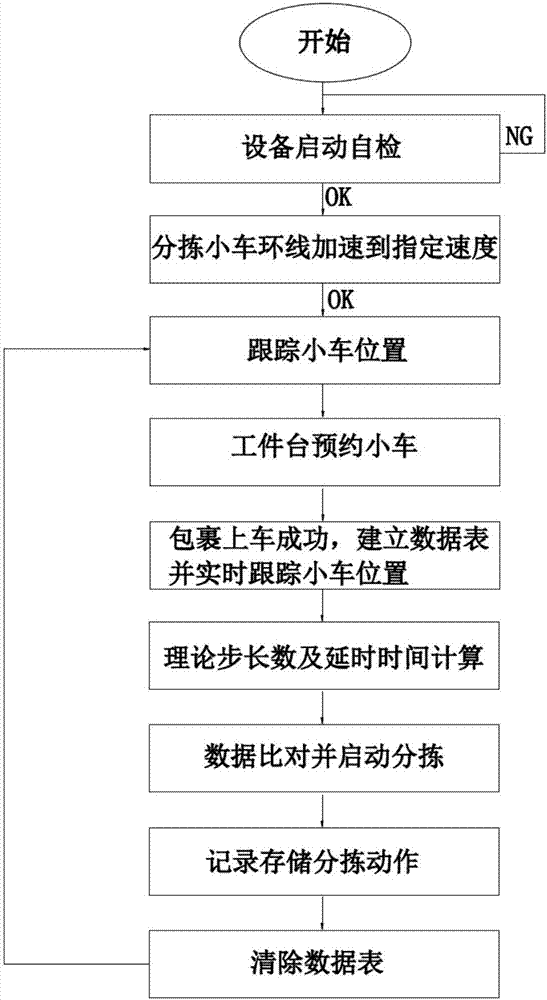

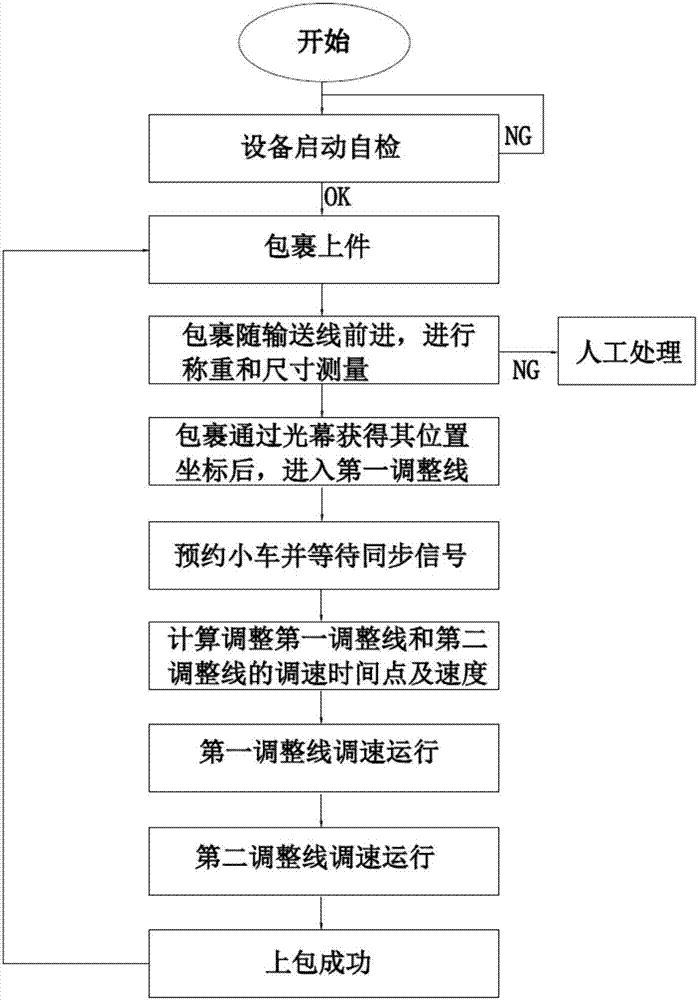

Sorting method for carbel loop line sorting system and package discharging control system

ActiveCN106892253AExquisite designSimple processControl devices for conveyorsMechanical conveyorsTime lossControl system

The invention discloses a sorting method for a carbel loop line sorting system and a package discharging control system. The sorting method comprises the following steps: S1, a package supply line reserves a sorting trolley and supplies a package to the sorting trolley determined by the reservation, and the control system does not stop a first adjusting line and a second adjusting line from completing package loading after the sorting trolley is reserved and determined for the package through a light curtain; and S2, after the package is successfully loaded on the sorting trolley, the control system controls the sorting trolley to start discharging the package at a package discharging cell opening corresponding to the package. The sorting method for the carbel loop line sorting system and the package discharging control system have the advantages that the design is elaborate and the process is simple. According to the sorting method, the center of mass of the package is determined by the light curtain so that the trolley can be reserved according to the distance from the center of mass to the package loading point, the speed change time point and the target speed of the first adjusting line and the second adjusting line are adjusted according to the position of the trolley, no sections need to be stopped in the whole package conveying process, and therefore time loss caused by stop is avoided, the sorting speed can be increased, and the sorting efficiency can be improved.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

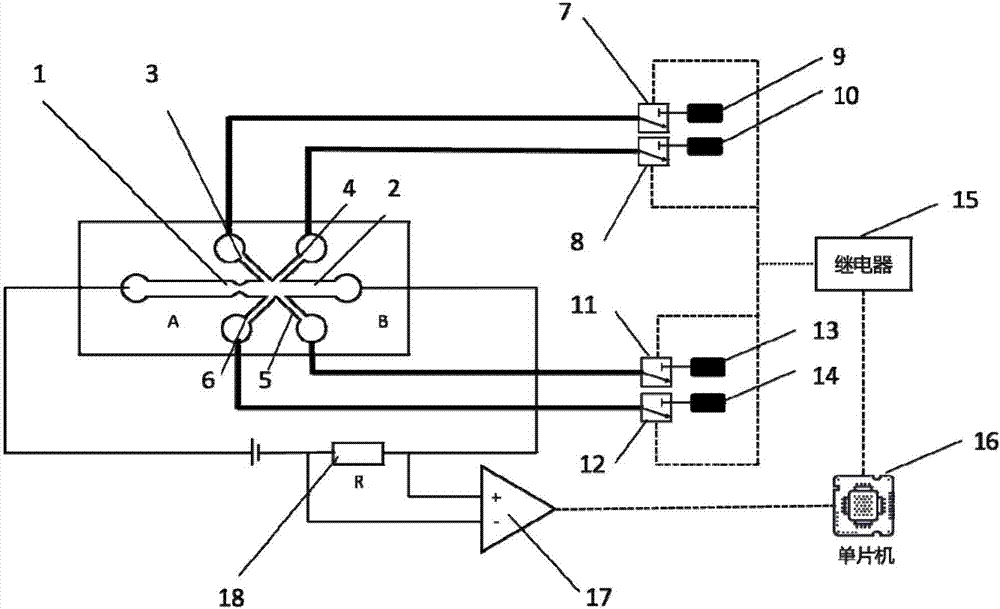

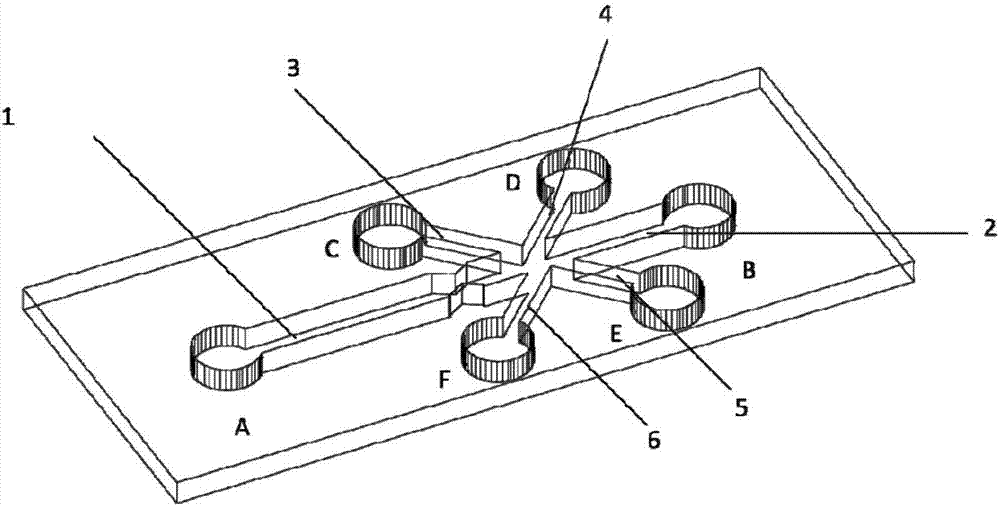

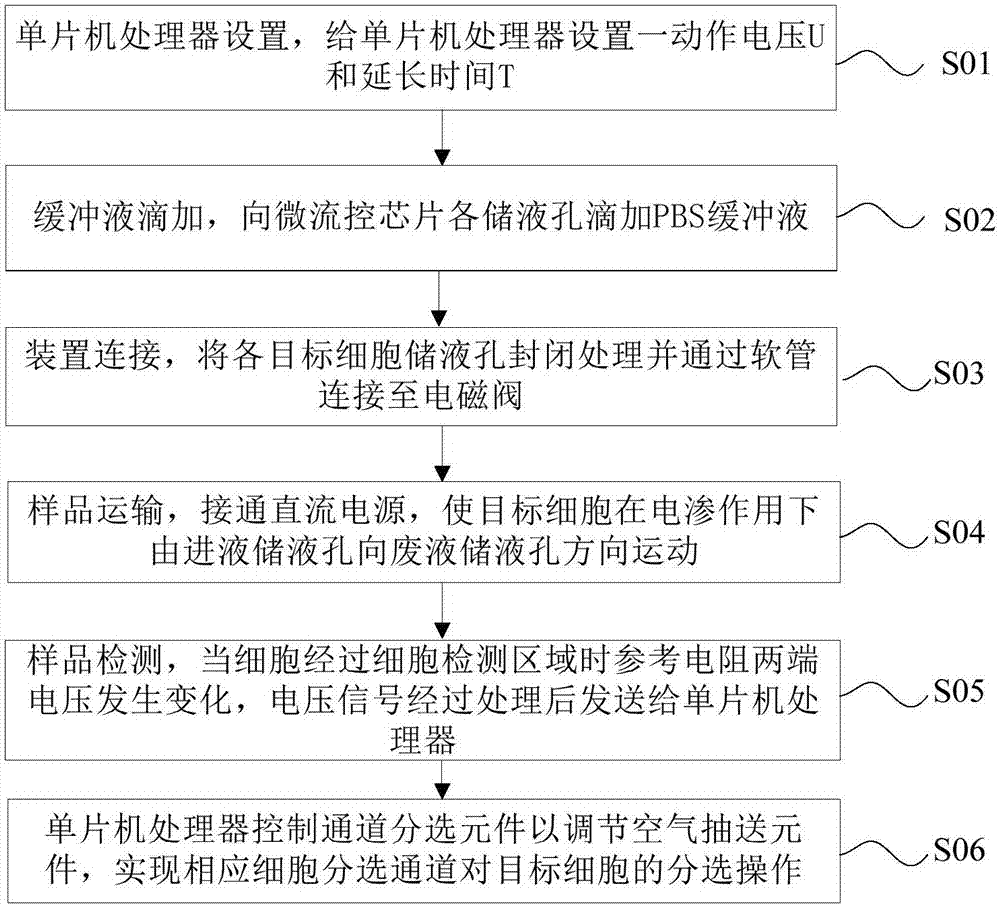

Single cell automatic control sorting device and method based on micro-fluidic chip

PendingCN107164212AAvoid entering the same sorting channelSorting speed is fastBioreactor/fermenter combinationsBiological substance pretreatmentsComputer hardwareAutomatic control

The invention discloses a single cell automatic control sorting device and a single cell automatic control sorting method based on a micro-fluidic chip. The device comprises a cell sorting substrate, a pressure control element, a signal processing element, a channel sorting element and a signal collection control device, wherein the cell sorting substrate comprises the micro-fluidic chip engraved with micro-channels, the micro-channels comprise a main channel provided with a sample liquid storage hole and a waste liquid storage hole arranged at the head and the tail, respectively, and a plurality of cell sorting channels communicating with the main channel and provided with target cell liquid storage holes at tail ends. According to the device and the method provided by the invention, the signal collection control device is used for controlling the channel sorting element to control actions of the element by regulating pressure, so that selection of the cell sorting channel is achieved, and automatic sorting and control of the corresponding cell sorting channel to the target cells are achieved by a negative pressure effect. The device and the method provided by the invention are simple in principle and convenient to use, and the device has the characteristics of small volume and low cost, and can efficiently and conveniently complete sorting of the single cells.

Owner:DALIAN MARITIME UNIVERSITY +1

Efficient screening device for corn seeds

The invention relates to a screening device, in particular to an efficient screening device for corn seeds. The technical purpose refers to that the efficient screening device for corn seeds is high in separating speed and efficiency and convenient and flexible to adjust. In order to realize the technical purpose, the efficient screening device for corn seeds comprises a bottom board, a support, a sliding rail, a collection case I, a collection case II, an iron screening box, a sliding block, a rack, a sector gear, an electromagnet, a string, an arc-shaped connecting rod, a supporting rod, a rotary motor, a barrel cam, a milling groove, a clamping block, an L-shaped guide board, a bearing pedestal I, a gear motor, a winding drum, a bearing pedestal II, a top board, a servo motor, a bearing pedestal III, a nut, a bearing pedestal IV, a fixing board, a rotary shaft and a lead screw. The support, the sliding rail, the collection case I and the collection case II are sequentially arranged on the top of the bottom board from left to right. The efficient screening device for corn seeds has the effects of being high in separating speed and efficiency and convenient and flexible to adjust.

Owner:李德玲

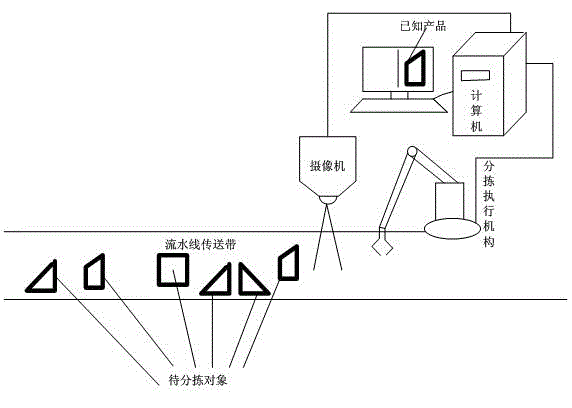

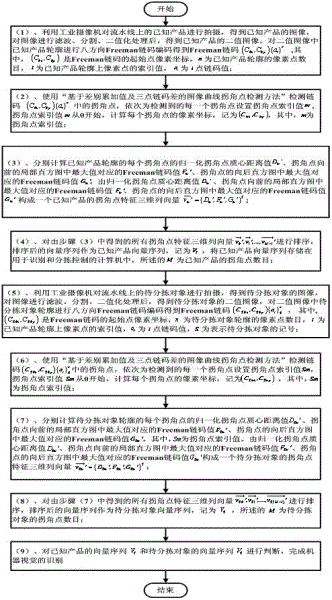

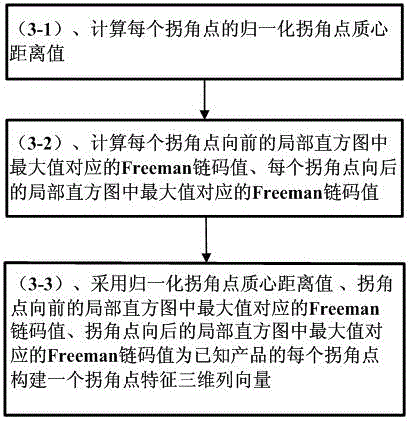

Machine visual identification method for sorting products with corner point characteristics

ActiveCN102615052AAchieve accurate identificationSimple matching algorithmSortingMachine visionVisual perception

The invention discloses a machine visual identification method for sorting products with corner point characteristics. The method comprises the steps as follows: performing Freeman chain code encoding on the image outlines of known products, detecting the corner points by using the Freeman chain codes, calculating the corner point characteristic three-dimensional column vectors of all the corner points, sequencing the corner point characteristic three-dimensional column vectors and taking the vector sequence as the vector sequence of the known products; performing Freeman chain code encoding on the image outlines of objects to be sorted, detecting the corner points by using the Freeman chain codes, calculating the corner point characteristic three-dimensional column vectors of all the corner points, sequencing the corner point characteristic three-dimensional column vectors and taking the vector sequence as the vector sequence of the objects to be sorted; and judging the vector sequence of the known products and the vector sequence of the objects to be sorted and finishing machine visual identification. According to the method, the shapes of the known products and the objects to be sorted are simply represented by the chain codes; the subsequent calculation quantity is small; the extracted vector sequence has zooming and rotation invariance can be accurately identified; and the algorithm is simple.

Owner:上海机器人产业技术研究院有限公司

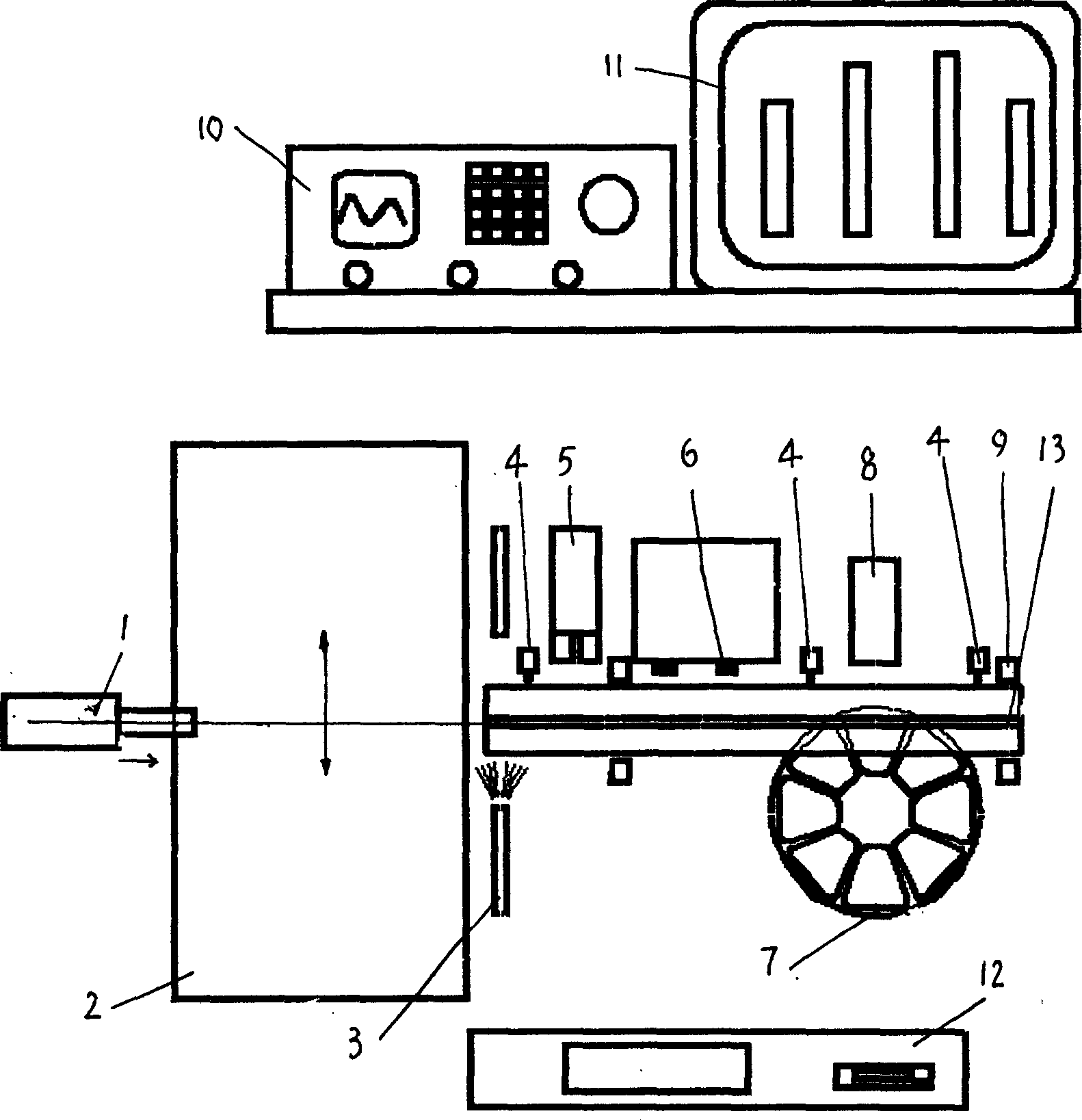

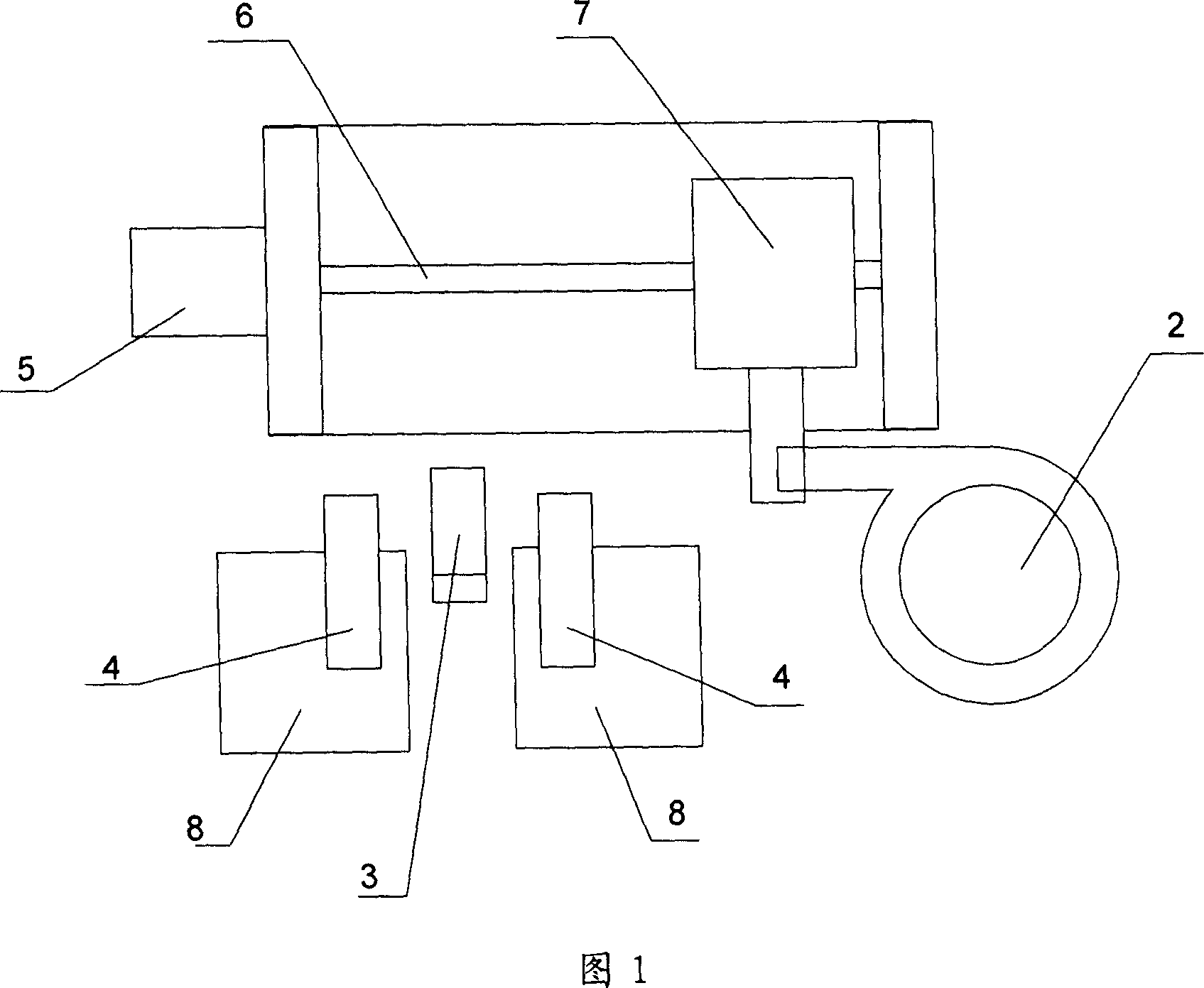

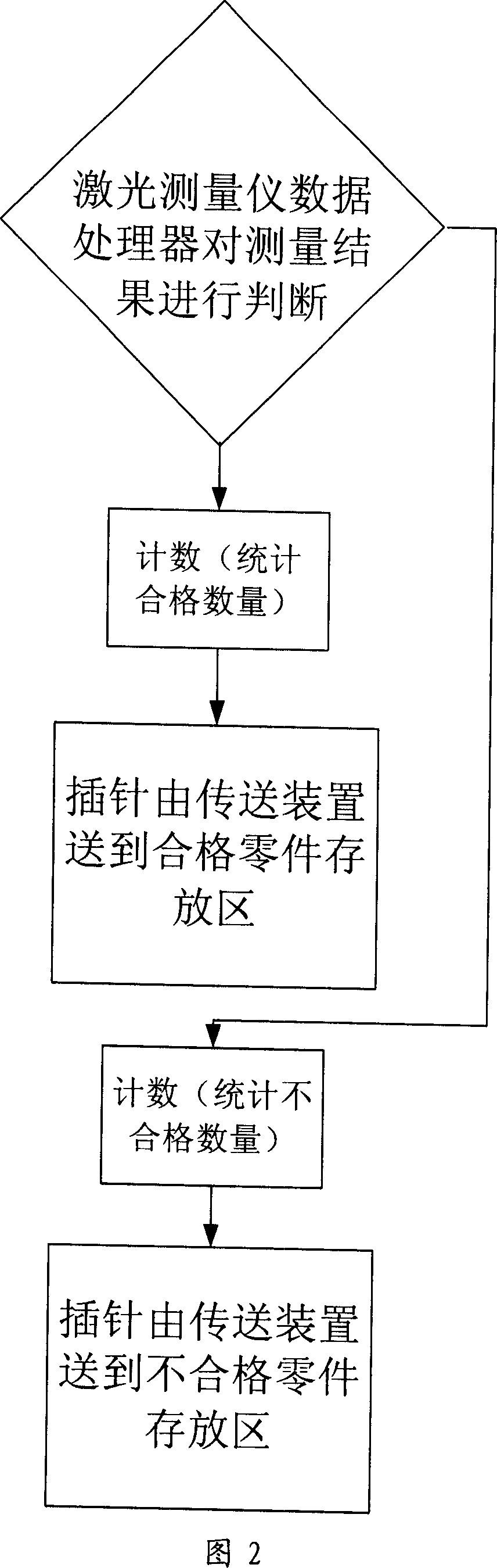

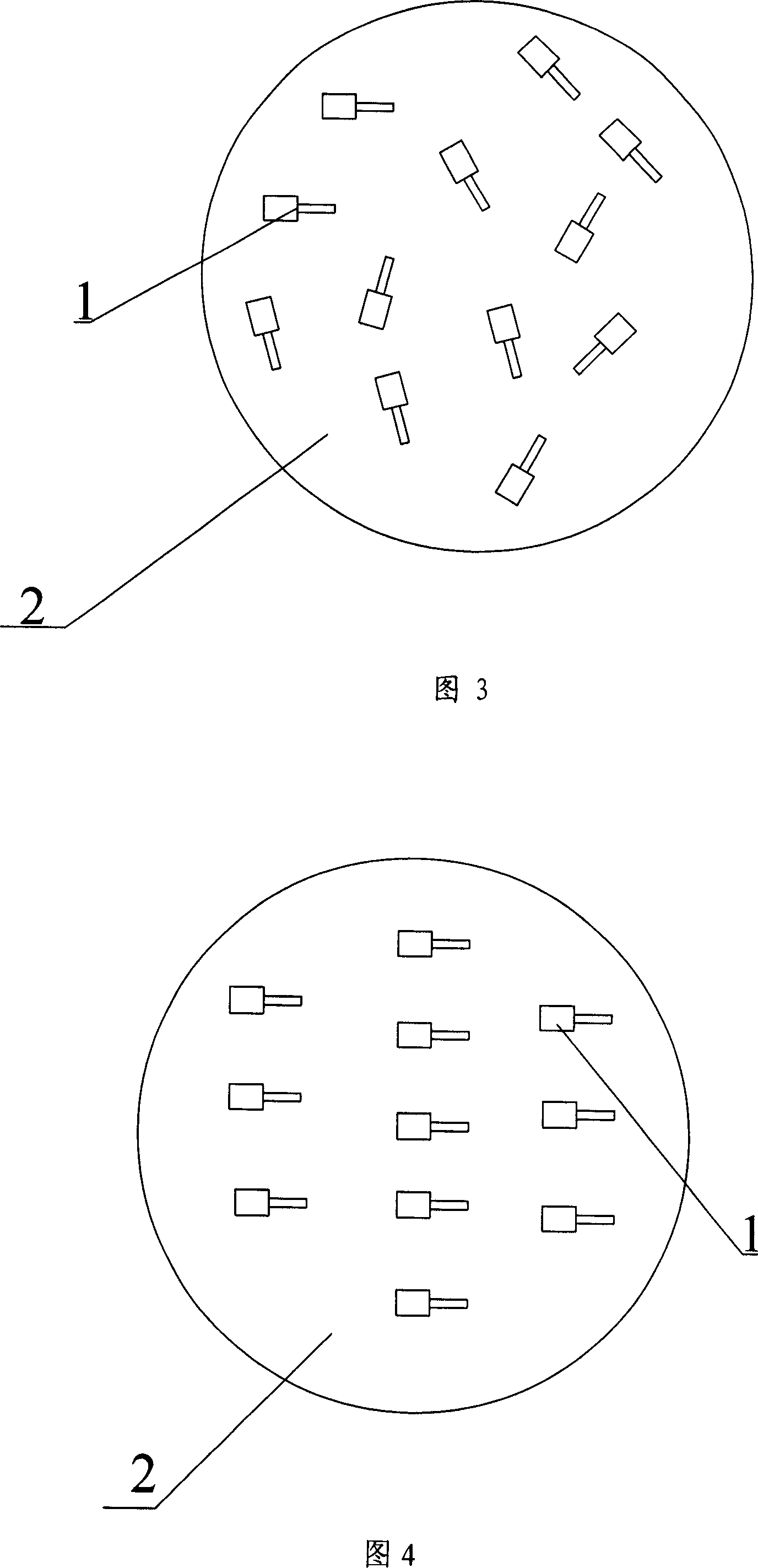

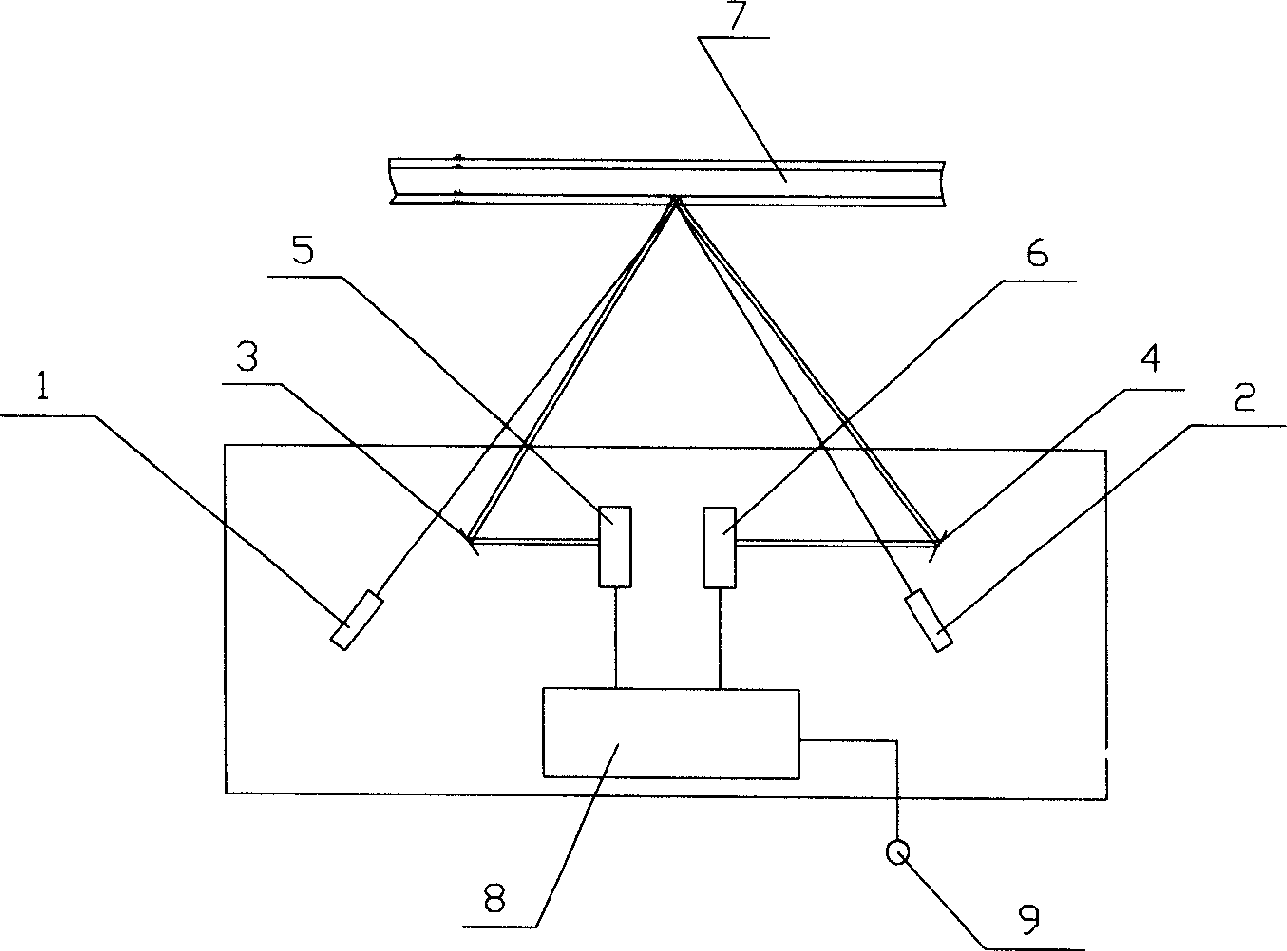

Pin diameter automatic detecting and sorting system

InactiveCN1962089AQuality improvementSorting speed is fastUsing optical meansSortingNeedle guideEngineering

The invention relates to a needle diameter automatic checking selecting system, wherein it comprises vibration disc, laser tester, and the transmitter for transmitting needle between vibration disc and tester. The disc via the transmitter transmits needle to the laser tester. The invention also comprises a tested needle guide outlet groove and a needle storage device. The invention can improve efficiency.

Owner:薛云智

LED (Light Emitting Diode) device sorting machine

The invention provides an LED (Light Emitting Diode) device sorting machine which comprises a feeding mechanism, a lifting device, a rotating disc, a testing mechanism and a sorting device, wherein the rotating disc is connected with a step motor; the feeding mechanism comprises a vibrating feeding disc and two rows of straight vibrating tracks; two feeding channels are arranged on the vibrating feeding disc; one ends of the two straight vibrating tracks are respectively connected with outlets of the feeding channels of the vibrating feeding disc. According to the LED device sorting machine, measurement of brightness, hue and electric parameter characteristics can be alternately carried out on two LED devices at the same time; feeding is carried out through the two feeding channels of the vibrating feeding disc and the two rows of tracks, so that the feeding efficiency can be enhanced. The lifting device is provided with a double-head lifting mouth, so that the two LED devices can be lifted at the same time; the sorting device is provided with two rows of suction devices, so that the damage to the LED devices caused by single-channel suction negative pressure in the prior art can be decreased, the sorting correctness is high, the sorting speed is high, the manual interference is less, the production process is continuous, the automation degrees is high and the production cost is reduced.

Owner:苏州嘉大电子有限公司

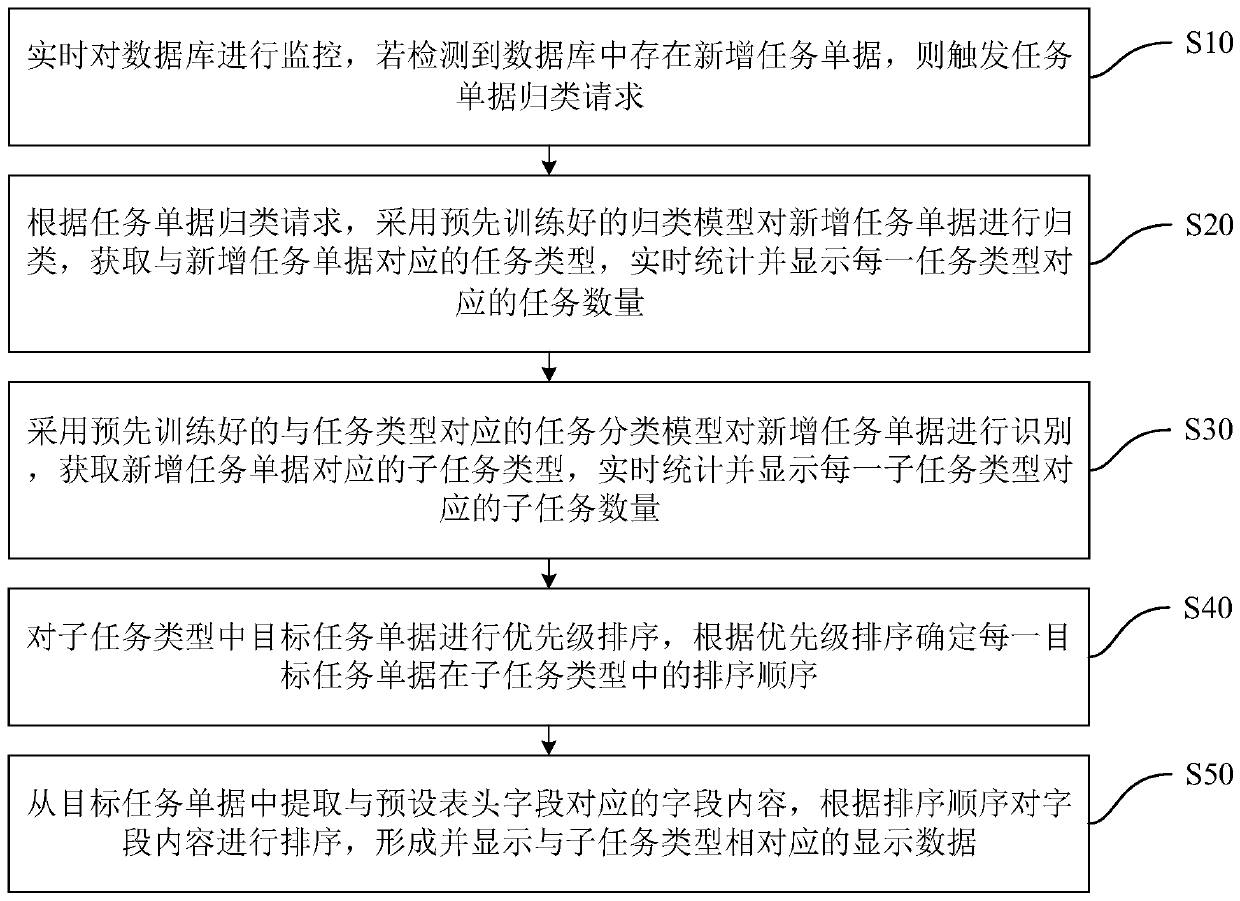

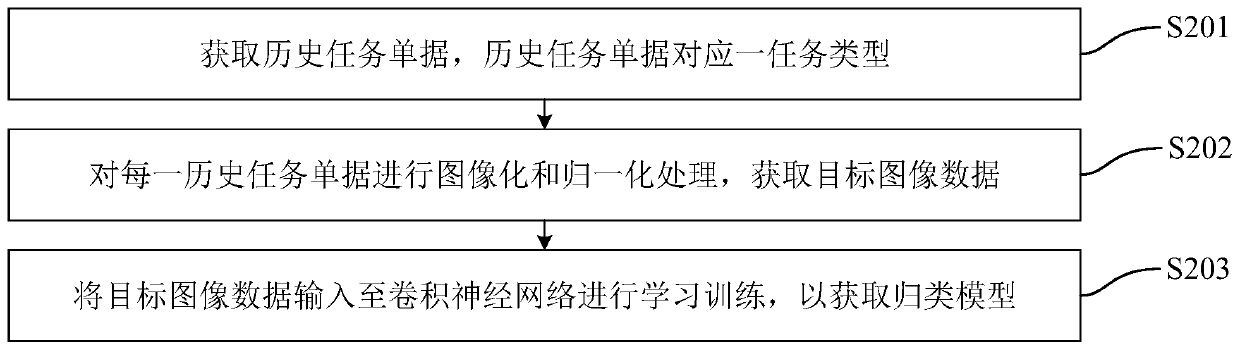

Task monitoring processing method and device, computer equipment and storage medium

PendingCN110288193AImprove processing timeSorting speed is fastDigital data information retrievalResourcesRankingPaper document

The invention discloses a task monitoring processing method and device, computer equipment and a storage medium, and the method comprises the steps: monitoring a database in real time, and triggering a task bill classification request if it is detected that a newly added task bill exists in the database; according to the task document classification request, adopting a pre-trained classification model to classify the newly-added task documents, and obtaining a corresponding task type; identifying the newly-added task bills in the task types by adopting a task classification model, and obtaining sub-task types corresponding to the newly-added task bills; carrying out priority ranking on the target task bills in the subtask types, and determining the ranking sequence of the target task bills in the subtask types according to the priority ranking; and extracting field content corresponding to the preset header field from the target task document, sorting the field content according to a sorting sequence, and forming and displaying display data corresponding to the type of the sub-task so as to monitor each task document.

Owner:CHINA PING AN LIFE INSURANCE CO LTD

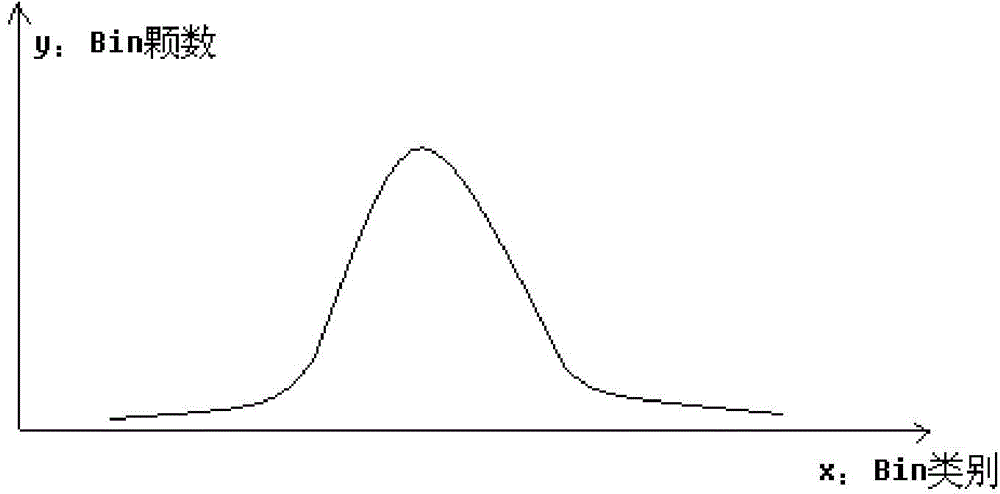

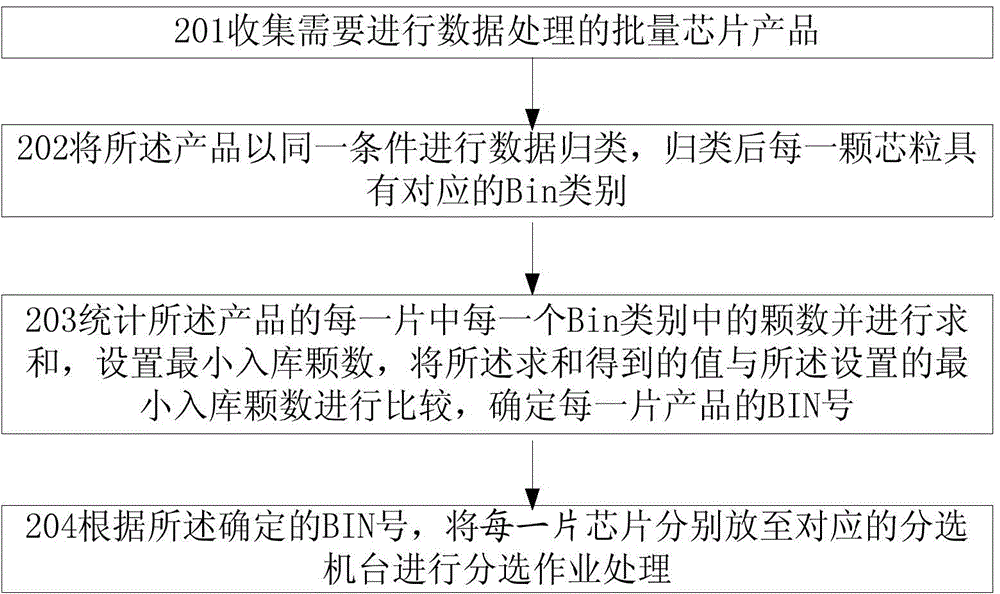

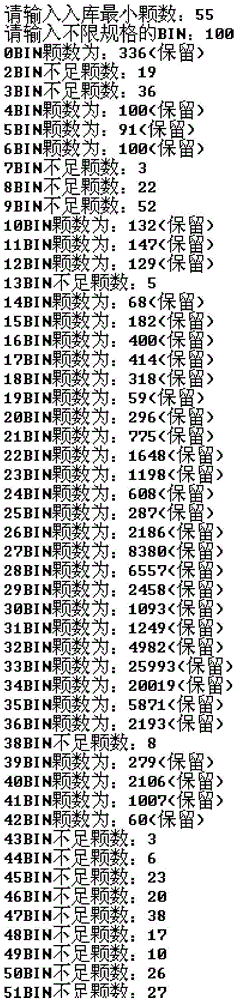

Method and system for improving separation efficiency of LED chips

ActiveCN104409394AImprove sorting efficiencyAvoid rescheduling jobsSemiconductor/solid-state device manufacturingSortingStatistical analysisComputer science

The invention discloses a method and a system for improving separation efficiency of LED chips. The method includes the following steps: collecting batch chips which needs for data processing; classifying the chips in the same conditions, wherein each chip core of every chip has a corresponding Bin category; calculating the number of chip cores corresponding to each Bin category of every chip and summing the chip core of the chips to a total number, and comparing the total number with a preset minimum inventory number, and confirming the Bin number of each chip core according to the comparison results; placing each chip on a corresponding separating machine to separate and process. The invention also provides a system for improving separation efficiency of LED chips. The method and the system can reduce the time of separating scattered Bin, and avoid the small square from reorder operations or suction operation, thus without a lot of manpower for statistical analysis.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

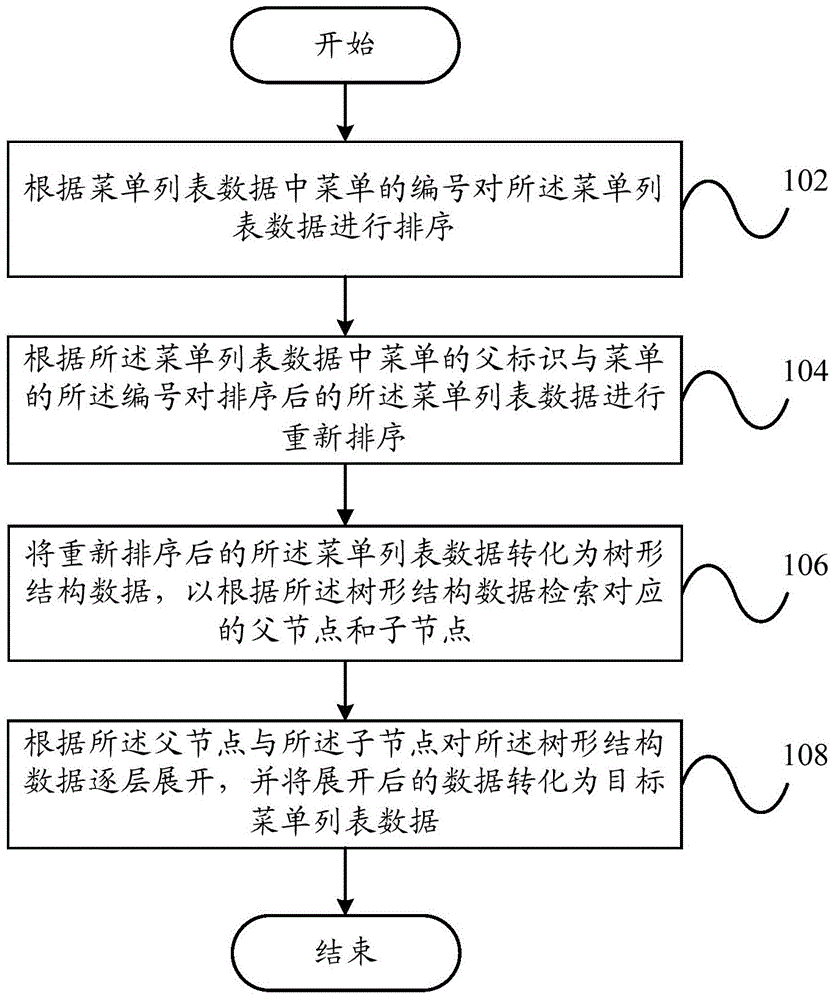

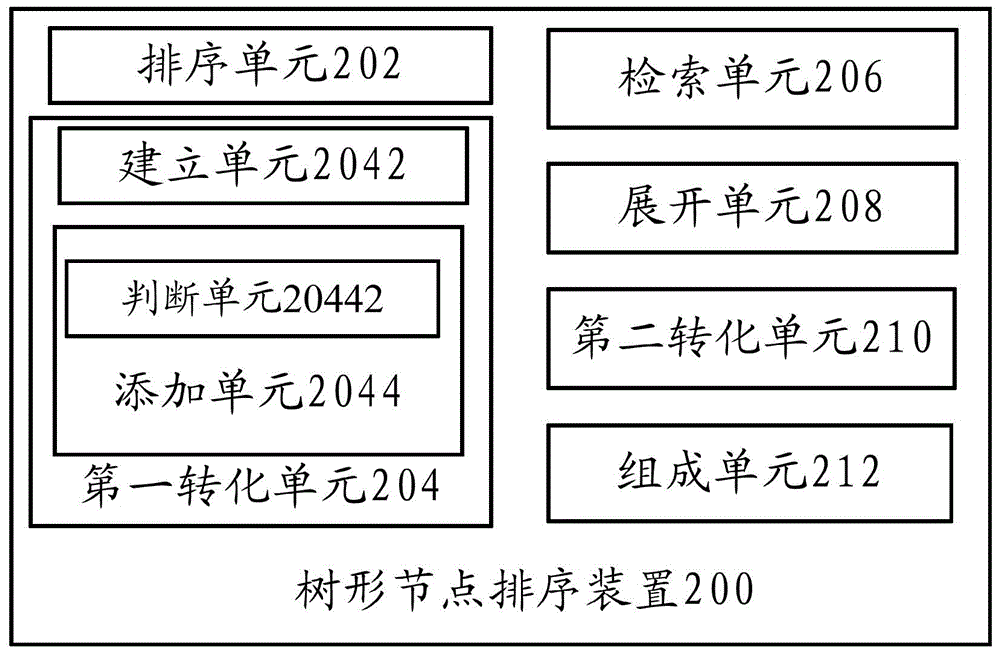

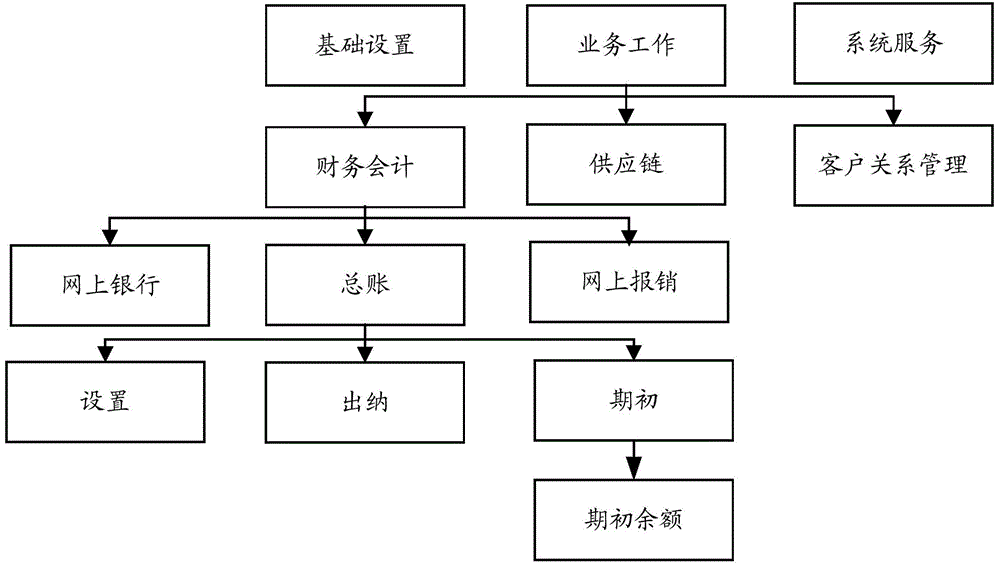

Tree node sorting method and tree node sorting device

ActiveCN104102694ASorting speed is fastImprove sorting experienceSpecial data processing applicationsData retrievalSorting time

The invention provides a tree node sorting method and a tree node sorting device. The tree node sorting method comprises the steps of sorting menu list data according to serial numbers of menus of the menu list data; resorting the sorted menu list data according to parent marks of the menus of the menu list data and the serial numbers of the menus; transforming the resorted menu list data into tree structure data, and retrieving corresponding parent nodes and child nodes according to the tree structure data; expanding the tree structure data layer by layer according to the parent nodes and the child nodes, and transforming the expanded data into target menu list data. By the technical scheme of the invention, sorting time of the tree structure data can be greatly shortened, the application of recursive program is reduced, the sorting speed is greatly increased, and the sorting experience of a user is effectively improved.

Owner:YONYOU UP INFORMATION TECH

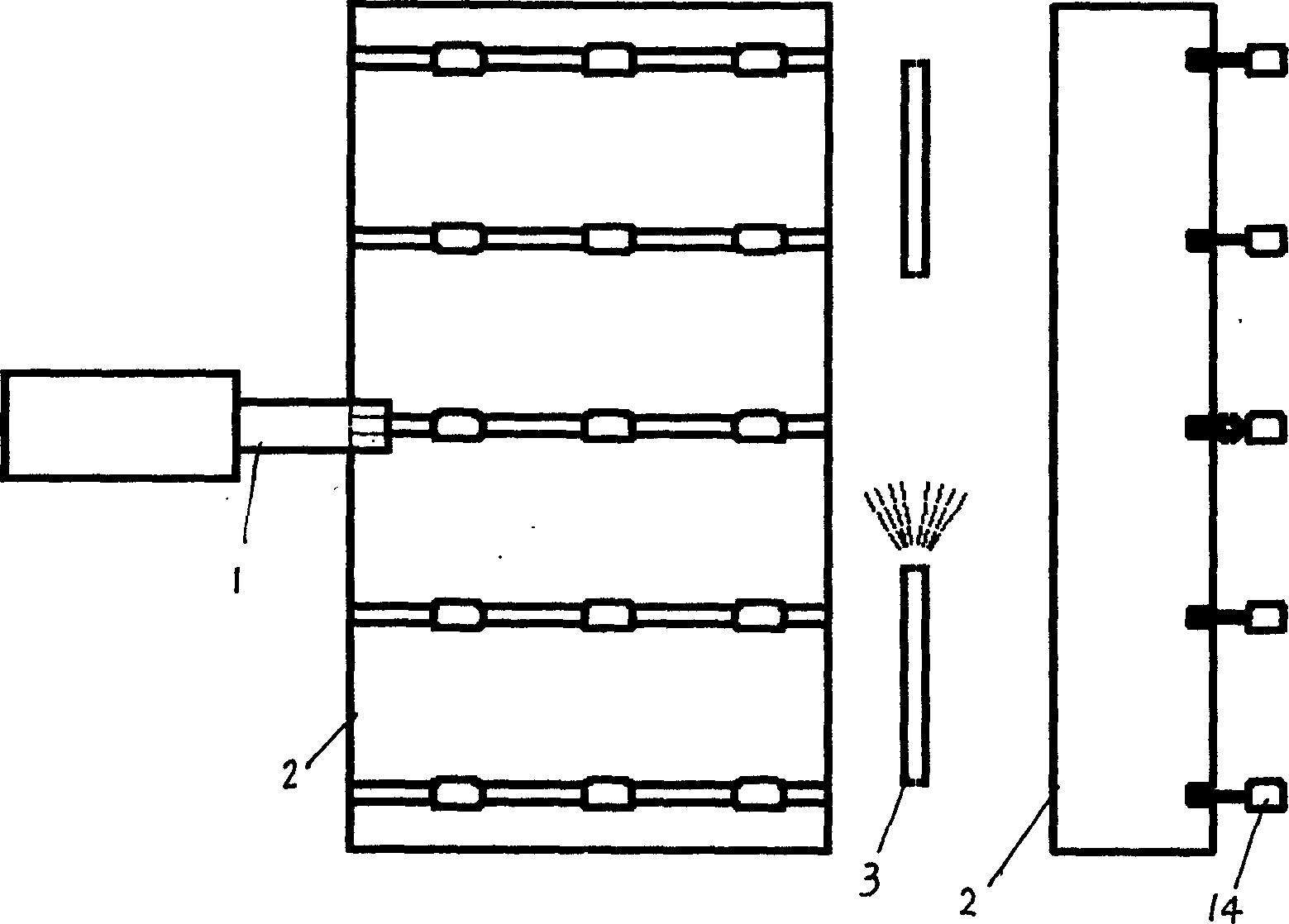

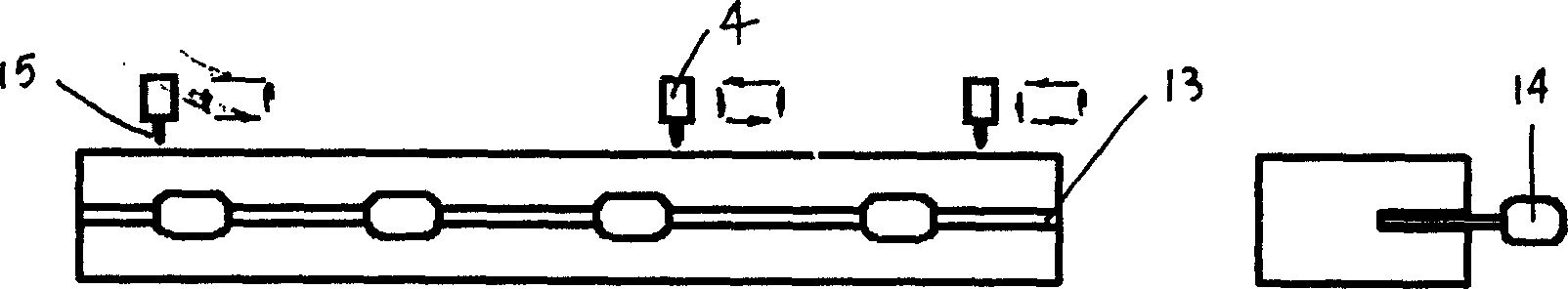

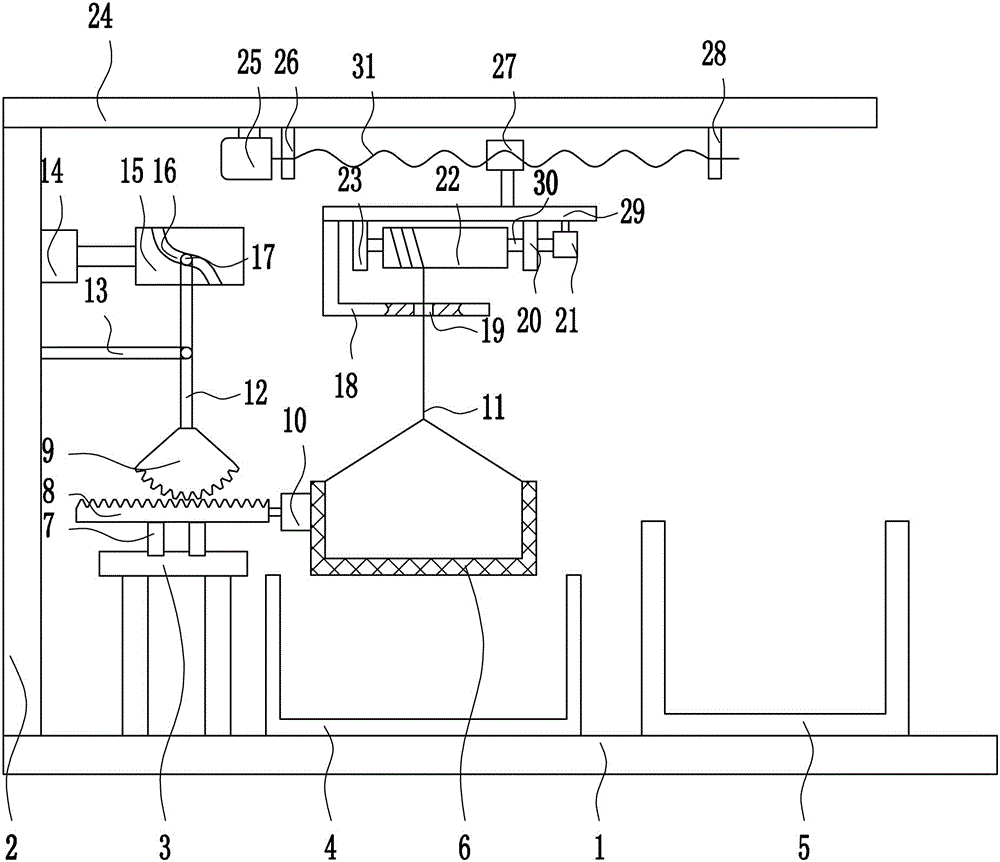

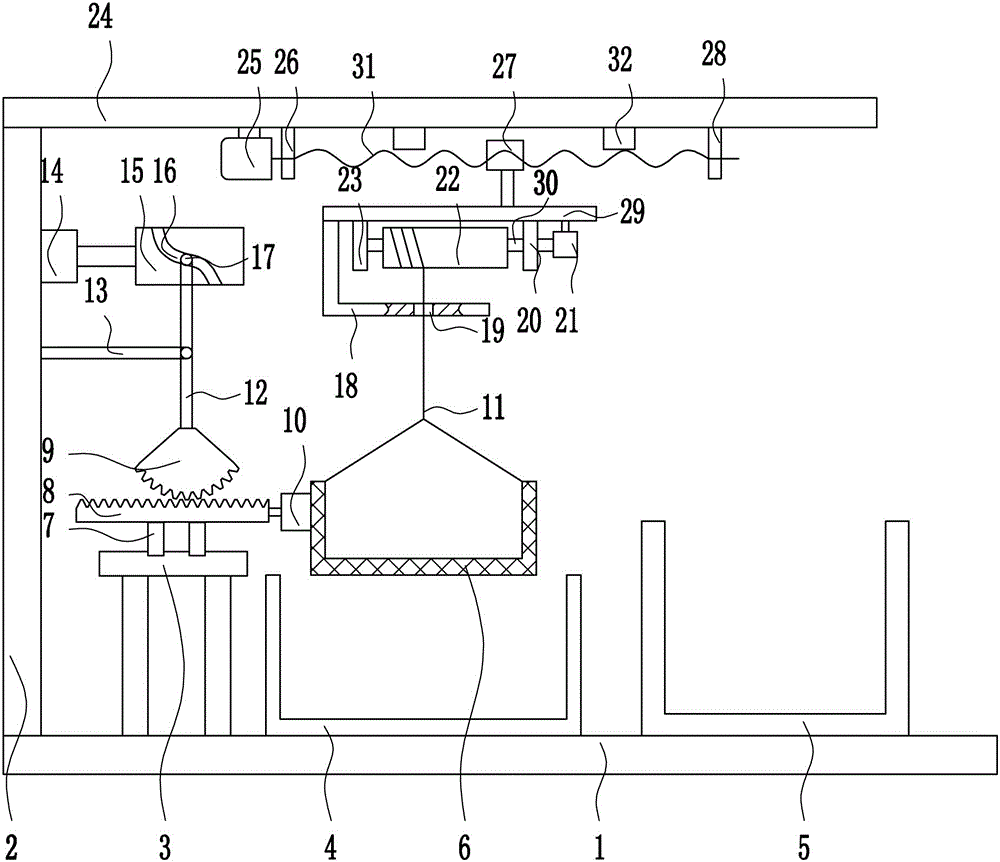

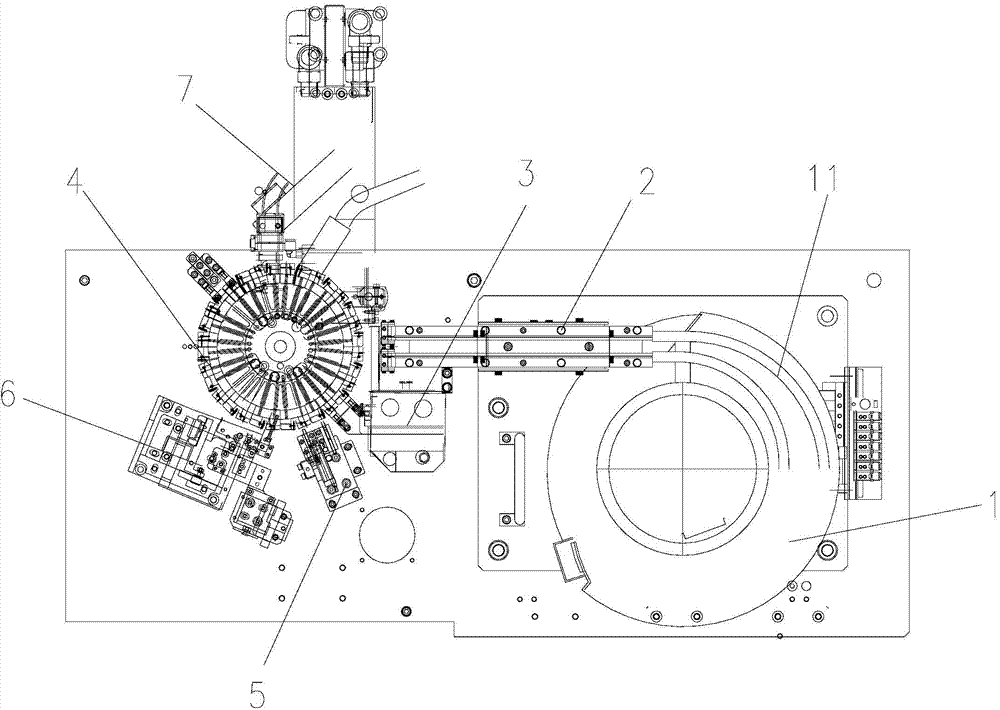

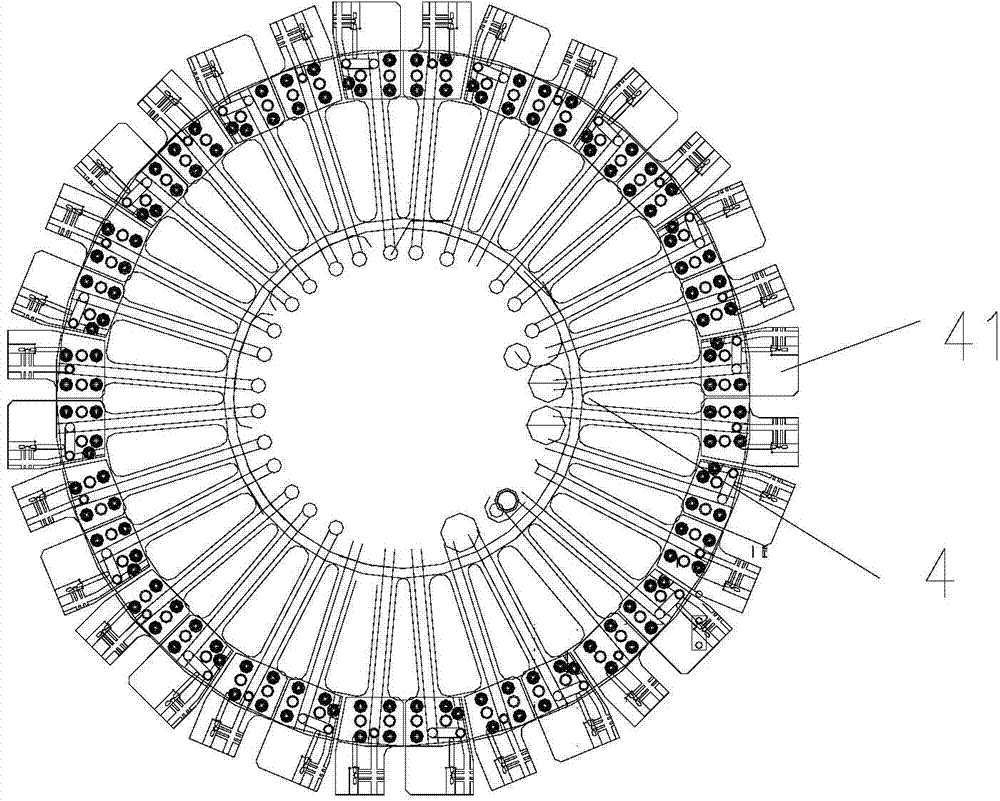

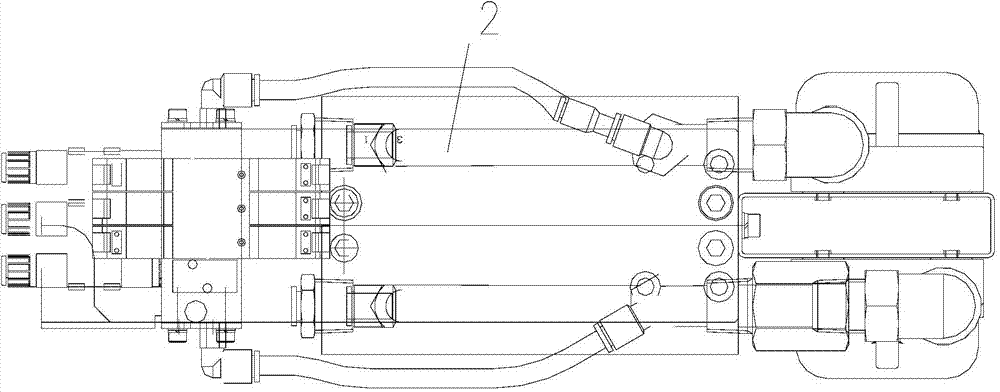

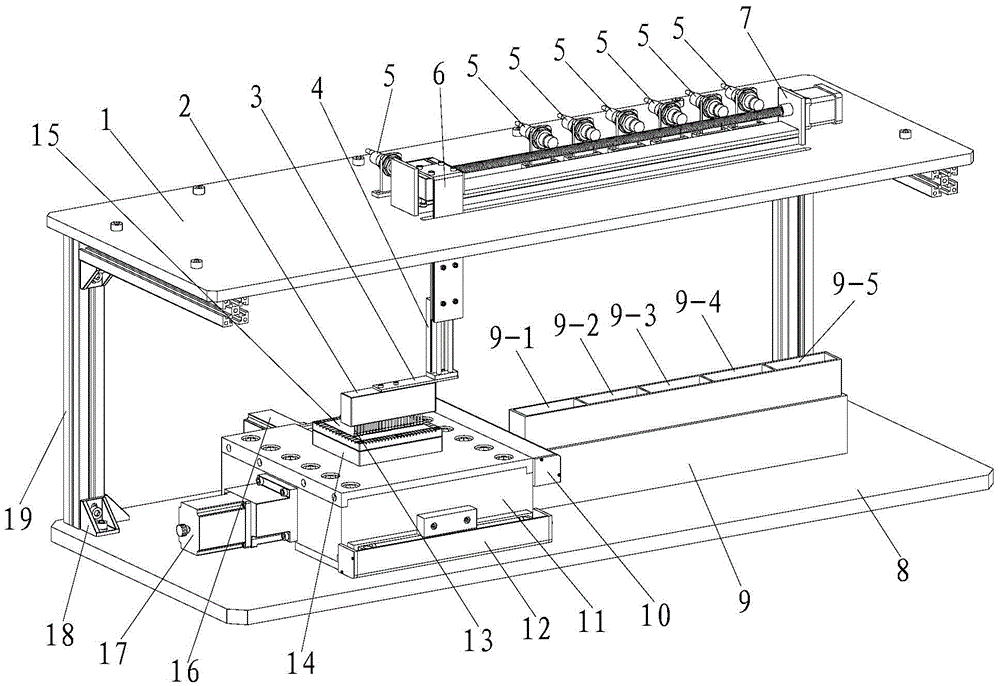

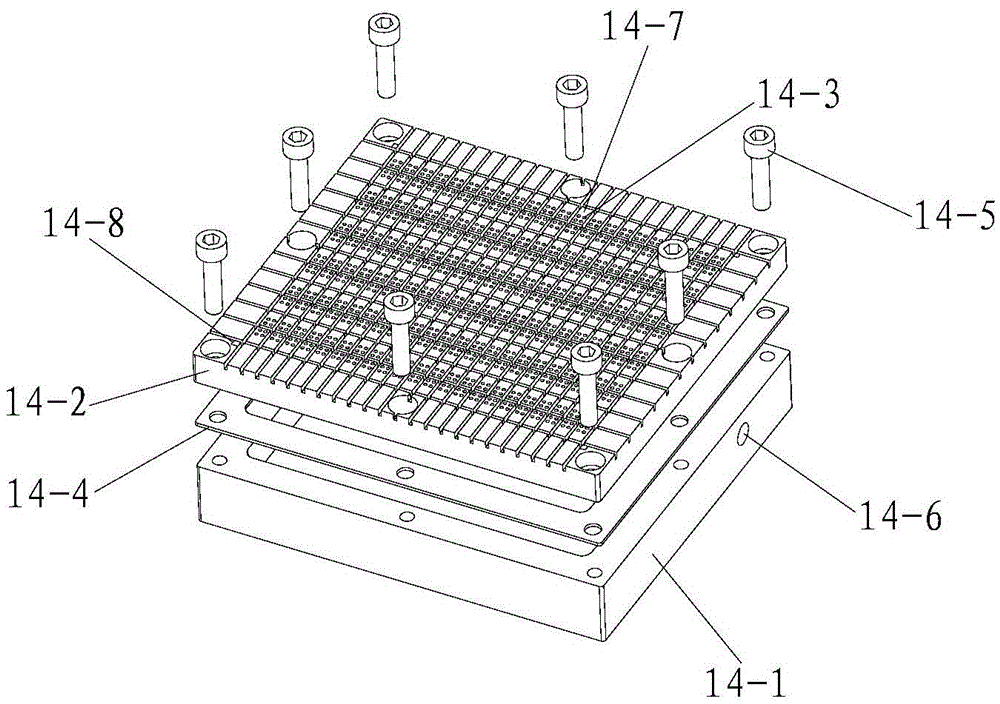

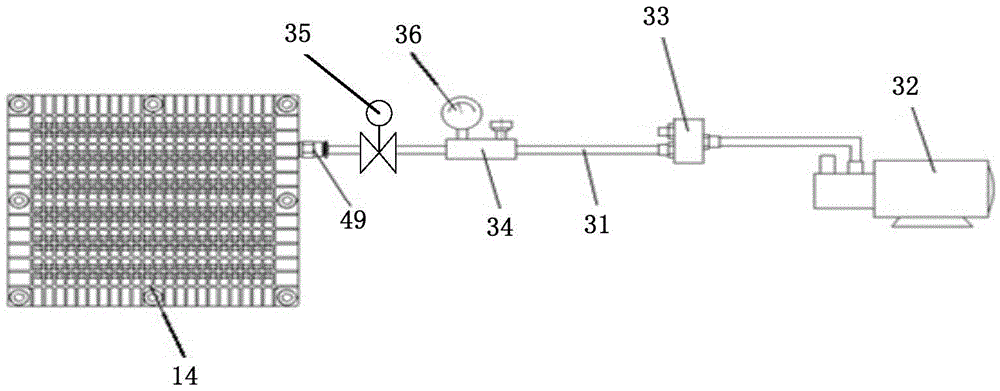

Automatic sorting device and method for large-array resistance strain plates

InactiveCN105618394ACompact structureNovel and reasonable designSortingPneumatic circuitData acquisition

The invention discloses an automatic sorting device for large-array resistance strain plates. The device comprises a frame, a positioning and fixing mechanism, an adsorption and sorting mechanism, a positioning and sorting mechanism, a computer, a data acquisition board card and an output amplifier board. The frame comprises an upper top plate, a lower bottom plate and supporting columns. The positioning and fixing mechanism comprises a two-dimensional moving platform, a vacuum adsorption table and a first vacuum adsorption loop. The adsorption and sorting mechanism comprises an adsorption head mounting box, multiple vacuum adsorption heads, a second vacuum adsorption loop and a pneumatic loop, wherein the vacuum adsorption heads are arranged in the adsorption head mounting box, and the lower ends of the vacuum adsorption heads stretch out of the adsorption head mounting box. The positioning and sorting mechanism comprises a ball screw sliding table, a cylinder sliding table and a second pneumatic loop. The invention further discloses an automatic sorting method for the large-array resistance strain plates. The device and method are novel and reasonable in design, low in realizing cost, high in work reliability and practicability, capable of improving the production efficiency, lowering the labor intensity of workers and product production cost, and high in application and popularization value.

Owner:SHAANXI UNIV OF TECH

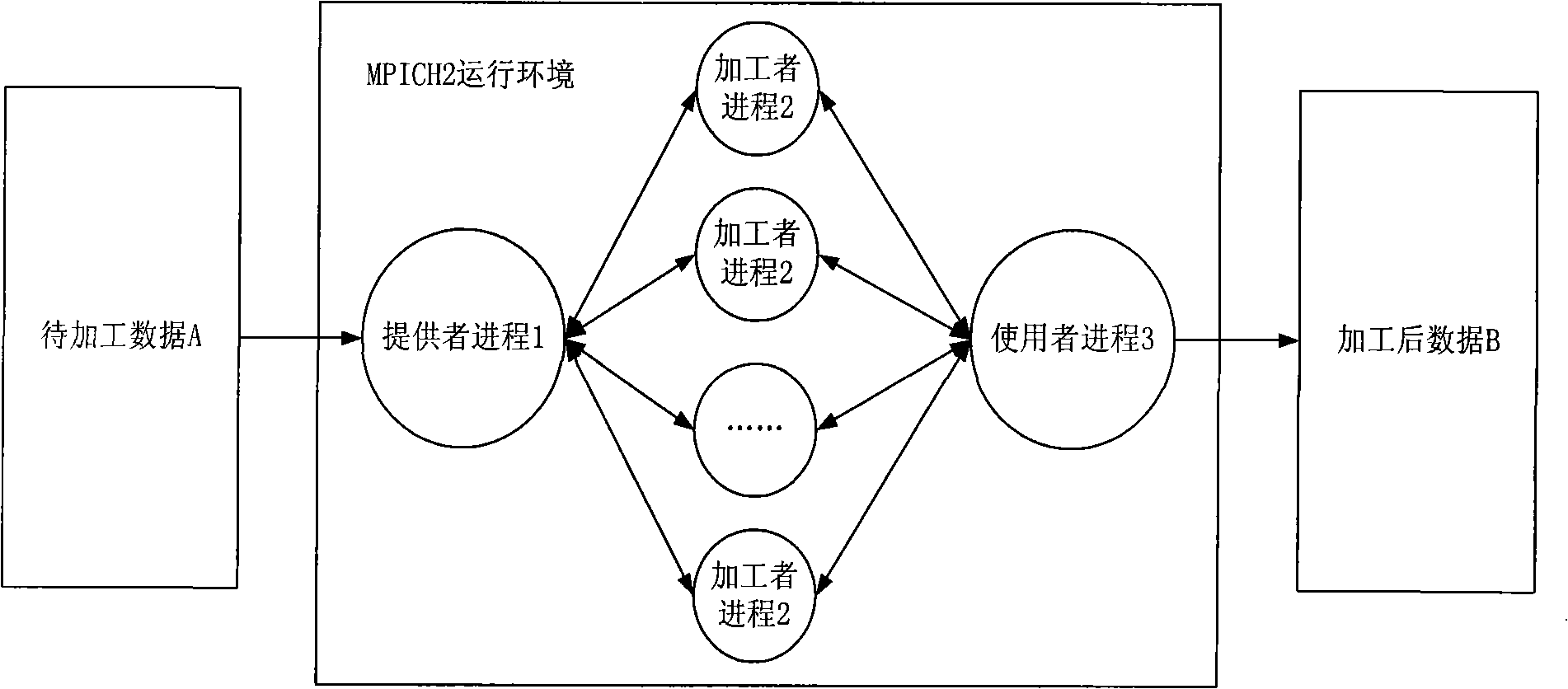

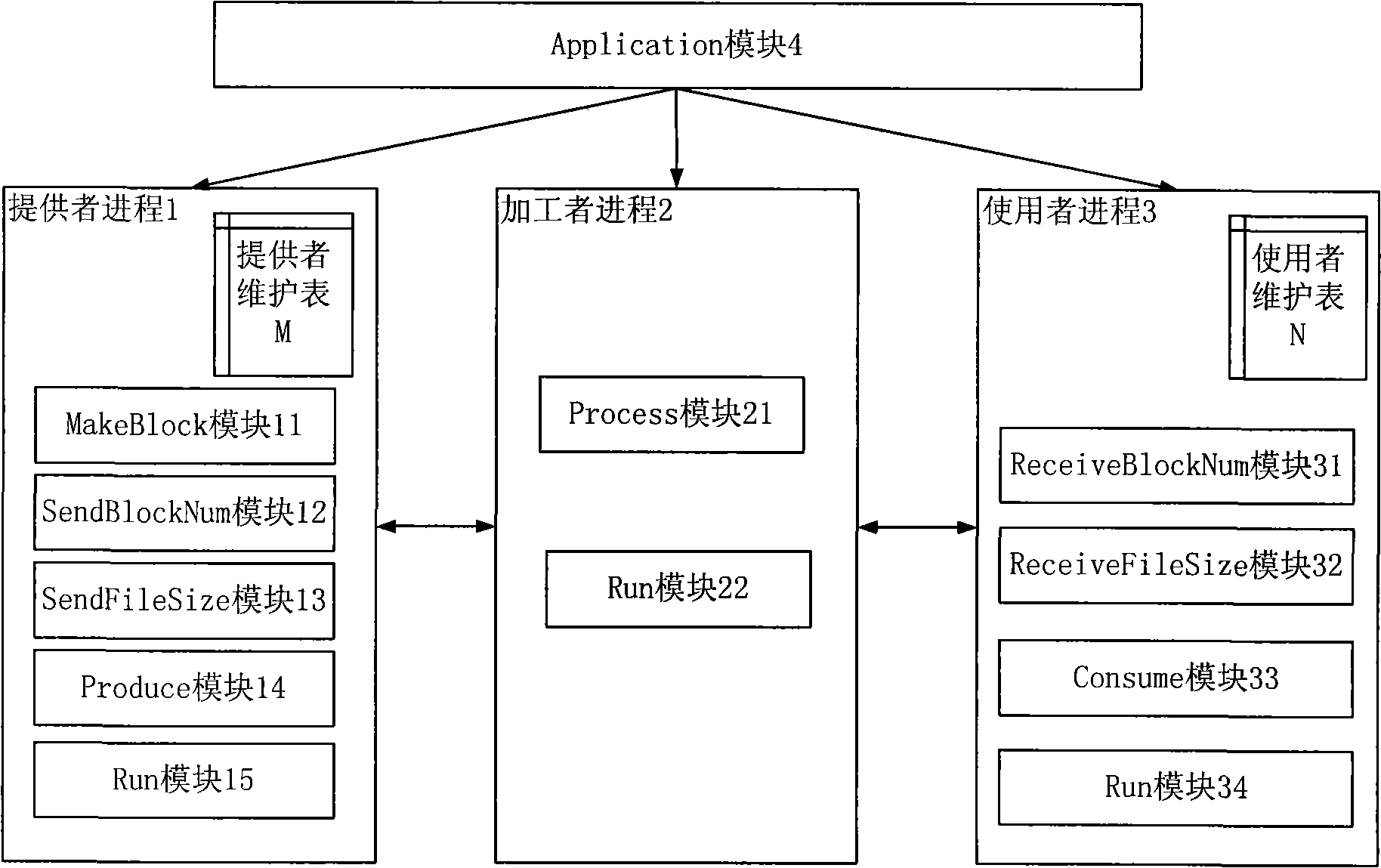

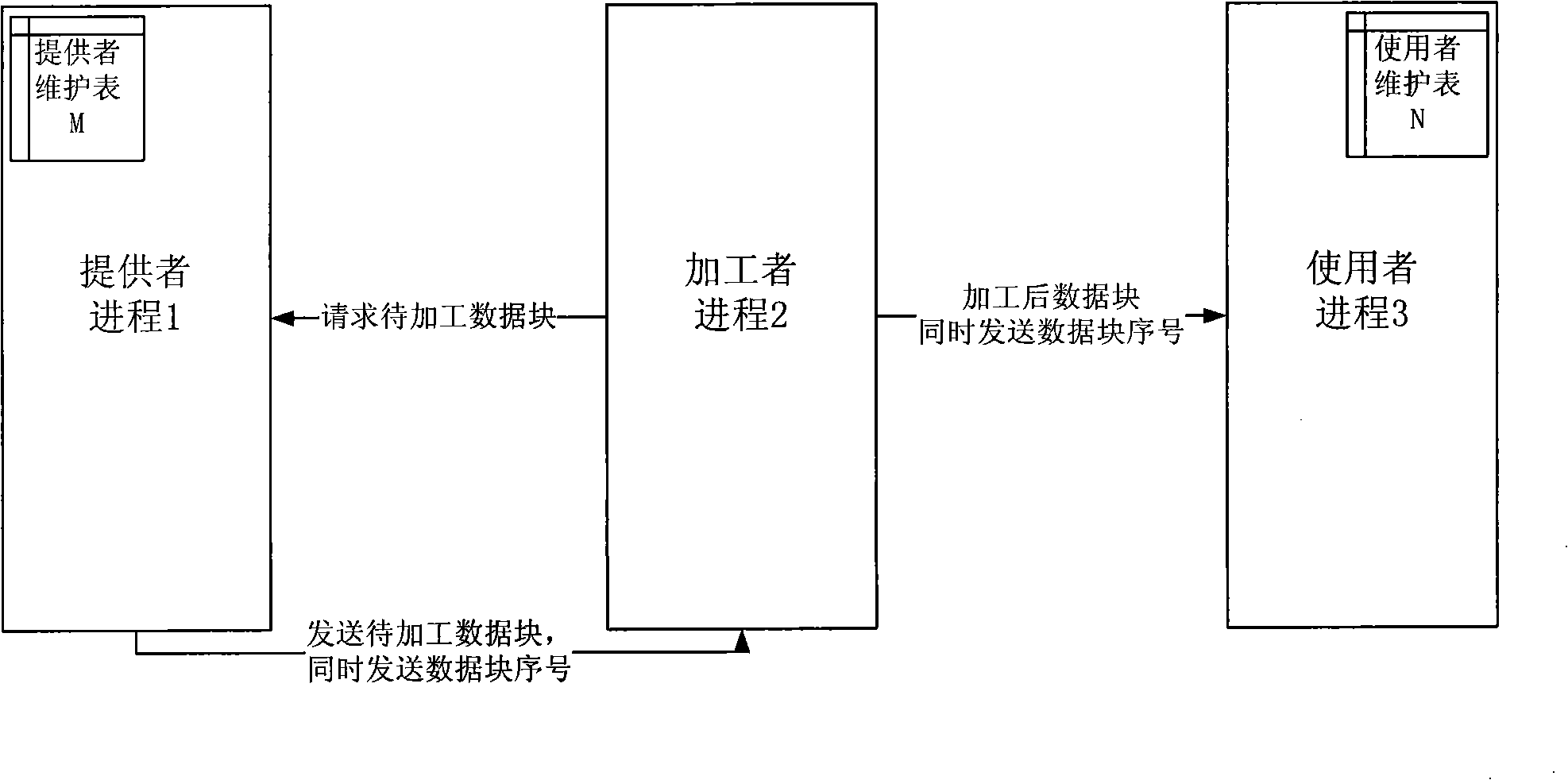

Method for processing compression program parallelization based on computer clusters

InactiveCN101556546AMaintain different characteristicsGuaranteed efficiencyInterprogram communicationComputer clusterComputer based

The invention relates to a method for processing compression program parallelization based on computer clusters. The method is characterized by comprising a provider-processor-producer frame, wherein the provider-processor-producer frame comprises a provider process, a processor process and a producer process; the provider process divides data to be processed into a plurality of fixed-length data blocks to be sent and then sends the data blocks to be sent to the processor process; idle processer process is gradually stopped after the data blocks to be sent are completely sent out; the processor process requests data blocks to be sent from the provider process and sends processed data blocks to a user process; after receiving the processed data blocks sent by the processor process, the user process outputs the processed data blocks sequentially; the processor comprises a plurality of serial compression algorithms and executes the serial compression algorithms in parallelization manner; and when the data blocks to be sent and the processed data blocks are transferred among the provider process, the processor process and the user process, unique data block serial numbers are respectively attached to the data blocks to be sent and the processed data blocks.

Owner:BEIJING UNION UNIVERSITY

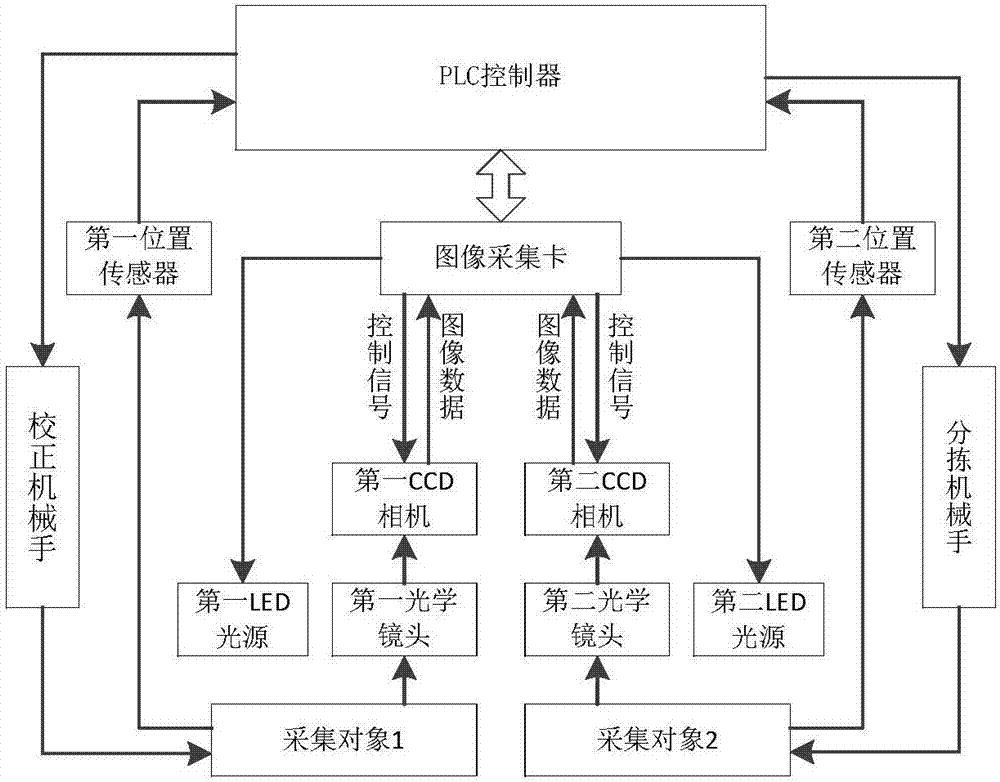

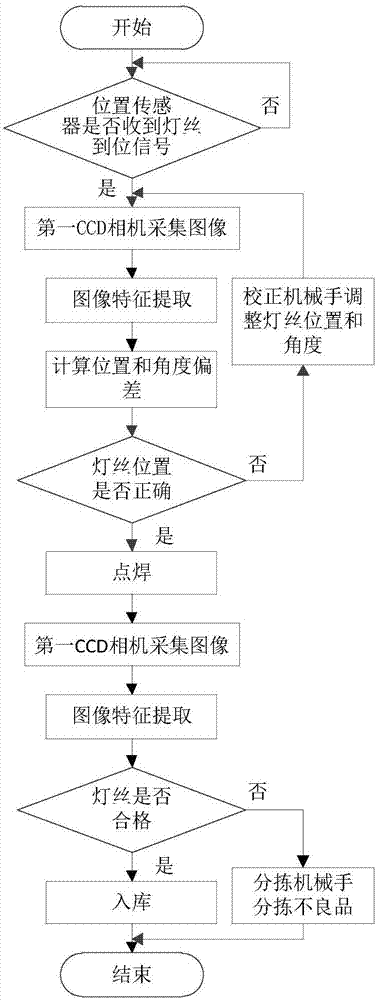

Visual detection system and detection method for LED lamp filament spot-welding correction

InactiveCN107167072ASorting speed is fastImprove accuracyUsing optical meansSortingCcd cameraSpot welding

The invention discloses a visual detection system and detection method for LED lamp filament spot-welding correction. The visual detection system comprises a PLC controller, an image acquisition card, two position sensors, a calibration manipulator, a sorting manipulator, two LED light sources, two optical lenses, and two CCD cameras. The CCD cameras, the LED light sources, and the optical lenses form a visual acquisition system to carry out image acquisition on products during a welding process and a sorting process; the collected image data are processed at the image acquisition card. The position sensors are installed in LED filament spot welding and sorting positions and are responsible for collecting position information of LED filaments and transmitting the information to the PLC controller. The PLC controller and the image acquisition card are connected by an RS232 bus; after obtaining of a processing result from the image acquisition card, the calibration manipulator and the sorting manipulator carry out corresponding operations, thereby completing precise welding and rapid sorting of the LED lamp filaments.

Owner:SOUTH CHINA UNIV OF TECH

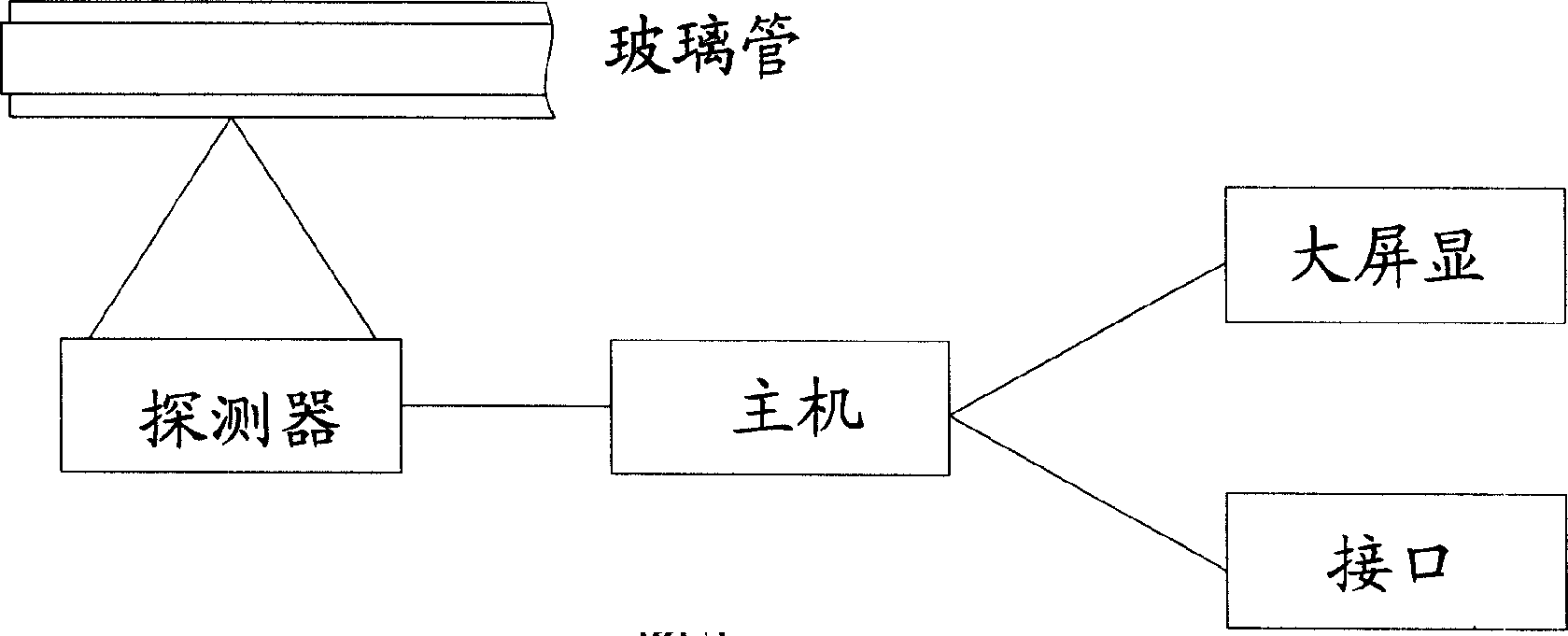

Instrument for detecting wall thickness of glass tube

InactiveCN1755320ASorting speed is fastSpecification qualityUsing optical meansOutput deviceCharge couple device

The invention discloses a glass pipe thickness detector which comprises a probe, a host machine, an output device and an interface, wherein the probe comprises a catalytic combustion detector and a semiconductor laser. It uses double light beam measurement; the driving circuit of the catalytic combustion detector includes a oscillation circuit, a frequency divider and a converter.

Owner:宋才秀 +1

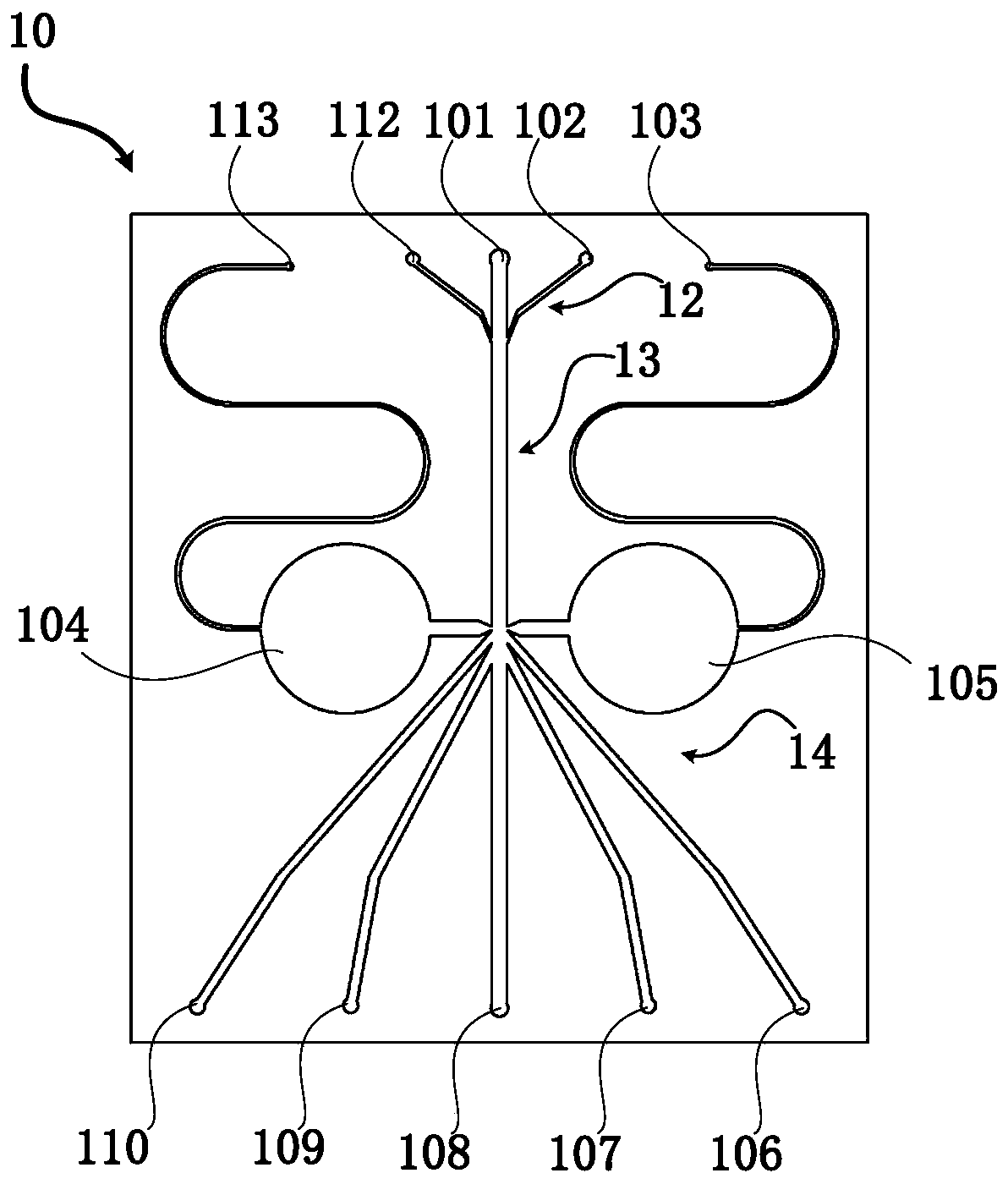

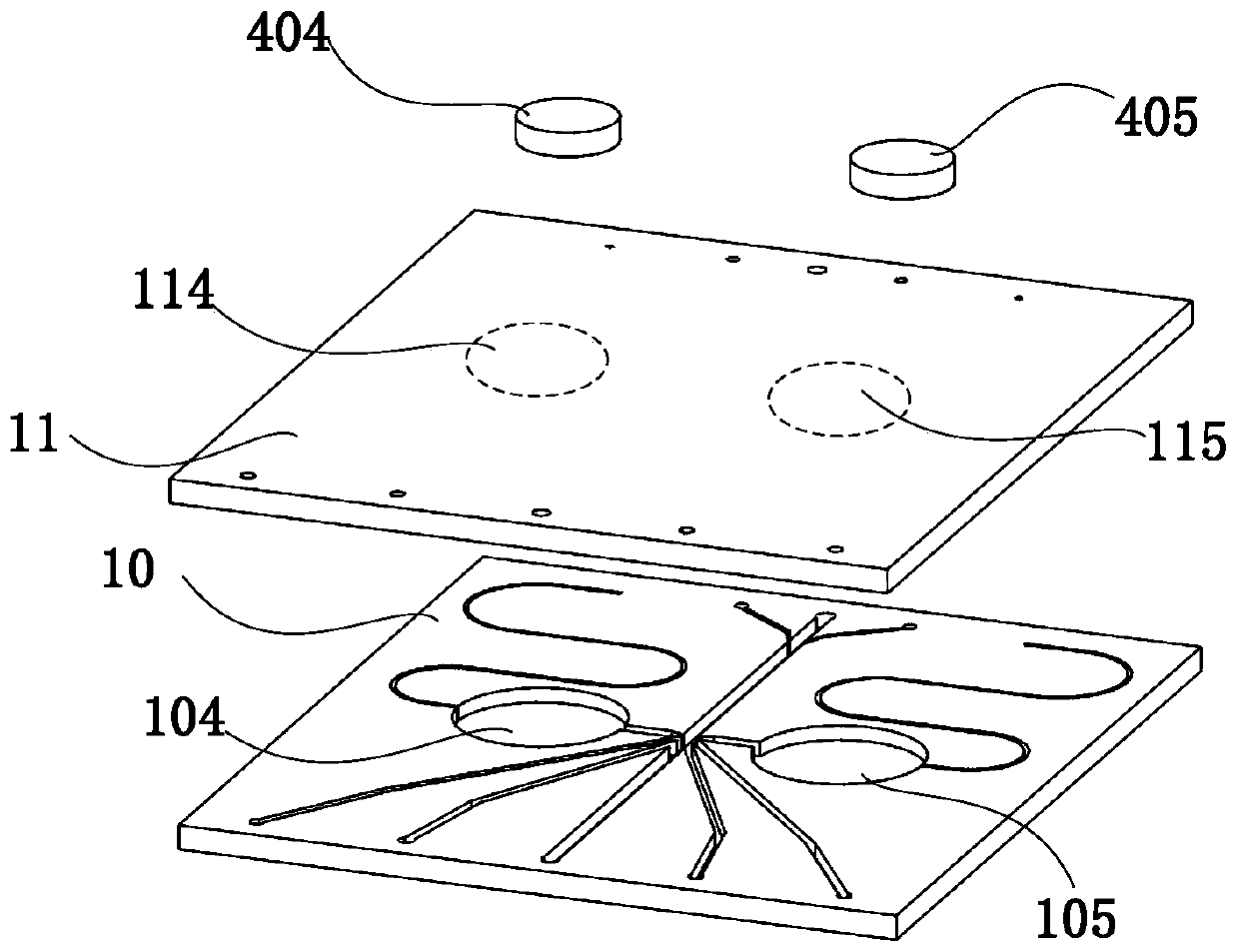

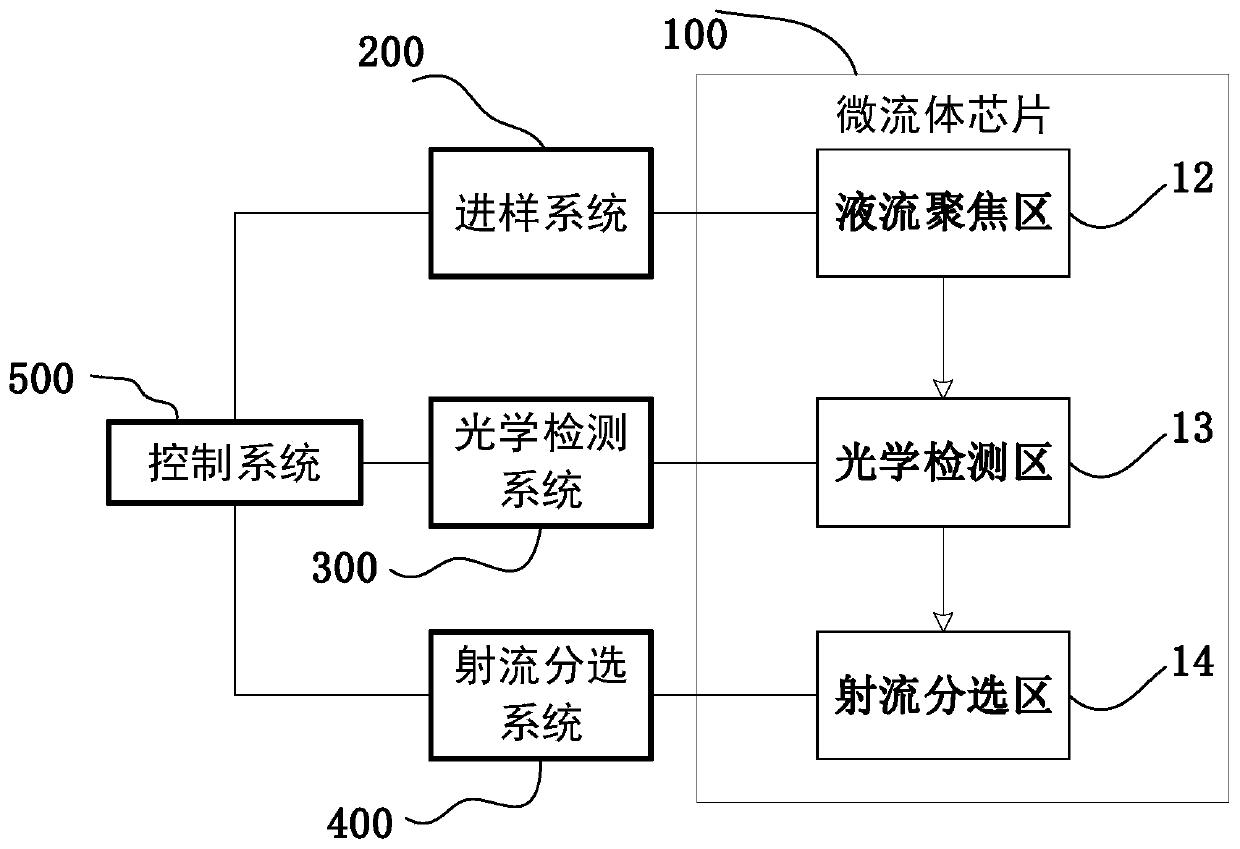

Microfluidic chip and microfluidic cell sorting system

PendingCN110793905ASimple processEasy to processLaboratory glasswaresIndividual particle analysisCell activityControl system

The invention relates to a microfluidic chip and a microfluidic cell sorting system. A cell sample sequentially passes through a liquid flow gathering area, an optical detection area and a jet flow sorting area on the microfluidic chip, and then is sorted to obtain target cells; and the jet flow sorting area comprises at least one jet flow pool, at least one surface of the jet flow pool is of a membrane structure, the volume of the jet flow pool is changed by the change of the membrane structure, jet flow is generated, and the jet flow impacts the cells to enter different outlets. Meanwhile, the microfluidic cell sorting system provided by the invention comprises the microfluidic chip, a sample injection system, an optical detection system, a jet flow sorting system and a control system. The technology provided by the invention has small influence on cell activity, the microfluidic chip can be replaced, and cross contamination is not generated; and the microfluidic chip adopts a two-layer design, the processing is simple and cheap, the jet flow pool and the membrane structure are directly made of materials such as glass forming the microfluidic chip, and when the processing of themicrofluidic chip is completed, the jet flow sorting structure is completed, the membrane structure does not need to be additionally processed, and the process is simpler.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

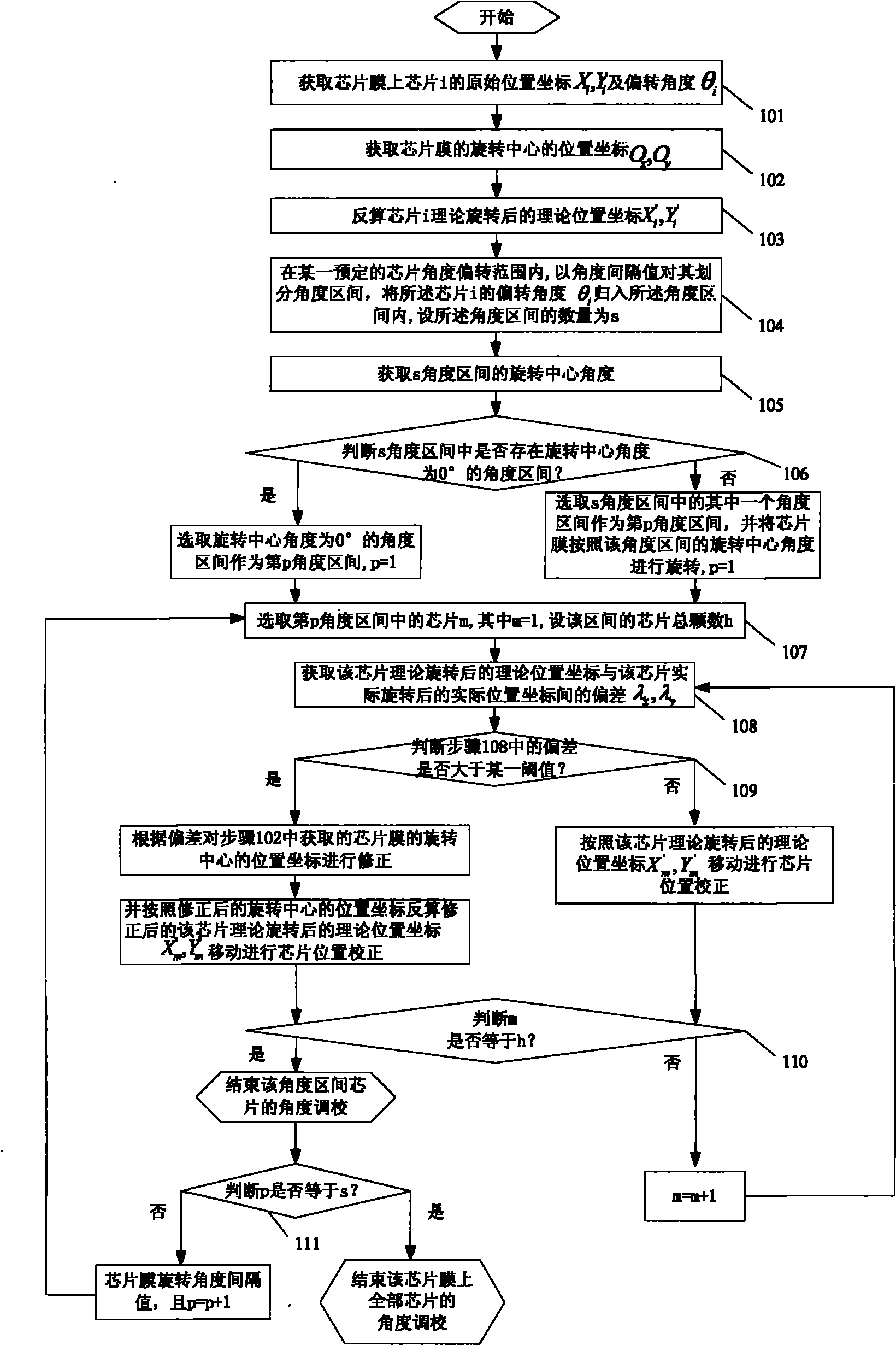

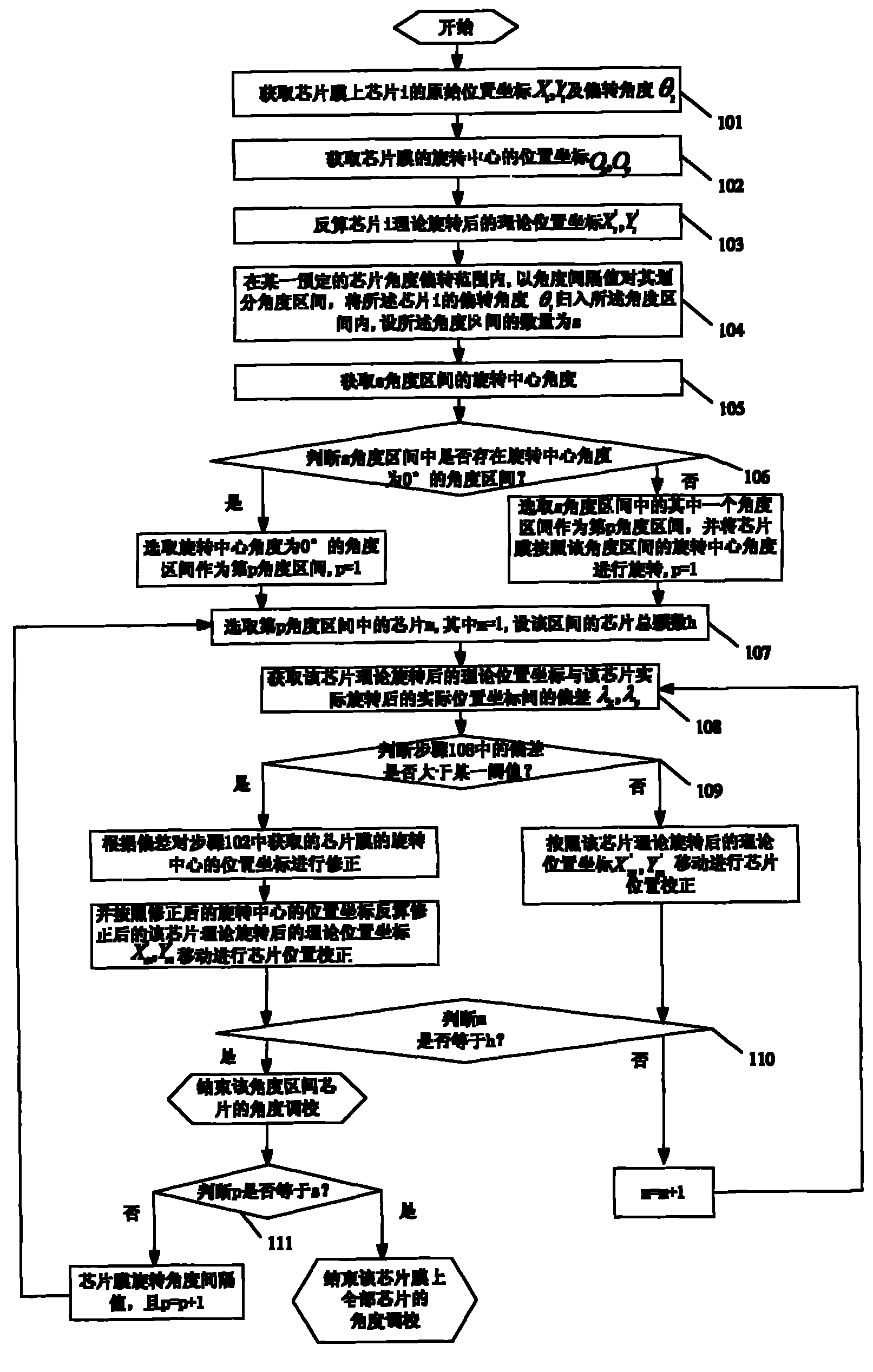

Method for fast tuning angle of LED chip

The invention relates to a method for fast tuning the angle of LED chip. The method mainly comprises: including the chip into an angle interval; obtaining a rotating pivot angle of the angle interval; selecting the p angle interval, and rotating the chip film according to the rotating pivot angle of the angle interval, wherein, p is equal to 1; positioning the chip m according to the theoretical position coordinates X'm and Y'm after theoretical rotation, and obtaining deviation Lambada x and Lambada y between X'm and Y'm and the actual position of the chip after actual rotation; judging whether Lambada x and Lambada y are larger than a certain threshold, if yes, amending Ox and Oy according to Lambada x and Lambada y and correcting the position of the chip; if no, correcting the position of the chip according to the theoretical position coordinates X'm and Y'm after theoretical rotation; judging whether the chip in the p angle interval is selected and finished, if yes, ending the angle tuning of the chip in the angle interval; proceeding to the angle tuning of the chip of the next angle interval. The invention can improve accuracy of chip angle tuning, effectively reduce the overall chip tuning times and enhance chip angle tuning efficiency, and increase chip sorting speed.

Owner:DG HUST MFG ENG RES INST +1

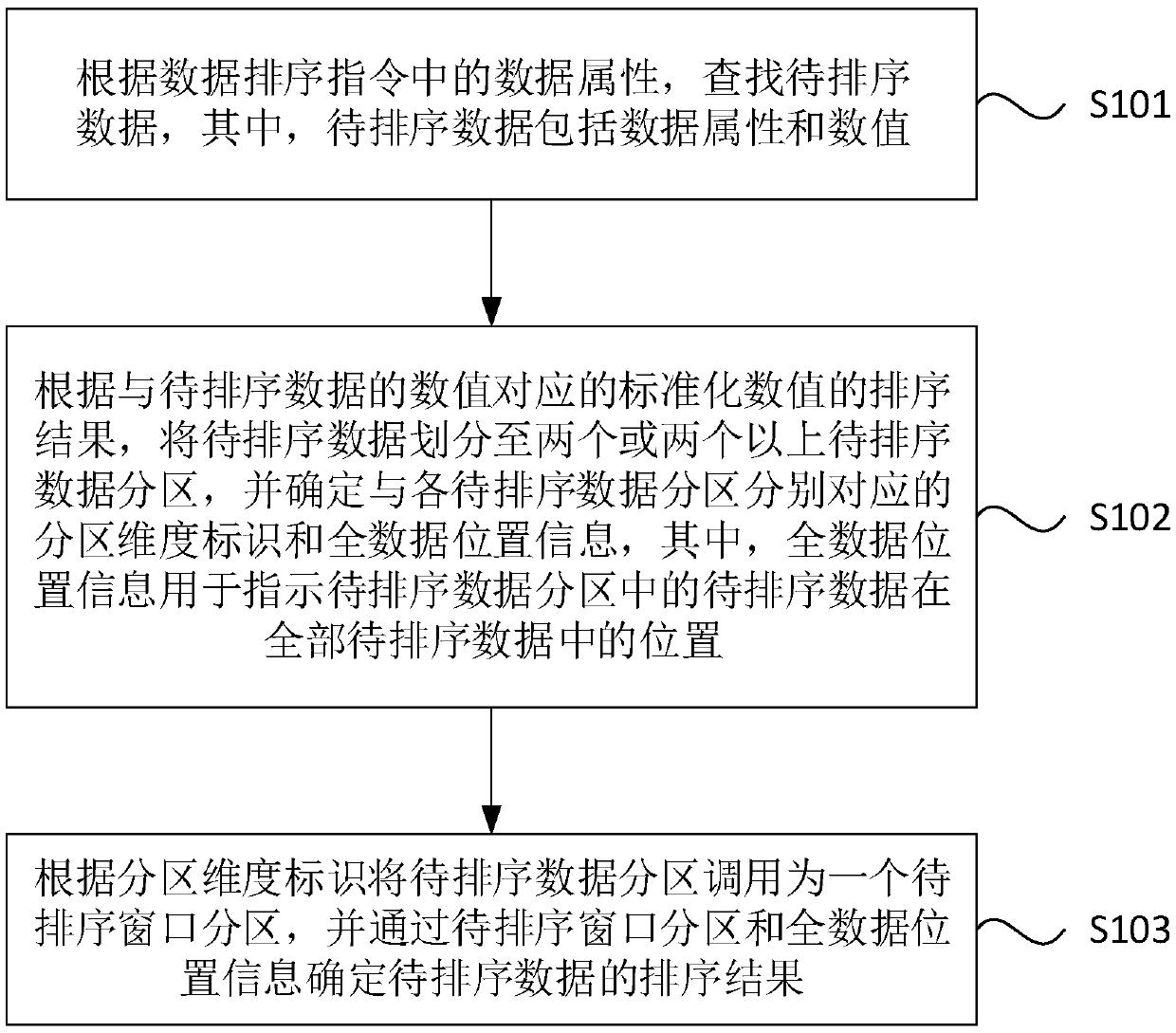

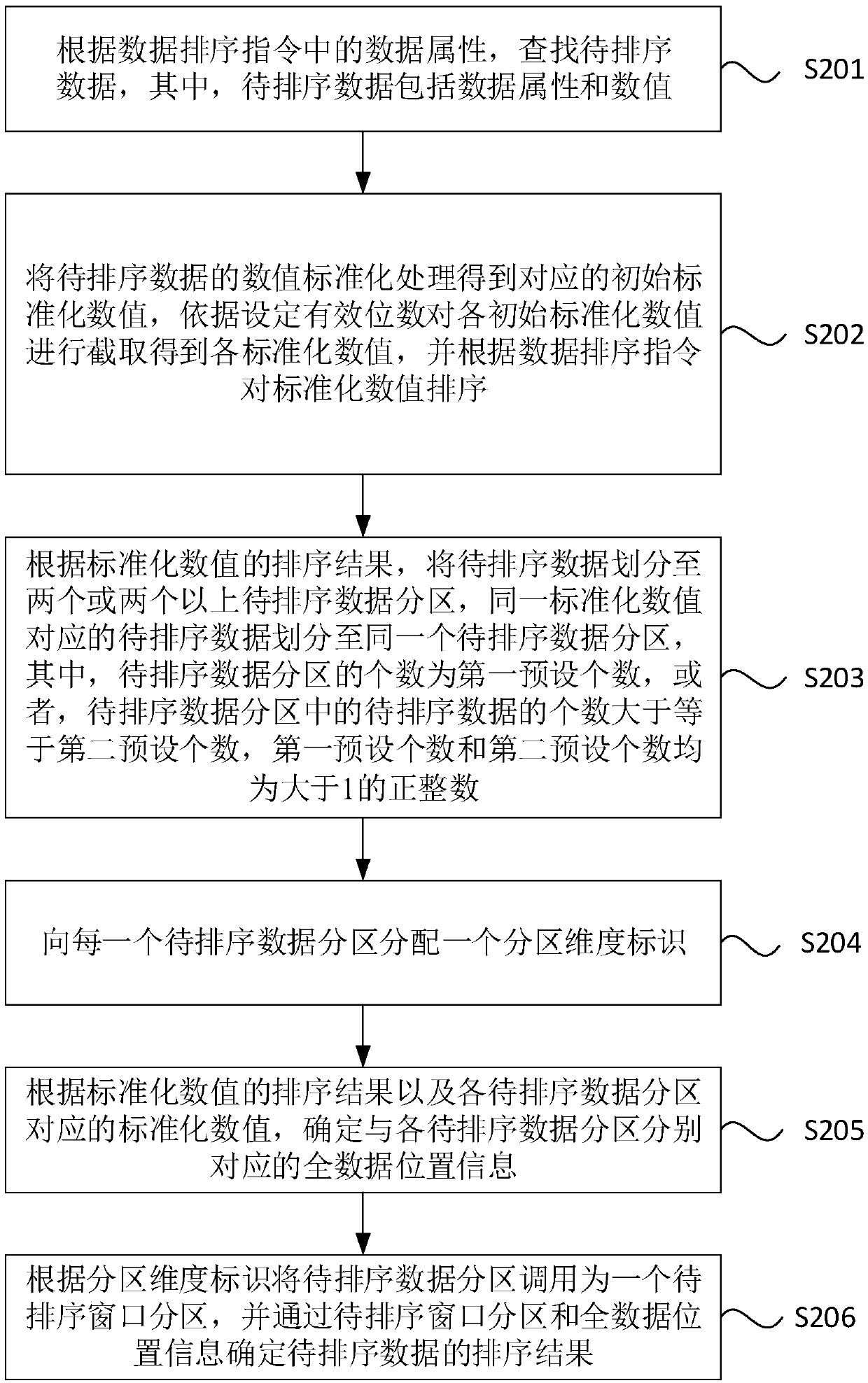

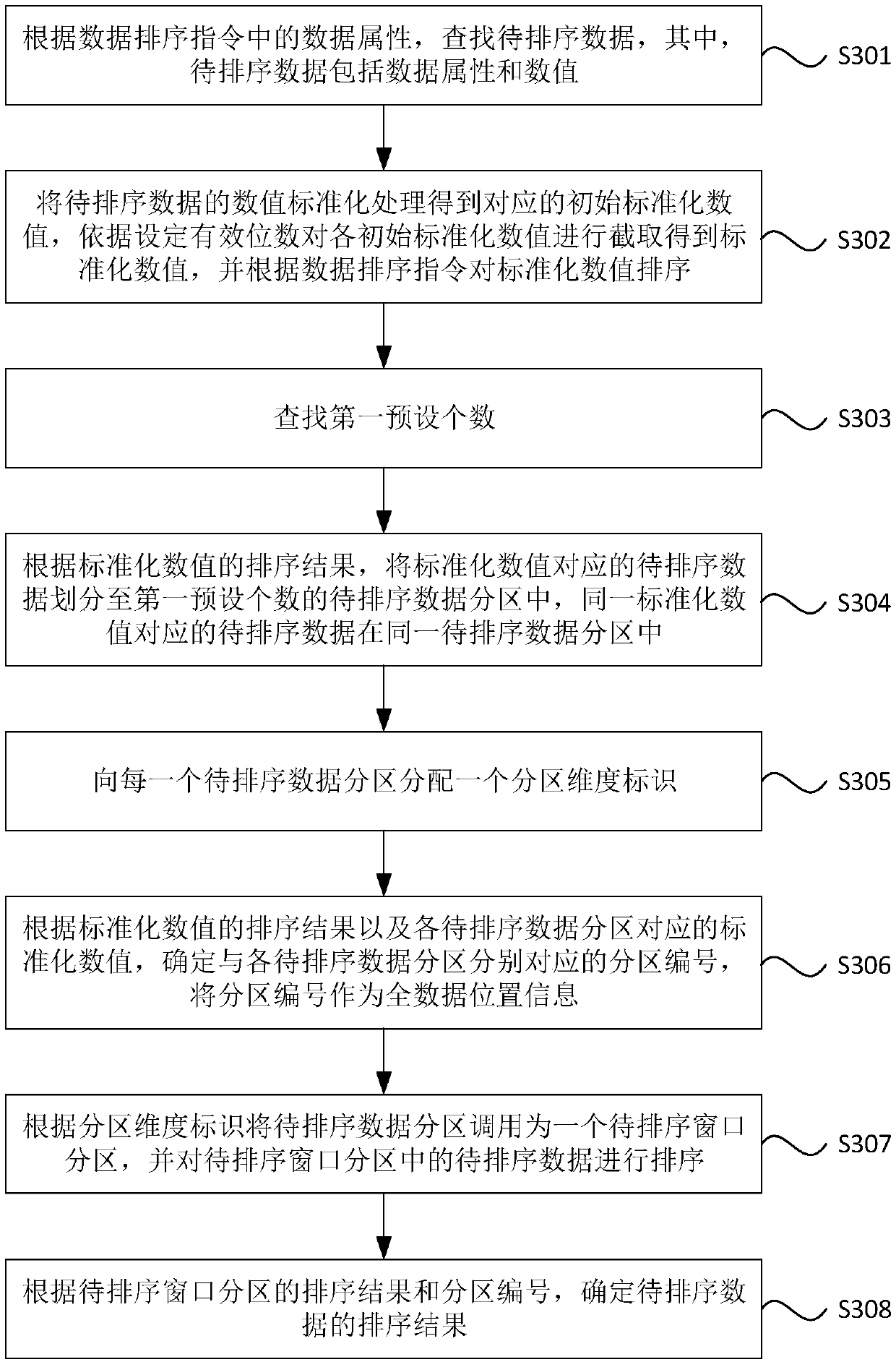

Data ranking method and device, server and storage medium

ActiveCN108733790ASorting speed is fastText processingSpecial data processing applicationsData warehouseData storing

The embodiment of the invention discloses a data ranking method and device, a server and a storage medium. The data ranking method comprises the following steps: finding data to be ranked according todata properties in a data ranking command, wherein the data to be ranked include data properties and values; partitioning the data to be ranked into two or more data partitions to be ranked accordingto a ranking result of standard values corresponding to the values of the data to be ranked, and determining partition dimension identifiers and total data position information corresponding to the data partitions to be ranked; and calling the data partitions to be ranked according to the partition dimension identifiers into one window partition to be ranked, and determining a sequencing result through the window partition to be ranked and the total data position information. According to the technical scheme in the embodiment of the invention, a plurality of window partitions make responsesto a ranking window function for a Hive data warehouse, and the ranking speed of data stored in the Hive data warehouse is increased.

Owner:GUANGZHOU HUYA INFORMATION TECH CO LTD

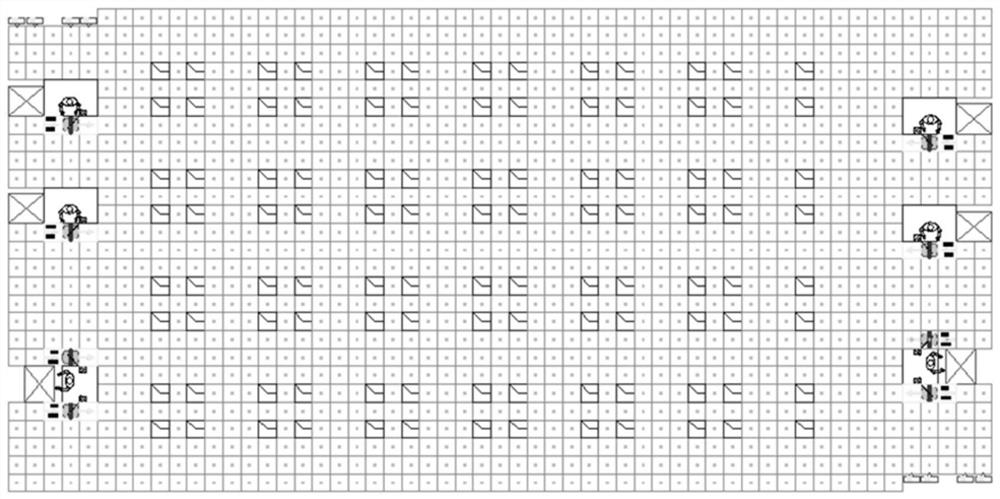

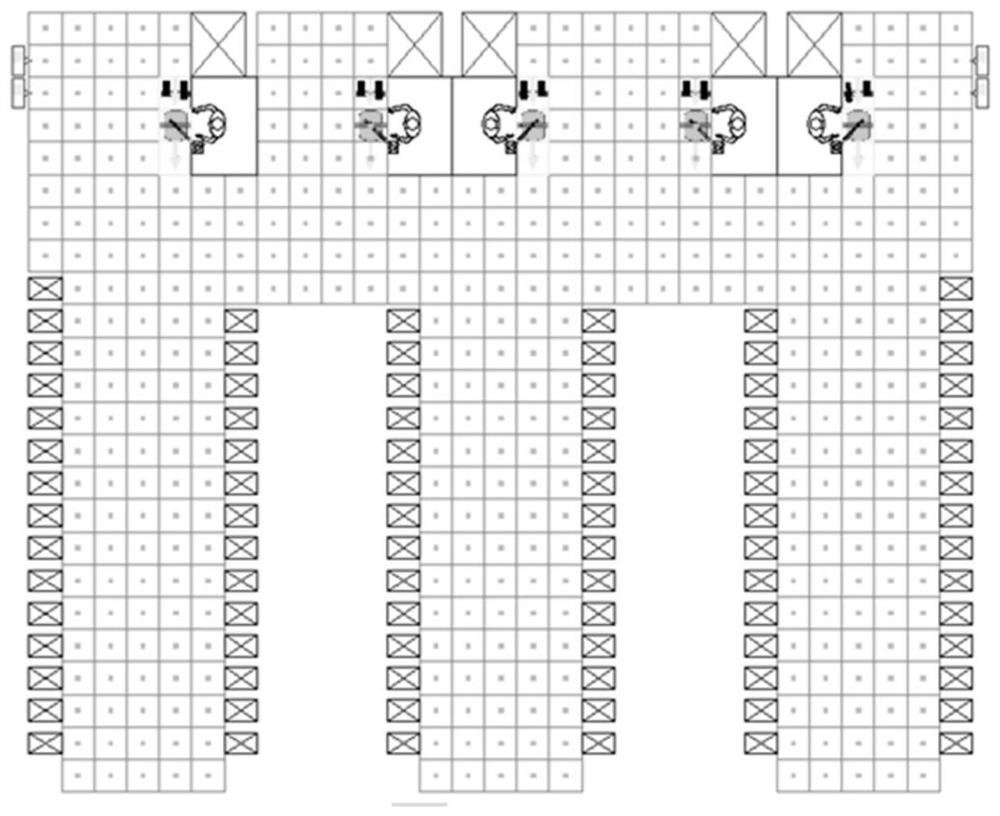

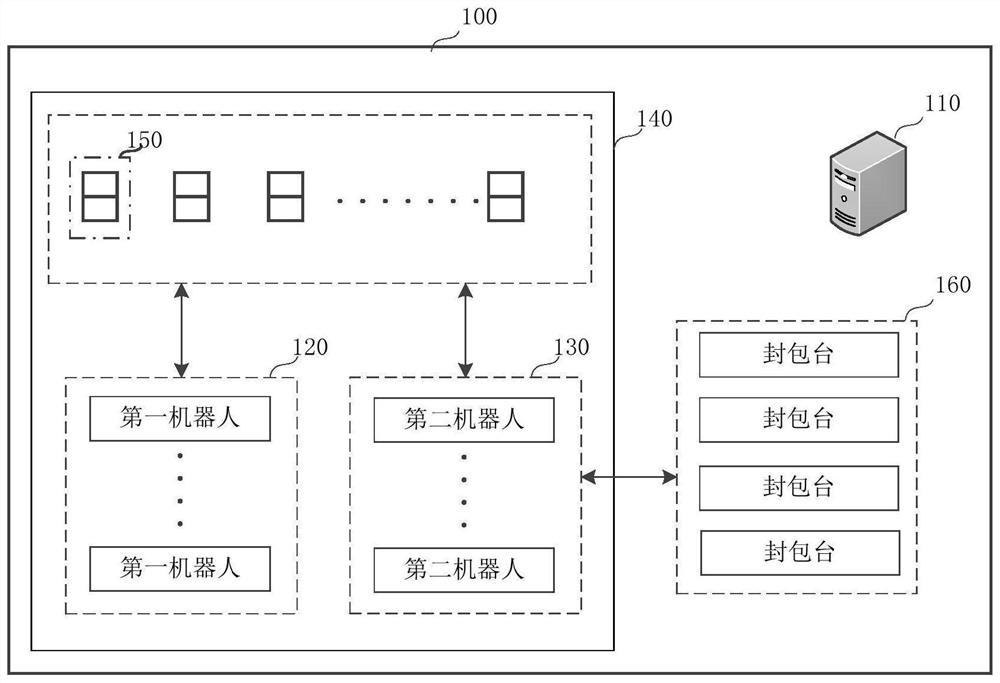

Article sorting system and method

ActiveCN112371518AAvoid the problem of reduced sorting efficiencySorting speed is fastControl devices for conveyorsSortingServerSystems engineering

The invention discloses an article sorting system and method. The system involves a control server, a first robot and a second robot; the first robot and the second robot operate in a storage area ofthe article sorting system; at least one cargo collection container is arranged in the storage area, and each cargo collection container comprises at least two sub-grids; the control server is configured to determine a target sub-grid from the at least two sub-grids of the at least one cargo collection container and send a sorting instruction to the first robot, and send a carrying instruction tothe second robot when the target sub-grid is the first sub-grid of the first cargo collection container and articles contained in the first sub-grid reach a first preset threshold value; the first robot is configured to respond to the sorting instruction and deliver the articles to the first sub-grid; and the second robot is configured to respond to the carrying instruction, travel to the positionof the first cargo collection container and carry the first cargo collection container to a packaging table specified by the carrying instruction. According to the system and method, the article sorting efficiency is improved.

Owner:BEIJING JIZHIJIA TECH CO LTD

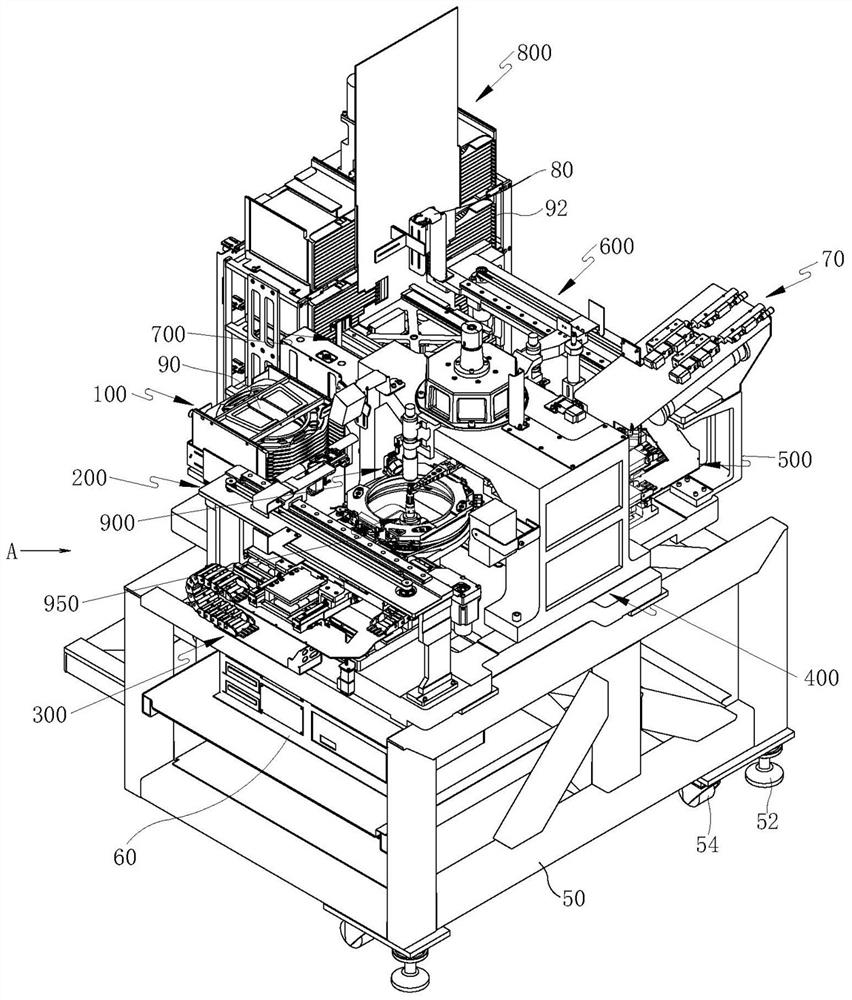

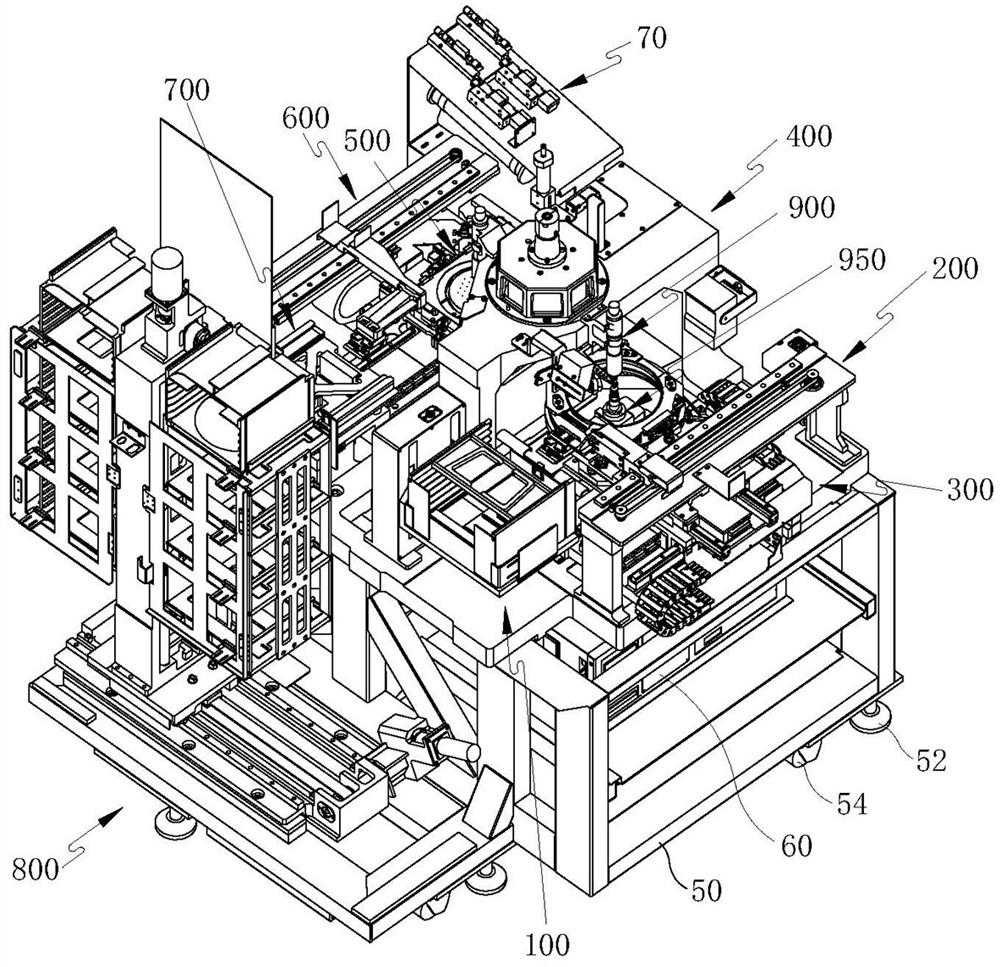

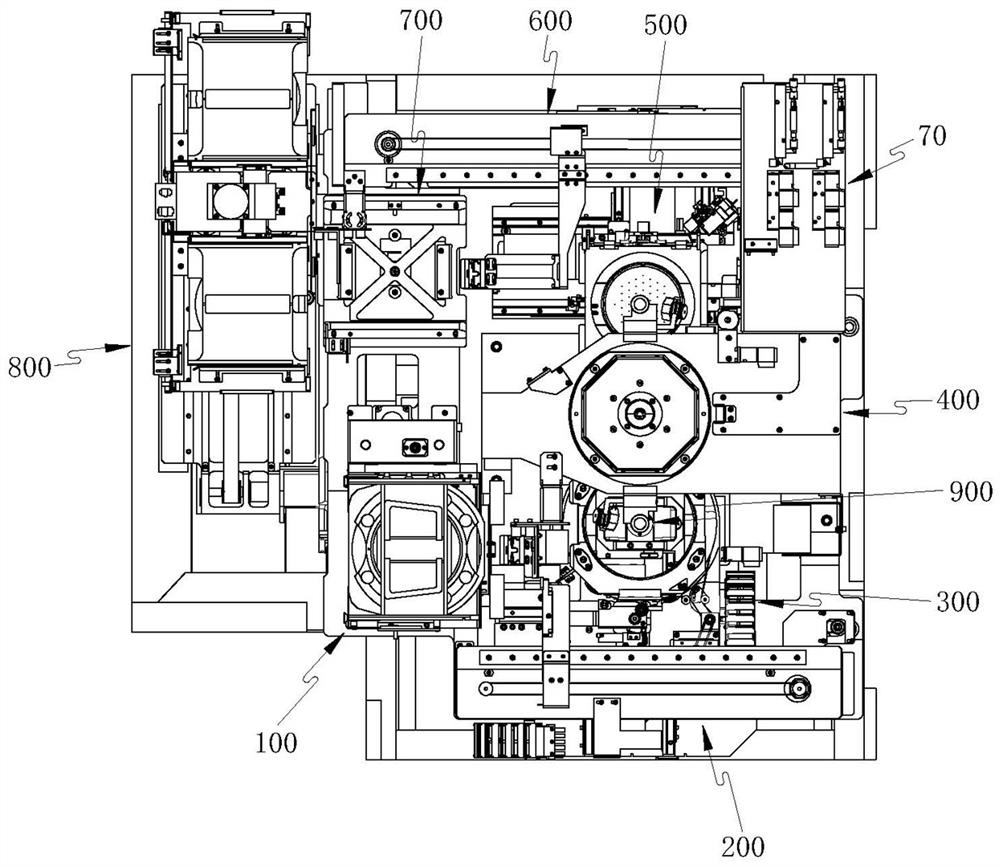

LED and semiconductor laser chip sorting machine control method and sorting machine

The invention discloses an LED and semiconductor laser chip sorting machine control method and a sorting machine, and relates to the technical field of mechanical equipment control. The method comprises the steps that a silicon wafer lifting table moves, and a silicon wafer to be grabbed is conveyed to a silicon wafer mechanical arm grabbing position; the silicon wafer manipulator grabs the silicon wafer and places the silicon wafer on a silicon wafer workbench; the material sheet lifting bin moves to convey the material sheets to be grabbed to a material sheet manipulator grabbing position; the material sheet manipulator is used for grabbing the material sheet and placing the material sheet on the placing workbench; and the chip is sucked up by a suction nozzle of the suction and release device through recognition of a CCD camera, the suction nozzle of the suction and release device swings to a placement position to place the chip on the material sheet, meanwhile, the other suction nozzle swings to the suction position to suck the next chip, and the process is repeated until the chips of the same grade on the silicon wafer are all placed on the material sheet.

Owner:山东泓瑞光电科技有限公司

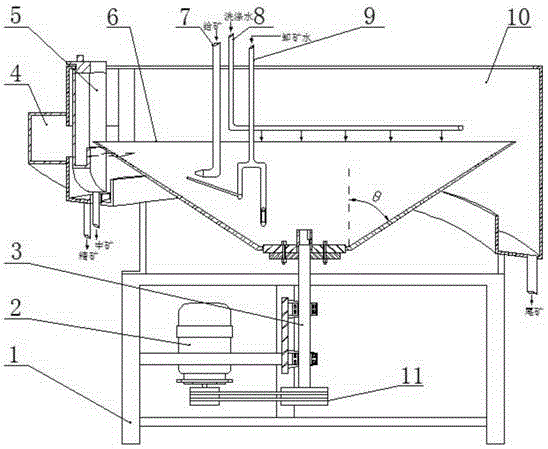

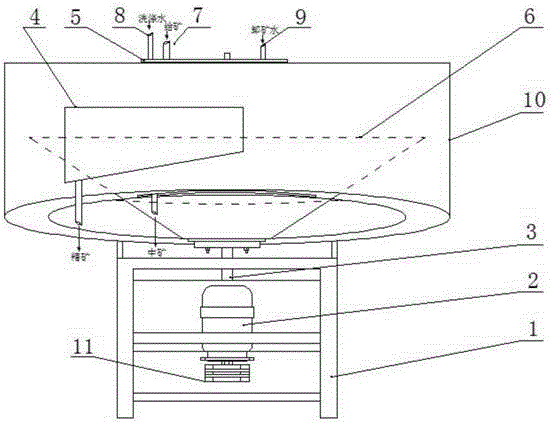

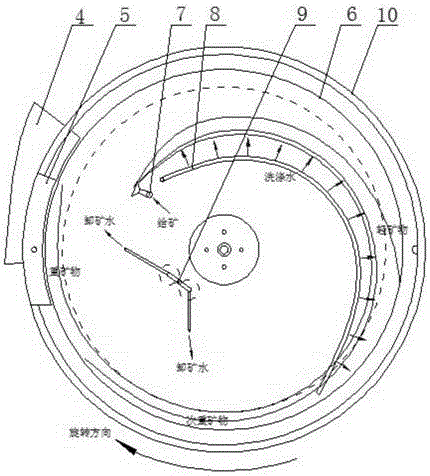

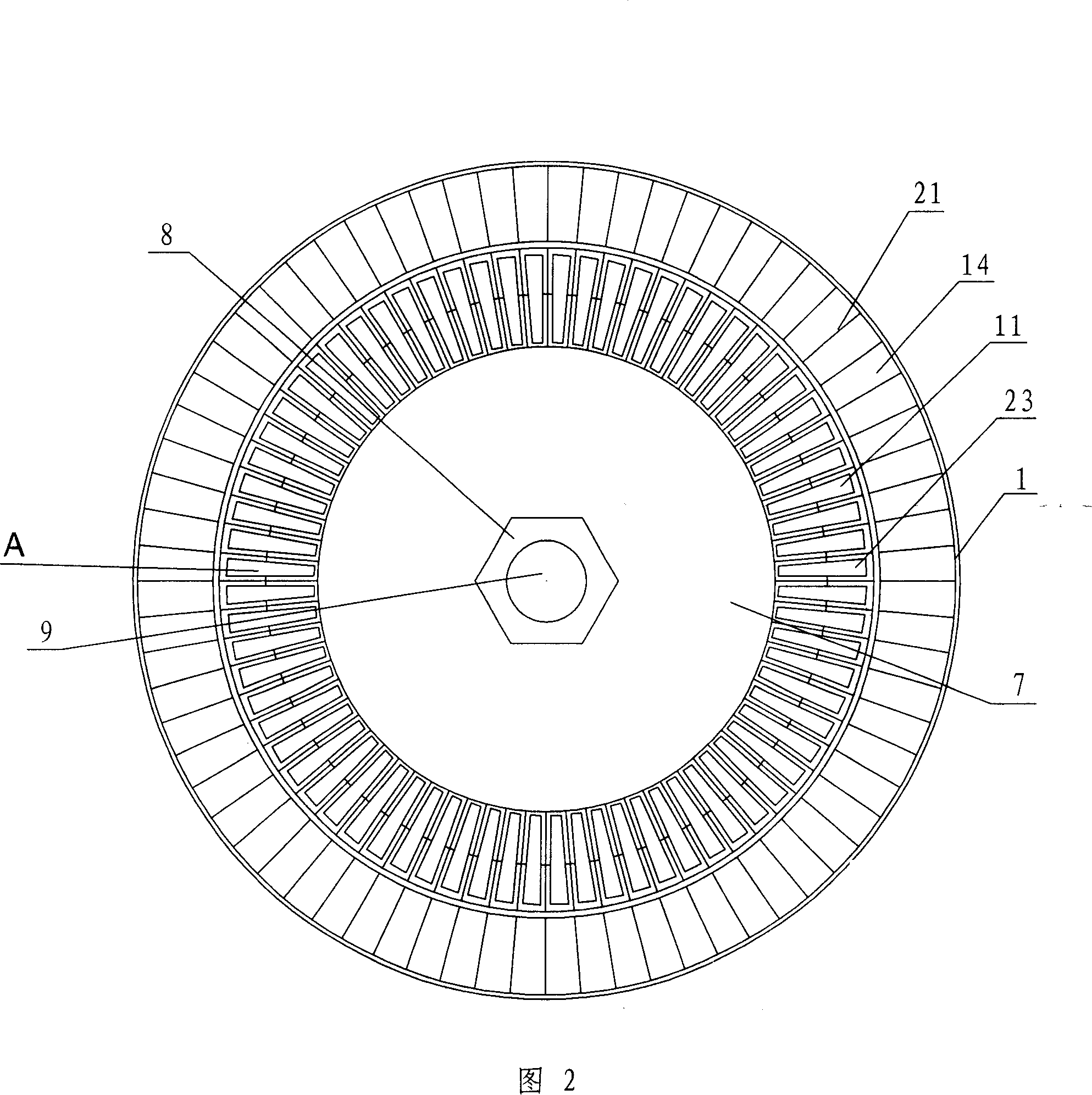

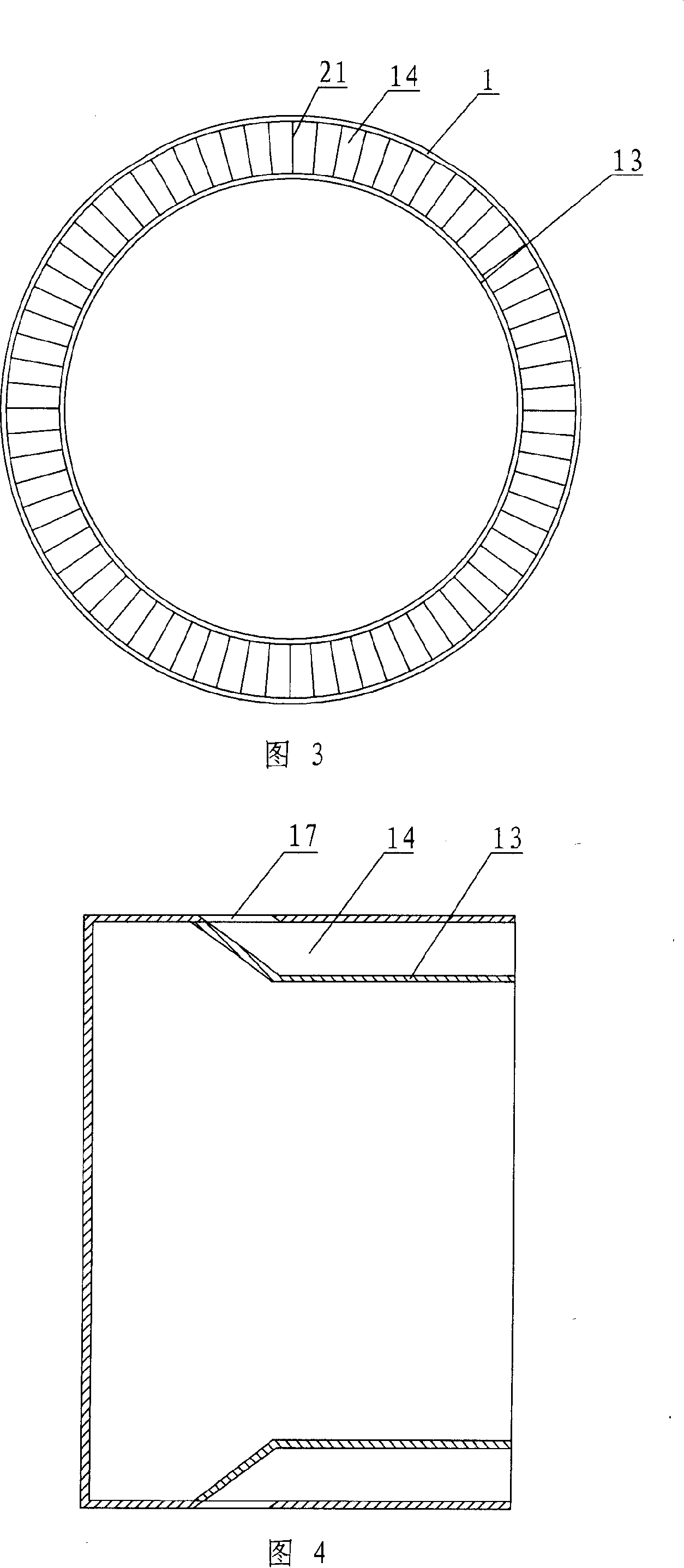

KGS concentrating machine

The invention belongs to the technical field of fine-grain mineral separation equipment, and discloses a KGS concentrating machine. The KGS concentrating machine comprises a frame, a motor, a turntable main shaft, a concentrate tank, a middling cutter, a separation turntable, a feeding device, a washing water pipe, an unloading water pipe, a tailing cover and a belt wheel; the motor is arranged on one side of the frame; the turntable main shaft and the belt wheel arranged at the bottom of the turntable main shaft are arranged on the other side of the frame; the belt wheel is connected with the motor through a belt; the separation turntable is arranged at the top of the turntable main shaft, and is connected with the turntable main shaft; the tailing cover is arranged at the top of the frame; the separation turntable is arranged in the tailing cover; and the bottom of the tailing cover is set as a certain inclination, and the lowest point is connected with a tailing discharge port. The KGS concentrating machine designs a sorting machine with reasonable structure and capable of controlling the concentrate quality through adjusting the middling yield according to the motion trail pitch difference of light and heavy minerals in a composite force field and a centrifugal flowing film beneficiation principle.

Owner:杨波

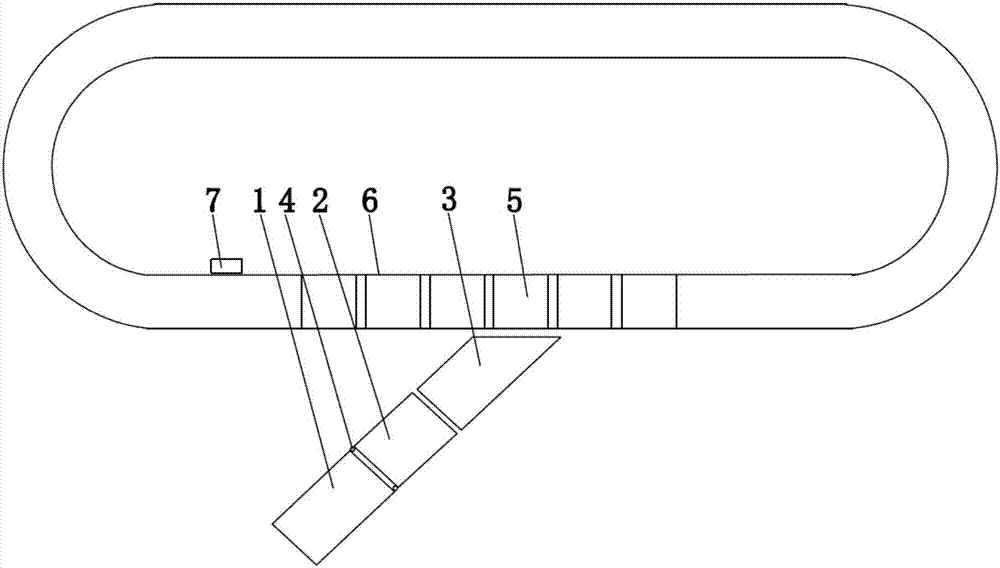

Parcel feeding method for halved belt loop line sorting system

The invention discloses a parcel feeding method for a halved belt loop line sorting system. The method includes the following steps that S1, a parcel is put into a conveying line moving forwards at a first speed; S2, after position coordinates of the parcel are obtained through a light curtain, the parcel enters a first adjusting line moving at the first speed; S3, a control system acquires the position coordinates of the parcel, books a sorting trolley and waits for synchronizing signals of a sorting trolley loop line; S4, after the control system receives the synchronizing signals, a first speed governing time point for adjusting the first adjusting line to be at a second speed and a second speed governing time point for adjusting a second adjusting line to be at a third speed are calculated; S5, the first adjusting line conveys the parcel to the second adjusting line moving at the second speed according to the adjusting parameters in the step S4; and S6, the second adjusting line conveys the parcel onto the booked sorting trolley according to the adjusting parameters in the step S4. By the adoption of the parcel feeding method, there is no need to stop all the sections in the whole parcel feeding process, and therefore time consumption caused by stopping can be avoided, the sorting speed can be better increased, and the sorting efficiency can be better improved.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

Bearing channel automatic sorting machine

The automatic bearing channel separating machine for separating bearings based on the sizes of the inner and outer channels during assembling bearings consists of one frame with separating slipway, fixed crossbeam and lower support, one central shaft passing through the lower support and fixed on the crossbeam, one driving mechanism fixed onto the lower support, one rotary conveying mechanism set on the central shaft, and one platform fixed on the top of the central shaft. The automatic bearing channel separating machine is for separating bearings based on the sizes of the inner and outer channels during assembling bearings.

Owner:HEILONGJIANG UNIV

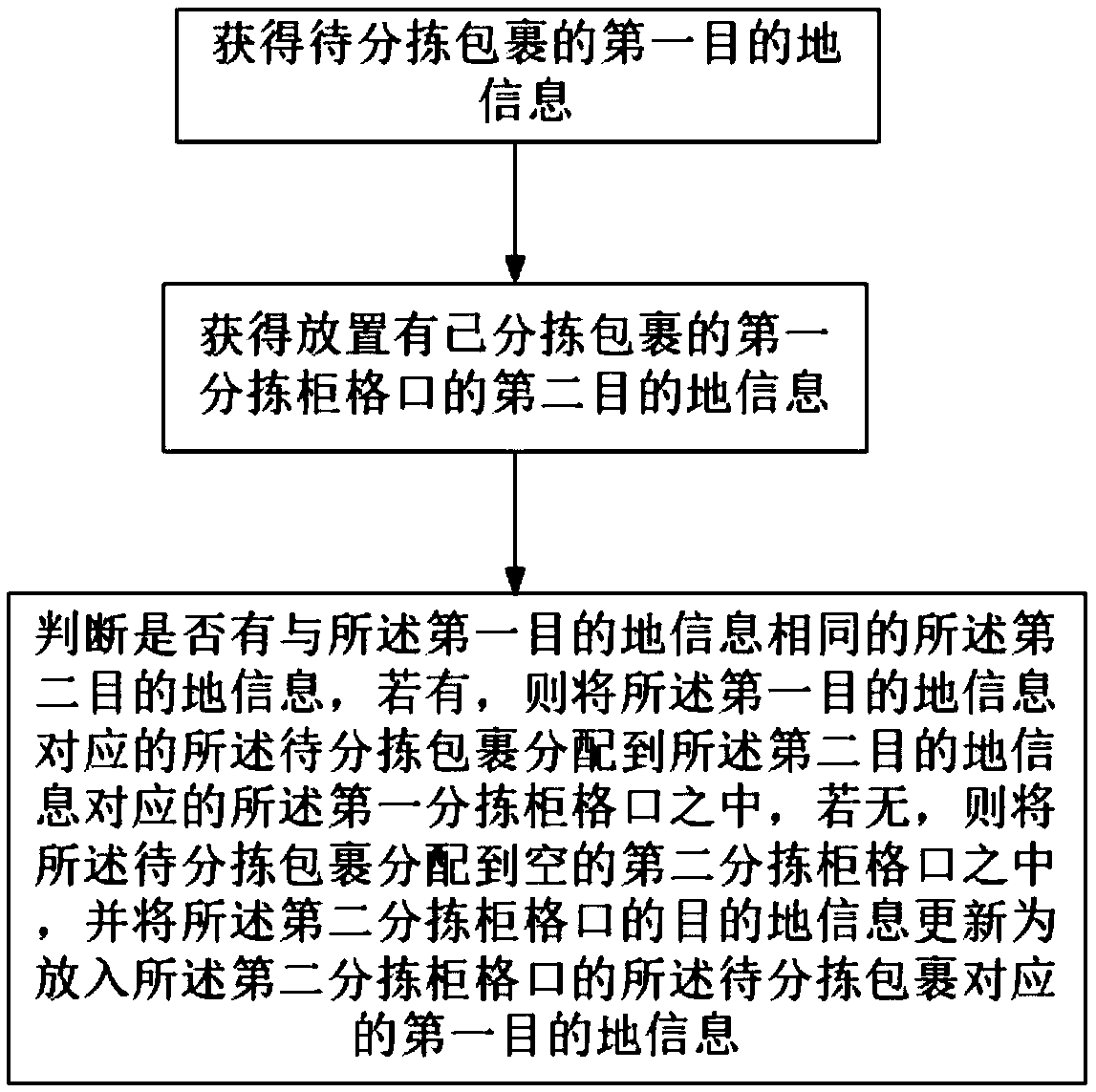

Sorting method and sorting system

The invention discloses a sorting method and a sorting system. The sorting method comprises the following steps of obtaining first destination information of a to-be-sorted parcel; obtaining second destination information of a first sorting cabinet grid containing a sorted parcel; judging whether second destination information is the same as the first destination information, and if yes, putting the to-be-sorted parcel with the corresponding first destination information into the first sorting cabinet grid with the corresponding second destination information; and if not, putting the to-be-sorted parcel into an empty second sorting cabinet grid, and updating the destination of the second sorting cabinet grid to the corresponding first destination information of the to-be-sorted parcel in the second sorting cabinet grid. According to the method, sorting efficiency and sorting speed are improved, and manpower investment of sorting and wrapping is reduced.

Owner:SF TECH

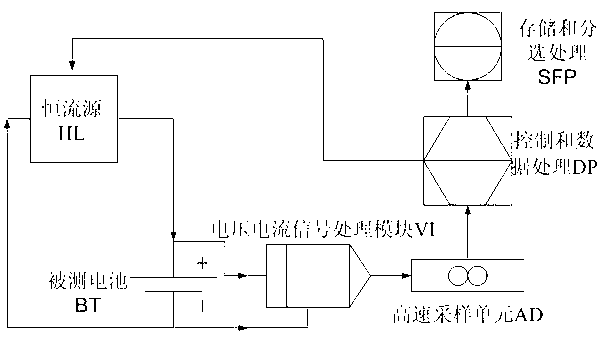

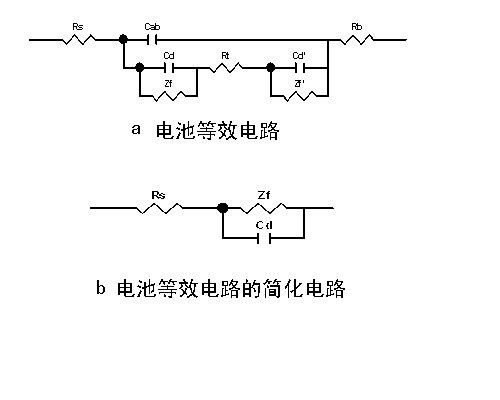

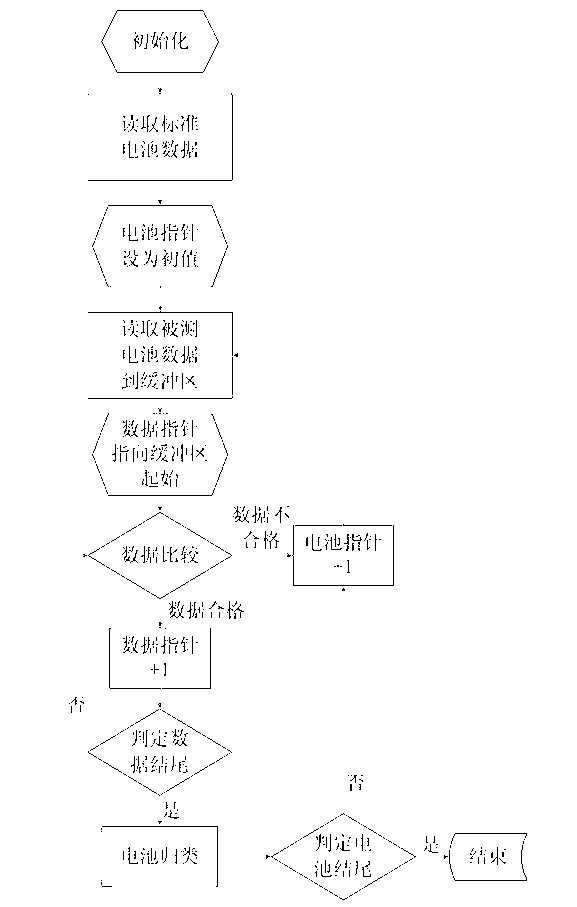

Separation device making use of battery impedance spectrum

InactiveCN103128059ASorting speed is fastAccelerateSortingConstant current sourceComputational physics

The invention relates to a separation device making use of battery impedance spectrum, provides a process simplifying battery impedance spectrum measurement and further provides a battery separation method according to the battery impedance spectrum. Batteries to be measured are connected to a circuit through a special four-wire clamp, control and data processing (DP) first controls a high speed sampling unit analogue digital (AD) to start high speed sampling, then constant flow source horizontal line (HL) current is controlled to charge the batteries (British telecom) BT to be measured, and after being conditioned through a voltage current processing module VI, the voltage and current signals of the batteries BT to be measured are processed in a digital mode through the high speed sampling AD and are obtained by the control and data processing DP. After the measurement is completed, the control and data processing DP closes the output of the constant flow source HL, then the high speed sampling AD is stopped, then the obtained voltage and current data are uploaded to storage and separation system file protection (SFP), the same batteries are organized in a category by the storage and separation SFP according to separation conditions set by a user, and thereby the battery separation is completed.

Owner:HARBIN ZHIMU TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com