Patents

Literature

711results about How to "High sorting accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

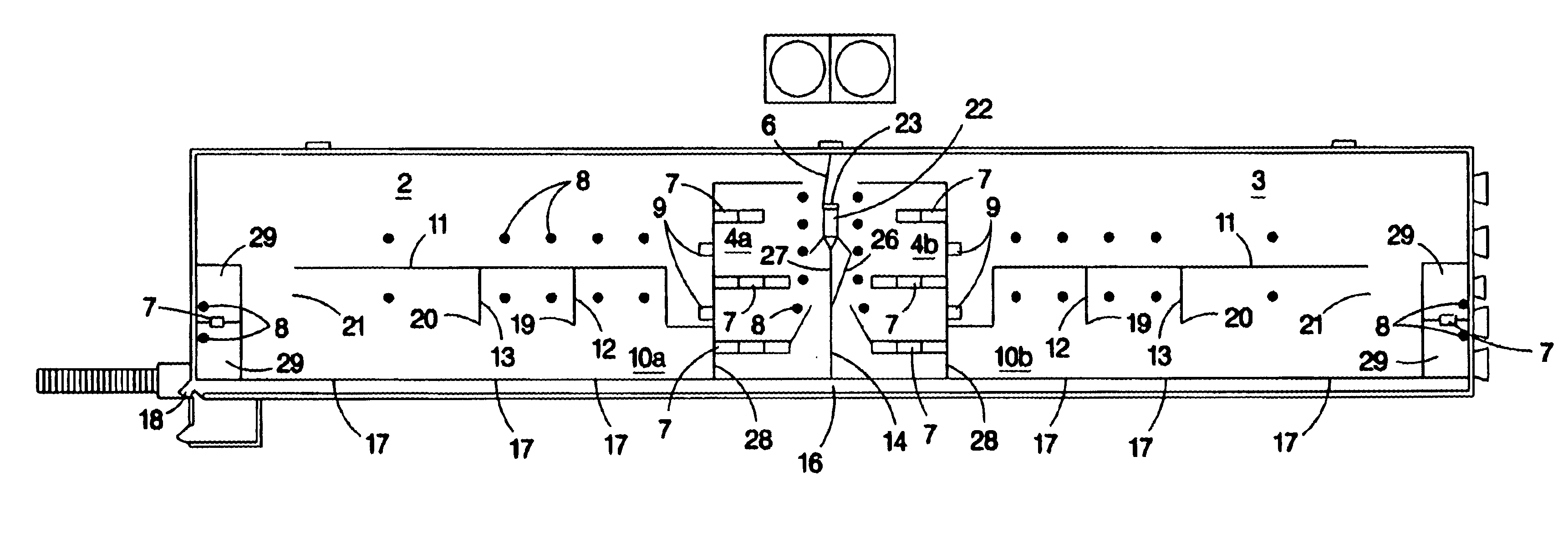

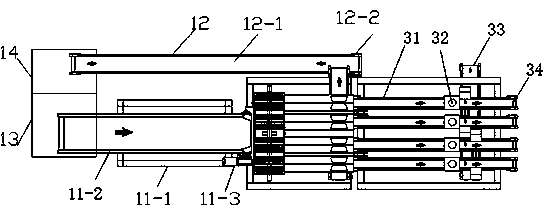

Delivery point sequencing mail sorting system with flat mail capability

InactiveUS6953906B2Shorten the timeHigh sorting accuracySeparation devicesCharge manipulationEngineeringMechanical engineering

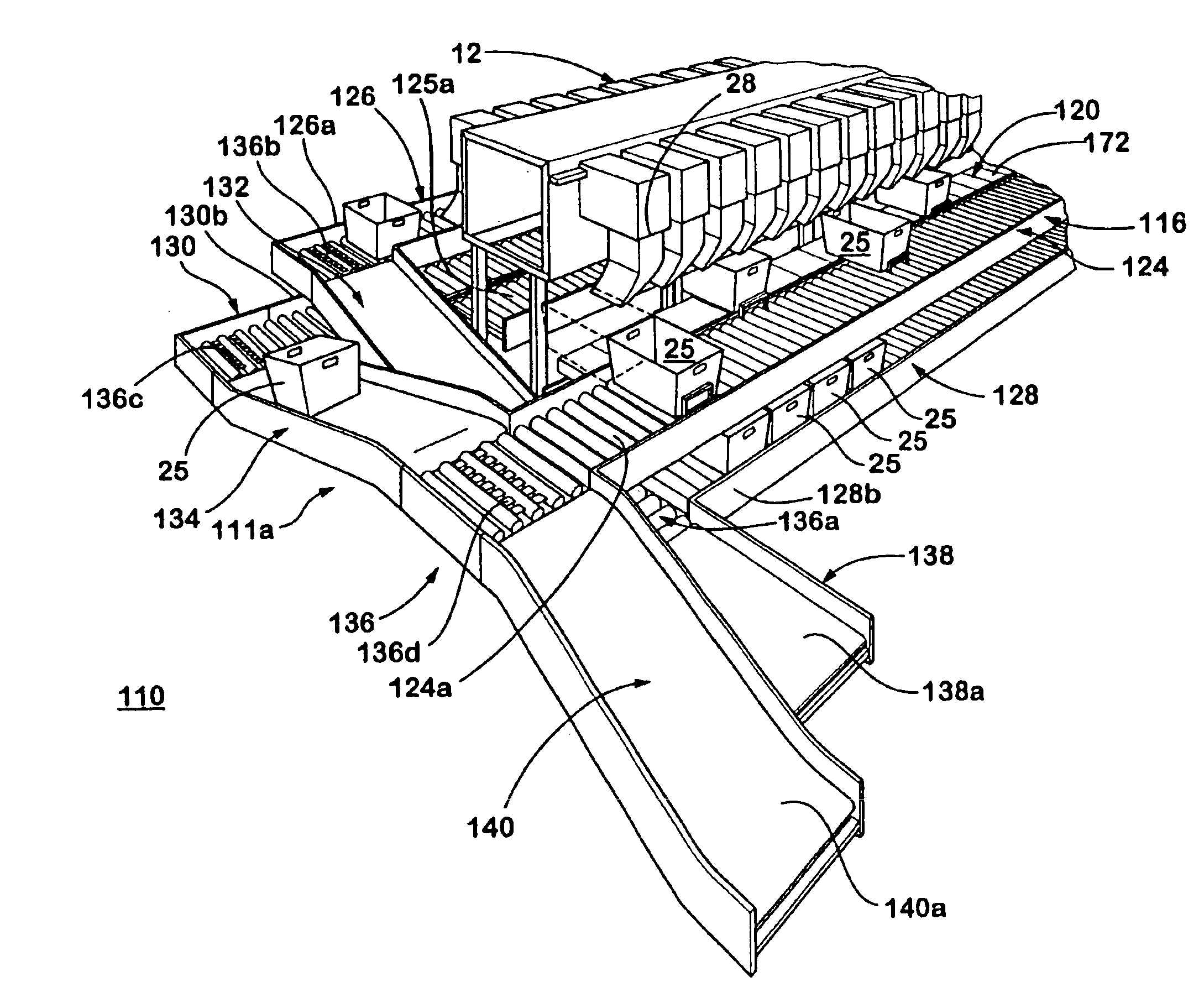

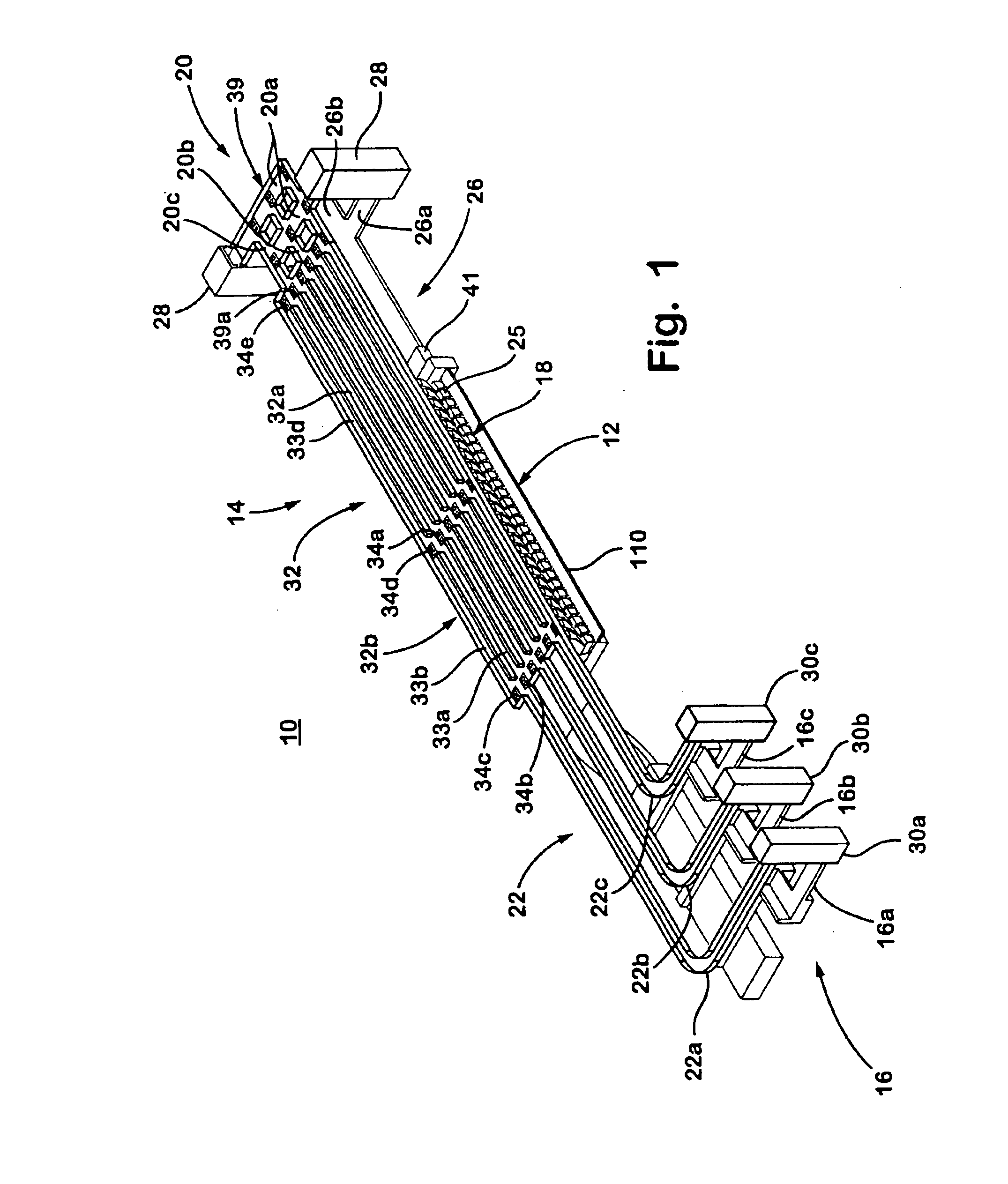

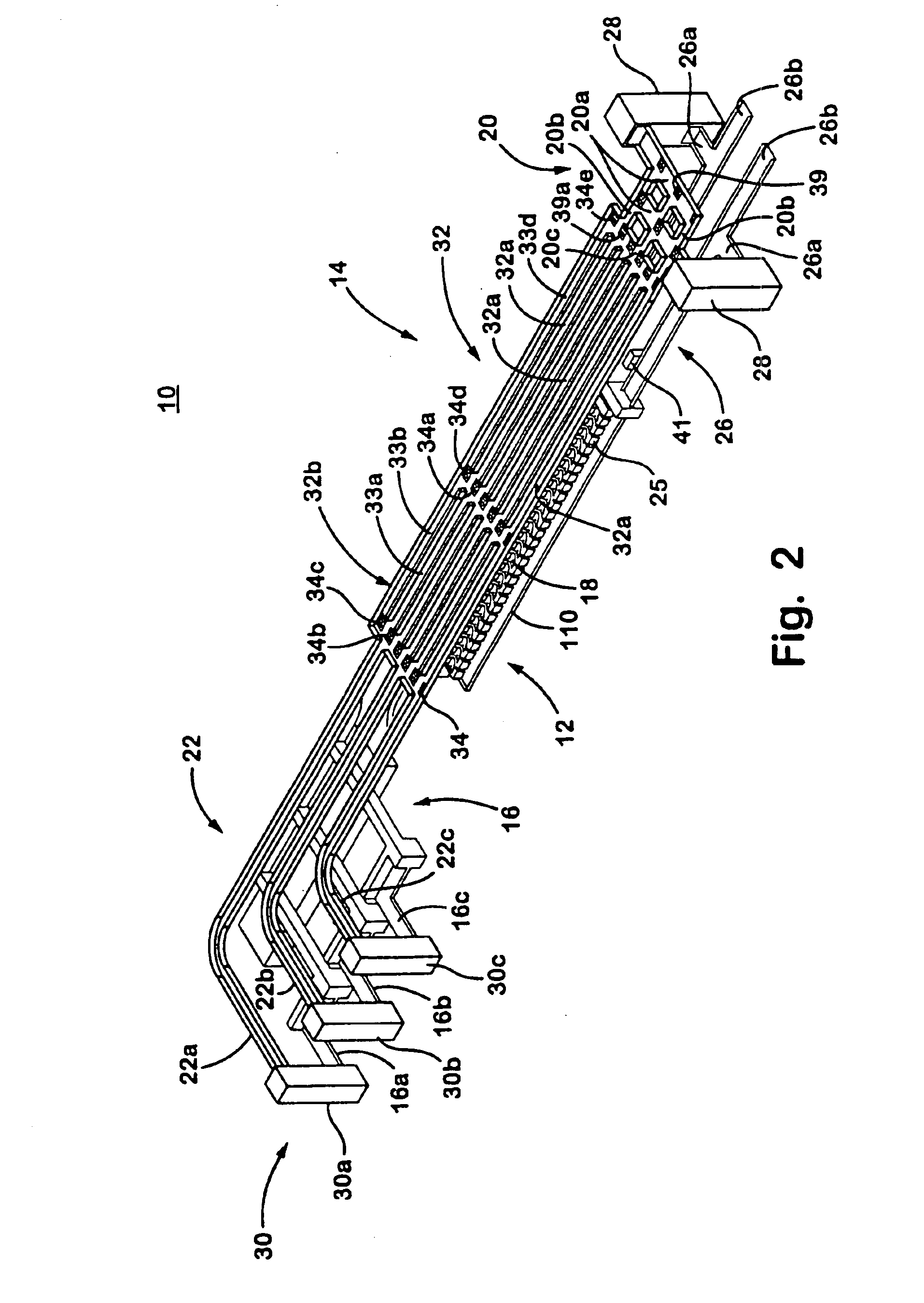

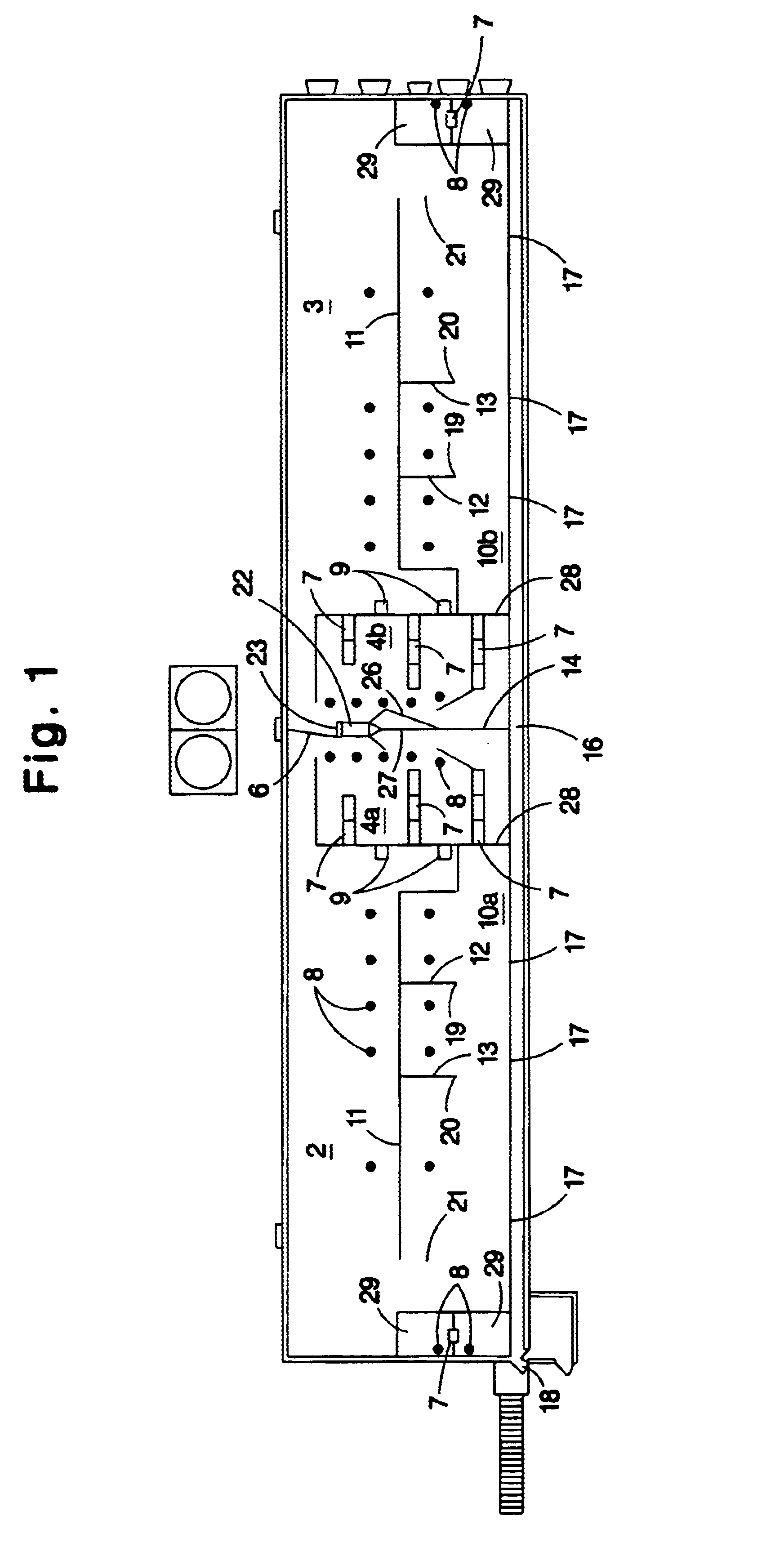

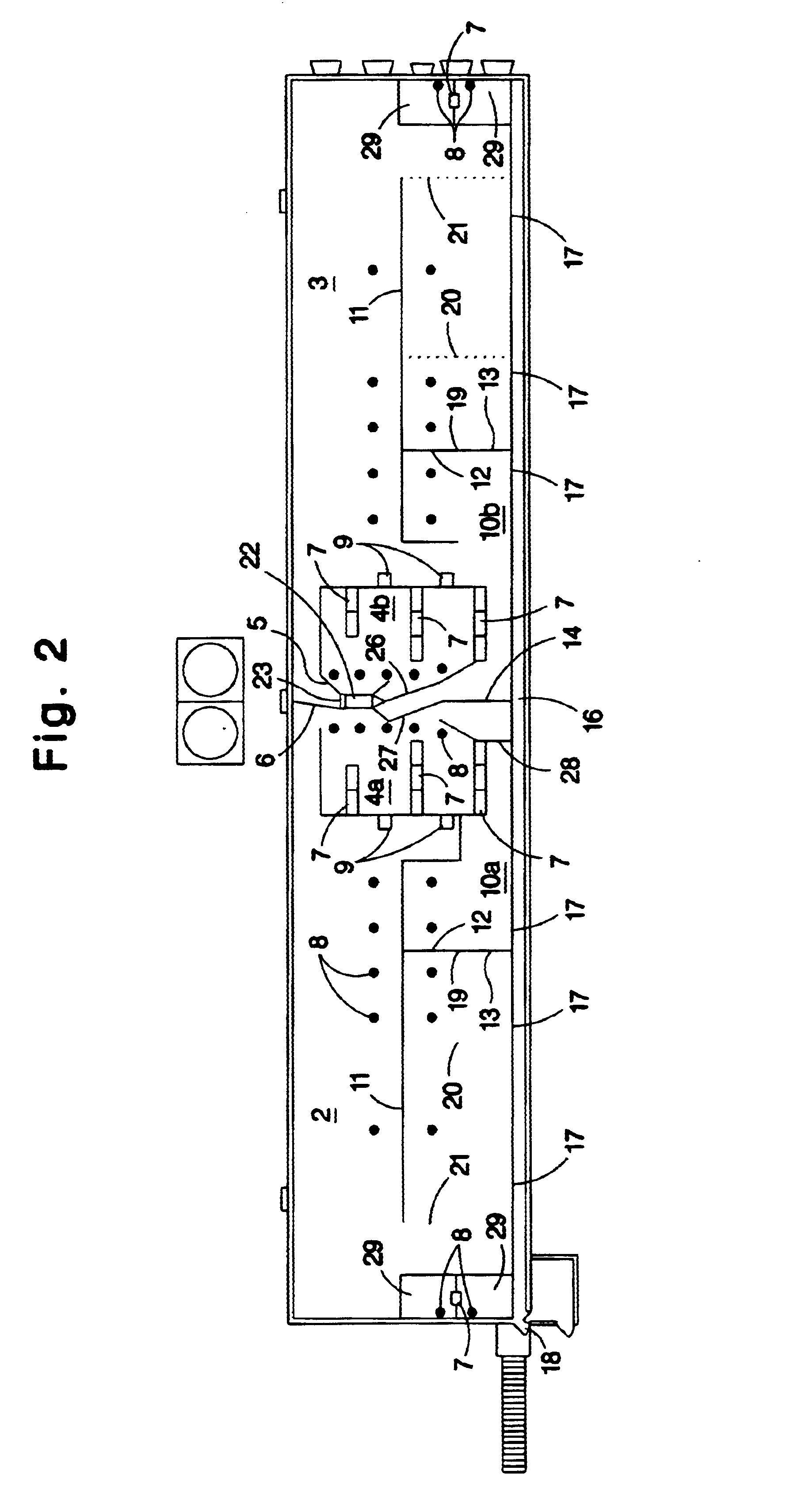

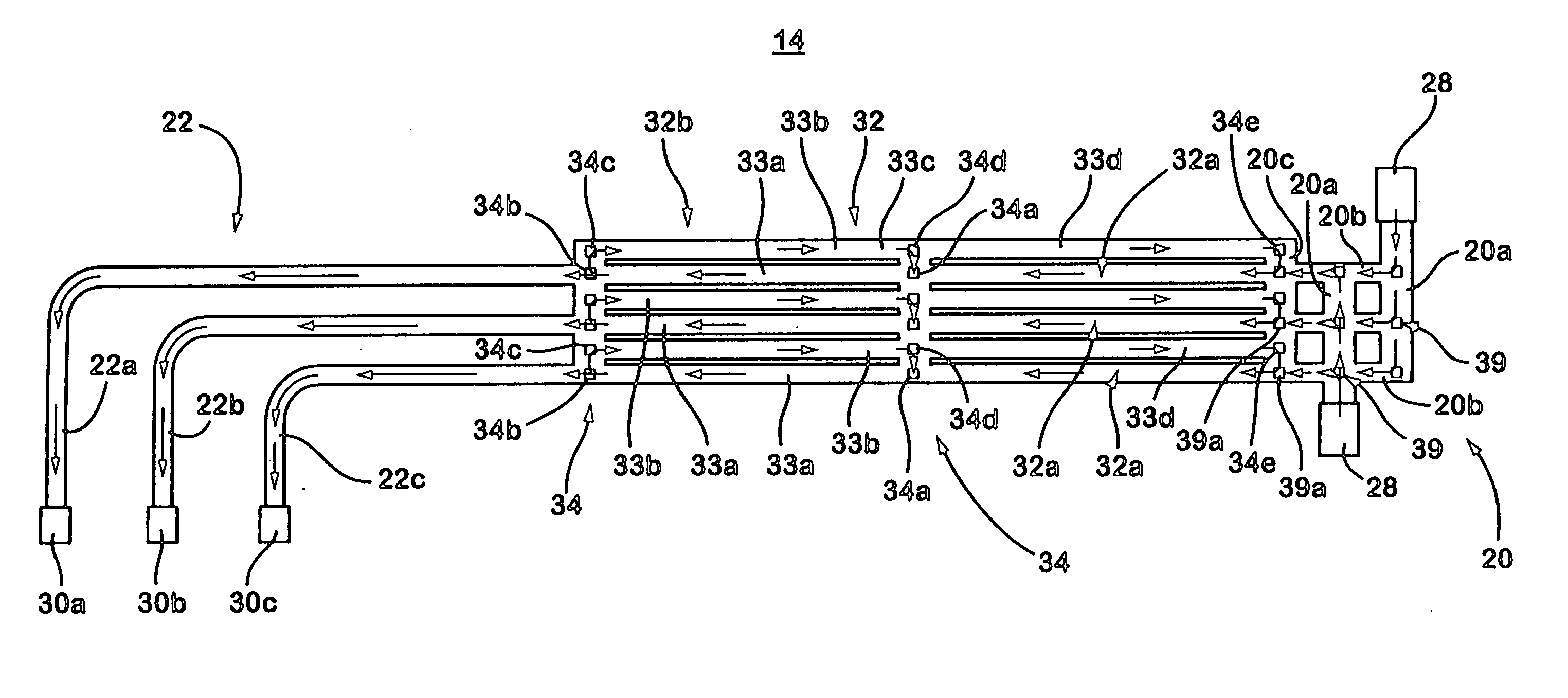

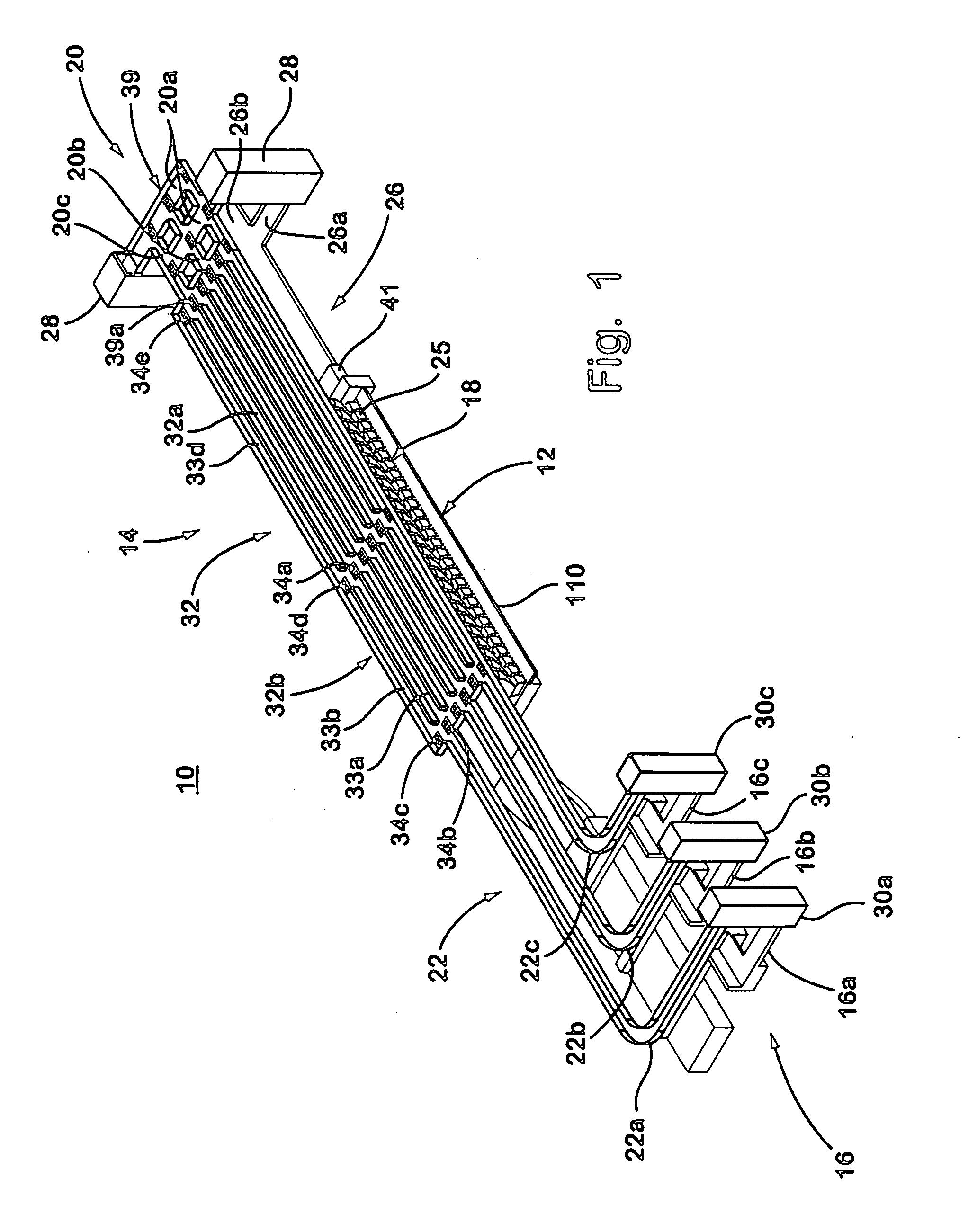

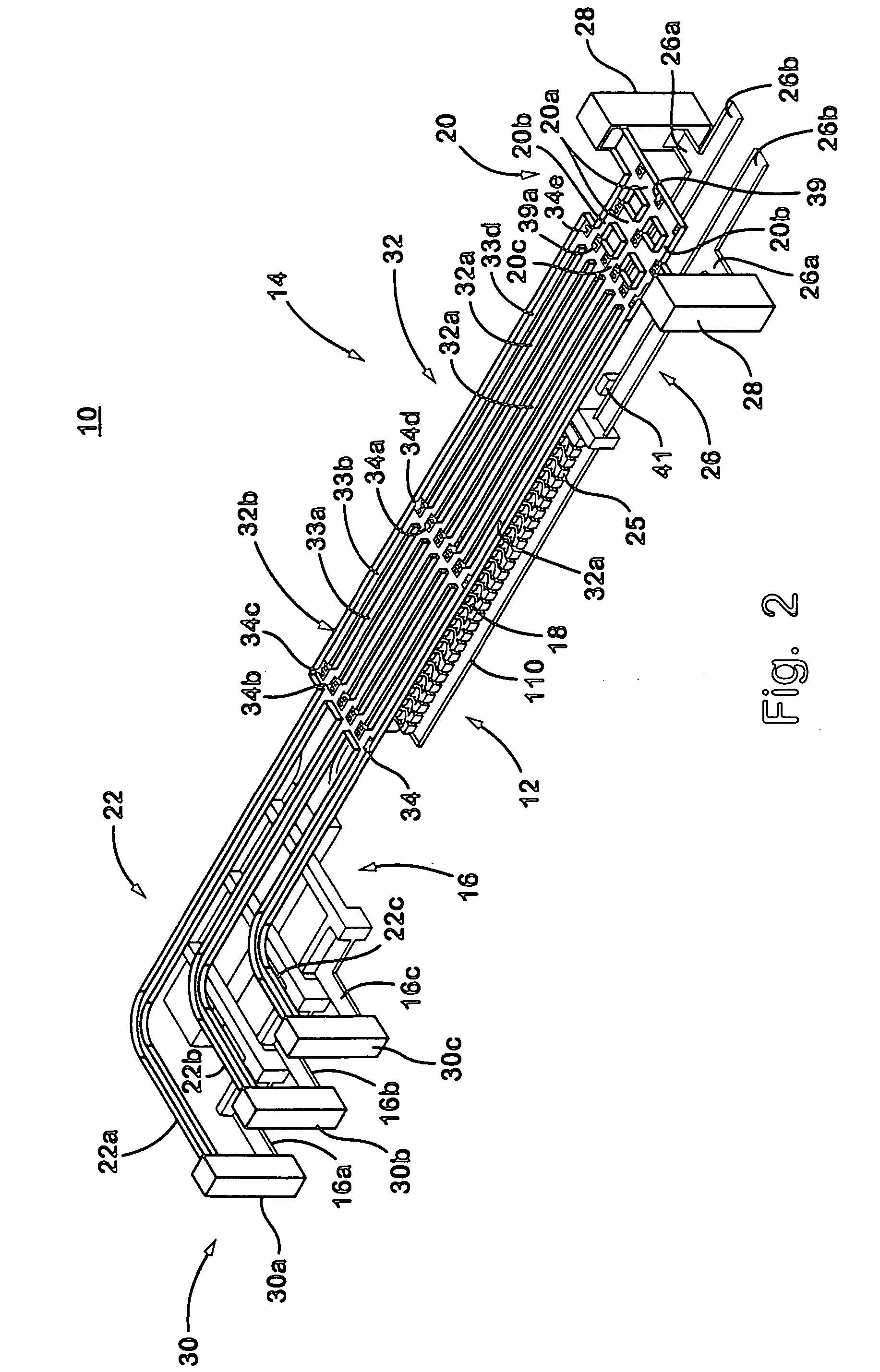

A method and apparatus for sorting articles to a delivery point sequence includes at least one sortation assembly adapted to sort articles and a buffer. The buffer is operable to arrange and convey containers of articles sorted in a first sort pass to an induct of the at least one sortation assembly for a second sort pass or process of the articles. The buffer automatically arranges the containers in an arranged manner prior to conveying the containers and articles to the induct of the at least one sortation assembly for the second sort process. The second sort process is then performed to sort the articles to a delivery point sequence or carrier walk sequence depth of sort. A conveyor assembly may be operable to convey containers to an appropriate one of multiple sortation assemblies and / or buffers to increase the sequencing matrix capability of the apparatus.

Owner:SIEMENS LOGISTICS LLC

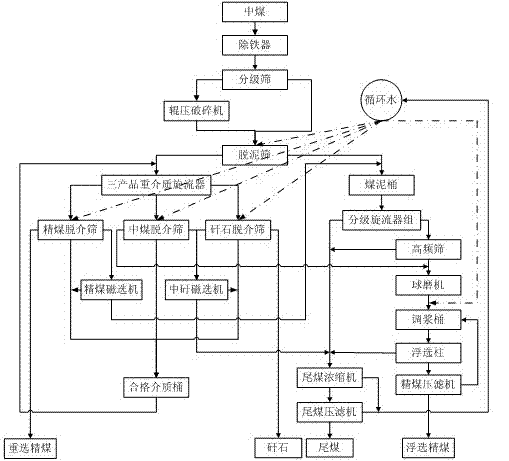

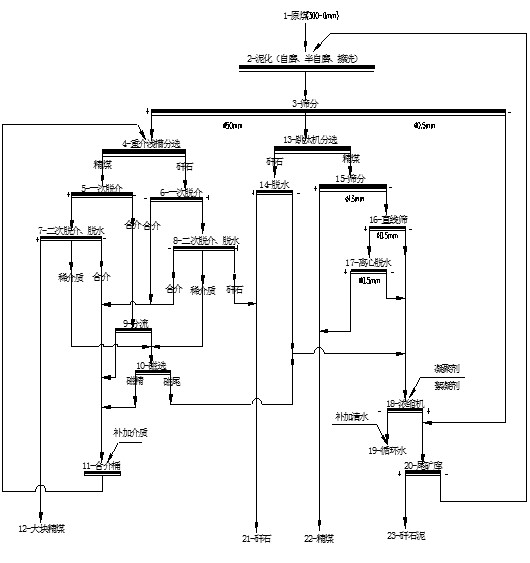

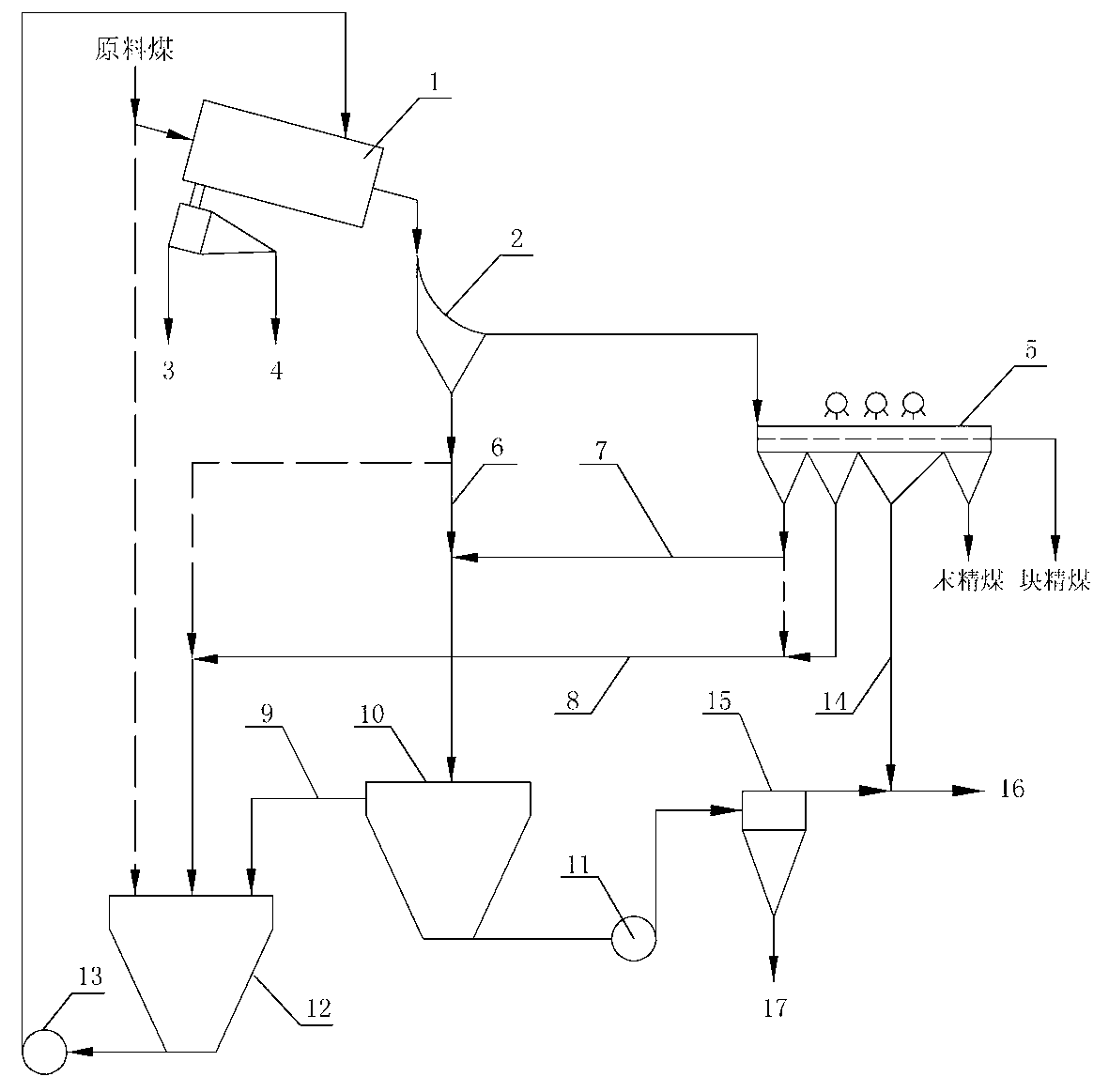

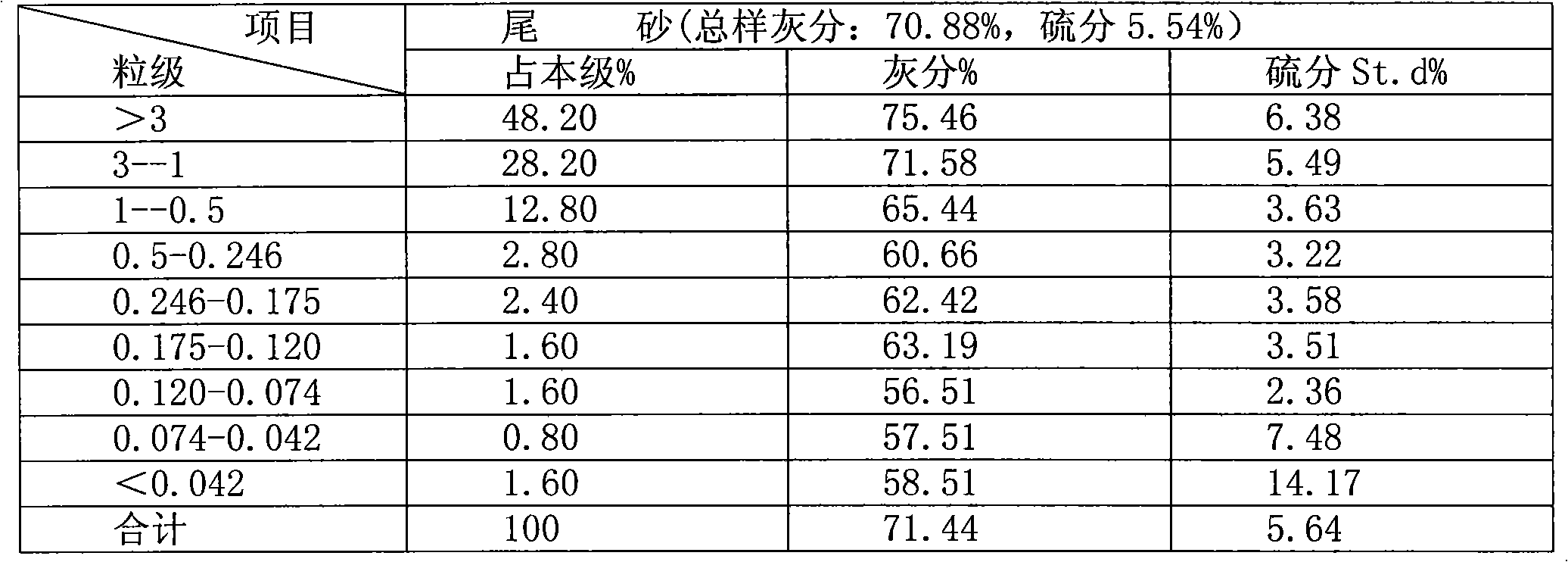

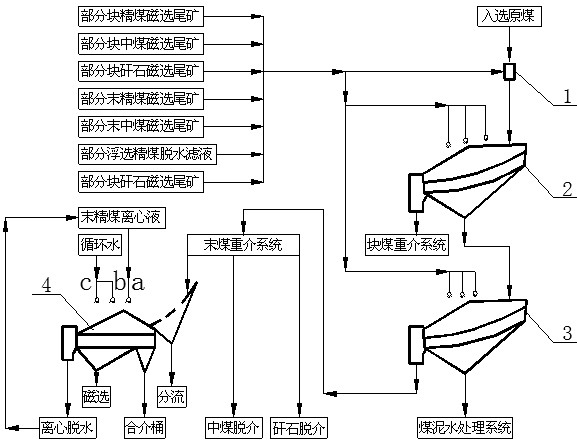

Efficient crushing and three-section type screening method of coking coal gravity middings

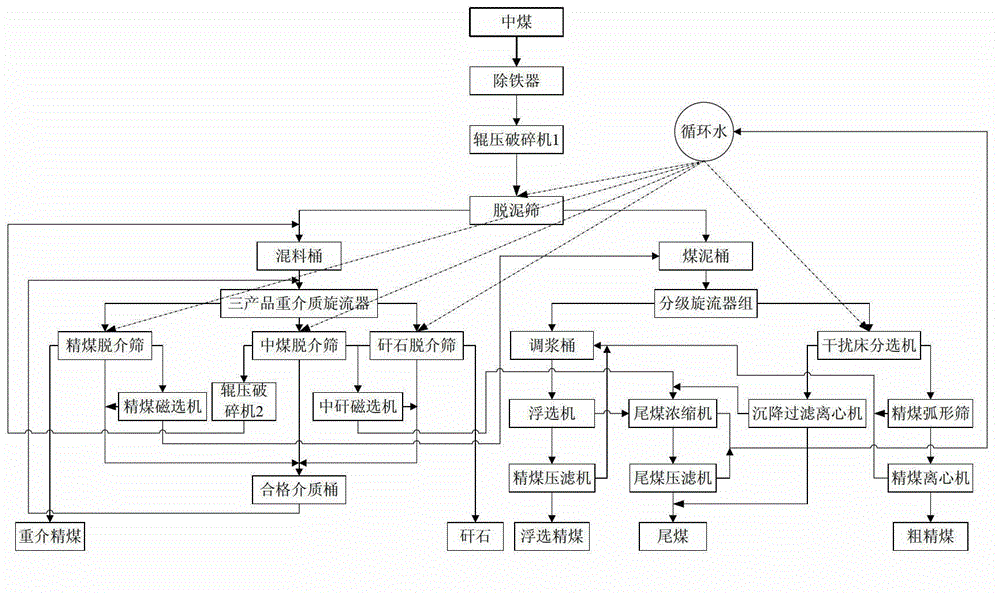

An efficient crushing and three-section type screening method of coking coal gravity middings belongs to coal crushing, dissociating and screening processes. Gravity middings in a coking coal preparation plant are taken as a raw material to be crushed through rolling to the fraction being below 6 mm or 3 mm; a desliming screen is used to deslime a material with the fraction being 1 mm, a material with the fraction being 6 to 1 mm or 3 to 1 mm enters into a three-product dense medium cyclone, and clean coal, middings and gangues are respectively obtained after two sections are subjected to medium drainage; the material with the fraction being 1 mm is mixed with tailings in a clean coal magnetic separator, fine coal slimes with the fraction being 0.25 mm are deslimed by a classifying cyclone; coarse coal slimes with the fractions being 1 to 0.25 mm enter into a teetered bed separator for screening, light products are dewatered by a sieve bend and a coal slime centrifuge to obtain coarse clean coal, and heavy products are dewatered by a screen bowl centrifuge to obtain tailings; the fine coal slimes with the fractions being 0.25 mm enter into a flotation machine for flotation, and foamed clean coal and the tailings are sequentially subjected to concentration and pressure filtration dewatering to obtain flotation clean coal and the tailing product; and after the gravity middings are crushed through rolling, the product returns to a mixing barrel. The method has the advantages that the graded screening is carried out on the preselected coal slimes with coarse fraction and fine fraction, and the equipment screening precision is improved.

Owner:CHINA UNIV OF MINING & TECH

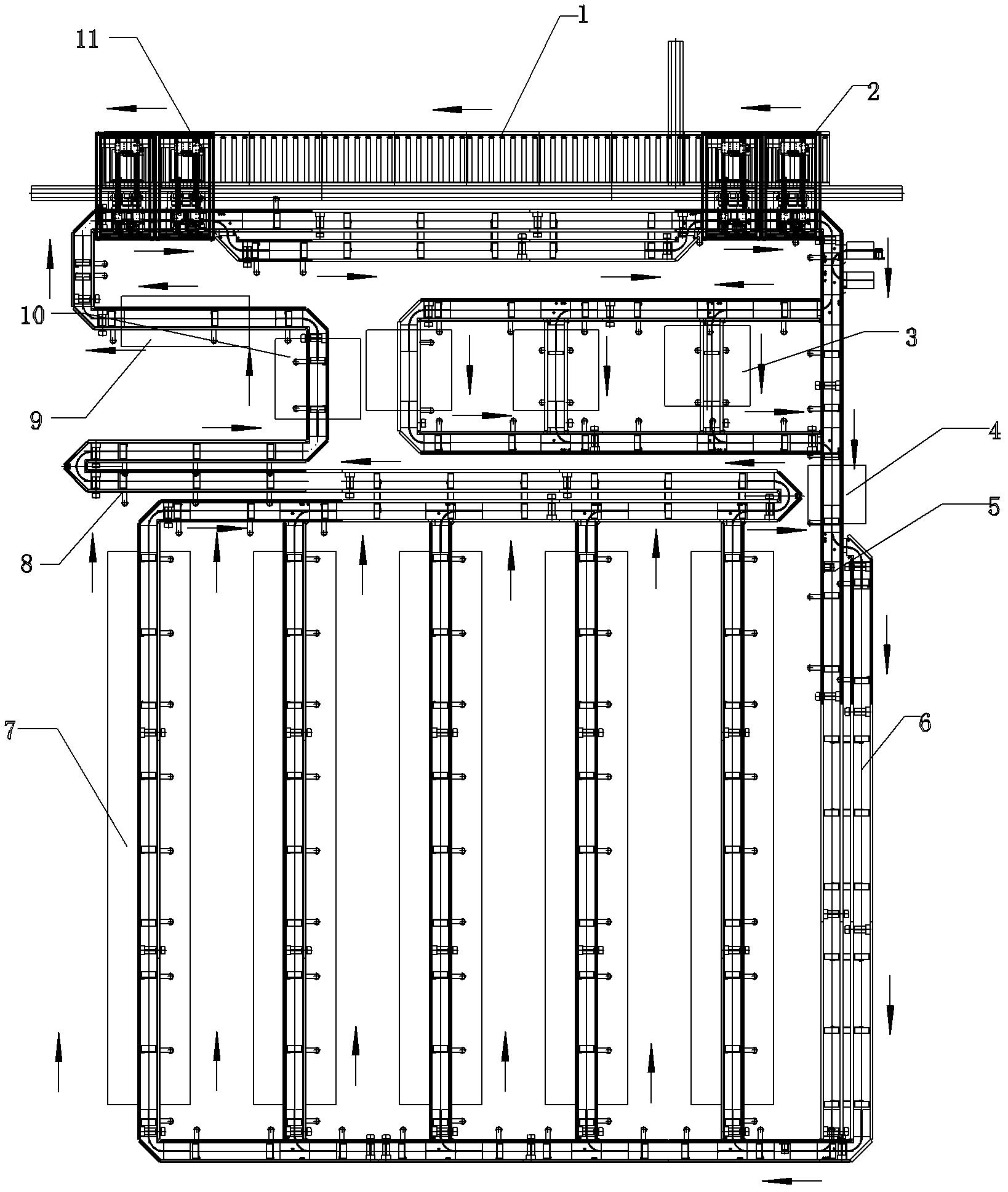

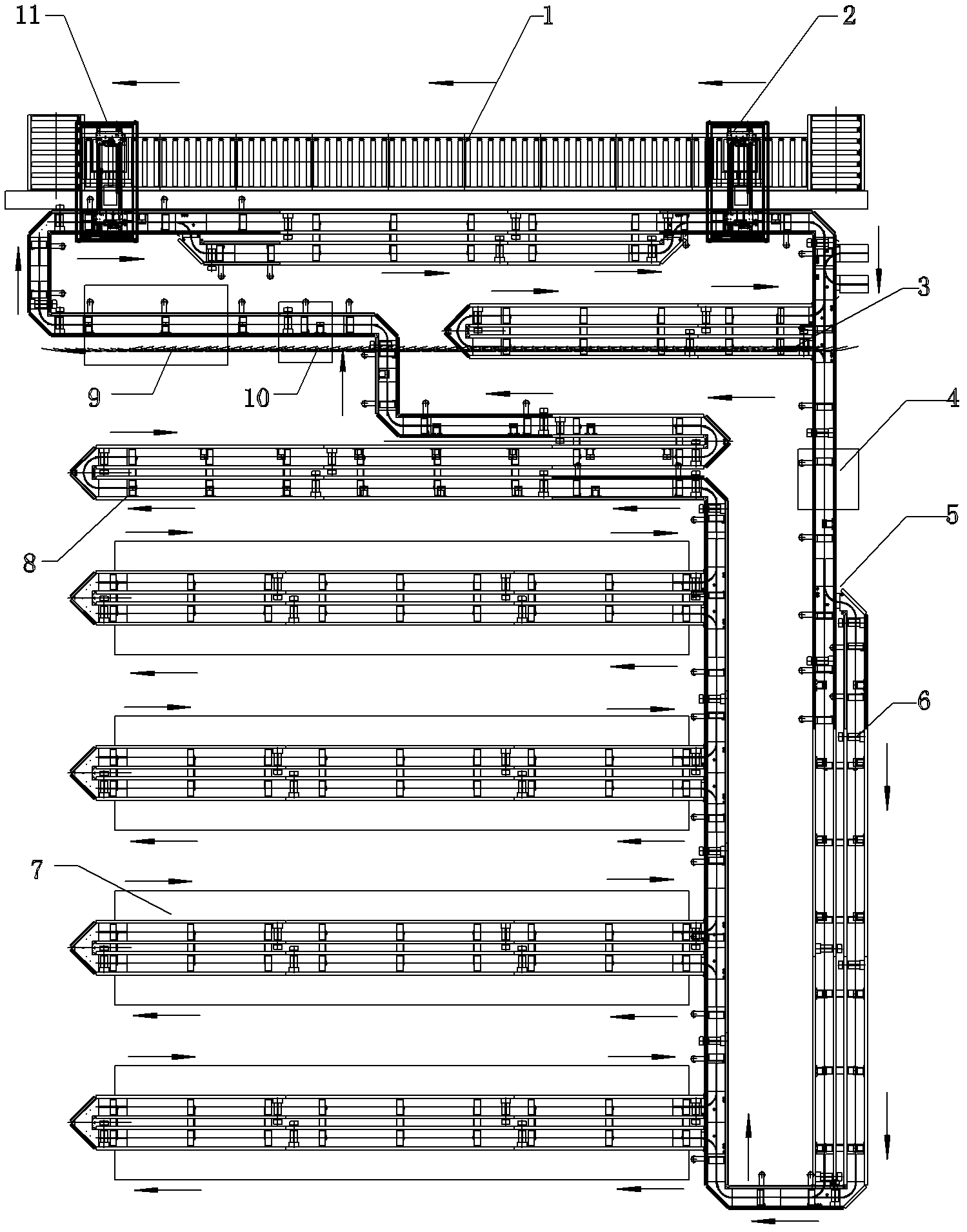

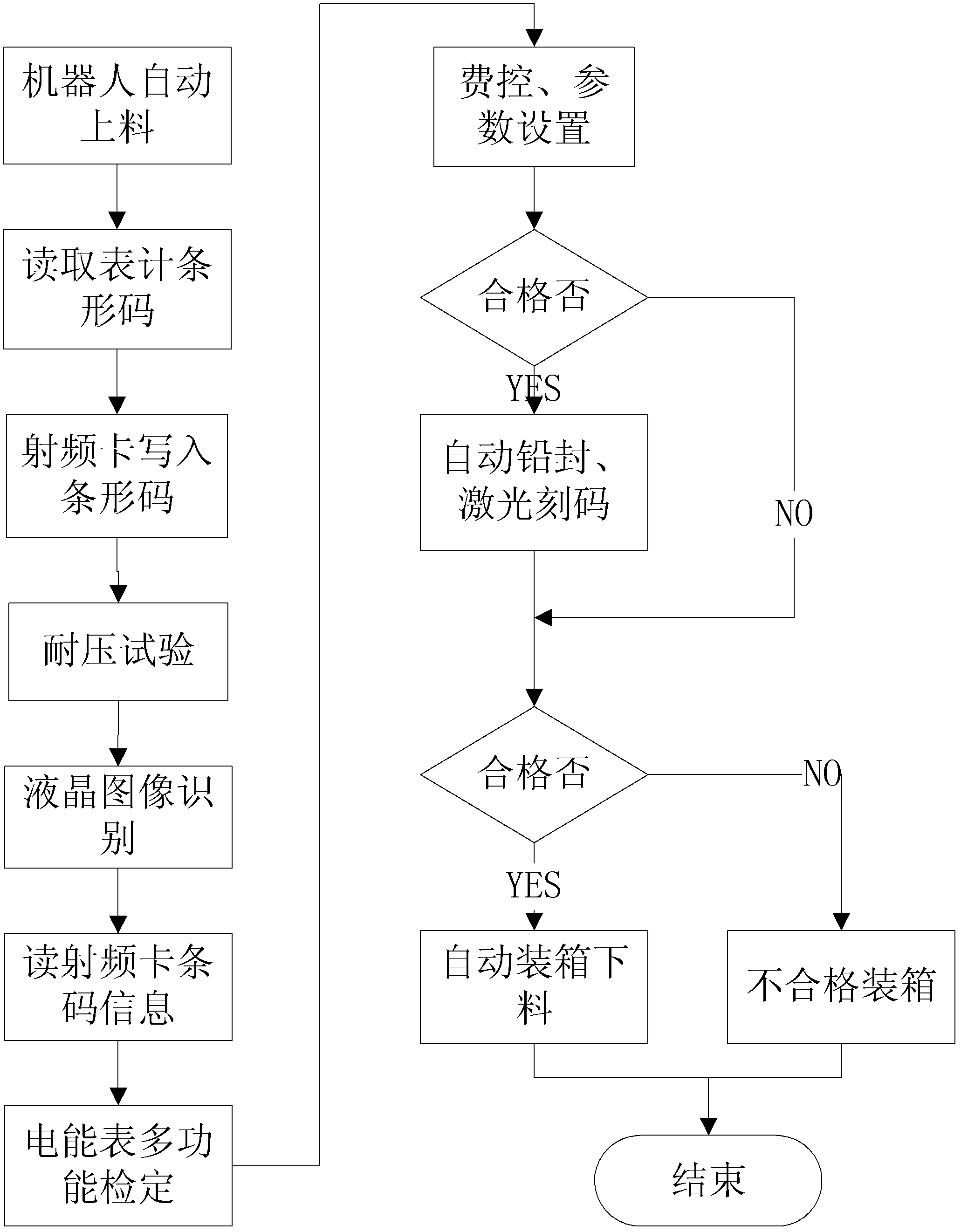

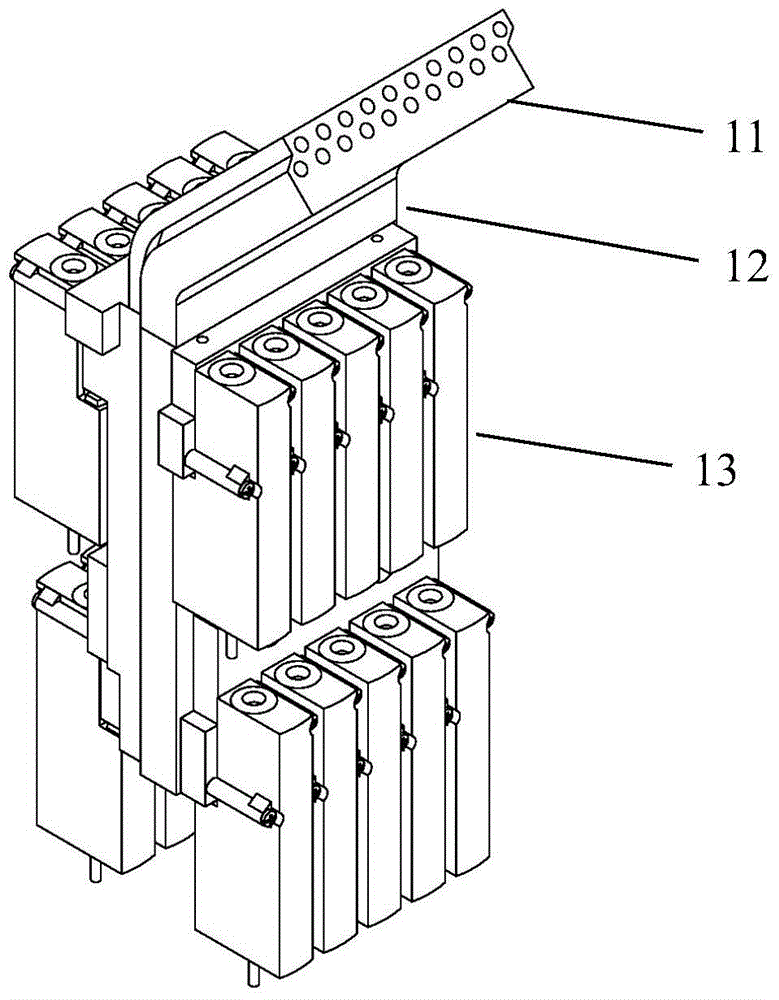

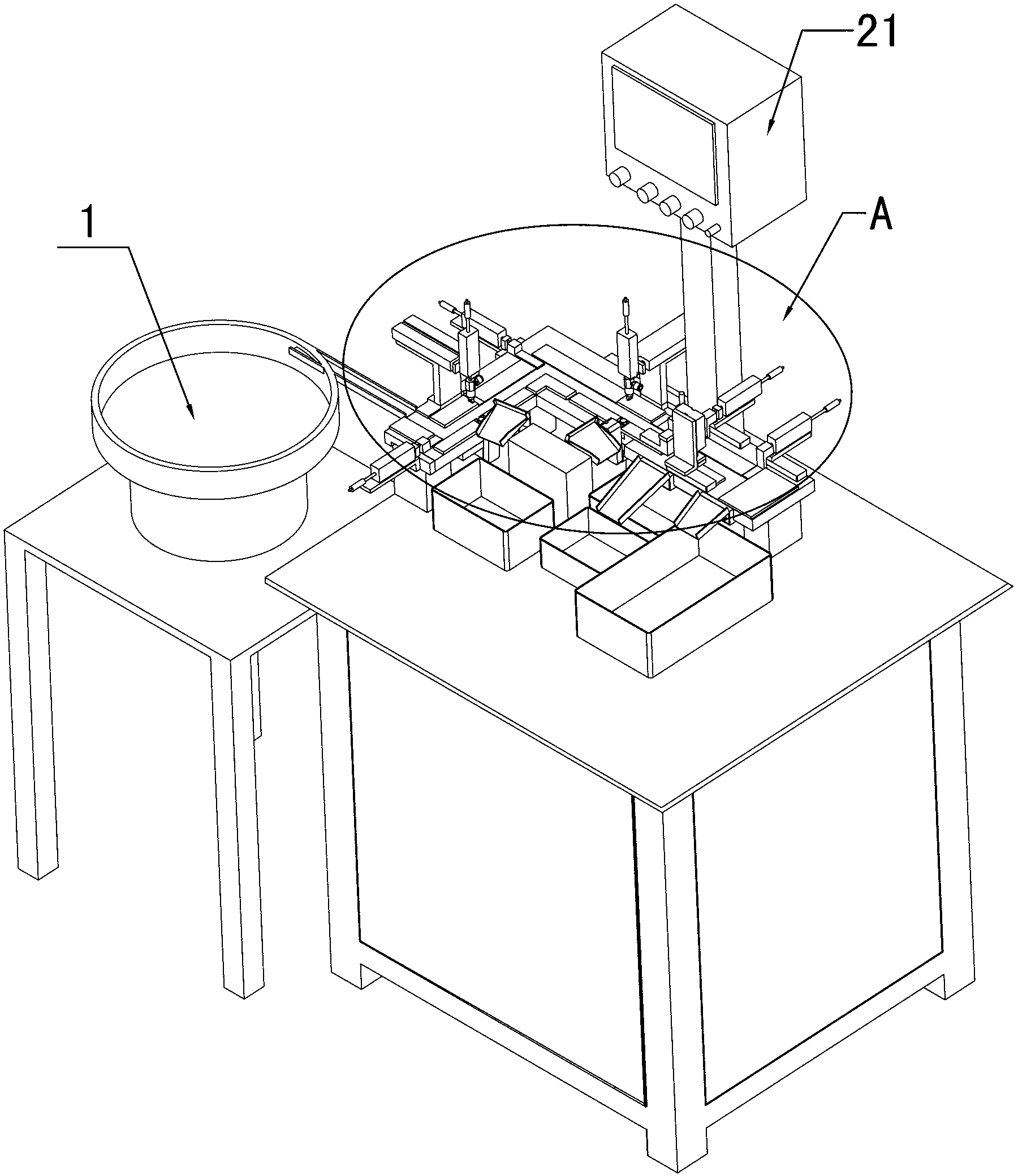

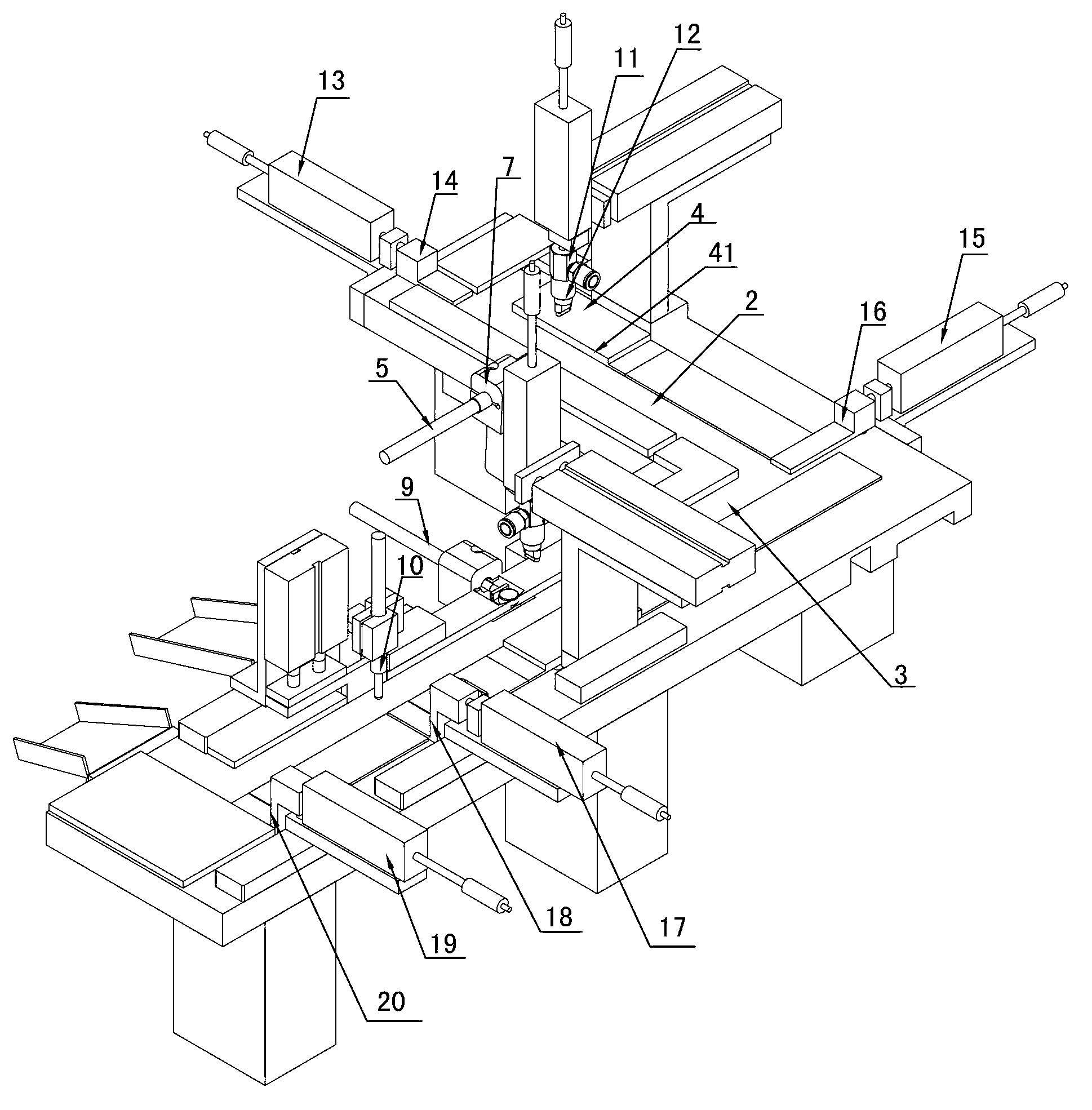

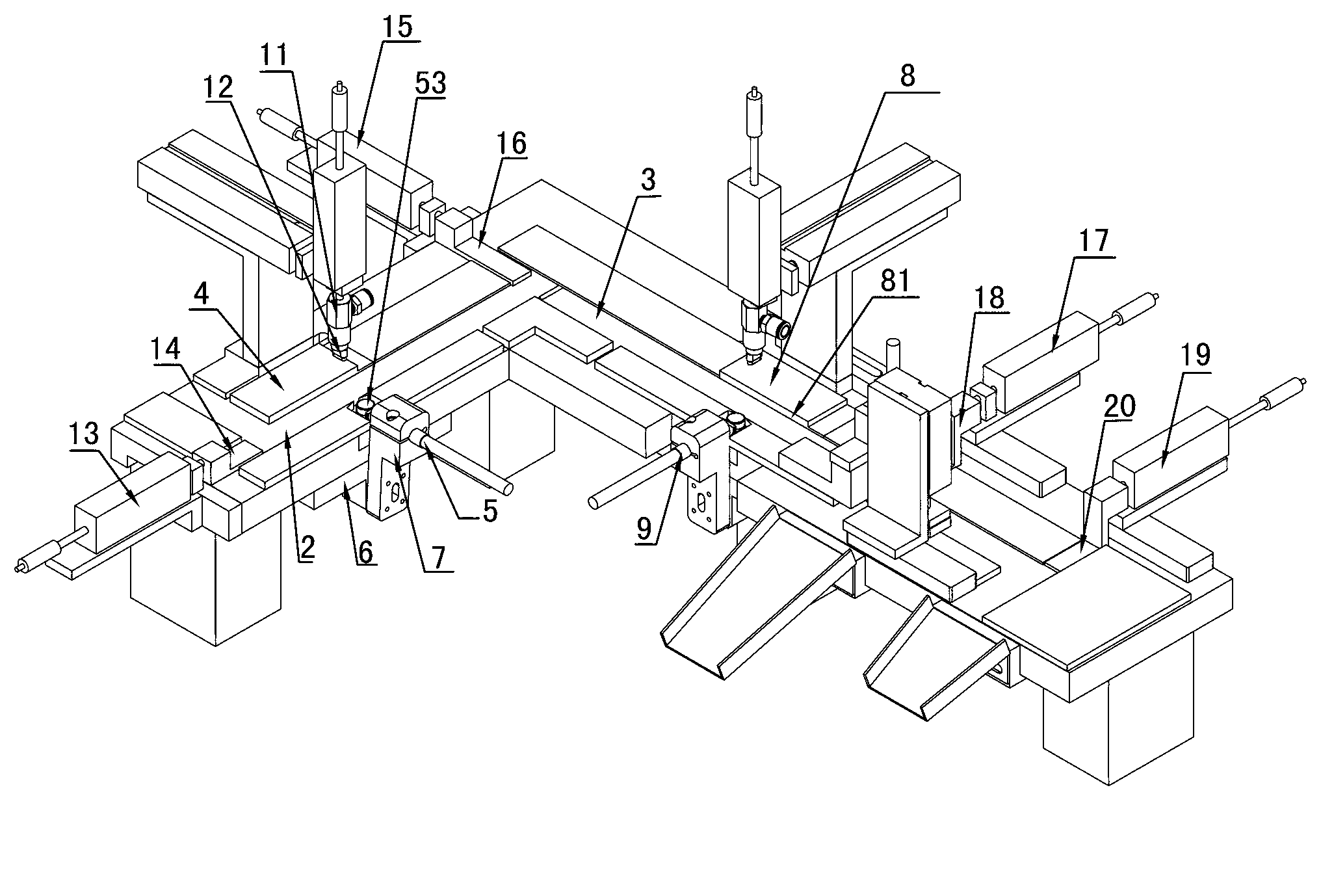

Electric energy meter verification unit and working method thereof

ActiveCN102323564ARealize fully automatic verificationEasy to manageMaterial analysis by optical meansElectrical testingLogistics managementComputer module

The invention claims an electric energy meter verification unit and a working method thereof, relates to a single-phase, three-phase electric energy meter verification unit and the working method thereof. At present, in the electric energy meter verification process, a verification system is artificial and mainly comprises a plurality of groups of artificial detection table bodies, and the method has the disadvantages of large labor intensity, manual errors and slow integral verification speed. The electric energy meter verification unit provided by the invention comprises a logistics conveying line, a feeding device, a verification conveying line, a pressure withstand testing device, a program switch triggering device, a verification device, a lead seal and laser making device, a discharging device and an electric energy meter verification management module, wherein the feeding device, the pressure withstand testing device, the program switch triggering device, the verification device, the lead seal and laser marking device and the discharging device are orderly arranged along a forward direction of the verification conveying line. The electric energy meter is in full automatic verification, high in efficiency, free from of manual detection errors, and can improve the accuracy of sorting; and the laser marking replaces the traditional form of sticking a certification so that the electric energy meter is convenient for management and use.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +1

Hog facility management system and method

InactiveUS6837189B2Reduce equipmentReduce maintenance costsAnimal housingOther apparatusEngineeringReady to use

A highly automated hog management system and method for housing, feeding and sorting hogs comprising a finishing barn partitioned into two separate pens each capable of holding at least 400 hogs in a large open area, with each room having a living or pen area and central shared but divided feeding area, such that through the adjustment of a gating and fencing system enclosing the feeding area, two pens of hogs can be sorted using a single electronic sorting scale, and wherein hogs are made to sort themselves by weight upon passing through the electronic sorting scale, which designates the animals as either light or heavy, and whereafter a diversion gate ushers them either into the regular feeding area with access back to the living area if they are designated as “light,” or into a separate holding pen if they are designated as “heavy. In addition, light and heavy hogs can be sorted between pens rather than in each pen separately. A sick pen area at each end of the building, having its own feed and water supply, is also provided.

Owner:SCHICK PAUL H

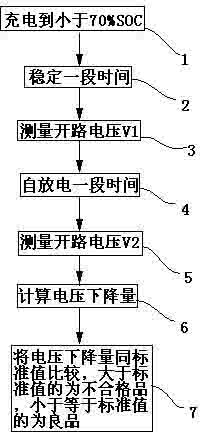

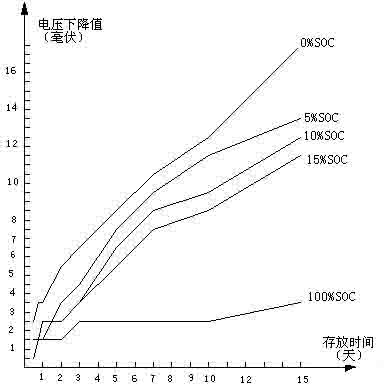

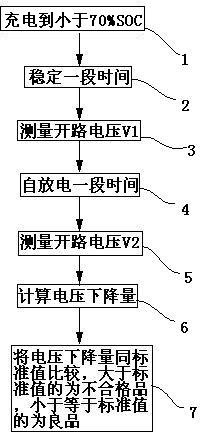

Method for detecting and sorting self-discharge performance of lithium iron phosphate battery

ActiveCN102303023AHigh sorting accuracyReduce sorting timeSortingLithium vanadium phosphate batteryElectricity

The invention relates to a method for detecting and sorting self-discharge performance of a lithium iron phosphate battery. The method comprises the following steps of: charging to less than 70 percent of a SOC ( State Of Charge); 2, storing for a period of time, wherein the period of time is called as a stabilization time; 3, testing an open-circuit voltage of the battery, wherein the tested voltage in the step is called as V1; 4, storing for one period of time, wherein the period of time is called as a self-discharge time; 5, testing an open-circuit voltage of the battery, wherein the tested voltage in the step is called as V2; 6, calculating a voltage drop amount of the battery, the voltage drop amount is called as a delta V, wherein the delta V is equal to the V1 minus the V2; and 7, determining that a battery of which the delta V is greater than a standard value is an unqualified product, and determining that a battery of which the delta V is smaller than the standard value is a good product. According to the method provided by the invention, the self-discharge performance of the lithium iron phosphate battery can be sorted in a short time without needing a high temperature aging, the problem of high detection cost caused by shortening the detection time by using the traditional method needing using the high temperature aging to accelerate the electricity discharge speed is solved.

Owner:WANXIANG 123 CO LTD

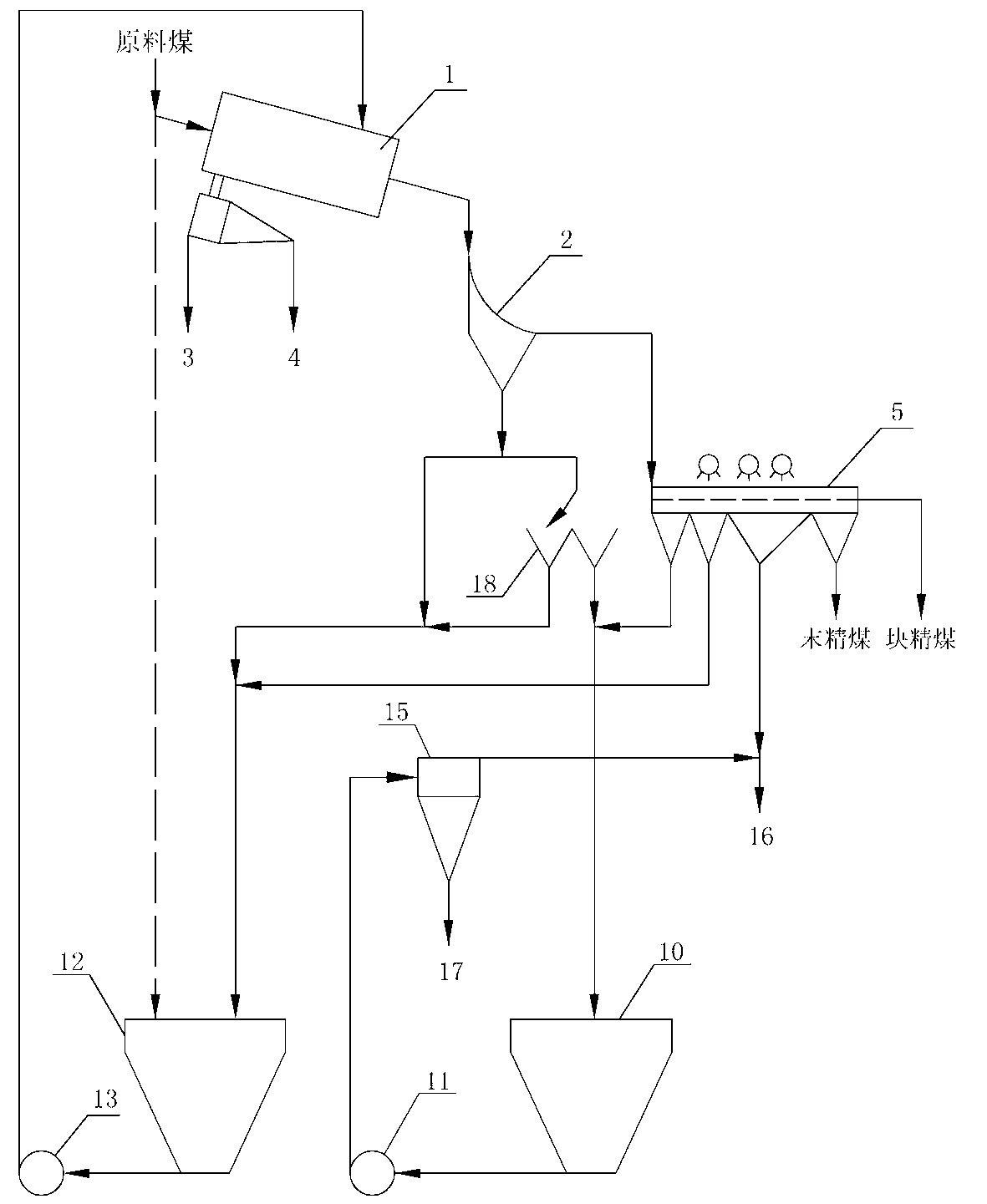

Breaking grinding dissociation and re-flotation two-stage recovery process of coal in scarce coking

A breaking grinding dissociation and re-flotation two-stage recovery process of coal in scarce coking belongs to a coal breaking dissociation flotation process. (1) coal products in a coal preparation plant serve as raw materials, and the coal which is larger than 6mm is rolled and broke into size smaller than 6mm; (2) a desliming screen is used for desliming on middings smaller than 6mm, middings which is 6-0.5mm enters a three-product dense medium cyclone, and dense medium, middings and gangue are obtained after two-stage medium separation is carried out; (3) the middings smaller than 0.5mm is mixed with clean coal magnetic separation gangue, a grading hydrocyclones group is adopted to conduct high frequency screening to obtain high ash fine silt contained slurry water, and coarse particle are mixed with middings on the midding sculping screen to enter a ball mill for wet grinding; and (4) products after grinding enter a flotation column to conduct flotation, foam clean coal and tailing are respectively concentrated, filtered and dewatered to obtain flotation clean coal and tailing products. The breaking grinding dissociation and re-flotation two-stage recovery process has the advantages that the high ash fine silt in fine fraction is pre-selected, pollution of the high ash fine silt is reduced, equipment separation particle size range is reduced, separation accuracy of equipment is improved, and scarce coking coal resources are recovered as far as possible.

Owner:CHINA UNIV OF MINING & TECH

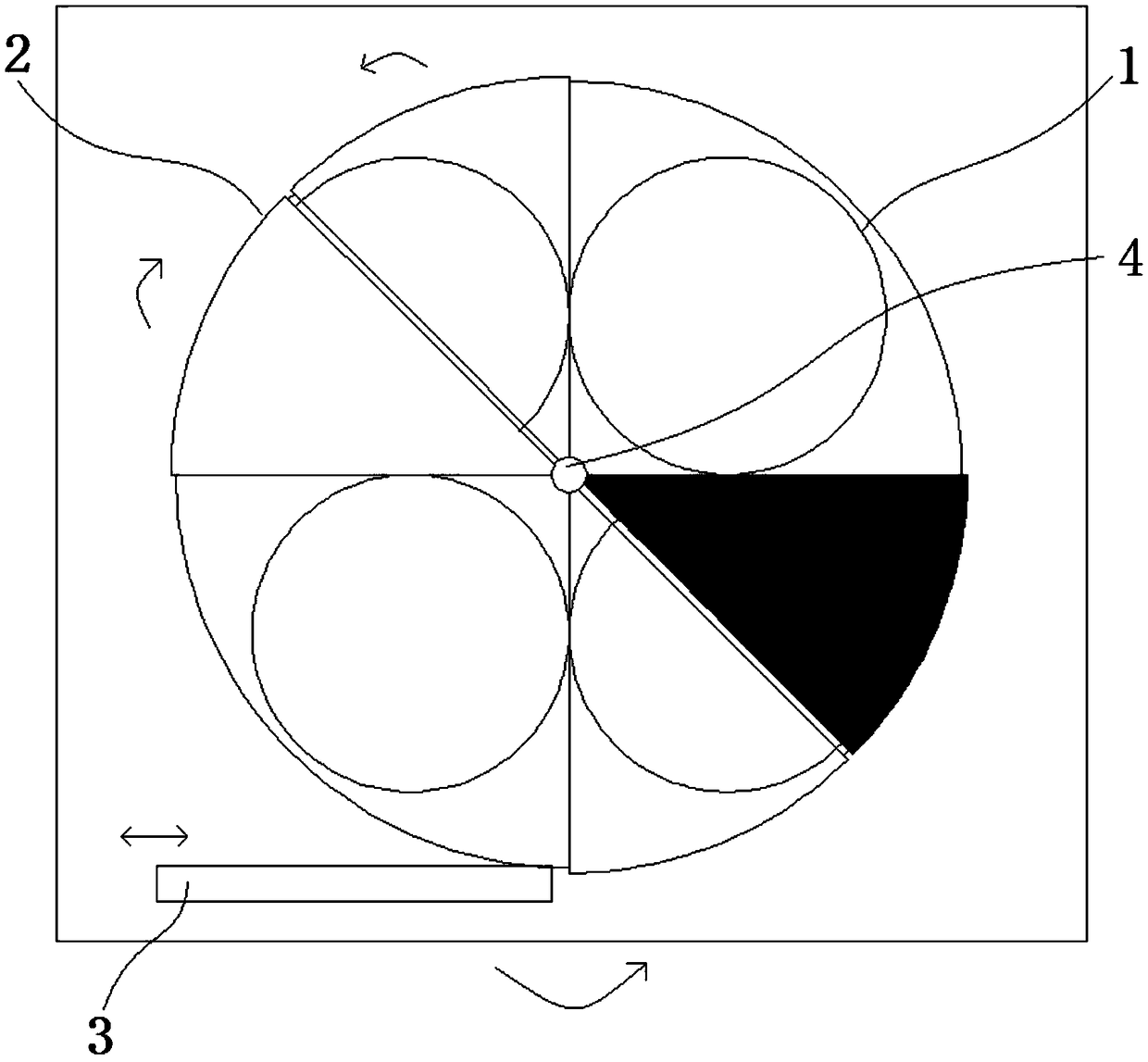

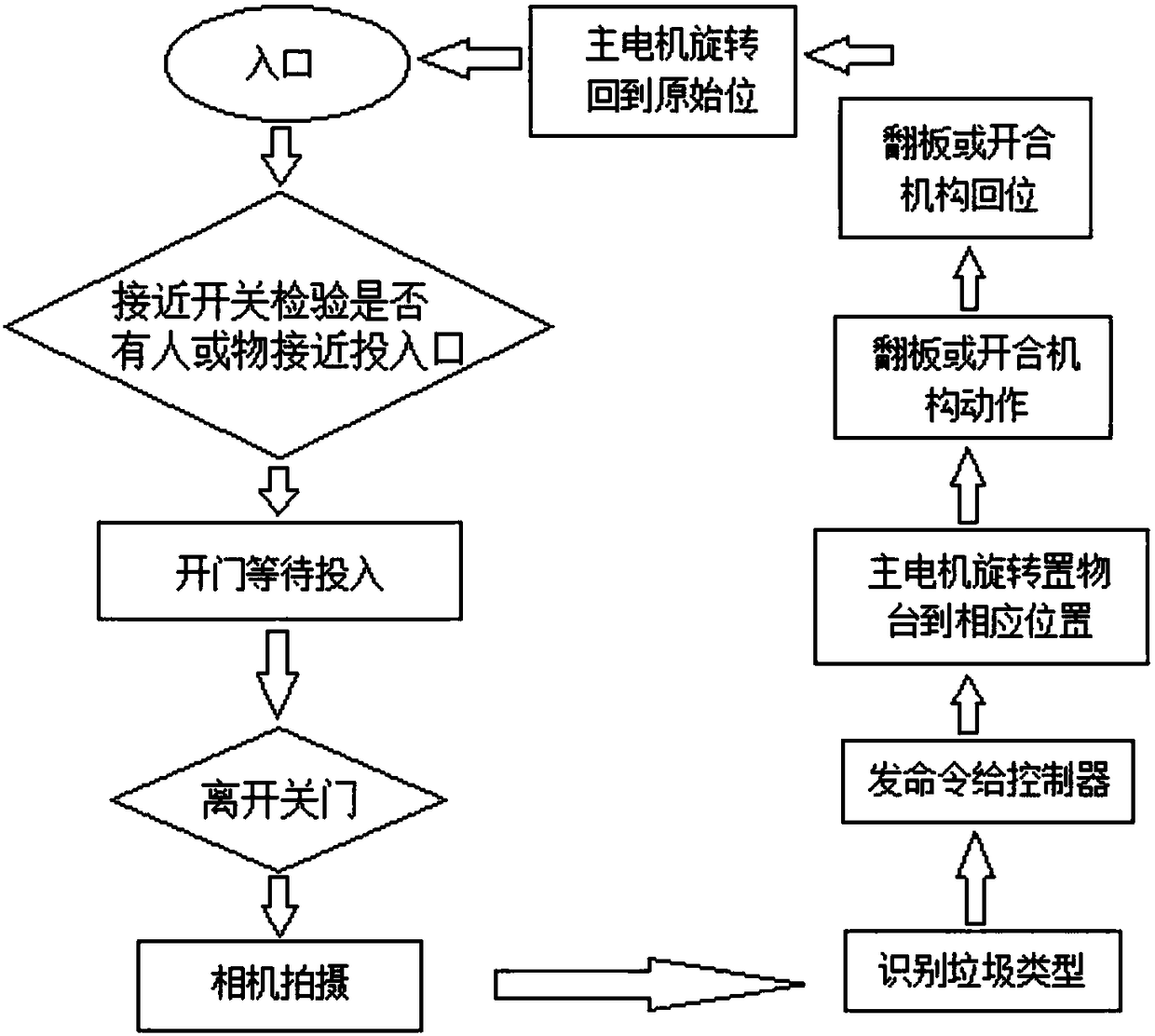

Intelligent sorting garbage can

InactiveCN108341184AAvoid influenceReduce the impactWaste collection and transferRefuse receptaclesControl systemEngineering

The invention discloses an intelligent sorting garbage can, and relates to the technical field of garbage sorting. The intelligent sorting garbage can comprises a garbage can body; a plurality of sorting sub-garbage can bodies are arranged in the garbage can body; an throw-in door is arranged on a garbage can cover; a sorting device comprises a moving device, a positioning device and a placing platform; a main controller controls a turnover plate mechanism or an opening and closing mechanism in a driving mode and controls opening and closing of the throw-in door in a driving mode; and an automatic garbage identification system based on artificial intelligence and a machine deep learning algorithm comprises a camera arranged in the garbage can body. According to the intelligent sorting garbage can, multi-angle shooting is carried out on garbage on the placing platform through the camera, the types of the garbage to be detected can be identified through the artificial intelligence and the machine deep learning algorithm, a sorting mechanism rotates a sorting platform to the position above collecting ports of the different sub-garbage can bodies through a control system, the turnoverplate mechanism or the opening and closing mechanism is controlled to be opened, the garbage fall into the different collecting ports, so that the garbage can be automatically sorted and processed, the sorting precision can be improved, and the labor amount of garbage sorting can be decreased.

Owner:ANHUI PROTOSS INFORMATION TECH CO LTD

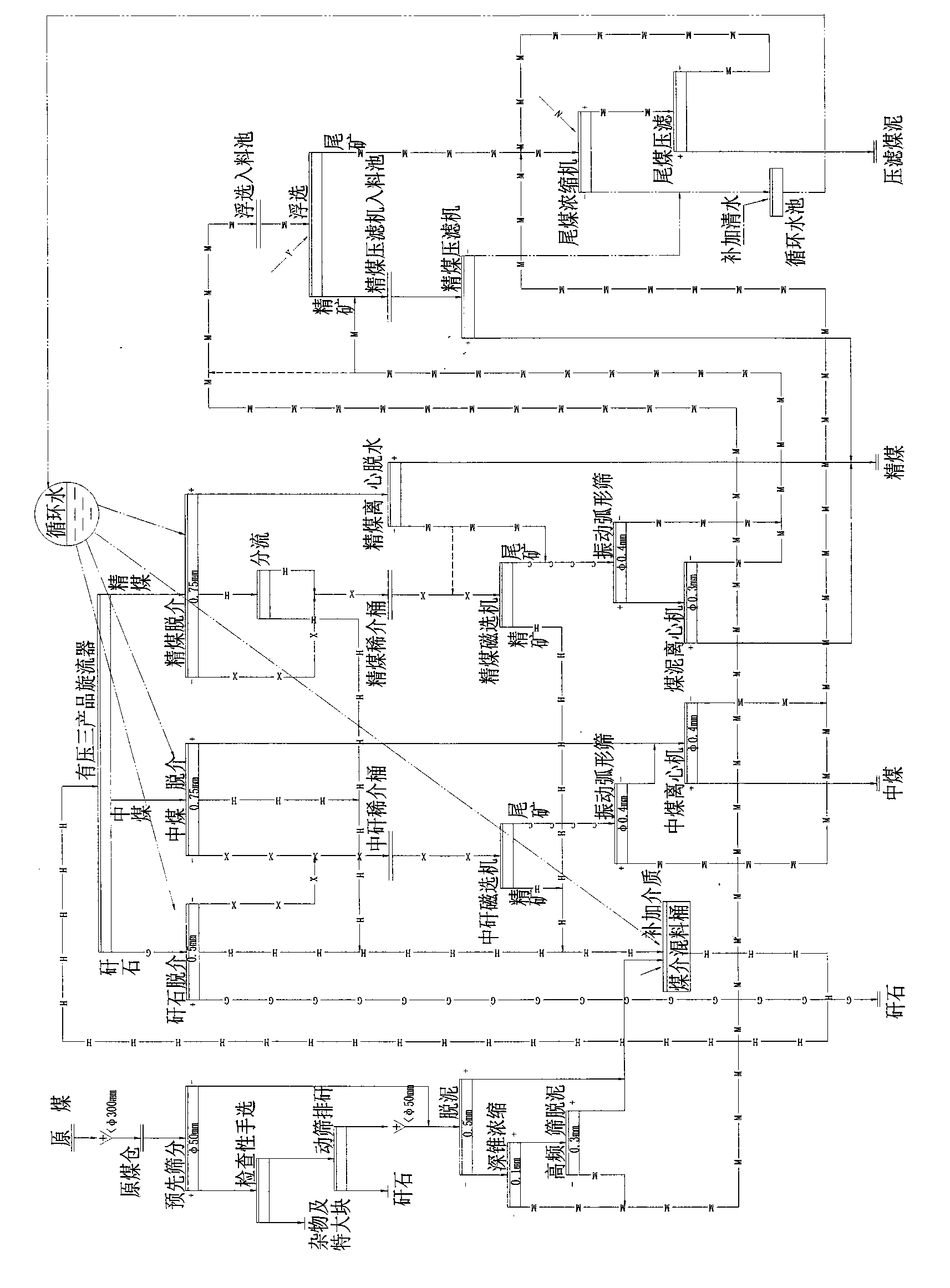

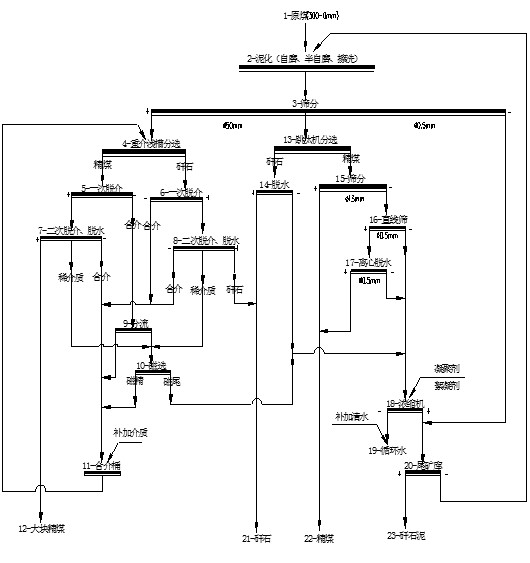

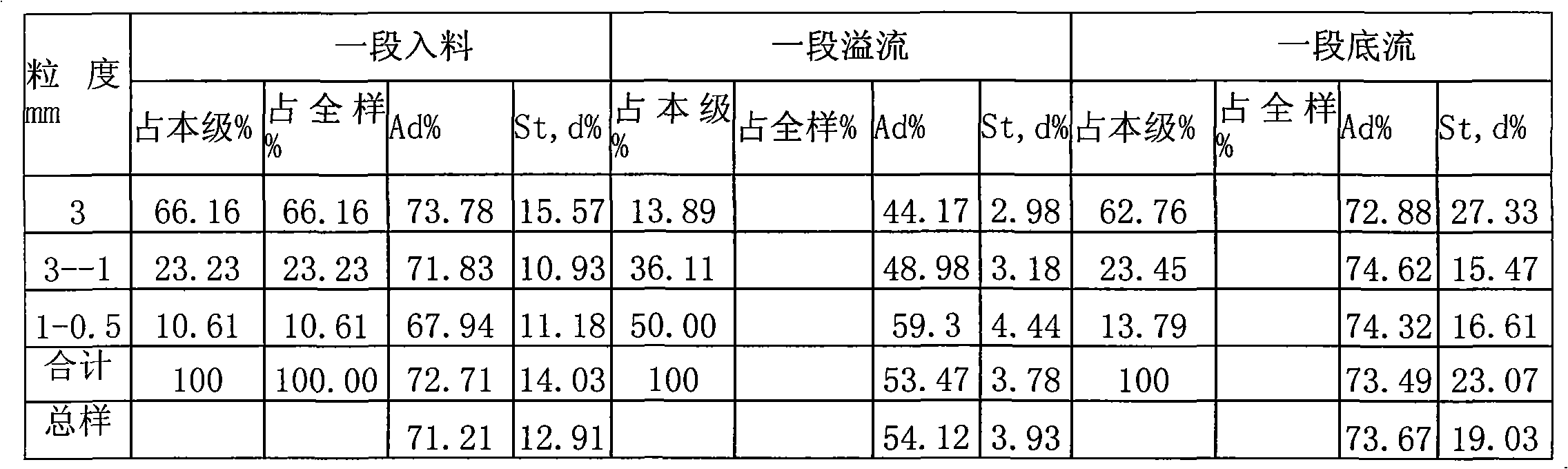

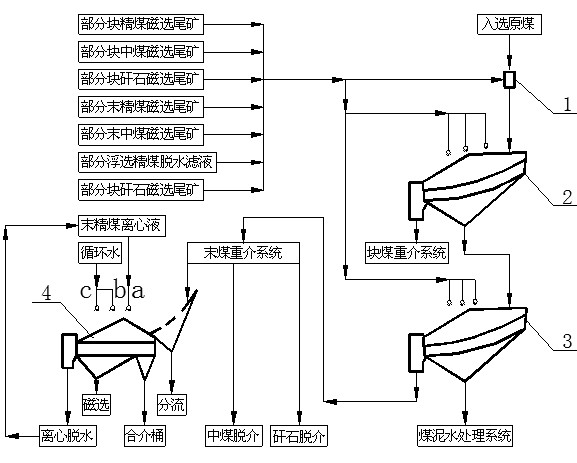

Classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process

InactiveCN103350027AImprove sorting efficiencyFlexible structureWet separationThermodynamicsMagnetic separator

Provided is a classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process. The process comprises the steps that wet classification and primary desliming are carried out on raw coal after prescreening, gangue predischarging and breaking are carried out on the raw coal, secondary desliming is carried out on the screen underflow of the raw coal after the screen underflow is concentrated, the oversize products of the secondary desliming and the screen underflow of the primary desliming are together fed in a pressurized three-product cyclone, three products are obtained after separation, and clean coal, middle coal and gangue are obtained after medium separation and dehydration are carried out on the three products. Part of qualified suspension liquid and dilute suspension liquid are obtained when the medium separation is carried out on the three products, magnetic concentrate is obtained after the dilute suspension liquid is recovered by a magnetic separator, and the magnetic concentrate and the qualified suspension liquid are directly fed in a medium blending barrel. The magnetic tailings of the dilute suspension liquid and the undersize mixtures of pre-desliming, the overflow of concentration classifying equipment and a secondary desliming screen enter a coal slime recovery processing system together. The process is high in separation efficiency, flexible in product structure, low in producing and operating cost and prone to achieving the large-scale single system, the modularization and the integrating intellectualization of plant layout.

Owner:煤炭科学研究总院唐山研究院

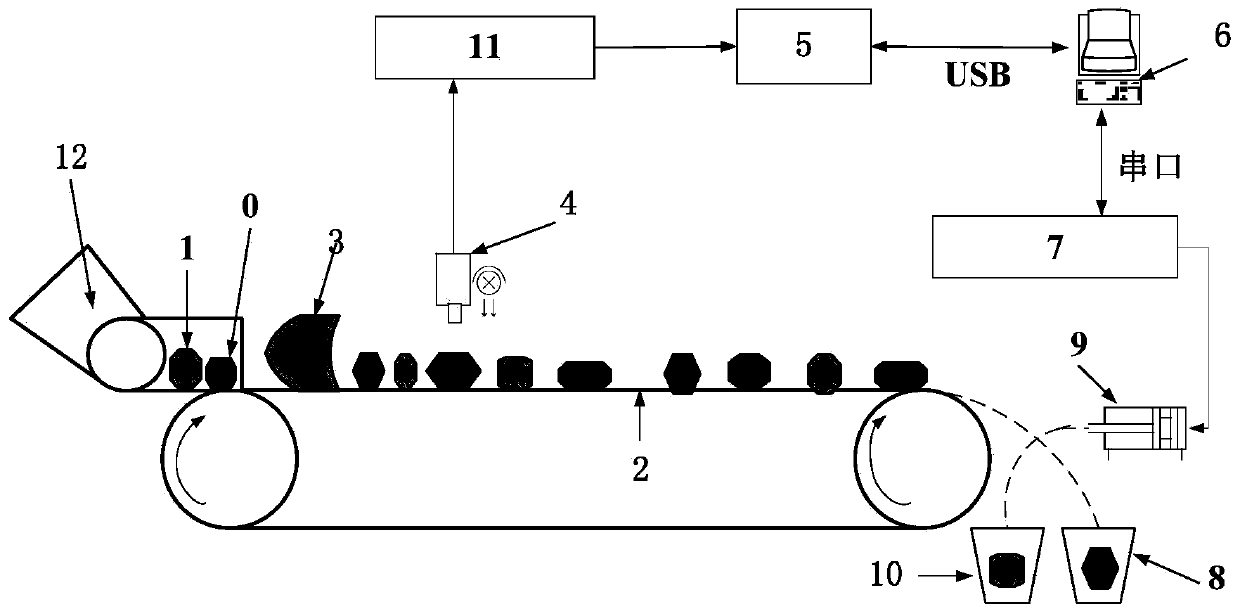

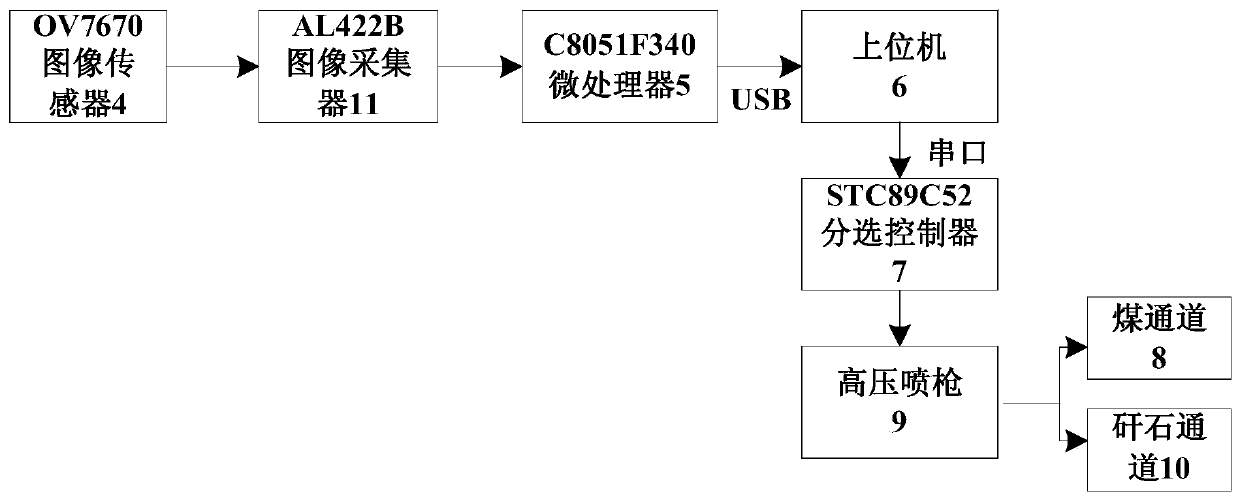

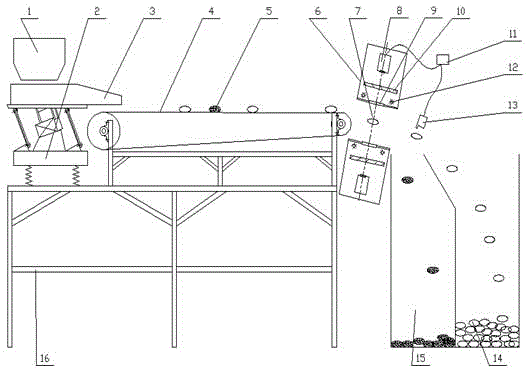

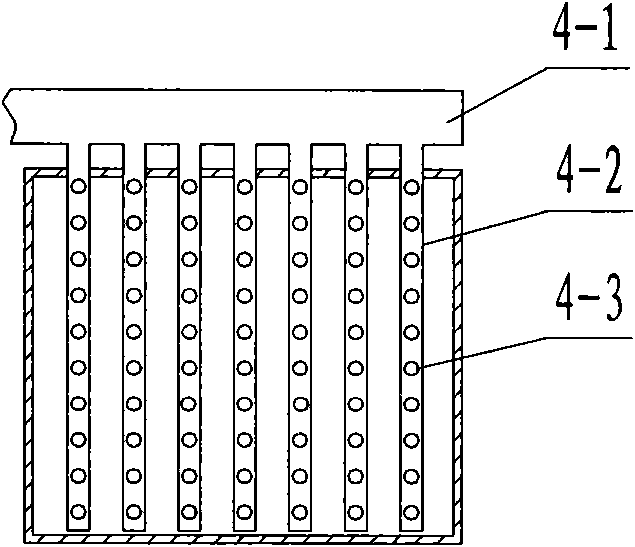

Separation device for coal and waste rocks and separation method thereof

InactiveCN103473568AReduce pollutionHigh sorting accuracyCharacter and pattern recognitionSortingCoal briquetteFeature extraction

The invention provides a separation device for coal and waste rocks. The separation device comprises a vibrating coal feeder, a conveying belt, a queuing device, an image sensor, an image collector, a microprocessor, an upper computer, a separation controller, a high-pressure spray gun, a coal briquette channel and a waste rock channel. Information of the image sensor is processed in real time through the microprocessor and then sent to the upper computer, image information preprocessing, feature extraction, soft measurement model establishing and separation signal outputting are carried out, separation signals are sent to the separation controller, raw coal naturally falls into the coal briquette channel, and the waste rocks fall into the waste rock channel through the high-pressure spray gun. The invention further provides a separation method. The separation device and the separation method have the advantages that the defects of a low recognition rate, heavy environmental pollution and the like existing in an existing coal and waste rock separation method are effectively overcome, the recognition rate of the separation method is high, the environmental pollution can be effectively lightened, the separation device is small in size, easy to install and maintain and low in cost, separation precision and the automation degree of the raw coal are greatly improved, and manual waste rock picking is replaced.

Owner:SHANDONG UNIV OF SCI & TECH

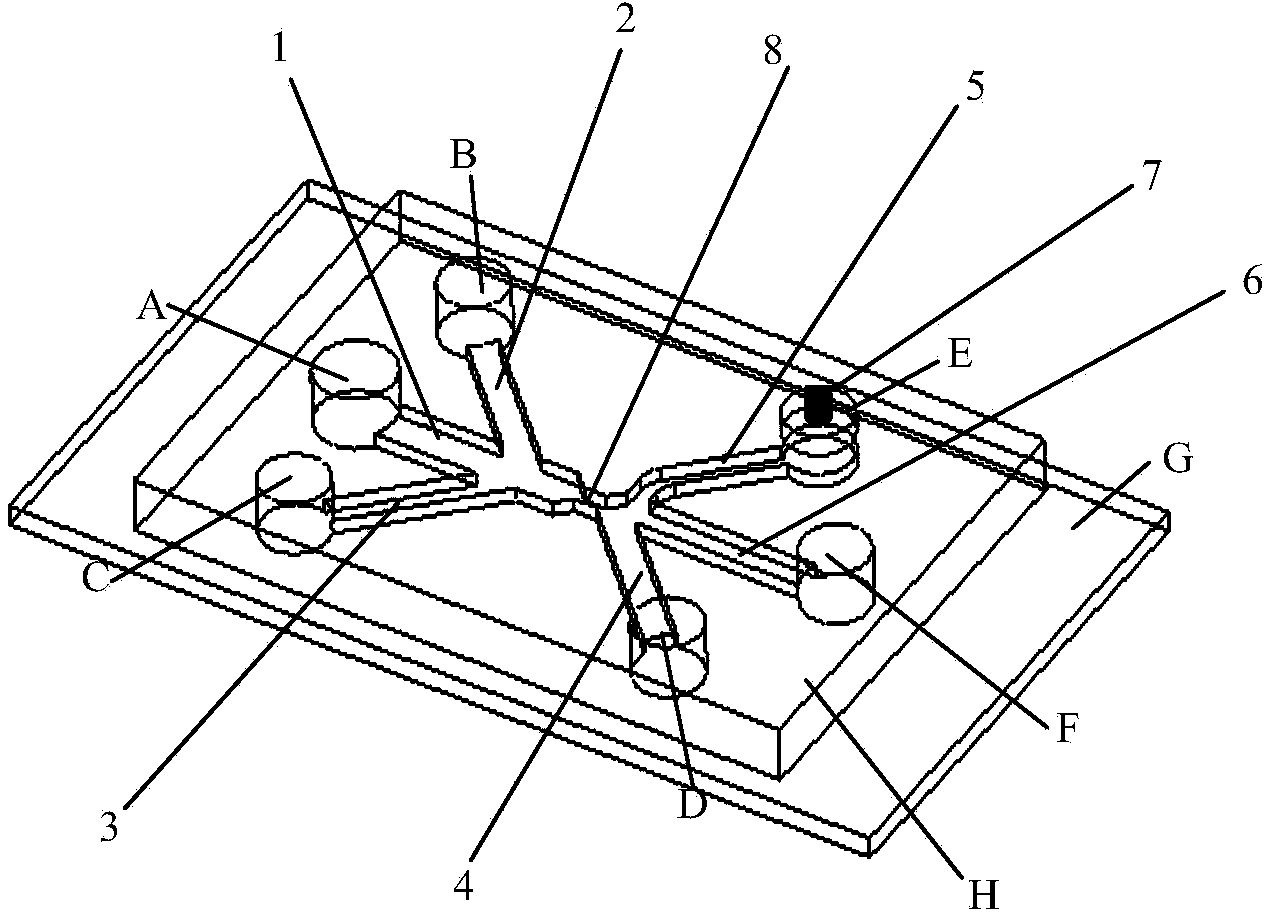

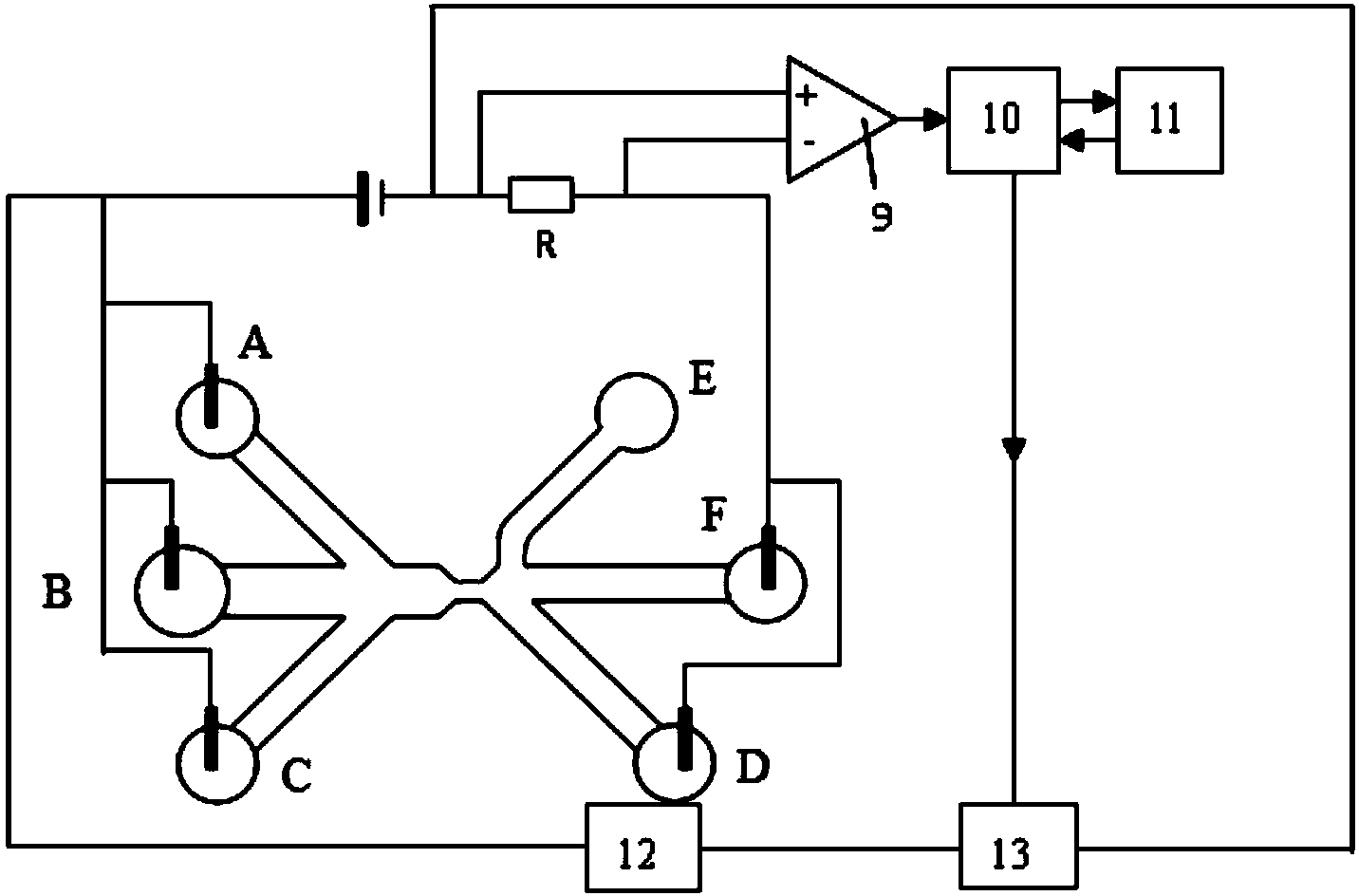

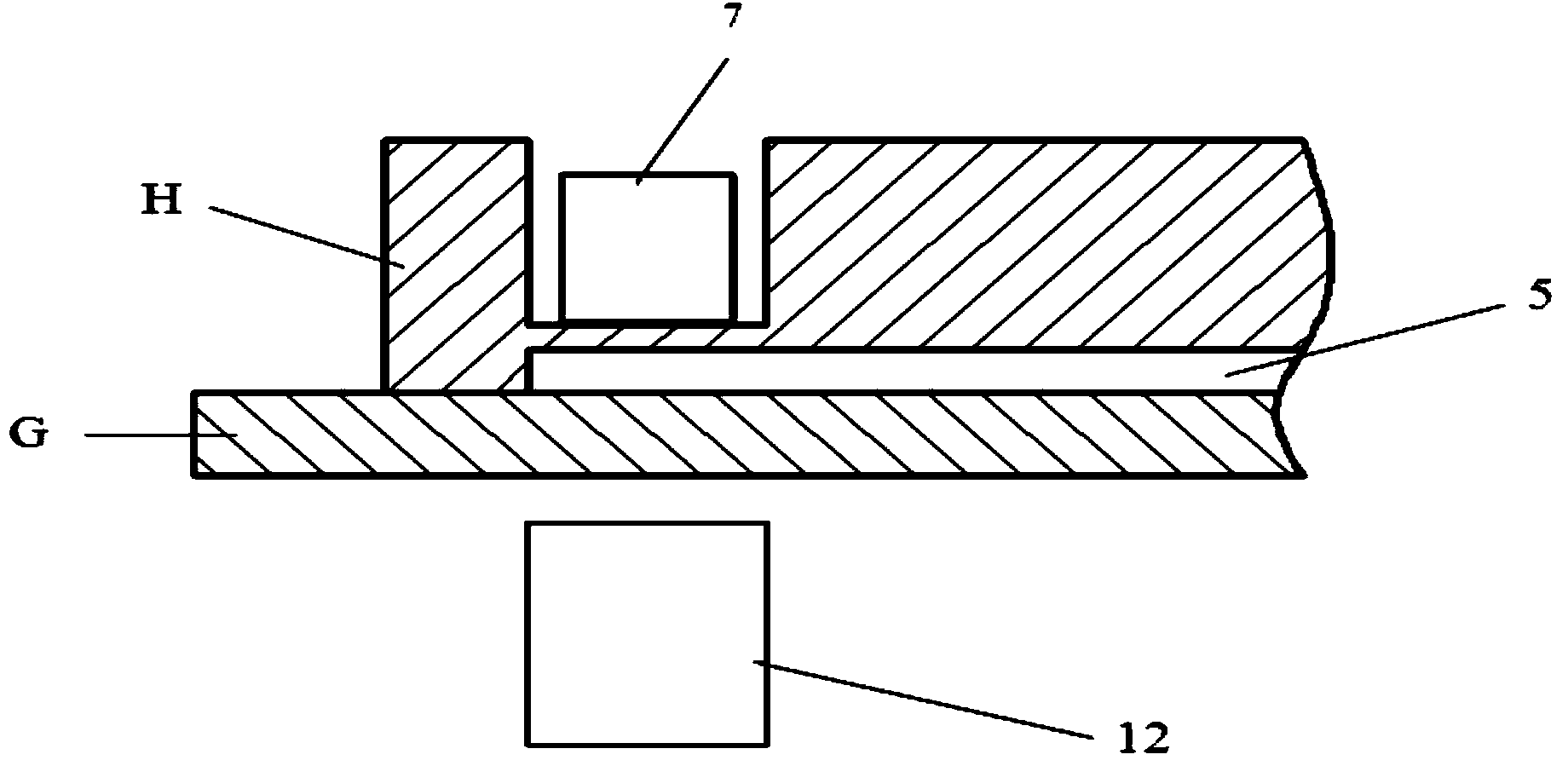

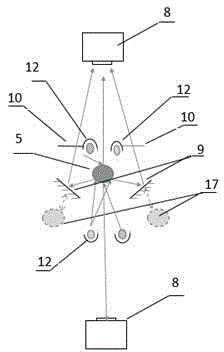

Device and method for full-automatically sorting circulating tumor cells on micro-fluidic chip

ActiveCN104140926AEasy accessReduce volumeBioreactor/fermenter combinationsBiological substance pretreatmentsMain channelEngineering

The invention discloses a device and method for full-automatically sorting circulating tumor cells on a micro-fluidic chip. The device mainly comprises the PDMS micro-fluidic chip and an electromagnetism microvalve structure. The PDMS micro-fluidic chip comprises liquid storage holes (A, B, C, D, E and F), a detecting channel, a main channel, a first focusing channel, a second focusing channel, a sample outlet channel, a target cell collecting channel and an electromagnetic sorting channel. When the circulating tumor cells pass through the detecting channel, produced voltage signals are detected and sent to an NI collecting card and a processing terminal, the processing terminal sends out a voltage signal through the NI collecting card so that an electromagnetic relay can be switched off, the electromagnetic microvalve structure presses a PDMS layer below the electromagnetic microvalve structure, the PDMS layer deforms, a part of liquid is drained out of the liquid storage hole E, and the circulating tumor cells are pushed to flow to the target cell collecting channel. According to the device, the embedded type electromagnetic microvalve structure is used for providing driving force for sorting, electroosmosis driving and electroosmosis focusing are adopted on samples, and the circulating tumor cells can be detected and sorted in a full automatic mode.

Owner:THE SECOND HOSPITAL OF DALIAN MEDICAL UNIV +1

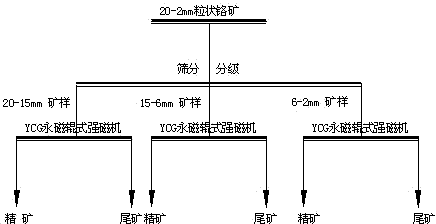

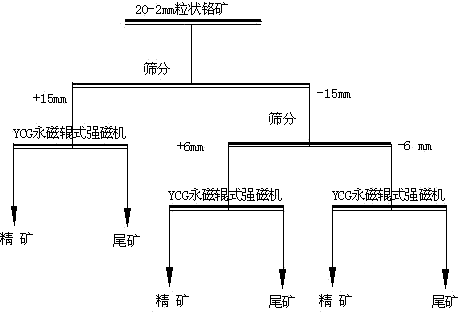

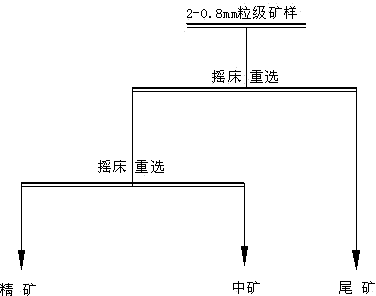

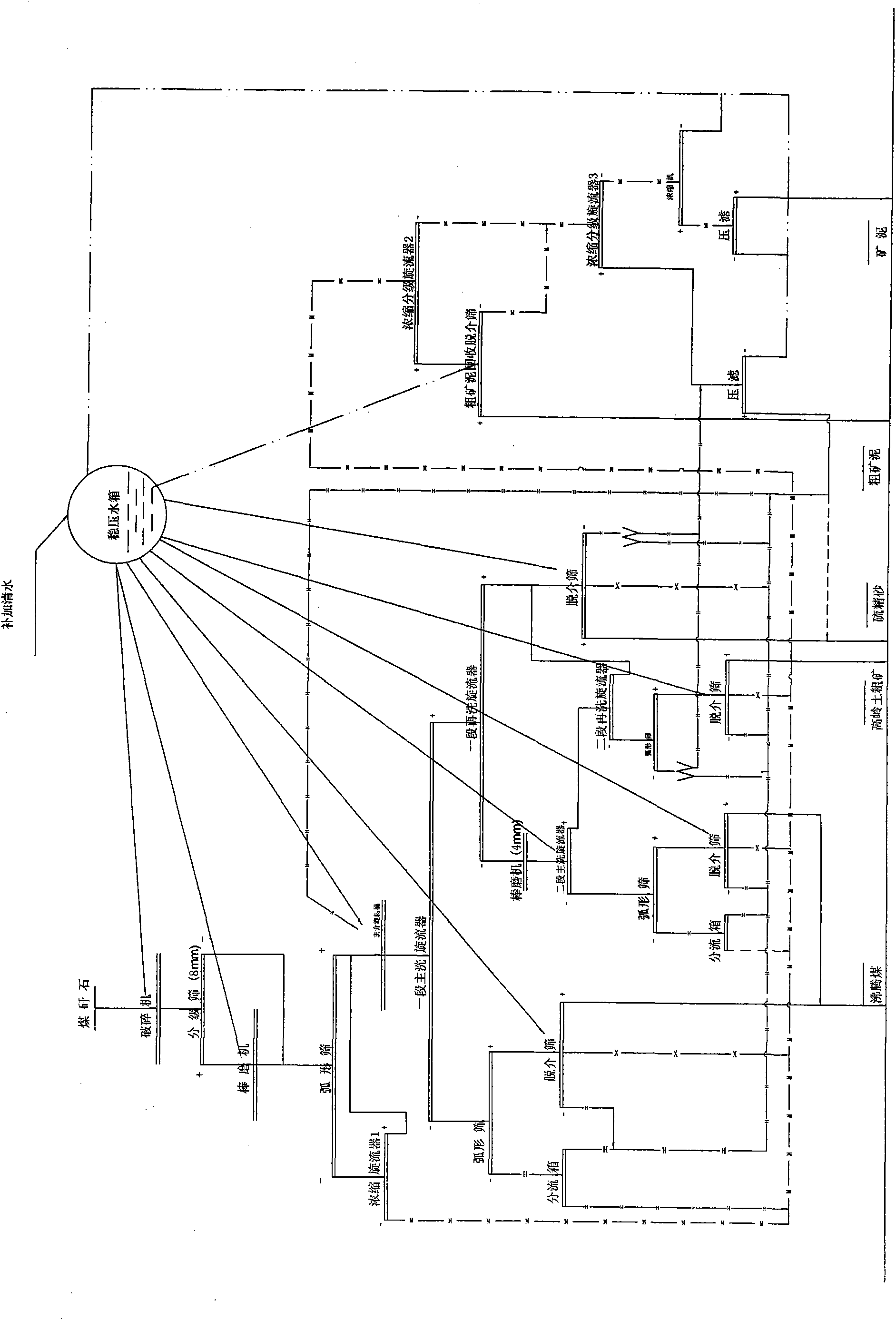

Novel beneficiation technology of high-grade ferrochrome ore

The invention discloses a novel beneficiation technology of high-grade ferrochrome ore. The novel beneficiation technology includes the following technological processes that ferrochrome ore is broken and is screened and classified into the ore of +20 mm fraction and the ore of -20 mm fraction. The ore of the +20 mm fraction receives manual back picking or hotching, large waste ore is thrown, and block concentrate is obtained. The narrow grade of the -20 mm fraction is screened and classified into four fractions, namely the 20-15 mm fraction, the 15-6 mm fraction, the 6-2 mm fraction and the 2-0 mm fraction. For the 20-15 mm fraction, the 15-6 mm fraction and the 6-2 mm fraction, a permanent magnet roller type intensity magnetic separator is used for performing dry intense magnetic separation. The 2-0 mm fraction is further screened and classified into the 2-0.8 mm fraction and the 0.8-0 mm fraction. For the 2-0.8 fraction, a shaker is selected again to obtain shaker gravity concentrate, and for the 0.8-0 mm fraction, a spiral chute and the shaker are used and a united procedure is selected again to obtain the thin-particle gravity concentrate. The novel beneficiation technology can be used for obtaining the concentrate and removing tailings in advance and has the advantage of being lower in energy consumption compared with other technologies. The technology can be used for grading chrome ore and can also be used for grading other weak magnetic iron minerals such as manganese ore, goethite, siderite and limonite.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Fruit picking type sorting method

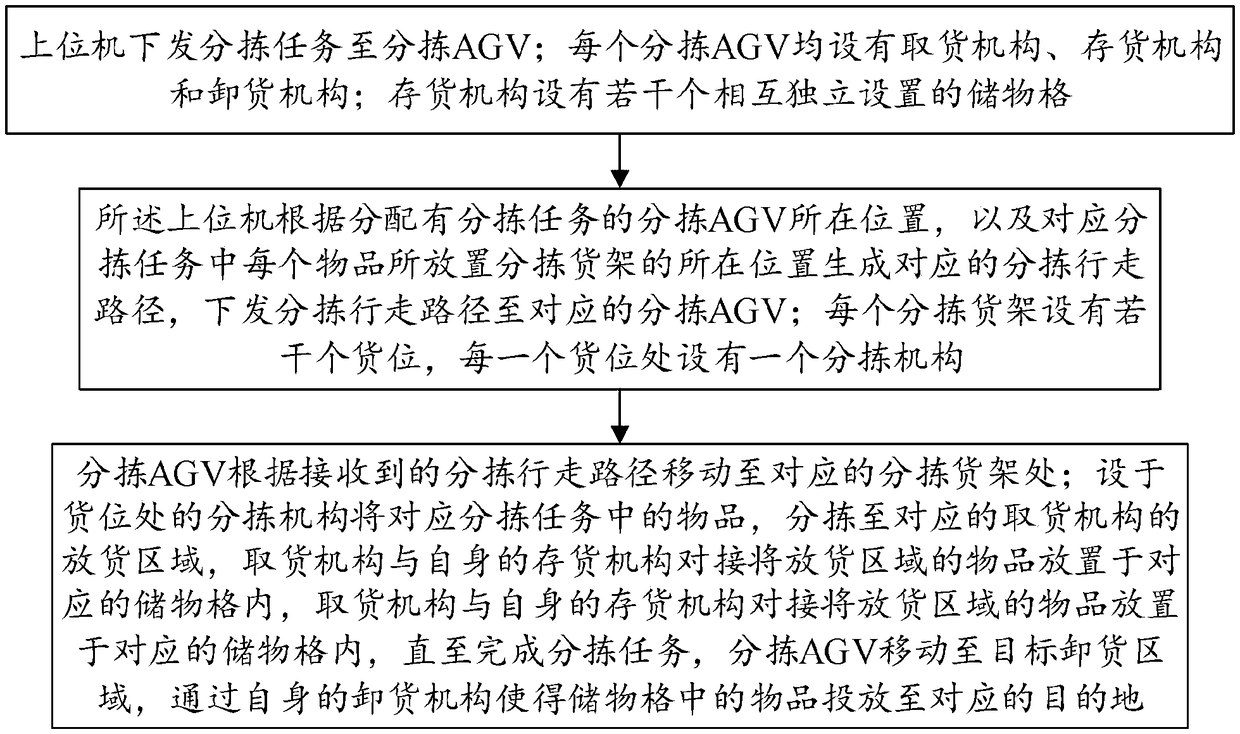

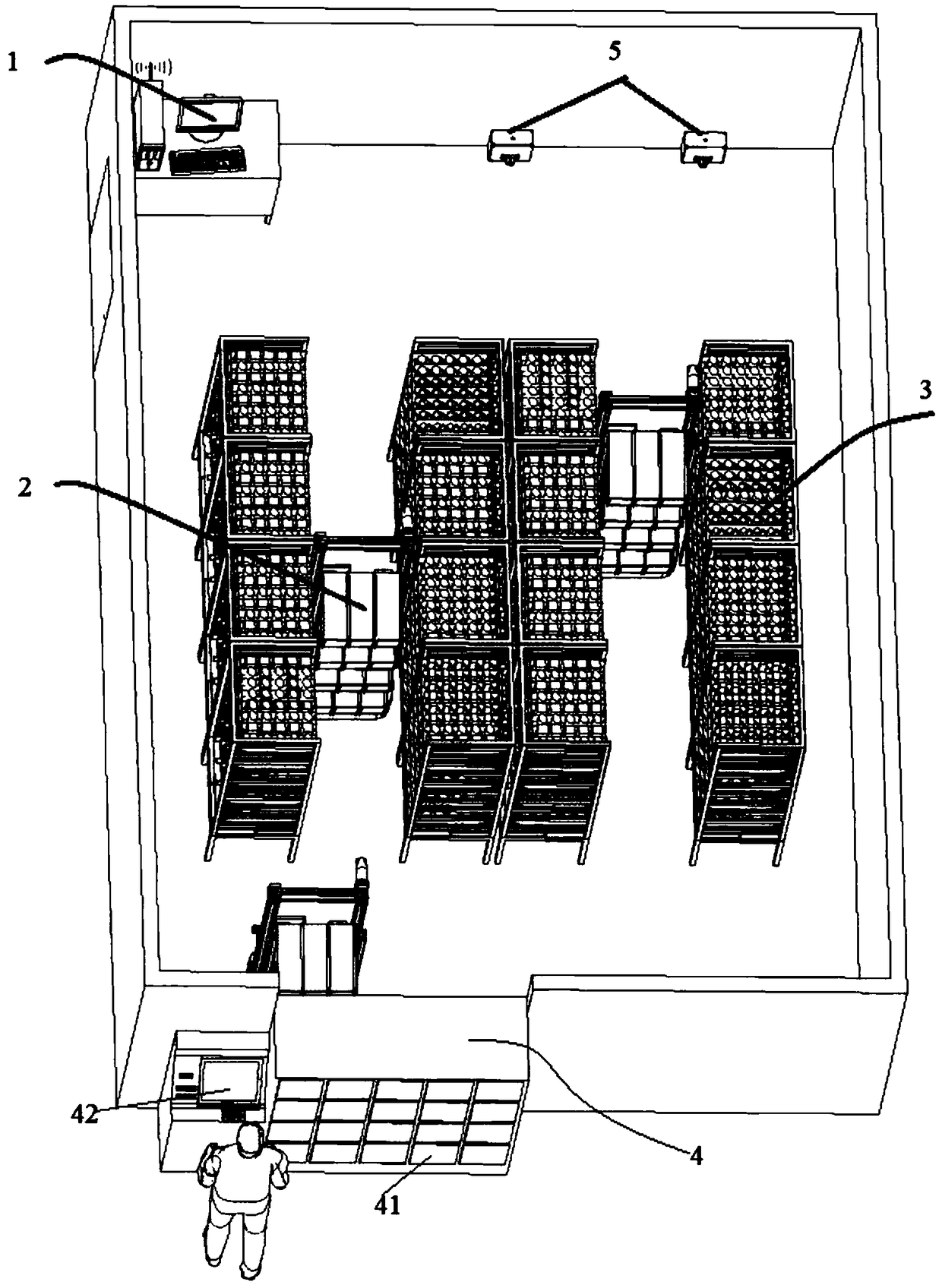

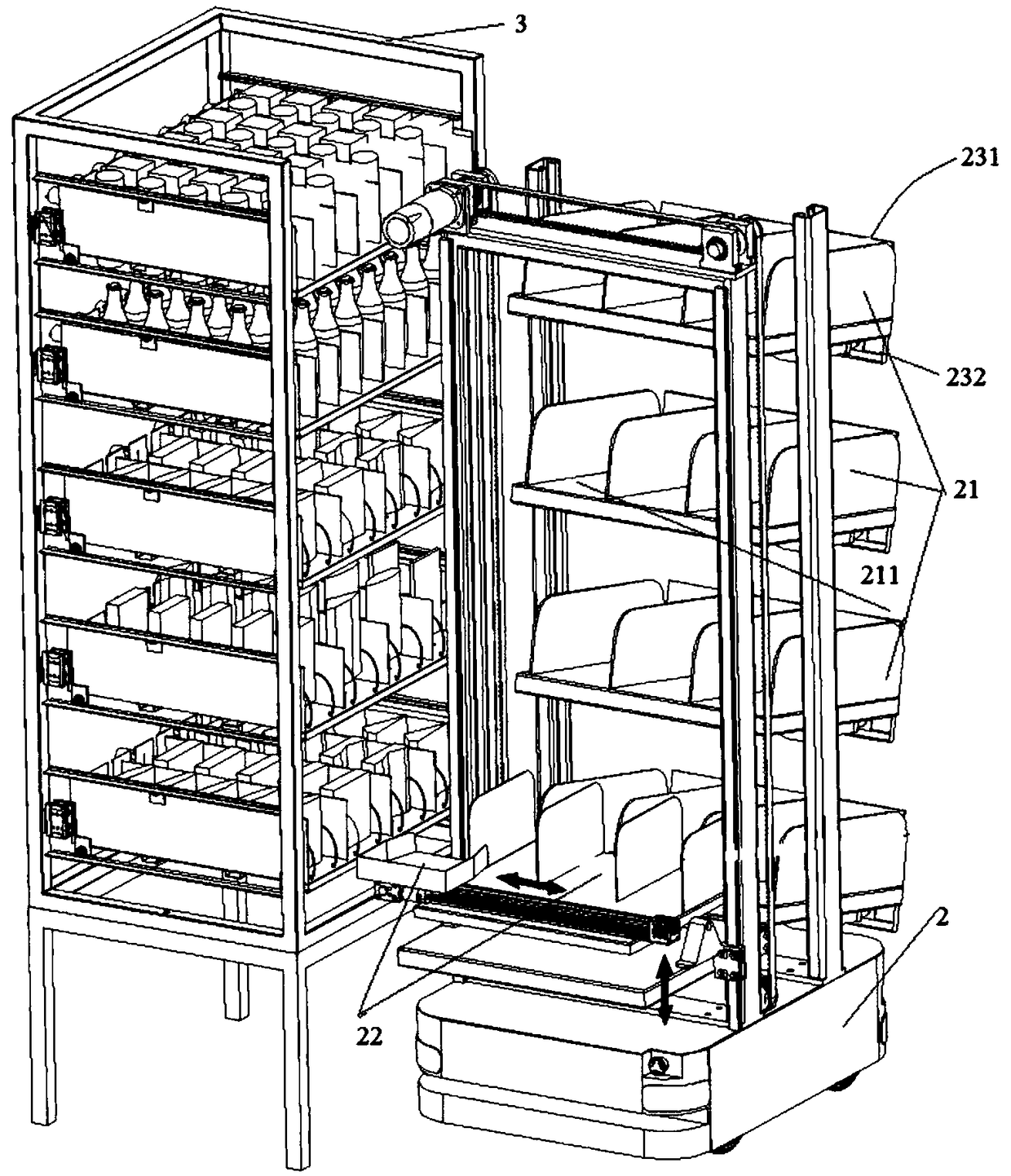

The invention provides a fruit picking type sorting method. The fruit picking type sorting method comprises the steps that an upper computer issues a sorting task to a sorting AGV; the upper computeris positioned according to the position where the sorting AGV is distributed with the sorting tasks, and a corresponding sorting walking path is generated according to the position where each articleis placed in the corresponding sorting task, and issues a sorting walking route to a corresponding sorting AGV; the sorting AGV moves to the corresponding sorting goods shelf according to the receivedsorting walking path; the sorting mechanism is arranged at the goods position, the sorting mechanism corresponds to the goods in the sorting task, sorting the goods to the goods placing area of the corresponding goods taking mechanism, the goods taking mechanism is in butt joint with an inventory mechanism of the goods taking mechanism, articles in the goods placing area are placed in the corresponding storage grids, until the sorting task is completed, the sorting AGV moves to the target unloading area, and the goods in the storage grid are enabled to be thrown to the corresponding destination through the unloading mechanism of the sorting AGV. According to the fruit picking type sorting method, the purposes of simplifying the sorting process, realizing efficient sorting and reducing theoccupied area of the sorting operation are achieved.

Owner:SHANGHAI ATOVO ROBOTICS CO LTD

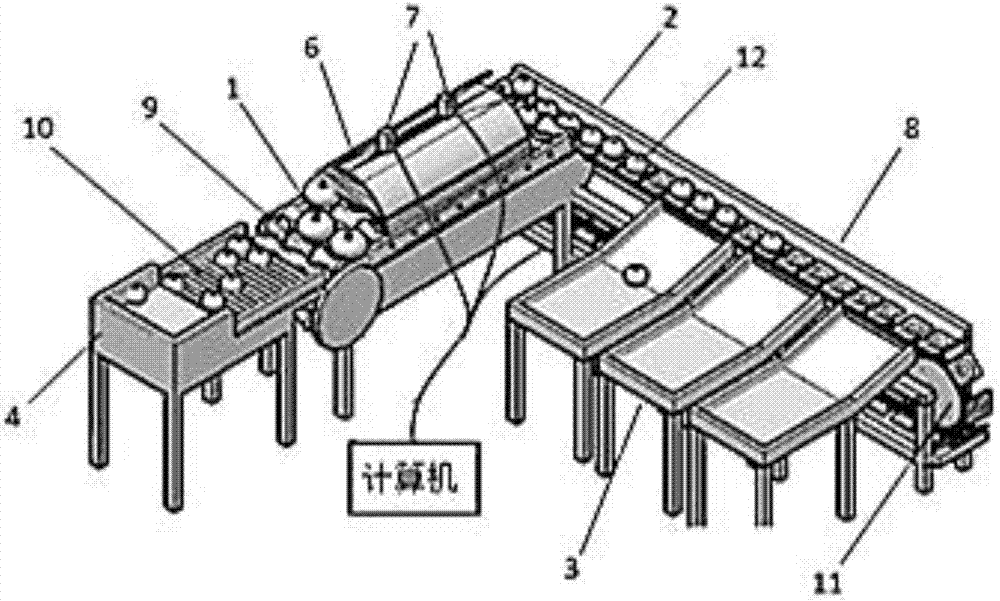

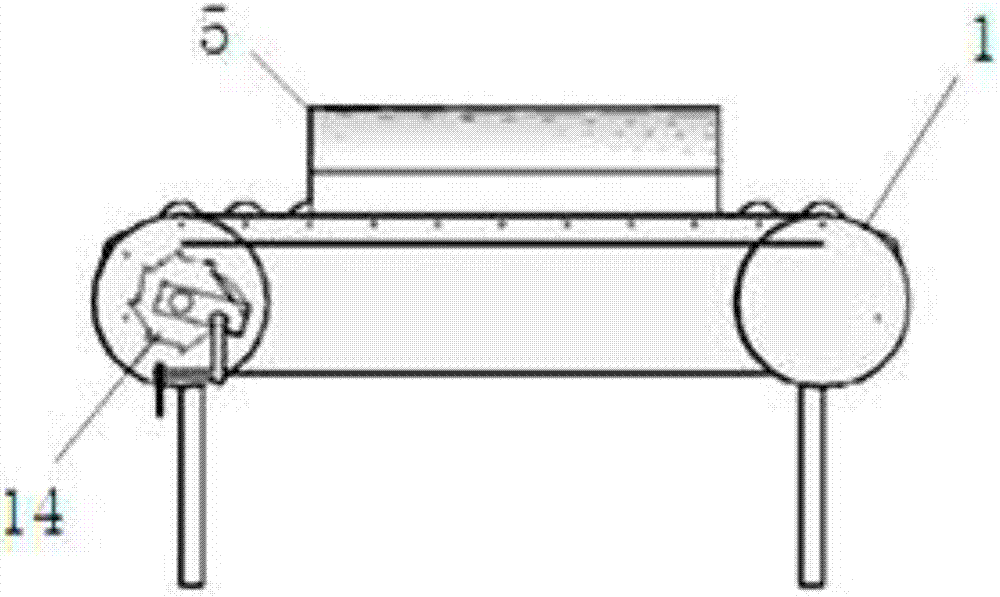

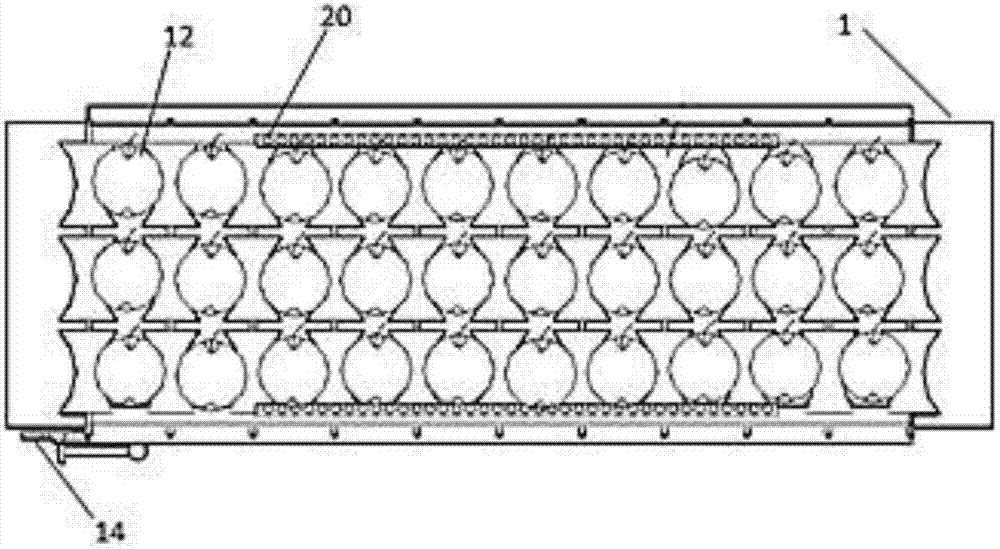

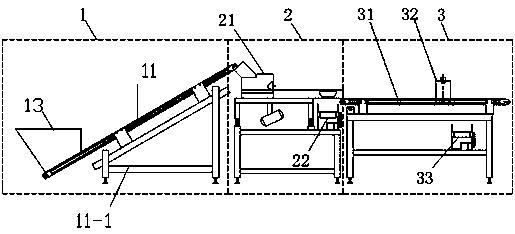

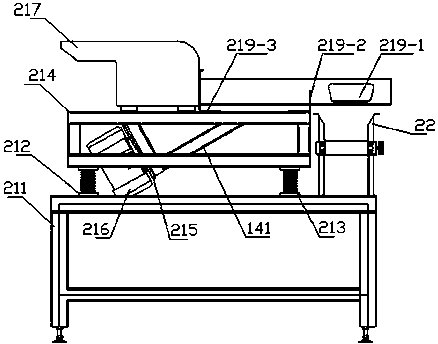

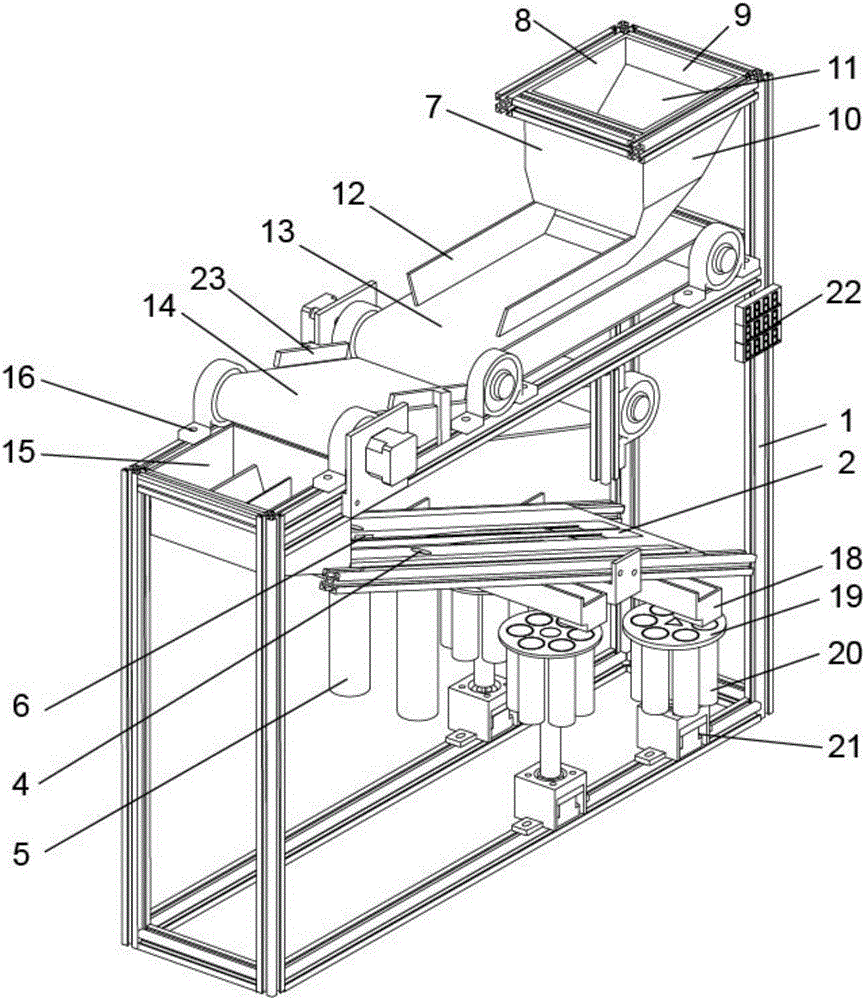

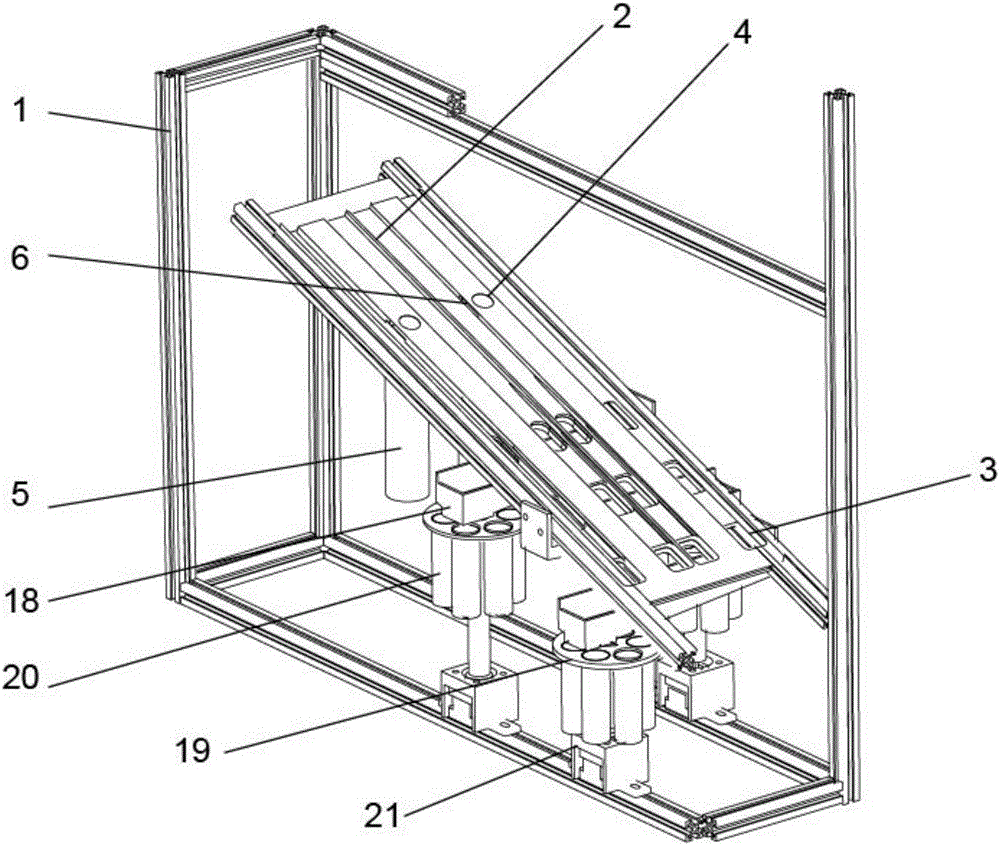

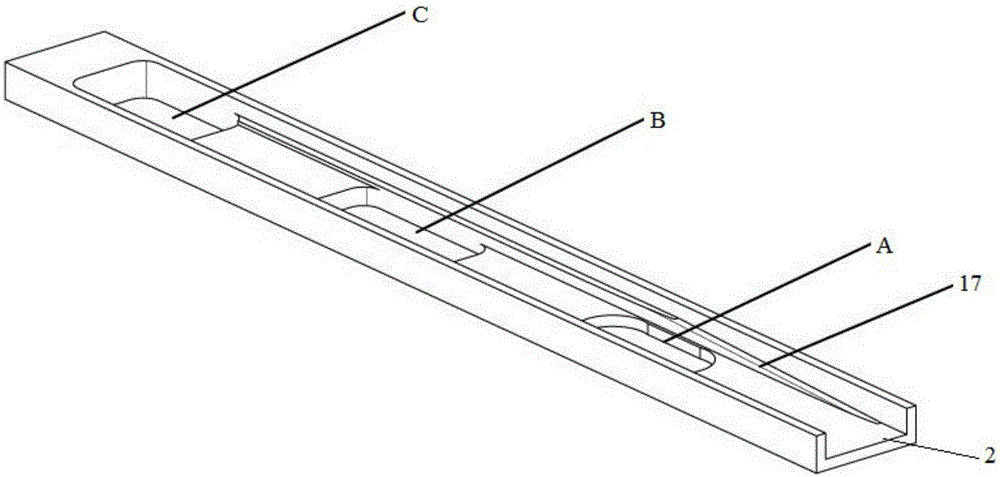

Fruit grader based on image processing

A fruit grader based on image processing belongs to the technical field of agricultural machinery and comprises a loading mechanism, a batch-type multi-channel material transport mechanism, a continuous single-channel material transport mechanism, a sorting box and a fruit information collecting mechanism. The front end of the batch-type multi-channel material transport mechanism is provided with the loading mechanism, the upper part of the batch-type multi-channel material transport mechanism is provided with the fruit information collecting mechanism, and the tail part of the batch-type multi-channel material transport mechanism is in vertical connection with the continuous single-channel material transport mechanism which is connected with the sorting box. Due to the effective machinery design, the fruit grader based on image process disclosed by the invention effectively avoids the ghost phenomenon when images are collected without lowering the grading efficiency and effectively improves the grading precision and the grading efficiency by combining with a schedule control method.

Owner:SHANGHAI JIAO TONG UNIV

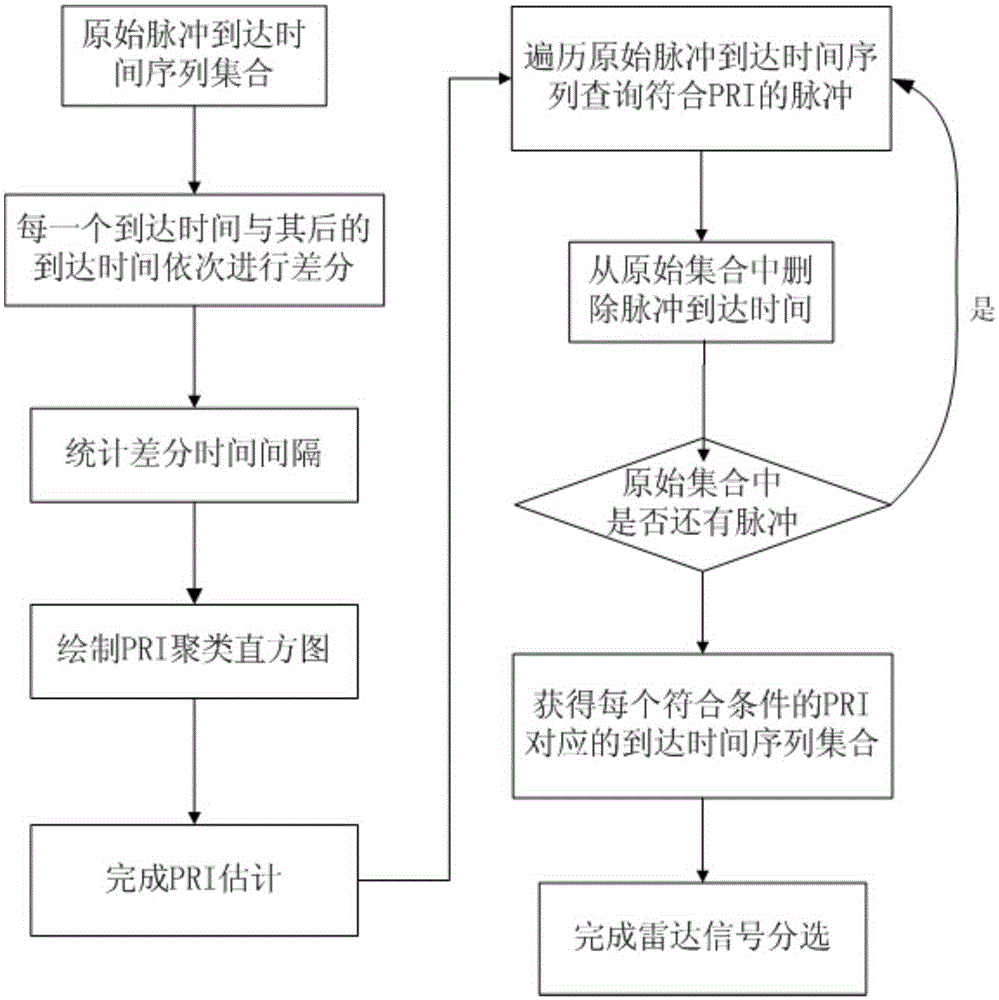

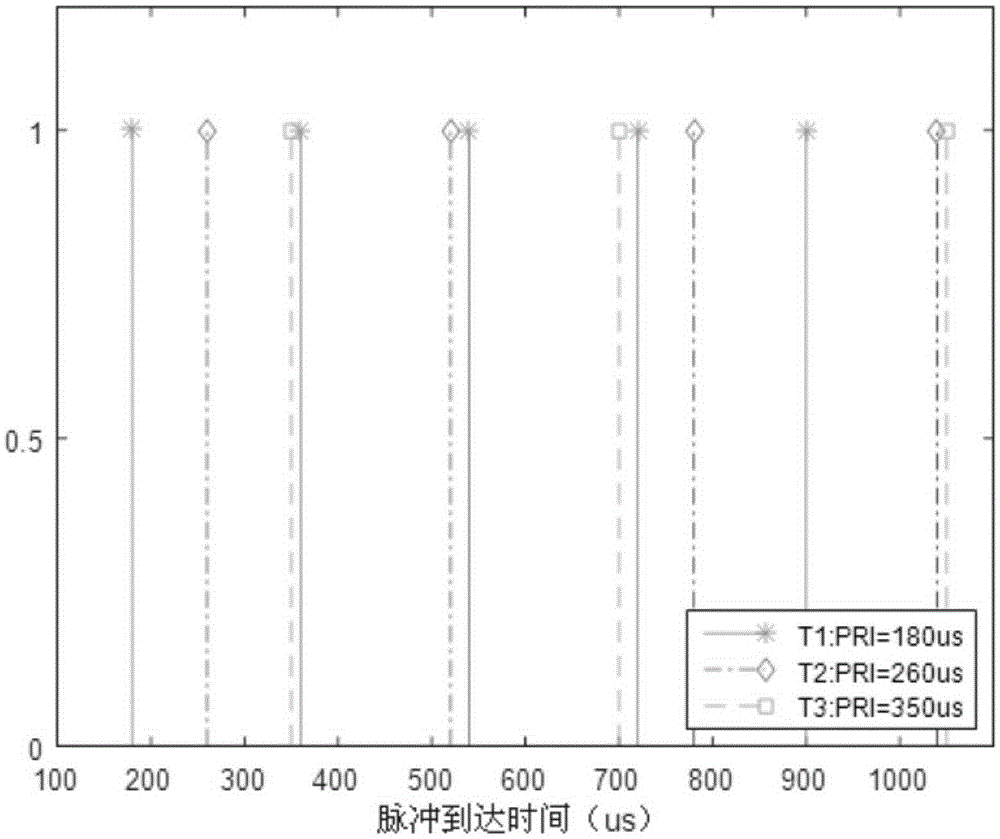

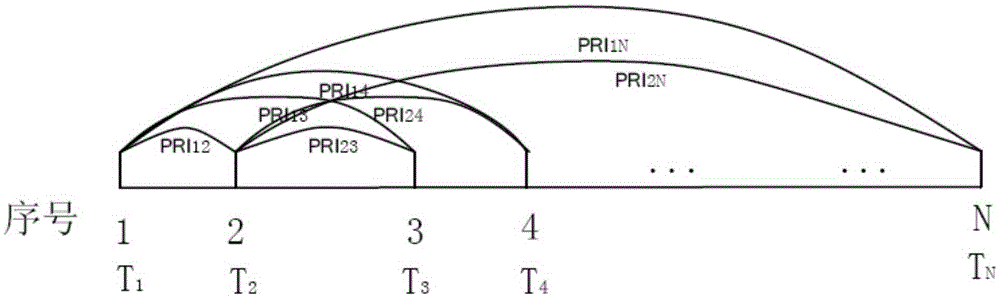

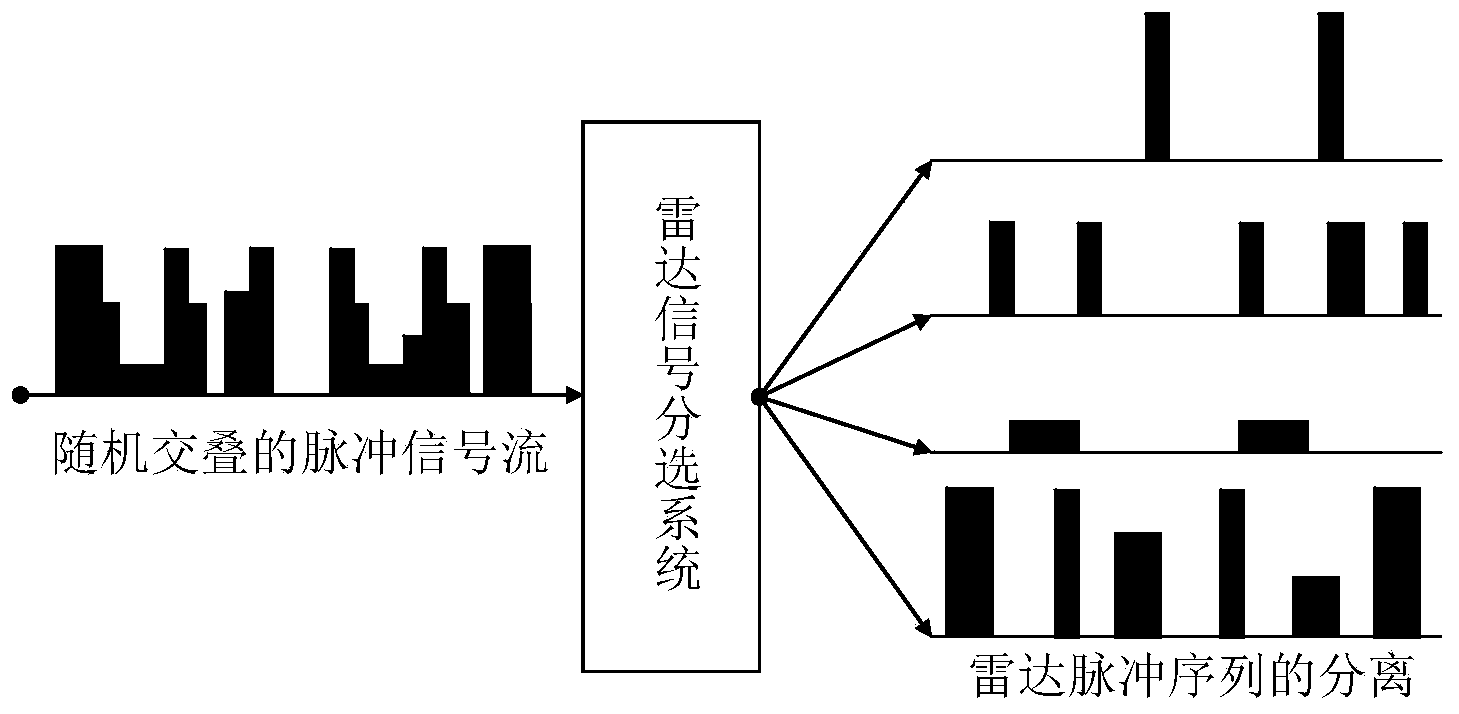

Single channel radar signal sorting method

ActiveCN105277923AImprove applicabilityHigh sorting accuracyWave based measurement systemsRadar signalsHistogram

The invention relates to a single channel radar signal sorting method, which comprises the following steps: 1) selecting one N-length section of arrival time sequence to form an original pulse arrival time sequence set; 2) performing a multidimensional difference processing for the original pulse arrival time sequence; 3) performing grouping for the time interval obtained by difference processing for each arrival time, and performing statistical counting; 4) drafting a PRI clustering statistical histogram according to the statistical counting result of the time interval obtained by difference processing for the arrival time included in each group, and comparing the PRI clustering statistical histogram with a detection threshold to obtain possible PRI estimated values; 5) rejecting the harmonic component of the possible PRI estimated values to obtain eligible PRI estimated values; and 6) successively extracting the corresponding arrival time sequence from the original pulse arrival time sequence according to each eligible PRI estimated value, forming a sequence of the extracted arrival times according with the same PRI estimated value in time order, and finishing the signal sorting process.

Owner:TSINGHUA UNIV

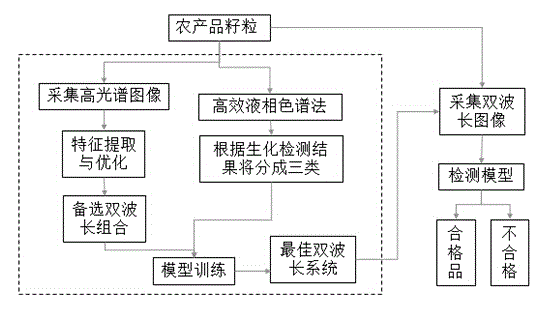

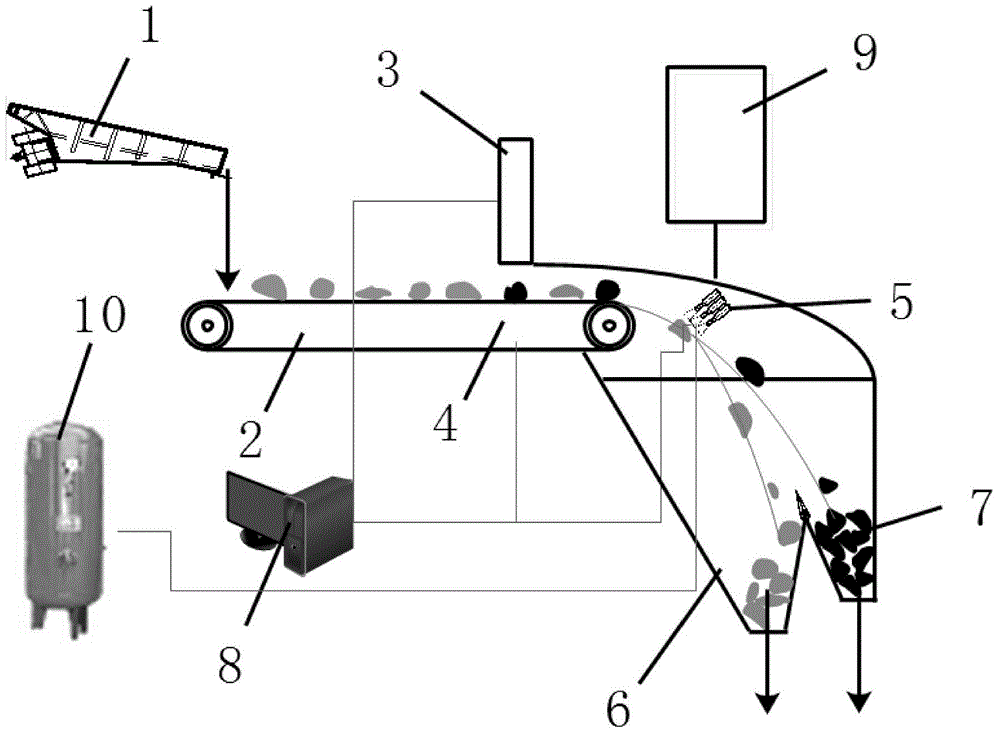

Intelligent agricultural product sorting machine with aflatoxin detection function

ActiveCN104646315ALow costRealize online automatic detectionFluorescence/phosphorescenceSortingManufacturing intelligenceCcd camera

The invention discloses an intelligent agricultural product sorting machine with an aflatoxin detection function. The device takes an aflatoxin sorting detection unit as a core, and an ultraviolet and visible light source, a dual-wavelength filter set, a double-mirror reflecting system and a linear-array CCD camera and the like are arranged in the sorting detection unit. Materials are conveyed to the sorting detection unit by a crawler conveyor, the linear-array CCD camera acquires visible light images of the materials and two ultraviolet fluorescence images shot by filters, and the on-line detection of aflatoxin contaminated grains is realized by using a computer detection algorithm. The wavelengths of double filters used in the invention are determined by using a hyperspectral imaging method, and different filters can be replaced for detecting different agricultural products, particularly, the filters with the wavelengths of 437 and 537nm can be used for detecting corns, the filters with the wavelengths of 420 and 450nm can be used for detecting peanuts, and the filters with the wavelengths of 400 and 420nm can be used for detecting hot peppers. The device can be widely used in the field of processing trade of agricultural products, and the on-line aflatoxin inspection efficiency can be improved.

Owner:QINGDAO AGRI UNIV +4

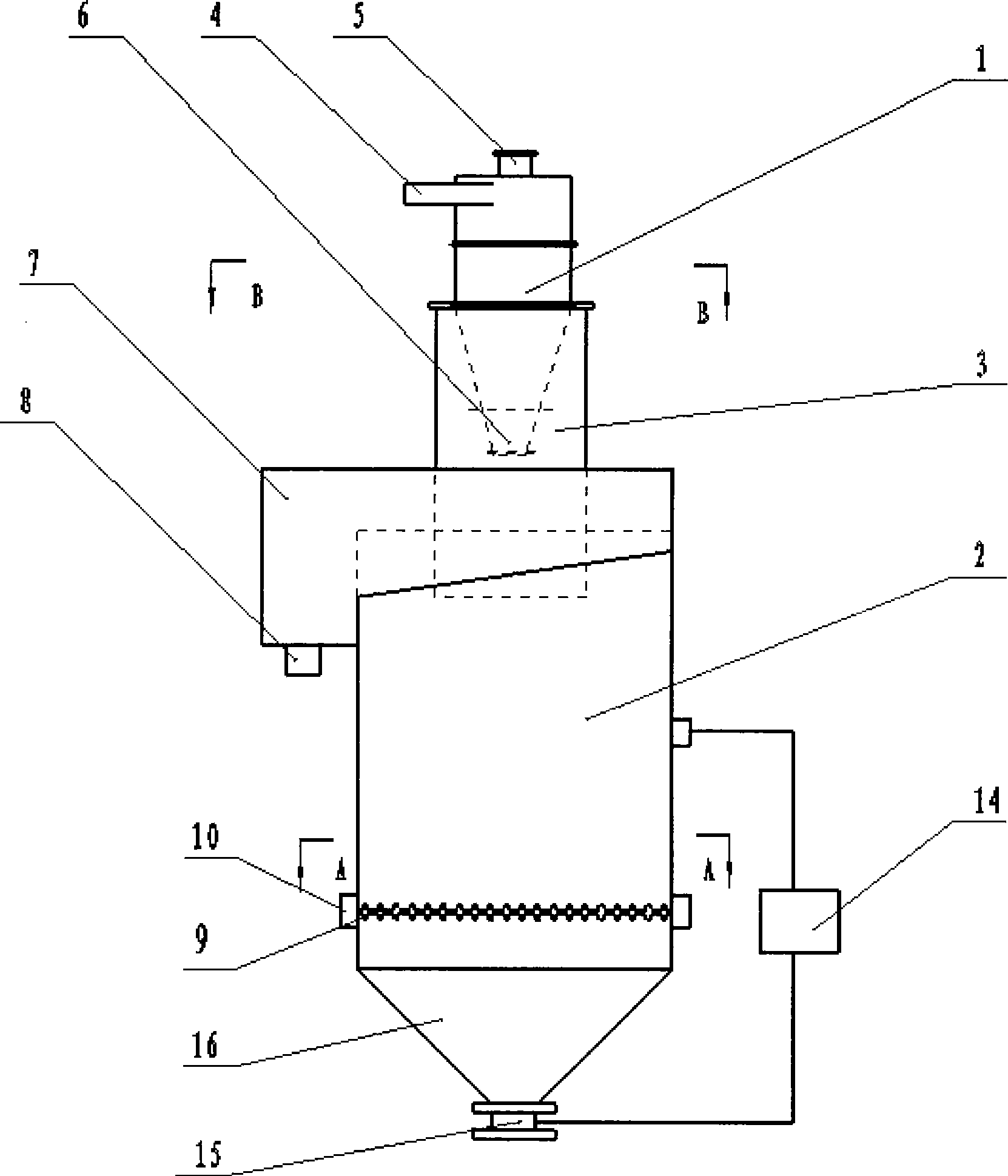

Integrated device for hydraulic classification and sorting of coarse slime as well as classification and sorting system

InactiveCN101502818AReduce construction investment and operating costsLess investmentSievingScreeningEngineeringIntegrated devices

A coarse coal slime hydraulic grading and sorting integration device and a sorting system using the device belong to the technical field of cleaning unit and are used for shortening technological processes of coal separation and improving the sorting accuracy of the coal slime. The grading and sorting integration device comprises a hydraulic grading swirler, an upwelling current sorter and a connecting barrel, which are connected in sequence. A coarse coal slime grading and sorting system is composed of the grading and sorting integration device, a hydraulic grading swirler barrel, a hydraulic grading swirler pump, an arc-shaped sieve, a coal slime centrifuge, a gangue dewatering sieve, a cleaned coal belt conveyer, a gangue belt conveyer and a main pipeline. The hydraulic grading swirler barrel is connected with the feeding hole of the hydraulic grading swirler, the overflow port of the hydraulic grading swirler is connected with the pipeline of a floatation system. The overflow port of the upwelling current sorter, the arc-shaped sieve, the coal slime centrifuge and the coal slime belt conveyer are connected in sequence. The overflow port at the bottom of the upwelling sorter is connected with the gangue dewatering sieve, the gangue belt conveyer and a thickener in sequence.

Owner:煤炭科学研究总院唐山研究院

Delivery point sequencing mail sorting system with flat mail capability

InactiveUS20050252836A1Maximizing numberHigh sorting accuracySeparation devicesCharacter and pattern recognitionPoint sequenceEngineering

A method and apparatus for sorting articles to a delivery point sequence includes at least one article sorter adapted to sort articles and a conveying system operable to arrange and convey containers of articles sorted in a first sort pass to an induct of the article sorter for a second sort pass or process of the articles. The conveying system may include at least one transport conveyor and a plurality of zone conveyors or staging zones. The transport conveyor conveys trays from the discharge of the article sorter to the induct of the article sorter, and the zone conveyors are positioned along the transport conveyor. The conveying system is operable to arrange and accumulate trays in a sequenced manner on the transport conveyor. The transport conveyor is operable to discharge the sequenced trays to the induct of the article sorter.

Owner:SIEMENS LOGISTICS LLC

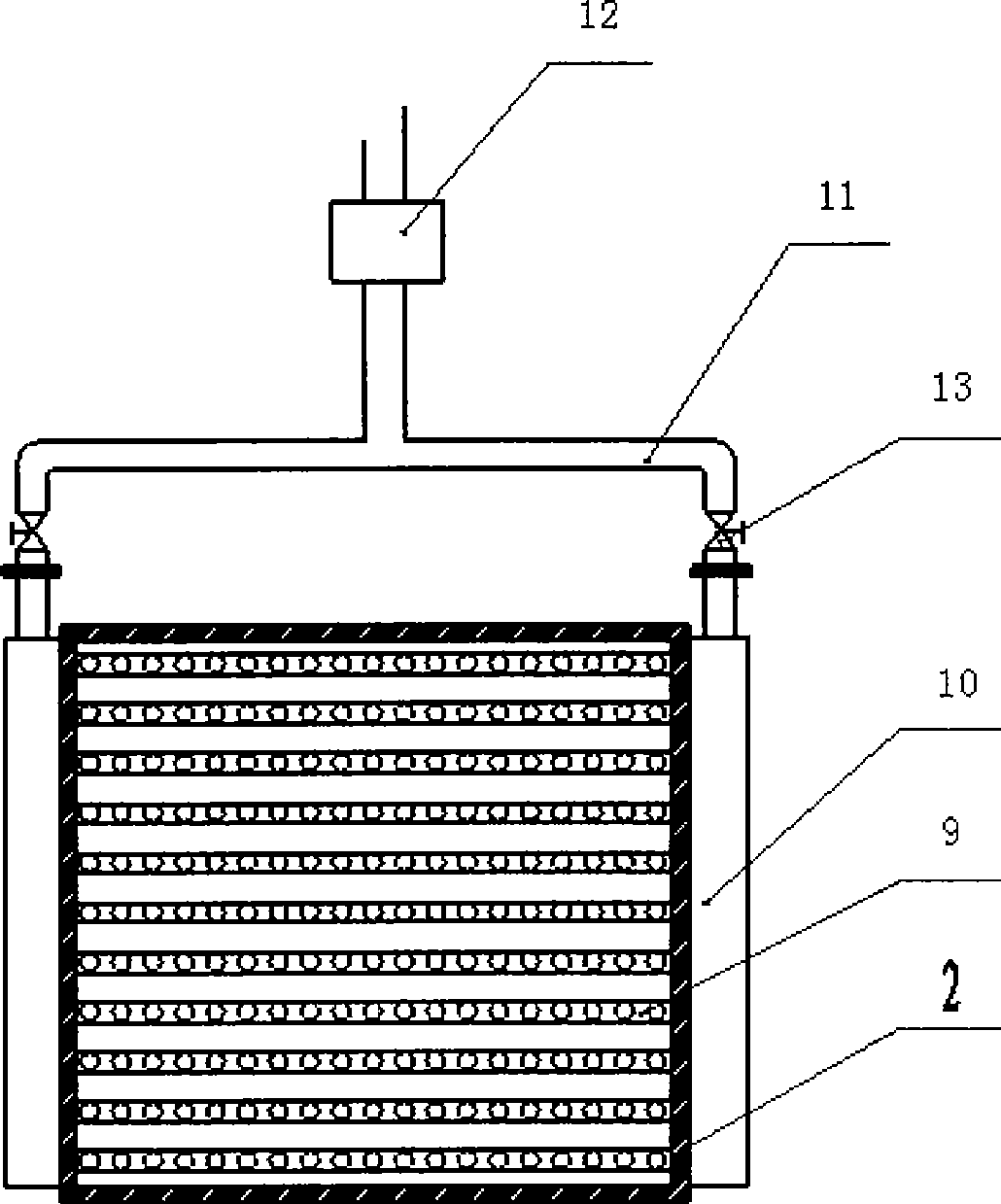

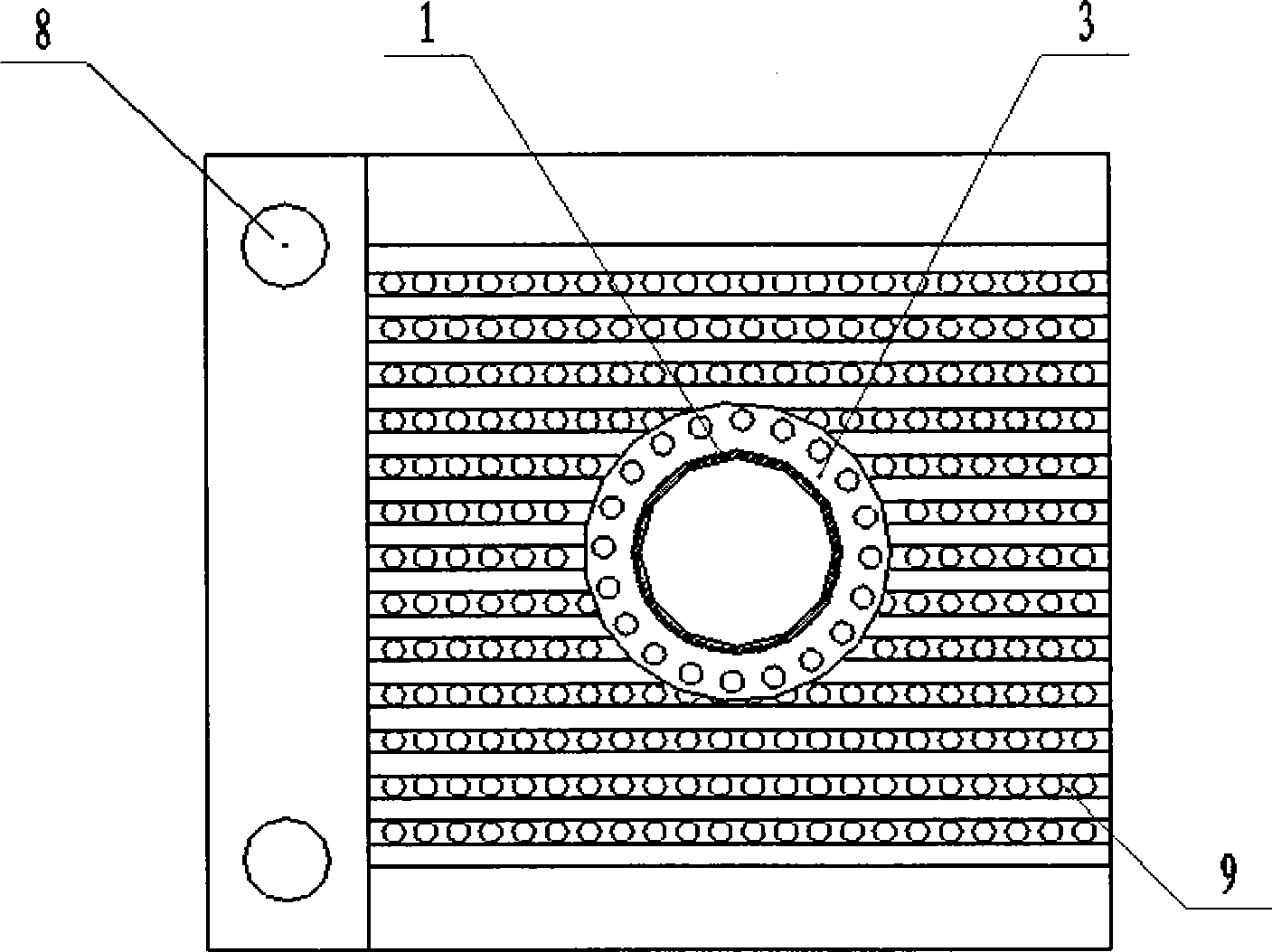

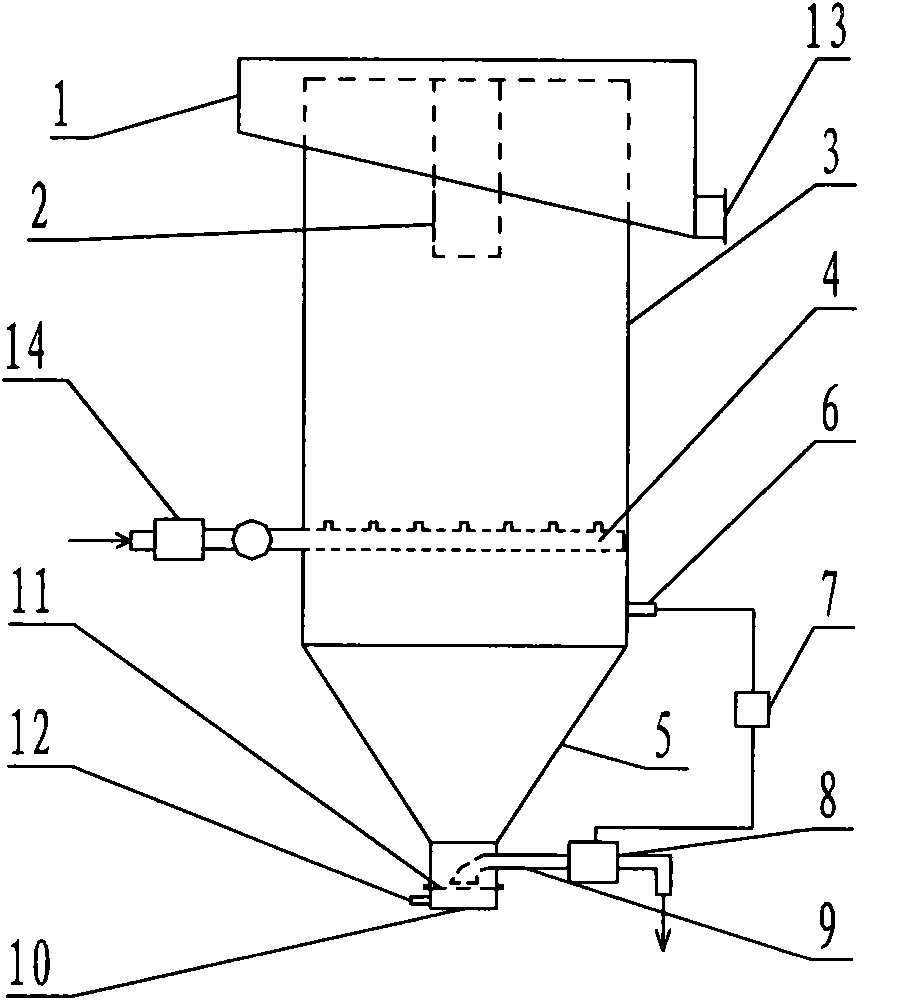

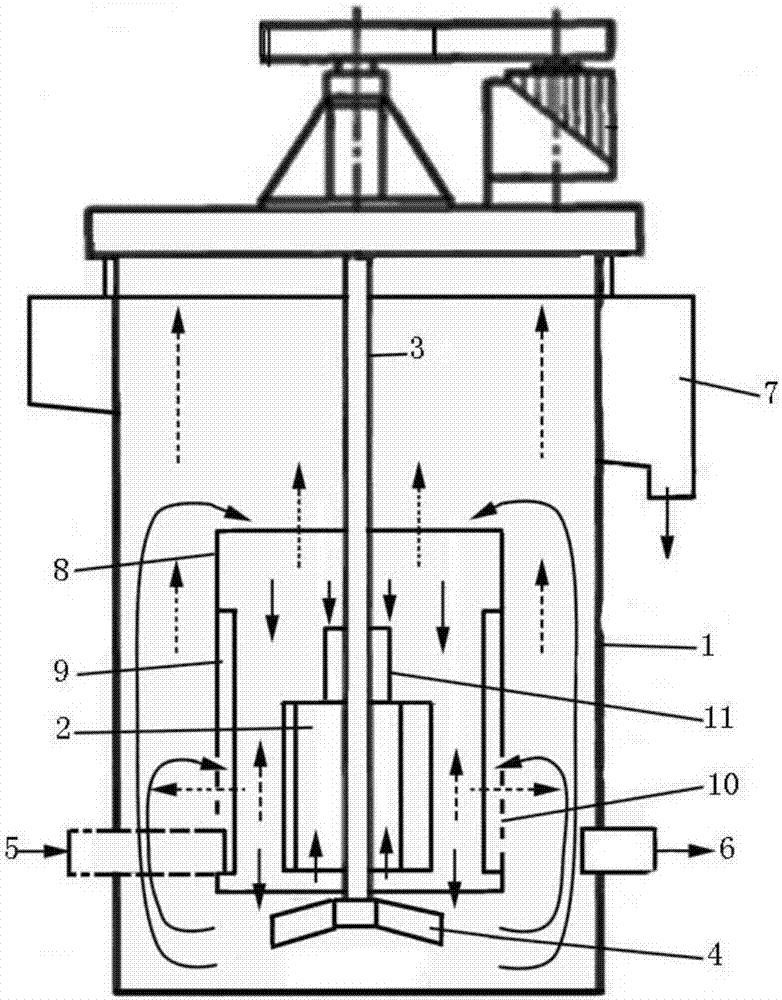

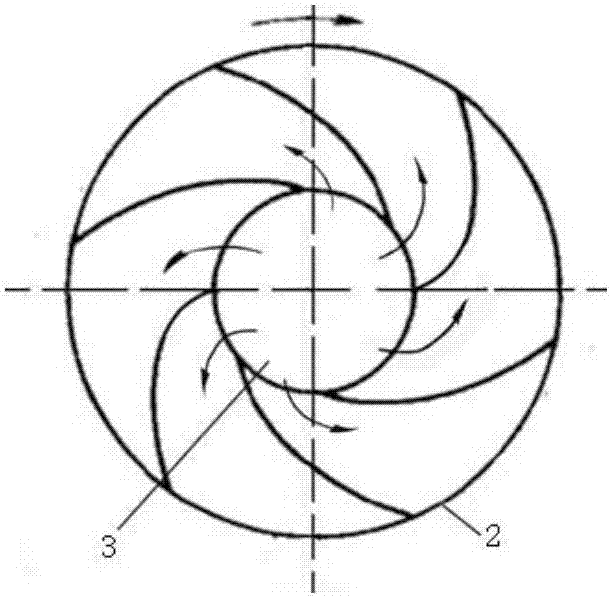

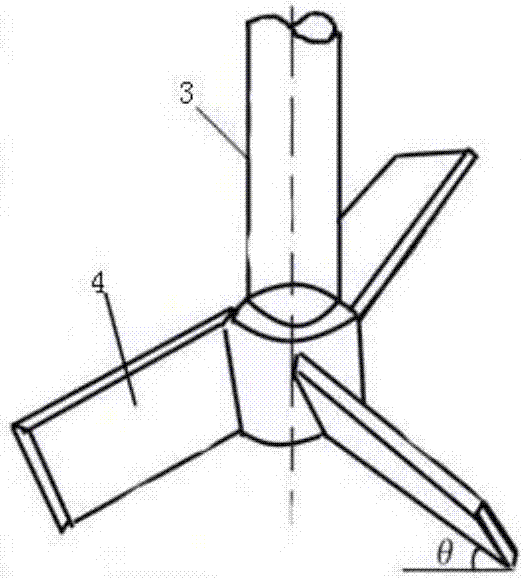

Sorting and grading device of pulsating liquid-solid fluidized bed and method thereof

InactiveCN101804382AGood for automatic dischargeHigh densityWet separationAutomatic controlVolumetric Mass Density

The invention provides a sorting and grading device of a pulsating liquid-solid fluidized bed and a method thereof. The sorting and grading device comprises a light product overflow trough, a central feed pipe, a sorting tank, a pulsating liquid distributor, a pulsating current generator, a heavy product collecting base-cone section, a sensor for measuring the concentration of the heavy product layer, a programmable controller, a heavy product discharging fluidized chamber and an underflow discharging automatic control actuator. The method comprises the following steps: firstly, water is thrown into a sorting machine in a pulsating way by the pulsating current generator, to form an upward varying-accelerated pulsating-type ascending current; accordingly, low-density or fine-fraction materials can be subjected to upward accelerated movement under the action of the accelerated pulsating-type ascending current, thus achieving the overflow discharge of the low-density or fine-fraction materials as the light or fine-fraction products; and high-density or coarse-fraction materials can be settled downwards in the fluidized bed, thus achieving the discharge of the high-density or coarse-fraction materials as the heavy or coarse-fraction products. Accordingly, the process for sorting materials by density on the basis of pulsating fluidization or the process for grading materials by fraction on the basis of pulsating fluidization can be achieved. The device and method of the invention have the advantages of simple operation, low energy consumption, low sorting lower limit, wide fraction range, high sorting accuracy and high reliability.

Owner:CHINA UNIV OF MINING & TECH

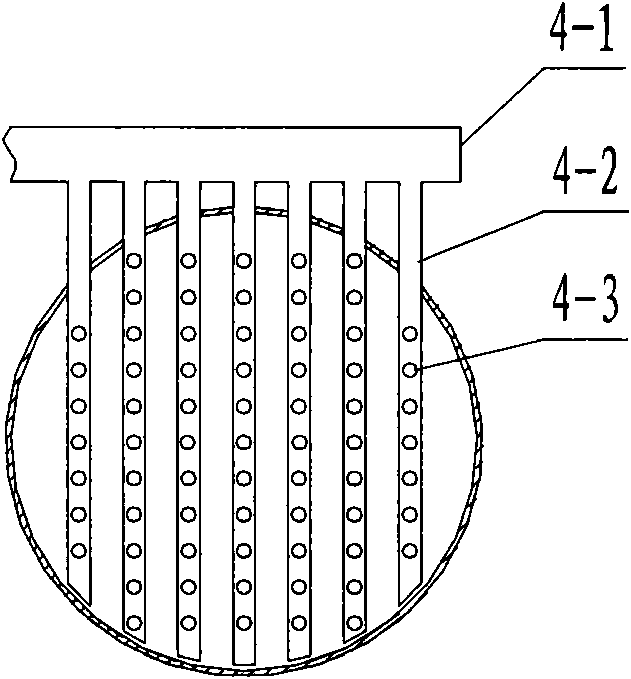

Intelligent mineral dry separation system based on intelligent arrayed air nozzles

InactiveCN105268634AImprove space utilizationEasy to handleGas current separationIdentification deviceEngineering

The invention relates to an intelligent mineral dry separation system based on intelligent arrayed air nozzles. The intelligent mineral dry separation system based on the intelligent arrayed air nozzles is mainly composed of a distribution device, an identification device and an execution mechanism. The identification device comprises a radiation source located above the distribution device and a radiation detector located below the distribution device. The execution mechanism comprises the air nozzles with outlets facing moving tracks of concentrates and tailings. The radiation detector of the identification device is a radiation linear array detector. Except for identifying the concentrates and the tailings through the physical properties of the concentrates and the tailings, position information of the concentrates and the tailings on the distribution device is further output to the execution mechanism. The air nozzles of the execution mechanism are arranged in arrays and the air nozzles in the corresponding positions are opened intelligently according to the positions of executed objects. By the adoption of the intelligent mineral dry separation system, separation accuracy is improved, the lower separation limit is further reduced, conditions are created for adopting an intelligent dry separation process for all blocky raw materials with the diameter ranging from 300-3 mm, and more energy is saved.

Owner:TIANJIN MEITENG TECH CO LTD

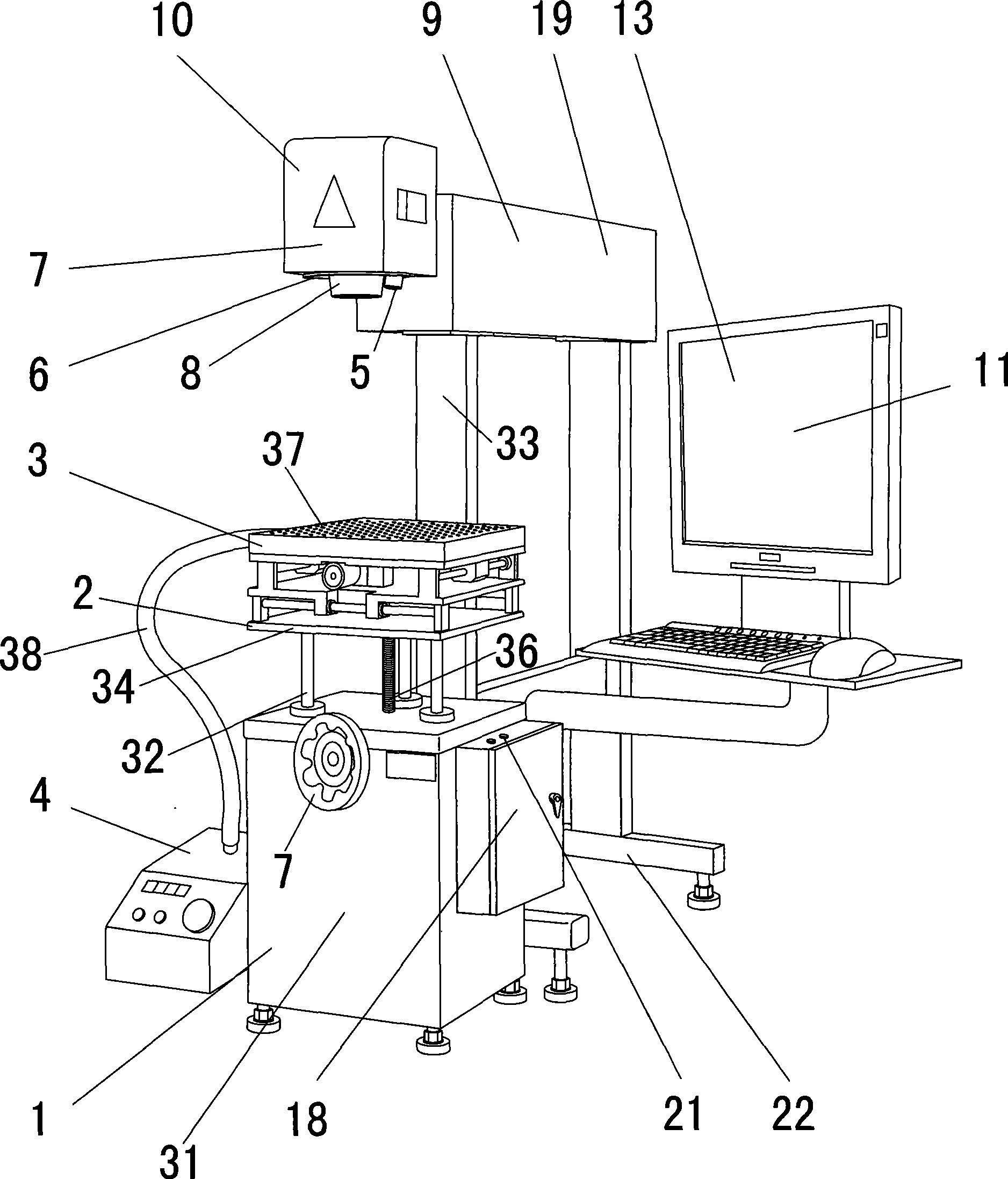

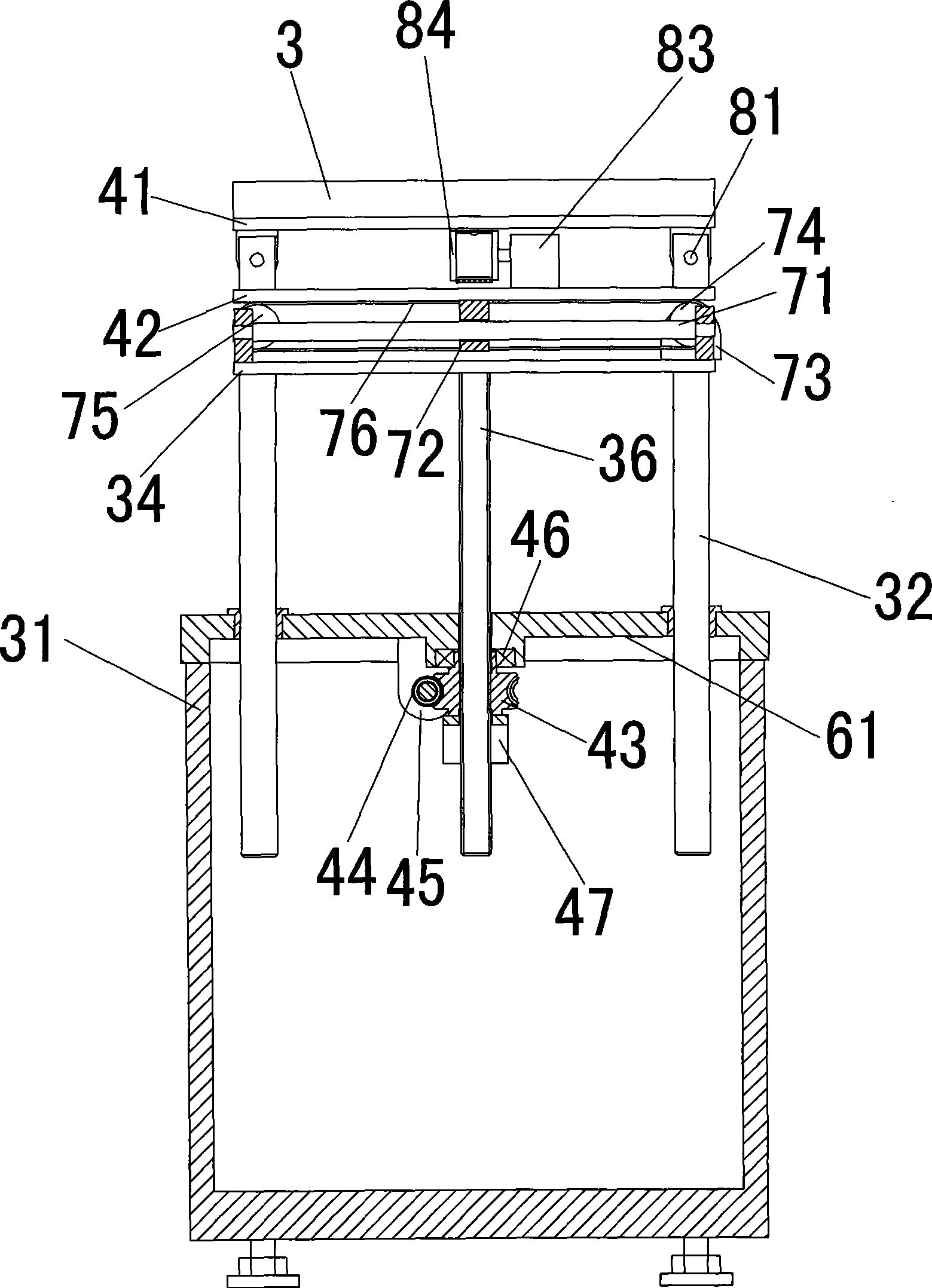

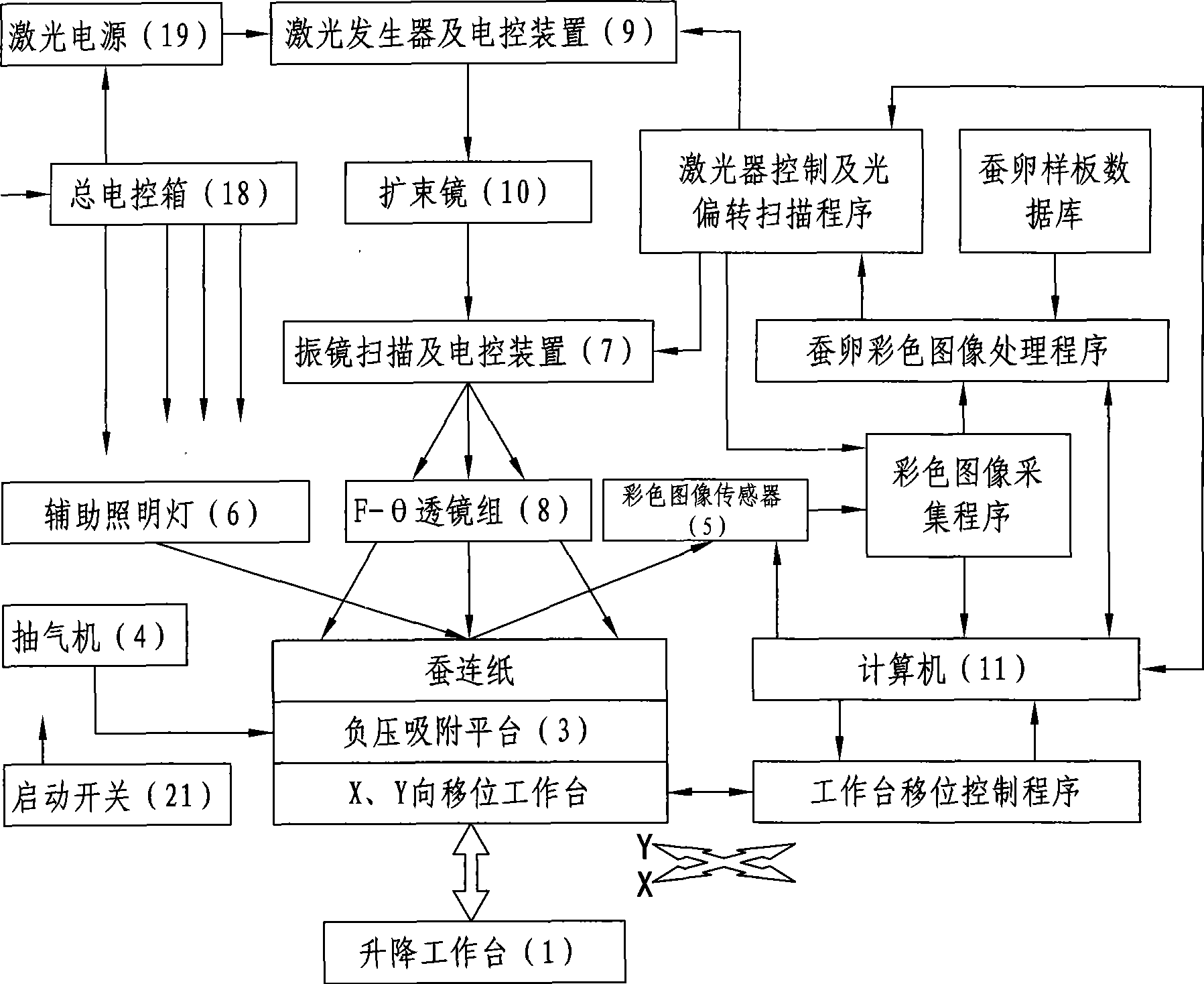

Laser instrument and method for sorting male and female graines

InactiveCN101462112ASorting high speedAccurate sortingSortingAnimal husbandryElectric controlLaser beams

The invention discloses a male and female graine laser separator and a separation method thereof. The separator comprises an elevated working platform, an egg raising paper positioning system, a graine color image processing system, a laser generation and light deflection scanning and egg launching system, and a computer. The separation method comprises the following steps: starting the separator, resetting the shifted working platform, placing egg raising paper on a negative-pressure adsorption platform, and starting an air pump to absorb the egg raising paper to be flat; starting a color image acquisition program, and controlling a color image sensor to shoot an egg raising paper image and transmit the egg raising paper image to the computer which processes data, gives out a work instruction for launching time-sequence laser pulse to a laser generator and an electric control device, and gives out a work instruction for light deflection scanning to a galvanometric scanning and electric control device, and generating laser beams to shoot female graine; and placing novel egg raising paper after the task is completed, and repeating the steps. The separator can automatically and accurately separate male and female graines with different graine colors at a high speed so as to save labor and improves the separation precision.

Owner:ANHUI ZHONGKE OPTIC ELECTRONICS COLOR SORTER MACHINERY

Automatic sorting equipment of red date cockles

InactiveCN103639121AImprove sorting efficiencyHigh sorting accuracySievingScreeningEngineeringConveyor belt

The invention relates to automatic sorting equipment of red date cockles. The automatic sorting equipment comprises a feeding mechanism, a feeding and sorting mechanism and a classifying mechanism, wherein a lower port of a feeding hopper is connected with a feeding end of a lifting conveyor belt, and a discharging end of the lifting conveyor belt is connected with the feeding end of the feeding sorting mechanism; the feeding sorting mechanism comprises a screening mechanism and a recycling line fixed on a rack, and a discharging end of the feeding and sorting mechanism is connected with a feeding end of the classifying mechanism; red dates can enter the feeding and sorting mechanism through a lifting machine of the feeding mechanism and are arranged into a row through the screening mechanism, the red dates can successively enter a transmission line of the classifying mechanism and can pass through a detection system along a transmitting flat belt, and a high speed area-array camera collects the light reflecting data of the red date surfaces; through comparison with the set standard parameters, normal red dates and the cockle red dates are distinguished. The automatic sorting equipment provided by the invention has the advantages that the classifying operation of the red dates can realize automation through combining a machine and an optical electron technology, the sorting efficiency is improved, the labour cost is reduced, the sorting precision is improved, and the deficiency of the prior art is overcome.

Owner:天津市环新光学精密机械研究有限公司

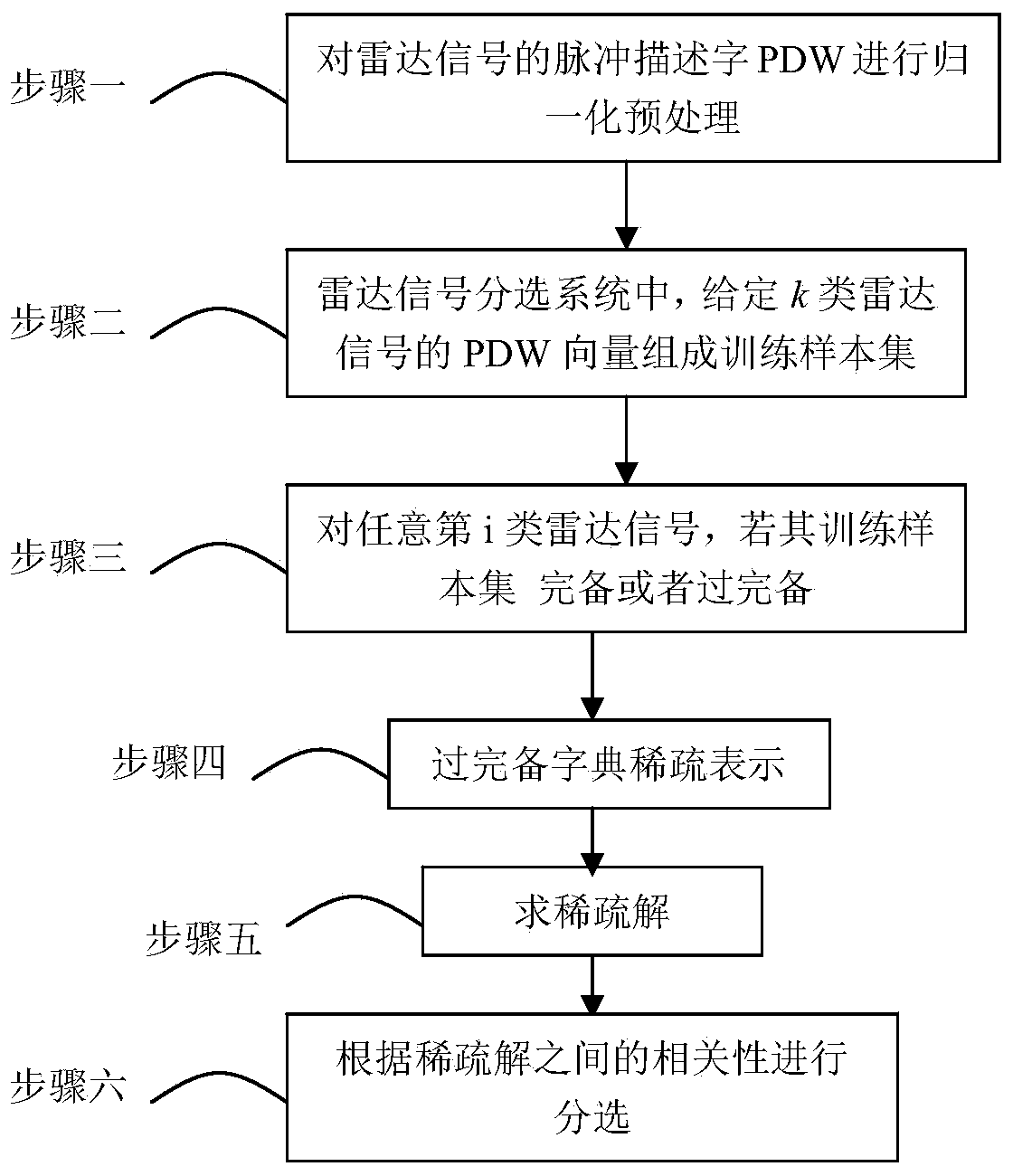

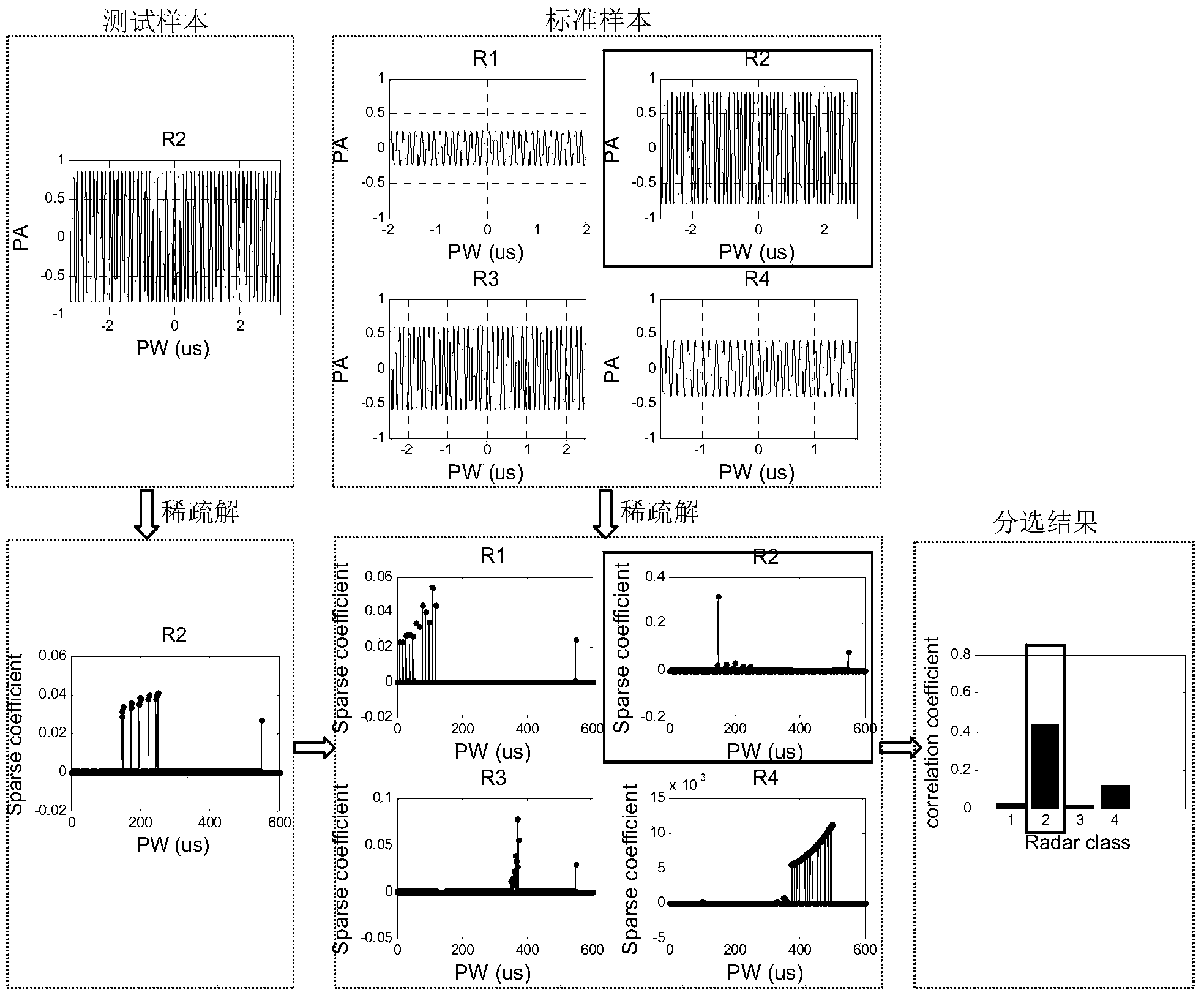

Radar signal sorting method under minimum L1 bound norm

InactiveCN103954935AHigh sorting accuracyStrong anti-noise abilityWave based measurement systemsHigh concentrationSorting problem

The invention relates to the field of radar signal processing, in particular to a radar signal sorting method under the minimum L1 bound norm. The radar signal sorting method under the minimum L1 bound norm solves the radar signal sorting problem under the high concentration and complex signal environment and comprises the first step of performing preprocessing: performing normalization preprocessing on PDWs of a radar signal, the second step of building a sample set, the third step of building an overcomplete dictionary, the fourth step of performing sparse representation on the overcomplete dictionary, the fifth step of solving the sparse solutions, and the sixth step of performing sorting according to correlation between the sparse solutions. The method is applied to the field of communication.

Owner:HARBIN INST OF TECH

Product three-dimensional dimension automatic selector

ActiveCN103316848AImplement automatic detectionRealize automatic eliminationSortingEngineeringAutomation

The invention discloses a product three-dimensional dimension automatic selector, which comprises a control mechanism, a feeding mechanism, a first transfer passage and a second transfer passage that are horizontal and mutually perpendicular, wherein the inlet of the first transfer passage is provided with a first pneumatic mechanism; the inlet of the second transfer passage is provided with a second pneumatic mechanism; the first transfer passage is provided with a first width sorting mechanism and a first width detection mechanism; the second transfer passage is provided with a second width sorting mechanism and a second width detection mechanism; the first transfer passage or the second transfer passage are provided with a height sorting mechanism and a height detection mechanism; the first width sorting mechanism, the second width sorting mechanism, the height sorting mechanism, the first width detection mechanism, the second width detection mechanism and the height detection mechanism are connected with the control mechanism respectively; the control mechanism is provided with a qualified dimension scope for the first width, the second width and the height of the product. The selector has high automation and work efficiency.

Owner:NINGBO YUNSHENG +5

Double-impeller mechanical stirring self-suction flotation machine and flotation method

ActiveCN107971143AOptimizing the intensity of counterflowGood mineralization effectFlotationImpellerField separation

The invention provides a double-impeller mechanical stirring self-suction flotation machine and a flotation method. The double-impeller mechanical stirring self-suction flotation machine comprises a column type flotation cell, a rotary shaft, an upper impeller and a lower impeller, wherein the rotary shaft is vertically inserted into the center of the inner part of the column type flotation cell;the upper impeller is fixed to the middle lower part of the rotary shaft; the lower impeller is fixed to the lower part of the rotary shaft; a guide cylinder sleeves outside the upper impeller; the lower impeller is located on the outer side of the bottom part of the guide cylinder; guide plates are arranged on an inner wall of the guide cylinder along a circumferential direction at intervals; circulation holes are uniformly distributed on the lower part of the guide cylinder along the circumferential direction; an ore feeding pipe and an ore discharging pipeline are symmetrically arranged ontwo sides of the lower part of the flotation cell; the ore feeding pipe is connected with the guide cylinder; and a foam tank is arranged on the upper part outside the flotation cell. According to thedouble-impeller mechanical stirring self-suction flotation machine and the flotation method provided by the invention, a flotation bubble mineralization effect can be improved, a flotation three-phase flow field separation environment is optimized, the reverse flow of an ore pulp and bubbles is realized, and the efficiency and the separation precision of a flotation process are improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Process for washing and selecting high-ash, high-water easily-argillized lignite

ActiveCN102553708ASolve the problem of not being able to wash in waterHigh sorting accuracySolid separationBrown coalProcess engineering

The invention relates to a process for washing and selecting high-ash, high-water easily-argillized lignite. The process comprises the following steps of: manually argillizing gangue in the lignite by using argillization equipment; then screening and grading argillized raw coals according to particle sizes of 50 mm and 0.5 mm, putting the raw coals with the particle sizes of more than 50 mm into a heavy-medium shallow trench system for washing and selecting, and obtaining large clean coals and gangue products; and putting the raw coals with the particle sizes of 50 mm and 0.5 mm into a jigging system for washing and selecting, and obtaining clean coals and gangue products, wherein coal slime with the particle size of -0.5 mm is mainly formed by argillizing the gangue, has high ash content, and can be directly discharged into a tailing base for depositing and cleaning; coal slime water formed during washing and selecting by the heavy-medium system and the jigging system enters a concentrator for clarifying and depositing; a polycoagulant and a flocculant are added into the concentrator; overflow of the concentrator is used as circulation water for the heavy-medium system and the jigging system; bottom flow is discharged to the tailing base; and clarified water in the tailing base can be used by the argillization equipment. The cost is saved, and the washing and selecting precision is improved; and furthermore, a coal slime water treatment process is simple, and the problems that the lignite is easy to argillize, and cannot be washed and selected in water are solved effectively.

Owner:CHINA UNIV OF MINING & TECH

Method for guaranteeing high separation precision of coal slime heavy medium hydrocyclone

ActiveCN103230829AAvoid the phenomenon that the liquid level is unstable or even emptiedGuaranteed uptimeWet separationThermodynamicsProcess engineering

Disclosed is a method for guaranteeing high separation precision of a coal slime heavy medium hydrocyclone. A shunt is cancelled in a device which is utilized in the method; a minus sieve chute of a clean coal medium discharge curved screen and a first section of a minus sieve chute of a clean coal medium drainage screen are respectively connected with a pipeline; one ends of the pipelines are inserted into a slime qualified medium barrel which is provided with an overflow pipe; all or partial minus sieve qualified heavy suspension liquid of the clean coal medium discharge curved screen and the first section of the minus sieve chute of the clean coal medium drainage screen enters into the slime qualified medium barrel; and heavy suspension liquid inside the slime qualified medium barrel flows into a raw coal qualified medium barrel after a liquid level of the slime qualified medium barrel is increased to a certain height. The method for guaranteeing the high separation precision of the coal slime heavy medium hydrocyclone has the advantages of enabling the shunt to be cancelled, saving equipment investment, simplifying the operation process, avoiding unstable liquid level even emptying of the slime qualified medium barrel due to improper manual operation, being capable of providing stable working conditions for the coal slime heavy medium hydrocyclone and guaranteeing the high separation precision of the coal slime heavy medium hydrocyclone.

Owner:唐山国华科技国际工程有限公司

Coal gangue sorting process

InactiveCN101869877ASmall footprintEasy to handleReversed direction vortexPulverized fuel ashChloride

The invention discloses a coal gangue sorting process. The coal gangue is separated through the steps including the steps of making the coal gangue enter a sulfur recovery sorting system after crushing and graded milling and the like. The invention is characterized in that the sulfur recovery sorting system adopts a cyclone device for separating the coal gangue in the sorting step, and the conical angle of the cyclone device is between 70 and 90 DEG C. The sulfur ore concentrate products produced by the invention are between 4 and 0 mm, the sulfur content is more than or equal to 28.40 percent, the sulfur ore concentrate products are mainly used for chemical plants, the produced boiling ash coal content can be lower than 70 percent, the sulfur content is lower than 4.0 percent, the products are mainly used for power plants (to be merged with electric coal and coal discharged from a dense medium system), and the system full sulfur recovery rate is more than or equal to 70 percent. The produced kaolin coarse ore ash content is more than 80 percent, and products can be used as raw materials for producing aluminium oxide, aluminium sulphate or basic aluminum chloride. The percentage is metered by mass percent.

Owner:重庆南桐矿业有限责任公司选煤厂

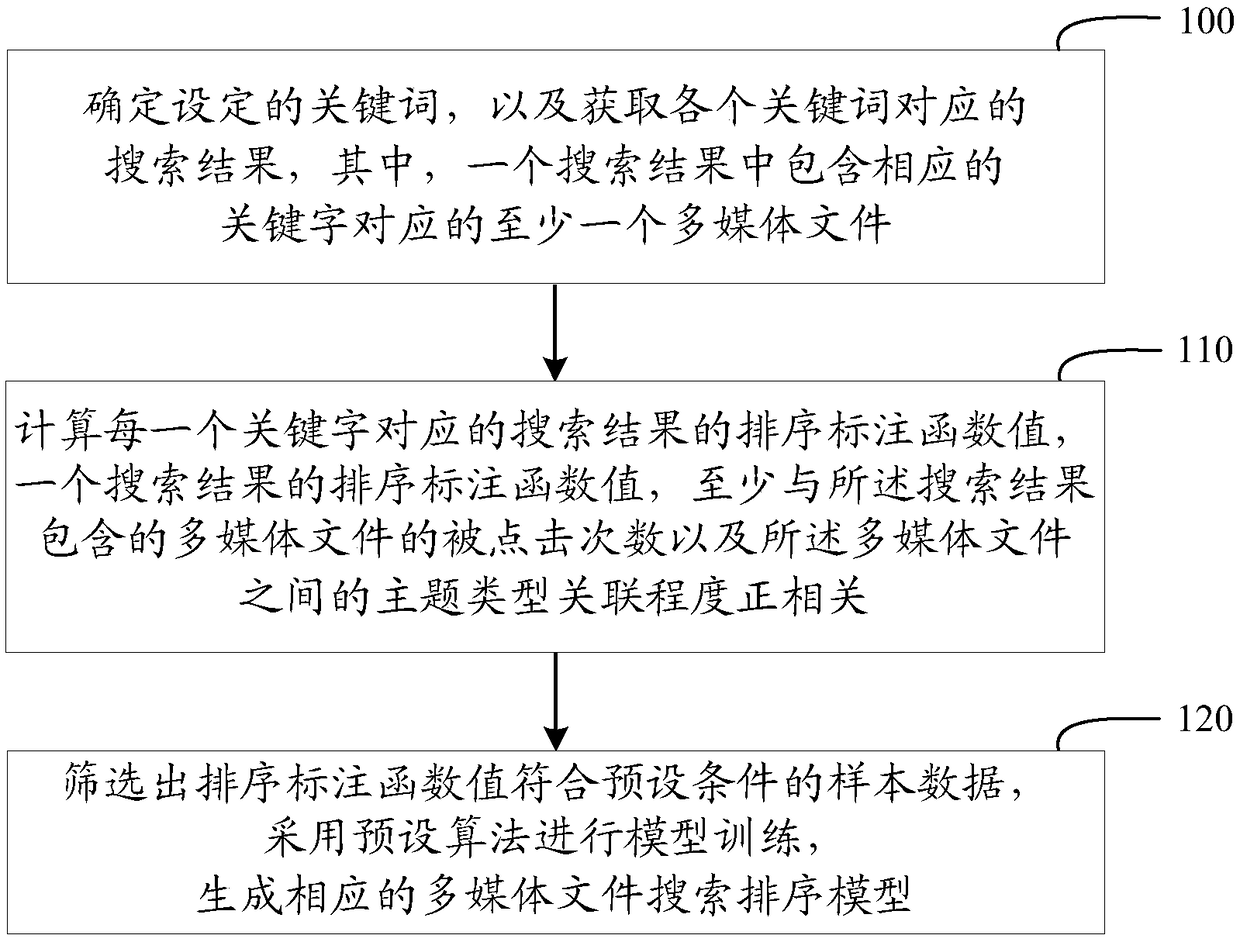

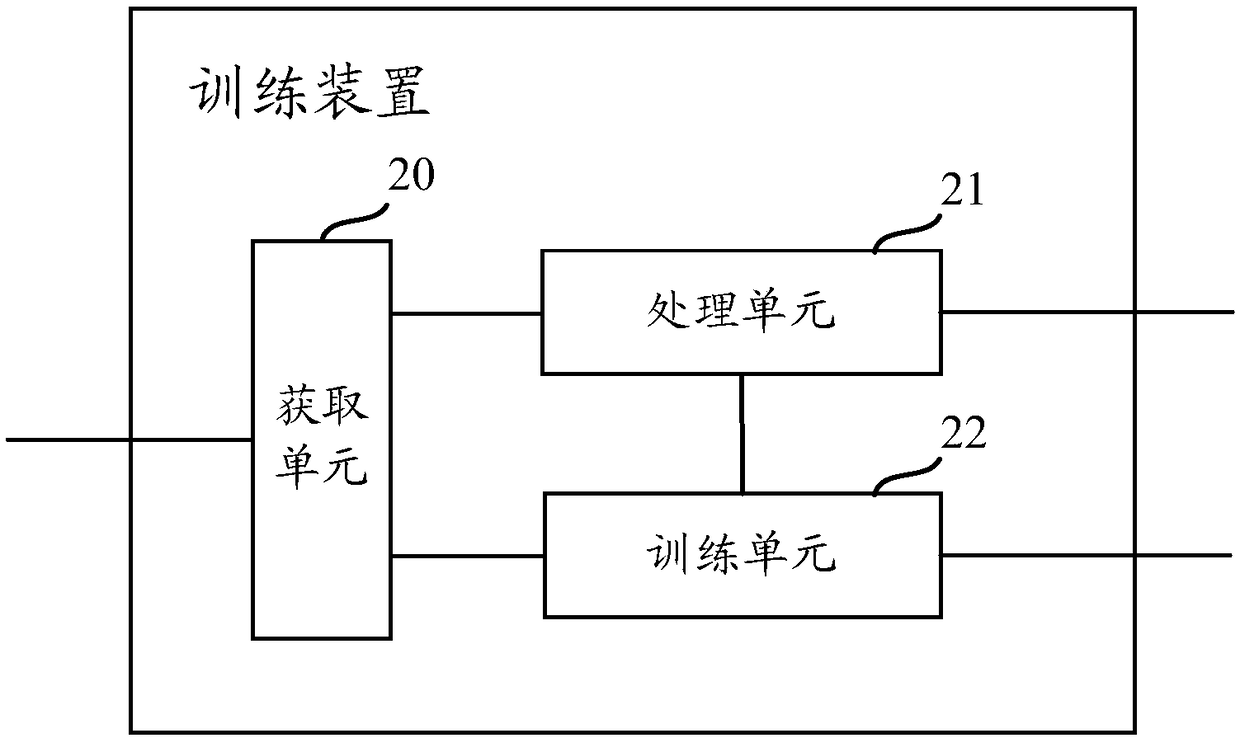

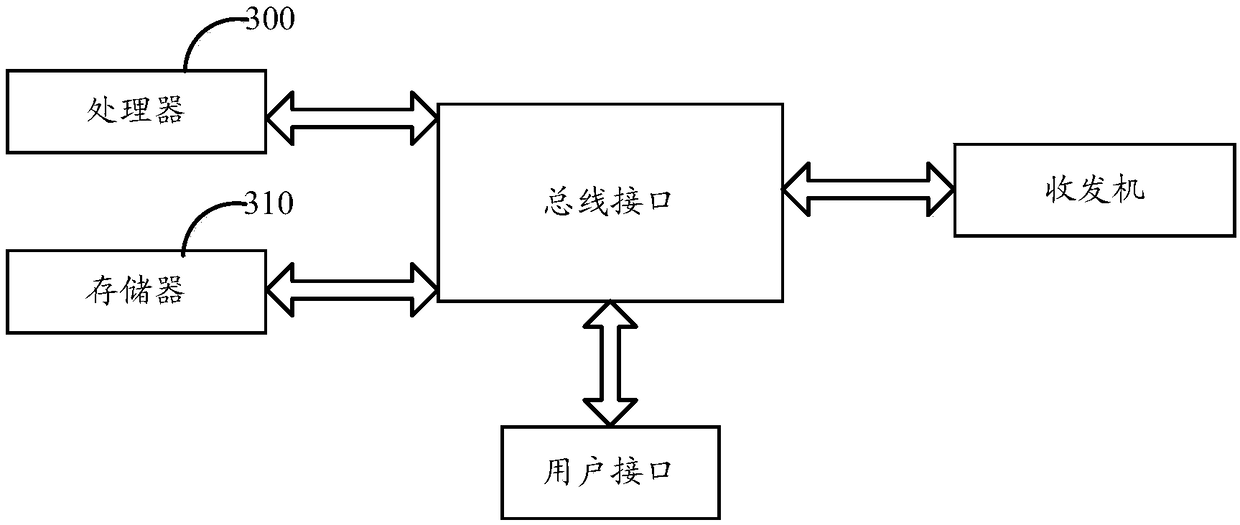

A method and apparatus for training a multimedia file search ranking model

PendingCN109508394ASolve sorting optimization problemsLabeling is validMultimedia data queryingSpecial data processing applicationsSubject matterComputers technology

The invention relates to computer technology and discloses a method and apparatus for training a multimedia file search ranking model, which is used for improving the sorting accuracy of search results. The method is, After identifying the keywords and the corresponding search results, calculating a ranking annotation function value of a search result corresponding to each keyword, and generates corresponding sample data, wherein, the sorting label function value is positively correlated with the clicked times of the multimedia file and the association degree of the subject type between the multimedia files, and the sample data whose sorting label function value meets the preset condition is screened out, the preset algorithm is used for model training, and the corresponding multimedia file search sorting model is generated. In this way, the sample data whose keywords are consistent with the search intention of the search results can be screened, the quality of the sample data is improved, the ranking accuracy of the multimedia file search ranking model obtained by training can be effectively improved, and the ranking optimization problem of the search results is solved.

Owner:青岛聚看云科技有限公司

Multi-coin sorting and packing device

The invention relates to a multi-coin sorting and packing device. The multi-coin sorting and packing device includes a coin entrance container, a coin layered transmission mechanism, a coin authenticity check and sorting mechanism, coin counting and packing mechanisms and a control module which is connected with the coin layered transmission mechanism and the coin counting and packing mechanisms, wherein the coin entrance container, the coin layered transmission mechanism, the coin authenticity check and sorting mechanism and the coin counting and packing mechanisms are sequentially arranged from top to bottom; the coin authenticity check and sorting mechanism includes a plurality of coin sorting slope channels which are arranged obliquely, strong magnets and counterfeit coin collection tubes; the tops of the coin sorting slope channels are aligned with the exit of the coin layered transmission mechanism; counterfeit coin attraction slot holes are formed at side walls at the middle portions of the coin sorting slope channels; the strong magnets are arranged at the outer sides of the counterfeit coin attraction slot holes; the counterfeit coin collection tubes are aligned with the counterfeit coin attraction slot holes; a plurality of sorting slot holes of which the widths are increased progressively are formed at the bottoms of the coin sorting slope channels, wherein the sorting slot holes are distributed from top to bottom along the oblique direction of the coin sorting slope channels; a plurality of coin counting and packing mechanisms are adopted; and the coin counting and packing mechanisms are aligned with the sorting slot holes in various sizes. Compared with the prior art, the multi-coin sorting and packing device of the invention has the advantages of high simplicity, low manufacture cost, high efficiency, convenience and the like.

Owner:SHANGHAI UNIV OF ENG SCI

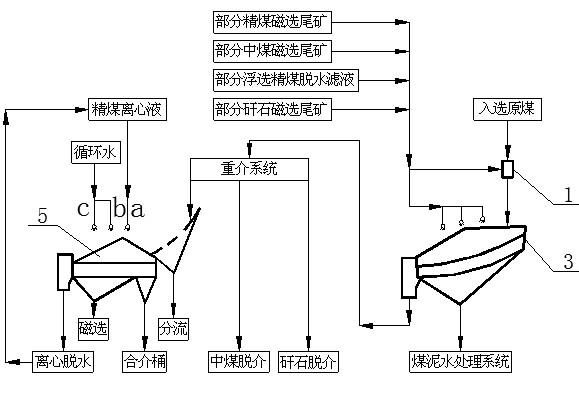

Coal slime treatment process for deslimed dense-medium coal separation

Disclosed is a coal slime treatment process for deslimed dense-medium coal separation. In the process, part of coal slime including magnetically separated clean coal tailings, magnetically separated middling coal tailings, magnetically separated gangue tailings and dehydrated filtrate of floatation separated clean coal is used as flush water for a wet-process classifying screen or a desliming screen and used as spray water for the same, and clean coal centrifugate is used as the primary spray water for a clean coal medium drainage screen. On the premise of guaranteeing feed concentration in floatation separation, work load of a concentrator can be lowered (by 20-40%), higher separation precision in gravity separation operation is maintained, better separation effect can be achieved in thecrude slime separation link and the fine slime flotation link, the recovery rate of crude particles in centrifugate is increased while medium consumption of coal separation plants is reduced, primaryinvestment, floor area and processing cost for deslimed dense-medium coal separation plants are decreased, product quality is improved, and higher economic benefit can be achieved.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com