LED and semiconductor laser chip sorting machine control method and sorting machine

A control method and semiconductor technology, which is applied in the field of mechanical equipment control, can solve the problems of restricting the development of LED and semiconductor laser chip industries, poor sorting accuracy, and slow sorting speed, so as to improve the technical level and mass production capacity. The effect of small area and improved sorting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

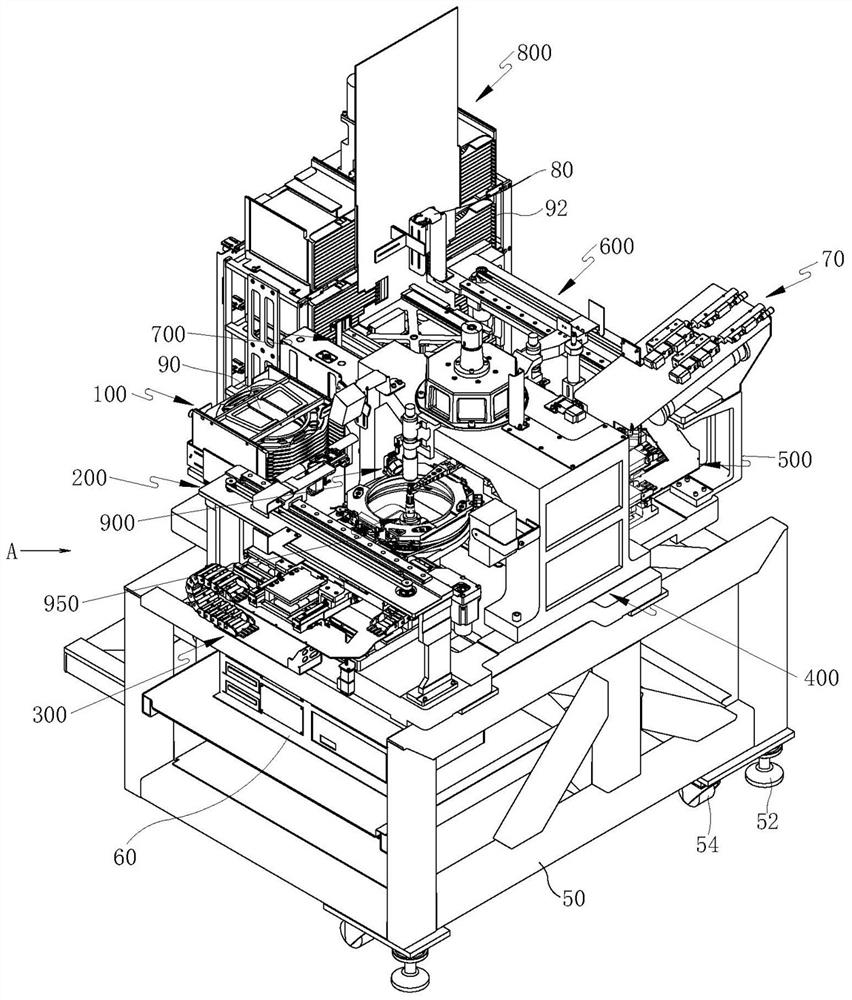

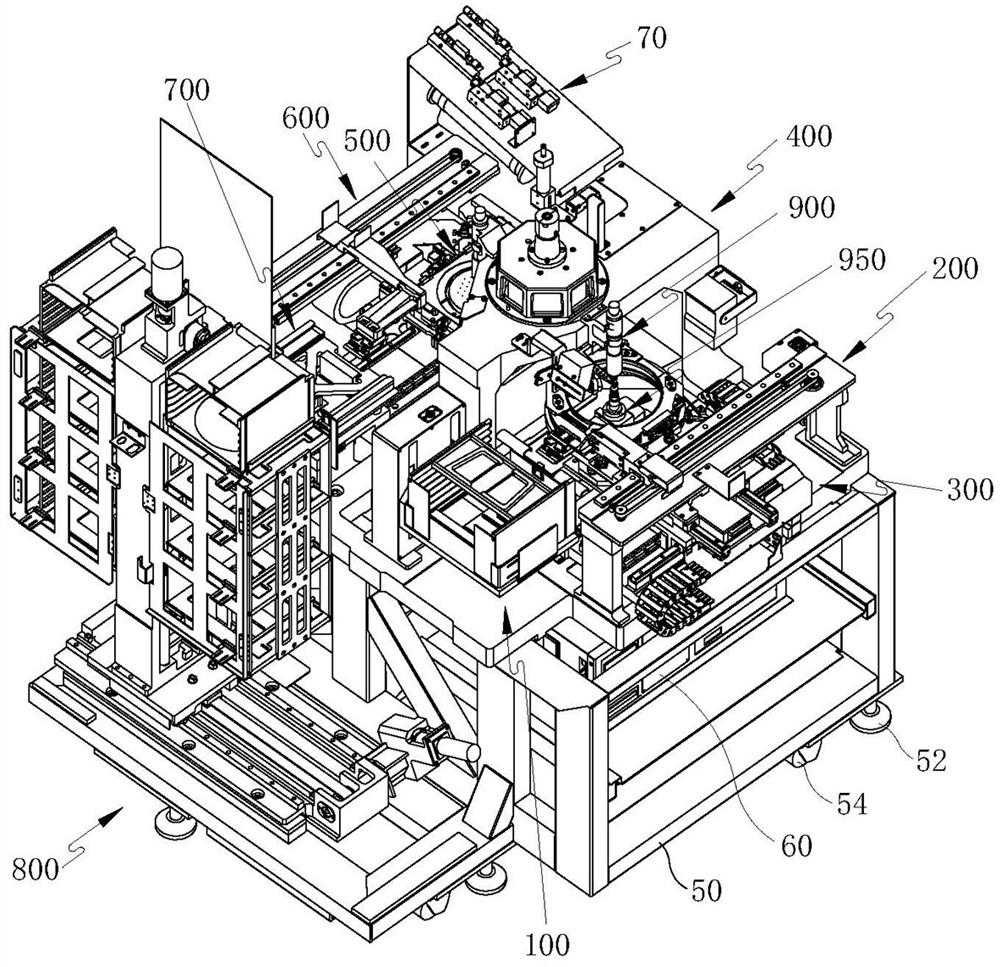

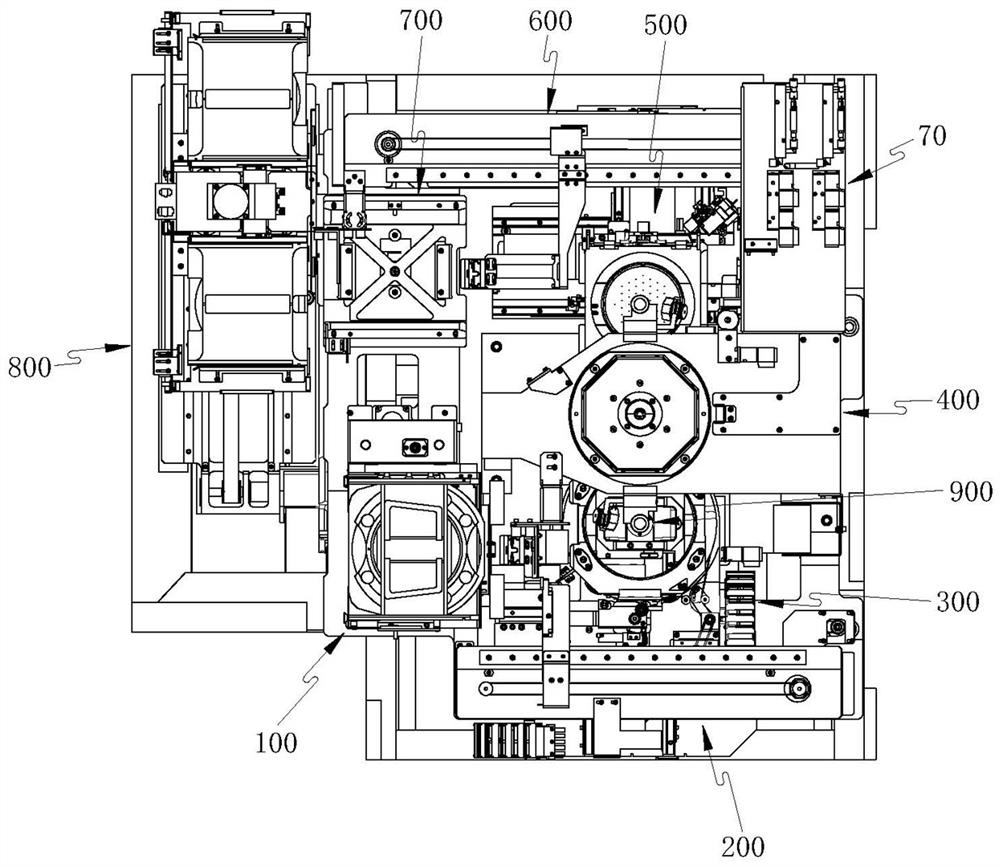

[0063] like figure 1 As shown, a control method for an LED and semiconductor laser chip sorting machine includes an initial step, a loading and unloading step of silicon wafers, a loading and unloading step of blanks, and a rapid sorting step of chips. The CCD camera performs image recognition to obtain the precise position information of the chip, and adopts double suction nozzles to pick up and place the chip, so that the sorting of the chip can be realized quickly and accurately.

[0064] Initial steps:

[0065] like figure 1 , image 3 , Figure 16 ,and Figure 22 As shown in common, first, through manual adjustment, the center of the lens of the CCD camera 900 on the side of the wafer table 300, the suction nozzle 407 and the ejector pin 973 of the ejector 950 are adjusted to a straight line in the vertical direction. The center of the lens of the CCD camera 900 on the side of the table 500 and the two points of the suction nozzle 407 are adjusted to a straight line ...

Embodiment 2

[0087] like figure 1 , figure 2 and image 3 Commonly shown, an LED and semiconductor laser chip sorting machine for implementing the control method for the LED and semiconductor laser chip sorting machine described in the first embodiment includes a rack 50, and a silicon wafer lifting table 100 is installed on the rack 50. , Silicon wafer robot 200, wafer table 300, suction and release device 400, placing table 500, material robot 600, buffer table 700, material lifting bin 800, CCD camera 900 and ejector 950. A control box 60 , an air circuit assembly 70 , a barcode scanner 80 and various positioning and limit sensors are also installed on the rack 50 . The bottom of the frame 50 is provided with supporting feet 52 and universal wheels 54 .

[0088] like figure 1 and Figure 4 As shown in common, the wafer lifting platform 100 includes a wafer cassette bracket 110 and a power box 140 for driving the wafer cassette bracket 110 to ascend and descend, and the wafers carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com