KGS concentrating machine

A mineral concentrator and sorting technology, which is applied in the direction of solid separation, chemical instruments and methods, wet separation, etc., can solve the problems of difficult recycling of fine-grained minerals, inability to obtain wide application, and difficulty in realizing large-scale equipment, etc., to achieve Convenience of concentrate grade, shortening of ore discharge distance, and convenient maintenance and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

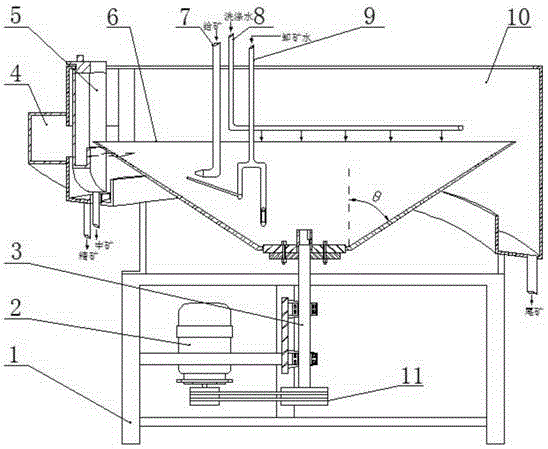

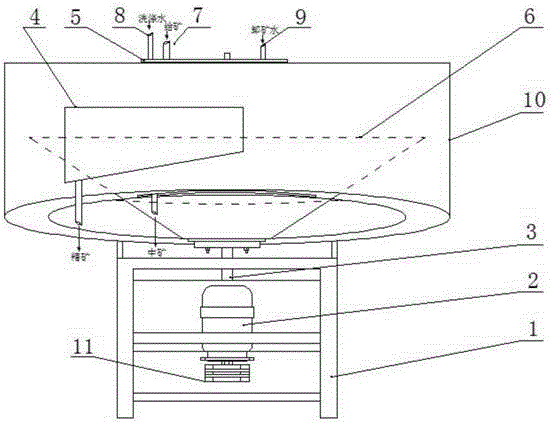

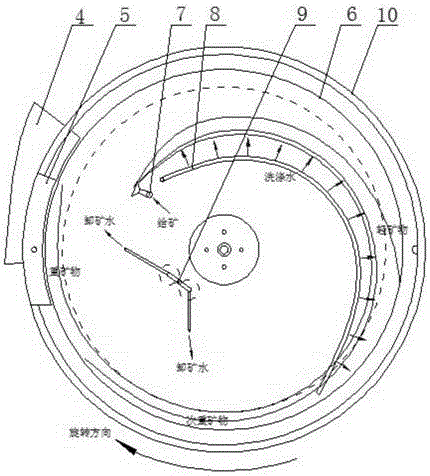

[0019] Example: see Figure 1-4 , a KGS concentrator of the present invention, comprising a frame 1, a motor 2, a turntable spindle 3, a concentrate tank 4, a medium ore cutter 5, a sorting turntable 6, an ore feeding device 7, a washing water pipe 8, and an ore unloading water pipe 9 , tailings cover 10 and belt pulley 11, described frame 1 side is provided with motor 2, described frame 1 other side is provided with turntable main shaft 3 and the pulley 11 that is arranged on the bottom of turntable main shaft 3, described belt pulley 11 and The motor 2 is connected by a belt, the top of the turntable main shaft 3 is provided with a sorting turntable 6, and the sorting turntable 6 is connected with the turntable main shaft 3, and the top of the frame 1 is provided with a tailings cover 10. The sorting turntable 6 is set inside the tailings cover 10, the bottom of the tailings cover 10 is provided with a certain inclination, and the lowest point is connected with a tailings di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com